Abstract

Present study addresses the fortification of mayonnaise with fish protein hydrolysate by partial replacement of egg yolk in the product. Red meat of yellowfin tuna (Thunnus albacares), a by-product from tuna canning industry was used as the source of protein hydrolysate (TPH). Substitution of egg yolk with hydrolysate imparted noticeable fish flavor to the product only at higher levels of replacement (50% and above). Emulsion stability of mayonnaise samples was not significantly affected at the given range of substitution. The preliminary product acceptability parameters indicated higher desirability with a sensory score of 7.6 ± 0.7 for a replacement ratio of 1:2::TPH:egg yolk. Hence, the same combination was further subjected to morphological, rheological characterization, and opted for storage stability studies. Fortified mayonnaise exhibited lower particle size, indicative of higher emulsion quality which was also evident in the rheological properties of the sample. Results indicated better oxidative and physicochemical stability for fortified samples compared to control under chilled conditions, suggesting the applicability of fish protein hydrolysate as fortifying and stabilizing agent in mayonnaise preparations.

Keywords: Fish protein hydrolysate, Yellowfin tuna, Mayonnaise, Fortification, Emulsion

Introduction

Consumer’s preference for nutritionally rich healthier diet has shifted the market demand towards more fortified supplies. Simultaneously, the health problems associated with the intake of certain lipid rich foods has diverted the food sector towards the development of low fat products. Previously, authors like Nader et al. (2016); Mozafari et al. (2017) have reported challenges associated with the development of low fat products, having comparative appearance, texture, stability, and flavor as their full-fat counterparts. Mayonnaise, being a semi-solid oil-in-water emulsion, is extensively studied in this context. Mayonnaise is traditionally prepared from a mixture of egg yolk, vinegar, oil and other optional ingredients. Egg yolk plays a major role as emulsifying and stabilizing agent in this product. However due to some health concerns like high cholesterol content, allergic problems of some consumers to egg protein as well as easy susceptibility to microbial contamination and spoilage, an urge for partial or total replacement with cholesterol-free ingredients is upcoming. In this perspective, several plant and animal proteins have been extensively investigated as egg substitute in mayonnaise emulsion systems (Ma and Boye 2013; Ghazaei et al. 2015). Alternatively, fish roe (egg) protein powder was reported to have superior emulsifying properties (Binsi et al. 2017), and hence, suggested as an ideal egg substitute in mayonnaise (Sathivel et al. 2009).Siripongvutikorn et al. (2016) used tuna roe and inulin as oil replacer in mayonnaise preparation. Similarly, several studies highlighting enzymatic hydrolysis as an effective mean for improving the emulsifying properties of fish proteins have been documented (Binsi et al. 2016; Parvathy et al. 2018a). Even though many of these reports highlight the superior surface active properties of the hydrolysates compared to their native proteins, limited data is available on the application of fish meat hydrolysate as egg substitute in mayonnaise preparations.

Tuna is a species of high relevance in the present market scenario on account of its value for canning and retorting. Currently, only the white meat is used for canning operations and remaining is going as by-products with low commercial value of which tuna red meat also has a major share. Previous studies have established the superior surface active properties of tuna red meat including emulsion properties, which can be explored in the stabilization of emulsion based food formulations such as mayonnaise (Chi et al. 2015; Parvathy et al., 2018a). As a further step, in the present study, attempt was made to evaluate the usefulness of tuna red meat hydrolysate as egg substitute in mayonnaise formulation, with emphasis on physico-chemical, rheological, sensory and microbiological indices. Further, an optimized substitution rate was established based on selected product acceptability parameters, and the storage life of the selected formulation was monitored under chilled condition.

Materials and methods

Materials

Protein hydrolysate from red meat of yellowfin tuna was used as fortifier in mayonnaise. Mayonnaise ingredients were purchased from commercial suppliers. Egg yolk was carefully separated from theegg white after puncturing of the yolk membrane and used. Further analytical grade chemicals (Merck; Himedia, India) were used for the study.

Preparation of tuna red meat hydrolysate

Red meat from yellowfin tuna which had undergone prior heat treatment at 121 °C for 1 h, was collected as by-product after canning / retorting from Forstar Frozen Foods Pvt. Ltd., Mumbai. This meat was given an initial washing with hot water (1:4 (w/v)) and further with sodium bicarbonate solution (0.2% w/v) in the ratio 1:4 (w/v) (meat: solution) to minimize the fat content. This treated meat was used as starting material for preparing protein hydrolysate by using papain enzyme (Activity of ~ 30,000 USP units/mg, Hi Media, India) under previously optimized hydrolytic conditions (Parvathy et al. 2018b). Response Surface Methodology with a central composite design (CCD) with input factors viz., enzyme–substrate ratio (E/S) and hydrolysis time at three levels was chosen for optimization of hydrolytic conditions. pH was maintained constant and optimized hydrolysis temperature was adopted. The responses for functionality optimization included protein recovery, foaming, emulsifying, oil absorption and sensory properties. Multi response optimization of response variables for functionality of hydrolysate with emphasis to protein recovery indicated the optimum combination of enzyme–substrate ratio and hydrolysis time as 0.34% and 30 min, respectively at a temperature of 60 °C and pH of 6.5. Based on these conditions, functionally superior tuna protein hydrolysate (molecular weight: 10% (> 30 kDa); 50% (10–30 kDa); 35% (3–10 kDa); 5% (< 3 kDa) as determined by Molecular weight cut off centrifugal filters (Amicon®Ultracel®, Merck Millipore Ltd, Ireland)) was derived. The resultant hydrolysate solution was further spray dried (Hemaraj Enterprises, Mumbai) to get protein hydrolysate powder, hereafter, referred as TPH and used for the study.

Preparation of mayonnaise

Mayonnaise was prepared using the following ingredient composition viz., soybean oil (45%, w/w),fresh egg yolk (15%, w/w), sugar (20% w/w), vinegar (17%, w/w), mustard (2%, w/w) and salt (1%, w/w) adopting the procedure described by Gaonkar et al. (2010) with slight modifications. Egg yolk was thoroughly mixed, into which sugar and salt were dissolved with continuous stirring. Further soybean oil was added in small proportions. One minute after the incorporation of oil, vinegar was added and stirring was continued for another minute. The resultant coarse emulsion was further homogenized (230 VAC T-25 digital Ultra-turrax, IKA, India) to get smooth textured mayonnaise which was filled in air tight containers for further analysis. Protein fortified mayonnaise was prepared by replacing egg yolk with TPH in different proportions.

