Abstract

Effect of four different cultivars and salt pretreatment on drying of Amla (Emblica officinalis) gratings were studied. Quality attributes namely, ascorbic acid, total phenolic content, antioxidant activity and colour were evaluated for dried (using Cabinet tray dryer at 55 ± 2 °C for 8 h) and stored (refrigerated, ambient and accelerated condition) samples of four cultivars (Krishna, Kanchan, NA-7 and Chakaiya). Salt pretreated dried samples showed better retention of nutrients and colour as compared to untreated. Retention of ascorbic acid, total phenolic content and antioxidant activity (IC50 value) in pretreated dried samples were in the range of 79.51–84.89%, 176.5–220.3 mg GAE/g db and 9.48 to 17.74 mg/µl, respectively. Colour retention was also found to be better in salt pretreated samples. Ambient storage condition resulted in higher retention of ascorbic acid and colour compared to accelerated condition. Taking into consideration, the nutritional value of the fresh Amla, ability to retain nutritional value and color during drying and storage, NA-7 cultivar Amla (pretreated with 1% salt, tray dried at 55 °C for 8 h) is the most suitable for preparation of Amla powder. The method developed in the present work is devoid of blanching step and found to be effective in retaining the nutrients during drying and storage and can be employed also for drying of similar fruits and vegetables.

Electronic supplementary material

The online version of this article (10.1007/s13197-019-04131-8) contains supplementary material, which is available to authorized users.

Keywords: Amla grating, Salt pretreatment, Drying, Ascorbic acid, Colour, Principal component analysis

Introduction

Amla, also known as Indian gooseberry (Emblica officinalis), is an important fruit crop widely grown in the various region of Indian sub-continent. It is commonly used in Ayurveda and Unani systems due to its therapeutic values (Agrawal and Chopra 2004). Amla is one of the excellent sources of vitamin C containing about 20 and 160 times more vitamin C as compared to orange and apple, respectively (Mitra et al. 2008). Application of fresh Amla is restricted due to its sour and strong astringent in taste (Pareek et al. 2009) and short shelf life (Pathak et al. 2009). Therefore, it is consumed in various processed forms out of which dehydrated powder (Karla 1988; Deka et al. 2001; Tripathi et al. 1988) is in very high demand. Drying is one of the oldest and most widely used techniques in the food industry to prolong the shelf life of fruits and vegetables. It extends the shelf life of food products by reducing the water activity to the level at which microbial growth and deterioration reactions are minimum. In addition, drying also saves packaging, storage and transportation costs by substantially reducing the volume (Okos et al. 1992). Attention towards nutritionally superior food with higher shelf life has increased in the 21st century after problems related to basic food needs of human beings such as health and food security came to the fore. In the present condition, a dried powder should not only have a higher shelf life but also are expected to have high nutritional value. It is unavoidable to stop reduction in the nutritional value of a sample during drying. The challenge is to what extent the nutritional value can be retained even after drying. There are three possible ways for achieving this (a) Using the most suitable drying method which is mild enough to retain as much as nutrients as possible besides being suitable to be operable on a large scale. (b) Selecting a cultivar that exhibits higher nutritional value and nutrient retention ability during drying. (c) A suitable pretreatment which promotes the retention of nutrients during drying.

The conventional method for processing Amla is blanching, followed by solar drying. Hot water or steam blanching of raw material inactivates enzymes (responsible for changes in colour and flavor) thereby making the dried product more shelf-stable (Tembo et al. 2008). However, blanching process has few disadvantages such as leaching of colour and nutrients (Lavelli et al. 2007), quality deterioration (Gornicki and Kaleta 2007), and environmental problems (Bomben 1977). Sun drying, the most economical traditionally practiced method offers a few disadvantages such as dependence on weather condition and requirement of long drying time besides the susceptibility of the product to contamination due to exposure to the open atmosphere (Akbulut and Durmuş 2009). Alternatively, solar dryers improve the quality of products, but the major problem with this technique is the limited availability of solar radiation and problems with the large scale adaptation of the technique. Cabinet tray drying can, to a great extent overcome the disadvantages mentioned above, as it is relatively fast, more hygienic and offers uniform drying (Kingsly et al. 2007; Doymaz 2004). Irrespective of the drying method used, it is unavoidable to stop reduction in the nutritional value of a sample during drying. The challenge is to what extent the nutritional value can be retained even after drying. Subjecting the fruit/Amla to pretreatment is a possible method to prevent colour and nutrition loss (by inactivating enzymes), reduce the drying time (by changing its structure) thereby resulting in the good quality dried product (Kingsly et al. 2007). Kadam et al. (2006) studied the effect of blanching followed by addition of different additives (sodium chloride, potassium meta-bisulphite, sodium benzoate) at various concentration (0.5–1.5%) on solar drying of cauliflower florets. Gudapaty et al. (2010) studied the quality characteristics of Amla fruits which were pretreated with hot water followed by osmotic dehydration with 2% hypertonic solution of salt and dried in a liquid petroleum gas drier. These studies reported that pretreatment improves quality as well as the drying rate of food products. However, reports on the drying of different cultivars of pretreated Amla grating without blanching is not available. Work reported till date does not involve selection of the most suitable cultivar, which involves judicious selection made based on the values of proximate analysis, nutritional analysis, colour analysis is scarce. Further, the ability of dried samples of different cultivars to retain these parameters during drying (both untreated and pretreated) besides during storage at different conditions is not reported to the best of our knowledge.

Accordingly, the objective of the present study is to evaluate the most suitable cultivar for the production of Amla powder by measuring the physico-chemical quality and colour of Amla. The ability of the untreated and pretreated cultivars to retain these physico-chemical qualities during both drying and storage (at refrigerated, ambient and accelerated conditions) is evaluated.

Materials and methods

Materials

The mature Amla fruit of four cultivars viz. Kanchan, Krishna, NA-7 and Chakaiya were procured from the University of Horticultural Sciences, Bagalkot, Karnataka, India. Gallic acid, methanol, FC reagent, 2-2 Diphenyl-1 Picrylhydrazyl (DPPH), 2-6 di chlorophenol indophenols, all other chemicals used were of analytical grade and procured from Sigma-Aldrich, India.

Methods

Pretreatment of Amla

Four cultivars of Amla were thoroughly cleaned in running tap water to remove dirt and extraneous matter as well as to reduce the microflora present on the surface. The cleaned fruit was then grated using an electrically operated grating machine, designed and developed at the Department of Food Engineering, CFTRI Mysore, India. The grated Amla shreds were divided into 2 parts, and based on preliminary trials one part was mixed with 1% common salt (referred as pretreated), and the other was without treatment (referred as untreated).

Drying

Untreated and pretreated grated Amla samples were subjected to drying for 8 h using cabinet tray dryer at a temperature of 55 ± 2 °C. The sample was spread as a thin layer of about 2 mm thickness in all the trays. The dryer consisted of 24 aluminum trays of size (800 × 400 × 30 mm) with temperature control and was fitted with a centrifugal fan for air circulation at velocity 1.2 m/s speed inside the drying chamber. Preliminary drying studies had shown that 8 h of drying yields optimally dried gratings (data not presented). At the end of 8 h, the trays were removed, samples were allowed to cool to room temperature and then packed in HDPE pouches before storing at 4 °C.

