Graphical abstract

Keywords: Bacillus species, Construction industry, Biological additives, In situ material, Road sector, Soil stabiliser

Highlights

-

•

Development of miniaturised techniques to assess the structural properties of in-situ material.

-

•

Structural criterion includes: abrasion, erosion, water absorption & compression load tests.

-

•

Designed models consistent with industry, on a smaller scale using 3D printing technology.

-

•

Development of methods for high-throughput screening of novel bio-based samples from Bacillus.

-

•

Proof of Concept established on the use of bio-based stabilisers.

Abstract

Roads are expensive to develop particularly in challenging environmental conditions, and a lack of understanding of the properties of soil can lead to poor design and premature failures contributing to costly maintenance. The construction industry is exploring new opportunities involving biological processes and products to modify the structural properties of the in situ material, in terms of strength, volume stability, durability and permeability. Through an integrative interdisciplinary approach several microorganisms and other existing bio-enzymatic products such as secondary metabolites, enzymes, endospores, and extracellular polymeric substances have been considered as possible alternatives to conventional methods for the development of sustainable road infrastructure. Limitations in the current state of technology to developing bio-based solutions include microorganism selection and the ability to evaluate derivative components in rapid structural tests that enhance the time to development of proper commercial products. This study focused on the testing of fermentation derived components of biological materials in a high-throughput manner, using miniaturised structural tests to validate screening and selection methodology. The methods tested included resistance to abrasion, resistance to erosion, water absorption and resistance to compression load. Unique miniaturised test equipment was successfully developed using computer-aided design (CAD) and 3D printing technologies. Effects were measured to enable the rapid evaluation of a target microorganism and for screening of biological components or fractions. Results obtained using a Bacillus isolate reported in the current study exhibit strength characteristics and can potentially be formulated as a product for soil stabilisation. This work forms the basis for in vitro selection methodology to enhance development of bio-based structural materials for application in the road sector.

Introduction

Increasing demand is placed on the design, construction and maintenance of road infrastructure, especially in developing countries that often have limited resources due to a constrained fiscus. An additional concern is the associated negative environmental impact of traditional cementitious additives opposite the preservation of scarce natural resources [1]. Material sourcing is one of the contributing factors to increased costs of construction, due to hauling distances, when local materials cannot be used. Stabilisation of in situ material is considered to be important for improving the strength and performance of the treated soil material, which contributes to prolonging the service life of the subgrade and a more economical design [2]. Therefore, innovation is required in the use of alternative materials and innovative construction techniques that enhance in situ materials and minimise environmental load. Biological stabilising additives such as secondary metabolites, enzymes, endospores, and extracellular polymeric substances have been shown to enhance strength and durability characteristics of soils, in addition to having the advantage of a lower carbon footprint compared to traditional stabilisers [3]. Research using Bacillus species has resulted in the identification of potential strains for these civil engineering applications, such as Bacillus pasteurii [4]. However limited knowledge is available on the application of bio-stabilisers in road construction, therefore a need has been identified for the development of new experimental techniques for the purpose of evaluation and selection of microbes and microbial components representative of whole broth, vegetative cells, spores, enzymes and biopolymers in a high-throughput screening process.

In accordance with civil engineering material specifications and test standards, the ability to measure the resistance to abrasion, resistance to erosion, resistance to compressive stress and water absorption of hardened soil allows simultaneous evaluation of strength properties [5], [6]. When the in-place soil does not meet the desired or required strength or other properties, stabilising the low quality materials to meet the desired performance criteria is needed. The traditional approach in testing and assessment involves subjecting a material to controlled large scale strength testing such as abrasion resistance, erosion resistance, moisture sensitivity, California bearing ratio (CBR) and/or unconfined compression strength test (UCS) whilst monitoring bulk mass loss or dimensional changes [7]. Considering the number of tests, the development of potential biological soil stabilisers would require multiple samples. Therefore, rapid screening of new biological stabilisers using standard size cylindrical blocks is limited due to the higher resources required to test multiple samples. Some studies on biological stabilisers include those reported by Ghosh, Mandal [8], Rao, Reddy [9] and Charpe, Latkar [10] that only showed bacteria impregnation improvement through compressive strength testing. More studies are necessary to complement the existing information on the performance of microbial based, enzyme, polymeric or ionic stabilisers in order to establish an acceptable standard for use of these alternatives in the road construction sector.

Limited miniaturised testing is available to enable the medium to high-throughput screening and evaluation of multiple biological stabilisation materials to reduce cost and enable technological advancement [11]. This has created a need for the development of novel miniaturised testing equipment and methodology, based on the larger scale tests, to evaluate the structural enhancement resulting from the addition of biological stabilisers to actual aggregate material used in the construction industry.

