Abstract

The European Food Safety Authority asked the Panel on Biological Hazards (BIOHAZ) to deliver a scientific opinion providing: (i) a review of the approaches used by the BIOHAZ Panel to address requests from risk managers to suggest the establishment of microbiological criteria; (ii) guidance on the required scientific evidence, data and methods/tools necessary for considering the development of microbiological criteria for pathogenic microorganisms and indicator microorganisms; (iii) recommendations on methods/tools to design microbiological criteria and (iv) guidelines for the requirements and tasks of risk assessors, compared to risk managers, in relation to microbiological criteria. This document provides guidance on approaches when: (i) a quantitative microbial risk assessment (QMRA) is available, (ii) prevalence and concentration data are available, but not a QMRA model, and (iii) neither a QMRA nor prevalence and/or concentration data are available. The role of risk assessors should be focused on assessing the impact of different microbiological criteria on public health and on product compliance. It is the task of the risk managers to: (1) formulate unambiguous questions, preferably in consultation with risk assessors, (2) decide on the establishment of a microbiological criterion, or target in primary production sectors, and to formulate the specific intended purpose for using such criteria, (3) consider the uncertainties in impact assessments on public health and on product compliance and (4) decide the point in the food chain where the microbiological criteria are intended to be applied and decide on the actions which should be taken in case of non‐compliance. It is the task of the risk assessors to support risk managers to ensure that questions are formulated in a way that a precise answer can be given, if sufficient information is available, and to ensure clear and unambiguous answers, including the assessment of uncertainties, based on available scientific evidence.

Keywords: indicator microorganisms, food safety targets, microbiological criteria, product compliance, public health, risk assessment

Summary

The European Food Safety Authority (EFSA) asked the Panel on Biological Hazards (BIOHAZ) to deliver a scientific opinion providing guidance for risk assessors on which information and assessments could be provided to risk managers to support them in their decision‐making on microbiological criteria, as defined in Regulation (EC) No 2073/2005, or on targets in primary production sectors, as defined in Regulation (EC) No 2160/2003 (see glossary). Within this opinion, when reference is made to microbiological criteria it includes both Food Safety Criteria (FSC) and Process Hygiene Criteria (PHC) as defined in the EC legislation. FSC are applicable for food products placed on the market during their shelf‐life, while PHC are applicable typically for food during processing or at the end of a production line before putting a product on the market. If a FSC is not met, then the food has to be removed from the market or reprocessed (if not at retail). If a process hygiene criterion, or a target in primary production sectors, is not met, the food business operator (FBO) sometimes in collaboration with the competent authority (CA), in the case of national prevalence targets, should take corrective actions. Currently within the EU legislation, FSC are set for pathogenic microorganisms but also, in a few cases, for indicator microorganisms. In addition, PHC are set for non‐pathogenic indicator microorganisms but also, in some cases, for pathogenic microorganisms.

In this opinion, the guidance on estimation of the effect of microbiological criteria is based on the assumption that all foods/batches comply with the microbiological criteria regardless of the action taken to meet this level of compliance. For these reasons, PHC and FSC are described together and are not considered separately in this document.

In particular, this scientific opinion addresses four terms of reference; namely to provide: (i) a review of the approaches used by the BIOHAZ Panel to address requests from risk managers to suggest the establishment of microbiological criteria; (ii) guidance on the required scientific evidence, data and methods/tools necessary for considering the development of microbiological criteria, including both PHC and FSC. These approaches should take into account the different purposes of applying microbiological criteria; (iii) recommendations on methods/tools to design microbiological criteria (limits, sampling plans, stage of the food chain, method, etc.) and (iv) guidelines for the requirements and tasks of risk assessors, compared to risk managers, in relation to microbiological criteria.

The establishment of microbiological criteria, targets in primary production sectors and/or food safety targets (e.g. Appropriate level of protection (ALOP), Food Safety Objective (FSO), Performance Objective (PO) and Performance Criterion (PC)) is a risk management activity where governments agree on the maximum level of a food safety hazard in a food animal population or food that is technically achievable and appropriate for consumer protection.

The role of risk assessors should be focused on assessing the impact of different microbiological criteria on public health and on the product compliance according to the needs of the risk managers, and, if relevant, to link different microbiological criteria with food safety targets (e.g. ALOP, FSO, PO and PC values). It is the task of the risk managers to (1) formulate unambiguous questions, preferably in consultation with risk assessors, (2) decide on the establishment of a microbiological criterion, or target in primary production sectors, and to specify the intended purpose for using the microbiological criteria (i.e. indicator of process failure, indicator of faecal contamination or general improved food safety), (3) consider the uncertainties in impact assessments on public health and on product compliance (performed by the risk assessors) and (4) decide the point in the food chain where the microbiological criteria are intended to be applied and decide on the actions which should be taken in case of non‐compliance. It is the task of the risk assessors to support risk managers to ensure that questions are formulated in a way that a precise answer can be given, if sufficient information is available, and to ensure clear and unambiguous answers, including the assessment of uncertainties, based on available scientific evidence.

In this document, former BIOHAZ scientific opinions related to microbiological criteria, and targets in primary production sectors, as part of their Terms of Reference (TOR) were reviewed and discussed giving examples of best practices in relation to phrasing of TOR's and addressing lack of data and/or incomplete knowledge.

Following this, the present guidance focuses on the required scientific evidence and data relevant for considering the development of microbiological criteria for pathogenic microorganisms and indicator microorganisms (depending on the requests from risk managers) without taking into account actions taken in case of unsatisfactory results.

The estimated public health risk related to a specific food/pathogen combination is a function of the hazard characterisation (i.e. the pathogenicity of the pathogen including the dose/response relationships) and the exposure assessment (i.e. the prevalence and concentration of the pathogen in the food at the time of consumption, combined with the consumption frequency and serving size). Information from risk assessors to risk managers in relation to decision‐making on microbiological criteria in specific foods includes: (1) evidence linking a food or animal reservoir/pathogen combination to human disease (hazard identification), (2) risk assessment (hazard characterisation, exposure assessment and risk characterisation) of the food or animal reservoir/pathogen (may be quantitative or qualitative), (3) the impact of different microbiological criteria/limits on the public health and product compliance and (4) uncertainties of the above evidence and assessments, including the main sources of such uncertainties. This document provides guidance on approaches when a quantitative microbial risk assessment (QMRA) is available, when prevalence and concentration data are available, but not a QMRA model and in situations when neither a QMRA nor prevalence and/or concentration data are available. In the latter case the risk assessors can only provide data and expert opinion on available epidemiological studies, including outbreak data, dose/response data (if available), and other relevant scientific data i.e. in the format of a risk profile.

This document also deals with the data needed to use indicator microorganisms like Enterobacteriaceae, coliform bacteria, enterococci or Escherichia coli in microbiological criteria, including data needed to evaluate the usefulness of an indicator microorganism and its concentration as the basis for monitoring adequate process hygiene and data needed to evaluate whether an indicator microorganism and its concentration could serve as a marker for a pathogen. If a relationship between an indicator microorganism and the pathogen of concern is found, a risk assessment approach may be applied. But it is concluded that even if data are available, caution should be taken in extrapolation of relationships between indicator microorganisms and pathogenic microorganisms as defined in a particular study to situations very different from those encountered in the initial data collection. In addition, it is concluded that the estimation of the impact of microbiological criteria on public health/food safety using indicator microorganisms is, if at all possible, more complicated, demanding of data, and with more uncertainty and variability, than when performed for pathogenic microorganisms.

The importance of addressing the uncertainties in the assessments is emphasised with reference to EFSA's draft guidance on uncertainty in EFSA scientific assessment (EFSA Scientific Committee, 2016), and finally, the document also deals with available online technical tools to operationalise microbiological criteria.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

A microbiological criterion is a risk management tool based on the outcome of sampling and testing for microorganisms, their toxins/metabolites or markers associated with pathogenicity or other traits at a specified point of the food chain that indicates the acceptability of a food, or the performance of either a process or a food safety control system. The Codex Alimentarius Commission (CAC) has established in 1997 general principles and considerations for the establishment of microbiological criteria which were revised in 2013 (CAC, 2013) as follows:

A microbiological criterion should be appropriate to protect the health of the consumer and, where appropriate, also ensure fair practices in food trade.

A microbiological criterion should be practical and feasible and established only when necessary.

The purpose of establishing and applying a microbiological criterion should be clearly articulated.

The establishment of microbiological criteria should be based on scientific information and analysis and follow a structured and transparent approach.

Microbiological criteria should be established based on knowledge of the microorganisms and their occurrence and behaviour along the food chain.

The intended, as well as the actual, use of the final product by consumers needs to be considered when setting a microbiological criterion.

The required stringency of a microbiological criterion used should be appropriate to its intended purpose.

Periodic reviews of microbiological criteria should be conducted, as appropriate, in order to ensure that microbiological criteria continue to be relevant to the stated purpose under current conditions and practices.

