Abstract

To meet the needs of new consumers, meat researchers need to develop healthier products. Dietary fibers can be added for structural purposes, to present functional characteristics or to change the composition of the final product. In this study, mixture design was used to investigate the effects of partial substitution of pork fat by inulin, fructooligosaccharides and α-cyclodextrin on the technological and sensory quality characteristics of low-fat Italian type salami. The partial substitution of fat using dietary fibers shows no effect on weight loss, Aw and pH during ripening time. However, the addition of up to 2% α-cyclodextrin increased lightness and reduced redness and yellowness. Up to 2% of inulin or fructooligosaccharides added improved the sensory acceptance, texture parameters and redness. Healthier low-fat Italian type salami can be produced using inulin or fructooligosaccharides as fat substitute for pork fat and still obtain good technological and sensorial results.

Keywords: Fat substitute, Inulin, Fructooligosaccharides, α-Cyclodextrin, Improved redness, Fermented sausage

Introduction

In Brazil, processed meat products represent a high percentage (95%) of the consumption of pork (ABPA 2012). Fermented sausage is a well-known preparation among Brazilian consumers, and the Italian type salami can be found throughout the country. Italian type salami can contain high levels of saturated fat (up to 32%) according to the physico-chemical parameters (Brazil 2000) and can have high salt content, a lack of bioactive molecules and poor fiber content (Pérez-Burillo et al. 2019). Changes in consumer behavior have steadily increased the trend towards healthier food products (Hilbig et al. 2019), and this consequently compromises the consumers’ interest in traditional products (Bis-Souza et al. 2019).

The reduction in the fat content of a meat product usually implies undesirable effects to technological, structural and sensory characteristics (Henning et al. 2016), such as a reduction in yield, negative changes in texture and a reduction in sensorial acceptance (Han and Bertram 2017). The use of dietary fiber offers a healthier meat product with higher fiber content. It is, also an alternative ingredient that can maintain the technological and sensory properties (Henning et al. 2016; Zhao et al. 2018). Additionally, consumer preference for meat products that provide benefits to physiological functions and have greater nutritional value has increased significantly (Han and Bertram 2017). Inulin, fructooligosaccharides and α-cyclodextrin are examples of oligosaccharides extracted from plants that have an important gelling property (Bis-Souza et al. 2019). The addition of this dietary fiber in fermented meat products can improve the content of short chain fatty acids (SCFAs), which represents a component associated with some health benefits (Pérez-Burillo et al. 2019).

Moreover, most of these fibers have a neutral flavor, which minimizes changes in the sensory acceptance of the meat product (Santos et al. 2013; Días-Vela et al. 2017; Marino et al. 2017; Glisic et al. 2019). Accumulated data suggests that a high-prebiotic fiber diet presents many health benefits, such as a decrease in the relative risks of developing obesity, coronary artery disease and diabetes (Casarotti et al. 2018). Prebiotic fibers, such as inulin and oligofructose, increase the concentration of acetate and propionate, improve gut-barrier function, induce weight-loss and reduce food intake (Bailey and Holscher 2018).

The use of dietary fiber, such as inulin, arabinogalactan, citrus fiber, fructooligosaccharides, oligofructose, lactulose, galactooligosaccharides, alone or in combination, has already been evaluated as a fat substitute in meat products. The efficiency of such fiber has already been proved in emulsified meat (Sarteshnizi et al. 2015; Alves et al. 2016), fermented sausages (Park et al. 2017; Glisic et al. 2019; Pérez-Burillo et al. 2019), cooked products (Keenan et al. 2014; Henning et al. 2016; Días-Vela et al. 2017, Han and Bertram 2017) and restructured meat (Bis-Souza et al. 2018). For example, the partial substitution of pork back fat by inulin gelled suspension decreased hardness and chewiness and showed no effect on the acceptability of the sensory attributes of fermented sausage (Glisic et al. 2019). Finally, a recent study with consumers found that the addition of dietary fiber in meat products can change the consumers’ perception about those products, turning frankfurters with dietary fiber and omega-3 added into a potential marketable product (Rocha et al. 2019).

The Simplex-centroid mixture design allows the study for the best condition of three different ingredients for a given response-variable and it is also possible to optimize the experiment (Anarjan et al. 2017; De Moraes Filho et al. 2018). We did not find references in the literature about the effect of a mixture of three types of prebiotic dietary fibers added in the same salami formulation. Thus, the aim of this study was to evaluate the effect of the partial substitution of pork fat by combinations of prebiotic dietary fiber (inulin, fructooligosaccharides and α-cyclodextrin) in Italian type salami on sensory and technological characteristics using the Simplex-centroid mixture design.

Materials and methods

Ingredients

The dietary fibers used in this study were: Clariant—Orafti® inulin (moisture 3 g 100 g−1 of moisture; total dietary fiber 90 g 100 g−1) (Beneo, Mannheim, Germany); Ingredion®—fructooligosaccharide (FOS) (4 g 100 g−1 of moisture; total dietary fiber 95 g 100 g−1 (Ingredion, Westchester, USA) and from the α-cyclodextrin (ACD) (Vogler Ingredients, São Bernardo do Campo, Brazil). The fresh pork meat and the pork fat were purchased from a local market (Carnes Pompéia, Campinas, Brazil).

Experimental design: simplex-centroid mixture design

The three dietary fibers: inulin—(X1), fructooligosaccharide (FOS)—(X2), α-cyclodextrin (ACD)—(X3), were used in the mixture design. The hypothesis was tested by a matrix composed of 10 mixtures (7 different assays and 3 replicates with 1 type of dietary fiber), 6 assays with only 1 type of dietary fiber, 3 assays were the binary mixtures of two ingredients and 1 assay was the ternary mixture of three ingredients (Table 1). The maximum amount of dietary fiber added was 2%. The amount of fiber added in the formulation was defined based on results from the literature and on the claim related to the fiber content prevailing in Brazilian legislation (Brazil 2012). A product can claim to be a “source of fiber” if it has a minimum concentration of 2.5 g of fiber per portion or 3 g of fiber per 100 g of product. Therefore, it was decided to add 2 g 100 g−1 of the dietary fiber, considering an average yield of 60% of the low-fat Italian type salami.

