Abstract

Tens of thousands of metal–organic frameworks (MOFs) have been developed in the past two decades, and only ≈100 of them have been demonstrated as porous and hydrophobic. These hydrophobic MOFs feature not only a rich structural variety, highly crystalline frameworks, and uniform micropores, but also a low affinity toward water and superior hydrolytic stability, which make them promising adsorbents for diverse applications, including humid CO2 capture, alcohol/water separation, pollutant removal from air or water, substrate‐selective catalysis, energy storage, anticorrosion, and self‐cleaning. Herein, the recent research advancements in hydrophobic MOFs are presented. The existing techniques for qualitatively or quantitatively assessing the hydrophobicity of MOFs are first introduced. The reported experimental methods for the preparation of hydrophobic MOFs are then categorized. The concept that hydrophobic MOFs normally synthesized from predesigned organic ligands can also be prepared by the postsynthetic modification of the internal pore surface and/or external crystal surface of hydrophilic or less hydrophobic MOFs is highlighted. Finally, an overview of the recent studies on hydrophobic MOFs for various applications is provided and suggests the high versatility of this unique class of materials for practical use as either adsorbents or nanomaterials.

Keywords: anticorrosion coating, competitive adsorption, hydrophobicity index, postsynthetic modifications, substrate‐selective catalysis

The structural design, preparation strategies, characterization methods, and potential applications of hydrophobic metal–organic frameworks (MOFs), a class of unique materials with both microporosity and hydrophobicity, are overviewed herein. It is highlighted that hydrophobic MOFs can be prepared by some facile procedures, and this type of materials can act as either advanced adsorbents or nanomaterials.

1. Introduction

Metal–organic frameworks (MOFs), also called porous coordination polymers (PCPs), are a class of porous materials commonly obtained by the facile hydrothermal or solvothermal reactions of metal ions and bridging organic ligands at relatively low temperatures.1, 2, 3, 4, 5, 6 In the past two decades, extensive research has been devoted to developing new MOFs7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30 and to exploring their application potential in many fields, such as gas storage,31, 32, 33, 34, 35 separation,36, 37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 47, 48 catalysis,49, 50, 51, 52 sensing,53, 54, 55, 56, 57, 58, 59, 60, 61 and biomedicine.62, 63, 64 Early on, a handful of MOFs was found to show a low affinity toward water and a permanent porosity, and this class of hydrophobic MOFs later received increasing attention due to their potential for use in practical adsorption and separation processes, even under humid conditions or in water. On the other hand, the stability of MOFs to water has long been regarded as the major weakness of MOFs in practical use. Many studies have demonstrated that the hydrolytic stability of MOFs could be enhanced by improving the hydrophobicity of their internal pore surface and/or external crystal surface.65, 66 Recently, a variety of synthetic approaches have emerged to make MOFs more hydrophobic. The integrated attributions of the reported hydrophobic MOFs with respect to porosity, hydrophobicity and stability lead to great promise for this unique class of materials in diverse applications, including humid CO2 capture, alcohol/water separation, pollutant removal from air or water, substrate‐selective catalysis, energy storage, anticorrosion coatings and self‐cleaning. Some excellent reviews about hydrophobic MOFs have been recently published.67, 68, 69, 70 However, the goal of this contribution is to present a comprehensive review of the development and advancement of hydrophobic MOFs.

In the following sections, the existing techniques for assessing the hydrophobicity of MOFs are first introduced, including the determination of crystal structure, water adsorption measurement, quantitative determination of the hydrophobicity index by the competitive breakthrough adsorption experiment of a hydrocarbon/water mixture, and water contact angle measurement. These measurements offer information about the extent of the hydrophobicity of MOFs at the internal pore surface or external crystal surface. Then, the reported methods to construct hydrophobic MOFs, which are categorized into three classes: presynthetic ligand design and functionalization, postsynthetic hydrophobization, and in situ synthetic hydrophobization, are summarized. A list of hydrophobic MOFs obtained from various predesigned ligands (carboxylic acids, azoles, and phosphonic acid monoesters) is provided. It is highlighted that hydrophobic MOFs normally synthesized from predesigned organic ligands can also be prepared by a postsynthetic modification of the internal pore surface and/or external crystal surface of hydrophilic or less hydrophobic MOFs. Last, the recent studies on hydrophobic MOFs for various applications are overviewed. The interplay of porosity, hydrophobicity, stability, and application performance of the MOF materials is discussed.

