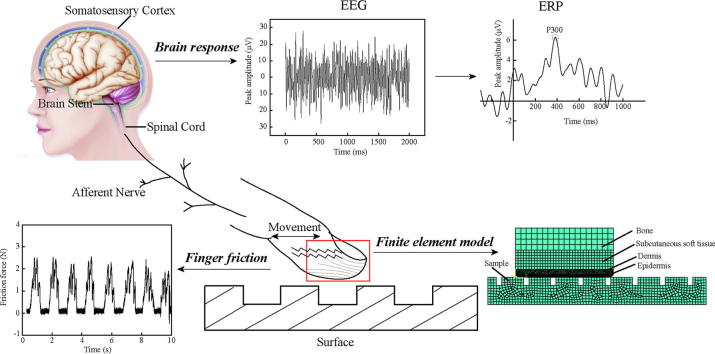

Graphical abstract

Keywords: Tactile perception, Brain activation, Friction, Gratings, Finite element analysis, P300

Abbreviations: EEG, electroencephalograph; ERP, event-related potential; SS-EP, steady-state evoked potentials; DOF, degree of freedom

Highlights

-

•

Tactile perception is investigated from finger friction to brain activation.

-

•

Stress concentrations around mechanoreceptors are affected by the grating textures.

-

•

Friction coefficient of finger increases with increasing grating width and spacing.

-

•

P300 peak latency is related to the difference between target and non-target stimulus.

-

•

P300 evoked by gratings is related with tribological and mechanical properties of skin.

Abstract

The formation of tactile perception is related to skin receptors and the cerebral cortex. In order to systematically study the tactile perception from finger friction to the brain response, a 32-channel Brain Products system and two tri-axial force sensors were used to obtain electroencephalograph (EEG) and friction signals during fingers exploring grating surfaces. A finite element finger model was established to analyze the stress changes of the skin receptors during tactile perception. Samples with different grating widths and spaces were chosen. The results indicated that different gratings induced different stress concentrations within skin that stimulated Meissner and Merkel receptors. Skin friction was affected by gratings during the tactile perception. It was also found that P300 evoked by gratings was related with the skin deformation, contact area, friction force, and stress around cutaneous mechanoreceptors. The wider grating width generated larger skin deformation, friction force, and stress, which induced stronger tactile stimulation. The smaller grating spacing generated higher vibration frequency, inducing stronger tactile stimulation. The latency of the P300 peak was related to the difference between the textured target stimulus and the smooth non-target stimulus. This study proofed that there was a relationship between the activation in brain regions, surface friction, and contact conditions of skin during the tactile perception. It contributes to understanding the formation process and cognitive mechanism of tactile perception of different surface textures.

Nomenclature

- P

sample without texture

- Wi

sample with different grating width

- Si

sample with different grating spacing

Introduction

Tactile perception is one of the five human senses. It plays an important role for human beings in object recognition [1], [2], [3]. During feeling the texture of a surface, we usually move our fingers across the surface to be able describe it in detail. It is hard to identify the texture when still [4]. This implies that the tactile perception depends on tribological motion between human skin and the sensed surface. The formation of tactile perception is a complex process of nerve conduction and processing. In the process of touching, the vibration and deformation caused by friction stimulate sensory receptors in the skin. The sensory receptors detect and transform this vibration and deformation to nerve action potentials that are conveyed to the corresponding sensing area of the cerebral cortex through the afferent nerve, spinal cord, and brain stem. Finally, tactile perception is formed in the somatosensory cortex [5], [6].

The sensory receptors in skin are the main receptors of tactile perception, and the cerebral cortex is the cognitive region for tactile perception. Tactile perception is related to skin receptors and the cerebral cortex. Currently, most research on tactile perception focuses on the tribological and biomechanical properties of skin. Tang et al. [7] studied the vibration and friction signals of skin during tactile perception and extracted eight characteristic features to represent tactile perception. Bhushan et al. [8] studied the effect of skin cream on the tribological properties of skin and found the amplitude of vibration decreased after cream treatment, leading to smoother perception.

However, there is little research focus on cerebral cortex tactile cognition. Research on tactile perception of materials based on EEG and event-related potential (ERP) technology can skip the usual tactile information transmission channels, such as human nerve endings and muscles, and directly focus on the tactile formation region of the brain [9], [10]. Li et al. [11] studied the tactile perception of fingertips when touching sandpaper with different roughness and found that there was a significant correlation between friction perceptions and EEG signals. Moungou et al. [9] studied the steady-state evoked potentials (SS-EP) under different amplitudes of texture exploration-induced vibration and found that textures generating stronger vibration also generated SS-EPs of greater magnitude.

It is known that EEG signals are usually accompanied by strong background noise. The ERP technique obtains the event related potentials evoked by surface texturing and further develops the relationship between tactile perception and surface texturing [12]. Among all the ERP components, P300, as a typical endogenous component, has high connection with the brain cognitive process [13]. It is generally believed that the amplitude and peak latency of P300 are mainly affected by the probability of stimulation [14]. Horiba et al. [15] applied ERP technology in fabric evaluation and found the P300 amplitude in an uncomfortable state was higher than in a comfortable state. Chen et al. [16] studied the P300 potential based on different fabric materials and found that fabric with a rougher surface induces higher P300 amplitude.

Tactile sensation of material properties can generally be classified into four fundamental dimensions: roughness, hardness, stickiness, and warmness [17]. Among the four perceptual dimensions, the roughness dimension has been demonstrated that is highly prominent perceptual dimensions of surface textures [18], [19]. Surface roughness is associated with several physical texture properties, including height differences, spacing between each texture elements, and shape of texture elements [20]. Previous studies have shown surface texturing can improve the tribological performance of contact surface by serving as a micro-hydrodynamic bearing in full or mixed lubrication, a micro-reservoir for lubricant in starved lubrication, and a micro-trap for wear debris in lubricated or dry sliding [21], [22], [23], [24]. When hydrated skin contact with a textured surface, the localised pressure perturbation produced by the thin dispersed moisture layers can create a lift to reduce the friction between the contact surfaces that is called micro-hydrodynamics [25]. The micro-hydrodynamics phenomenon was also been found in other biomaterials, such as hip joint [26] and keratin-based gecko feet [27]. Studies of tactile perception based on ERP mostly focus on specific materials such as different fabrics and paper with variable surface features. It is meaningful to study the specific surface texture features that affect material tactile sensation, as understanding these features can help explain the human brain’s cognitive mechanics for tactile perception.