Table 1.

Simplex-centroid mixture design matrix to low-fat Italian type salami

| Treatments | Matrix | Proportion (%) | ||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | Inulin | FOS | ACD | |

| I1 | 1 | 0 | 0 | 2 | 0 | 0 |

| F1 | 0 | 1 | 0 | 0 | 2 | 0 |

| A1 | 0 | 0 | 1 | 0 | 0 | 2 |

| I2 | 1 | 0 | 0 | 2 | 0 | 0 |

| F2 | 0 | 1 | 0 | 0 | 2 | 0 |

| A2 | 0 | 0 | 1 | 0 | 0 | 2 |

| IF | 0.5 | 0.5 | 0 | 1 | 1 | 0 |

| IA | 0.5 | 0 | 0.5 | 1 | 0 | 1 |

| FA | 0 | 0.5 | 0.5 | 0 | 1 | 1 |

| IFA | 0.33 | 0.33 | 0.34 | 0.66 | 0.66 | 0.68 |

I1; I2 (10% of pork fat + 2% of Inulin); F1; F2 (10% of pork fat + 2% of FOS); A1; A2 (10% of pork fat + 2% of ACD); IF (10% of pork fat + 1% Inulin + 1% FOS); IA (10% of pork fat + 1% Inulin + 1% ACD); FA (10% of pork fat + 1% FOS + 1% ACD); IFA (10% of pork fat + 0.66% Inulin + 0.66% FOS + 0.68 ACD)

The Simplex-centroid mixture design was used to evaluate in which proportion the added fibres presented the best results for the sensorial and technological characteristics studied. And so, it is possible to select the best formulation for fat reduction in Italian type salami.

The response-variables were moisture, fat content, weight loss, lightness, redness, yellowness, hardness, cohesiveness, springiness, chewiness and the 2-thiobarbituric reactive substances (TBARS) value.

Low-fat Italian type salami formulation and preparation

Ten formulations of low-fat Italian type salami were produced with 80 g 100 g−1 of fresh pork shoulder (Landrace, moisture 74 g 100 g−1, fat 6 g 100 g−1) and 10 g 100 g−1 of pork back fat (moisture 11 g 100 g−1, fat 82 g 100 g−1) obtained from a slaughterhouse with federal inspection service (FIS). The others ingredients were: sodium chloride (2.5 g 100 g−1), sucrose (2 g 100 g−1), sodium nitrite (0.015 g 100 g−1), sodium nitrate (0.015 g 100 g−1), garlic (0.2 g 100 g−1), white pepper (0.5 g 100 g−1), nutmeg (0.2 g 100 g−1), sodium erythorbate (0.3 g 100 g−1), and a starter culture (0.025 g 100 g−1; Bactoferm T-SPX (Chr. Hansen, Hoersholm, Denmark) composed of Pediococcus pentosaceus and Staphylococcus xylosus. The dietary fiber was added according to Table 1. The samples were produced in the Laboratory of Meat and Derivatives at the Faculty of Food Engineering, University of Campinas (São Paulo, Brazil). All the ingredients were mixed using an automatic blender for approximately 5 min. After, the samples were stuffed in cellulose cases (diameter of 50 mm) and separated into pieces of 15 cm, totaling 25 pieces (approximately 250 g) for each treatment. Afterwards, samples were soaked in a solution of potassium sorbate (20 g 100 g−1) and ripened for13 days. The temperature and relative humidity parameters (T °C and RH %) were controlled over the ripening time, 15–25 °C and 75–95%, respectively. The air velocity was also controlled throughout the processing (0.5 m s−1).

pH value and water activity evaluations during ripening time

The pH value was measured with a penetration probe in a PG 1800 digital pH meter (Gehaka, São Paulo, Brazil). Water activity (Aw) was measured using an Aqualab water activity meter (Decagon Devices Inc., Pullman, USA). The analyses were performed during ripening time on days 0, 3, 7, 10 and 13 after the stuffing process. The analyses were performed three times on each of the five salami sampled for each ripening time.

Weight loss and general composition

Five sausages (with an initial weight of approximately 250 g) from each treatment were initially weighed. The same samples were reweighed on days 3, 7, 10 and 13. Weight losses were expressed as the percentage of the initial weight (Glisic et al. 2019). All the treatments were characterized for moisture content according to Horwitz and Latimer (2007) and the fat content according to Bligh and Dyer (1959). These analyses were performed on day 0 and after the full ripening time (day 13). All analyses were performed in triplicate.

Lipid oxidation analysis (TBARS)

The degree of lipid oxidation was evaluated by measuring the TBARS value, according to Vyncke (1970) with modifications. The TBARS value was measured from a standard curve of malonaldehyde (MA) and expressed as mg MA kg−1 of sample. The analyses were performed in triplicate.

Characterization of color parameters

The instrumental color was measured in a ColorFlex 45/0 spectrophotometer (Hunterlab, Virginia, USA), observation angle of 10°, illuminant D65 and linked to Universal software version 4.10 (Hunterlab, Virginia, USA). The specification system used was the CIELAB color space expressing the three values: L* for the lightness from black to white, a* from green to red, and b* from blue to yellow. Ten readings were performed per sample (n = 5). The analyses were performed after the ripening process. The samples were left at room temperature for 30 min before analysis.

Texture profile analysis (TPA)

The instrumental texture profile analysis was performed at room temperature (25 °C) using a TA-XT/Plus/50 texture analyzer (Stable Micro Systems, Godalming, UK), equipped with a cylindrical probe of 36 mm in diameter. The parameters hardness (N), cohesiveness, springiness (mm) and chewiness (N mm−1) were determined, as described by Bourne (1978) and Szczesniak (2002). The samples of low-fat Italian type salami were cut into slices 1.5 cm thick and were axially compressed 50% of height (0.75 cm) in two consecutive cycles, at a constant speed test of 1 mm s−1 (n = 10).