2. Assessment of Hydrophobicity in MOFs

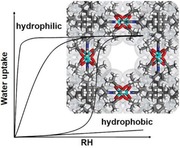

Among the over 20 000 MOFs reported so far,6 ≈100 MOFs have been described as hydrophobic. Although many of these MOFs were reported without extra experimental evidence except crystal structures supporting their hydrophobicity, some experimental analysis methods are often used to assess the hydrophobicity of MOFs qualitatively or quantitatively (Figure 1), namely, the water adsorption isotherm measurement, competitive adsorption of a vapor mixture of water and hydrocarbon vapor (mostly toluene) in a breakthrough experiment, and contact angle of liquid water. These methods are discussed in detail in the following sections. Occasionally, infrared (IR) spectroscopy and thermogravimetric (TG) analysis are also used for accessing the hydrophobicity of MOFs.71, 72, 73 IR spectroscopy can be used to determine the water content in the hydrophobic pore by monitoring absorption near 3680 cm−1 for the O–H stretching bands of water and absorption near 1621 cm−1 for the H–O–H bending bands of water. Due to hydrogen bonding interactions, O–H stretching bands are commonly observed near 3400 cm−1 as well. TG curves not only give the quantities of water adsorbed by the porous materials but also provide clues to evaluate the strength of the adsorbent–water interactions, which are indicated by the temperature range of the weight loss for adsorbed water molecules.

Figure 1.

Methods and indicators for assessing the hydrophobicity of MOFs.

2.1. Crystal Structures

The studies of MOFs start with the crystal structure. Most MOFs were structurally determined by single‐crystal X‐ray diffraction (SXRD) experiments. With the SXRD crystal structures, the pore surface of MOFs can be examined, leading to a general judgment of the hydrophobicity/hydrophilicity of their internal surfaces. When the pore surface is mostly covered by nonpolar or weakly polar contents that have low surface energies, such as alkyl groups, aryl groups, fluorinated alkyl and aryl groups, the pore surface hydrophobicity is clearly indicated. On the other hand, the presence of moieties prone to coordinate or hydrogen bond with water molecules (such as open metal sites, as well as hydroxyl, amine, and sulfonic acid groups) on the pore surface generates a high surface energy and thus enhances the hydrophilicity of the inner surface. Indeed, the crystal structures of MOFs provide information to predict their hydrophobicity, especially when the guest‐free crystal structures of MOFs are unambiguously determined. However, sometimes claims that MOFs were described to be hydrophobic based on only their crystal structures, without other supporting experimental results, are not convincing. In addition, it should be noted that the crystal structures of MOFs cannot be used to predict the hydrophobicity/hydrophilicity of their external surfaces, because the external surface is a kind of crystal defect, and the bonding environment of the atoms on the surface can be very different from those inside the bulk.

2.2. Water Adsorption

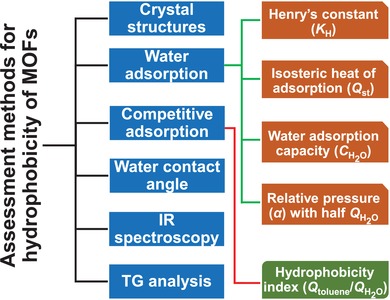

The adsorption isotherms of water vapor recorded near room temperature for MOFs offer important information about the hydrophobicity/hydrophilicity of their internal surfaces.39, 65, 74 There are six types of physisorption isotherms in the IUPAC recommendations updated in 2015 (Figure 2a).75 Hydrophobic microporous and mesoporous adsorbents commonly show type V isotherms, where the uptakes are low at the low‐relative‐pressure (P/P 0) range, indicating the presence of relatively weak adsorbent–adsorbate interactions, and molecular clustering is followed by pore filling at the high‐P/P 0 range. For the water adsorption isotherms of some highly hydrophobic MOFs, such as [Zn(2‐mim)2] (ZIF‐8),76, 77 Zn(2‐eim)2 (MAF‐6),78 Zn(4,5‐dcim)2 (ZIF‐71),79 and {Ag2[Ag4(3,5‐tftz)6]} (FMOF‐1),80 the uptakes are very low, even at the pressures near the saturation pressure (P 0), as with the type VII adsorption isotherm shown in Figure 2b.81 As the hydrophilicity of MOFs increases, their water adsorption isotherms gradually transform into type I isotherms (Figure 2b).

