Abstract

This scientific opinion of the EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids (CEF Panel) deals with the safety assessment of the EREMA recycling process (the EREMA Multi‐Purpose Reactor (MPR), EREMA Basic and EREMA Advanced technologies), with EU register number RECYC0134. The input to this process is hot washed and dried poly(ethylene terephthalate) (PET) flakes originating from collected post‐consumer PET containers, containing no more than 5% PET from non‐food consumer applications. In the MPR technology, post‐consumer washed and dried PET flakes are heated in a continuous reactor under vacuum. The EREMA MPR decontamination technology can be combined with an extrusion line for pellets or sheet (EREMA Basic) or with an additional reactor (EREMA Advanced). The decontamination efficiency of the main continuous reactor (EREMA MPR technology) was determined by the challenge test. The Panel noted that this reactor is the critical step that determines the decontamination efficiency of these three EREMA technologies. The operating parameters controlling its performance are well defined and are temperature, pressure and residence time. It was demonstrated that, depending on the operating conditions, the recycling process under evaluation is able to ensure that the level of migration of potential unknown contaminants into food is below a conservatively modelled migration of 0.1 μg/kg food, derived from the exposure scenario for infants, and 0.15 μg/kg food, derived from the exposure scenario for toddlers, when recycled PET is used at up to 100%. The Panel concluded that recycled PET obtained from the process is not of safety concern when used to manufacture articles intended for food contact applications if it is produced in compliance with the conditions and the percentage of recycled PET added to virgin PET specified in this opinion.

Keywords: EREMA, food contact materials, plastic, poly(ethylene terephthalate) (PET), recycling process, safety assessment

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

Recycled plastic materials and articles shall only be placed on the market if they contain recycled plastic obtained from an authorised recycling process. Before a recycling process is authorised, EFSA's opinion on its safety is required. This procedure has been established in Article 5 of Regulation (EC) No 282/20081 of the Commission of 27 March 2008 on recycled plastic materials intended to come into contact with foods and Articles 8 and 9 of Regulation (EC) No 1935/20042 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food.

According to this procedure, the industry submits applications to the Member States Competent Authorities which transmit the applications to the European Food Safety Authority (EFSA) for evaluation.

In this case, EFSA received, from the Federal Ministry of Health, Austria, an application for evaluation of the recycling process EREMA (EREMA Multi‐Purpose Reactor, EREMA Basic and EREMA Advanced technologies), with EU register No RECYC0134. The request has been registered in EFSA's register of received questions under the number EFSA‐Q‐2015‐000679. The dossier was submitted on behalf of EREMA Engineering Recycling Maschinen und Anlagen G.m.b.H., Austria.

According to Article 5 of Regulation (EC) No 282/2008 of the Commission of 27 March 2008 on recycled plastic materials intended to come into contact with foods, EFSA is required to carry out risk assessments on the risks originating from the migration of substances from recycled food contact plastic materials and articles into food and deliver a scientific opinion on the recycling process examined.

According to Article 4 of Regulation (EC) No 282/2008, EFSA will evaluate whether it has been demonstrated in challenge tests or by other appropriate scientific evidence that the recycling process EREMA (MPR, Basic and Advanced technologies) is able to reduce the contamination of the plastic input to a concentration that does not pose a risk to human health. The poly(ethylene terephthalate) (PET) materials and articles used as input of the process as well as the conditions of use of the recycled PET make part of this evaluation.

2. Data and methodologies

2.1. Data

The applicant has submitted a dossier following the ‘EFSA guidelines for the submission of an application for the safety evaluation of a recycling process to produce recycled plastics intended to be used for the manufacture of materials and articles in contact with food, prior to its authorisation’ (EFSA, 2008). Applications shall be submitted in accordance with Article 5 of the Regulation (EC) No 282/2008.

The following information on the recycling process was provided by the applicant and used for the evaluation:

-

General information:

-

1

— general description,

-

2

— existing authorisations.

-

1

-

Specific information:

-

1

— recycling process,

-

2

— characterisation of the input,

-

3

— determination of the decontamination efficiency of the recycling process,

-

4

— characterisation of the recycled plastic,

-

5

— intended application in contact with food,

-

6

— compliance with the relevant provisions on food contact materials and articles,

-

7

— process analysis and evaluation,

-

8

— operating parameters.

-

1

2.2. Methodologies

The principles followed up for the evaluation are described here. The risks associated to the use of recycled plastic materials and articles in contact with food come from the possible migration of chemicals into the food in amounts that would endanger human health. The quality of the input, the efficiency of the recycling process to remove contaminants as well as the intended use of the recycled plastic are crucial points for the risk assessment (see guidelines on recycling plastics; EFSA, 2008).