Microbiological analysis

After the ripening process, the analyses determined the count of the thermo-tolerant coliforms, the presence of coagulase-positive Staphylococci and Salmonella sp. in 25 g was investigated according to the Brazilian Health Surveillance Agency (Brazil 2001) and the results were expressed in log CFU g−1 of sample.

Sensory acceptance

A consumer study was conducted by 89 untrained panelists recruited among students and staff members from São Paulo State University (UNESP) at the São José do Rio Preto campus (SP, Brazil). These panelists were previously selected by a questionnaire related to the frequency of consumption of fermented meat products. All the panelist that agreed to participate in the sensory analysis had to declare their consent in a pre-filled form before the analysis began. The sensorial attributes evaluated in the acceptance test were appearance, color, taste, texture and overall acceptance using a structured hedonic scale of 9 points. Sensory evaluation was carried out only for the different formulations of low-fat Italian type salami (n = 7), after the ripening process. Each sample was coded with a three-digit number and the presentation was randomized in a sequential monadic way, following a balanced complete block design (Meilgaard et al. 1999). The tests were performed in two sessions, in individual booths under white light and at a temperature of 22 °C. All panelists evaluated one sample of all treatments in a randomized order. This project was approved by the Ethics in Research Committee of São Paulo State University (São José do Rio Preto, Brazil) under protocol number 2.126.575.

Statistical analysis

The results were expressed as the mean values and the standard error of the mean (SEM). Differences in pH and water activity (Aw) were analyzed statistically using mixed model ANOVA analyses and the means were compared using the Tukey HSD test (P < 0.05). Each triplicate of each batch was included as a random term and different times were included as fixed term.

To analyze the data of the response-variables: moisture, fat content, weight loss, lightness, redness, yellowness, hardness, cohesiveness, springiness, chewiness and TBARS value, the linear and quadratic models for the mixture design were used. Mixture analysis was used to determine the effects, the linear, quadratic, and cubic regression coefficients, the lack of fit and the coefficient of determination (R2) for each response-variables. The quadratic model showed better fit to the data, so the results were presented following Eq. 1.

| 1 |

For the sensory analysis the treatment was considered as the main effect and consumers as random variable. The data obtained in the sensorial analysis were analyzed statistically using the General Linear Model (GLM) and the means were compared using the Tukey test (P < 0.05). The results were also expressed as the mean values and the standard error of the mean. All experimental design, data analysis, regression and optimization steps were completed using Statistica 7.0 software (Statsoft Inc., USA).

Results and discussion

pH value and water activity during ripening time

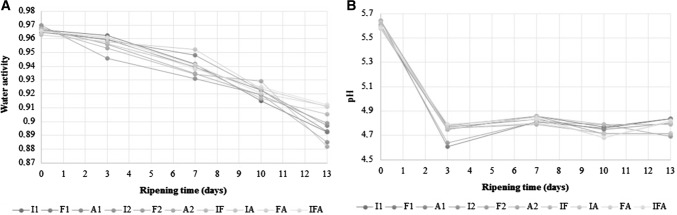

During the processing of fermented meat sausage, monitoring two technological parameters is extremely important to achieve product stability: (1) the decreasing of the pH which depends exclusively on the acidification caused by lactic acid bacteria and (2) water activity that is related to the product water loss to the environment during drying process (Prado et al. 2019). There were no significant (P > 0.05) differences between treatments of low-fat Italian type salami during the ripening time for water activity (Fig. 1a) and pH (Fig. 1b). The reduction in Aw and pH during the ripening process guarantee a safe and microbiologically stable product (Ferreira et al. 2006; Prado et al. 2019).

Fig. 1.

Water activity (a), pH value (b) of low-fat salami type Italian during ripening time. Not significantly results (P > 0.05) for both evaluations. I1; I2 (10% of pork fat + 2% of Inulin); F1; F2 (10% of pork fat + 2% of FOS); A1; A2 (10% of pork fat + 2% of ACD); IF (10% of pork fat + 1% Inulin + 1% FOS); IA (10% of pork fat + 1% Inulin + 1% ACD); FA (10% of pork fat + 1% FOS + 1% ACD); IFA (10% of pork fat + 0.66% Inulin + 0.66% FOS + 0.68 ACD)

The initial value of Aw for the batches were between 0.96 and 0.97. During ripening processes of dry fermented sausage, the product loses water because of evaporation (lower relative humidity in the maturation chamber), which causes the Aw to decrease. However, the addition of dietary fiber in low-fat Italian type salami had no effect (P > 0.05) on Aw. Similar results were found when amorphous cellulose gel (Campagnol et al. 2012) and a mixture of collagen and dietary fiber (Ham et al. 2016) were used as fat substitutes in low-fat fermented sausages.

The initial pH was around 5.6 for all the low-fat Italian type salami batches. After 3 days (fermentation), the pH value decreased to 4.6. This was observed for all low-fat salami. The use of inulin and corn oil as fat substitute in dry-fermented chicken sausage (Menegas et al. 2013) or orange fiber as fat substitute in Spanish “Salchichón” (Fernández-lópez et al. 2008) or FOS in dry fermented sausage (Salazar et al. 2009) or linseed oil gelled emulsion as pork back fat substitute in a dry fermented sausage (Alejandre et al. 2016) or with a fat content reduction in fermented sausage (Yim et al. 2016) no differences in the pH were reported.