Figure 2.

a) Five types of physisorption isotherms as classified by IUPAC. b) Representative water adsorption isotherms of porous adsorbents with different degrees of hydrophobicity/hydrophilicity.

Many MOFs have been characterized by their water adsorption isotherms, and some excellent reviews discussing the water adsorption isotherms of MOFs have also been reported.39, 65, 74, 82 From the water adsorption isotherms, several indicators for accessing the hydrophobicity of MOFs can be obtained, including Henry's constant (K H), the heat of water adsorption (Q st), the water adsorption capacity (), and the relative pressure (α) at which half of the water adsorption capacity is reached. K H is the slope of a water isotherm at the low‐pressure range (the so‐called Henry range), where the uptake is linearly dependent on the P/P 0 value. The quantity of K H is an indication of the interaction strength between water molecules and the MOF framework. Q st can be obtained from determining the heat released during a water adsorption process by an isothermal calorimeter83 or calculated from several adsorption isotherms recorded at close temperatures (≈10 K differences) with the Clausius–Clapeyron equation (Equation (1)),84, 85 where T is the temperature, R is the universal gas constant, and C is a constant. Q st also indicates how strong the adsorbent–adsorbate interaction strength is. , standing for the water uptakes at the pressures close to P 0, are dependent on not only the adsorbent–water affinity but also the pore volume of the adsorbent. Less hydrophobic adsorbents with larger pore volumes have higher . Normally, the pore volumes of nanoporous adsorbents can be precisely determined by N2 adsorption at 77 K or by Ar adsorption at 87 K. Especially, in some cases, when the SXRD structures of the guest‐free phases of MOFs are determined, the experimental pore volumes obtained from N2 or Ar adsorption can be very close to the theoretical pore volumes predicted from the guest‐free SXRD structures. By assuming that the pores are occupied by water in a liquid or quasi‐liquid status at a pressure near P 0, a theoretical water adsorption capacity () can be calculated by Equation (2), where ρ stands for the density of water confined in a pore and V is the pore volume determined experimentally. In the literature, either the density of liquid water (1 g cm−3)86, 87 or the density of crystallized water (ice) (0.9168 g cm−3)88 was adapted as ρ in the calculation. A comparison of the calculated and determined from water adsorption experiments offers information about how hydrophobic the adsorbent is. A large difference between and indicates a high hydrophobicity of the adsorbent. Several hydrophobic nanoporous adsorbents show type V water adsorption isotherms. Due to pore filling at relatively high P/P 0, at pressures near P 0 may be very close to the maximum water uptake . In such cases, α, the relative pressure at which half of is reached, is an important complementary indicator for assessing the hydrophobicity of adsorbents. A high α is an indication of a high hydrophobicity

| (1) |

| (2) |

| (3) |

2.3. Competitive Breakthrough Adsorption

Although water adsorption provides abundant important information, assessing the hydrophobicity of the internal surfaces of adsorbents with water adsorption isotherms and the derived indicators is qualitative. Directly comparing the hydrophobicity of different adsorbents by their water adsorption isotherms can sometimes be misleading because their pore sizes, shapes, and volumes are different, affecting their water adsorption isotherm significantly. In contrast, the hydrophobicity index (HI)—defined by the ratio of the adsorption capacity of toluene (Q toluene) to that of water (Q water), which can be determined by the competitive breakthrough adsorption experiment with a toluene/water mixture (Equation (3))—is a promising indicator for quantitatively assessing the hydrophobicity of MOFs. However, the HIs of only two MOFs have been reported so far, namely, [FeIII 3O(H2O)2F(btc)2] (MIL‐100(Fe)) (HI = 2.8)89 and [Cr3O(H2O)2F(1,4‐bdc)3] (MIL‐101(Cr)) (HI = 11.0).90 For comparison, the reported HIs of some zeolites and activated carbons are listed in Table 1. The HI of MIL‐100(Fe) is only slightly higher than that of typical hydrophilic zeolites, such as Zeolites beta (1.4) and Zeolites Y (0), but is clearly lower than that of all‐silica zeolites and activated carbons, which are commonly regarded as hydrophobic adsorbents, thus suggesting the relatively high hydrophilicity of MIL‐100(Fe). The HI of MIL‐101(Cr) is higher than those of hydrophilic zeolites, but lower than those of typical hydrophobic adsorbents, suggesting that MIL‐101(Cr) is in an intermediate status between hydrophilic and hydrophobic. This identification explains why MIL‐101(Cr) was described as hydrophobic in some papers,91, 92 but hydrophilic in others.90, 93

Table 1.