Our research details the development of small bench-scale (miniaturised) testing equipment (produced through 3D printing) and the associated testing procedures, followed by the statistical evaluation of the suitability of the tests to measure the criteria of interest regarding structural stabilisation of in situ material. The choice of introducing small scale testing to enable high-throughput screening is reflected in the fact that the effectiveness in bonding is dependent on the interaction of the bio-additive with fines in the bulk material. A correct interpretation and detailed analysis of the effects produced by the bio-additive on the bonding effectiveness using small scale testing should contribute to the overall understanding of the binding effectiveness of the bio-additive and allowing for conservation of materials for testing during the screening process. Results were also compared to the associated full scale standardised tests as part of the validation of these bench-scale methods. This paper outlines the bench-scale test methodology that can be used for the prediction of structural performance thereby enabling higher throughput screening and selection of microbes and microbial components for further development.

Material and methods

Preparation of crude additives for soil stabilisation

A cryo-preserved culture of B. licheniformis was used for the study (the Netherlands Culture Collection of Bacteria, NCCB 100133) [12]. The inoculum was prepared by adding a cryovial containing this isolate (2 mL stored at – 80 °C in an ultra-freezer (Forma™ 88,000 Series, Thermo Scientific, Massachusetts, USA)) to 700 mL sterile Tryptone Soy Broth (TSB) and incubated at 32 °C on a platform rotary shaker (New Brunswick Scientific, Innova 2300 series, New Jersey, USA) at 180 RPM for 13 h until an optical density (OD), measured at 660 nm (Spectroquant Pharo 300, Merck, Gauteng, South Africa), of between 4 and 5 was obtained. The inoculum flask was used to inoculate a 10 L bioreactor containing culture medium (protein source 29.49 g.L-1, carbon source 51.33 g.L-1 and salts ((NH4)2SO4, Ca(NO3)2·4H2O, MgSO4·7H2O, MnSO4·4H2O and FeSO4·7H2O ranging from 0.03 to 5.00 g.L-1 respectively) (Merck, Darmstadt, Germany). The fermentation was carried out in a 10 L Biostat Braun C reactor (Sartorius BBI Systems, Melsungen, Germany). Temperature was controlled at 32 °C, agitator and airflow ramped from 500 to 1300 RPM and 10 to 20 SLPM over six hours respectively. Dissolved oxygen (DO) was monitored during the course of the cultivation to ensure oxygen sufficiency whilst pressure was maintained at 500 mBar. The pH was set at 6.80 and controlled using 10% v.v-1 H2SO4 or 30% v.v-1 NH4OH.

Once the culture reached the stationary phase at ~ 12:00 – 20:00 h’s fermentation age, the whole broth was recovered and stored in sterile containers at 4 °C for 24 h. This whole broth was termed Fraction A for use in the subsequent test experiments and added as a bio-additive at a concentration of 0.025 L/kg of soil [2].

Preparation of miniature test blocks

Two different types of soils denoted as soil type I (dolerite soil) and II (weathered granite) were retrieved from specific sites in South Africa (SA) (Table S1-S2; Fig. S1-S2). Soil samples used for the tests, are those classified to be of good quality for use in road construction and collected at depth from borrow pits, to avoid the presence of organic matter. The bio-additive mixtures and each of the soil types listed above were mixed using 25 g of bio-additive (Fraction A) and 55 g deionised water per 1000 g soil material (at a bio-additive concentration of 2.5% i.e. the mass of Fraction A as a proportion to the mass of soil). The soil/bio-additive mix was left to mellow for 12 h at room temperature. The optimum moisture content (OMC) was determined by conducting the density-moisture content test (South African National Standard test SANS 3001-GR30:2015 Determination of the maximum dry density and optimum moisture content) (Table S3; Fig. S3). The moisture content (±8%) (Tables S1–S2) was confirmed at lab scale using a moisture analyzer (Moisture analyzer, HS153, Mettler Toledo, Ohio, USA) for integration of the bio-additives mix to the soils to achieve uniformity during compaction. The studies also included a positive control (soil treated with a Permazyme product (Specialised Protection Products, Gauteng, South Africa) prepared according to the manufacturer’s instructions; a negative control (untreated soil wetted with water). A test standard (Ordinary Portland cement, OPC) (Pretoria Portland Cement, Gauteng, South Africa) 0.3 to water was prepared by mixing 100 g of OPC with 30 g of deionised water and similarly mixed into the soil. All formats were then fully compressed manually using a tablet press (Korsch, Berlin, Germany) to produce miniature compacted blocks with dimension of 9 mm height × 13 mm diameter. The soil blocks were cured in a 25 °C incubator for 7 days at a relative humidity between 50 and 60%, and the OPC blocks cured at 21 °C for 7 days, immersed in water. After 7 days, the compaction diameter and height of the blocks were checked for uniformity using a digital caliper of each treated and untreated soil block.