Weight loss and general composition

The addition of dietary fiber as fat substitute in low-fat Italian type salami showed (P > 0.05) no effect on the weight loss (Table 2). The weight loss of a fermented sausage is related to the yield of the final product. Therefore, partial substitution of fat by dietary fibers without the need to add another ingredient to increase the yield is a technological advantage. The average weight loss of low-fat Italian type salami was 40%. Ruiz et al. (2014), Blaiotta et al. (2018a, b) and Cruxen et al. (2018) also reported a similar weight loss during the process of fermented sausages. This technological characteristic depends on different factors, such as the temperature and relative humidity used in the processing, the air velocity inside the maturation chamber, the maturation time, the material of the wrapper and the amount of fat added in the batch (Yim et al. 2016).

Table 2.

Experimental results of moisture, fat and weight loss for low-fat Italian salami before and after the ripening time

| Treatments | Initial | Final | |||

|---|---|---|---|---|---|

| Moisture | Fat | Moisture | Fat | Weight loss (%) | |

| I1 | 66.01 | 9.72 | 36.22b | 22.85ab | 40.39 |

| F1 | 66.24 | 9.60 | 39.43a | 22.44ab | 40.52 |

| A1 | 66.97 | 9.07 | 36.86b | 21.08ab | 39.89 |

| I2 | 66.21 | 10.51 | 36.94b | 23.39a | 40.54 |

| F2 | 66.47 | 9.93 | 38.95a | 21.95ab | 41.05 |

| A2 | 65.55 | 10.23 | 35.98b | 20.75b | 40.50 |

| IF | 67.66 | 9.52 | 35.99b | 21.26ab | 39.57 |

| IA | 66.13 | 10.23 | 36.51b | 22.09ab | 39.73 |

| FA | 66.67 | 9.21 | 36.62b | 22.46ab | 40.68 |

| IFA | 66.84 | 9.17 | 39.70a | 22.15ab | 40.49 |

| SEM | 0.16 | 0.13 | 0.32 | 0.21 | 0.20 |

| P value | 0.131ns | 0.112ns | < 0.0001 | 0.036 | 0.914ns |

SEM, Standard error of mean; ns, not significant. I1; I2 (10% of pork fat + 2% of Inulin); F1; F2 (10% of pork fat + 2% of FOS); A1; A2 (10% of pork fat + 2% of ACD); IF (10% of pork fat + 1% Inulin + 1% FOS); IA (10% of pork fat + 1% Inulin + 1% ACD); FA (10% of pork fat + 1% FOS + 1% ACD); IFA (10% of pork fat + 0.66% Inulin + 0.66% FOS + 0.68 ACD)

a,bAccording to the Tukey test, samples on the same column with different letters show present significant differences between them (P < 0.05)

There was no effect (P > 0.05) of the addition of dietary fibers on the moisture and fat results of the batch (initial) for all treatments, since all formulations were made with the same amount of raw materials, the only difference being the dietary fibers added. After the processing, the highest (P > 0.05) moisture content was observed in the samples with 2% FOS (F1 and F2) and in the treatment with the 3 dietary fibers (IFA). In similar studies, the treatments with reduction in fat content and addition of amorphous cellulose gel (Campagnol et al. 2012) and inulin with corn oil (Menegas et al. 2013) as fat substitute show higher values of moisture in relation to the control formulation. The low-fat Italian type salami treatments presented different values (P < 0.05) of fat content at the end of the ripening time (Table 2).

Additionally, the substitution of pork fat in fermented sausages with non-fat ingredients helps to reduce the total caloric value and cholesterol levels of the product. It could improve the viability of developing of healthier meat products from a nutritional point of view (Ham et al. 2016).

Lipid oxidation analysis (TBARS value)

The amount of malonaldehyde formed during the oxidation process of each low-fat Italian type salami formulation is quantified based on the thiobarbituric acid reactive substances (TBARS). The inulin, FOS and ACD added in low-fat salami show a positive effect (P < 0.05) on the lipid oxidation, increasing the TBARS value (Table 3). The coefficients of binary and ternary mixtures of components were not significant (P > 0.05). That is, only the addition of 2% of each dietary fiber alone had a significant effect on lipid oxidation. Similar results were reported by Ham et al. (2016), Yim et al. (2016), Bis-Souza et al. (2018), when using dietary fibers as fat substitute in low-fat meat product. The highest value for TBARS was observed with addition of 2% FOS (Fig. 2a). The addition of dietary fiber increases the carbohydrate content of the product and alters the food matrix, causing an increase in lipid oxidation. Glisic et al. (2019) suggest that the addition of inulin gelled suspension in dry fermented sausage increases the polyunsaturated fatty acids (PUFA) content, compounds highly susceptible to oxidation, thus affecting the TBARS value.

Table 3.

Regression models to experimental data in mixtures design for technological properties, textural parameters and color parameters of low-fat Italian salami

| Response | Equationa | Model | R2 | P value | Lack of fit |

|---|---|---|---|---|---|

| TBARS value | Linear | 0.93 | 0.019* | 0.408 | |

| Lightness | Quadratic | 0.95 | 0.009* | 0.529 | |

| Redness | Linear | 0.94 | 0.014* | 0.664 | |

| Yellowness | Linear | 0.90 | 0.041* | 0.838 | |

| Cohesiveness | Quadratic | 0.92 | 0.027* | 0.956 | |

| Chewiness (N mm−1) | Quadratic | 0.94 | 0.014* | 0.084 |

*Significant (P < 0.05) of regression coefficient according to ANOVA

aX1: Inulin, X2: FOS, X3: ACD

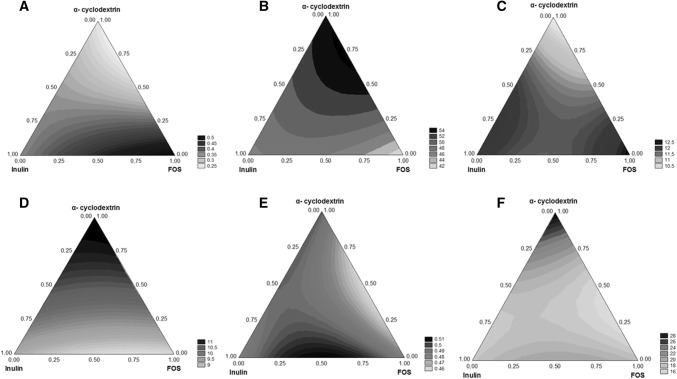

Fig. 2.