Proximate analysis

Estimation of moisture content

Moisture content was estimated using IR moisture meter (HMB100, Wenser, Chennai, India). Sample (2 g) was weighed into an aluminium pan and heated to 80 °C (IR) untill no loss in weight was noticed. The moisture content of samples was expressed in terms of % weight basis (wb) (Chandralekha et al. 2016, 2017).

Estimation of protein

The protein content was determined using Nitrogen analyzer (Thermo Flash 2000). Sample (250 mg) was taken in aluminium cup and subjected to digestion in Nitrogen analyzer. Total nitrogen content was determined in percentage. Protein (%) was calculated using the conversion factor (Nitrogen content % × 6.25).

Estimation of fat and crude fiber

Fat content Sample (5 g) was taken into a pre-weighed thimble and refluxed with petroleum ether (40–60) using a Soxhlet extraction apparatus for 6 h. The solvent from the extract was evaporated and residual solvent was removed in a stream of hot air (AOAC 200). Fat content was calculated by the following Eq. (1)

| 1 |

where S = Weight of initial sample (g); S1 = Weight of empty flask (g); S2 = Weight of the flask with oil (g).

Crude fiber Residue obtain after fat extraction was taken for the determination of crude fiber using Fiberaplus (FES6, Pelican equipment, India).

Estimation of ash content

Sample (5–10 g) was taken into silica dishes and kept in a muffle furnace (at 525 °C) for 6 h. After cooling the samples to room temperature in a desiccator, the residue was weighed (AOAC 2005).

Determination of carbohydrate

Carbohydrate content of the sample was calculated by the difference method using the following Eq. (2)

| 2 |

Colour measurement

Colour of the all samples was measured using a Colorimeter (CM-5, Konica Minolta, Japan) and values were expressed as colour space coordinates, namely, L*, a*, and b* values. L* represents lightness/darkness of the product; + a* redness, − a* greenness; + b* yellowness, –b* blueness and ∆E represents the total colour difference between fresh and dried samples, which was calculated by following Eq. (3).

| 3 |

where the subscript “0” denotes the colour space coordinates of the fresh Amla.

Estimation of ascorbic acid content

Ascorbic acid content was estimated by the 2, 6-dichlorophenol-indophenol visual titration method (Ranganna 1986). The sample (10 g) was mixed with 3% metaphosphoric acid, filtered using a muslin cloth, and made up to 100 ml. Then aliquot (5 ml) was transferred to a 100 ml conical flask and titrated against dye till a light pink colour appeared, which retains for at least 15 s. Vitamin C was expressed as mg of ascorbic acid/100 g of the sample and estimated using the following Eq. (4)

| 4 |

Estimation of total polyphenol content

Extraction was carried out using Kumari and Khatkar (2016) method with slight modification. Fresh (5 g) and dried sample (1 g) of each cultivar of Amla was extracted with (1:25, w/v) in 70% methanol. The samples were heated for 30 min at 60 °C in a water bath followed by centrifugation for 10 min at 5000×g. Then the supernatant was collected and stored at 4 °C further use.

Total phenolic content (TPC) was measured according to the procedure detailed by Mishra et al. (2015). A volume of 60 µl of supernatant was taken in a test tube, and 300 µl of Folin-Ciocalteu reagent was added to this solution and allowed to react for 6 min at room temperature (25–30 °C). Then, 900 µl of 20% sodium carbonate solution was added, and the final volume was made up to 6 ml with distilled water. The mixture was kept in the dark for 60 min, and absorbance was taken at 765 nm using spectrophotometer (UV-1800, Shimadzu, Japan). A standard curve was drawn using graded concentration (0–100 ppm) of gallic acid standard. The concentration of total polyphenols was calculated by referring to the standard curve and expressed as mg GAE/100 g dry matter (DM). All experiments were carried out in triplicate, and average values were reported.

Estimation of Free radical scavenging activity

The DPPH Free radical scavenging activity of the samples was estimated according to the procedure detailed by Liu et al. (2008) with some modification. 1 ml of extract was added to a test tube containing 2 ml of 0.15 mM DPPH radical prepared in ethanol. The reaction mixture was mixed vigorously for 20–30 s and kept for 20 min in the dark at room temperature. The absorbance was measured at 517 nm using spectrophotometer (UV-1800, Shimadzu, Japan). The control sample was prepared, as above, by replacing extract with 70% ethanol (v/v). The percentage inhibition of the DPPH radical was calculated by using following Eq. (5)

| 5 |

The IC50 value is defined as the concentration of substrate required to bring 50% scavenging activity of the DPPH radicals. It was calculated from the graph showing radical scavenging activities (%) against concentration (30–180 µl). Gallic acid was used as positive control and results are expressed as IC50 (mg/ml).

Storage study

100 g of each sample was packed in HDPE pouches of 150 gauge and stored under refrigerated (4 ± 1 °C), ambient (27 ± 1 °C, 65% RH) and accelerated (37 ± 1 °C, 92% RH) conditions. The stored samples withdrawn after 60 days were analysed for changes in colour and ascorbic acid content.

Statistical analysis

The inter-relationship among the various cultivars and the quality attributes was determined by using the methodology of principal component analysis (PCA) (Lawless and Heymann 2010). The quality attributes considered for PCA were the IC50, ascorbic acid, total phenolic content and colour parameters. The statistical software Minitab software version 16 (Stat Soft, Tulsa, Ohio) was employed to develop the biplot and perform associated analysis.

All statistical analyses were carried out in triplicate results using the SPSS software (SPSS Ins., version 20). Duncan’s Multiple Range Test (DMRT) was applied to differentiate among the means of different cultivars and treatments, and other attributes (Duncan 1955) at 95% confidence level (p < 0.05).