Preliminary product acceptability study

Preliminary trials were carried out to finalise the replacement levels of egg yolk with TPH in mayonnaise for further characterisation and storage analysis. For this, egg yolk (15%) in mayonnaise was replaced with TPH up to 5% (1:2::TPH:egg yolk), 7.5% (1:1) and 10% (2:1),hereafter referred to as fortified mayonnaise: F5, F7.5 and F10, respectively. Mayonnaise without any egg yolk replacement was kept as control (C). Sensory evaluation was carried out with ten trained panellists for attributes viz., appearance, odour, flavour, colour, texture and overall acceptability using a 9 point hedonic scale (Meilgaard et al. 2006). Other parameters viz., colour and emulsion stability index (Mun et al. 2009) were also analysed. Colour of the samples was measured using colorimeter (Colorflex EZ 45/0, Hunter Associates Lab inc., Reston, Virginia, USA) at D-65 illuminant and 10° observer. Colour determinants were expressed in terms of L*(lightness), a*(+redness/−greenness), b*(+yellowness/−blueness). For the emulsion stability test, about 15 g mayonnaise sample was transferred to a test tube which was tightly sealed with parafilm and stored at 50 °C for 48 h. After storage, the emulsion was centrifuged for 10 min at 3000×g to remove the top oil layer. The emulsion stability was characterised from the proportion of precipitated layer to the initial volume and expressed as percentage. Based on the results of preliminary study, selected fortified mayonnaise combination along with control was taken for proximate analysis, particle analysis, morphological characterisation, rheological properties and storage stability studies.

Characterization of mayonnaise

Proximate composition

Evaluation of proximate composition of mayonnaise samples viz., fortified and control were carried out as per AOAC (2012). Total carbohydrate was estimated from the difference in weight of other constituents (protein, fat, water, ash) to the total weight of the sample. Caloric value of the sample was calculated as per Souci et al. (2000) as:

Emulsion microstructure and particle size

Microstructure of the emulsion was analysed by smearing sample directly onto a microscope slide and analysing under an inverted microscope (Leica Microsystems, Wetzlar, Germany) at room temperature (25 °C). The images were obtained at 4× magnification and dimensions were determined using image processing software (Leica Microsystems Imaging Solutions, Cambridge, UK) with a CCD camera. The mean particle size of the mayonnaise samples were determined by particle size analyzer using DLS principle (Particle Sizing Systems, Inc. Santa Barbara, Calif., USA).

Rheological properties

Linear dynamic viscoelasticity measurements, including strain sweep, frequency sweep, temperature ramp, were analyzed using a Controlled-Stress Rheometer (Physica MCR 101, TruGapTM system, Anton Paar GmbH, Austria) in oscillatory mode in the range of 1–200 Pa at 25 °C. A 20 mm parallel-plate geometry was used with a gap setting of 1 mm between peltier plate and geometry. Sample was loaded onto the temperature-controlled peltier plate, equilibrated to 25 °C and the plate geometry was lowered to the gap previously adjusted. Shear stress was measured at varying shear rates from 0 to 100 s−1. The elastic modulus (G′) and viscous modulus (G″) were measured as a function of frequency. Frequency was varied from 1 Hz to 10 Hz and storage and loss modulus were obtained as a function of frequency. The slope of the regression of G′ and G″ (on log scale) with change in frequency was obtained in order to assess the viscoelastic nature of the sample. Oscillation stress sweep was plotted for storage modulus against oscillation stress from 0.2 to 100 Pa. Temperature sweep of the sample was carried at temperatures ranging from 0 to 100 °C (heating rate: 5 °C/min) at a constant shear of 100 s−1. Changes in viscosity with shear rates ranging from 0 to 100 s−1 at constant temperature of 25 °C was carried out and the flow curve was obtained by plotting log shear rate with log viscosity values. Among the various rheological models, Herschel-Bulkley model was found to be most appropriate for explaining the flow behavior of fish mayonnaise with the following equation:

where τ is the shear stress (Pa), τo the yield stress (Pa), γ is the shear rate (s−1), k is the consistency coefficient (Pa sn) and n is the flow behavior index (dimensionless).

Storage stability studies

Selected fortified mayonnaise and control mayonnaise were packed in airtight plastic bottles, stored at 4 °C and subjected to weekly analysis for indices viz., pH (ECPH S1042S, Eutech Instruments, Singapore), emulsion stability index (ESI) (Mun et al. 2009), viscosity (DV-E Brookfield digital viscometer), peroxide value (PV) and free fatty acid (FFA) (AOAC2012),sensory (Meilgaard et al. 2006) and microbiological parameters (USFDA 2001) for a period of four weeks.

Statistical analysis

The analytical data obtained in triplicate were subjected to analysis of variance (ANOVA) and the differences between means were evaluated by duncan’s multiple range test. SPSS statistic programme (SPSS 16.0 for Windows, SPSS Inc., Chicago, IL) was used for result interpretation.

Results and discussion

Characteristics of tuna protein hydrolysate

Protein hydrolysate, derived from red meat of yellowfin tuna under optimized hydrolytic condition for superior functional properties was used for fortifying mayonnaise sample. The chain length/molecular size of peptides which is influenced by the degree of hydrolysis, are in turn of interest with regard to the functional as well as sensory attributes (Gbogouri et al.2004). Generally, lower the extent of hydrolysis, higher the molecular weight of peptides, contributing better to the functional properties (Baharuddin et al. 2016). The protein hydrolysate used in the present study possessed major share of the peptides with a molecular weight of more than 10 kDa (60%) and exhibited comparatively superior functional properties (Data not shown) than previously reported studies (Taheri et al. 2013; Chi et al. 2014). Based on these attributes, TPH could be considered ideal for using as egg substitutes.

Preliminary product acceptability study

Preliminary trials were carried out to finalise the replacement levels of egg yolk with TPH in mayonnaise for further stability studies. Fortified mayonnaises viz., F5, F7.5, F10 and control sample were primarily subjected to sensory acceptability and evaluation of selected physico-chemical properties which are generally considered as crucial in determining the acceptability and stability of mayonnaise viz., colour and emulsion stability. The results indicated a significant decrease (p < 0.05) in overall sensory acceptability with higher levels of protein hydrolysate (at and beyond 50%), as inferred from sensory evaluation scores. This must be on account of the intensification of fish flavor as well as slight bitterness imparted by protein hydrolysate when incorporated at higher concentrations (Table 1). The development of bitterness in hydrolysate is generally associated with the levels of hydrophobic amino acids. There are previous studies reporting the release of bitter tasting peptides during hydrolysis creating acceptability issues during food applications (Yarnpakdee et al. 2015).

Table 1.