Contour plots of lipid oxidation (a) (mg MDA/kg), Lightness (b), Redness (c), Yellowness (d), Cohesiveness (e) and Chewiness (N mm−1) (f) showing the effect of dietary fiber added as fat substitute in low-fat Italian salami

Despite these increases in the TBARS values through the addition of dietary fibers, all formulations were below 2.0 mg MDA/kg, which is accepted as the deterioration level (Greene and Cumuze 1982).

Characterization of color parameters

The addition of fiber in low-fat Italian type salami as partial fat substitutes directly and significantly (P < 0.05) influences the lightness of the final product. The three components when added alone increase the value of the lightness, according to the regression models (Table 3). A positive effect of the interaction between FOS and ACD on the increase of lightness is also seen (Table 3). When up to 2% of ACD was added, the lightness increased to 54 (Fig. 2b). The addition of inulin, FOS and ACD up to 2% decreased the lightness of low-fat Italian type salami, which may justify its use in this type of product. The increased lightness of the fermented meat product may be related to the white color of dietary fibers.

Other authors have also reported an effect on lightness when adding soluble dietary fiber as a substitute for fat in meat products. This effect was reported as increasing (Caceres et al. 2004; Menegas et al. 2013) and decreasing lightness of low-fat meat products (Salazar et al. 2009; Keenan et al. 2014).

Fructooligosaccharide and inulin added to low-fat beef burger (3 and 6%) caused a reduction in lightness (Bis-Souza et al. 2018) and the addition of albedo-fiber powder from yellow passion fruit in pork burger showed no effect on the lightness (López-Vargas et al. 2014).

The use of inulin, FOS and ACD as fat substitute in low-fat Italian salami produced a significant increase (P < 0.05) in redness (Table 3, Fig. 2c) changing from 10.5 to 12.5, when 2% of each fiber was added. Similar results were reported when 20% of fat was substituted by regenerated cellulose fiber in emulsified sausage (Zhao et al. 2018). The use of green banana flour as fat substitute in bologna type sausage also increased the redness compared to a control (Alves et al. 2016). In contrast, the use of whole buckwheat flour as pork fat substitute in salami sausage did not affect the redness (Park et al. 2017).

The three components added separately as fat substitute in low-fat salami increased the yellowness (P < 0.05) (Table 3). The study conducted by Zhuang et al. (2016) also reported a significant increase in yellowness when sugarcane dietary fiber was used as fat substitute in low-fat meat batter.

The addition of inulin and FOS decreased the yellowness compared to the ACD, which ranged from 9 to 11 (Fig. 2d). A similar finding was reported by Keenan et al. (2014), who associated the reduction in the yellowness to the increase in the inulin concentration added in the formulation of low-fat pork sausage.

Texture profile analysis (TPA)

Regarding the texture profile analysis, only cohesiveness and chewiness were significantly affected by the addition of the dietary fibers (P < 0.05) and these parameters could be fitted to the proposed model (Table 3). The hardness and springiness of low-fat salami were not affected by the addition of dietary fiber as pork fat substitute. Ham and Bertram (2017) also reported that the partial substitution of fat for different fibers showed no significant effect on springiness.

On the other hand, some authors argue that the use of a short chain soluble dietary fiber such as inulin, FOS or ACD may lead to increased hardness of meat products, since the gel formed by the fiber is more compact than the protein matrix (Caceres et al. 2004; Lopez-Lopez et al. 2010). The use of resistant starch also shows an increased hardness in prebiotic cooked sausage (Sarteshnizi et al. 2015).

The addition of the single components (inulin, FOS or ACD) and the binary mixture of inulin and FOS result in increased cohesiveness (Table 3). However, the addition of FOS + ACD decreased this texture parameter. The highest value of cohesiveness (Fig. 2e) was observed when 1% inulin + 1% FOS were used, resulting in a more compact fermented meat product than when only ACD was used.

Only the use of the binary mixture of FOS + ACD decreased the chewiness (Table 3). ACD promoted an increase in chewiness values, as observed in Fig. 2f. Similar results were reported by Glisic et al. (2019) when they replaced pork back fat with inulin gel in dry fermented sausage.

The partial substitution of fat in salami using whole buckwheat flour showed no influence in hardness and chewiness; however, this fat substitute contributed to decrease springiness and cohesiveness (Park et al. 2017). The differences in texture profile parameters in low-fat Italian type salami could be explained by the higher moisture content and moisture/protein ratios (Glisic et al. 2019). And, consequently, the water loss during ripening time also affects the texture parameters of the product (Zhou et al. 2018).

Microbiological analysis

The absence of Salmonella spp. in 25 g of sample was confirmed at the end of the test. Thermo tolerant coliforms and coagulase-positive Staphylococci showed final counts lower than 1 log CFU g−1. All the results were in accordance to the Brazilian Legislation (Brazil 2001). These results can be attributed to the low pH value and high amount of lactic acid bacteria present in the product, which are conservation factors for fermented sausages and promote the safety of the product. The good quality of raw material and good manufacturing practices used in the process also could contribute to those results.

Sensory acceptance

The lowest (P < 0.05) score for appearance (Table 4) was for the sample with the addition of 2% of ACD. In contrast, the addition of 2% inulin or 2% FOS or 1% inulin + 1% FOS or 0.66% inulin + 0.66% FOS + 0.68% ACD resulted in a higher score for appearance (P < 0.05) of low-fat salami. The use of ACD (up to 2%) seems to have negative effect (6.31) on the color sensory acceptance of low-fat Italian type salami, compared to inulin or FOS added up to 2% (7.66 and 7.72, respectively). Possibly because of the reduction in redness due to the white coloration of the fibers added.

Table 4.