Hydrophobicity indexes of some adsorbents obtained from the co‐adsorption of toluene and water

| Adsorbent | Hydrophobicity index (HI) | Reference |

|---|---|---|

| MIL‐100(Fe) | 2.8 | 89 |

| MIL‐101(Cr) | 11.0 | 90 |

| Zeolites beta | 1.4 | 94 |

| Zeolites beta, all‐silica | 66 | 94 |

| Zeolites Y | 0 | 94 |

| ZSM‐5 | 8 | 95 |

| Silicalite‐1 | 15.2 | 96 |

| MCM‐41 | 9 | 94 |

| Activated carbon (Darco‐KBB) | 26.3 | 97 |

| Activated carbon (SX1G) | 26.2 | 97 |

| Activated carbon (F300) | 160 | 94 |

| Activated carbon (Duksan) | 296 | 90 |

It should be noted that other methods exist to define the HI of porous adsorbents.81 Fox example, the HI can also be determined by the competitive adsorption of mixtures of water and hydrocarbons other than toluene, including methylcyclohexane.96 In addition, Anderson and Klinowski introduced an HI for zeolites, which is defined as the ratio of the loss of water at 150 °C to that at 400 °C obtained by thermogravimetric analysis (TGA).98 In any case, when assessing the hydrophilicity/hydrophilicity by comparing HIs, the same method for determination of the HIs should be adopted.

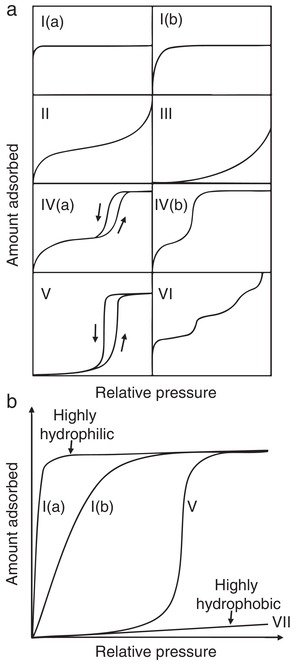

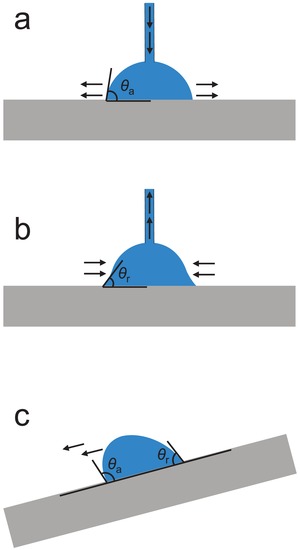

2.4. Water Contact Angle

The hydrophobicity of the external surface of MOFs is commonly evaluated by the measurement of the water contact angle of their crystal, powder or/and compressed pellet samples. Water contact angles less than 90° suggest a favorable wetting of the external surfaces of MOFs by water, which are regarded to be hydrophilic (Figure 3a). Water contact angles greater than 90° indicate an unfavorable wetting and a hydrophobic external surface of MOFs. The external surface of MOFs is commonly described to be superhydrophobic when it shows water contact angles greater than 150° (Figure 3b).

Figure 3.

Water contact angles for a) a hydrophilic solid surface and b) a hydrophobic solid surface.