Variations in parameters viz., colour, emulsion stability index and overall sensory acceptability of mayonnaise samples

| Parameters | C | F5 | F7.5 | F10 |

|---|---|---|---|---|

| L* (Lightness) | 80.87d ± 0.14 | 67.98c ± 0.06 | 62.78b ± 0.03 | 59.34a ± 0.02 |

| a* (Redness) | 1.78a ± 0.00 | 3.26b ± 0.01 | 3.34c ± 0.01 | 5.15d ± 0.01 |

| b* (Yellowness) | 28.55a ± 0.02 | 30.69c ± 0.02 | 29.32b ± 0.01 | 33.87d ± 0.03 |

| Emulsion Stability Index | 99.89c ± 0.04 | 98.67a ± 0.5 | 99.17ab ± 0.16 | 99.75bc ± 0.06 |

| Overall sensory acceptability | 8.30c ± 0.48 | 7.60c ± 0.70 | 5.90b ± 0.57 | 4.80a ± 0.59 |

Values are expressed as Mean ± SD; n = 3; different superscript within the row indicate significant difference (p < 0.05); C: Control (15 egg yolk: 0 protein hydrolysate); F5 (10 egg yolk:5 protein hydrolysate); F7.5 (7.5 egg yolk: 7.5 protein hydrolysate); F10 (5 egg yolk: 10 protein hydrolysate) in 100 g mayonnaise formulation

Instrumental colour characteristics of the mayonnaise formulations were evaluated (Table 1). Incorporation of TPH as egg yolk substitute in mayonnaise formulation resulted in significant changes (p < 0.05) to the product colour with higher levels of substitution imparting reddish-brown colour to the mayonnaise (Table 1). The colour variations are bound to occur on account of the compositional variations in the samples. Normally, a product appeal is affected when it deviates from the standard colour range and this variation also had an influence on the overall acceptability of the fortified samples.

Emulsion stability refers to the ability of an emulsion to resist changes in its physicochemical properties overtime and is influenced by various physicochemical mechanisms viz., gravitational separation,flocculation,coalescence,partialcoalescence,ostwaldripeningandphaseinversion (McClements 2005). Emulsion stability index (ESI) of mayonnaise samples also indicated similar higher values with narrow range of variations between control and fortified samples (98.67–99.89%). Similar range of ESI between 98.77–99.80% was reported by Siripongvutikorn et al. (2016) in both control mayonnaise and samples containing different levels of tuna roe with inulin gel. Based on the preliminary analysis, fortified mayonnaise: F5 (containing 10:5::eggyolk:TPH (g/100 g mayonnaise)) was considered having superior properties, hence selected for further storage stability studies.

Characterization of selected mayonnaise formulation

Proximate composition

The direct effect of egg yolk substitution in mayonnaise with TPH was a statistically significant (p < 0.05) increase in protein content from 3.58 ± 0.09 to 6.16 ± 0.38% and reduction in fat content by 4.93%, from 50.22 ± 0.97 to 45.29 ± 0.37% in fortified mayonnaise (F5) compared to control. Previously, El-Bostany et al.(2011) reported a reduction in total fat content in emulsion based products on account of their fat components being replaced with non-fat ingredients. Moisture content in fortified sample was significantly (p < 0.05) lower (24.56 ± 0.11%) than control (28.24 ± 0.87%) which might be on account of the replacement of egg yolk with protein hydrolysate which is a dry powder with negligibly low moisture content. Rashed et al. (2017) reported a broad range of moisture content values, ranging between 16.63–59.93% in selected commercially available mayonnaise samples in Malaysia. Ash content of the control sample was 0.9 ± 0.02% which increased to 1.04 ± 0.05% upon fortification. Similarly the carbohydrate value was higher in fortified one (22.95 ± 0.84%) in comparison to control (17.06 ± 1.91%) which must be due to the proportional decrease in other components like moisture and fat. As per USDA/NASS (2005), traditional mayonnaises present a caloric value of 717 kcal/100 g while the light versions contain 324 kcal/100 g. The present study indicated a value in medium range with control sample having a caloric value of 534.54 kcal/100 g while it was slightly lower for fortified one (524.05 kcal/100 g).

Emulsion microstructure

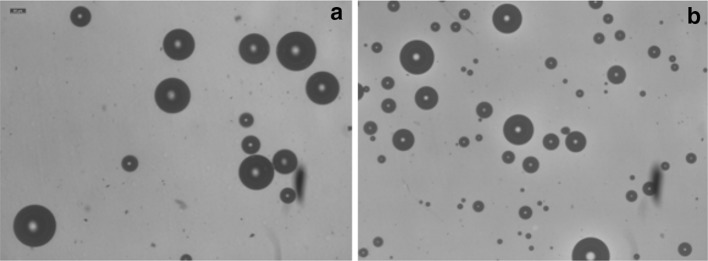

Observations on the microstructure of emulsion under an inverted microscope indicated stabilized emulsion droplets with adequate protection by aqueous phase around core oil molecules indicating the high emulsifying capacity of yolk protein as well as protein hydrolysate (Fig. 1). The emulsions showed particles in the size range of 40–120 μ in control while the particle size was comparatively lower (5–100 μ) in fortified one indicating the better interfacial stability provided by smaller peptides. Studies suggest that emulsifiers with superior capacity are capable of reducing the average oil droplet size as well as increase the droplet interaction forming an extensive structural network in emulsion influencing the appearance, texture as well as mouth feel of the product (Ma and Boye 2013).

Fig. 1.