Design of the apparatus

Abrasion test – Fabrication

The brush test is one of several strength tests that are carried out to assess the material’s durability and resistance to abrasion, simulating harsh shearing forces exerted on road wearing courses in field studies [13]. The miniaturised device was designed using CAD software (SolidWorks, USA) and printed using a Wanhao Duplicator 4S running Sailfish firmware (Slic3r Prusa Edition software). The block holder was designed to accommodate the miniaturised blocks (in terms of size, compaction and soil materials) and the rotating case was printed as two separate components, the interlocking mechanism allows for easy removal of the holding case. The fixed base of the rotating case and the base of the brush was printed using PETG filament (3D printing factory, Centurion, South Africa). Aluminium (Micro Robotics, Centurion, South Africa) was used for the fixed arm, adjustable load arm and base stand of the apparatus. The rollers provide a downward mechanism that minimised frictional force. The load serves as a constant force calculated at 3.3 N against the block, to ensure abrasion occurs consistently as the test block wears over time. Due to the scaling down of the sample a fixed load and rotating holding case set at 115 RPM and was sufficient to test abrasion in relation to the standard of the larger scaled test [5]. The apparatus was connected with Arduino UNO R3 (UNOR3), power supply 12 V 2A (12V2A) and DC worm gear motor − 12 V 160 RPM (JGY-370-12V-160) (Micro Robotics, Centurion, South Africa) (Fig. 1a – g). The nylon bristle brush placed above the surface of the bio-stabilised block gradually removed material (at 1, 2, 5, 10 and 20 min intervals) which allowed for assessment of the material’s durability and resistance to abrasion over time. On the basis of preliminary testing, the brush was changed every 100 cycles to avoid discrepancies due to wearing of the brushes.

Fig. 1.

CAD model (left) showing (a) load arm, (b) brush holders, (c1, c2) material block and holding case, (d1, d2) rotating case, (e1, e2) gearbox and motor, (f) adjustable rollers, (g) control box; the mean compaction (h) dolerite soil, height 7.30 ± 0.19 mm, width 13.17 ± 0.06 mm; (i) weathered granite soil, height 7.93 ± 0.19 mm, width 12.96 ± 0.06 mm; and Fabricated apparatus (right).

Erosion test – Fabrication

The erosion test is one of several strength tests that are carried out to assess the material's resistance to running water, simulating rainy and humid weather conditions for field studies [6], [7]. Earth and gravel roads are vulnerable to weather, especially during rainy seasons as soil material can lose cohesiveness, such as fine material possessing a higher permeability [14]. Therefore, the use of bio-stabilisers to prevent erosion due to water action needs to be investigated. The erosion test was designed using CAD software (SolidWorks, USA) and Wanhao Duplicator 4S running Sailfish firmware (Slic3r Prusa Edition software to generate the gcode) for printing, similar to the abrasion test. The holding block (45°flow angle) was designed to accommodate the miniaturised blocks (in terms of size, compaction and soil materials) such that they could be secured without damage and was printed using PETG filament (3D printing factory, Centurion, South Africa). A port was inserted for a 5 mm drain pipe (to allow excess water to drain off) and a notch to mount the dripper line using silicone tubing (3 mm diameter) for the flow of water. Since the water pressure used would be relatively low (simulating water surface flow not water impact) a needle was insert and orientated such that it was in line with the uppermost surface of the bio-stabilised block thus allowing for even distribution of deionised water over a prepared block. A filling tank and pump system was fitted to allow a constant flow rate of 2.5 mL/min at all times. The optimum duration of water flow was assessed to finalise the test method. The test blocks were tested at two minutes interval and provided sufficient time to distinguish erodibility of different soils and the effectiveness of the potential stabilisers [6].

Water absorption test

This test provides a modified model of the capillary rise process [15]. Chemically/biochemically stabilised material on unsurfaced roads should have adequate compressive strength under dry conditions; however, the material will lose strength under adverse moisture content. The amount of water absorption permitted by the stabilised soil is therefore of importance in this case. A water absorption test method can provide a basis for analysis of test data for characterisation, such as the water absorption coefficient (Aw) (indicating water absorbent properties of the material), and the point at which material deforms (amount of water absorbed before failure) thus showing the effect of moisture migration on the cohesion of the soil material. Modification of the capillary absorption rate data was obtained using the standard procedure [15] whereby the cylindrical test blocks of 9 mm height × 13 mm diameter were placed in contact with the test liquid (deionised water) in a shallow graduated tray (2 mm depth of immersion). Water was absorbed through the bottom face. The weight gain of the sample was measured at 1 min intervals over a period of 6 min or until the water level mark reached the top of the block. This was noted by observing the sample wetness.

Compressive strength test

The compression load test is one of several strength tests that are carried out to assess the material's resistance to compressive forces. Compression testing determines the compressive strength parameters which will be used to assess the suitability of the mixture for use in pavement bases and sub-bases, stabilised subgrades and structural fills. A tablet press (Korsch, Berlin, Germany) was used to assess the breakage point. The equipment consisted of a lower punch piston and an upper punch piston; a uniform force was exerted on the block until breakage point. The breakpoint force was recorded in KN and converted to compressive stress in mega Pascal’s (MPa) (Pharma-Research software, Berlin, Germany). Deformation was not measured as the current focus is on maximum achievable strength and not deformation characteristics.