During tactile perception, the electrical system in brain will respond to the changes in vibration, friction, and surface properties between the perceived textured surface and human skin. There are few related studies. The goal of this paper is to systematically study the tactile perception from the surface textures, surface friction, stress response of the skin receptors, and neurophysiological response of the brain. In this study, ERP and friction measurement were carried out during fingers exploring grating surfaces. A finite element finger model was established to analyze the stress changes of the skin receptors during tactile perception This study contributes to understanding the formation process and cognitive mechanism of tactile perception of different surface textures. It also provided an objective feeling evaluation method for skin touched surfaces, skin cream, and fabrics by combining physiological response of brain, skin friction, and surface properties.

Experimental methods

This research was conducted under the guidance of international ethical standards [28] and was approved by our ethics committee. The experiments were conducted in accordance with the approved guidelines. We obtained informed consent from all study subjects.

Test bed and samples

To ensure the synchronous triggering of events, a tactile trigger device was designed that consists of two tri-axial force sensors and one square-wave generator. The tri-axial force sensors were used to obtain the friction force and touching normal load. The touching normal load was changed into an electric pulse by a square-wave generator that triggered the EEG system amplifier and marked the start of touch. In this way, the synchronization of touching action and EEG data collection could be ensured.

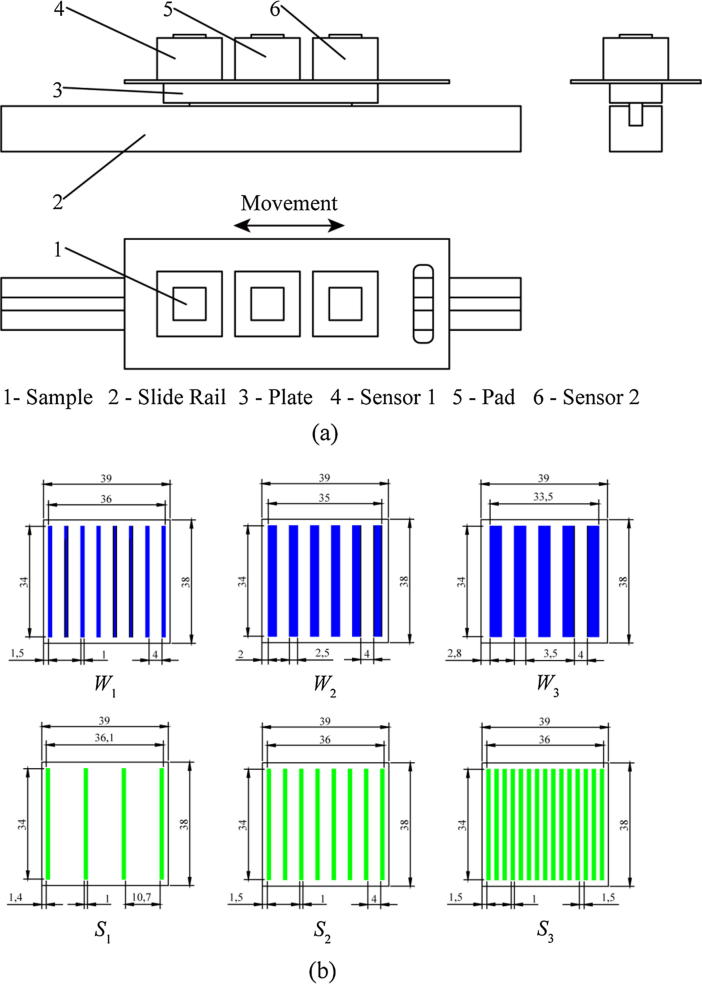

A test bed was designed. As shown in Fig. 1(a), the non-target sample was placed on the pad, and the two target samples were placed on the tri-axial force sensors. The height and the distance between the three samples were consistent. During the test, the assistant moved the slide rail to change the samples.

Fig. 1.

Schematic of (a) test bed and (b) samples with different gratings. Blue and green color represented the gratings. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

Sample without any grating texture was selected as non-target sample and was represented by P. Samples with different grating width and spacing were represented by Wi and Si as shown in Fig. 1(b). The sample materials are acrylic plates with Young’s modulus of 3000 MPa and passion rate of 0.39. The gratings on the samples were made by laser processing. The detailed parameters of the samples were shown in Table 1.

Table 1.

Grating features of samples.

| Samples with width features |

Samples with space features |

|||||

|---|---|---|---|---|---|---|

| Samples | W1 | W2 | W3 | S1 | S2 | S3 |

| Grating width (mm) | 1 | 2.5 | 3.5 | 1 | 1 | 1 |

| Grating spacing (mm) | 4 | 4 | 4 | 10.7 | 4 | 1.5 |

| Grating depth (mm) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

Stimuli

An oddball paradigm was used to evoke P300 wave, which was widely applied in the investigation of multiple cognitive functions. The oddball paradigm usually requires two kinds of stimuli simultaneously, namely target and non-target stimuli [29]. In this paradigm, presentations of sequences of repetitive non-target stimuli are infrequently interrupted by a deviant target stimulus. P300 wave only occurs if the subject is actively engaged in the task of detecting the target stimuli. During the test, the subject’s attention was required to focus on the rarely presented target stimuli, while the brain electrical response (EEG signals) to unexpectedly occurring “novel” target stimuli is recorded and investigated [30]. This method can reduce any extraneous neural activity and extract the specific response to the target stimuli. The traditional oddball paradigm has only two stimuli. Under this paradigm, it is impossible to directly compare the effects of two kinds of stimulation on P300. Therefore, an oddball variation paradigm was chosen to evoke P300 in this study. This mode allows one non-target sample and two target samples. The non-target sample occurs more than 70% of the time, and the two target samples occur less than 30% separately. The participants were required to respond to the feeling of the two target samples. The sample test order used a pseudorandom sequence that was not revealed to the participants. It included a total of 120 stimulations (15 times for the two target stimulations, respectively, and 90 times for the non-target stimulation). In this study we want to study the brain response to the grating textures, so the grating samples were chosen as target samples and the non-textured sample (smooth sample) was chosen as non-target sample.

To compare the tactile perception of two different kinds of grating samples, six group tests were carried out as shown in Table 2.

Table 2.