There may be multiple reasons for establishing and applying microbiological criteria. The purposes of microbiological criteria include, but are not limited to, the following:

Evaluating a specific lot of food to determine its acceptance or rejection, in particular, if its history is unknown.

Verifying the performance of a food safety control system or its elements along the food chain, e.g. prerequisite programmes and/or HACCP systems.

Verifying the microbiological status of foods in relation to acceptance criteria specified between food business operators.

Verifying that the selected control measures are meeting Performance Objectives (POs) and/or Food Safety Objectives (FSOs).

Providing information to food business operators on microbiological levels, which should be achieved when applying best practices (CAC, 2013).

The microbiological safety of foods is managed by the effective implementation of control measures within a food safety management system (FSMS) including prerequisite programme (PRP) and hazard analysis and critical control points (HACCP) that have been validated, where appropriate, throughout the food chain to minimise contamination and improve food safety. This preventative approach offers more advantages than sole reliance on microbiological testing through acceptance sampling of individual lots of the final product to be placed on the market. The establishment of microbiological criteria may also be appropriate for verifying that these FSMS are implemented correctly (EFSA, 2007; CAC, 2013).

When recommending the establishment of microbiological criteria, a variety of approaches can be used, depending on the risk management objectives and the available level of knowledge and data. These approaches can range from developing microbiological criteria based on empirical knowledge related to Good Hygienic Practices (GHP), to using scientific knowledge of FSMS such as PRP and HACCP, or by conducting risk assessments. The choice of the approach should be aligned with the risk management objectives and decisions relating to food safety and suitability. The need for a microbiological criterion should be demonstrated, e.g. by epidemiological evidence and/or as the result of a risk assessment indicating that the food under consideration represents a significant public health risk and that a criterion is meaningful for consumer protection. Although meeting microbiological criteria offers some assurance that particular pathogens are not present at unacceptably high concentrations, these do not guarantee ‘absence’ of those pathogens (EFSA, 2007). However, microbiological criteria can also be used as a way to communicate the level of hazard control that should be achieved.

Regulation (EC) No 2073/20051 on microbiological criteria for foodstuffs introduces two different criteria: Food Safety Criteria (FSC) and Process Hygiene Criteria (PHC). An advantage of establishing food safety criteria for pathogenic microorganisms is that harmonised standards on the acceptability of food are provided for both authorities and industry within the EU and for products imported from third countries. Food safety criteria will impact the entire food chain, as they are set for products placed on the market. Risk of recalls and the economic losses, as well as loss of consumer confidence, will be a strong motivation to meet the criteria. Food Safety Criteria are assumed to have an impact on food safety and public health where there is an actual or perceived risk. However, it has proved difficult to evaluate the extent of public health protection provided by a specific food safety criterion (EFSA, 2007).

The EFSA Panel on Biological Hazards (BIOHAZ Panel) previously undertook a self‐tasking activity to: (i) provide an overview of FSMS including microbiological criteria; (ii) provide a short description of the current Codex concepts, viz. Appropriate Level of Protection (ALOP), Food Safety Objective (FSO), Performance Objective (PO), Performance Criteria (PC) and microbiological criteria; (iii) describe the types of microbiological criteria (food safety criteria, process hygiene criteria) and targets contained in the EU legislation in regard to public health and (iv) consider the application of microbiological criteria and targets in the food chain at the EU level based on risk analysis (EFSA, 2007). This Opinion envisaged that there would be the need for periodic review as subsequent advances in this field have taken place, both in the technologies available for the detection of a wider range of hazards as well as in understanding their prevalence and distribution in foods, and the evolution of the science of risk assessment, including the estimation of variabilities and uncertainties.

EFSA's BIOHAZ Panel has previously received mandates where risk managers ask the Panel to provide suggestions, where relevant, for the establishment of microbiological criteria. However, despite the existing CAC document (CAC, 2013) and EFSA Opinion (EFSA, 2007) on general principles and terminology for microbiological criteria, as described above, addressing mandates to the BIOHAZ Panel have proved problematic. Thus these requests generated much discussion on what would be an appropriate approach and end‐point to address questions from risk managers, and how to deal with data gaps, variability and uncertainties in an open and transparent way.

In order to increase clarity and transparency in EFSA's future work, as well as to capitalise on advances in the application of risk assessment, it is suggested to initiate a BIOHAZ self‐tasking mandate on the required scientific evidence, data and methods/tools for supporting decision‐making on microbiological criteria in the future. This should include a clear framework/agreement of the tasks of risk assessors and what are the tasks of risk managers.

1.1.1. Terms of reference (TOR)

The BIOHAZ Panel is asked to issue an opinion that specifies a framework to increase the transparency and clarity of EFSA's future BIOHAZ opinions where considerations of microbiological criteria are a part of the mandate.

The mandate should provide:

A review of the approaches used by the BIOHAZ Panel to address requests from risk managers to suggest the establishment of microbiological criteria.

Guidance on the required scientific evidence, data and methods/tools necessary for considering the development of microbiological criteria, including both Process Hygiene Criteria and Food Safety Criteria. These approaches should take into account the different purposes of applying microbiological criteria.

Recommendations on methods/tools to design microbiological criteria (limits, sampling plans, stage of the food chain, method, etc.).

Guidelines for the requirements and tasks of risk assessors, compared to risk managers, in relation to microbiological criteria.

1.2. Interpretation of the Terms of Reference (TOR)

This scientific opinion aims to provide guidance for risk assessors on which information and assessments could be provided to risk managers to support them in their decision‐making on microbiological criteria, as defined in Regulation (EC) No 2073/20051, or on targets in primary production sectors, as defined in Regulation (EC) No 2160/20032 (see Glossary). This guidance takes into account the different degrees of evidence and tools available for specific assessments and also aims to provide guidance on the different roles of risk managers and risk assessors.

Within this opinion, when reference is made to microbiological criteria, it includes both FSC and PHC as defined in the EC legislation. FSC are applicable for food products placed on the market during their shelf‐life, while PHC are applicable typically for food during processing or at the end of a production line before putting a product on the market. If a FSC is not met, then the food has to be removed from the market or reprocessed (if not at retail). If a process hygiene criterion, or a target in primary production sectors, is not met, the food business operator (FBO) sometimes in collaboration with the competent authority (CA) in the case of national prevalence targets, should take corrective action.

To be consistent with the European legislation, this opinion considers targets in primary production sectors as well as PHC and FSC further up in the food chain using both pathogenic and indicator microorganisms. Currently within the EU legislation, FSC are set for pathogenic microorganisms but also, in a few cases, for indicator microorganisms. In addition, PHC are set for non‐pathogenic indicator microorganisms but also, in some cases, for pathogenic microorganisms.

In this opinion, the guidance on estimation of the effect of microbiological criteria is based on the assumption that, no matter which stage in the food chain, all foods/batches comply with the microbiological criteria regardless of the action taken to meet this level of compliance. For these reasons, PHC and FSC are described together and are not considered separately in this document.

In addition, this opinion also addresses briefly the food safety targets (ALOP, FSO, PO and PC), although these are not yet used in the current EU legislation.

This scientific opinion does not include evaluations of microbiological criteria included in the existing legislation (Commission Regulation (EC) No 2073/2005) but provides a framework for a structured approach to be used by risk assessors when risk managers (e.g. the European Commission or the national competent authorities) seek advice on microbiological criteria. The establishment of microbiological criteria by FBOs is outside the scope of this Opinion.

1.3. Additional information

Microbiological criteria are used worldwide as one of several risk management tools to ensure the safety of foods. The CAC, International Commission on Microbiological Specifications for Foods (ICMSF) and others have provided guidelines to Food Safety Authorities and industries and all these guidelines emphasise that establishment of microbiological criteria should be risk based. Several scientific publications in the last decade have shown how a microbiological criterion can be linked to, or be derived from, a quantitative microbiological risk assessment (QMRA) (Uyttendaele et al., 2006; Nauta et al., 2012; Andersen et al., 2015; Lee et al., 2015; Zwietering et al., 2015; Seliwiorstow et al., 2016) but little information or guidance is provided on how to deal with microbiological criteria in the absence of such QMRAs. Older literature provides information to set, in particular, PHC to evaluate hygiene during meat animal slaughtering or in food processing. The objective of many of these publications was to assess baseline data on hygiene indicators and the relationship between the indicators and zoonotic agents to support the basic assumption that adherence to Good agricultural practices (GAP), Good manufacturing practices (GMP) and GHP (being PRPs) throughout the food chain will contribute to a reduction in public health risks (Zeitoun et al., 1994; Mossel et al., 1998; Ghafir et al., 2008).