Development of test methodology

The verification of methods is described in Table 1 according to the thresholds that were defined [5], [6]. Following this approach provided an increased level of confidence in the test results. The following tests were defined to measure the structural performance of the bio-additive mixtures: The abrasion test (1), measured the resistance to abrasion, simulating constant wear or gradual loss of material on the bio-stabilised blocks in a uniform manner over time (Equation (1)).

| (1) |

Where,

Ma = Percentage of material abraded,

Mi = Initial mass of block,

Mf = Final mass of block.

Table 1.

Method verification and characteristic requirements.

| Method | Indicator | Result | Threshold |

|---|---|---|---|

| Abrading resistance | |||

| Repeatability | 6.12 | CV < 10% | |

| Range | 14.58–16.67 | Loss of material < 10% | |

| Linearity | 0.97 | r2 > 0.90 | |

| Water absorption | |||

| Repeatability | 6.50 | CV < 10% | |

| Range | 28.99–32.50 | Loss of material < 10% | |

| Linearity | 0.97 | r2 > 0.90 | |

| Erosion resistance | |||

| Repeatability | 7.71 | CV < 10% | |

| Range | 53.76–62.50 | Loss of material < 10% | |

| Linearity | 0.99 | r2 > 0.90 | |

| Compression test | |||

| Repeatability | 8.53 | CV < 10% | |

| Range | 0.75–15.10 | Max breakage point > 75 MPa | |

| Linearity | 0.95 | r2 > 0.90 | |

The erosion test (2), measured the resistance to erosion, simulating a flow of water and hence gradual loss of material over a set time (Equation (2)).

| (2) |

Where,

Wm = Percentage loss due to erosion,

Ww = Weight of block before testing,

Wd = Weight of block after drying.

The water absorption test (3) was a modification of a validated test method and measured the resistance to water absorption using miniaturised bio-stabilised soil as well as the effect of hydration i.e. the point deformation of the bio-stabilised soil (Equation (3), (4)).

| (3) |

| (4) |

Where,

M0 (g) = Dry weight of the specimen at time (t) = 0,

Mt (g) = Weight of the specimen at time t,

ΔMt (g) = Weight of absorbed water after time (t),

m (kg·m−2) = Weight of absorbed water per unit area,

d (mm) = Diameter of the specimen.

The resistance to compression (4) was a modification of validated test equipment, utilising set specifications of the miniaturised bio-stabilised blocks, and the stress required to breakage point describes this test (compressive stress in MPa). Ordinary Portland cement was used as the test reference material for the above mentioned tests. These methods (1–4) provide a rapid screening of the biological fractions to provide a basis for selection for subsequent larger scale testing by assessing the observed changes in performance as a function of level of treatment.

Large scale tests

The study used soil type II (weathered granite) for the preliminary assessment in order to validate the test methodology. The water ratio normalisation in the analysis was determined (MDD/OMC) (Table S3, Fig. S3) as the Broth mixture required (absorbed) more water to achieve uniformity during compaction (cylindrical block samples, 100 mm diameter & 115 mm height). Standard erosion and abrasion tests [16] were used as an indication of the stabilised soil properties.

Statistical analysis

Results were expressed as mean ± S.E.M. Univariate analysis of variance was carried out and the statistical comparisons were done with the Bonferroni test and t-test using a statistical package program (GraphPad Prism® 5.03 software for Windows).

Results

Test methodology

The test methodology was successfully verified as shown in Table 1 which shows that the results were within close proximity to the defined thresholds using soil type I and II (Tables S4–S9). Table 2 summarises the descriptions of each test and the measurements taken.

Table 2.

Summary of the quantitative analysis.

| Strength tests | Measurement | Description |

|---|---|---|

| Brush test | Relative resistance to abrasion (%) | Expressed relative to the reference |

| Rate of loss (g/min) | Rate of change (calculated from the slope) | |

| Maximum loss of material (%) | Materials' ability to resist abrasion | |

| Water absorption test | Water absorbance (kg·m−2) | Water absorption coefficient (Aw) |

| Effect of hydration (mL) | The amount of absorbed water a material can bear before failure (point of deformation). | |

| Erosion test | Relative resistance to erosion (%) | Expressed relative to the reference |

| Maximum loss of material (%) | Materials' ability to resist erosion | |

| Compression load test | Compression stress (MPa) | Maximum/peak breakage point |

| Relative resistance to compression (%) | Expressed relative to the reference |

Miniaturisation of bio-stabilised blocks

Miniaturised blocks were successfully produced using the selected soils. Fig. 1 (h and i) illustrates soil I and soil II blocks that enabled method screening on different soil types. Due to the vast differences in soil types only two soils were selected for testing; a clayey soil (soil type I, dolerite soil) and a non-plastic soil or varying course fraction (soil type II, weathered granite).

Miniaturisation of test equipment

Miniaturised test equipment was successfully designed for the brush and erosion tests via CAD and fabricated into detailed engineered 3D models (Table 3). The equipment was successfully functionalised.

Table 3.