Effect of addition of dietary fiber in sensory acceptance of the different formulations of low-fat salami type Italian

| Treatment | Appearance | Color | Flavor | Texture | Global acceptance |

|---|---|---|---|---|---|

| I | 7.78a | 7.66a | 7.35 | 7.58a | 7.52a |

| F | 7.64ab | 7.72a | 7.52 | 7.60a | 7.48a |

| A | 6.15d | 6.31c | 7.19 | 6.92b | 6.79b |

| IF | 7.37ab | 7.65a | 7.25 | 7.38ab | 7.40ab |

| IA | 6.82c | 6.79bc | 7.51 | 7.26ab | 7.21ab |

| FA | 7.13bc | 7.25ab | 7.22 | 7.18ab | 7.08ab |

| IFA | 7.54ab | 7.57a | 7.35 | 7.38ab | 7.43a |

| SEM | 0.060 | 0.056 | 0.055 | 0.056 | 0.053 |

| P value | 0.0023 | 0.0095 | 0.9288ns | 0.0179 | 0.0019 |

SEM, Standard error of mean; ns, not significant (P > 0.05); I (10% of pork fat + 2% of Inulin); F (10% of pork fat + 2% of FOS); A (10% of pork fat + 2% of ACD); IF (10% of pork fat + 1% Inulin + 1% FOS); IA (10% of pork fat + 1% Inulin + 1% ACD); FA (10% of pork fat + 1% FOS + 1% ACD); IFA (10% of pork fat + 0.66% Inulin + 0.66% FOS + 0.68 ACD)

a,b,cAccording to the Tukey test, samples on the same column with different letters show present significant differences between them (P < 0.05)

The addition of dietary fibers as fat substitute in low-fat Italian type salami showed no effect (P > 0.05) on flavor, regardless of the concentration (up to 2%) and the type of dietary fiber (inulin, FOS or ACD). Similar findings were presented by Zhao et al. (2018) when regenerated cellulose (1.8%) was used as fat substitute in low-fat emulsified sausage; the flavor score showed no difference to the control.

The addition of 2% ACD increased hardness and showed the lowest score (P < 0.05) for sensorial texture (Table 4). Grigelmo-Miguel et al. (1999) also observed a significant negative correlation between hardness and acceptability of low-fat high fiber frankfurter, meaning that the consumers preferred the softer products. The sensorial texture also affected the global acceptance results (Table 4), in which sample A (2% ACD) showed the lowest (P < 0.05) score for this attribute.

The results for global acceptance are in line with the previous sensorial attribute scores. The treatment with addition of 2% ACD (treatment A) showed the lowest global acceptance score (P < 0.05). The tertiary mixture of dietary fiber (treatment IFA) showed positive results for the sensory attributes of appearance, color and texture, and also for overall acceptance.

The addition of up to 2% inulin and 2% FOS by themselves or the use of 1% inulin and 1% FOS appears to have a positive effect on the sensory acceptance of low-fat Italian type salami; the treatments I, F and IF showed the highest (P < 0.05) score for appearance, color, texture and global acceptance. The ability of FOS to maintain the sensorial characteristics of the low-fat cooked sausage when used as a fat substitute had already been reported by Campagnol et al. (2012). The use of inulin as partial oil replacement in dry chicken sausages showed no significant effect in sensory characteristics during storage at 4 °C for 45 days (Menegas et al. 2013).

Conclusion

Short-chain dietary fibers can be effectively used as a pork fat substitute to develop a healthier fermented meat product. The mixture design considering those dietary fibers carried out in this study showed a positive effect on the texture and color parameters in low-fat Italian type salami while the ripening parameters were not affected. Additionally, the sensory acceptance of the low-fat Italian type salami improved when up to 2% inulin or FOS were used. Therefore, the partial substitution of pork fat by inulin or FOS is a potential strategy for the meat industry to support the fermented product a functional claim related to the benefits of dietary fiber intake.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- ABPA (2012) Associação Brasileira de Proteína Animal (ABPA). Relatório anual ABIPECS 2011/2012- Carne Suína. São Paulo, Brasil

- Alejandre M, Poyato C, Ansorena D, Astiasaran I. Linseed oil gelled emulsion: a successful fat replacer in dry fermented sausages. Meat Sci. 2016;121:107–113. doi: 10.1016/j.meatsci.2016.05.010. [DOI] [PubMed] [Google Scholar]

- Alves LAAS, Lorenzo JM, Gonçalves CAA, Santos BA, Heck RT, Cichoski AJ, Campagnol PCB. Production of healthier Bologna type sausages using pork skin and green banana flour as fat replacers. Meat Sci. 2016;121:73–78. doi: 10.1016/j.meatsci.2016.06.001. [DOI] [PubMed] [Google Scholar]

- Anarjan N, Fahimdanesh M, Malmiri-Jafarizadeh H. β-Carotene nanodispersions synthesis by three-component stabilizer system using mixture design. J Food Sci Technol. 2017;54:3731–3736. doi: 10.1007/s13197-017-2764-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bailey MA, Holscher HD. Microbiome-mediated effects of the Mediterranean diet on inflammation. Adv Nutr. 2018;9:193–206. doi: 10.1093/advances/nmy013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bis-Souza CV, Henck JMM, Barretto ACS. Performance of low-fat beef Burger with added soluble and insoluble dietary fibers. Food Sci Technol. 2018;38:522–529. [Google Scholar]

- Bis-Souza CV, Barba FJ, Lorenzo JM, Penna ALB, Barretto ACS. New strategies for the development of innovative fermented meat products: a review regarding the incorporation of probiotics and dietary fibers. Food Rev Int. 2019;35:467–484. [Google Scholar]

- Blaiotta G, Murru N, Cerbo AD, Romano R, Aponte M. Production of probiotic bovine salami using Lactobacillus plantarum 299v as adjunct. J Sci Food Agric. 2018;98:2285–2294. doi: 10.1002/jsfa.8717. [DOI] [PubMed] [Google Scholar]