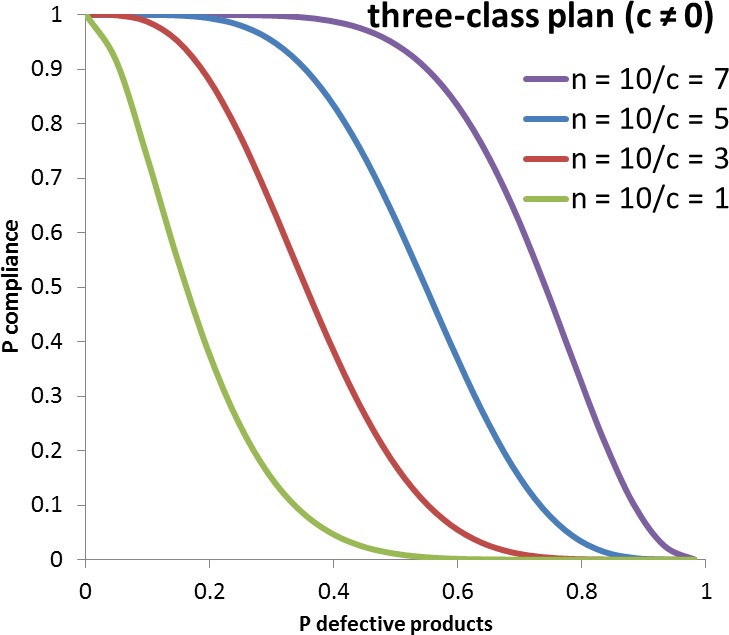

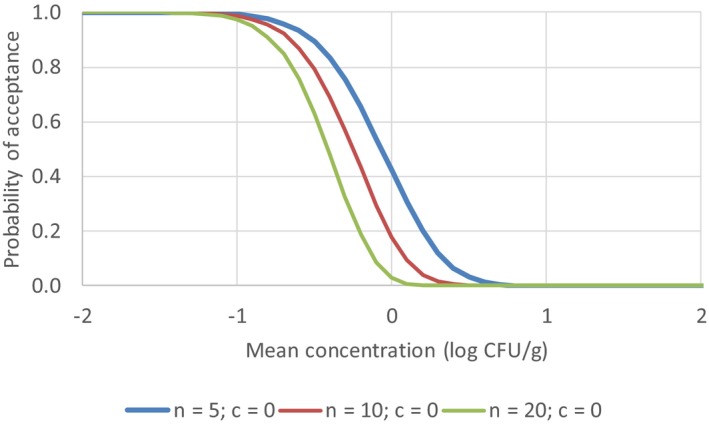

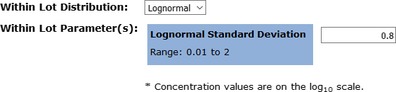

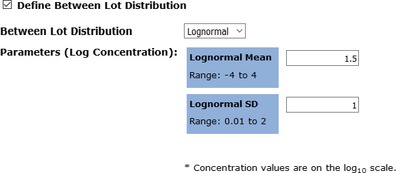

A microbiological criterion consists of the following components: (i) the purpose of the microbiological criterion; (ii) the food, process or food safety control system to which the microbiological criterion applies; (iii) the specified point in the food chain where the microbiological criterion applies; (iv) the microorganism(s) and the reason for its selection; (v) the microbiological limits (m, M) or other limits (e.g. a level of risk); (vi) a sampling plan defining the number of sample units to be taken (n), the size of the analytical unit and where appropriate, the acceptance number (c); (vii) depending on its purpose, an indication of the statistical performance of the sampling plan; and (viii) analytical methods and their performance characteristics. Consideration should be given to the action to be taken when the microbiological criterion is not met and the action should be specified (CAC, 2013).

2. Data and methodologies

Data used for this opinion are tools and methods for risk assessments and establishment of microbiological criteria that have been published as stand‐alone scientific reports or guidance documents by international organisations (Codex Alimentarius, FAO/WHO, EFSA, ICMSF, ILSI) or in peer‐reviewed scientific journals.

Scientific opinions from the BIOHAZ Panel that have been adopted between 2003 and 2016 where questions related to microbiological criteria, or to targets in primary production sectors, have been part of the TORs were searched. These opinions were reviewed to summarise, compare and evaluate the different approaches used to answer the TORs in the past.

The general EFSA guidelines on ‘the general principles of transparency in the scientific aspects of risk assessments carried out by EFSA’ (EFSA, 2009a) and ‘uncertainty in EFSA scientific assessment’ (EFSA Scientific Committee, 2016) from EFSA's scientific committee have been taken into account in answering the TOR of this scientific opinion document.

3. Requirements and tasks of risk assessors, compared to risk managers, in relation to Microbiological Criteria (TOR 4)

The impact of application of microbiological criteria on public health is not straightforward, but with the help of recent advantages in QMRA and the development of tools, risk‐based microbiological criteria can be derived from the level of protection deemed appropriate by risk managers (e.g. European Commission or national competent authorities) to protect human life or health within its territory, also known as the ALOP. The format of an ALOP is most often referred to as the number of human cases of illness per 100,000 people per year. Competent authorities and food business operators may use microbiological criteria to operationalise the ALOP, either directly, or through other food safety targets such as FSO, PO and PC (EFSA, 2007; Zwietering et al., 2015). The FSOs and POs only represent targets set as microbial concentration and/or prevalence, whereas a microbiological criterion consists of more specific elements such as the analytical method, the sampling plan, microbiological limit(s), the specified point of the food chain where the limit(s) apply, the number of analytical units that should confirm to the limit(s) and the actions to be taken when the criterion is not met (EFSA, 2007). The FSO concept translates the ALOP into a definable goal with a specified maximum frequency and/or concentration of a microbiological hazard in a food at the time of consumption, which can be defined as the acceptable level of the exposure (ICMSF, 2002) (Cole and Tompkin, 2005). Although the competent authorities are in charge of defining the ALOP, this is very seldom performed in an explicit way.

The establishment of microbiological criteria and food safety targets (e.g. ALOP, FSO, PO and PC values), as defined in Codex Alimentarius, is a risk management activity where governments agree on the maximum level of a food safety hazard in a food animal population or food that is technically achievable and tolerable for consumer protection.

The role of risk assessors should be focused on assessing the impact of different microbiological criteria on public health and on the product compliance, and if relevant to link different microbiological criteria with food safety targets (e.g. ALOP, FSO, PO and PC values). In addition, it is also the task of the risk assessors to: (i) support risk managers to ensure that questions are formulated in a way that a precise answer can be given, if sufficient information is available; and (ii) ensure clear and unambiguous answers, including the assessment of uncertainties, based on available scientific evidence.

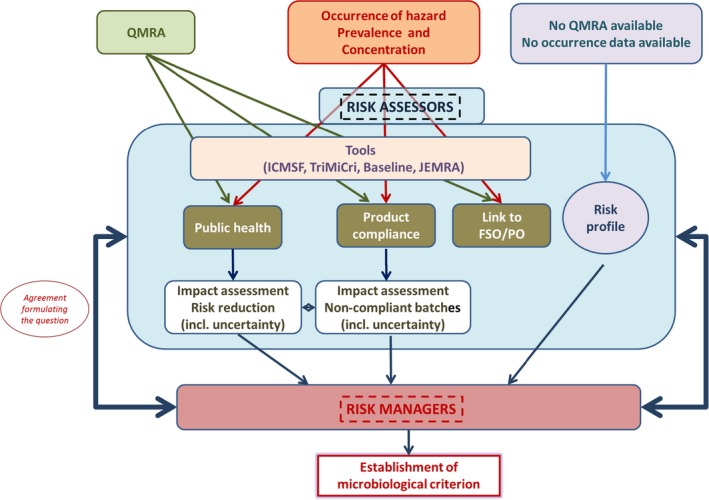

Figure 1 represents a schematic overview of the different tasks and processes performed by the risk assessors and risk managers, respectively, in relation to microbiological criteria.

Figure 1.

- FSO/PO: Food Safety Objective/Performance Objective; ICMSF: International commission on microbiological specifications on foods; JEMRA: Joint FAO/WHO expert meetings on microbiological risk assessment; QMRA: Quantitative microbial risk assessment; TRiMiCri: Tool for risk‐based microbiological criteria; Baseline: Baseline tool.

Risk managers always have the possibility to establish a microbiological criterion, as long as a method to detect the relevant microorganism is available. But before deciding on the establishment of a microbiological criterion they may approach risk assessors with specific questions. Questions for risk assessment must be specified in precise terms. Imprecise or ambiguous questions make it difficult for assessors to focus their efforts efficiently, and may result in the answer being less useful to managers, or even being misleading. If the meaning of the question is imprecise or ambiguous (could be interpreted in diverse ways by different people), more answers become possible, hence adding to the overall uncertainty about the response. Assessors and decision‐makers should therefore aim to agree on a formulation of the question such that a precise answer can be given if sufficient information is available (EFSA Scientific Committee, 2016). This will optimise the possibility that risk assessors will focus their work and produce a useful result in a timely manner.

Ambiguous questions include questions related to risk management tasks like asking for what is safe, acceptable, appropriate etc. When questions are ambiguous it is more likely that risk assessors may step into risk management judgements. Thus, risk assessors should bear in mind that judgements about what is acceptable in relation to both risk and costs are judgements that should be made by risk managers.