Test Groups.

| Non-target sample | Target sample 1 | Target sample 2 | |

|---|---|---|---|

| Group 1 | P | W1 | W2 |

| Group 2 | P | W1 | W3 |

| Group 3 | P | W2 | W3 |

| Group 4 | P | S1 | S2 |

| Group 5 | P | S1 | S3 |

| Group 6 | P | S2 | S3 |

Participants

Twelve healthy, right-handed male undergraduates from China University of Mining and Technology, 23–27 years (mean ± standard deviation = 24.7 ± 1.2 years), took part in this study. Hair was cleaned before the test. Informed consent and personal information were obtained before the experiment. The task was to feel the surface gratings. Training was given to all participants before the test. The training samples were different from the formal test samples. In training, the participants (ears covered and hands free) were asked to use their right index finger to slide along the sample surfaces with a constant normal load about 1.5 N and a 20 mm sliding distance for 0.5 s. A touch was considered one stoke. After the first touch test, the participants lifted their finger, and waited for approximately 1.5 s for the next touch. Therefore, one trial lasted approximately 2 s. In order to trigger the amplifier of EEG system and mark the start of touch, the tests were carried out until the participants could reach almost constant normal load of 1.5 N which can be monitor by the signal collecting system. The participants were asked to maintain this constant rhythm for each formal trial.

During the formal test, the assistant moved the slide rail to change the samples and the participants only needed to slide their finger on the sample with the constant rhythm and focus on feeling the grating textures. There were 120 touches that took 4 min for one trial. The participants rested for 10 min. Each trial was repeated twice.

EEG and friction measurement

All experiments were carried out in a screened EEG laboratory that insulates sound and electromagnetic interference. The ambient condition was 18–22 °C, and the relative humidity was 40–55%. The friction and touching normal load were collected by the tri-axial force sensors which was simultaneous with EEG measurement.

EEG data were recorded by a 32-channel EEG-System (BrainAmp, Brain Products, Munich, Germany) with sampling frequency of 1000 Hz. Electrode impedance was maintained below 5 kΩ throughout the study.

EEG data were processed through the Brain Vision Analyzer (Brain Products, GmbH, Munich). The data were referenced to an averaged ears montage, the bandpass was filtered between 0.1 and 30 Hz, and the baseline correction was done.

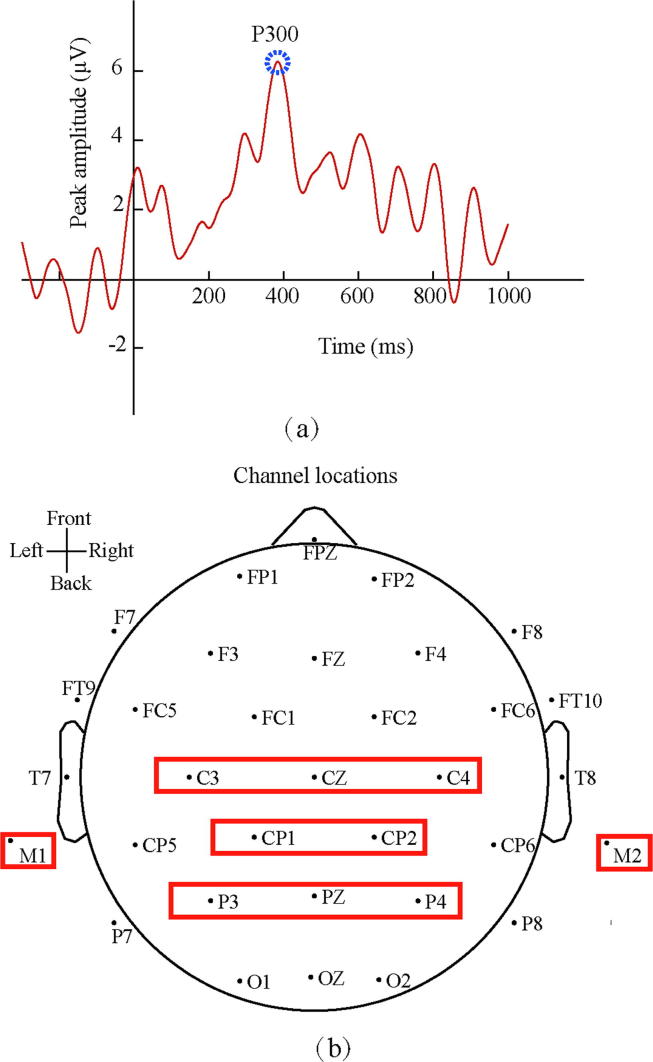

The data was then further processed and analyzed using MATLAB toolboxes (Lopez-Calderon&Luck, 2014). The analysis process included curve fitting and identification of P300 waves. The ERP waveform was obtained by superimposing and averaging the EEG data for all touches in one trail. The P300 is an ERP component elicited in the process of decision making, which usually happens after approximately 300 ms in the ERP waveform. So, a MATLAB platform (MathWorks, Inc., Natick, MA, USA) was designed to obtain the peak voltage of the ERP waveform between 250 and 450 ms for each electrode, and this was chosen as the P300 peak amplitude. The time corresponding to the peak voltage was chosen as the latency of P300. Fig. 2(a) shows a typical ERP waveform of one trial for one electrode. The average peak amplitude and latency of P300 for all trials for each electrode were calculated.

Fig. 2.

(a) Typical ERP waveform of one trial for one electrode and (b) electrode distribution pattern.

The parietal and occipital lobes are mostly related with cognition [31], [32]. The electrodes of C3, CZ, C4, CP1, CP2, P3, PZ and P4 were in the corresponding positions on the EEG cap and were chosen as the test electrodes to collect the EEG signals, shown in Fig. 2(b). The M1 and M2 earlobe electrodes were chosen as reference electrodes.

Subjective evaluation

Thirty healthy, right-handed undergraduates from China University of Mining and Technology, 23–27 years (mean ± standard deviation = 24.2 ± 1.5 years), took part in subjective evaluation. Training was given to all participants before the test which was same with the EEG test. In the test, the feelings of the gratings were divided into smooth, scratchy, and distinctive. The distinctive feeling means feeling the difference between smooth and grating samples. The participants graded samples according to the three dimensions, and the scores (ranging 0–5) were averaged for each subject. Higher human evaluation scores for smooth, scratchy, and distinctive feelings correspond to smoother feeling, scratchier feeling, and more recognizable feeling, respectively.

The smooth sample (P) was initially presented to participants as reference stimulus. It was informed that evaluation scores for smooth, scratchy, and distinctive feelings were 5, 0, and 0 for reference stimulus. In each trial, participants first felt the reference stimuli, followed by experiencing one of the six stimuli (W1, W2, W3, S1, S2, and S3), and orally reported the perceived feelings of the given stimulus. Each stimulus was presented twice per participant.