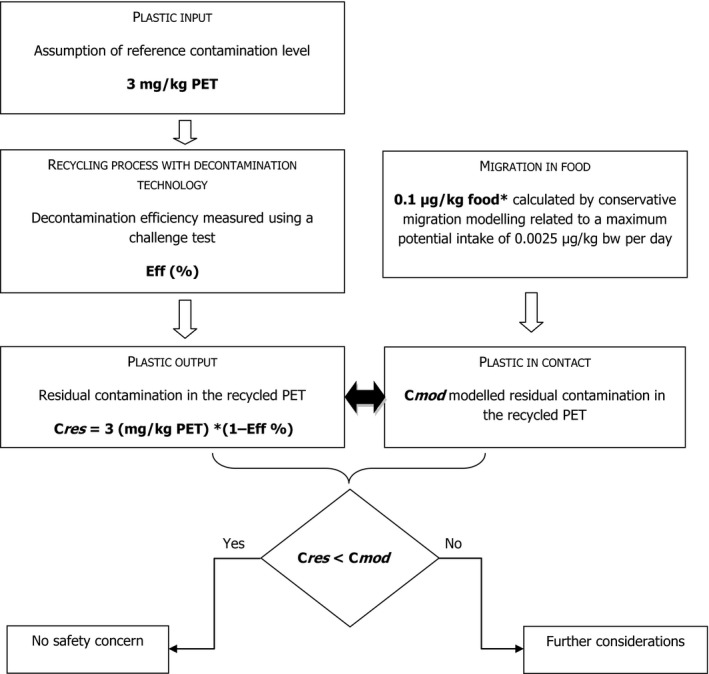

The criteria for the safety evaluation of a mechanical recycling process to produce recycled PET intended to be used for the manufacture of materials and articles in contact with food are described in the scientific opinion developed by the EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids (EFSA CEF Panel, 2011). The principle of the evaluation is to apply the decontamination efficiency of a recycling technology or process, obtained from a challenge test with surrogate contaminants, to a reference contamination level for post‐consumer PET, conservatively set at 3 mg/kg PET for contaminants resulting from possible misuse. The resulting residual concentration of each surrogate contaminant in recycled PET (Cres) is compared with a modelled concentration of the surrogate contaminants in PET (Cmod). This Cmod is calculated using generally recognised conservative migration models so that the related migration does not give rise to a dietary exposure exceeding 0.0025 μg/kg body weight (bw) per day (i.e. the human exposure threshold value for chemicals with structural alerts for genotoxicity), below which the risk to human health would be negligible. If the Cres is not higher than the Cmod, the recycled PET manufactured by such recycling process is not considered of safety concern for the defined conditions of use (EFSA CEF Panel, 2011).

The assessment was conducted in line with the principles described in the EFSA Guidance on transparency in the scientific aspects of risk assessment (EFSA, 2009) and considering the relevant guidance from the EFSA Scientific Committee.

3. Assessment

3.1. General information

According to the applicant, the EREMA recycling process (MPR, Basic and Advanced technologies) is intended to recycle food grade PET containers to produce recycled PET. The recycled flakes, pellets and sheets are intended to be used in a mass fraction up to 100% to manufacture new food packaging articles, typically bottles and PET sheets for thermoformed trays and containers for all kind of foodstuffs. These final materials and articles are intended to be used in direct contact with all kinds of foodstuffs for long‐term storage at room temperature. The applicant is the manufacturer of the recycling equipment providing the technology for the EREMA process, in contrast to all previously evaluated applications using EREMA technologies, where the applicants were the producers of recycled PET (EFSA CEF Panel, 2013a,b,c, 2014, 2015a,b,c).

3.2. Description of the process

3.2.1. General description

The recycling process EREMA (MPR, Basic and Advanced technologies) produces PET flakes, pellets and sheets from PET containers, coming from post‐consumer collection systems (kerbside and deposit systems). It involves two to four steps, whereby the grinding and washing of PET flakes (step 1) and the decontamination in a multi‐purpose reactor (step 3) are always applied. The EREMA MPR technology consists of these two steps only. EREMA Basic adds an extrusion step (step 4) for the production of pellets or sheets. In the EREMA Advanced technology, the washed flakes from step 1 run through a continuous reactor (step 2) before decontamination and extrusion (steps 3 and 4). The four steps are described below.

In step 1, used for all EREMA technologies, post‐consumer PET containers are ground and processed into washed and dried flakes used as the input for the next steps. This step is performed by third parties.

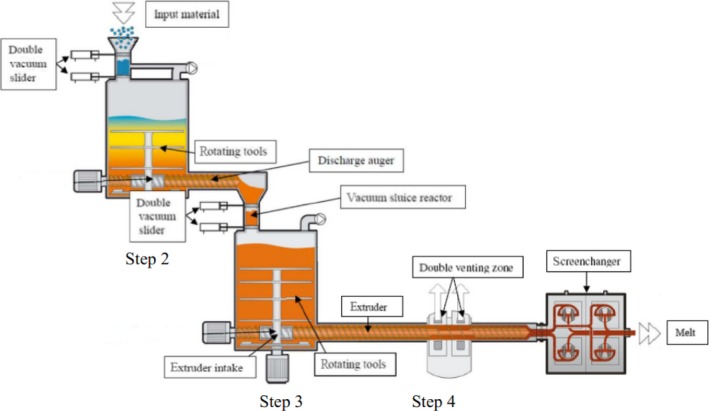

In step 2, only used in EREMA Advanced technology, the flakes are treated in a continuous reactor at high temperature and under vacuum.