Although the overall purpose of establishing microbiological criteria is improvement of food safety, it is recommended that the more specific objectives are formulated by the risk managers before the risk assessors start assessing the efficacy and establishment of a specific microbiological criterion, or target in primary production sectors. Risk managers may ask questions related to microbiological criteria (FSC and/or PHC) using both pathogenic microorganisms and indicator microorganisms. Questions from risk managers about using indicator microorganisms may arise, either with the purpose of using these as an indicator of a failure in a process, or, if possible, as a marker for a pathogen, for example, in situations where methods for detecting a specific pathogenic microorganism in a food commodity are lacking.

FSC are, e.g. used for Escherichia coli in ‘live bivalve mussels and live echinoderms, tunicates and marine gastropods’ as an indicator for faecal contamination but not linked directly to food safety. On the other hand, pathogenic microorganisms (e.g. Salmonella spp. and Campylobacter spp.) are used for carcases as PHC where there is a direct link to food safety. So, although defined as such in the EC Reg. 2073/2005, PHC do not necessarily relate only to process hygiene and FSC in legislation are not necessarily linked directly to public health. It is the risk managers who decide the point in the food chain where the microbiological criteria are intended to be applied and decide on the actions which should be taken in case of non‐compliance. Whether it is cost‐effective to establish targets in primary production sectors and/or microbiological criteria (including PHC and or FSC) is a management decision and the risk assessors should mainly assess the possible impact of these on public health and product compliance.

As mentioned in Section 1.2, the assessment approaches described in this opinion do not take into account either the point in the food chain where the microbiological criterion is established or the actions which will be taken if the microbiological criterion is not met and therefore FSC and PHC are described and considered together.

Since the consequences of not complying with a FSC and a PHC differ significantly and may impact both public health and the food industry, risk managers need to consider carefully whether one or the other is the most appropriate to use in a given situation, taking into account the evidence related to impact on public health and product compliance, as provided by the risk assessors.

Since product testing for microbiological criteria (both FSC and PHC) represents a very small proportion of the food produced, testing as such and the removal of the tested batch from the market/or reprocessing of products not yet placed on the market does not often contribute significantly to food safety in itself. The public health impact of microbiological criteria (both PHC and FSC) lies in the FSMS and actions taken by the food business operators to ensure compliance with the microbiological criteria.

4. Approaches used by the BIOHAZ Panel to address requests from risk managers related to the establishment of Microbiological Criteria (TOR 1)

From 2003 to 2016, 14 BIOHAZ scientific opinions addressed questions related to microbiological criteria, and to targets in primary production sectors, as part of their TOR. These opinions were reviewed regarding the approach followed by the BIOHAZ Panel to answer those TOR. An overview of this exercise can be seen in Table A.1 in Appendix A where the title of the opinions, framing of the TOR, the approach and the answers to the TOR are summarised. In the text below, some examples of appropriate and inappropriate phrasing and reasoning are given in order to illustrate challenges in separating risk assessment and risk management.

Table A.1.

Overview of EFSA Opinions where microbiological criteria are considered in relation to specific food/pathogen combinations

| Title of scientific opinion (Year of publication, Reference) | Specific TOR related to microbiological criteria (FSC or PHC) | Assessment of impact on: (i) public health, (ii) product compliance | Approach used for the assessment | Answers to TOR (extracts from the Opinions) |

|---|---|---|---|---|

|

Microbiological risks of infant formulae and follow‐on formulae (2004) (EFSA, 2004) |

Identify the best control options, special attention should be paid to assessing the possible use of microbiological testing, through guidelines or standards, as well as measures applicable at the time of preparation and storage of these foods until their consumption | Assessment of impact on public health and product compliance was not performed | Based on epidemiological evidence |

It is recommended that a Performance Objective (PO) for powdered infant formula and follow‐on formula, aiming at very low levels of Salmonella and E. sakazakii (e.g. absence in 1, 10 or 100 kg) is introduced and that verification of compliance with the PO is confirmed by testing for Enterobacteriaceae in the environment and in the product. …. In some situations, in order to ensure that a Performance Objective is reached, microbiological testing might be an option. In the case of E. sakazakii and Salmonella in infant formula, the introduction of a microbiological criterion for these specific pathogen organisms is not recommended. |

|

Biological Hazards on Bacillus cereus and other Bacillus spp. in foodstuffs (2005) (EFSA, 2005) |

List and evaluate specific control measures, including microbiological testing and temperature requirements, to manage the risk caused by Bacillus cereus, other Bacillus spp. and their toxins in foodstuffs | Assessment of impact on public health was performed | Based on epidemiological evidence |

For the development of new food product, or food product that support growth of B. cereus, either by their nature or their conditions of storage (e.g. extended shelf life), processors should ensure that numbers of B. cereus between 103 and 105 per g are not reached at the stage of consumption under anticipated conditions of storage and handling. This should also apply for dehydrated foods reconstituted by hot water before consumption. The maximum limit at consumption described in the above bullet point should be used as a target for food business operators to verify their HACCP system and could be considered as microbiological criteria to test the acceptability of a process. |

|

Updating the former SCVPH opinion on Listeria monocytogenes risk related to RTE foods and scientific advice on different levels of L. monocytogenes in RTE foods and the related risk for human illness (2008) (EFSA, 2008b) |

To provide scientific advice on different levels of L. monocytogenes in ready‐to‐eat foods and the related risk for human illness | Assessment of impact on public health and product compliance was performed |

Based on risk assessment (qualitative MRA) and epidemiological evidence |

Microbiological criteria will assist in controlling the levels of L. monocytogenes, e.g. absence in 25 g or ≤100 CFU/g at the point of consumption. The most recent Codex document on microbiological criteria for L. monocytogenes in ready‐to‐eat foods suggests a zero tolerance throughout the shelf life of the product for ready‐to‐eat foods in which growth of this microorganism can occur. Applying this criterion throughout the shelf life may prevent consumption of ready‐to‐eat foods representing a high risk. However, applying this criterion close to the end of shelf life could classify products as unsatisfactory, although they are of low risk. An additional option proposed in this Codex document is therefore to tolerate 100 CFU/g throughout the shelf life provided that the manufacturer is able to demonstrate that the product will not exceed this limit throughout the shelf life. For ready‐to‐eat foods that support growth of L. monocytogenes, it is impossible to predict with high degree of certainty that the level will or will not exceed 100 CFU/g during the shelf life of these products. Thus, applying this option may result in accepting a probability that foods with more than 100 CFU/g will be consumed. The impact on public health would depend whether the levels markedly above 100 CFU/g are reached. |

|

Risk based control of biogenic amine formation in fermented foods (2011) (EFSA BIOHAZ Panel, 2011b) |

Characterise concentration levels of biogenic amine in relevant fermented foods that are not associated with adverse health effects of defined consumer groups including susceptible consumers | Assessment of impact on public health was performed | Based on risk assessment |

Consumption data and the exposure assessment were used to define the concentrations in food that would be allowable; however, this will vary between individuals, regions and countries. No adverse health effects have been observed in healthy volunteers to a level of 25 to 50 mg of histamine per person per meal. This level may be occasionally exceeded by consumption of one or more food items containing high amounts of histamine during the same meal. Further research is needed on the evaluation of the need for and, if/where necessary, development of process hygiene criteria for histamine and tyramine in fermented foods, as well as food safety criteria for histamine in fermented foods other than fish. |

|

Campylobacter in broiler meat production: control options and performance objectives and/or targets at different stages of the food chain (2011) (EFSA BIOHAZ Panel, 2011a) |

To evaluate potential performance objectives and/or targets at different stages of the food chain in order to obtain, e.g. 50% and 90% reductions of the prevalence of human campylobacteriosis in the EU caused by broiler meat consumption | Assessment of impact on public health and product compliance was performed | Based on risk assessment |

Compliance with microbiological criteria is effective to reduce risks for Campylobacter on broiler meat because of high within‐batch prevalence and low within‐batch variability enabling detection of highly contaminated batches even when taking a limited number of samples. They stimulate improved control of Campylobacter during slaughter. The public health benefits of setting microbiological criteria were evaluated using data from the 2008 EU baseline survey. These estimates are average values for the whole EU; the impact could be very different between MSs. Theoretically, a public health risk reduction > 50% at the EU level could be achieved if all batches that are sold as fresh meat would comply with microbiological criteria with a critical limit of 1000 CFU/gram of neck and breast skin. Theoretically, a public health risk reduction > 90% at the EU level could be achieved if all batches that are sold as fresh meat would comply with microbiological criteria with a critical limit of 500 CFU/gram of neck and breast skin. |

|

Shiga toxin‐producing Escherichia coli and other pathogenic bacteria in seeds and sprouted seeds (2011) (EFSA BIOHAZ Panel, 2011b) |

To recommend, if considered relevant, microbiological criteria for seeds and sprouted seeds, water and other material that may contaminate the seeds and sprouts throughout the production chain | Assessment of impact on public health was performed | Based on epidemiological evidence (outbreak data) and microbiological data |