Results and discussion

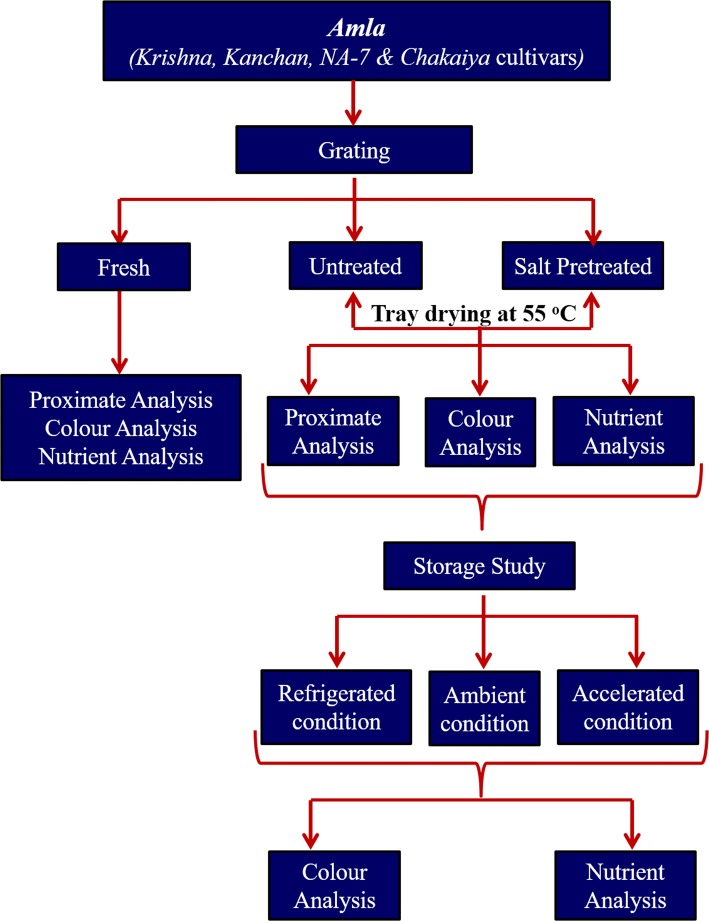

The overall plan of the work is presented in Fig. 1. The selection of the most suitable cultivar has to be judiciously made based on the values of proximate analysis, nutritional analysis, colour analysis and their ability to retain these parameters during drying (both untreated and pretreated) besides during storage (at refrigerated, ambient and accelerated conditions). Accordingly, these parameters were analysed, and the results are discussed in terms of content and retention (%) in the following sections.

Fig. 1.

Overall work plan

Proximate analysis

The chemical composition of different cultivars of fresh and dried grated Amla is presented in Table 1. Different cultivars showed significant differences in the chemical composition of fresh and dried samples. Moisture content is essential to evaluate the quality of fresh fruits and vegetables as the shelf life of food products mainly depends upon this parameter. Therefore, appropriate preservation techniques must be applied to get a longer shelf life. The moisture content of different cultivars was ranged from 85.63 to 87.68% wb for fresh samples. While dried samples ranged from 11.51 to 13.89% wb and 11.30 to 12.48% wb for untreated and pretreated, respectively. Dehydrated pretreated samples except Krishna showed slightly lower moisture content as compared to untreated samples.

Table 1.

Proximate composition of Amla gratings of different cultivars

| Cultivars | Moisture (%) | Protein (%) | Fat (%) | Fiber (%) | Ash (%) | Carbohydrate (%) | |

|---|---|---|---|---|---|---|---|

| Krishna | F | 85.63 ± 1.16c | 3.34 ± 0.34f | 0.51 ± 0.01d | 14.87 ± 0.31g | 2.41 ± 0.11d | 72.91 ± 0.84b |

| U | 11.51 ± 0.13a | 3.08 ± 0.02de | 0.49 ± 0.02d | 12.64 ± 0.01d | 2.17 ± 0.02ab | 81.49 ± 0.05e | |

| P | 12.48 ± 0.24ab | 2.50 ± 0.02c | 0.42 ± 0.02c | 12.14 ± 0.02c | 2.11 ± 0.01a | 82.69 ± 0.03f | |

| Kanchan | F | 86.59 ± 1.35cd | 2.92 ± 0.21d | 0.65 ± 0.01e | 16.53 ± 0.41j | 2.78 ± 0.09g | 70.66 ± 0.76a |

| U | 12.48 ± 0.09ab | 2.63 ± 0.01c | 0.60 ± 0.01e | 14.84 ± 0.01g | 2.67 ± 0.03f | 79.12 ± 0.01c | |

| P | 11.61 ± 0.17a | 2.10 ± 0.02a | 0.54 ± 0.02d | 14.12 ± 0.01f | 2.25 ± 0.02bc | 80.86 ± 0.02de | |

| NA-7 | F | 87.68 ± 1.47d | 3.61 ± 0.25g | 0.62 ± 0.03e | 15.23 ± 0.33h | 2.51 ± 0.04e | 70.91 ± 1.21a |

| U | 12.51 ± 0.03ab | 2.20 ± 0.02ab | 0.55 ± 0.01e | 13.61 ± 0.02e | 2.38 ± 0.02d | 81.12 ± 0.02e | |

| P | 11.30 ± 0.08a | 2.49 ± 0.02c | 0.47 ± 0.01c | 14.15 ± 0.03f | 2.31 ± 0.01c | 80.45 ± 0.02de | |

| Chakaiya | F | 86.24 ± 1.68cd | 3.25 ± 0.14ef | 0.52 ± 0.03d | 13.87 ± 0.13ef | 2.27 ± 0.07c | 73.82 ± 1.04b |

| U | 13.89 ± 0.07b | 2.18 ± 0.01a | 0.46 ± 0.02d | 10.57 ± 0.01a | 2.24 ± 0.03bc | 84.39 ± 0.04g | |

| P | 11.50 ± 0.14a | 2.44 ± 0.02bc | 0.42 ± 0.02a | 10.96 ± 0.01b | 2.09 ± 0.01a | 83.96 ± 0.01g |

F fresh; U untreated; P pretreated; Values followed by different superscripts within each column are significantly different (p < 0.05)

Protein content was found maximum in NA-7 (3.61%) followed by Krishna (3.34%), Chakaiya (3.25%) and Kanchan (2.92%). The slight reduction was observed in protein after drying in both untreated and pretreated samples. The fat content of fresh samples varied from 0.51 to 0.62%. After drying, a slight reduction of fat content was found in untreated and pretreated samples ranged (0.46–0.60%) and (0.42–0.54%), respectively. A significant difference in fiber was observed among the fresh samples, and the values were found in the range from 13.87 to 16.53%. Dried untreated and pretreated samples showed a reduction in fiber which varied from 10.57 to 14.84% and 10.96 to 14.15%, respectively. Ash content of fruits and vegetables could be directly related to mineral constituents. Ash content among fresh cultivars was found to be the highest (2.78%) in Kanchan. Dehydrated samples had slightly lower ash content compared to fresh. The carbohydrate content among cultivars (fresh) was in the range from 70.66 to 73.82% in which Chakaiya was having the highest carbohydrate, followed by Krishna, NA-7 and Kanchan. Dried untreated and pretreated samples showed significantly higher in carbohydrate content, irrespective of cultivars. Chakaiya untreated was found maximum carbohydrate content with 84.39% among all dried samples.