Inverted microscopic image of a control mayonnaise, b fortified mayonnaise

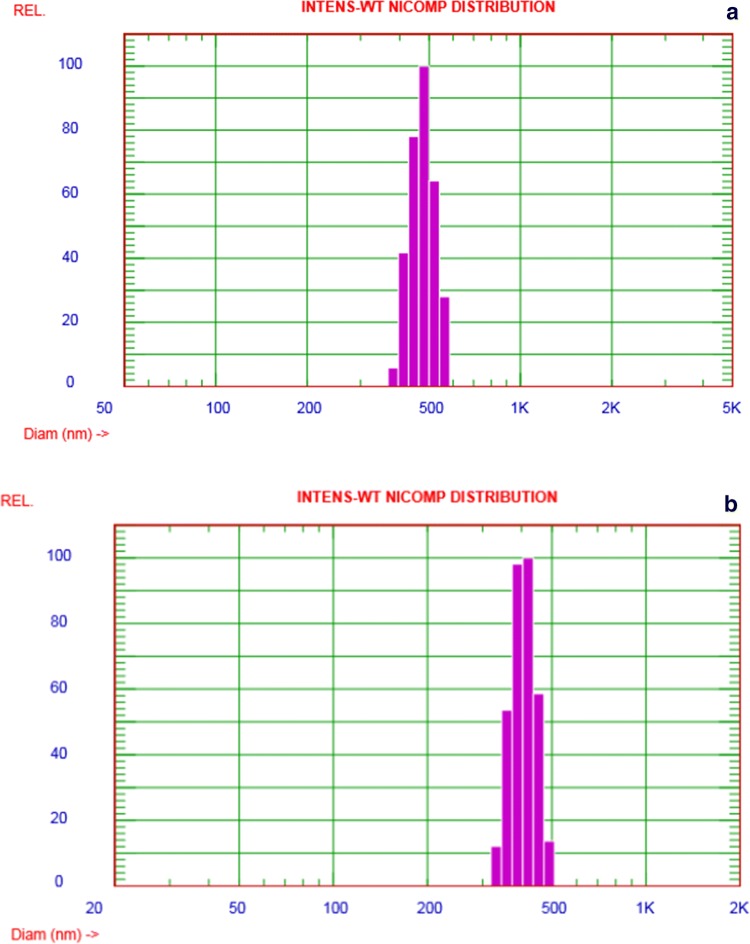

Particle size analysis

Measurement of particle size within an emulsion is important as it has strong impact on its stability, optical properties, rheology as well as its sensory attributes (McClements 2005). The three most commonly used mean particle size values are the number-weighted mean diameter (d10), the surface-weighted mean diameter (d32) and the volume-weighted mean diameter (d43). Generally, a significant difference between these values indicates broad particle size distribution.

In the present study, the average particle size (d32) of control mayonnaise was about 476.1 µm (Fig. 2a) and that of fortified mayonnaise was 406.6 µm (Fig. 2b). Lower particle size, indicative of higher emulsion quality was observed for fortified mayonnaise which must be on account of superior emulsifying properties of TPH used to partially replace egg yolk. Previous studies suggest better emulsification activity for hydrolyzed proteins than their parent source due to the fact that enzymatic hydrolysis results in unfolding of the globular structure and increase hydrophobicity of proteins enhancing their interaction with the oil droplets (Klompong et al. 2007). The variations observed in the particle size values were 999.3 µm (d43) and 70.6 µm ((d10) for control and 849.6 µm (d43) and 84.2 µm (d10) for fortified one implying the wide distribution in particle size within the samples viz., both control as well as fortified one. The particle size distribution curves (Fig. 2) also revealed that samples in the present study contained droplets of different size range referred to as poly disperse curves. However the range of particle size were comparatively more in control sample (about 6 particle size range) whereas it was limited to three size range in fortified one confirming the superior emulsifying properties of protein hydrolysate to generate more uniform sized emulsion droplets compared to control.

Fig. 2.

Particle size distribution of a control mayonnaise, b fortified mayonnaise

Rheological properties

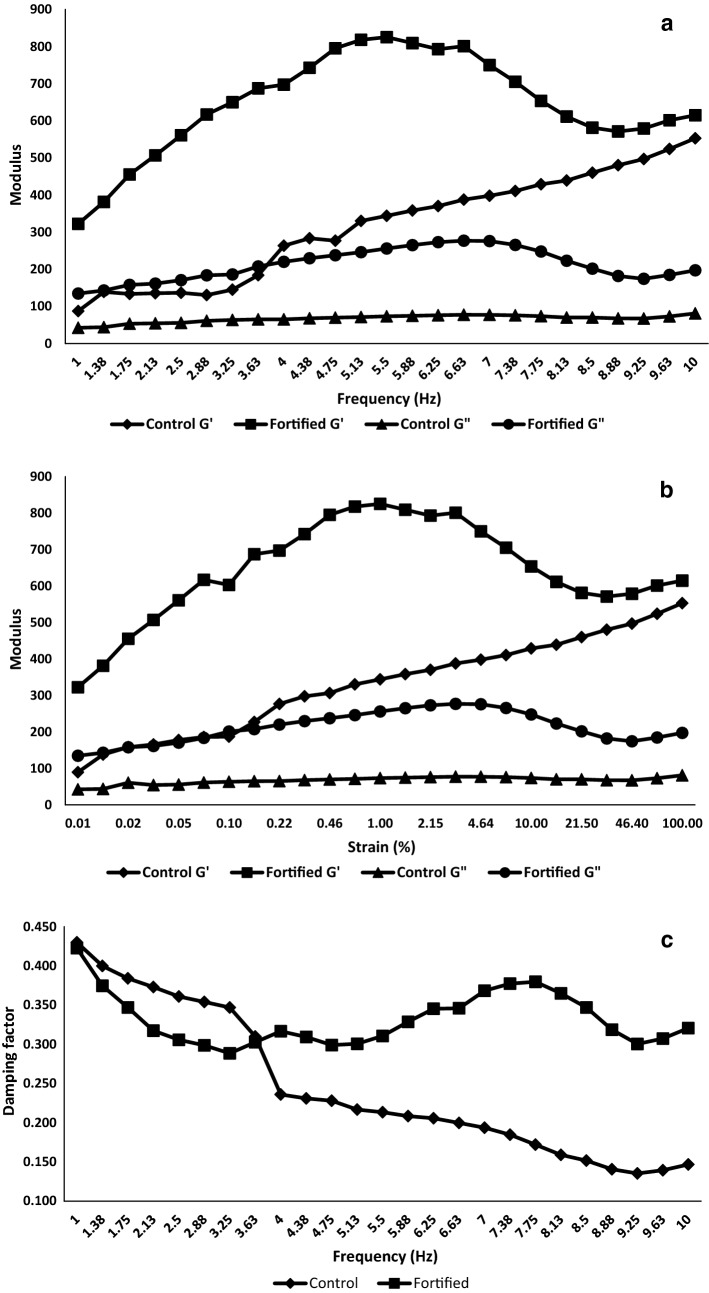

Frequency sweep

In order to assess the stability of mayonnaise emulsion, frequency sweep was carried out at constant temperature of 25 °C, in the frequency range of 1–10 Hz. The rheological behavior of fortified and control samples showed distinct differences as a function of frequency, with the fortified sample having significantly higher storage and loss modulus values compared to that of control sample (Fig. 3a). Slope indicated the strength of the network with the applied frequency. The significantly higher G′ values of fortified samples suggested the superior elastic behavior of fortified sample compared to that of control samples which may be due to the formation of strong intermolecular network in the fortified samples. The viscoelastic profile of the mayonnaise samples obtained by the frequency sweep measurement classifies both the samples as ‘weak gels’ as G′ values were higher than G″ values; however strength of fortified sample gel is considered as comparatively stronger, as the recorded G′ values were much higher than that of control sample. Previously, the weak gelling characteristics of mayonnaise were reported by Aslanzadeh et al. (2012) in low fat mayonnaise containing modified wheat bran. The slope of the G′ curve as a function of frequency was determined as 0.832 for control against a much lower value of 0.237 for fortified samples, indicating the superior stability of the fortified sample against the application of stress. The frequency sweep curve gives a good rheological description of how the product will behave during storage and application as well as helps to characterize or classify dispersion. Gallegos et al. (1992) observed that higher oil content produces a significant increase in the elastic characteristics of mayonnaise. However, in the present study such a correlation was not evident, which might be due to the presence of peptides carrying exposed hydrophilic and hydrophobic groups which further limited the diffusion of oil and water phase.