It is currently not possible to evaluate the extent of public health protection provided by specific microbiological criteria for seeds and sprouted seeds. This highlights the need for data collection to conduct quantitative risk assessment. Consideration should be given to the development of new or revision of the existing microbiological criteria for pathogens most frequently associated with outbreaks involving sprouts – Salmonella spp. and pathogenic E. coli. Currently, there are no criteria for pathogenic E. coli. If such criteria were to be proposed serotypes of concern and associated with severe human disease should be considered. Microbiological criteria for Salmonella, pathogenic E. coli and L. monocytogenes could be considered for seeds before the start of the production process, during sprouting and in the final product. During the industrial sprouting process testing spent irrigation water for pathogenic bacteria has been proposed as an alternative strategy to the analysis of a large number of sprout samples. However, there are some uncertainties regarding the sensitivity of this strategy. Sampling could be conducted on sprouted seed production environments. It could be applied for pathogenic bacteria such as L. monocytogenes as well as indicator bacteria. There are currently no indicator organisms that can effectively substitute for the testing of pathogens in seeds, sprouted seeds or irrigation water. Testing for E. coli, Enterobacteriaceae and Listeria spp. can inform process hygiene control. Further work may be required to assess the value of tests for these indicator organisms. |

|

Update on the present knowledge on the occurrence and control of foodborne viruses (2011) (EFSA BIOHAZ Panel, 2011d) |

To discuss the scientific reasons for and against the establishment of food safety criteria and process hygiene criteria for viruses for certain food categories (e.g. fresh produce, bivalve molluscs etc.). | Assessment of impact on public health and product compliance was not performed | Based on epidemiological evidence (outbreak data) |

Microbiological criteria for HAV and NoV are useful for validation and verification of HACCP‐based processes and procedures, and can be used to communicate to food business operators what is an acceptable or unacceptable viral load. Regulation (EC) 2073/2005 indicates that criteria for pathogenic viruses in live bivalve molluscs should be established when the analytical methods are developed sufficiently. Furthermore, regulation (EC) No 853/200410 provides a possibility to lay down additional health standards for live bivalve molluscs including virus testing procedures, and virological standards. Assuming that quantitative data on viral load is available, it would be possible to establish criteria for NoV in bivalve molluscs, while considering the impact of a given criteria on the exposure of the consumer. Viruses can be detected in fresh produce, but prevalence studies are limited, and quantitative data on viral load is scarce making establishment of microbiological criteria for these food categories difficult. Although there are documented cases of derived illness, the relative contribution of fresh produce to the overall public health FBV risk has not been established. |

|

Norovirus (NoV) in oysters: methods, limits and control options (2012) (EFSA BIOHAZ Panel, 2012a) |

Limits that do not pose an unacceptable risk to consumers for NoV genogroups GI and GII in oysters as determined by real‐time PCR (e.g. copy number per gram) |

Assessment of impact on public health and product compliance was performed | Based on exposure assessment |

Compliance with any of the above NoV limits would reduce the number of contaminated oysters placed on the market and therefore the risk for consumers to become infected. The lower the limit the greater the consumer protection achieved. However, it is not currently possible to quantify the public health impact of establishment of different limits. Microbiological criteria for NoV in oysters are useful for validation and verification of HACCP‐based processes and procedures, and can be used to communicate to food business operators and other stakeholders what is an acceptable or unacceptable viral load for oysters to be placed on the market. Microbiological criteria for NoV in oysters could also be used by competent authorities as an additional control to improve risk management in production areas, during processing and retail. On the basis of the data presented in this Opinion, risk managers should consider establishing an acceptable limit for NoV in oysters to be harvested and placed on the market. |

|

Risk posed by Salmonella and Norovirus in leafy greens (2014) (EFSA BIOHAZ Panel, 2014a) |

To recommend, if considered relevant, microbiological criteria throughout the production chain | Assessment of impact on public health was performed | Based on epidemiological evidence (outbreak data) |

The current legal framework does not include microbiological criteria applicable at the primary production stage. It is here proposed to define criteria to validate and verify Good Agricultural Practices (GAP) and Good Hygiene Practices (GHP). These criteria will be designated as Hygiene Criteria and are defined as criteria indicating the acceptable functioning at pre‐harvest, harvest and on farm post‐harvest production prior to processing. E. coli was identified as suitable for a Hygiene Criterion at primary production of leafy greens and could be considered for validation and verification of Good Agricultural Practices (GAP) and Good Hygiene Practices (GHP) and on the basis of this, growers should take appropriate corrective actions. A Process Hygiene Criterion for E. coli in leafy green packaging plants or fresh cutting plants will give an indication of the degree to which collectively GAP, GHP, GMP or HACCP programmes have been implemented. A Food Safety Criterion for Salmonella in leafy greens intended to be eaten raw as salads could be used as a tool to communicate to producers and processors that Salmonella should not be present in the product. Noroviruses can be detected in leafy greens, but prevalence studies are limited, and quantitative data on viral load are scarce making establishment of microbiological criteria for these foods difficult. Information is lacking on the relationships between the occurrence of Norovirus as detected by real time RT‐PCR, infectivity and the actual risk to public health. |

|

Risk posed by Salmonella and Norovirus in berries (2014) (EFSA BIOHAZ Panel, 2014b) |

To recommend, if considered relevant, microbiological criteria throughout the production chain | Assessment of impact on public health was performed | Based on epidemiological evidence (outbreak data) |

It is currently not possible to assess the suitability of an EU‐wide E. coli Hygiene Criterion at primary production for berries. However, using E. coli as an indicator of recent human or animal faecal contamination is likely to be useful for verification of GAP and GHP when applied to berries in individual production sites. It is currently not possible to assess the suitability of an EU‐wide Norovirus Hygiene Criterion at primary production for raspberries and strawberries, but this should be considered for the future, as well as for other berry fruits if additional public health risks are identified. Currently, there are no Process Hygiene criteria covering whole frozen berries and for these products there are no available data on occurrence of E. coli or Salmonella. It is therefore not possible to assess the suitability of an EU‐wide E. coli Process Hygiene Criterion for whole frozen berries. However, using E. coli as an indicator for verification of GMP and food safety management systems (including HACCP) might be useful for frozen berries in individual processing premises. Microbiological criteria for Norovirus in berries are useful for validation and verification of food safety management systems, including HACCP‐based processes and procedures, and can be used to communicate to food business operators and other stakeholders what is acceptable or unacceptable viral load for berries to be placed on the market It is currently not possible to provide a risk base for establishing a Process Hygiene Criterion for these foods. However, on the basis of the emerging public health risk, the collection of appropriate data and subsequent development of a Norovirus Process Hygiene Criterion for frozen raspberries and strawberries should be considered as a priority. On the basis of public health risk, there is currently insufficient evidence to justify the establishment of a Food Safety Criterion for Salmonella for fresh and minimally processed berries (including frozen berries). It is currently not possible to provide a risk base for establishing a Norovirus Food Safety Criterion for these foods. |

|

Risk posed by Salmonella and Norovirus in tomatoes (2014) (EFSA BIOHAZ Panel, 2014c) |

To recommend, if considered relevant, microbiological criteria throughout the production chain. | Assessment of impact on public health was performed | Based on epidemiological evidence (outbreak data) |

The current lack of data does not allow the proposal of a Hygiene Criterion for E. coli at primary production of tomatoes. There is insufficient information available on the occurrence and levels of E. coli in pre‐cut, mashed and other minimally processed tomatoes and therefore the suitability of this criterion cannot be assessed. For this reason, it is therefore not possible to assess the suitability of an EU‐wide E. coli Process Hygiene Criterion for these products. Using E. coli as an indicator for verification of GMP and food safety management systems (including HACCP) might be useful for tomatoes in individual processing premises. A Food Safety Criterion for Salmonella in whole tomatoes could be considered as a tool to communicate to producers and processors that Salmonella should not be present in the product. Testing of whole tomatoes for Salmonella could be limited to instances where other factors indicate breaches in GAP, GHP, GMP or HACCP programmes. Although Noroviruses have been detected in tomatoes, occurrence studies are limited, and quantitative data on viral load are scarce. For Norovirus, there is very limited occurrence data in the world‐wide literature and only one outbreak was reported in the EU between 2007 and 2012, due to a (vomiting) food handler during buffet preparation in catering, thus it is currently not possible to provide a risk base for establishing a Food Safety Criterion for these foods. |

|

Risk posed by Salmonella in melons (2014) (EFSA BIOHAZ Panel, 2014d) |

To recommend, if considered relevant, microbiological criteria throughout the production chain | Assessment of impact on public health was performed | Epidemiological evidence (outbreak data) |