In step 3, used in the MPR, Basic and Advanced technologies, the flakes are treated in a second continuous reactor at a higher temperature than step 2 and under vacuum.

In step 4, used in the Basic and Advanced technologies, the decontaminated flakes from the previous step(s) are extruded at high temperature and under vacuum to produce pellets or sheets.

In order to maintain consistency, for the steps in the three technologies, the Panel will use only the numbering as indicated above independent of whether the steps are present or not.

Recycled PET flakes, pellets or sheets, the final products of the process, are checked against technical requirements on intrinsic viscosity, colour, black spots, etc. According to the applicant, recycled flakes, pellets and sheets are intended to be converted by other companies into recycled articles used for long‐term storage at room temperature, such as bottles for mineral water or other beverages and extruded sheets which are thermoformed to make food trays. The trays are not intended to be used in microwaves or conventional ovens.

The operating conditions of the process have been provided to EFSA.

3.2.2. Characterisation of the input

According to the applicant, the input material for the EREMA recycling process (MPR, Basic and Advanced technologies) consists of washed and dried flakes obtained from PET containers, previously used for food packaging, from post‐consumer collection systems (kerbside and deposit systems). A small fraction may originate from non‐food applications, such as soap bottles, mouth wash bottles, kitchen hygiene bottles, etc. According to information from the applicant, the amount of this non‐food container fraction depends on the re‐collection system and will be between (nearly) 0% and about 5%.

Technical data for the hot washed and dried flakes are provided, such as information on residual content of poly(vinyl chloride) (PVC), glue, polyolefins, cellulose, metals, polyamides and physical properties (see Appendix A).

3.3. EREMA process (MPR, Basic and Advanced technologies)

3.3.1. Description of the main steps

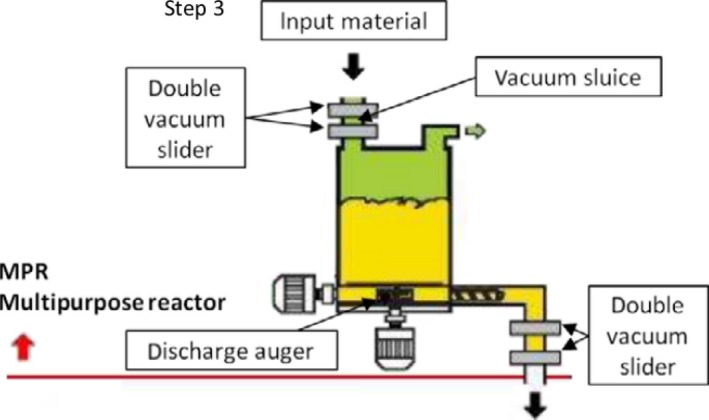

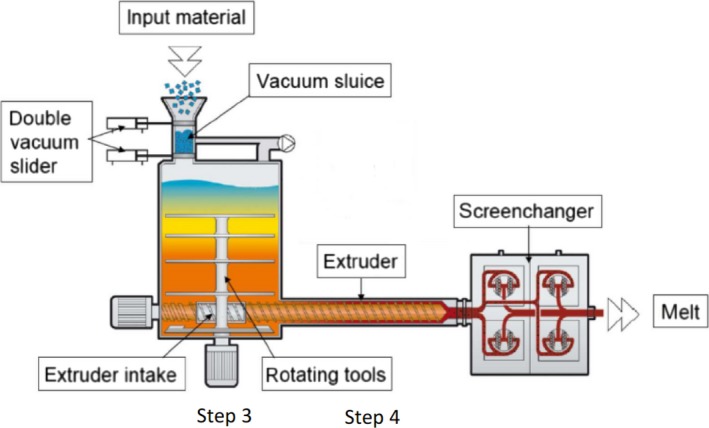

The EREMA recycling technologies MPR, Basic and Advanced are described below. The general schemes provided by the applicant are shown in Figures 1, 2 and 3, respectively. Hot washed and dried flakes from step 1 are used as input to the next steps, which are:

Step 2 (Advanced): The flakes are introduced into a continuous reactor with a bottom‐mounted rotating mixing device, in which high temperature and vacuum are applied for a predefined residence time.

Step 3 (MPR, Basic and Advanced): The washed and dried flakes from steps 1 or 2 (Advanced) are fed into a continuous reactor equipped with a bottom‐mounted rotating mixing device, running under higher temperature and vacuum for a predefined residence time. These process conditions favour the desorption of contaminants from PET and the crystallisation of PET flakes.

Step 4 (Basic and Advanced): The flakes continuously introduced from the previous reactor are molten in the extruder at atmospheric pressure or with vacuum through a double venting zone. In this process, residual solid particles (e.g. paper, aluminium, etc.) are filtered out of the extruded plastic before the final pellets and sheets are produced.

Figure 1.

General scheme of the EREMA MPR technology

Figure 2.

General scheme of the EREMA Basic technology

Figure 3.

General scheme of the EREMA Advanced technology

The process is operated under defined operating parameters of temperature, pressure and residence time.