The contact angle of a liquid drop on an ideal solid surface is defined by Young's equation (Equation (4)), where σl is the surface tension of the liquid, θ is the contact angle, σs is the surface free energy of the solid, and σsl is the interfacial tension between the liquid and solid. Interfacial tension is defined as the work that is required to increase the area of the interface between two adjacent phases, which do not mix completely with one another, in the unit of mJ m−2 (also frequently used as mN m−1). The liquid/gas interfacial tension is also termed as surface tension, while the solid/gas interfacial tension is also termed as the surface free energy. Therefore, σl and σs in Young's equation are sometimes described as the liquid–gas interfacial tension (σlg) and solid–gas interfacial tension (σsg), respectively.99 When the liquid is water, the surface tension of water, σl, is a constant at a specific temperature, thus, the water contact angle (θ) is dependent on the surface free energy of the solid surface σsl and the interfacial tension between the solid surface and the liquid water, σsl. When the surface free energy of the solid is high and dominative (θ < 90°), the small water drop expands and covers more solid surface until the water contact angle reduces to a value by which the Young's equation is balanced (Figure 3a). When the affinity between the solid surface and water is low (low wettability), the solid–water interfacial tension is high and dominative (θ > 90°), and the water drop prefers not to increase the area of the solid–water interface (Figure 3b)

| (4) |

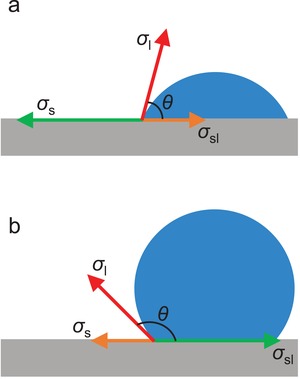

In Young's equation, the solid surface is assumed to be ideally homogeneous, smooth and inert. However, the surfaces of MOF samples (crystals, powder, and pellets) for the water contact angle measurement are normally heterogeneous and rough. To study how the real surfaces differ from the ideal surface, the dynamic contact angle measurement is commonly performed. Dynamic contact angles can be measured by slowly introducing or removing water from a water drop on the solid surface (the so‐called volume changing method). When water is added slowly enough, the water contact angle increases as the three‐phase boundary remains unchanged. The maximum contact angle obtained before three‐phase boundary starts to expand is termed as the advancing contact angle, θa (Figure 4a). When water is removed from the water drop very slowly, the water contact angle gradually decreases. The minimum water contact angle recorded at the moment the three‐phase boundary starts to contract is called the receding contact angle, θr (Figure 4b). Contact angle hysteresis is defined as the difference between θa and θr. Dynamic contact angles are also often recorded by the so‐called tilted plate method. In this measurement, the water drop on a solid surface gradually deforms as the solid surface is tilted slowly enough to keep the water drop stationary. In addition, the contact angle of the downhill side of the water drop gradually increases, and that of the uphill side of the water drop gradually decreases. When the surface is tilted to a specific angle, a maximum contact angle at the downhill side and a minimum contact angle at the uphill side are reached, and the water drop starts to move. The obtained maximum and minimum contact angles are θa and θr, respectively (Figure 4c).

Figure 4.

Measurement of dynamic contact angles a,b) by the volume changing method and c) by the tilted plate method.

3. Preparation of Hydrophobic MOFs

The reported hydrophobic MOFs are mostly synthesized by ligands with attached hydrophobic groups. In the past few years, some excellent works have demonstrated that hydrophobic MOFs or MOF‐derived materials can also be obtained by the postsynthetic or in situ synthetic modification of less hydrophobic or hydrophilic MOFs. Some representative reported hydrophobic MOFs are listed in Table 2 together with their pore characteristics and hydrophobicities.

Table 2.

A list of representative hydrophobic MOFs reported in the literature

| MOF | Formula | Ligand a) | S BET/S L b) [m2 g−1] | V p c) [cm3 g−1] | d a d) [Å] | d p e) [Å] | f) [mg g−1] | α g) (P/P 0) | CA h) [°] | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| [Cd(O2C‐CH2‐CO2)(H2O)] | [Cd(ma)(H2O)] | H2ma | 6.95 | 100 | ||||||

| [Mn(O2C‐(CH2)3‐CO2)] | [Mn(glu)] | H2glu | 6.6 | 100 | ||||||

| CPM‐300 | [Zn4O(RR‐cam)3] | RR‐H2cam | 310.5/ 429.9 | 8 | 138.7 | 101 | ||||

| CPM‐301 | [Zn4O(RRcam)3][Zn9(btz)12(RR‐cam)3] | RR‐H2cam, Hbtz | 145.0 | 101 | ||||||

| MIL‐140A | [ZrO(1,4‐bdc)] | 1,4‐H2bdc | 415/– | 0.18 | 3.2 | – i) | 0.5 | 71 | ||