There are limited studies available on the presence and levels of enteric bacteria such as E. coli on melons and watermelons and therefore it is currently not possible to assess the suitability of an EU‐wide E. coli Hygiene Criterion at primary production. Using E. coli as an indicator of recent human or animal faecal contamination is likely to be useful for verification of GAP and GHP at individual production sites. The existing Process Hygiene Criterion for E. coli in pre‐cut melons and watermelons aims to indicate the degree to which GAP, GHP, GMP or HACCP programmes have been implemented. There is insufficient information available on the occurrence and levels of E. coli in pre‐cut melons and watermelons and therefore the suitability of this criterion cannot be assessed. There are Food Safety Criteria for the absence of Salmonella in 25 g samples of ready‐to‐eat pre‐cut fruit and vegetables which is applicable to cut melon and watermelon placed on the market during their shelf life (Regulation (EC) No 2073/2005). This regulation is also applicable to unpasteurised melon and watermelon juices placed on the market during their shelf life. A Food Safety Criterion for Salmonella in whole melons and watermelons could be considered as a tool to communicate to producers and processors that Salmonella should not be present in the product. Since the occurrence of Salmonella is likely to be low, testing of whole melons or watermelons for this bacterium could be limited to instances where other factors indicate breaches in GAP, GHP, GMP or HACCP programmes. |

|

Risk posed by Salmonella, Yersinia, Shigella and Norovirus in bulb and stem vegetables, and carrots (2014) (EFSA BIOHAZ Panel, 2014e) |

To recommend, if considered relevant, microbiological criteria throughout the production chain | Assessment of impact on public health was performed | Based on epidemiological evidence (outbreak data) |

Considering the limited evidence for both the occurrence and public health risks from contamination of Salmonella, Shigella, Yersinia and Norovirus in the primary production and minimal processing of bulb and stem vegetables and carrots, no conclusions can be made on the impact of the establishment of microbiological Hygiene Criteria, Process Hygiene Criteria or Food Safety Criteria on public health. There is a lack of data on the occurrence and levels of E. coli in bulb and stem vegetables as well as carrots. Thus, the effectiveness of E. coli criteria to verify compliance to Good Agricultural Practices (GAP), Good Hygiene Practices (GHP), Good Manufacturing Practices (GMP) and food safety management systems (including HACCP) in the production and minimal processing of bulb and stem vegetables as well as carrots cannot be assessed. |

|

Risks for public health related to the presence of Bacillus cereus and other Bacillus spp. including B. thuringiensis in foodstuffs (2016) (EFSA BIOHAZ Panel, 2016) |

Indicate, if possible, the maximum levels of Bacillus, and specifically of B. thuringiensis, in food that could be regarded as safe for human consumption. | Assessment of impact on public health was performed | Based on epidemiological evidence (outbreak data) |

Most cases of food‐borne outbreaks caused by the B. cereus group have been associated with concentrations above 105 CFU/g. However, cases of both emetic and diarrhoeal illness have been reported involving between 103 and 105 CFU/g of B. cereus. Recently, in some food‐borne outbreaks associated with emetic B. cereus, the level of contamination of food ranged from less than 102 CFU/g to 6 × 107 CFU/g. The levels of B. cereus group posing a health risk to consumers are highly strain‐dependent due to the highly diverse pathogenic potential. The possibility of multiplication in foods after storage and/or handling must be taken into account when defining safe levels for human consumption, as well as the composition of the food, which can affect toxin production. All these factors can be responsible for the large variation in the estimated infectious dose, which makes a valid dose–response relationship hard to establish. Taking the enterotoxigenic potential into account, as well as the fact that B. thuringiensis cannot be distinguished from B. cereus at the chromosomal level, the levels of enterotoxigenic B. cereus that can be considered as a risk for consumers are also likely to be valid for B. thuringiensis. |

CFU: colony‐Forming Unit(s); FSC: Food Safety Criterion(a); GAP: Good Agricultural Practices; GHP: Good Hygienic Practices; GMP: Good Manufacturing Practices; HACCP: Hazard Analysis and Critical Control Points; HAV: Hepatitis A virus; NoV: Norovirus; PHC: Process Hygiene Criterion(a); RTE: ready‐to‐eat; RT‐PCR: reverse transcription polymerase chain reaction; SCVPH: Scientific Committee on Veterinary Measures relating to Public Health; TOR: Terms of reference.

Two general issues which are important to flag, in the review of the opinions dealing with targets in primary production sectors, and microbiological criteria, are (1) the phrasing of the TOR and (2) how EFSA addresses lack of data and/or incomplete knowledge.

When reviewing the phrasing of the TORs in the opinions in Table A.1 (Appendix A), the best practice was for the opinions on Listeria monocytogenes from 2008 and the Campylobacter spp. opinion from 2011 (EFSA, 2008b; EFSA BIOHAZ Panel, 2011c). EFSA was asked to assess either the risk related to: (i) different levels of a specific pathogenic microorganism in specific foods (L. monocytogenes opinion from 2008) or (ii) the performance objectives/microbiological criteria related to specific risk reductions (Campylobacter spp. opinion from 2011). In these cases, the phrasing used illustrates a clear separation between risk assessment and risk management.

An example of an inappropriate phrasing of a TOR was the opinion from 2012 on Norovirus (NoV) in oysters (EFSA BIOHAZ Panel, 2012a) where EFSA was asked to assess ‘… limits that do not pose an unacceptable risk for Norovirus …’. In this case, EFSA was actually asked to make judgements on what is acceptable and not acceptable and this is not the task of the risk assessors but of the risk managers. In the assessment, however, this was addressed by not answering the TOR directly but by assessing only the impact of different limits on the consumer exposure and impact on the market (percentage of compliance if a specific limit was chosen). In addition, the phrasing of the TOR in all the opinions related to the food of non‐animal origin (fresh produce including e.g. leafy greens and berries among others) was not optimal (EFSA BIOHAZ Panel, 2014a–2014b, 2014c, 2014d, 2014e) as EFSA was asked: ‘To recommend, if considered relevant, microbiological criteria’ and with no definition of what is meant by relevant. Without specification of or relation to a certain level of protection/risk this question could not be answered without stepping into the task of risk managers.

When reviewing the answers to the TOR, i.e. how lack of data and/or incomplete knowledge were addressed, there are also lessons to be learnt. When the TOR had been properly and unambiguously phrased, the answers were also objective and unambiguous. However, some examples of ambiguous phrasing of answers are seen in the opinions on Salmonella spp. and NoV in leafy greens eaten raw as salads where phrasings are used like ‘…prevalence studies are limited, and quantitative data on viral load are scarce making establishment of microbiological criteria for these foods difficult’ (EFSA BIOHAZ Panel, 2014a). The message is ambiguous because it is not clear what is meant by stating that it is difficult to establish a microbiological criterion. In addition, it is a risk manager task to decide how to deal with lack of data/uncertainties in relation to management options. Having said that these opinions still provide useful information for risk managers. Generally, it can be concluded that in most cases where questions have been asked about microbiological criteria, there is limited availability of quantitative data related both to prevalence and concentration of the relevant microorganisms in foods, consumption data and dose/response relationship, which makes the assessment of risks related to different criteria highly uncertain. Thus, in only three of the reviewed opinions, the microbiological criteria were linked to a QMRA and in one case to an exposure assessment, while in the rest of the opinions the approach was qualitative, based on epidemiological data and evidence. When linking the assessment of a microbiological criterion to exposure or to risk and when assessing the expected level of product compliance, it is very important also to include the uncertainty in this assessment since this information is important for the risk managers in their decision‐making. The reviewed opinions have not addressed uncertainties in an explicit way.

In addition to the 14 reviewed scientific opinions, the BIOHAZ Panel has issued six opinions related to Salmonella spp. in different animal species. Four dealt with the establishment of targets in poultry (i.e. breeding hens, laying hens, broilers and turkeys) (EFSA, 2009b; EFSA BIOHAZ Panel, 2010a, 2011a, 2012a). These opinions were based on analysis of the data from the EU baseline surveys (BLSs) and harmonised monitoring programmes in order to investigate the potential public health benefit of introducing more strict flock Salmonella spp. prevalence targets at the 3 year review point of the statutory control programmes. The BIOHAZ Panel also provided the EC with knowledge relevant for decision‐making on establishment of other targets in primary production sectors in the EU, as summarised in Messens et al. (2013). Member States are expected to meet such targets on an annual basis, and although no sanctions against countries that have failed to meet targets have so far been imposed by the European Commission, the possibility of trade restrictions exists and the publication of monitoring data may influence commercial decisions made by importing countries. Both introduction of a more strict prevalence target for the Salmonella spp. serovars already included in the target and widening the range of serovars, including the possibility of including all serovars, was investigated by means of literature and surveillance data review, expert opinion and analytical modelling. Although in all cases a benefit in terms of reduced human cases relating to each specific poultry reservoir could be anticipated if the target was tightened, or more relevant serovars included, the individual contribution of each reservoir, apart from laying hens, to the total number of human cases was relatively small, so the benefit compared to the complications of implementation was likely to be limited at that time. Furthermore, other measures such as more sensitive sampling protocols, beginning sampling of laying hens earlier in lay and more effective use of official validation testing in relation to existing targets was considered to potentially offer equivalent or greater additional public health benefits compared to extending the targets. It was also emphasised that Member States (MS) should consider the impact of additional targets applying to their specific national situations in cases where additional Salmonella spp. serovars are contributing to an important proportion of human cases.