Finite element model

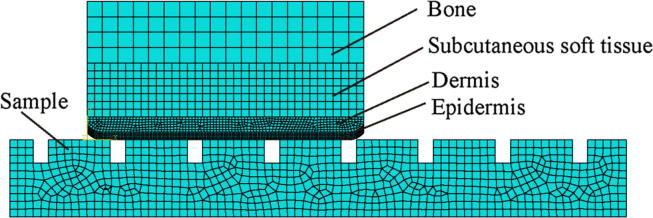

The mechanoreceptors embedded in skin are the tactile stimulus receptors. Since it is difficult to obtain the stress on cutaneous mechanoreceptors during tactile perception, a multilayer finite element model was established to analyze the stress using a commercial software package, ABAQUS/Standard (Version 6.12).

It is known that skin is a nonlinear, inhomogeneous, and anisotropic material. Previous studies showed that a two-dimensional plane strain model of fingertip composed of a homogeneous linear elastic material can predict the stress and strain distributions within skin, and thus the response profiles of the mechanoreceptors under rectangular gratings [33], [34], [35]. Meanwhile, the deformation of skin was small for the applied pressure in the model. Therefore, we simplified the fingertip model as a two-dimensional plane strain model composed of a homogeneous linear elastic material. This finger model was divided into four parts, namely, the epidermis, dermis, subcutaneous soft tissue, and bone as shown in Fig. 3. The parameters of four finger layers and the samples are shown in Table 3. The constraint types of different layers were set as “Tie”. The resolutions of the epidermis, dermis, subcutaneous soft tissue, and bone were set as 0.1 mm, 0.2 mm, 0.5 mm, and 1 mm. Because subcutaneous soft tissue and bone were not analyzed so they were set with lower resolutions. “Surface to surface contact(Standard)” was chosen as the contact element type. The perceived sample was fixed by constructing constraints for all degrees of freedom of its base line, namely DOF (degree of freedom) is 0. The DOF of finger model was not restricted and it is 3.

Fig. 3.

Finite element model of the finger.

Table 3.

| Epidermis | Dermis | Subcutaneous soft tissue | Bone | Sample | |

|---|---|---|---|---|---|

| Young’s Modulus (MPa) | 0.18 | 0.1 | 0.03 | 17,000 | 3000 |

| Passion Rate | 0.48 | 0.48 | 0.48 | 0.3 | 0.39 |

| Thickness (mm) | 0.5 | 1 | 3.5 | 4 | 5 |

According to the references [38], the mechanoreceptors can be considered as infinitesimal elements. The Meissner and Merkel corpuscles are located near the interface between the epidermis and dermis [39]. In the model, the locations of the two mechanoreceptors were simplified as nearby soft tissues. To simplify the analysis process, the finite element model only establishes the contact part between finger skin and the sample, and the outline of the fingertip was ignored.

The simulation process was divided into two steps: static loading and dynamic sliding. In the first analysis step, the perceived sample was fixed by constructing constraints for all degrees of freedom of its base line. A pressure of 1 kPa was uniformly loaded on the finger model. In the second analysis, a boundary condition of 16 mm/s velocity was applied to finger model. Then, the finger scanned over the surface of the perceived sample at the given speed and pressure. The formula of finite sliding was defined between the finger and the perceived sample. Friction formulation was set as “Penalty”. The coefficient of friction between the finger and the perceived sample was set as 0.5 in this model. The applied pressure, velocity, and coefficient of friction were set based on the tactile perception experiment results.

Results and discussions

Finite element analysis

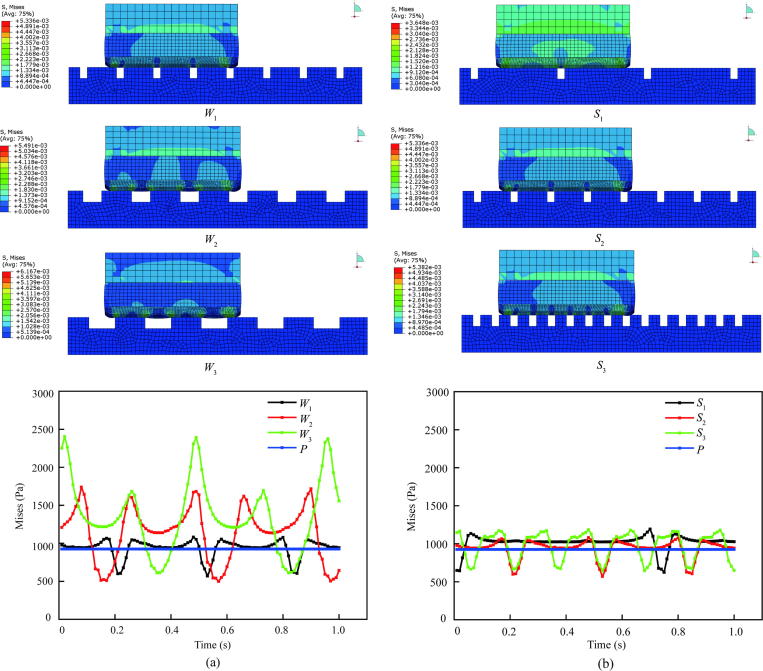

The perception processes were simulated according to the six grating samples in the experiment. Fig. 4 show the nephogram and graph of Mises stress when the finger contacted different grating widths and spacing. Fig. 4(a) show that the deformation of finger skin and the Mises stress near the Meissner and Merkel corpuscles increased with increasing grating width, indicating that larger skin deformation generates greater stress. The greater stress then induces greater tactile stimulation to the mechanoreceptors. Fig. 4(b) shows that the frequency of stress increased with decreasing grating spacing. The periodic stress causes vibration stimulation to the Meissner and Merkel corpuscles, and higher stimulation vibration frequency induces stronger tactile stimulation to the mechanoreceptors. The finite element results support the friction and ERP experimental results discussed in the following section.

Fig. 4.

Nephogram and graph of Mises stress when the finger contacted different (a) grating widths and (b) grating spacing. The selected element was near the interface between the epidermis and dermis.