Miniaturised test equipment.

| Test | Equipment type | Design | Device Fabrication | Successfully Functionalised |

|---|---|---|---|---|

| Abrasion | Brush tester | Electronically controlled abrasion model | 3D printed and assembled | Yes |

| Erosion | Erosion tester | Pump type water flow system | 3D printed and assembled | Yes |

| Water absorption | Immersion tester | Graduated sample holders | Purchased Lab equipment | Yes |

| Compression test | Compression load tester | Modified equipment | Stable equipment | Yes |

Abrasion analysis

The blocks were analysed by determining net weight lost for a specific time period (g/min), the weight of the block before and after the test was recorded using Equation (1) (Fig. S4). The percentage loss of material for standard ordinary Portland cement was shown as relative loss (Tables S10 and S11). From the results the positive and negative controls performed as expected and enabled comparisons to the biological fractions that were tested (Fig. 2). Data from here was used as an input for the design of experiments for large scale testing.

Fig. 2.

Abrasion test results showing soil type I (a) and soil II (b), Results expressed as mean ± SEM; N = 3; p-value (two-tailed) p < 0.05 vs control.

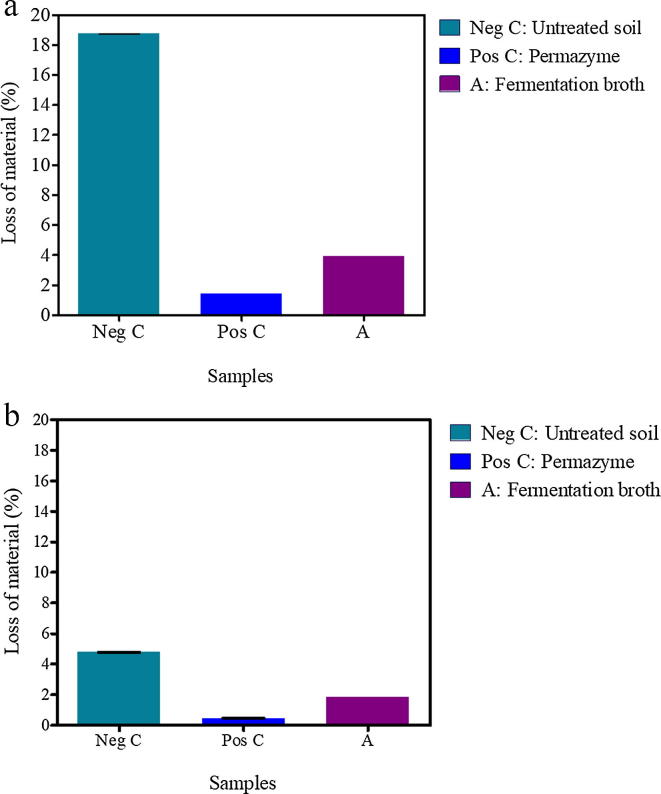

Erosion analysis

Erosion properties of the material were measured by determining the net weight loss of the blocks (Equation (2)). The material’s erosion properties are shown over a two minute time period. The assessment of erosion properties was calculated relative to the test standard, the fractions displayed significant differences compared to the negative and positive controls (e.g. Table S12). This test was found to simulate erosion loss due to the flow of water over the surface of the compacted soil blocks, which satisfied the requirements for this test. A graphical summary of the erosion test results is shown in Fig. 3. The results clearly show as expected, that the addition of stabilising additives (positive control) increased the effect on erosion resistance.

Fig. 3.

Erosion test results showing soil type I (a) and soil II (b), Results expressed as mean ± SEM; N = 3; p-value (two-tailed) p < 0.05 vs control.

Water absorption analysis

Water repellent agents are considered an effective measure of preventing moisture damage in construction materials. Water absorption coefficient (Aw) expresses the rate of capillary action in a certain time (Aw (kg m−2·s−1/2)). The slope (m) was calculated from the weight of absorbed water per area (kg·m−2) versus the square root of time (s). The positive and negative controls were used to determine the Aw, and indicate that the higher the water absorption coefficient, the lower the water repellent properties of the material. For the determination of the water absorption coefficient refer to Equations (3), (4) (Fig. S5). No inconsistencies were observed in the data, as both the positive and negative controls performed as expected (Fig. 4). The second response measured the point of deformation of the bio-stabilised blocks using time as a variable. This indicates the cohesive properties of the particles started to fail at a particular point and onwards (Fig. S6).

Fig. 4.

Summary of results of the water absorption coefficient (Aw) using soil type I (a) and soil II (b), Results expressed as mean ± SEM; N = 3; p-value (two-tailed) p < 0.05 vs control.