- Blaiotta G, Murru N, Cerbo AD, Romano R, Aponte M. Production of probiotic bovine salami using Lactobacillus plantarum 299v as adjunct. J Sci Food Agric. 2018;98:2285–2294. doi: 10.1002/jsfa.8717. [DOI] [PubMed] [Google Scholar]

- Bligh EG, Dyer WJ. A rapid method of total lipid extraction and purification. Can J Biochem Physiol. 1959;37:911–917. doi: 10.1139/o59-099. [DOI] [PubMed] [Google Scholar]

- Bourne MC. Texture profile analysis. Food Technol. 1978;32:62–66. [Google Scholar]

- Brazil (2000) Ministério da Agricultura, Pecuária e Abastecimento (MAPA). Instrução Normativa IN No 22/2000. Regulamento técnico de identidade e qualidade de salame tipo italiano. Diário Oficial da União; Poder Executivo, Brasília

- Brazil (2001) Agência Nacional de Vigilância Sanitária (ANVISA). Resolução RDC No 12/2001. Regulamento Técnico sobre Padrões Microbiológicos para Alimentos. Diário Oficial da União; Poder Executivo, Brasília

- Brazil (2012) Ministério da Saúde. Agencia Nacional de Vigilância Sanitária (ANVISA) Resolução RDC No 54/2012. Regulamento Técnico sobre Informação Nutricional Complementar. Diário Oficial da União; Poder Executivo, Brasília

- Caceres E, Garcia ML, Toro J, Selgas MD. The effect of fructooligosaccharides on the sensory characteristics of cooked sausages. Meat Sci. 2004;68:87–96. doi: 10.1016/j.meatsci.2004.02.008. [DOI] [PubMed] [Google Scholar]

- Campagnol PCB, Santos BA, Wagner R, Terra NN, Pollonio MAR. Amorphous cellulose gel as a fat substitute in fermented sausages. Meat Sci. 2012;90:36–42. doi: 10.1016/j.meatsci.2011.05.026. [DOI] [PubMed] [Google Scholar]

- Casarotti SN, Borgonovi TF, Batista CL, Penna ALB. Guava, orange and passion fruit by-products: characterization and its impacts on kinetics of acidification and properties of probiotic fermented products. LWT Food Sci Technol. 2018;98:69–76. [Google Scholar]

- Cruxen CES, Braun CLK, Fagundes MB, Gularte MA, Wagner R, Silva WP, Fiorentini AM. Development of fermented sausage produced with mutton and native starter cultures. LWT Food Sci Technol. 2018;95:23–31. [Google Scholar]

- De Moraes Filho ML, Busanello M, Prudencio SH, Garcia S. Soymilk with okara flour fermented by Lactobacillus acidophilus: simplex-centroid mixture design applied in the elaboration of probiotic creamy sauce and storage stability. LWT Food Sci Technol. 2018;93:339–345. [Google Scholar]

- Días-Vela J, Totosaus A, Escalona-Buendía BH, Pérez-Chabela ML. Influence of the fiber from agro-industrial co-products as functional food ingredient on the acceptance, neophobia and sensory characteristics of cooked sausages. J Food Sci Technol. 2017;54:379–385. doi: 10.1007/s13197-016-2473-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fernández-López J, Sendra E, Sayas-Barberá E, Navarro C, Pérez-Alvarez JA. Physico-chemical and microbiological profiles of “salchichón” (Spanish dry-fermented sausage) enriched with orange fiber. Meat Sci. 2008;80:410–417. doi: 10.1016/j.meatsci.2008.01.010. [DOI] [PubMed] [Google Scholar]

- Ferreira V, Barbosa J, Vendeiro S, Mota A, Silva F, Monteiro MJ, Hogg T, Gibbs P, Teixeira P. Chemical and microbiological characterization of alheira: a typical Portuguese fermented sausage with particular reference to factors relating to food safety. Meat Sci. 2006;73:570–575. doi: 10.1016/j.meatsci.2006.02.011. [DOI] [PubMed] [Google Scholar]

- Glisic M, Baltic M, Trbovic D, Jokanovic M, Pnrunovic N, Dimitrijevic M, Suvajdzic B, Boskovic M, Vasilev D. Inulin-based emulsion-filled gel as a fat replacer in prebiotic and PUFA-enriched dry fermented sausages. Int J Food Sci Technol. 2019;54:787–797. [Google Scholar]

- Greene BE, Cumuze TH. Relationship between TBA numbers and inexperienced panelists’ assessments of oxidized flavor in cooked beef. J Food Sci. 1982;47:52–54. [Google Scholar]

- Grigelmo-Miguel N, Abadías-Serós MAI, Martín-Belloso O. Characterisation of low-fat high-dietary fibre frankfurters. Meat Sci. 1999;52:247–256. doi: 10.1016/s0309-1740(98)00173-9. [DOI] [PubMed] [Google Scholar]

- Ham YK, Hwang KE, Kim HW, Song DH, Kim YJ, Choi YS, Kim CJ. Effect of fat replacement with a mixture of collagen and dietary fiber on small caliber fermented sausages. Int J Food Sci Technol. 2016;51:96–104. [Google Scholar]

- Han M, Bertram HC. Designing healthier comminuted meat products: effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017;133:159–165. doi: 10.1016/j.meatsci.2017.07.001. [DOI] [PubMed] [Google Scholar]

- Henning SSC, Tshalibe P, Hoffman LC. Physico-chemical properties of reduced-fat beef species sausage with pork back fat replaced by pineapple dietary fibres and water. LWT Food Sci Technol. 2016;74:92–98. [Google Scholar]

- Hilbig J, Gisder J, Prechtl RM, Herrmann K, Weiss J, Loeffler M. Influence of exopolysaccharide-producing lactic acid bacteria on the spreadability of fat-reduced raw fermented sausages (Teewurst) Food Hydrocolloids. 2019;93:422–431. [Google Scholar]