3.3.2. Decontamination efficiency of the recycling process

To demonstrate the decontamination efficiency of the EREMA recycling process, a challenge test was submitted to EFSA. According to the applicant, it was performed at the EREMA facilities at industrial scale. Only the decontamination step in the continuous reactor (step 3), common to the MPR, Basic and Advanced technologies, was challenged. For this reason, the three technologies described in the process were jointly considered.

PET flakes were contaminated with toluene, chlorobenzene, chloroform, methyl salicylate, phenylcyclohexane, benzophenone and methyl stearate, selected as surrogate contaminants in agreement with the EFSA guidelines and in accordance with the recommendations of the US Food and Drug Administration (FDA). The surrogates include different molecular weights and polarities to cover possible chemical classes of contaminants of concern and were demonstrated to be suitable to monitor the behaviour of PET during recycling (EFSA, 2008).

For this purpose, solid surrogates (benzophenone and methyl stearate) were mixed with liquid surrogates (toluene, chlorobenzene, chloroform, methyl salicylate and phenylcyclohexane). This mixture was admixed to 5 kg recycled post‐consumer green PET flakes (masterbatch). The masterbatch was mixed with approx. 50 kg of green PET flakes and stored for 7 days at 50°C with periodical agitation. The contaminated flakes were washed and rinsed in a batch process in pilot plant scale. The concentration of surrogates in this material was determined.

The EREMA technologies were challenged on the reactor of step 3 only, using an industrial‐scale plant. To process a sufficiently large amount of material compatible with the high capacity of the continuous industrial plant, the reactor was initially fed with non‐contaminated flakes (white colour) and, after process conditions are stabilised, with a defined amount of contaminated flakes (green colour) and then with a much larger quantity of non‐contaminated flakes. The flakes were continuously fed into the reactor. The ratio between contaminated and non‐contaminated flakes was approximately 1:22. Samples were taken at the outlet of the reactor at regular intervals. The green flakes were separated from the white flakes and the evolution of the fraction of green flakes with time (residence time distribution curve) was determined by weighing. The green flakes were then analysed for their residual concentrations of the applied surrogates.

The Panel noted that decontamination efficiencies, calculated only on the basis of residual surrogates in contaminated (green coloured) flakes could be overestimated. In fact, based on EFSA CEF Panel (2011), cross‐contamination3 by transfer of contaminants from green to white flakes does occur.

Therefore to take into account the cross‐contamination phenomenon, the following considerations and assumptions were made:

The mass fraction of green to white flakes at various residence time points was derived from the data provided. A best fitting mass fraction/residence time distribution curve was derived from the experimental data and was used to calculate the percentage of green and white flakes at given different residence times.

The residual concentrations of surrogates in the green flakes after decontamination were derived for the different residence time points from the data provided. A best fitting curve was derived from the experimental data and was used to interpolate the residual concentrations in green flakes at different residence times.

The Panel made the assumption that cross‐contamination of surrogates from green to white flakes in the reactor occurred to the extent of 10% of the residual concentration measured in the green flakes. This percentage reflects the experience gained from previous evaluations.

A new study was provided by the applicant. Based on the results provided as an Annex of the technical dossier and subsequently published (Welle, 2016), cross‐contamination was found at low mixing (dilution) ratios (e.g. 1:1), but the author argued that moving to higher mixing (dilution) ratios (e.g. 1:50) cross‐contamination does no longer play a significant role. Therefore, the applicant requested that the 10% cross‐contamination should not apply for the industrial process under evaluation (EREMA MPR, Basic and Advanced). The Panel noted that the test (Welle, 2016) had shortcomings and the conclusion that cross‐contamination was negligible had to be questioned due to the poor detection limits of the analytical method used as it had a major impact on calculations for the high mixing (dilution) ratio. Moreover, the Panel considered that the laboratory tests to investigate cross‐contamination were not representative of the industrial process under evaluation: different technologies (types of equipment and operational conditions) were used, for example in terms of heating technique (hot gas vs friction) and removal of contaminants from the reactor (inert gas vs vacuum). The Panel concluded that the argumentation is insufficiently supported. Therefore, the provided study allows neither to exclude cross‐contamination from the calculation of the decontamination efficiency nor to refine the previous estimate of 10%.

To take into account the cross‐contamination between green and white flakes, the evolution of the total residual surrogate content at the outlet of the continuous reactor (step 3) as a function of residence time was calculated by adding the amounts transferred into the white flakes (based on the assumption of 10% of the concentration measured in the green flakes) to the amounts measured in the green ones, taking into account the mass fractions of green and white flakes.

Correspondingly corrected concentrations of the surrogates after decontamination were compared with their initial concentrations in green flakes at the inlet of the reactor to derive the decontamination efficiencies. This was done for different residence times in the step 3 reactor to reflect different possible commercial processes.

As an example, the calculated decontamination efficiencies at the minimum residence time provided in the challenge test are shown in Table 1.

Table 1.