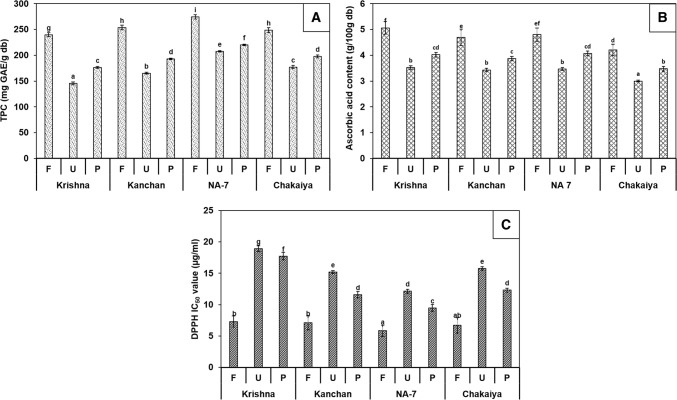

Total phenolic content

According to literature, phenolic compounds are the main reason for the antioxidant properties of Amla fruit and retention of polyphenol content is an important criterion for the quality of the Amla powder (Kumar et al. 2006). Effect of pretreatment on retention of total polyphenol content during drying was studied for different cultivars of Amla. The TPC retention in case of fresh samples was taken as control, and the cultivar that results in maximum retention of TPC during drying (untreated and pretreated) samples and the one which is close to that observed in fresh samples was considered. For the selection of the best cultivar, both TPC and its retention were considered. Total polyphenolic content of different Amla cultivars (fresh) ranged from 239.6 to 274.3 mg GAE/g db (Fig. 2A). A significant difference (p < 0.05) was observed in TPC of different cultivars except in Kanchan and Chakaiya. Among all the cultivars, in case of TPC content in fresh samples, the highest results were observed in NA-7 cultivar (274.3 g/100 db) and the lowest in Krishna cultivar (239.6 g/100 db). The TPC content was in the decreasing order NA-7 (274.3 g/100 db) > Kanchan (253.7 g/100 db) > Chakaiya (248.6 g/100 db) > Krishna (239.6 g/100 db). Variation in the polyphenol content might be due to difference in genetic, maturity stages and agronomic conditions (Zheng and Wang 2001), and the difference in polyphenoloxidase enzyme activity (Kumari and Khatkar 2018) among the cultivars.

Fig. 2.

Effect of cultivars and treatment on A total phenolic content (TPC); B ascorbic acid content; C IC50 values of DPPH scavenging activity of dried Amla gratings. F fresh; U untreated; P pretreated; Different superscripts within figure are significantly different (p < 0.05)

Drying resulted in significant loss of total phenolic content in all cultivars. Among all the cultivars, in case of untreated samples, the highest TPC was observed in NA-7 cultivar (207.3 g/100 db, translating into retention of 75.57%). The TPC was in the decreasing order NA-7 (274.3 g/100 db) > Kanchan (253.7 g/100 db) > Chakaiya (248.6 g/100 db) > Krishna (239.6 g/100 db). However, the retention ability of cultivar didn’t follow the same order. The TPC retention ability of cultivars was in the decreasing order NA-7 (75.57%) > Chakaiya (71.20%) > Krishna (60.73%) > Kanchan (65.12%). It can be seen that both in terms of TPC and TPC retention ability, NA-7 (75.57%) variety was the best during untreated drying. Alfaro et al. (2014) also observed a reduction in total phenolic content of Murtilla fruit during hot air drying at 65 °C.

Pretreated samples after drying showed higher (176.5–220.3 mg GAE/g db) content as compared to untreated samples (145.5–207.3 mg GAE/g db). In case of NA-7, highest TPC of 220.3 g/100 db was observed, which was the closest to the TPC observed in the fresh sample (274.3 g/100 db). Among all the cultivars, in case of pretreated samples, the highest TPC was observed in NA-7 cultivar (220.30 g/100 db, translating into retention of 80.31% which is 4.74% higher retention than the untreated samples). The TPC was in the decreasing order NA-7 (220.3 g/100 db) > Chakaiya (197.50 g/100 db) > Kanchan (192.80 g/100 db) > Krishna (176.50 g/100 db). However, unlike untreated samples in case of pretreated, the retention ability of cultivar followed the same order of TPC. The TPC retention ability of cultivars was in the decreasing order NA-7 (80.31% which is 4.74% higher retention than the untreated samples) > Chakaiya (79.44% which is 8.25% higher retention than the untreated samples) > Kanchan (76.00% which is 10.88% higher retention than the untreated samples) > Krishna (73.66% which is 12.94% higher retention than the untreated samples). It can be seen that both in terms of TPC and TPC retention ability, NA-7 variety was the best during pretreated drying.

In case of all the cultivars, a significant retention of TPC was observed in the pretreated samples compared to untreated samples after drying which reiterates the positive effects of pretreatment. The presence of high fiber content in NA-7 variety allows the Amla to show higher tolerance to the effect of temperature during drying, which in turn results in higher TPC retention.

Ascorbic acid content

Similar to total polyphenol content retention, the effect of pretreatment on ascorbic acid retention during drying was studied. Effect of treatment on ascorbic acid content of fresh and dried grated Amla is presented in Fig. 2B. The ascorbic acid content of fresh samples was taken as reference (100%), and the cultivar that results in maximum retention of ascorbic acid was determined by comparing the results with that obtained from fresh samples. Cultivars showed significant (p < 0.05) difference in the ascorbic acid content of fresh Amla and the values varied in the range from 4.21 to 5.06 g/100 g db. Among all the cultivars Krishna was observed to contain maximum ascorbic acid content (5.06 g/100 db) followed by NA-7 (4.80 g/100 db).

Significant reduction in ascorbic acid was found between the fresh and dried sample in all cultivars. Ascorbic acid content in untreated samples were in the decreasing order of Krishna (3.52) > NA-7 (3.47) > Kanchan (3.43) > Chakaiya (3.00). But the retention ability didn’t follow the same order. The retention ability of different cultivars was in the decreasing order of Kanchan (72.98%) > NA-7 (72.29%) > Chakaiya (71.26%) > Krishna (69.57%). The difference between the retention abilities of Kanchan and NA-7 were not significantly different. This reduction might be due to the adverse effect of exposure to high air temperature for long duration as ascorbic acid is a heat-sensitive compound. Similarly, reduction in ascorbic acid content during drying of different cultivars of Amla (without any treatment) using cabinet drying was noted by Kumari and Khatkar (2018).

Untreated samples after drying by cabinet tray dryer at 55 ± 2 °C was compared with that of pretreated samples. In the present study, it was observed that treatment of Amla gratings with 1% salt before drying had a beneficial effect on the retention of ascorbic acid. In case of all the cultivars pretreated samples were observed to show significantly higher ascorbic acid retention (79.51–84.89%) of ascorbic acid compared to untreated (69.63–73.15%) samples (Fig. 2B). Gudapaty et al. (2010) made a similar observation for Amla segments Osmo-dehydrated with 2% salt solution prior to drying. Prajapati et al. (2011) also observed that adding black salt to Amla shreds helped in retaining ascorbic acid. It may be due to salt helps to inactivate the oxidizing enzyme and offers a protective barrier to ascorbic acid. Among all the cultivar, highest retention was observed in case of NA-7 (though it is the second-best in terms of total ascorbic content in the fresh samples) where pretreated samples retained 84.89% ascorbic acid compared to 72.39% in case of untreated samples that is, a retention of more than 12%. The retention of ascorbic acid was in the order of NA-7 (84.89% which is 12.50% higher than untreated samples) > Chakaiya (82.74% which is 11.40% higher than untreated samples) > Kanchan (82.52% which is 9.36% higher than untreated samples) > Krishna (79.51% which is 9.88% higher than untreated samples). Higher retention of ascorbic acid in case of NA-7 compared to other cultivars can be attributed to the fiber content of the NA-7 cultivar, which is among the highest fiber-containing cultivars in the present study. The presence of high fiber content allows the Amla to show higher tolerance to the effect of temperature during drying, which in turn results in higher ascorbic acid retention.