Frictional properties of skin

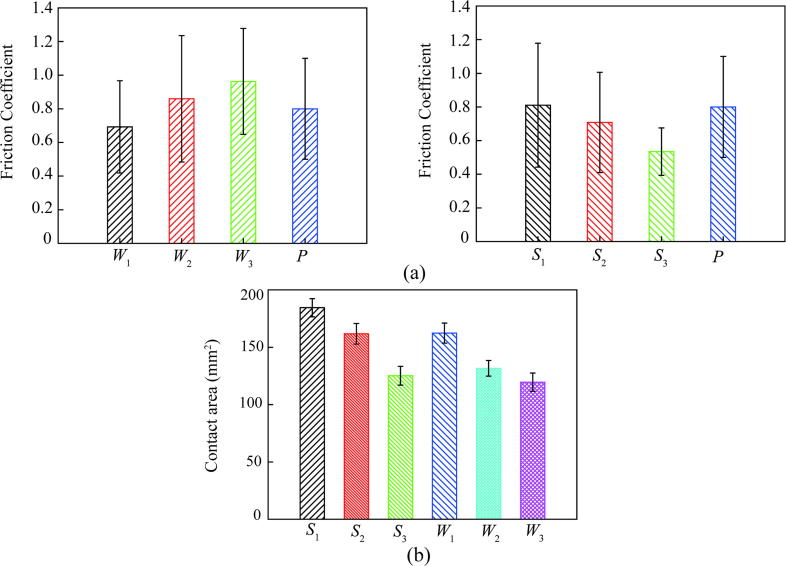

The friction coefficients and contact areas of fingers when touching the different gratings are shown in Fig. 5. The normal load W and friction force F were obtained from the tri-axial force sensor. The friction coefficient μ was calculated with μ = F/W. In order to obtain the contact area, a streak camera was used to get the contact images during the touching of surface. Then the contact areas were extracted and calculated.

Fig. 5.

(a) Average friction coefficients and (b) contact areas of fingers when touching the different gratings.

The results show that the friction coefficient increases with increasing grating width when the grating spacing is constant. As the fingers scan over the surface, deformation increases with increasing grating width, resulting in a larger coefficient of friction.

When the grating width is constant, the friction coefficient increases with grating spacing. Due to the small 1 mm grating width, finger deformation does not play a key role in the friction force. In this case, the force mainly comes from adhesive friction. As shown in Fig. 5(b), it was found that the reduction of grating spacing and the increase of grating width decreased the effective contact areas between the skin and the samples. The reduction of grating spacing decreases the effective contact area between the skin and the samples, thus resulting in a smaller adhesive friction and coefficient of friction.

The friction force produces deformation and vibration stimulating the mechanoreceptors embedded in skin. The mechanoreceptors have the ability to detect, code, and transform this tactile information to the corresponding sensing area of the cerebral cortex through the sense-conducting pathway. Friction affects the tactile perception. The grating width and spacing induce different friction coefficients, implying the different tactile perceptions formed in the brain. It is necessary to discuss the electroencephalogram when humans feel different textural features.

Subjective evaluation

The average evaluation scores of the three feelings for all gratings are shown in Table 4.

Table 4.

Scoring summary of subjective evaluation.

| Samples with width features |

Samples with space features |

|||||

|---|---|---|---|---|---|---|

| Samples | W1 | W2 | W3 | S1 | S2 | S3 |

| Smooth feeling | 3.4 ± 0.6 | 2.2 ± 0.6 | 1.3 ± 0.4 | 4.2 ± 0.7 | 3.4 ± 0.6 | 2.1 ± 0.4 |

| Scratchy feeling | 1.8 ± 0.5 | 4.2 ± 0.5 | 4.4 ± 0.5 | 1.2 ± 0.5 | 1.8 ± 0.5 | 3.1 ± 0.5 |

| Distinctive feeling | 2.6 ± 0.5 | 4.1 ± 0.5 | 4.6 ± 0.5 | 1.4 ± 0.5 | 2.6 ± 0.5 | 3.9 ± 0.3 |

The result shows that the smooth feeling decreases, and the scratchy and distinctive feelings increase with increasing grating width. The larger grating width increases the surface roughness and friction coefficient leading to decreasing smooth feeling. The wider the texture grating is, the higher the contact pressure and skin deformation, which induce a larger scratching feeling that is easier to identify.

It also shows that smooth feeling scores decrease with decreasing grating spacing. The smaller grating width increases the surface roughness, leading to decreasing smooth feeling. The scratchy and distinctive feelings increase with decreasing grating spacing. The smaller the grating spacing is, the larger the skin vibration, which induces a greater scratching feeling that is easier to identify.