One opinion also dealt with a QMRA on Salmonella spp. in slaughter and breeding pigs and includes the impact of reductions of prevalence and numbers on human risk (EFSA BIOHAZ Panel, 2010b). Although European Commission and MS decided, on the basis of a cost‐benefit analysis, not to introduce targets for breeding or commercial pig herds in primary production sectors, the QMRA was useful for exploration of the contribution of carcass contamination to human Salmonella spp. cases and thereby informed the decision of European Commission to tighten the PHC relating to the proportion of carcass swabs testing positive for Salmonella spp. Another Opinion dealt with the link between Salmonella spp. criteria at different stages of the poultry production chain (EFSA BIOHAZ Panel, 2010c). Using different scenarios, it was possible to simulate the implementation of the monitoring procedures at slaughterhouse level and to relate carcass Salmonella spp. prevalence to the probability of meeting the criteria and to calculate the actual level of carcass contamination from PHC data, assuming sensitive sampling and test methodology. Studies such as these, although not defining microbiological criteria as such, provide risk managers with options based on data from bespoke analyses and expert opinion that serve as useful background for regulatory decision‐making and prioritisation.

5. Required scientific evidence and data relevant for considering the development of Microbiological Criteria (TOR 2)

This section focuses on the required scientific evidence and data relevant for considering the development of microbiological criteria for pathogenic microorganisms and indicator microorganisms (depending on the requests from risk managers) without taking into account the stage in the food chain where the microbiological criterion applies and actions taken in case of unsatisfactory results.

5.1. Microbiological criteria for pathogenic microorganisms in food

The estimated public health risk related to a specific food/pathogen combination is a function of the hazard characterisation (i.e. the pathogenicity of the pathogenic microorganism including the dose/response relationships) and the exposure assessment (i.e. the prevalence and concentration of the pathogenic microorganism in the food at the time of consumption, combined with the consumption frequency and serving size).

Information from risk assessors to risk managers in relation to decision‐making on microbiological criteria in specific foods includes:

evidence linking a food or animal reservoir/pathogen combination to human disease (hazard identification);

risk assessment (hazard characterisation, exposure assessment and risk characterisation) of the food or animal reservoir/pathogen (may be quantitative or qualitative);

the impact of different microbiological criteria/limits on the public health and product compliance;

uncertainties in the assessments for points 1‐3, including the main sources of such uncertainties.

In the sections below, the information to be considered by risk assessors to provide answers to risk managers is described, discussed and exemplified.

5.1.1. Evidence linking a food or animal reservoir/pathogen combination to human disease (Hazard identification)

A specific human food‐borne illness may be linked to different sources i.e. foods, water, environmental or animal contact or human‐to‐human contact based on monitoring and surveillance data. Attribution to such sources can be achieved using different methods such as microbial subtyping, outbreak data, other epidemiological studies, comparative exposure assessment, and structured expert opinion. Each of these methods has different strengths and weaknesses and addresses different points in the food chain that have been previously described (EFSA, 2008a).

The importance of a specific food for human illness caused by the specific pathogen in question should be assessed (qualitatively or quantitatively) and compared with other food commodities to provide the risk managers with options to decide on the establishment of a target in primary production sectors, or microbiological criterion, for a specific hazard on the most important primary production sources or food commodities, respectively. One way of doing this is through source attribution models (EFSA, 2008a–2008b, 2008c; EFSA BIOHAZ Panel, 2011a) or risk ranking, either looking into multiple pathogens per food commodity or one pathogen for various commodities (EFSA BIOHAZ Panel, 2012b).

Data on prevalence and concentrations of a pathogenic microorganism in a food may be scarce since random sampling and testing for many pathogens in many foods are not regularly carried out. There will be several situations where the evidence arises only through investigations of food‐borne outbreaks. Examples are the Opinions on Shiga toxin‐producing Escherichia coli (STEC) in sprouted seeds and on Norovirus in berries (EFSA BIOHAZ Panel, 2011d, 2014b).

5.1.2. Risk assessment (hazard characterisation, exposure assessment and risk characterisation) of the food/pathogen combination

5.1.2.1. Hazard characterisation

The public health relevance of any pathogen/food or animal reservoir combination, relates both to the incidence and the severity of the human illness and both should be estimated to the greatest extent possible. However, as public health relevance includes other aspects than incidence and severity, the concept of DALYs (Disability Adjusted Life Years) has been introduced. The DALY is calculated by adding (a) the number of years of life lost (YLL) due to mortality to (b) the time spent in less than perfect health due to morbidity and disability, expressed in healthy year equivalents lost due to disability (YLD) (Murray and Acharya, 1997; Haagsma et al., 2013). The DALYs metric enables comparison between the public health impact of various hazards and has been used to evaluate different intervention options (Havelaar et al., 2000). However, within specific pathogen/food commodity risk assessment studies, the DALYs metric is often not applied to express public health impact. More information on DALYs can be found in EFSA BIOHAZ Panel (2012b) and WHO (2015).

Knowledge of the dose–response relationship is important when considering different limits in a microbiological criterion, and to evaluate the risk related to these different limits. The dose–response relationship describes the link between the dose of a hazard and the magnitude and type of biological response occurring (for microbiological hazards usually defined as infection or defined symptoms of disease). The dose–response relationship is preferably constructed based upon human epidemiological studies including food‐borne outbreaks or, exceptionally, from well‐controlled human volunteer studies. An alternative is to derive the relationship based on animal bioassays. However, usually data to construct dose–response curves are only available for a few biological hazards. In dose–response models used in QMRAs, it is often assumed that different exposure events are independent, hence there is no protective immunity in the target population, e.g. as mentioned by (Ayuso‐Gabella et al., 2011). In addition, in many microbial risk assessments, the ‘default’ assumption used for dose–response does not account for strain or serotype variability in pathogenicity and virulence, other than perhaps, recognising the existence of avirulent strains (Coleman et al., 2004). Also, it is known that the dose–response relationship may differ for healthy adults vs those persons being part of a more susceptible population, which is particularly well documented for L. monocytogenes (Goulet et al., 2012; Pouillot et al., 2016). For example, in EFSA Panel on Biological Hazards (BIOHAZ) et al. (2017), the dose–response relationship for L. monocytogenes was derived for 14 age/gender groups, while Pérez‐Rodríguez et al. (2017) considered three groups, >65 years old, pregnant women and <65 years old.

In such cases, it is suggested to consider using models for groups with different susceptibilities and to discuss the needs for this with the risk managers.

5.1.2.2. Exposure assessment

To assess the risks of human disease following exposure to a specific pathogen in the food, it is necessary to know the prevalence and concentration of the pathogen in the food, the factors that affect it (potential for microbial growth, inactivation, e.g. during cooking, seasonal effects, etc.) as well as knowledge of the factors that have a direct effect on consumer exposure to the hazard, including frequency of consumption of the food (product or commodity) and serving size. Thus, exposure assessments will usually include as a first step the definition and description of the food chain, or sections of it relevant to the particular food and hazard combination and the country or region of interest.

The prevalence and concentration data are usually derived from surveys either published in scientific literature or preferably from dedicated BLSs set up at regional, national or European level.

Data from the annual European Union summary reports on trends and sources of zoonoses, zoonotic agents and food‐borne outbreaks produced in collaboration by EFSA and ECDC (e.g. from EFSA and ECDC (2016)) are particularly relevant for hazard identification, but may not be fully representative or most appropriate to serve as an input for risk assessment (Banach et al., 2016). Prevalence data from the EFSA/ECDC annual summary reports are often not derived from sampling plans that are statistically designed, and results are generally not directly comparable between Member States and sometimes not even between different years in one country.

In those cases that a sampling plan is statistically designed, reported prevalence or concentration data can be also influenced by the objectives and how the sampling plan was designed (e.g. food categories, sampling region), which might not be representative for the scope of the risk assessment. In addition, reported data could be strongly biased by the microbiological techniques used to generate them.

The use of validated standard methods, such as ISO/CEN methods, or national standard methods with known performance characteristics is recommended for surveys and to provide confidence in, and acceptance of, the data collected.

ISO/CEN methods are available for most of the established food‐borne pathogens and hygiene indicators under consideration to serve as microbiological parameters in a target in primary production sectors, or microbiological criterion. However, for some food‐borne pathogens that were in the scope of some of the prior opinions of the EFSA BIOHAZ Panel, some reflections were made on the interpretation of data collected from published surveys due to the limitations of the (standard) methods of analysis used.