| MIL‐101(Cr) | [Cr3O(H2O)2F(1,4‐bdc)3] | 1,4‐H2bdc | 3124/– | 1.58 | 12, 16 × 14.5 | 29, 34 | 1360 | 0.48 | 102 | |

| MIL‐101‐NO2 | [Cr3O(H2O)2F(1,4‐bdc‐2‐NO2)3] | 1,4‐H2bdc‐2‐NO2 | 2146/– | 1.19 | 1060 | 0.47 | 102 | |||

| MIL‐68(In) | [In(OH)(1,4‐bdc)] | 1,4‐H2bdc | 1100/– | 0.42 | 6.0–6.4; 16–17 | 320 | 0.58 | 103 | ||

| Banasorb‐22 | [(Zn4O)(1,4‐bdc‐2‐CF3O)3] | 1,4‐H2bdc‐2‐CF3O | 1113/– | 80 | 72 | |||||

| UiO‐66 | [Zr6O4(OH)4(1,4‐bdc)6] | 1,4‐H2bdc | 1105/– | 0.55 | 7 | 8–11 | 453 | 0.27 | 104 | |

| UiO‐66−1,4‐Naphyl | [Zr6O4(OH)4(1,4‐ndc)6] | 1,4‐H2ndc | 757/– | 0.42 | 297 | 0.31 | 104 | |||

| UiO‐66‐(C2H5)2 | [Zr6O4(OH)4(1,4‐bdc‐(C2H5)2)6] | 1,4‐H2bdc‐(C2H5)2 | 340/– | 0.16 | 122 | 0.5 | 87 | |||

| UiO‐66‐C2F5 | [Zr6O4(OH)4(1,4‐bdc‐C2F5)6] | 1,4‐H2bdc‐C2F5 | 570/– | 0.26 | 252 | 0.6 | 87 | |||

| UiO‐66‐(CF3)2 | [Zr6O4(OH)4(1,4‐bdc‐(CF3)2)6] | 1,4‐H2bdc‐(CF3)2 | 630/– | 0.30 | 190 | 0.35 | 87 | |||

| UiO‐66‐CH3 | [Zr6O4(OH)4(1,4‐bdc‐CH3)6] | 1,4‐H2bdc‐CH3 | 760/– | 0.32 | 253 | 0.22 | 87 | |||

| UiO‐66‐(CH3)2 | [Zr6O4(OH)4(1,4‐bdc‐(CH3)2)6] | 1,4‐H2bdc‐(CH3)2 | 790/– | 0.35 | 279 | 0.38 | 87 | |||

| UiO‐66‐CF3 | [Zr6O4(OH)4(1,4‐bdc‐CF3)6] | 1,4‐H2bdc‐CF3 | 815/– | 0.36 | 279 | 0.32 | 87 | |||

| MIL‐140B | [ZrO(2,6‐ndc)] | 2,6‐H2ndc | 460/– | 0.18 | 4.0 | % | 0.5 | 71 | ||

| MIL(Cr)‐Z1 | [Cr3O(H2O)2F(1,4‐ndc)3] | 1,4‐H2ndc | 2086/– | 1.23 | 6.9 | 23.3 | 318.6 | 0.64 | 105 | |

| Al(OH)(1,4‐ndc) | [Al(OH)(1,4‐ndc)] | 1,4‐H2ndc | –/546 | 3.0–7.7 | 165 | 0.47 | 106 | |||

| [Cu(1,4‐ndc)(MeOH)] | [Cu(1,4‐ndc)(MeOH)] | 1,4‐H2ndc | –/133.7 | ≈3.8 | 22 | 0.4 | 107 | |||

| UiO‐67‐BN | [Zr6O4(OH)4(bn)6] | H2bn | 1416/– | 495 | 0.54 | 108 | ||||

| UiO‐67‐4MS | [Zr6O4(OH)4(tmbpd)6] | H2tmbpd | 1153/– | 82 | 109 | |||||

| UiO‐66D‐(CF3)2 | [Zr6O4(OH)4(abdc‐(CF3)2)6] | H2abdc‐(CF3)2 | 2180/– | 0.88 | 281 | 0.87 | 87 | |||

| NMOF‐1 | [Zn(ope‐C18)(H2O)2] | H2ope‐C18 | ≈3.3 | 16 | ≈0.45 | 160–162 | 110 | |||