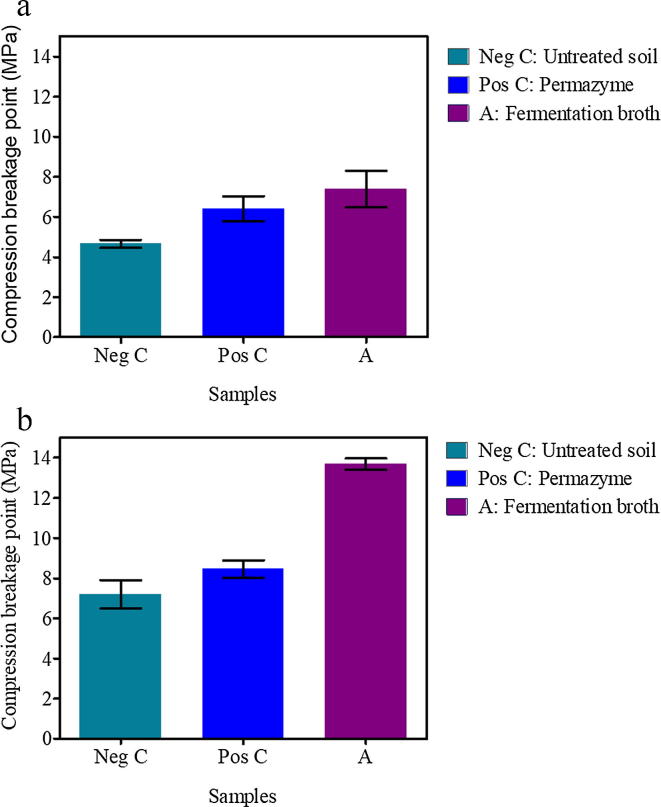

Compression load analysis

Fig. 5 shows the compression breakage point of soil types I and II, the sample size was modified from N = 3 to N = 6 so that outliers could be eliminated (Q = 1) and thus follows a non-linear fit using a second order polynomial (quadratic). The test control result was >75 MPa showing a greater force was required to break the miniaturised concrete block. Descriptive statistics were outlined, showing the results of the method and performance of the biological fractions. The addition of biological components and fractions extracted from a B. licheniformis fermentation at vegetative state to soil type I and II displayed increased resistance to compression against the Permazyme product (positive control) and in comparison, to the untreated soil material (negative control) (Fig. S7; Tables S13–S14).

Fig. 5.

Compression breakage point of soil type I (a) and soil II (b), Results expressed as mean ± SEM; N = 6; p-value (two-tailed) p < 0.05 vs control.

Large scale testing

Standardised methods were performed using similar test parameters on soil type II, to demonstrate that the miniaturised assay test results are valid and consistent with those at large scale [16]. The results show the resistance to abrasion and resistance to erosion at large scale (Fig. 6). The tests utilise loss of material as a primary measure in both methods. From the statistical comparison Table 4 shows the small scale tests (method A) and the large scale tests (method B), as well as the mean values obtained for the positive and negative controls at small scale versus large scale. Comparison of results at small scale versus large scale testing enables the prediction of technical requirements for large scale testing such as improvement of erosion and abrasion characteristics. What we infer from the statistical comparison is that the small scale tests provide similar first order result (attractive level of probability) to that at large scale. Therefore, the small scale methods provide a fast, cost-effective screening tool for selection of biological material to proceed to large scale tests.

Fig. 6.

(a) Abrasion test results from the large scale method (250 RPM; additive concentration 2.3% by mass); (b) Erosion test results from the large scale method (additive concentration 2.3% by mass).

Table 4.

Comparison of results small scale vs large scale testing.

| Test | Mean (% loss) | CV % | p-value* | Are the means statistically similar? |

|---|---|---|---|---|

| Abrasion test | ||||

| Small scale: Neg C | 4.78 | 0.91 | 0.13 | Yes |

| Large scale: Neg C | 4.90 | 1.19 | ||

| Small scale: Pos C | 0.50 | 10.00 | 0.001 | No |

| Large scale: Pos C | 3.26 | 1.77 | ||

| Small scale: Fraction A | 1.84 | 0.31 | 0.001 |

No |

| Large scale: Fraction A | 3.13 | 1.84 | ||

| Erosion test | ||||

| Small scale: Neg C | 50.87 | 2.42 | 0.14 | Yes |

| Large scale: Neg C | 46.97 | 0.12 | ||

| Small scale: Pos C | 15.48 | 13.81 | 0.16 | Yes |

| Large scale: Pos C | 17.17 | 1.21 | ||

| Small scale: Fraction A |

25.98 |

7.77 |

0.15 | Yes |

| Large scale: Fraction A | 27.93 | 0.21 | ||

Key: Neg C – negative control; Pos C – positive control; * p-value <0.05 rejects the null hypothesis, therefore shows a statistical difference.

Discussion

This study demonstrated the feasibility of evaluating the strength properties of biological samples via a miniaturised high-throughput method. The abrasion, erosion, water absorption and compression strength tests were all designed to evaluate the resistance nature or strength properties of Bacillus derived macro-components and fractions. The rationale used in this study was to systematically select isolates, macro-components and/or various fractions with potential strength enhancing properties using the developed bench scale methods followed by validation at large scale.