P300 analysis

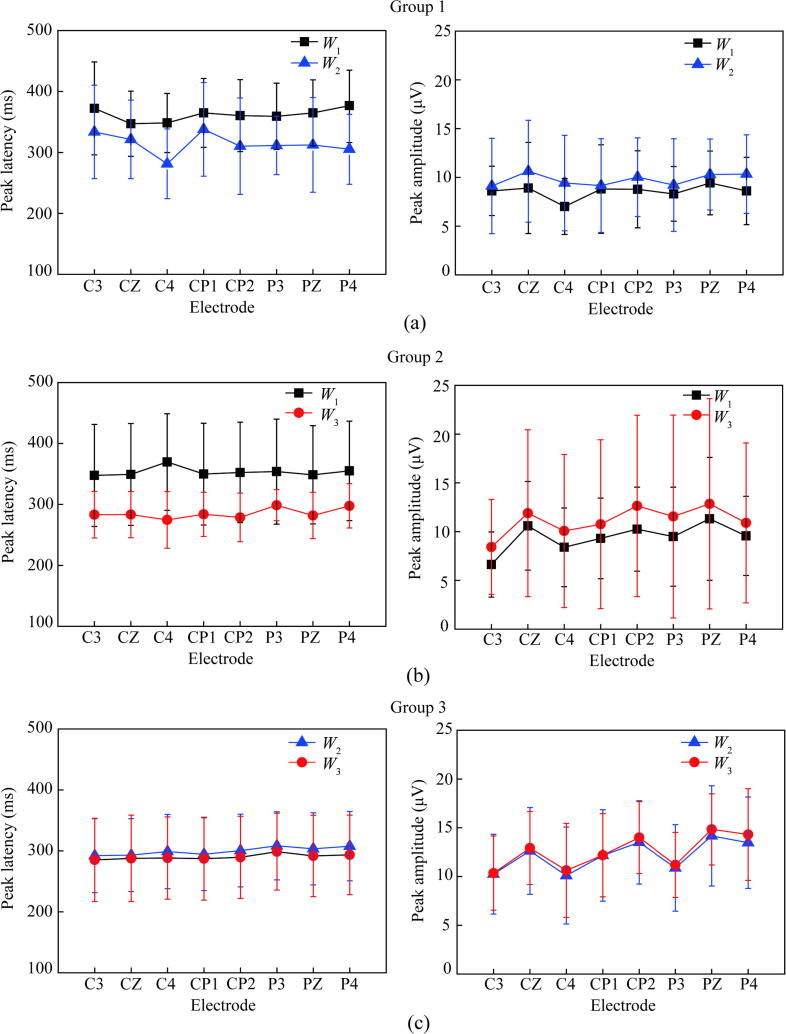

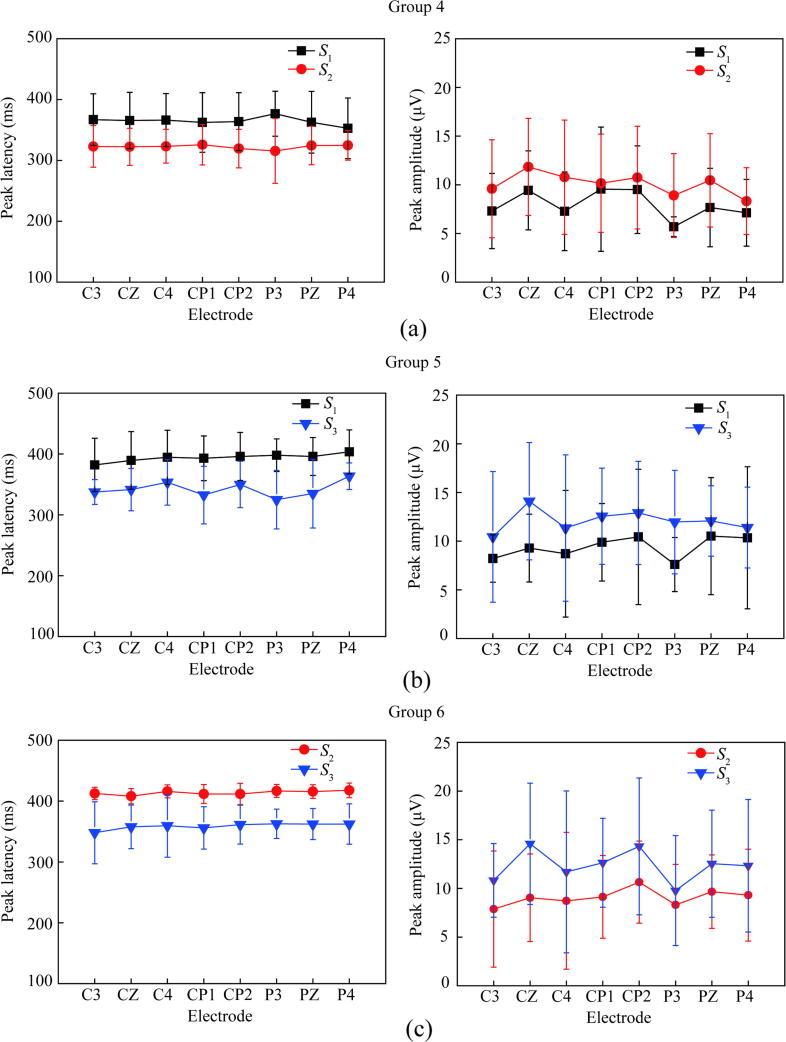

The P300 is an ERP component elicited in the process of decision making. It usually happens after approximately 300 ms in the ERP waveform. In this section, the peak amplitude and peak latency of P300 are discussed. Fig. 6 and Fig. 7 summarize the P300 components induced by samples with different grating widths and spaces.

Fig. 6.

Summary of P300 components induced by samples with different grating widths.

Fig. 7.

Summary of P300 components induced by samples with different grating spacing.

Peak latency of P300

The P300 peak latency is usually interpreted as the speed of stimulus classification resulting from discrimination of one event from another. It is an index of classification speed proportional to stimulus evaluation timing that is sensitive to task processing demands, and the P300 peak latency varies with individual differences in cognitive capability [40]. In this study, the P300 latency shows the volunteer’s judgment speed for tactile distinction between the target grating samples and smooth non-target samples. As shown in Fig. 6, the peak latency of W1 is larger than for W2 in group 1; the peak latency of W1 is larger than for W3 in group 2, and the peak latency of W2 is larger than for W3 in group 3. The results suggest that the textural characteristics of grating width affect the P300 peak latency. It shows that the sample with larger grating width can induce a shorter P300 peak latency, indicating the participants that recognize the wider grating quickly and easily. The subjective evaluation of distinctive feeling and the difference between the smooth non-target sample and grating target samples on Mises stress reveal that W1 < W2 < W3. The larger scores of distinctive feeling and larger differences of Mises stress lead to easier recognition of the grating texture, further inducing a shorter P300 peak latency for the samples with larger grating width.

Also, the difference of P300 peak latency between samples W2 and W3 is particularly small, which is coincident with the results of the P300 amplitude. As shown in Table 4, the subjective evaluation of W2 and W3 are close, suggesting that the surfaces with similar texture feeling will induce a similar P300 component.

As shown in Fig. 7, the peak latency of S1 is larger than S2 in group 4, the peak latency of S1 is larger than S3 in group 5, and the peak latency of S2 is larger than S3 in group 6. The results suggest that the textural characteristics of grating spacing affect the P300 peak latency; samples with smaller grating spacing can induce shorter P300 peak latency. Taken together, the subjective evaluation of distinctive feeling and the difference between the grating and smooth samples in regard to friction coefficient and stress show that S1 < S2 < S3. The larger scores for distinctive feeling and the larger differences in friction coefficient and Mises stress lead to easier texture recognition, further inducing a shorter P300 peak latency for samples with smaller grating spacing.

Peak amplitude of P300

The P300 peak amplitude is defined as the voltage difference between the largest positive peaks from the baseline of the EEG waveform within the latency window [41]. The peak amplitude of the P300 is proportional to the amount of attentional resources engaged in processing a given stimulus, and it is not influenced by factors related to response selection or execution [42]. The P300 peak amplitude is significantly affected by perception and attention factors that reflect the excitability of the brain.

As shown in Fig. 6, the peak amplitude in W2 is larger than in W1 in group 1, the peak amplitude of W3 is larger than in W1 in group 2, and the peak amplitude of W3 is slightly larger than in W2 in group 3. The results suggest that grating width textural characteristics affect the P300 peak amplitude. These findings demonstrate that the sample with larger grating width evokes higher P300 peak amplitude, indicating that the participants use more attentional resources in the tactile perception of wider gratings.

Taken together, the subjective evaluation of scratchy feeling, the coefficient of friction, and the Mises stress values show W1 < W2 < W3. The larger grating width generates greater skin deformation, friction force, and stress, and it induces stronger tactile stimulation to the mechanoreceptors, further evoking a higher P300 peak amplitude.