Increasingly, DNA‐based detection methods are used as alternative methods to the standard culture methods for detection of pathogenic microorganisms in foods. In some cases, the standard methods also include, although sometimes only as an optional confirmation step, the use of DNA techniques to detect virulence factors or suggest an additional typing method to distinguish pathogenic strains of concern for public health among these isolates. However, in many published surveys, it is not mentioned to which extent the prevalence estimates relate to the overall target species or to the pathogenic isolates being detected.

In case of food‐borne viruses, such as NoV and Hepatitis A virus (HAV), as well as for food‐borne parasites such as Cryptosporidium, standard methods in specific commodities such as fresh produce have been only recently established. These methods are specialised and labour intensive, and are still in the process of continuous improvement by specialist reference laboratories. For this reason, few surveys for these emerging pathogens in at‐risk foods are available, and published reports on prevalence and concentration may still be using a variety of test methods, which may create bias or high uncertainty in the prevalence estimates.

Standard methods for detection of microorganisms are progressively based on the use of molecular techniques. This complicates the interpretation of results, as molecular methods detect genomic fragments and may not necessarily indicate the presence of viable or functional (e.g. infectious) intact cells being present in the sample (Stals et al., 2013; Ceuppens et al., 2014). It is clear that using data on estimated prevalence from any source, one should be aware or acknowledge the uncertainties, including the limitations of the sampling plan (including frequency and number of samples), the sampling methods, and the performance characteristics of the analytical methods used.

The possibilities for growth or decline of pathogenic microorganisms in a food, after the point in the food chain where the microbiological criterion is supposed to be applied, should be taken into account when estimating the impact on setting a possible microbiological criterion. Predictive models can be useful in providing an estimation of microbial concentration together with its uncertainty and variability, which can be further used to assess the impact of different microbial limits.

Regarding consumption data, the information usually included in the exposure assessment phase is the serving size and the number of servings. The serving size is defined as the portion of food consumed in a single eating event and is often referred in grams. The number of servings refers to the number of food portions of a specific food (sub)category consumed in a specified time period by a specific (risk‐based) population group in a region or country. The EFSA Comprehensive European Food Consumption Database (Comprehensive Database) has been built from existing national information on food consumption at a detailed level (EFSA, 2011). EFSA has developed a standardised hierarchical food classification and description system called FoodEx23 to codify all foods and beverages present in the Comprehensive Database. Although the database is potentially useful for performing risk assessment at EU level, some limitations can be found regarding methodological differences in the collection of the food consumption data (Merten et al., 2011). This mainly affects dietary assessment methods, the number of assessment days per subject, sampling design or quantification of portion sizes. Other limitations are related with the sparseness in the number of data per EU country, seasonality and description of food ingredients and culinary preparations reported in the Comprehensive Database. If consumption data is missing, standard serving sizes and frequencies of use may be considered.

If no or few data are available for the pathogen/food combination of concern, a qualitative or semi‐quantitative exposure assessment may be undertaken based on the information available. To provide the decision support needed by the risk manager, it is necessary in all cases to specify the limitations of the study, the assumptions made and the uncertainty in the outcome of the estimate of exposure.

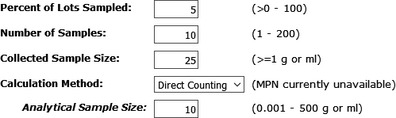

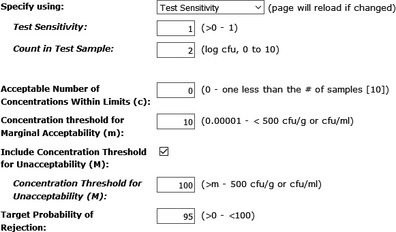

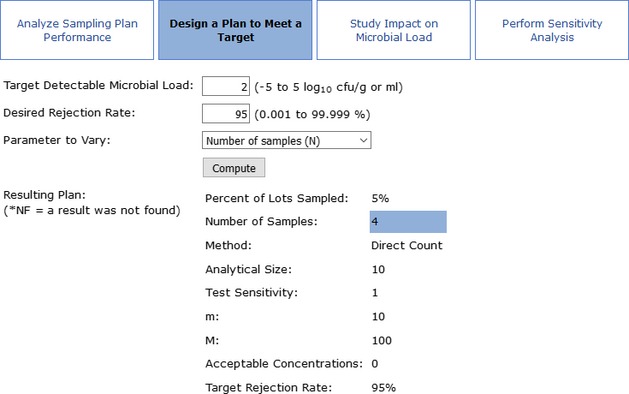

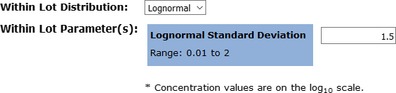

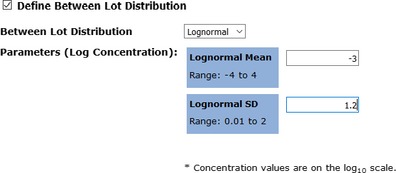

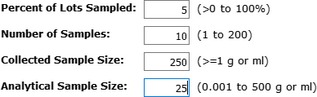

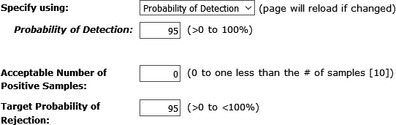

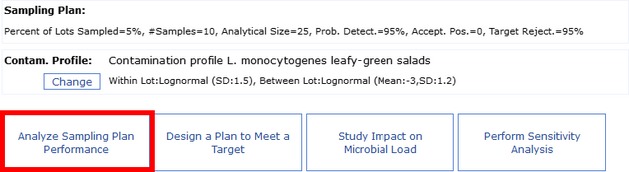

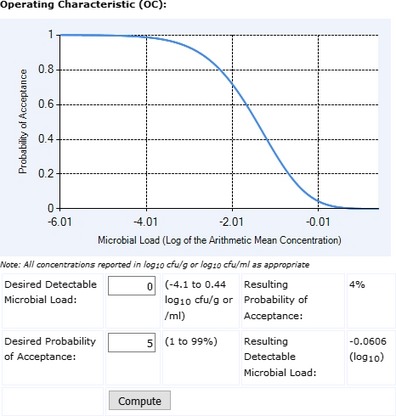

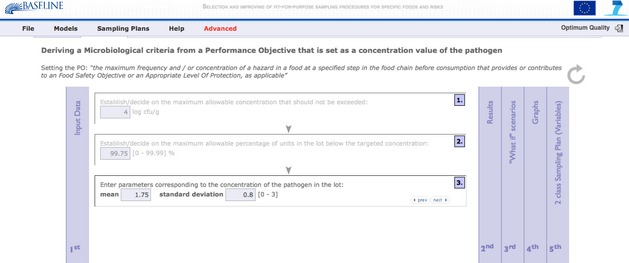

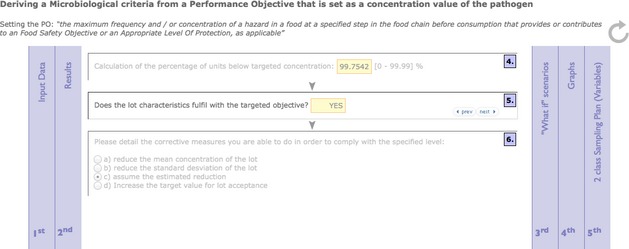

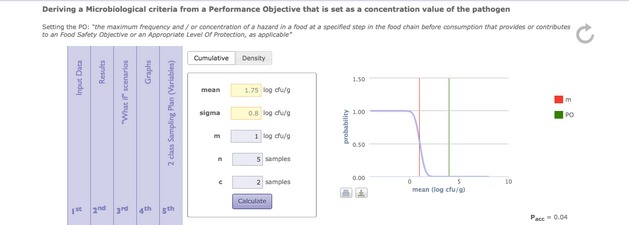

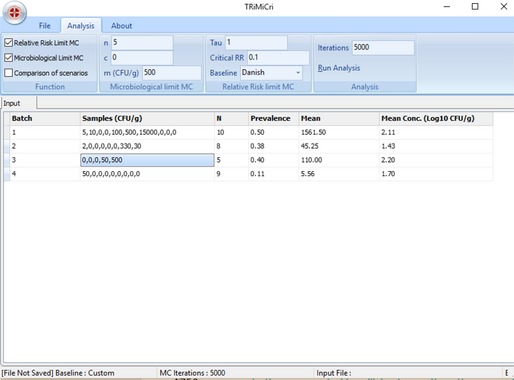

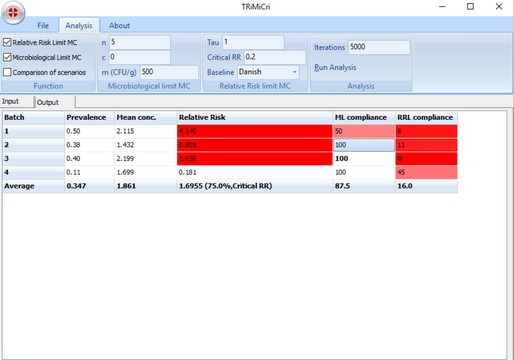

5.1.2.3. Risk characterisation