The use of one fraction derived from a B. licheniformis isolate provided a good starting point for selection of potential soil stabilisers, as its associated properties were in line with the selected pre-determined structural criteria. Research shows that the most suitable candidates that produce enzymes, endospores and extracellular polymeric substances (EPS) with the potential mechanism to bind soil particles and fill in soil pores belong to the Bacillus sp. [17]. Similarly other researchers state that functional by-product production by bacteria in soil is a basis to investigate different geotechnical applications [9], [18], [19] such as long-term stabilisation of weak soil for road applications. To date, many authors investigated whole-cell bacteria and other associated biological samples using standardised testing methods [20], [21], however, none used the strategy to screen a larger number of biological samples with potential applications in the construction industry.

The in vitro high-throughput screening of macro-components and fractions derived from Bacillus sp. has been achieved using miniaturised strength tests described herein. The setup of the necessary strength tests to measure the structural functionality criteria (resistance to abrasion, resistance to erosion, water absorption and resistance to compression load tests) in a miniaturised format were successfully demonstrated. The designs for the models were consistent with standard tests, by replicating large scale tests on a smaller scale using 3D printing technology where applicable. These models and procedures were validated based on the ability to repeatedly measure degree of abrasion, erosion, water absorption and compression of the bio-stabilised soil. Descriptions of the methods used were outlined for in vitro high-throughput screening of novel bio-derived samples from a Bacillus isolate. The quantification results (based on the performance data) obtained by using the small scale tests demonstrated that the method for operation of all the models was robust and reliable. By using the miniaturised tests, we can successfully evaluate, select and prioritise the candidate microbes and microbial components by the investigation of specific structural criteria of interest to the soil stabilisation, i.e. abrasion resistance, erosion resistance, compression load resistance and water repulsion properties. The product prototype requires further national large scale tests and will serve as the standard for performance of strength. Further implications in terms of strength requirements will need to be assessed (e.g. focus on materials in response to pressure, temperature or moisture).

From the statistical comparison, the study infers that the small scale tests provide a similar first order result to large scale tests, with the mean values obtained for the negative controls at small scale versus large scale showing similarity. Variations in the comparison obtained with the positive control tests can be attributed to method limitations such as additive binding between the soil particles, surface area and compaction variables due to factors such as material skeletal distribution in large scale samples. By using these systems microbes and microbial components can be rapidly evaluated to enable selection of component types of target microorganisms and for later screening of new isolates of interest. This study has introduced a new and scientifically based paradigm in the development of bio-based structural materials.

The different behaviours exhibited by the small scale samples as a function of bio-additive content provides the performance indication on inspection of the abrasion and erosion resistance results. The total bulk behaviour could be well correlated with the standard scale sample by means of a bio-additive binding effectiveness through the abrasion and erosion tests.

Micro-bonding is deemed to be the contributing factor to effective bonding performance measured at the macro-level. The hypothesised mechanisms includes the generation of particle-binding materials through microbial processes in situ so that the shear strength of soil can be increased; as well as the production of pore-filling materials through microbial means, to significantly reduce the hydraulic conductivity of soil or porous matrices. Products of microbial fermentation processes usually consist of a functional consortium of fermented organic matter, active whole cell bacteria, spores, enzymes, biopolymers, biosurfactants and other proprietary ingredients. New research into these novel primary and secondary metabolites from Bacillus sp. and understanding the micro-structural soil characteristics stability will result in greater knowledge for more macro applications. The initial testing programme focused on demonstrating the effectiveness of the bio-additive in terms of bonding performance. The next phase of the study focuses on the characterisation of agents (physiological, biochemical, and mechanisms of the bio-geochemical processes). Strength properties for the design, including compressive strength testing will form part of the next phase of the testing programme, and lastly field verification.

Conclusion

In summary, miniaturised structural tests were developed using 3D printing technology and modified equipment. More importantly, this is the first study that outlines the processes and methods that can be used for biological samples that undergo high-throughput screening for potential applications in the construction industry. Inclusion of crude fermentation fractions increased resistance to abrasion, resistance to erosion, resistance to compression load and water repulsion properties in comparison to the test control. These observations, in addition to evidence of comparable results obtained for the standard controls, indicate the relevance of further studies. Currently work is being conducted to test the efficacy of the multiple fermentations biological components and fractions on the selected soil types. It is hypothesised that one or more of the microbial components and fractions will have positive effects on the key measurements (i.e. erosion, abrasion, and water absorption and compression resistance) and therefore possess the potential for improving weak subgrade soils and aid in dust and water erosion control on upper surfaces of unpaved low volume roads. Subsequent design of experiments following the small scale tests provides a basis to then select the most promising fractions for further testing on large scale samples. The testing methods described therefore offer a fast, reliable and a cost-effective screening tool for early assessment of structural properties, allowing for prioritisation and selection of microbes and microbial components. Future work involves investigating the potential biological additive’s mode of action.

Compliance with ethical standards

Research involving human participants and/or animals: This article does not contain any studies with human participants or animals performed by any of the authors.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors will like to thank the Department of Science and Technology (DST), South Africa (ZA) and the Council for Scientific and Industrial Research, South Africa (ZA) for financial support; as well as T. Ramohomane and T. van Reenen (Council for Scientific and Industrial Research, Pretoria, South Africa) for assisting with the 3D modelling and design.