- Horwitz W, Latimer GW. Association of official analytical chemistry—AOAC. 2007. Official methods of analysis. 18. Gaithersburg: AOAC International; 2007. [Google Scholar]

- Keenan DF, Resconi VC, Kerry JP, Hamill RM. Modelling the influence of inulin as a fat substitute in comminuted meat products on their physico-chemical characteristics and eating quality using a mixture design approach. Meat Sci. 2014;94:1384–1394. doi: 10.1016/j.meatsci.2013.11.025. [DOI] [PubMed] [Google Scholar]

- Lopez-Lopez I, Cofrades S, Yakan A, Solas MT, Jimenez-Colmenero F. Frozen storage characteristics of low-salt and low-fat beef patties as affected by Wakame addition and replacing pork backfat with olive oil-in-water emulsion. Food Res Int. 2010;43:1244–1254. [Google Scholar]

- López-Vargas J, Fernández-López J, Pérez-Álvarez JA, Viuda-Martos M. Quality characteristics of pork burger added with albedo-fiber powder obtained from yellow passion fruit (Passiflora edulis var. flavicarpa) co-products. Meat Sci. 2014;97:270–276. doi: 10.1016/j.meatsci.2014.02.010. [DOI] [PubMed] [Google Scholar]

- Marino R, Malva AD, Seccia A, Caroprese M, Sevi C, Albenzio M. Consumers’ expectations and acceptability for low saturated fat ‘salami’: healthiness or taste? J Sci Food Agric. 2017;97:3515–3521. doi: 10.1002/jsfa.8205. [DOI] [PubMed] [Google Scholar]

- Meilgaard M, Civille GV, Carr BT. Sensory evaluation techniques. 3. Boca Raton: CRC; 1999. [Google Scholar]

- Menegas LZ, Pimentel TC, Garcia S, Prudencio SH. Dry-fermented chicken sausage produced with inulin and corn oil: physicochemical, microbiological, and textural characteristics and acceptability during storage. Meat Sci. 2013;93:501–506. doi: 10.1016/j.meatsci.2012.11.003. [DOI] [PubMed] [Google Scholar]

- Park W, Kim JR, Ju MG, Hong GE, Yeon SJ, Seo HG, Lee CH. Enhancing quality characteristics of salami sausages formulated with whole buckwheat flour during storage. J Food Sci Technol. 2017;54:326–332. doi: 10.1007/s13197-016-2465-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pérez-Burillo S, Mehta T, Pastoriza S, Kramer DL, Paliy O, Rufián-Henares JÁ. Potential probiotic salami with dietary fiber modulates antioxidant capacity, short chain fatty acid production and gut microbiota community structure. LWT Food Sci Technol. 2019;105:355–362. [Google Scholar]

- Prado N, Sampayo M, González P, Lombó F, Díaz J. Physicochemical, sensory and microbiological characterization of Asturian Chorizo, a traditional fermented sausage manufactured in Northern Spain. Meat Sci. 2019;156:118–124. doi: 10.1016/j.meatsci.2019.05.023. [DOI] [PubMed] [Google Scholar]

- Rocha YJP, Noronha RLF, Trindade MA. Relations between consumer’s concern with own health and their perception about frankfurters with functional ingredients. Meat Sci. 2019;155:91–101. doi: 10.1016/j.meatsci.2019.05.003. [DOI] [PubMed] [Google Scholar]

- Ruiz JN, Villanueva NDM, Favaro-Trindade CS, Contreras-Castillo CJ. Physicochemical, microbiological and sensory assessments of Italian salami sausage with probiotic potential. Sci Agric. 2014;71:204–211. [Google Scholar]

- Salazar P, García ML, Selgas MD. Short-chain fructooligosaccharides as potential functional ingredients in dry fermented sausages with different fat levels. Int J Food Sci Technol. 2009;44:1100–1107. [Google Scholar]

- Santos BA, Pollonio MAR, Cruz AG, Messias VC, Monteiro RA, Oliveira TLC, Faria JAF, Freitas MQ, Bolini HMA. Ultra-flash profile and projective mapping for describing sensory attributes of prebiotic mortadella. Food Res Int. 2013;54:1705–1711. [Google Scholar]

- Sarteshnizi RA, Hosseini H, Bondarianzadeh D, Colmenero FJ, Khaksar R. Optimization of prebiotic sausage formulation: effect of using b-glucan and resistant starch by D-optimal mixture design approach. LWT- Food Sci Technol. 2015;62:704–710. [Google Scholar]

- Szczesniak AS. Texture in a sensory property. Food Qual Prefer. 2002;13:215–225. [Google Scholar]

- Vyncke W. Direct determination of the thiobarbituric acid value in trichloracetic acid extracts of fish as a measure of oxidative rancidity. Eur J Lipid Sci Technol. 1970;72:1084–1087. [Google Scholar]

- Yim DG, Jang KH, Chung KY. Effect of fat level and the ripening time on quality traits of fermented sausages. Asian Australas J Anim Sci. 2016;29:119–125. doi: 10.5713/ajas.15.0180. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhao Y, Hou Q, Zhuang X, Wang Y, Zhou G, Zhang W. Effect of regenerated cellulose fiber on the physicochemical properties and sensory characteristics of fat-reduced emulsified sausage. LWT- Food Sci Technol. 2018;97:157–163. [Google Scholar]

- Zhou T, Zhao Y, Wu X, Wang W, Liu A. Production of squid emulsion sausages using pork skin and coconut powder mixture as fat replacers. Int J Food Sci Technol. 2018;53:747–754. [Google Scholar]

- Zhuang XB, Han MY, Kang ZL, Wang K, Bai Y, Xu XL. Effects of the sugarcane dietary fiber and pre-emulsified sesame oil on low-fat meat batter physicochemical property, texture, and microstructure. Meat Sci. 2016;113:107–115. doi: 10.1016/j.meatsci.2015.11.007. [DOI] [PubMed] [Google Scholar]