Efficiencies of the decontamination of the continuous reactor (step 3) at the shortest residence time tested in the reactor of step 3

| Surrogates | Concentrationa of surrogates before step 3 (mg/kg PET) | Concentrationb of surrogates after step 3 (mg/kg PET) | Decontamination efficiencyc (%) |

|---|---|---|---|

| Toluene | 202 | 1.9 | 95.4 |

| Chlorobenzene | 361 | 3.4 | 95.4 |

| Chloroform | 291 | 2.0 | 96.5 |

| Methyl salicylate | 143 | 4.9 | 83.1 |

| Phenylcyclohexane | 364 | 6.8 | 90.8 |

| Benzophenone | 480 | 14.5 | 85.0 |

| Methyl stearate | 360 | 6.8 | 90.6 |

PET: poly(ethylene terephthalate).

Initial concentration in the contaminated PET flakes.

Residual concentration calculated for green flakes after decontamination.

Decontamination efficiency of the step 3 reactor in the challenge test and after correction for cross‐contamination (see text).

The decontamination efficiencies as presented in Table 1 were calculated at the time of exit from the continuous decontamination reactor of step 3 (MPR technology) in the challenge test. The overall decontamination efficiencies of the process are expected to be higher in the cases of the ‘Basic’ and ‘Advanced’ recycling technologies as further decontamination will occur during the pre‐decontamination in a continuous reactor, step 2, and the extrusion, step 4.

3.4. Discussion

Considering the high temperatures used during the process, the possibility of contamination by microorganisms can be discounted. Therefore, this evaluation focuses on the chemical safety of the final product.

Technical data such as information on residual content of PVC, glue, polyolefins, cellulose, metals, polyamides and physical properties are provided for the input materials (washed and dried flakes (step 1)), for the submitted recycling process. The input materials are produced from PET containers, mainly bottles, previously used for food packaging collected through post‐consumer collection systems. However, a small fraction of the input may originate from non‐food applications such as soap bottles, mouth wash bottles, kitchen hygiene bottles, etc. According to the applicant, the proportion of this non‐food container fraction depends on the collection system and the process is managed in such a way that in the input stream of the recycling process this amount will be lower than 5%, as recommended by the EFSA CEF Panel in its ‘Scientific opinion on the criteria to be used for safety evaluation of a mechanical recycling process to produce recycled PET intended to be used for manufacture of materials and articles in contact with food’ (EFSA CEF Panel, 2011).

The process is well described. The production of washed and dried flakes from collected containers (step 1) is conducted by third parties. The following steps are those of the EREMA technologies used to recycle the PET flakes into decontaminated PET pellets:

MPR: continuous reactor (step 3).

Basic: continuous reactor (step 3) and extrusion (step 4).

Advanced: first continuous reactor (step 2), second continuous reactor (step 3) and extrusion (step 4).

The operating parameters of temperature, pressure and residence time ranges for the steps 2–4 have been provided to EFSA.

A challenge test was conducted at industrial plant scale on the process step 3 (continuous decontamination reactor) to measure the decontamination efficiency. In the challenge test, the continuous decontamination reactor was operated under pressure and temperature conditions equivalent to those of the commercial process. The challenge test was performed according to the recommendations in the EFSA Guidelines (EFSA, 2008). Since a mixture of flakes not contaminated with surrogates (white) and contaminated flakes (green, spiked with surrogates) was collected at the outlet of the reactor used for this challenge test, the Panel calculated the decontamination efficiencies taking into account also the amount possibly transferred to the white flakes due to cross contamination phenomena during the challenge test. The Panel considered that the decontamination in the continuous reactor (step 3) is the critical step for the decontamination efficiency of the process. Consequently, temperature, pressure and residence time parameters of the step 3 of the process should be controlled to guarantee the performance of the decontamination. These parameters have been provided to EFSA.

The decontamination efficiencies obtained for each surrogate contaminant from the challenge test, have been used to calculate the residual concentrations of potential unknown contaminants (Cres) according to the evaluation procedure described in the Scientific Opinion on ‘the criteria to be used for safety evaluation of a mechanical recycling process to produce recycled PET’ (EFSA CEF Panel, 2011; Appendix B). By applying the decontamination efficiency percentage to the reference contamination level of 3 mg/kg PET, the Cres values for the different surrogates are obtained (Tables 2 and 3).

Table 2.

Calculated concentration of surrogate contaminants in PET (Cmod) corresponding to a modelled migration of 0.1 μg/kg food after 1 year at 25°C, decontamination efficiencies from the challenge test, residual concentration (Cres) of surrogate contaminants in recycled PET (rPET). As an example, the calculations correspond to the minimum residence time provided in the challenge test

| Surrogates | Decontamination efficiency (%) | Cres for 25% rPET (mg/kg PET) | Cmod (mg/kg PET) |

|---|---|---|---|

| Toluene | 95.4 | 0.035 | 0.090 |

| Chlorobenzene | 95.4 | 0.035 | 0.090 |

| Chloroform | 96.5 | 0.026 | 0.100 |

| Methyl salicylate | 83.1 | 0.127 | 0.130 |

| Phenylcyclohexane | 90.8 | 0.069 | 0.140 |

| Benzophenone | 85.0 | 0.112 | 0.160 |

| Methyl stearate | 90.6 | 0.070 | 0.320 |

PET: poly(ethylene terephthalate).