Fig. 3.

Rheological properties viz., a frequency sweep, b strain sweep, c damping factor curve, d and e flow properties, f temperature sweep of mayonnaise samples

Strain sweep

The G′ values of mayonnaise samples as a function of strain (%) values indicated distinctly higher values for fortified sample compared to that of control sample, suggesting the higher consistency of fortified sample. A structure build-up and break down phenomenon was observed in fortified sample, as indicated by a maximum G′ value of 825.3 Pa at 1% strain value, and thereafter showing a decreasing trend. On the other hand, control sample showed much lower, still gradually increasing values throughout the given range of strain values. The G″ values of fortified sample also followed a similar trend as that of G′, whereas the G″ values of control samples were independent of strain values within linear viscoelastic region, and remained nearly constant with increase in % strain (Fig. 3b). The changes in damping factor also followed a concurrent trend with a minimum value at the intermediary frequency in fortified sample, whereas control sample followed a gradually decreasing pattern till the end of strain sweep (Fig. 3c). The fortified mayonnaise may be considered as a concentrated emulsion as the moisture content is much less than that of control mayonnaise, and hence more inter-droplet interactions may be expected leading to the formation of an ordered three-dimensional network of aggregated droplets. As the strain crosses a critical limit, aggregates tend to deform and eventually disrupt the ordered network once formed.

Flow profile

Variations in viscosity with shear rates (0–100 s−1) at constant temperature of 25 °C (Fig. 3d) indicated non-Newtonian behavior with shear thinning characteristics for the control sample, whereas distinct shear thickening behavior was observed for fortified samples. The apparent viscosity of the fortified mayonnaise sample was significantly higher (94,400 cP) than control sample (33,433 cP) at any given shear rate. Shear stress–shear rate data of mayonnaise samples were fitted to various rheological models using the software provided along with the rheometer. Based on standard error data obtained, Herschel–Bulkley model was found to be most appropriate in explaining the flow behavior ofmayonnaise samples. Both control and fortified samples showed distinct yield stress values, with almost five fold higher value for fortified sample (Table 2). This might be on account of higher non-specific interactions by the lipophilic and hydrophilic side chains of shorter peptides limiting the fluidity of the emulsion. Concurrent to that, the consistency coefficient (k) of fortified sample was nearly quintuple times higher than that of control sample. Similarly, the flow behavior index ‘n’ of fortified was lower than that of control sample, indicating the viscous nature of fortified sample at ambient temperature. The farther the flow behavior index from 1, the more the deviation from Newtonian behavior (Lewis 1990). A high value of ‘n’ tends to impart slimy mouth feel to the food preparations. Hence, a lower n value is desirable for the preparations, when a thicker solution with good mouth feel characteristics are desired. From the viscosity data, it is apparent that addition of fish protein improved the mouth feel of mayonnaise. Reports indicate a flow behavior index values (n) ranging from 0.13 to 0.91 for some commercial emulsions and model emulsion systems (Steffe 1992).

Table 2.

Herschel–Bulkley model parameters for mayonnaise samples

| Samples | Yield stress (τo) | Consistency coefficient (k) | Flow behavior index (n) | Regression coefficient (R2) |

|---|---|---|---|---|

| Control | 2.133 | 37.37 | 0.27 | 0.99 |

| Fortified | 9.896 | 178.64 | 0.18 | 0.99 |

The flow properties of the samples were evaluated from shear-stress sweep curves which provided information on resistance to shearing as well as any structural impairment (Dileep et al. 2012). Variations in shear stress with shear rates ranging from 0 to 100 s−1 indicated an increasing trend in stress up to shear rate of 6 s−1, more prominent in control than fortified one, reaching a constant on further increase in shear rate (Fig. 3e). The significantly higher stress value registered for fortified sample (94.5 Pa) compared to that of control (33.5 Pa) indicated higher intermolecular interactions resulting in greater resistance to flow.

Viscosity as influenced by variations in temperature (0–100 °C) at constant shear rate of 100 s−1 indicated decreasing trend for both the samples, however the reduction was more prominent up to 40 °C, and thereafter followed by a nearly constant rate of change (Fig. 3f). Among the two samples, the rate of decrease was higher in fortified sample compared to control sample, indicating a structural alteration in fortified sample initiated by temperature fluctuations. However, the absolute value was higher in fortified sample throughout the range of temperature. Viscosity ranged from 1810 cP (0 °C) to 234 cP (100 °C) for control sample whereas for fortified one, it ranged from 2797 cP (0 °C) to 318 cP (100 °C). The higher viscosity values coupled with the structural alterations induced by heating suggest the presence of an originally structurally ordered emulsion formation in the fortified mayonnaise. At higher temperatures, unfolded proteins and peptides have the tendency to dissociate from the micellar structure which ultimately lead to phase separation.