Antioxidant activity

To determine the antioxidant activity of fresh and dried grated Amla gratings, DPPH assay was performed as it is considered as an easy, rapid, economical and widely used method (Suhaj 2006). DPPH is a stable free radical of dark purple colour which gets reduced in the presence of the antioxidant compound and turns into yellow colour (Brand-Williams et al. 1995). Antioxidant activity of all the samples was presented as IC50 value. It can be seen from Fig. 2C, that fresh samples of all four cultivars showed high antioxidant activity as they had lower IC50 value (in the range of 5.83 to 7.31 mg/µl for different cultivars). In case of fresh samples of different cultivars, NA-7 exhibited the highest antioxidant activity corresponding to the lowest IC50 value (5.83 mg/µl).

As mentioned earlier, antioxidant properties in Amla fruit is due to the presence of phenolic compounds (Kumar et al. 2006). A significant reduction in the antioxidant activity (similar to a reduction in total phenolic content) was observed after drying, especially in untreated samples. It can be observed from the Fig. 2C that IC50 increased significantly to 12.14 in case of the untreated sample indicating a significant reduction in the antioxidant activity. However, retention of antioxidant activity was predominant in pretreated samples wherein IC50 increased to only 9.48 mg/µl which is less than that observed in untreated samples clearly indicating the retention of antioxidant activity compared to untreated samples. The IC50 value was found to range from 12.14 to 18.92 mg/µl and 9.48 to 17.74 mg/µl for untreated and pretreated samples, respectively. Among the pretreated samples, NA-7 showed the highest antioxidant activity with least IC50 value (9.48 mg/µl) followed by Kanchan, Chakaiya and Krishna.

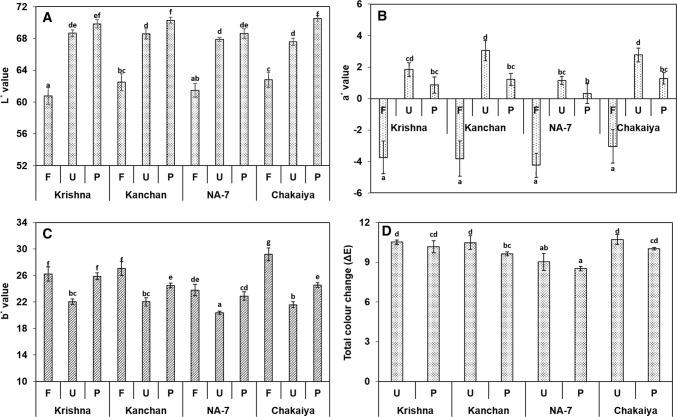

Color analysis

Colour is an external quality attribute and plays in a very Colour is an external quality attribute and plays in a very significant role to acceptance or rejection of product by consumers. For a good quality Amla powder, the main attribute is the presence of or retention of as much as green colour (− a*) as possible. Besides this, higher lightness (+ L*) and yellow tinge (+ b*) is desirable. Colour of grated Amla (fresh) was determined in term of L*, a* and b* and the values were found in the range from 60.79 to 62.79, − 4.24 to − 3.05 and 23.79–29.19, respectively, for all cultivars (Fig. 3A–C).

Fig. 3.

Effect of cultivars and treatment on colour of Amla gratings A L* values; B a* values; C b* values; D ΔE values. F fresh; U untreated; P pretreated; Different superscripts within figure are significantly different (p < 0.05)

As a primary selection criterion, a* value is given more importance as it indicates the presence of chlorophyll which in fact also a polyphenol. It can be seen from Fig. 3B that no significant difference was found in greenness values of fresh samples of different cultivars. NA-7 cultivar had maximum greenness with a* value (− 4.24) followed by Kanchan (− 3.82), Krishna (− 3.75) and Chakaiya (− 3.05) in fresh samples, shown in Fig. 3B. These observations were also supported by Goyal et al. (2007), who reported the highest greenness in NA-7 cultivar. Dried samples showed significant lower greenness than fresh for all the four cultivars evident by significantly increasing a* values indicating the loss of green colour. However, out of all the cultivars, NA-7 exhibited the lowest a* value of 1.15 indicating maximum retention of green colour. Unlike untreated samples, the pretreated samples were found to preserve greenness significantly. NA-7 samples dried after pretreatment was observed to exhibit a* value of 0.32 indicating increased retention of green colour when compared to untreated samples (1.15) followed by Krishna, Kanchan and Chakaiya. In fact, it is the closest value to the a* value of the fresh NA-7 sample (− 4.24). It can be concluded that NA-7 is the most suitable cultivar for preparation of Amla powder based on the a* value.

Other than this L* and b* values were also considered for selection of the most suitable powder since higher values of L* and b* values are also equally important as they determine the overall acceptability of the product. It can be seen from (Fig. 3A and C) that pretreatment and drying had a significant effect on the colour parameters. Pretreated dried samples showed a significant increase in lightness with comparison to fresh and slightly higher than untreated dried samples in Fig. 3A. As mentioned earlier, higher L* values are desirable, and in case of both untreated and pretreated samples of all the cultivars, the L* values of dried samples were higher than the fresh sample. Though there was no significant difference between untreated and pretreated samples the values of pretreated samples were always observed to be on the higher side. Chakaiya cultivar had maximum lightness (70.52) among the all dried samples.

Similar observation was made even in case of b* value, wherein significant differences were observed in yellowness in all cultivars (fresh). Maximum b* value was found in Chakaiya (29.19) followed by Kanchan (27.05), Krishna (26.19) and NA-7 (23.79), among fresh grated Amla cultivars, (Fig. 3C). After drying the value of b* was reduced significantly in both untreated and pretreated samples. However, pretreated samples showed slightly higher values than untreated with highest b* value (25.87) in the case of Krishna cultivar.

To represent the total change in colour from the fresh, ΔE was calculated using Eq. (3). It can be inferred from Fig. 3D that pretreated dried samples showed less colour change (8.51–10.47) than the untreated (9.03–10.71). Treatment was shown to result in better retention of overall colour during drying. Dried NA-7 (pretreated) had the least change in colour (ΔE = 8.51) among all the samples.