Table 3.

Calculated concentration of surrogate contaminants in PET (Cmod) corresponding to a modelled migration of 0.15 μg/kg food after 1 year at 25°C, decontamination efficiencies from the challenge test, residual concentration (Cres) of surrogate contaminants in recycled PET (rPET). As an example, the calculations correspond to the minimum residence time provided in the challenge test

| Surrogates | Decontamination efficiency (%) | Cres for 35% rPET (mg/kg PET) | Cmod (mg/kg PET) |

|---|---|---|---|

| Toluene | 95.4 | 0.049 | 0.125 |

| Chlorobenzene | 95.4 | 0.049 | 0.147 |

| Chloroform | 96.5 | 0.036 | 0.154 |

| Methyl salicylate | 83.1 | 0.178 | 0.197 |

| Phenylcyclohexane | 90.8 | 0.097 | 0.205 |

| Benzophenone | 85.0 | 0.157 | 0.240 |

| Methyl stearate | 90.6 | 0.098 | 0.470 |

PET: poly(ethylene terephthalate).

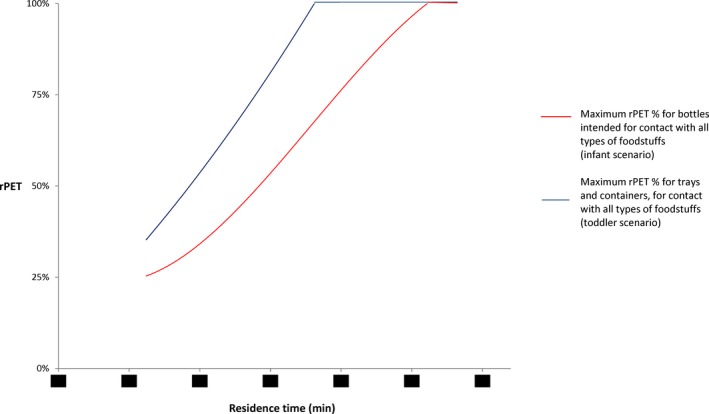

According to the evaluation principles (EFSA CEF Panel, 2011), the Cres should not be higher than a modelled concentration in PET (Cmod) corresponding to a migration, after 1 year at 25°C, which cannot give rise to a dietary exposure exceeding 0.0025 μg/kg bw per day, the exposure threshold below which the risk to human health would be negligible.4 For processes that produce PET intended to manufacture bottles, the default exposure scenario for infants has been applied as worst case. A maximum dietary exposure of 0.0025 μg/kg bw per day corresponds to a maximum migration of 0.1 μg/kg of a contaminant substance into the infant's food, as calculated by conservative migration modelling. For processes that produce PET intended to manufacture trays and containers and not used to pack water (since water could be used to prepare infant formula), the exposure scenario for toddlers has been applied as worst case, where a maximum dietary exposure of 0.0025 μg/kg bw per day corresponds to a maximum migration of 0.15 μg/kg of the contaminant into the toddler's food. Therefore, the corresponding migration of 0.1 μg/kg (scenario of infants) and 0.15 μg/kg (scenario of toddlers) into food have been used to calculate Cmod (EFSA CEF Panel, 2011). If the PET produced by a recycling process is used up to 100% to produce new articles and they do not meet these targets, recycled PET should be mixed with virgin PET to make sure that the Cres value does not exceed the Cmod value. The Panel established the maximum percentages of recycled PET in final articles for which the risk to human health is demonstrated to be negligible. These percentages are reported in Tables 2 and 3 for the scenarios of infants and toddlers, respectively. The percentages of recycled PET reported in Tables 2 and 3 are, therefore, the maximum percentages for which the risk to human health is demonstrated to be negligible and may differ from the initial request from the applicant. The relationship between the key parameters for the evaluation scheme is reported in Appendix B.

On the basis of the provided data from the challenge test and the applied conservative assumptions, the Panel considered that the recycling process under evaluation using the EREMA MPR, Basic and Advanced Recycling technologies are able to ensure that the level of migration of unknown contaminants from the recycled PET into food is below the conservatively modelled migration of:

-

0.1 μg/kg food at which the risk to human health would be negligible when the recycled PET is used for bottles intended for contact with all types of foodstuffs (scenario of infants) and when:

-

0.15 μg/kg food at which the risk to human health would be negligible when the recycled PET is used for trays and containers intended for contact with all types of foodstuffs except packaged water (scenario of toddlers) and when:

Table 4.

Maximum percentage of recycled PET allowed in mixtures with virgin PET, calculated as a function of residence time

| Residence timea | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t1 | t2 | t3 | t4 | t5 | t6 | t7 | t8 | t9 | t10 | t11 | t12 | |

| Maximum rPET % for bottles intended for contact with all types of foodstuffs | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 75 | 85 | 95 | 100 | 100 |

| Maximum rPET % for trays and containers, for contact with all types of foodstuffs except packaged water | 35 | 45 | 55 | 65 | 75 | 90 | 100 | 100 | 100 | 100 | 100 | 100 |

PET: poly(ethylene terephthalate).

t1 < t2 < t3 < t4 < t5 < t6 < t7 < t8 < t9 < t10 < t11 < t12.