Storage stability analysis

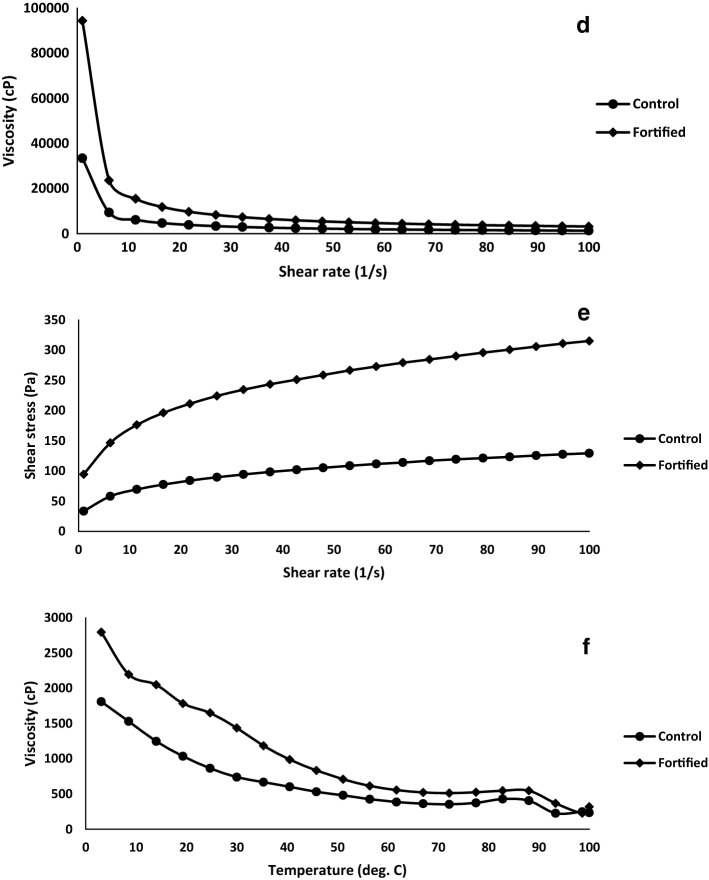

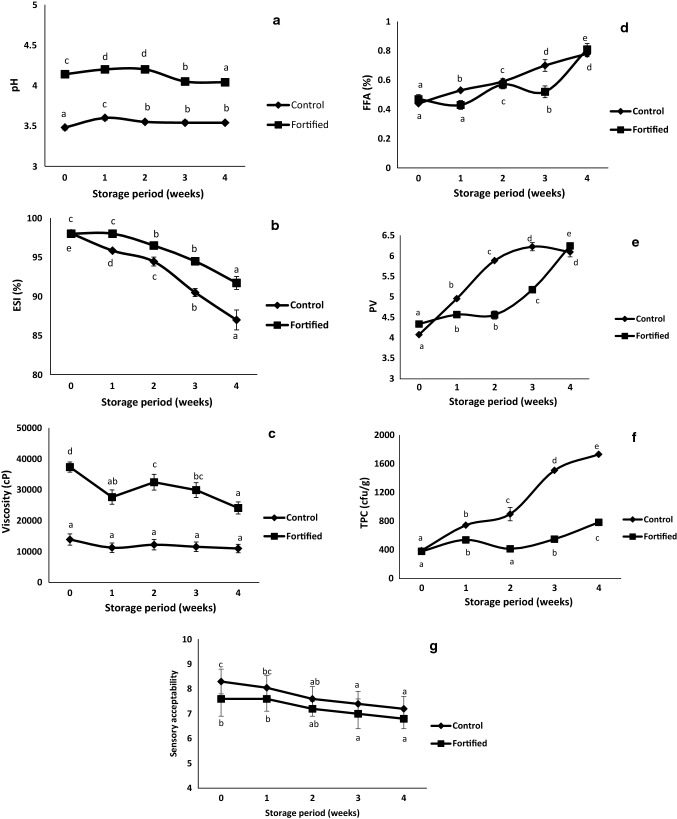

pH

The pH of mayonnaise can have a dramatic effect on the structure of the emulsion. Studies suggest viscoelasticity and stability of the mayonnaise to be highest when the pH is close to the isoelectric point of the egg yolk proteins which range between 4 and 5 (Depree and Savage 2001). In the present study, pH of the samples was influenced by protein hydrolysate incorporation with significantly higher values for fortified one (4.14 ± 0.03) compared to control (3.48 ± 0.01). The reason behind higher pH of fortified mayonnaise might be the partial replacement of egg yolk which normally have a pH of 6.0 with protein hydrolysate that had a pH of 6.24. During storage, pH was observed to remain nearly steady, with deviation within a range of not more than 0.2 pH units, for fortified samples as well as control (Fig. 4a) giving the interpretation that both samples were moreover stable during the study period.

Fig. 4.

Variations in a pH, b ESI, c viscosity, d FFA, e PV, f microbiological, g sensory indices of mayonnaise samples during storage at 4 °C

Esi

During storage, a significant decrease (p < 0.05) in ESI values was observed in control sample, by about 11% of initial value (Fig. 4b), whereas fortified sample showed minimum reduction of about 6% from the initial value. The result confirms that TPH acted as an effective emulsion stabiliser in mayonnaise sample. Previously, Mun et al. (2009) reported higher stability for mayonnaise samples with low fat compared to full fat samples on account of increased viscosity of the aqueous phase reducing the oil droplet movement. In the present study, the superior stability observed in fortified sample might be on account of more exposed hydrophilic and hydrophobic peptides, which in turn acted as an interphase stabilizer between the aqueous and oil phase. In the present study, even though both the samples had almost similar ESI values, incorporation of TPH improved the stability of the mayonnaise during storage.

Viscosity

The viscosity of fortified sample registered higher values (p < 0.05) during chilled storage compared to control which was substantiated from the rheological properties of the samples (Fig. 4c). The higher viscosity observed in the case of fortified sample might be due to the higher total protein content as well as its higher water binding ability thereby inhibiting its continuous phase mobility. Gaonkar et al. (2010) also observed higher viscosity and yield stress values for mayonnaise samples prepared using whey protein concentrate and whey protein isolate, compared to that of control (egg component). However a gradual decrease in viscosity was observed for the samples during storage which might be probably associated with the changes in ESI, which largely affects the homogeneity of the sample by releasing the oil phase from the emulsion, and thereby decreasing its viscosity.

FFA and PV

FFA, indicative of hydrolytic rancidity also exhibited a gradual but significant increase (p < 0.05) in both the samples during storage (Fig. 4d). Though initially the FFA levels were comparable between samples, further on storage a significant variation was observed between them with higher oxidation exhibited by control than fortified sample. The control sample exhibited consistently increasing values of FFA, whereas a slightly fluctuating trend was observed for fortified sample. This variable trend observed in FFA values during the storage of fortified samples might be on account of interaction of the generated FFA with peptides and free amino acids in the hydrolysate, to form conjugated intermediates.

Oxidation of unsaturated fatty acids is regarded as one of the main reasons behind chemical instability of emulsions. Lipid oxidation in mayonnaise leads to the development of potentially toxic reaction products, undesirable off-flavours and phase separation (Alemán et al. 2015). Peroxide value, indicative of primary oxidation of fat content in the sample indicated almost similar initial values 4.08 ± 0.01 and 4.34 ± 0.07 mEq O2/kg, respectively in control and fortified one which on storage (p < 0.05) showed distinctly higher values for control sample (Fig. 4e). This might be partly due to the compositional variation with higher fat content in control from egg yolk than fortified one which was partially replaced with TPH. Further, bioactive peptides present in the hydrolysate might have imparted oxidative protection on account of their antioxidant properties as reported previously in literature (Klompong et al. 2007). The in vitro antioxidant activity of tuna red meat protein hydrolysates was established in our earlier studies as well (Parvathy et al. 2018a).

Microbiological studies

The Total plate count (TPC) of both samples were close to 2.6 logs, initially. However during storage, a markedly higher value was registered by control sample, even during the first week of chilled storage. The microbial growth was more prominent in control sample during the entire period of storage, approaching a value of 3.24 log (1735 cfu/g) and 2.89 log (785 cfu/g), respectively in control and fortified sample, at the end of 4 weeks of chilled storage (Fig. 4f). The results further suggests the possible antimicrobial property of TPH, similar observations were reported previously for hydrolysates from various protein sources (Da Rocha et al. 2018). Further, it is also possible that the higher fat content in control mayonnaisehad a protective effect on microorganisms to reside safely in the oil phase without having an effect ofchange in the microenvironment the aqueous phase (Pourkomailian 2000). Studies by Karas et al. (2002) also suggest chances of more bacterial contamination on account of higher moisture content in control, which was dominated by lactic acid bacteria.