Storage study

Retention of ascorbic acid and colour (a*) in dried (both untreated and pretreated) samples were determined after storage for 60 days at ambient, refrigerated as well as at accelerated conditions and compared with that of the fresh samples. The retention (%) was calculated considering the values of the ascorbic acid content in the fresh samples as reference (100%). The results are presented in Table 2. It can be seen that there is not much reduction in the ascorbic acid content and green colour during storage when compared to the values of 0th day. Taking into consideration, the initial ascorbic acid content (4.80 g/100 g db) in the fresh sample, retention ability of ascorbic acid at refrigerated (84.28%), ambient (76.80%) and accelerated conditions (70.29%), NA-7 was concluded as the best (Table 2). The reason for higher retention of ascorbic acid in NA-7 variety (both untreated and pretreated) during storage can be the presence of higher fiber content in this cultivar which acts as a shock absorber for the negative effect of drying and storage temperature helping in the retention of higher ascorbic acid.

Table 2.

Effect of cultivars and treatment on ascorbic acid content of dried Amla gratings stored for 60 days

| Cultivars | Initial (0 days) | Refrigerated at 4 ± 1 °C | Ambient at 27 ± 1 °C, 65% RH | Accelerated at 37 ± 1 °C, 92% RH | |||||

|---|---|---|---|---|---|---|---|---|---|

| AA g/100 g db | a* | AA g/100 g db | a* | AA g/100 g db | a* | AA g/100 g db | a* | ||

| Krishna | U | 3.52 ± 0.07b | 1.84 ± 0.44cd | 3.49 ± 0.05c | 1.34 ± 0.53bc | 3.15 ± 0.08b | 4.95 ± 0.66cd | 2.97 ± 0.02c | 6.79 ± 0.54bc |

| P | 4.02 ± 0.09cd | 0.86 ± 0.52bc | 4.01 ± 0.07e | 0.70 ± 0.44ab | 3.55 ± 0.06e | 3.67 ± 0.48ab | 3.19 ± 0.03d | 5.29 ± 0.86a | |

| Kanchan | U | 3.43 ± 0.06b | 3.05 ± 0.64d | 3.38 ± 0.03b | 2.03 ± 0.36c | 3.07 ± 0.04b | 6.25 ± 0.85e | 2.82 ± 0.09b | 7.95 ± 0.61d |

| P | 3.87 ± 0.08c | 1.22 ± 0.37bc | 3.85 ± 0.08d | 0.91 ± 0.97ab | 3.36 ± 0.02d | 4.94 ± 0.54cd | 3.03 ± 0.04c | 5.90 ± 0.55ab | |

| NA 7 | U | 3.47 ± 0.06b | 1.15 ± 0.25bc | 3.43 ± 0.05bc | 0.47 ± 0.41ab | 3.26 ± 0.07c | 4.42 ± 0.22bc | 2.92 ± 0.06bc | 5.18 ± 0.24a |

| P | 4.07 ± 0.09cd | 0.32 ± 0.63b | 4.04 ± 0.07e | 0.02 ± 0.39a | 3.68 ± 0.02f | 3.28 ± 0.31a | 3.37 ± 0.08e | 4.85 ± 0.36a | |

| Chakaiya | U | 3.00 ± 0.04a | 2.77 ± 0.45d | 2.98 ± 0.02a | 1.41 ± 0.76bc | 2.80 ± 0.08a | 5.82 ± 0.66de | 2.44 ± 0.04a | 7.22 ± 0.61cd |

| P | 3.48 ± 0.09b | 1.28 ± 0.36bc | 3.46 ± 0.03bc | 1.02 ± 0.47abc | 3.17 ± 0.05bc | 4.29 ± 0.45bc | 2.85 ± 0.09b | 5.69 ± 0.84ab | |

The ascorbic acid content of fresh samples (F) of Krishna, Kanchan, NA-7 and Chakaiya are 5.06, 4.70, 4.80 and 4.21, respectively

The a* value of fresh (F) Krishna, Kanchan, NA-7 and Chakaiya are − 3.75, − 3.82, − 4.24 and − 3.05, respectively

F Fresh; U untreated; P pretreated; AA ascorbic acid; a*—greenness values followed by different superscripts within each column are significantly different (p < 0.05)

Storage studies of untreated dried samples of different cultivars are shown in Table 2. Untreated dried samples of NA-7 cultivar stored at refrigerated conditions lost ascorbic acid content by 28.44% while the samples stored at ambient conditions (27 ± 2 °C) lost ascorbic acid content by 32.00% over 60 days storage period. In the case of samples stored in accelerated conditions, the samples were observed to loose ascorbic acid content by 39.09%. In general, untreated dried samples lost ascorbic acid content much faster.

Retention of Ascorbic acid in case of pretreated dried samples of different cultivars are shown in Table 2. The results are explained by taking the results of NA-7 cultivar as an example. The loss of ascorbic acid content in pretreated dried samples of NA-7 was by 23.20% after a storage period of 60 days at room temperature. Those stored at refrigerated conditions lost ascorbic acid content by 15.72% while the samples stored at accelerated conditions lost ascorbic acid content by 29.71% over the storage period. Samples kept under accelerated condition showed a significant reduction in ascorbic acid content compared to those stored under other conditions, because of the increase in the rate of oxidation at relatively higher storage temperature. Similar results were observed in the case of other cultivars as well.

The higher retention of ascorbic acid in the dry powder samples (both untreated and pretreated) stored at refrigerated conditions than ambient temperature can be explained as follows. It is a known fact that the activity of enzymes that oxidize ascorbic acid is the lowest at lower temperatures and when stored in the dark. Ascorbic acid being thermolabile biomolecule tends to degrade with an increase in temperature and will be more when storage temperature is 4 °C compared to that at 27 °C. A similar trend was observed by Pareek and Kaushik (2012) in dried Amla stored for 90 days at ambient condition. Though higher retention was observed at refrigerated followed by the ambient condition, from an economic point of view, dried grated Amla can be stored at the ambient condition with maximum retention of ascorbic acid.

The ascorbic acid in pretreated dried samples was found to be more stable after 60 days when compared to untreated dried samples. For instance, in case of NA-7 cultivar stored at refrigerated conditions, the ascorbic acid retention was 99.26% (that is, a loss of content by 0.74%) in case of pretreated samples whereas it was 98.85% in case of untreated samples (that is, a loss of content by 1.15%). Even in case of ambient and accelerated conditions, higher value was observed in pretreated (70.23–76.80% and 63.12–70.29%, respectively) than untreated (62.30–68.00% and 58.27–60.91%, respectively) samples. The instance of pretreated samples retaining more ascorbic acid compared to untreated samples can be observed in the case of other cultivars as well. Hence, it can be inferred that pretreated powder samples exhibited good retention ability of ascorbic acid when compared to untreated ones. The variation in the retention of ascorbic acid in the pretreated dry powder samples when compared to untreated ones with respect to storage conditions can be explained based on the activity of the enzyme degrading the ascorbic acid. The presence of salt during both drying and storage helps to inactivate the oxidizing enzyme, effectively slowed down the oxidation by inactivating enzymes and offers a protective barrier to ascorbic acid. Among all the cultivars, NA-7 had the maximum retention followed by Chakaiya, Kanchan and Krishna.