■■■■■

Figure 4.

Percentage of recycled PET allowed for the manufacture of trays and containers, including (−) or excluding (−) packaged water, related to the residence time applied for the decontamination of PET in the continuous reactor (step 3)

4. Conclusions

The Panel considered that the EREMA recycling process is well characterised and the main steps used to recycle the PET flakes into decontaminated PET flakes, pellets or sheets have been identified. Having examined the challenge tests provided, the Panel concluded that the decontamination in the continuous reactor of step 3 is the critical step for the decontamination efficiency of the process. The operating parameters to control their performance are the temperature, the pressure and the residence time. Therefore, the Panel considered that the recycling process EREMA is able to reduce any foreseeable accidental contamination of the post‐consumer food contact PET to a concentration that does not give rise to concern for a risk to human health if:

it is operated under conditions that are at least as severe as those obtained from the challenge tests used to measure the decontamination efficiency of the process,

the input of the process is washed and dried post‐consumer PET flakes originating from materials and articles that have been manufactured in accordance with the European Union (EU) legislation on food contact materials containing no more than 5% of PET from non‐food consumer applications.

The Panel concluded that the recycled PET obtained from the process based on the EREMA technologies MPR, Basic and Advanced, intended to be used for the manufacture of bottles, thermoformed trays and containers for contact with all types of foodstuffs for long‐term storage at room temperature, is not considered of safety concern when final articles are manufactured with no more than the percentage of recycled post‐consumer PET specified above (Table 4 and Figure 4), depending on the intended use. The trays are not intended to be used and should not be used in microwaves and conventional ovens.

5. Recommendations

The Panel recommended periodic verification that the input to be recycled originates from materials and articles that have been manufactured in accordance with the EU legislation on food contact materials and that the proportion of PET from non‐food consumer applications is no more than 5%. This adheres to good manufacturing practice and the Regulation (EC) No 282/2008, Art. 4b. Critical steps in recycling should be monitored and kept under control. In addition, supporting documentation should be available on how it is ensured that the critical steps are operated under conditions at least as severe as those in the challenge test used to measure the decontamination efficiency of the process.

Documentation provided to EFSA

Dossier “EREMA Recycling Process”. March 2016. Submitted on behalf of EREMA Engineering Recycling Maschinen und Anlagen G.m.b.H.

Additional data for the dossier “EREMA Recycling Process”. August 2016. Submitted on behalf of EREMA Engineering Recycling Maschinen und Anlagen G.m.b.H.

Abbreviations

- bw

body weight

- CEF

Food Contact Materials, Enzymes, Flavourings and Processing Aids

- Cmod

modelled concentration in PET

- Cres

residual concentration in PET

- FDA

US Food and Drug Administration (FDA)

- MPR

Multi‐Purpose Reactor

- PET

poly(ethylene terephthalate)

- PVC

poly(vinyl chloride)

- rPET

recycled poly(ethylene terephthalate)

Appendix A – Technical data of the washed flakes as provided by the applicant

1.

| Parameter | Value |

|---|---|

| Moisture max. | 1.0% |

| Moisture variation | ± 0.3%/h |

| Bulk density | 230–850 kg/m3 |

| Bulk density variation | ± 150 kg m−3 h−1 |

| Material temperature | 10–60°C |

| Material temp. variation | ± 10°C/h |

| PVC max. | 200 ppm |

| Glue max. | 100 ppm |

| Polyolefins max. | 300 ppm |

| Cellulose (paper, wood) | 100 ppm |

| Metals max. | 100 ppm |

| Polyamide max. | 100 ppm |

Appendix B – Relationship between the key parameters for the evaluation scheme (EFSA CEF Panel, 2011)

1.

Figure 5.

*Default scenario (infant). For adults and toddlers, the migration criterion will be 0.75 and 0.15 μg/kg food, respectively.

Suggested citation: EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids) , Silano V, Bolognesi C, Castle L, Cravedi J‐P, Engel K‐H, Fowler P, Grob K, Gürtler R, Husøy T, Kärenlampi S, Mennes W, Penninks A, Smith A, Tavares Poças MF, Tlustos C, Wölfle D, Zorn H, Zugravu C‐A, Dudler V, Gontard N, Lampi E, Nerin C, Papaspyrides C, Lioupis A and Milana MR, 2017. Scientific Opinion on the safety assessment of the process ‘EREMA Recycling (MPR, Basic and Advanced technologies)’, used to recycle post‐consumer PET into food contact materials. EFSA Journal 2017;15(6):4842, 16 pp. 10.2903/j.efsa.2017.4842

Requestor: Austrian Competent Authority (Federal Ministry of Health), Austria

Question number: EFSA‐Q‐2015‐00679

Panel members: Claudia Bolognesi, Laurence Castle, Jean‐Pierre Cravedi, Karl‐Heinz Engel, Paul Fowler, Roland Franz, Konrad Grob, Rainer Gürtler, Trine Husøy, Sirpa Kärenlampi, Wim Mennes, Maria Rosaria Milana, André Penninks, Vittorio Silano, Andrew Smith, Maria de Fátima Tavares Poças, Christina Tlustos, Detlef Wölfle, Holger Zorn and Corina‐Aurelia Zugravu.