As shown in Fig. 7, the peak amplitude of S2 is larger than that of S1 in group 4, the peak amplitude of S3 is larger than that of S1 in group 5, and the peak amplitude of S3 is larger than that of S2 in group 6. The results suggest that grating space features affect the P300 peak amplitude. This finding reveals that samples with smaller grating spacing evoke higher P300 peak amplitudes. As the results show in the finite element analysis, smaller grating spacing generates higher frequency vibration stimulation to the mechanoreceptors, thus inducing stronger tactile stimulation and further evoking higher P300 peak amplitude.

Conclusions

This paper systematically studied the tactile perception from the surface textures, surface friction, stress response of the skin receptors, and neurophysiological response of the brain. The conclusions are as follows.

The stress concentrations around the Meissner and Merkel receptors are affected by the grating textures during tactile perception. The deformation of finger skin and the Mises stress near the Meissner and Merkel corpuscles increase with increasing grating width. The frequency of stress increases with decreasing grating spacing.

The friction on the skin is affected by grating textures during tactile perception. The friction coefficient increases with increasing grating width and spacing. Skin deformation increases with increasing grating width and generates larger deformation friction. The skin contact area increases with increasing grating spacing, generating larger adhesive friction.

P300 evoked by gratings are related with the skin deformation, contact area, friction force, and stress around cutaneous mechanoreceptors. P300 latency is related to the difference between the grating target stimulus and the smooth non-target stimulus. The larger the distinctive feeling value is, the larger the difference in friction coefficient and stress between the smooth non-target sample and the grating target samples is, and the easier the grating texture can be recognized. The P300 peak amplitude increases with increasing grating width and decreasing spacing. The wider grating width generates larger skin deformation, friction force, and stress, which induces stronger tactile stimulation. The smaller grating spacing generates higher vibration frequency, inducing stronger tactile stimulation.

This study objectively proofed that ERP methods are useful to study the brain's response to tactile perception and there is a relationship between the activation in brain regions, surface friction, and contact conditions of skin during the tactile perception.

Compliance with ethics requirements

All procedures followed were in accordance with the ethical standards of the responsible committee on human experimentation (institutional and national) and with the Helsinki Declaration of 1975, as revised in 2008 (5). Informed consent was obtained from all patients for being included in the study.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors acknowledge financial support from National Natural Science Foundation of China (No. 51875566 and No. 51775546), the Fundamental Research Funds for the Central Universities (No. 2015XKMS017), and A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions. The authors acknowledge the technical support from Scientific Research Support Program of Beijing Jingfa Science and Technology Co.

Footnotes

Peer review under responsibility of Cairo University.

References

- 1.Dunbar R.I. The social role of touch in humans and primates: behavioural function and neurobiological mechanisms. Neurosci Biobehav Rev. 2010;34(2):260–268. doi: 10.1016/j.neubiorev.2008.07.001. [DOI] [PubMed] [Google Scholar]

- 2.Dargahi J., Najarian S. Human tactile perception as a standard for artificial tactile sensing-a review. Int J Med Robot Comput Assist Surg. 2004;1(1):23–35. doi: 10.1002/rcs.3. [DOI] [PubMed] [Google Scholar]

- 3.Vermeij G.J. The world according to the hand: observation, art, and learning through the sense of touch. J Hand Surg. 1999;24(2):215–218. doi: 10.1053/jhsu.1999.0215. [DOI] [PubMed] [Google Scholar]

- 4.Schwarz Cornelius. The slip hypothesis: tactile perception and its neuronal bases. Trends Neurosci. 2016;39:449–462. doi: 10.1016/j.tins.2016.04.008. [DOI] [PubMed] [Google Scholar]

- 5.Johnson K.O., Hsiao S.S. Neural mechanisms of tactual form and texture perception. Annu Rev Neurosci. 1992;15(1):227–250. doi: 10.1146/annurev.ne.15.030192.001303. [DOI] [PubMed] [Google Scholar]

- 6.Bodegård A., Ledberg A., Geyer S. Object shape differences reflected by somatosensory cortical activation in human. J Neurosci. 2000;20(1):RC51. doi: 10.1523/JNEUROSCI.20-01-j0004.2000. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Tang W., Chen N., Zhang J., Chen S., Ge S., Zhu H. Characterization of tactile perception and optimal exploration movement. Tribol Lett. 2015;58(2):1–14. [Google Scholar]

- 8.Ding S., Bhushan B. Tactile perception of skin and skin cream by friction induced vibrations. J Coll Interf Sci. 2016;481:131–143. doi: 10.1016/j.jcis.2016.07.034. [DOI] [PubMed] [Google Scholar]

- 9.Moungou A., Thonnard J.L., Mouraux André. EEG frequency tagging to explore the cortical activity related to the tactile exploration of natural textures. Sci Rep. 2016;6(1):20738. doi: 10.1038/srep20738. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Brigitte C., Marie-Ange B., Marie F., Benjamin J., Betty L.S., Laurence M. From finger friction and induced vibrations to brain activation: Tactile comparison between real and virtual textile fabrics. Tribol Int. 2018;126:283–296. [Google Scholar]

- 11.Li W., Zhan M.L., Yu Q.Y., Zhang B.Y., Zhou Z.R. Quantitative assessment of friction perception for fingertip touching with different roughness surface. Biosurf Biotribol. 2015;1(4):278–286. [Google Scholar]

- 12.Zhang D., Fei X.U., Heng X.U., Shull P.B., Zhu X. Quantifying different tactile sensations evoked by cutaneous electrical stimulation using electroencephalography features. Int. J. Neural Syst. 2016;26(2):1650006. doi: 10.1142/S0129065716500064. [DOI] [PubMed] [Google Scholar]

- 13.Polich J. Updating P300: an integrative theory of P3a and P3b. Clin Neurophysiol. 2007;118(10):2128–2148. doi: 10.1016/j.clinph.2007.04.019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Pritchard W.S. Psychophysiology of P300. Psychol Bull. 1981;89(3):506–540. [PubMed] [Google Scholar]

- 15.Horiba Y., Kamijo M., Hosoya S., Takatera M., Shimizu Y., Sadoyama T. Evaluation of tactile sensation forwearing by using event related potential. Fiber. 2000;56(1):47–54. [Google Scholar]

- 16.Chen S., Ge S. Experimental research on the tactile perception from fingertip skin friction. Wear. 2016;376–377:305–314. [Google Scholar]

- 17.Yeon J., Kim J., Ryu J., Park J.Y., Chung S.C., Kim S.P. Human brain activity related to the tactile perception of stickiness. Front Hum Neurosci. 2017;11:1–13. doi: 10.3389/fnhum.2017.00008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Hollins M., Bensmaia S., Karlof K., Young F. Individual differences in perceptual space for tactile textures: evidence from multidimensional scaling. Percept Psychophys. 2000;62:1534–1544. doi: 10.3758/bf03212154. [DOI] [PubMed] [Google Scholar]