Colour parameters (L*, a* and b*) were measured for the dried grated Amla stored at three different storage conditions and results were presented in Table 2 and Table S1. Maximum retention of lightness was observed during refrigerated (68.32–72.13) followed by ambient (51.53–60.58) and accelerated (48.52–55.58) condition. Among the cultivars, highest L* value was observed in pretreated samples Chakaiya (72.13), Krishna (60.58) and NA-7 (55.58) at refrigerated, ambient and accelerated condition, respectively as compared to untreated samples. Refrigerated condition retains maximum greenness (0.02–2.03) as compared to ambient (3.28–6.25) and accelerated (4.85–7.95) conditions. Pretreated NA-7 showed the highest greenness with a* value at refrigerated (0.02) followed by ambient (3.28) and accelerated (4.85) condition, among all the cultivars. Yellowness (b* value) varied from 22.89 to 28.21, 19.94 to 26.31 and 18.15 to 27.76 during the refrigerated, ambient and accelerated storage, respectively. It means accelerated condition showed least b* value compared to the other two storage conditions. The reduction in L* and b* values at ambient and accelerated condition might be due oxidation of sample at stored temperature. These results suggest that salt pretreatment improves ascorbic acid retention and colour during storage.

As mentioned earlier, the selection of the most suitable cultivar has to be judiciously made based on the values of proximate analysis, nutritional analysis, colour analysis, their ability to retain these parameters during drying (both untreated and pretreated) besides their ability to retain these parameters during storage (at refrigerated ambient and accelerated conditions).

Based on the values of a*, L*, b*, ΔE and percentage retention of colour, NA-7 cultivar can be considered as the most suitable

Based on the values of these parameters, NA-7 cultivar Amla grated by pretreated by 1% salt (NaCl) and dried in cabinet tray dryer at 55 ± 2 °C temperature for 8 h can be concluded the most suitable in terms of retention of TPC, ascorbic acid, antioxidant activity and colour and hence are the best conditions for preparation of Amla powder.

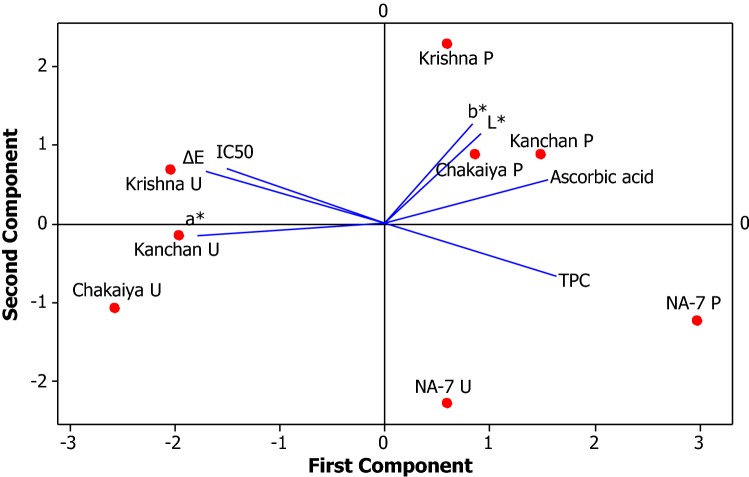

Inter-relationship

The principal component analysis (PCA) was applied to dried Amla grating samples of different cultivars and treatment to characterized total phenolic content, ascorbic acid, antioxidant activity (IC50 value), and colour parameters (L*, a*, b* and ΔE). The PCA biplot of principal components (PC1 and PC2) is presented in (Fig. 4). PC1 (first principal component) had the highest eigenvalue of 3.87, and accounted for 55.3% of the variance, while PC2 (second principal component) had eigenvalue of 2.15 and accounted for 30.8% variability in the data set. Figure 4 showed that pretreated samples of cultivars Chakaiya and Kanchan formed a group which indicated that these items behaved similarly, and possessed a moderate relationship with ascorbic acid, L* and b*. Ascorbic acid content was near to Krishna P means that it had the highest ascorbic acid content. NA-7 P cultivar the showed highest total phenolic content as it was close to it. Krishna U sample showed the lowest antioxidant activity and second highest change in colour values as it was close to IC50 and ΔE, which were in the neighborhood in the biplot indicating similar behaviour. Kanchan U is closed to a*, that means highest a* value resulted in a maximum loss of green colour. This results showed that salt treatment helped to retain green colour during drying. These results indicated that the quality characteristics of dried grated Amla samples with treatment are different from their corresponding untreated samples, and there existed a significant effect of treatment and cultivars on the physicochemical properties of dried Amla gratings.

Fig. 4.

Principal component biplot of untreated and pretreated dried Amla gratings prepared from different cultivars. U Untreated; P Pretreated

Conclusion

Grating of different Amla cultivars showed significant differences in proximate composition, ascorbic acid retention, total phenolic content, antioxidant activity and colour. Salt pretreatment had a significant positive effect on the above quality parameters during drying. Among all the cultivars, pretreated NA-7 showed maximum retention of ascorbic acid (84.89%), total phenolic content (176.5 mg GAE/g db) and antioxidant activity with IC50 value (9.48 mg/µl). Among dried samples, pretreated Chakaiya showed maximum L* value followed by pretreated NA-7. Pretreated NA-7 also showed maximum retention of natural green colour after drying. Salt pretreatment was found to be useful in better retention of ascorbic acid and colour of packaged Amla gratings stored under ambient and accelerated conditions. Based on the study, NA-7 cultivar Amla grated by pretreated by 1% salt (NaCl) and dried in cabinet tray dryer at 55 ± 2 °C temperature for 8 h can be concluded the most suitable in terms of retention of TPC, ascorbic acid, antioxidant activity and colour and hence are the best conditions for preparation of Amla powder. The method used in the present work can be employed also for drying of similar fruits and vegetables.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

The authors gratefully acknowledge the Director CSIR-CFTRI, for providing the facilities, University Grant Commission (UGC) for fellowship and Ministry of Food Processing Industries for the financial aid.

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest related to this work.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Agrawal S, Chopra CS. Changes in ascorbic acid and total phenols in making aonla product. Bev Food World. 2004;31:32–34. [Google Scholar]

- Akbulut A, Durmuş A. Thin layer solar drying and mathematical modeling of mulberry. Int J Energy Res. 2009;33:687–695. doi: 10.1002/er.1504. [DOI] [Google Scholar]

- Alfaro S, Mutis A, Quiroz A, Seguel I, Scheuermann E. Effects of drying techniques on murtilla fruit polyphenols and antioxidant activity. J Food Res. 2014;3:73–82. doi: 10.5539/jfr.v3n5p73. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. 18. Gaithersburg: Association of Official Analytical Chemists; 2005. [Google Scholar]

- Bomben JL (1977) Effluent generation, energy use and cost of blanching. In: Proceedings eighth national symposium on food processing wastes: March 30–April 1, 1977, Seattle, Washington. US Environmental Protection Agency, Office of Research and Development, Industrial Environmental Research Laboratory, p 85

- Brand-Williams W, Cuvelier ME, Berset CLWT. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci Technol. 1995;28:25–30. doi: 10.1016/S0023-6438(95)80008-5. [DOI] [Google Scholar]