Competing interests: In line with EFSA's policy on declarations of interest, Panel member Roland Franz did not participate in the development and adoption of this scientific output.

Adopted: 4 May 2017

Notes

Regulation (EC) No 282/2008 of the European parliament and of the council of 27 March 2008 on recycled plastic materials and articles intended to come into contact with foods and amending Regulation (EC) No 2023/2006. OJ L 86, 28.3.2008, p. 9–18.

Regulation (EC) No 1935/2004 of the European parliament and of the council of 27 October 2004 on materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC. OJ L 338, 13.11.2004, p. 4–17.

‘Cross‐contamination’, (partitioning between green and white flakes) as meant in the Scientific Opinion on ‘the criteria to be used for safety evaluation of a mechanical recycling process to produce recycled PET intended to be used for manufacture of materials and articles in contact with food’, is the transfer of surrogate contaminants from the initially contaminated to the initially not contaminated material (EFSA CEF Panel, 2011).

0.0025 μg/kg bw per day is the human exposure threshold value for chemicals with structural alerts raising concern for potential genotoxicity, below which the risk to human health would be negligible (EFSA CEF Panel, 2011).

References

- EFSA (European Food Safety Authority), 2008. Guidelines for the submission of an application for safety evaluation by the EFSA of a recycling process to produce recycled plastics intended to be used for manufacture of materials and articles in contact with food, prior to its authorisation. EFSA Journal 2008;6(7):717, 12 pp. 10.2903/j.efsa.2008.717 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA (European Food Safety Authority), 2009. Guidance of the Scientific Committee on transparency in the scientific aspects of risk assessments carried out by EFSA. Part 2: general principles. EFSA Journal 2009;7(5):1051, 22 pp. 10.2903/j.efsa.2009.1051 [DOI] [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids), 2011. Scientific opinion on the criteria to be used for safety evaluation of a mechanical recycling process to produce recycled PET intended to be used for manufacture of materials and articles in contact with food. EFSA Journal 2011;9(7):2184, 25 pp. 10.2903/j.efsa.2011.2184 [DOI] [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids), 2013a. Scientific Opinion on the safety evaluation of the process “Sky‐Light MPR”, used to recycle post‐consumer PET into food contact materials. EFSA Journal 2013;11(11):3450, 14 pp. 10.2903/j.efsa.2013.3450 [DOI] [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids), 2013b. Scientific Opinion on the safety evaluation of the following processes based on EREMA Basic technology used to recycle post‐consumer PET into food contact materials “Octal”, “Pregis”, “Sabert”, “Linpac”, “ExtruPET”, “Evertis”, “Holfeld”, “Huhtamaki”, “Snelcore”, and “Re‐PET”. EFSA Journal 2013;11(11):3462, 26 pp. 10.2903/j.efsa.2013.3462 [DOI] [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids), 2013c. Scientific Opinion on the safety assessment of the following processes based on EREMA Advanced technology used to recycle post‐consumer PET into food contact materials “Kruschitz”, “Vogtland PET”, “Veolia”, “ITW Polyrecycling”, “Texplast”, “Alimpet” and “Esox Prodimpex”. EFSA Journal 2013;11(11):3463, 25 pp. 10.2903/j.efsa.2013.3463 [DOI] [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids), 2014. Scientific Opinion on the safety assessment of the process SOREPET GR based on EREMA Basic technology used to recycle post‐consumer PET into food contact materials. EFSA Journal 2014;12(4):3636, 16 pp. 10.2903/j.efsa.2014.3636 [DOI] [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids), 2015a. Scientific Opinion on the safety evaluation of the following processes based on EREMA Advanced technology used to recycle post‐consumer PET into food contact materials: ‘Greentech’, ‘Alimpet’ and ‘Polyrecycling’. EFSA Journal 2015;13(2):4017, 19 pp. 10.2903/j.efsa.2015.4017 [DOI] [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids), 2015b. Scientific Opinion on the safety evaluation of the following processes based on EREMA Basic technology used to recycle post‐consumer PET into food contact materials ‘Coveris’ and ‘Envaplaster’. EFSA Journal 2015;13(4):4065, 15 pp. 10.2903/j.efsa.2015.4065 [DOI] [Google Scholar]

- EFSA CEF Panel (EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids), 2015c. Scientific Opinion on the safety evaluation of the process ‘Evertis Iberica’, based on EREMA MPR technology, used to recycle post‐consumer PET into food contact materials. EFSA Journal 2015;13(5):4119, 14 pp. 10.2903/j.efsa.2015.4119 [DOI] [Google Scholar]

- Welle F, 2016. Investigation into cross‐contamination during cleaning efficiency testing in PET recycling. Resources, Conservation and Recycling, 112, 65–72. [Google Scholar]