- 19.Hollins M., Faldowski R., Rao S., Young F. Perceptual dimensions of tactile surface texture: a multidimensional scaling analysis. Percept Psychophys. 1993;54:697–705. doi: 10.3758/bf03211795. [DOI] [PubMed] [Google Scholar]

- 20.Bergmann Tiest W.M. Tactual perception of material properties. Vision Res. 2010;50:2775–2782. doi: 10.1016/j.visres.2010.10.005. [DOI] [PubMed] [Google Scholar]

- 21.Etsion I. State of the art in laser surface texturing. J Tribol. 2005;127(1):248–253. [Google Scholar]

- 22.Borghi A., Gualtieri E., Marchetto D., Moretti L., Valeri S. Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear. 2008;265:1046–1051. [Google Scholar]

- 23.Rapoport L., Moshkovich A., Perfilyev V., Gedanken A., Koltypin Y., Sominski E. Wear life and adhesion of solid lubricant films on lasertextured steel surfaces. Wear. 2009;267:1203–1207. [Google Scholar]

- 24.Kovalchenko A., Ajayi O., Erdemir A., Fenske G. Friction and wear behavior of laser textured surface under lubricated initial point contact. Wear. 2011;271:1719–1725. [Google Scholar]

- 25.Morris N., Leighton M., De la Cruz M., Rahmani R., Rahnejat H., Howell-Smith S. Combined numerical and experimental investigation of the micro-hydrodynamics of chevron-based textured patterns influencing conjunctional friction of sliding contacts. J Eng Tribol. 2015;229(4):316–335. [Google Scholar]

- 26.Dowson D., Jin Z.M. Micro-elastohydrodynamic lubrication of synovial joints. Eng Med. 1986;15(2):63–65. doi: 10.1243/emed_jour_1986_015_019_02. [DOI] [PubMed] [Google Scholar]

- 27.Teodorescu M., Rahnejat H. STLE/ASME 2008 International Joint Tribology Conference. 2008. Nano-scale contact model for microfiber tip attachment, detachment and friction; pp. 83–85. [Google Scholar]

- 28.International ethical guidelines for health-related research involving humans, Fourth Edition. Geneva. Council for International Organizations of Medical Sciences (CIOMS); 2016.

- 29.García-Larrea L., Lukaszewicz A.C., Mauguiére F. Revisiting the oddball paradigm. non-target vs neutral stimuli and the evaluation of ERP attentional effects. Neuropsychologia. 1992;30(8):723–741. doi: 10.1016/0028-3932(92)90042-k. [DOI] [PubMed] [Google Scholar]

- 30.Debener S., Makeig S., Delorme A., Engel A.K. What is novel in the novelty oddball paradigm? functional significance of the novelty P3 event-related potential as revealed by independent component analysis. Brain Res Cogn Brain Res. 2005;22(3):309–321. doi: 10.1016/j.cogbrainres.2004.09.006. [DOI] [PubMed] [Google Scholar]

- 31.Gottlieb J. Neuron review from thought to action: the parietal cortex as a bridge between perception, action, and cognition. Neuron. 2007;53(1):9–16. doi: 10.1016/j.neuron.2006.12.009. [DOI] [PubMed] [Google Scholar]

- 32.Chen Y.S., Chen H.L., Lu C.H., Chen M.H., Chou K.H., Tsai N.W. Reduced lateral occipital gray matter volume is associated with physical frailty and cognitive impairment in Parkinson’s disease. Eur Radiol. 2018;29:2659–2668. doi: 10.1007/s00330-018-5855-7. [DOI] [PubMed] [Google Scholar]

- 33.Srinivasan M.A., Dandekar K. An investigation of the mechanics of tactile sense using two-dimensional models of the primate fingertip. J Biomech Eng. 1996;118:48–55. doi: 10.1115/1.2795945. [DOI] [PubMed] [Google Scholar]

- 34.Phillips J.R., Johnson K.O. Tactile spatial resolution. II. Neural representation of bars, edges, and gratings in monkey primary afferents. J Neurophysiol. 1981;46:1192–1203. doi: 10.1152/jn.1981.46.6.1192. [DOI] [PubMed] [Google Scholar]

- 35.Phillips J.R., Johnson K.O. Tactile spatial resolution. III. A continuum mechanics model of skin predicting mechanoreceptor responses to bars, edges, and gratings. J Neurophysiol. 1981;46:1204–1225. doi: 10.1152/jn.1981.46.6.1204. [DOI] [PubMed] [Google Scholar]

- 36.Wu J.Z., Dong R.G., Smutz W.P., Schopper A.W. Modeling of time-dependent force response of fingertip to dynamic loading. J Biomech. 2003;36(3):383–392. doi: 10.1016/s0021-9290(02)00427-x. [DOI] [PubMed] [Google Scholar]

- 37.Dandekar K., Raju B.I., Srinivasan M.A. 3-D finite-element models of human and monkey fingertips to investigate the mechanics of tactile sense. J Biomech Eng-Trans ASME. 2003;125(5):682–691. doi: 10.1115/1.1613673. [DOI] [PubMed] [Google Scholar]

- 38.Moll I., Roessler M., Brandner J.M. Human merkel cells-aspects of cell biology, distribution and functions. Eur J Cell Biol. 2005;84(2):259–271. doi: 10.1016/j.ejcb.2004.12.023. [DOI] [PubMed] [Google Scholar]

- 39.Tang W., Zhang J., Shi X., Zhang S., Liu S., Zhu H. Investigation of mechanical responses to the tactile perception of surfaces with different textures using the finite element method. Adv Mech Eng. 2016;8(7):1–9. [Google Scholar]

- 40.Barceló F., Cooper P.S. An information theory account of late frontoparietal ERP positivities in cognitive control. Psychophysiology. 2018;55(3) doi: 10.1111/psyp.12814. [DOI] [PubMed] [Google Scholar]

- 41.Polich J., Alexander J.E., Bauer L.O., Kuperman S., Morzorati S., O'Connor S.J. P300 topography of amplitude/latency correlations. Brain Topogr. 1997;9(4):275–282. doi: 10.1007/BF01464482. [DOI] [PubMed] [Google Scholar]

- 42.Gray H.M., Ambady N., Lowenthal W.T., Deldin P. P300 as an index of attention to self-relevant stimuli. J Eep Soc Psychol. 2004;40(2):216–224. [Google Scholar]