- Chandralekha A, Tavanandi AH, Amrutha N, Hebbar HU, Raghavarao KSMS, Gadre R. Encapsulation of yeast (Saccharomyces cereviciae) by spray drying for extension of shelf life. Drying Technol. 2016;34(11):1307–1318. doi: 10.1080/07373937.2015.1112808. [DOI] [Google Scholar]

- Chandralekha A, Rani A, Tavanandi HA, Amrutha N, Hebbar U, Raghavarao KSMS. Role of carrier material in encapsulation of yeast (Saccharomyces cerevisiae) by spray drying. Drying Technol. 2017;35(8):1029–1042. doi: 10.1080/07373937.2016.1230626. [DOI] [Google Scholar]

- Deka BC, Sethi V, Prasad R, Batra PK. Application of mixtures methodology for beverages from mixed fruit juice/pulp. J Food Sci Technol. 2001;38(6):615–618. [Google Scholar]

- Doymaz I. Convective air drying characteristics of thin layer carrots. J Food Eng. 2004;61:359–364. doi: 10.1016/S0260-8774(03)00142-0. [DOI] [Google Scholar]

- Duncan DB. Multiple range and multiple f-test. Biometrics. 1955;11:1–5. doi: 10.2307/3001478. [DOI] [Google Scholar]

- Gornicki K, Kaleta A. Drying curve modelling of blanched carrot cubes under natural convection condition. J Food Eng. 2007;82:160–170. doi: 10.1016/j.jfoodeng.2007.02.002. [DOI] [Google Scholar]

- Goyal RK, Kingsly ARP, Kumar P, Walia H. Physical and mechanical properties of aonla fruits. J Food Eng. 2007;82:595–599. doi: 10.1016/j.jfoodeng.2007.03.019. [DOI] [Google Scholar]

- Gudapaty P, Indavarapu S, Korwar GR, Shankar AK, Adake RKV, Bandi V, Kanchu SR. Effect of open air drying, LPG based drier and pretreatments on the quality of Indian gooseberry (aonla) J Food Sci Technol. 2010;47:541–548. doi: 10.1007/s13197-010-0093-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kadam DM, Samuel DVK, Parsad R. Optimization of pretreatments of solar dehydrated cauliflower. J Food Eng. 2006;77:659–664. doi: 10.1016/j.jfoodeng.2005.07.027. [DOI] [Google Scholar]

- Karla CL. The chemistry and technology of Amla (Phyllanthus emblica)—a resume. Indian Food Packer. 1988;42(4):67–82. [Google Scholar]

- Kingsly RP, Goyal RK, Manikantan MR, Ilyas SM. Effects of pretreatments and drying air temperature on drying behaviour of peach slice. Int J Food Sci Technol. 2007;42(1):65–69. doi: 10.1111/j.1365-2621.2006.01210.x. [DOI] [Google Scholar]

- Kumar GS, Nayaka H, Dharmesh SM, Salimath PV. Free and bound phenolic antioxidants in Amla (Emblica officinalis) and turmeric (Curcuma longa) J Food Comp Anal. 2006;19(5):446–452. doi: 10.1016/j.jfca.2005.12.015. [DOI] [Google Scholar]

- Kumari P, Khatkar BS. Assessment of total polyphenols, antioxidants and antimicrobial properties of aonla cultivars. J Food Sci Technol. 2016;53(7):3093–3103. doi: 10.1007/s13197-016-2282-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kumari P, Khatkar BS. Nutritional composition and drying kinetics of aonla fruits. J Food Sci Technol. 2018;55(8):3135–3143. doi: 10.1007/s13197-018-3241-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lavelli V, Zanoni B, Zaniboni A. Effect of water activity on carotenoid degradation in dehydrated carrots. Food Chem. 2007;104(4):1705–1711. doi: 10.1016/j.foodchem.2007.03.033. [DOI] [Google Scholar]

- Lawless HT, Heymann H. Sensory evaluation of food principles and practices. New York: Chapman & Hall; 2010. [Google Scholar]

- Liu X, Cui C, Zhao M, Wang J, Luo W, Yang B, Jiang Y. Identification of phenolics in the fruit of emblica (Phyllanthus emblica L.) and their antioxidant activities. Food Chem. 2008;109(4):909–915. doi: 10.1016/j.foodchem.2008.01.071. [DOI] [PubMed] [Google Scholar]

- Mishra P, Dutta N, Mahanta CL. Partial extraction and identification of phenolics in Amla (Emblica officinalis) seed coat powder. J Food Sci Technol. 2015;52(11):6990–7001. doi: 10.1007/s13197-015-1835-y. [DOI] [Google Scholar]

- Mitra SK, Pathak PK, Chakraborty I. Underutilized tropical and subtropical fruits of Asia. Acta Hortic. 2008;770:67–76. doi: 10.17660/ActaHortic.2008.770.7. [DOI] [Google Scholar]

- Okos MR, Narsimhan G, Singh RK, Witnauer AC. Food dehydration. In: Heldman DR, Lund DB, editors. Handbook of food engineering. New York: Marcel Dekker; 1992. pp. 1–10. [Google Scholar]

- Pareek S, Kaushik RA. Effect of drying methods on quality of Indian gooseberry (Emblica officinalis Gaertn.) powder during storage. J Sci Ind Res India. 2012;71(11):727–732. [Google Scholar]

- Pareek S, Kitinoja L, Kaushik RA, Paliwal R. Postharvest physiology and storage of ber. Stewart Postharvest Rev. 2009;5(5):1–10. [Google Scholar]

- Pathak PK, Preeti D, Kumar S. Effect of post-harvest treatments on shelf-life of aonla (Emblica officinalis) fruits damaged during harvesting. J Food Sci Technol. 2009;46(3):283–285. [Google Scholar]

- Prajapati VK, Nema PK, Rathore SS. Effect of pretreatment and drying methods on quality of value-added dried aonla (Emblica officinalis) shreds. J Food Sci Technol. 2011;48(1):45–52. doi: 10.1007/s13197-010-0124-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. 2. New Delhi: Tata McGraw Publ Co., Ltd.; 1986. [Google Scholar]

- Suhaj M. Spice antioxidants isolation and their antiradical activity: a review. J Food Comp Anal. 2006;19:531–537. doi: 10.1016/j.jfca.2004.11.005. [DOI] [Google Scholar]

- Tembo L, Chiteka ZA, Kadzere I, Akinnifesi FK, Tagwira F. Blanching and drying period affect moisture loss and vitamin C content in Ziziphus mauritiana Lamk. Afr J Biotechnol. 2008;7(17):3100–3106. [Google Scholar]

- Tripathi VK, Singh MB, Singh S. Studies on comparative compositional changes in different preserved products of Amla (Emblica officinalis) var. Banarasi. Indian Food Packer. 1988;42(4):60–66. [Google Scholar]

- Zheng W, Wang SY. Antioxidant activity and phenolic compounds in selected herbs. J Agric Food Chem. 2001;49:5165–5170. doi: 10.1021/jf010697n. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.