Sensory evaluation

Sensory acceptability is one of the prime attribute to be considered for ready to eat products like mayonnaise. The foremost sensory impression of the quality of a food emulsion is its overall appearance which is a collective implication of its color as well as texture. During sensory evaluation of the product, overall acceptability was determined based on five main attributes viz., appearance, odour, flavour, colour and texture using a 9 point hedonic scale. Control sample had a better sensory acceptance with an initial score of 8.30 ± 0.48 compared to fortified one (7.60 ± 0.70). This score demarcation observed between the samples may be on account of the slight bitterness and fish flavor imparted by TPH in fortified one. Further, the colour of the fortified samples were also darker (Table 1), as indicated by decreased lightness and increased redness as well as yellowness (p < 0.05) in comparison to the control sample which must have influenced the sensory acceptance of fortified product. A decrease in the sensory score was observed for both the samples throughout the storage period, reaching 7.20 ± 0.50 and 6.80 ± 0.40 for control and fortified ones, respectively towards fourth week of storage (Fig. 4g). This must be due to the minor intensification of the egg yolk as well as fishy flavor in control and fortified samples, respectively during storage thereby affecting the acceptance score. However, both the samples were acceptable till the end of storage study. Similar to the present study, research conducted by Rahmati et al. (2014) in mayonnaise with soymilk replacement reported control with egg yolk to havethe highest score affected by its color and thickness. Color score of control yolk sample was the highest due to the highest amount of yolk. Taste scores established control with egg white to be highly acceptable in the same study. Challenges associated with the development of emulsions replacing traditional products with comparable sensory attributes like appearance, texture, and flavor have been previously reported by several authors (Puligundla et al. 2015; Mozafari et al. 2017).

Conclusion

Present study attempted the development of fortified mayonnaise by partial replacement of egg yolk with functionally optimized tuna protein hydrolysate. Incorporation of tuna protein hydrolysate improved the nutritional status of the mayonnaise formulation by increase in protein content as well as reduction in fat content in comparison to control. A diminution in particle size and increased viscosity was observed in fortified sample. Incorporation of TPH in mayonnaise caused variation in colour profile with an increased yellowness and redness in fortified formulation. Storage studies indicated better oxidative stability for fortified samples compared to control during storage at 4 °C. Current study explores the potentiality of protein hydrolysates in mayonnaise preparations for fortification as well as better stability.

Acknowledgements

The authors wish to thank the Director, ICAR-CIFT, Cochin, for providing the support and facilities to carry out this work. Financial support from Indian Council of Agricultural Research (ICAR), New Delhi is also greatly acknowledged. First author also thank all scientific, technical and supporting staffs of Mumbai Research Centre, ICAR-CIFT for the support rendered during the study.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Alemán M, Bou R, Guardiola F, Durand E, Villeneuve P, Jacobsen C, Sørensen ADM. Antioxidative effect of lipophilized caffeic acid in fish oil enriched mayonnaise and milk. Food Chem. 2015;167:236–244. doi: 10.1016/j.foodchem.2014.06.083. [DOI] [PubMed] [Google Scholar]

- AOAC . Official methods of analysis of the association ofofficial analytical chemists. 19. Washington, DC: Association of Official Analytical Chemists; 2012. [Google Scholar]

- Aslanzadeh M, Mizani M, AlimiM GeramiA. Rheological properties of low fat mayonnaise with different levels of modified wheat bran. J Food Biosci Technol. 2012;2:27–34. [Google Scholar]

- Baharuddin NA, Halim NRA, Sarbon NM. Effect of degree of hydrolysis (DH) on the functional properties and angiotensin I-converting enzyme (ACE) inhibitory activity of eel (Monopterus sp.) protein hydrolysate. Int Food Res J. 2016;23:1424–1431. [Google Scholar]

- Binsi PK, Viji P, Panda SK, Mathew S, Zynudheen AA, Ravishankar CN. Characterisation of hydrolysates prepared from engraved catfish (Nemapteryx caelata) roe by serial hydrolysis. J Food Sci Technol. 2016;53:158–170. doi: 10.1007/s13197-015-1998-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Binsi PK, Natasha N, Sarkar PC, Ashraf PM, George N, Ravishankar CN. Structural, functional and in vitro digestion characteristics of spray dried fish roe powder stabilised with gum arabic. Food Chem. 2017;221:1698–1708. doi: 10.1016/j.foodchem.2016.10.116. [DOI] [PubMed] [Google Scholar]

- Chi CF, Cao ZH, Wang B, Hu FY, Li ZR, Zhang B. Antioxidant and functional properties of collagen hydrolysates from spanish mackerel skin as influenced by average molecular weight. Molecules. 2014;19:11211–11230. doi: 10.3390/molecules190811211. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chi CF, Hu FY, Wang B, Li ZR, Luo HY. Influence of amino acid compositions and peptide profiles on antioxidant capacities of two protein hydrolysates from skipjack tuna (Katsuwonus pelamis) dark muscle. Mar Drugs. 2015;13:2580–2601. doi: 10.3390/md13052580. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Da Rocha M, Alemán A, Baccan GC, López-Caballero ME, Gómez-Guillén C, Montero P, Prentice C. Anti-inflammatory, antioxidant, and antimicrobial effects of underutilized fish protein hydrolysate. J Aqua Food Prod Technol. 2018;27:592–608. doi: 10.1080/10498850.2018.1461160. [DOI] [Google Scholar]

- Depree JA, Savage GP. Physical and flavour stability of mayonnaise. Trends Food Sci Technol. 2001;12:157–163. doi: 10.1016/S0924-2244(01)00079-6. [DOI] [Google Scholar]

- Dileep AO, Shamasundar BA, Binsi PK, Badii F, Howell NK. Composition, physicochemical and rheological properties of fresh bigeye snapper fish (Priacanthus hamrur) mince. J Food Biochem. 2012;36:577–586. doi: 10.1111/j.1745-4514.2011.00592.x. [DOI] [Google Scholar]

- El-Bostany AN, Ahmed MG, Amany AS. Development of light mayonnaise formula using carbohydrate-based fat replacement. Aust J Basic Appl Sci. 2011;5:673–682. [Google Scholar]

- Gallegos C, Berjano M, Choplin L. Linear viscoelastic behavior of commercial and model mayonnaise. J Rheol. 1992;36(3):465–478. doi: 10.1122/1.550354. [DOI] [Google Scholar]