Footnotes

Peer review under responsibility of Cairo University.

Supplementary data to this article can be found online at https://doi.org/10.1016/j.jare.2019.11.002.

Appendix A. Supplementary material

The following are the Supplementary data to this article:

References

- 1.Georgees R.N., Hassan R.A., Evans R.P. A potential use of a hydrophilic polymeric material to enhance durability properties of pavement materials. Constr Build Mater. 2017;148:686–695. [Google Scholar]

- 2.Mgangira M. Southern African Transport Conference (SATC) 2009. 2009. Evaluation of the effects of enzyme-based liquid chemical stabilisers on subgrade soils. [Google Scholar]

- 3.Ivanov V, Stabnikov V. Prodution of biopolymers for eco-efficient construction materials. Pacheco-Torgal F, Ivanov V, et al, eds. Biopolymers and biotechnological admixtures for eco-efficient construction materials. 1st ed: Woodhead 2016. p. 13.

- 4.Chu J., Stabnikov V., Ivanov V. Microbially induced calcium carbonate precipitation on surface or in the bulk of soil. Geomicrobiol J. 2012;29(6):544–549. [Google Scholar]

- 5.Jones D. Development of performance-based tests for nontraditional road additives. transportation research record. J Transport Res Board. 2007;1989–2(1):142–153. [Google Scholar]

- 6.Range H., Horak E. Southern African Transport Conference (SATC) 2005. 2005. Erosion of compacted wearing course gravels-relating material grading, plasticity and compaction to erosion potential. [Google Scholar]

- 7.Jones D., Ventura D., Van Wamelen J. Southern African Transport Conference (SATC) 2005. 2005. Fit-for-purpose certification of non-traditional road additives. [Google Scholar]

- 8.Ghosh P., Mandal S., Chattopadhyay B., Pal S. Use of microorganism to improve the strength of cement mortar. Cement and Concrete Res. 2005;35(10):1980–1983. [Google Scholar]

- 9.Rao M.V.S., Reddy V.S., Sasikala C. Performance of microbial concrete developed using Bacillus subtilus JC3. J Inst Eng (India): Series A. 2017;98(4):501–510. [Google Scholar]

- 10.Charpe A.U., Latkar M., Chakrabarti T. Microbially assisted cementation–A biotechnological approach to improve mechanical properties of cement. Constr Build Mater. 2017;135:472–476. [Google Scholar]

- 11.Rutherford K.L., Hutchings I.M. A micro-abrasive wear test, with particular application to coated systems. Surf Coat Technol. 1996;79(1–3):231–239. [Google Scholar]

- 12.Lalloo R., Ramchuran S., Ramduth D., Gorgens J., Gardiner N. Isolation and selection of Bacillus sp. as potential biological agents for enhancement of water quality in culture of ornamental fish. J Appl Microbiol. 2007;103(5):1471–1479. doi: 10.1111/j.1365-2672.2007.03360.x. [DOI] [PubMed] [Google Scholar]

- 13.Chang I., Im J., Cho G.-C. Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability. 2016;8(3):251. [Google Scholar]

- 14.Sicakova A., Draganovska M., Kovac M. Water absorption coefficient as a performance characteristic of building mixes containing fine particles of selected recycled materials. Procedia Eng. 2017;180:1256–1265. [Google Scholar]

- 15.Ioannou I., Hamilton A., Hall C. Capillary absorption of water and n-decane by autoclaved aerated concrete. Cement Concrete Res. 2008;38(6):766–771. [Google Scholar]

- 16.Mgangira M. Properties controlling the resistance to abrasion and erosion of stabilised sandy soils using non-traditional additives. Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering: The academia and practice of geotechnical engineering, Alexandria, Egypt, 5-9 October 2009. 2009;vol. 1 [Google Scholar]

- 17.Schallmey M., Singh A., Ward O.P. Developments in the use of Bacillus species for industrial production. Can J Microbiol. 2004;50(1):1–17. doi: 10.1139/w03-076. [DOI] [PubMed] [Google Scholar]

- 18.Mikutta R., Zang U., Chorover J., Haumaier L., Kalbitz K. Stabilization of extracellular polymeric substances (Bacillus subtilis) by adsorption to and coprecipitation with Al forms. Geochim Cosmochim Acta. 2011;75(11):3135–3154. [Google Scholar]

- 19.Raut S.H., Sarode D.D., Lele S.S. Biocalcification using B. pasteurii for strengthening brick masonry civil engineering structures. World J Microbiol Biotechnol. 2014;30(1):191–200. doi: 10.1007/s11274-013-1439-5. [DOI] [PubMed] [Google Scholar]

- 20.Umar M., Kassim K.A., Ping Chiet K.T. Biological process of soil improvement in civil engineering: A review. JRMGE. 2016;8(5):767–774. [Google Scholar]

- 21.Abo-El-Enein S., Ali A., Talkhan F.N., Abdel-Gawwad H. Application of microbial biocementation to improve the physico-mechanical properties of cement mortar. HBRC J. 2013;9(1):36–40. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.