- Gaonkar G, Koka R, Chen K, Campbell B. Emulsifying functionality of enzyme-modified milk proteins in O/W and mayonnaise-like emulsions. Afr J Food Sci. 2010;4:16–25. [Google Scholar]

- Gbogouri GA, Linder M, Fanni J, Parmentier M. Influence of hydrolysis degree on the functional properties of salmon byproducts hydrolysates. J Food Sci. 2004;69:C615–C622. doi: 10.1111/j.1365-2621.2004.tb09909.x. [DOI] [Google Scholar]

- Ghazaei S, Mizani M, Piravi-Vanak Z, Alimi M. Particle size and cholesterol content of a mayonnaise formulated by OSA-modified potato starch. Food Sci Technol (Campinas) 2015;35:150–156. doi: 10.1590/1678-457X.6555. [DOI] [Google Scholar]

- Karas R, Skvarc M, Žlender B. Sensory quality of standard and light mayonnaise during storage. Food Technol Biotechnol. 2002;40:119–127. [Google Scholar]

- Klompong V, Benjakul S, Kantachote D, Shahidi F. Antioxidative activity and functional properties of protein hydrolysate of yellow stripe travelly (Selaroides leptolepis) as influenced by the degree of hydrolysis and enzyme type. Food Chem. 2007;102:1317–1327. doi: 10.1016/j.foodchem.2006.07.016. [DOI] [Google Scholar]

- Lewis MJ. Physical properties of foods and food processing systems. New York: Ellis Harwood Ltd; 1990. [Google Scholar]

- Ma Z, Boye JI. Advances in the design and production of reduced-fat and reduced-cholesterol salad dressing and mayonnaise: a review. Food Bioproc Technol. 2013;6:648–670. doi: 10.1007/s11947-012-1000-9. [DOI] [Google Scholar]

- McClements DJ. Food emulsions: principles, practice, and techniques. Boca Raton: CRC Press; 2005. [Google Scholar]

- Meilgaard M, Civille GV, Carr BT. Sensory evaluation techniques. 4. Boca Raton: CRC Press; 2006. [Google Scholar]

- Mozafari HR, Hosseini E, Hojjatoleslamy M, Mohebbi GH, Jannati N. Optimization low-fat and low cholesterol mayonnaise production by central composite design. J Food Sci Technol. 2017;54(3):591–600. doi: 10.1007/s13197-016-2436-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mun S, Kim YL, Kang CG, Park KH, Shim JY, Kim YR. Development of reduced-fat mayonnaise using 4αGTase-modified rice starch and xanthan gum. Int J Biol Macromol. 2009;44:400–407. doi: 10.1016/j.ijbiomac.2009.02.008. [DOI] [PubMed] [Google Scholar]

- Nader J, Fawaz N, Afif C, Louka N. A novel process for preparing low-fat peanuts: optimization of the oil extraction yield with limited structural and organoleptic damage. Food Chem. 2016;197:1215–1225. doi: 10.1016/j.foodchem.2015.11.079. [DOI] [PubMed] [Google Scholar]

- Parvathy U, Binsi PK, Zynudheen AA, Ninan G, Murthy LN. Peptides from white and red meat of yellowfin tuna (Thunnus albacares): a comparative evaluation. Ind J Fish. 2018;65:74–83. [Google Scholar]

- Parvathy U, Binsi PK, Joshy CG, Jeyakumari A, Zynudheen AA, Ninan G, Ravishankar CN. Functional hydrolysates from yellow fin tuna red meat using RSM based optimization. Int J Curr Microbiol App Sci. 2018;7(11):1462–1474. doi: 10.20546/ijcmas.2018.711.169. [DOI] [Google Scholar]

- Pourkomailian B. Sauces and dressings. In: Kilcast D, Subramaniam P, editors. The stability and shelf-life of food. Washington, DC: CRC Press; 2000. pp. 311–329. [Google Scholar]

- Puligundla P, Cho YH, Lee YT. Physicochemical and sensory properties of reduced-fat mayonnaise formulations prepared with rice starch and starch-gum mixtures. Emir J Food Agr. 2015;27(6):463–468. doi: 10.9755/ejfa.2015.04.081. [DOI] [Google Scholar]

- Rahmati K, Tehrani MM, Daneshvar K. Soy milk as an emulsifier in mayonnaise: physico-chemical, stability and sensory evaluation. J Food Sci Technol. 2014;51:3341–3347. doi: 10.1007/s13197-012-0806-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rashed AA, Noh MFM, Khalid NM, Rahman NIAR, Tasirin A, Omar WSW, Nawi MNM, Jamilan MA, Selamat R. The nutritional composition of mayonnaise and salad dressing in the Malaysian market. Sains Malays. 2017;46:139–147. doi: 10.17576/jsm-2017-4601-18. [DOI] [Google Scholar]

- Sathivel S, Yin H, Bechtel PJ, King JM. Physical and nutritional properties of catfish roe spray dried protein powder and its application in an emulsion system. J Food Eng. 2009;95:76–81. doi: 10.1016/j.jfoodeng.2009.04.011. [DOI] [Google Scholar]

- Siripongvutikorn S, Usawakesmanee W, Hunsakul K. Utilization of tuna roe and using inulin as oil replacer for producing value added omega-3 mayonnaise product. Funct Foods Health Dis. 2016;6:158–172. doi: 10.31989/ffhd.v6i3.242. [DOI] [Google Scholar]

- Souci SW, Fachman W, Kraut H. Food composition and nutrition tables. 6. Stuttgart: Medpharm GmbH Scientific Publishers; 2000. [Google Scholar]

- Steffe JF. Yield stress: phenomena and measurement. In: Singh RP, Wirakaratakusumah MA, editors. Advances in food engineering. London: CRC Press; 1992. pp. 363–376. [Google Scholar]

- Taheri A, Anvar SAA, Ahari H, Fogliano V. Comparison the functional properties of protein hydrolysates from poultry by-products and rainbow trout (Onchorhynchus mykiss) viscera. Iran J Fish Sci. 2013;12:154–169. [Google Scholar]

- USDA-NASS (U.S. Department of Agriculture-National Agricultural Statistics Service) (2005) Agricultural statistics. In: Livestock data. Arkansas Statistical Office, http://www.nass.usda.gov/ar/bulllvsk.htm

- USFDA (2001) Aerobic plate count. In: Bacteriological analytical manual. United States Foods and Drugs Administration, USA

- Yarnpakdee S, Benjakul S, Kristinsson HG, Kishimura H. Antioxidant and sensory properties of protein hydrolysate derived from Nile tilapia (Oreochromis niloticus) by one- and two-step hydrolysis. J Food Sci Technol. 2015;52:3336–3349. doi: 10.1007/s13197-014-1672-4. [DOI] [PMC free article] [PubMed] [Google Scholar]