| IFMC‐29 | [Zn4O(CH3PhTDC)3] | H2CH3PhTDC | 1892/– | 0.64 | 93 | 111 | ||||

| MOFF‐1 | [Cu(bpdc‐F8)(MeOH)] | H2bpdc‐F8 | 580/– | 136 | 0.45 | 108 | 112 | |||

| Zn(tbip) | [Zn(tbip)] | H2tbip | 256/– | 0.15 | 4.5 | 110 | 0.56 | 113 | ||

| Zn‐hfipbb | [Zn(hfipbb)] | H2hfipbb | 287/288.9 | 0.112 | 6.7 | ≈0 | 114, 115 | |||

| [Cu(hfipbb)(H2hfipbb)0.5] | [Cu(hfipbb)(H2hfipbb)0.5] | H2hfipbb | 0.07 | 3.5 | 5.1 | 116, 117 | ||||

| Fe‐hfipbb | [Fe3O(hfipbb)3] | H2hfipbb | 269.5/– | 0.21 | 8–12.9 | 110 | 118 | |||

| MAMS‐2 | [Zn(H2O)(bbpdc)] | H2bbpdc | 2.9–4.6 | 119 | ||||||

| UHMOF‐100 | [Cu(tpda)(DMF)] | H2tpda | 660/469 | 1.07 | 5.9 | ≈0 | 177 | 120 | ||

| BUT‐66 | [Zr6O4(OH)4(1,3‐bdb)6] | 1,3‐H2bdb | 1096/1291 | 0.46 | 6.0 | 71 | 0.4 | 142.8 | 88 | |

| BUT‐67 | [Zr6O4(OH)4(2,7‐ndb)6] | 2,7‐H2ndb | 984/1141 | 0.41 | 7 | 124 | 0.45 | 137.9 | 88 | |

| CuMBTC | [Cu3(mbtc)2] | H3mbtc | 1471/– | 0.78 | 8.8–12.7 | 184 | 0.2 | 121 | ||

| CuEBTC | [Cu3(ebtc)2] | H3ebtc | 1434/– | 0.65 | 7.8–12.2 | 184 | 0.1 | 121 | ||

| BUT‐12 | [Zr6O4(OH)8(H2O)4(ctta)8/3] | H3ctta | 3387/– | 1.52 | 13–21 | 434 | 0.4 | 138.7 | 122 | |

| BUT‐13 | [Zr6O4(OH)8(H2O)4(ttna)8/3] | H3ttna | 3948/– | 2.20 | 14–28 | 494 | 0.52 | 118.3 | 122 | |

| PESD‐1 | [Zn4(OH)2(btmb)2(DMF)3(MeOH)] | H3btmb | 295/570 | >150 | 123 | |||||

| [Pb(H‐BTMB)] | [Pb(Hbtmb)(DMF)] | H3btmb | 155/– | ≈3.3 | 156.4 | 124 | ||||

| Cu2(TPTC‐OnHex) | [Cu2(TPTC‐OnHex)] | H4tptc‐onhex | 1083/1269 | 125 | ||||||

| UPC‐21 | [Cu2(pptc)] | H4pptc | 1253.6/– | 145 | 126, 127 | |||||

| BUT‐155 | [Cu4(tdhb)] | H8tdhb | 2070/– | 0.82 | 9.5 | 16 | 470 | 0.28 | 128 | |

| Znpbdc‐8a | – | pbdc‐8a | 856/– | 9 | 112 | 129 | ||||

| FMOF‐1 | {Ag2[Ag4(3,5‐tftz)6]} | 3,5‐Htftz | 810.5/– | 0.324 | 12. × 8 | 6.6 × 4.9 | 158 | 80, 130, 131 | ||

| FMOF‐2 | [Ag(Ag3(3,5‐tftz)4)] | 3,5‐Htftz | 18 | 10 | 80 | |||||

| MAF‐4/ZIF‐8 | [Zn(2‐mim)2] | 2‐Hmim | –/1870 | 0.67 | 3.2 | 11.4 | 26 | 0.88 | 77 | |

| ZIF‐318 | [Zn(2‐mim)(mim‐F3)] | 2‐Hmim, 2‐Hmim‐F3 | 835/1007 | 0.37 | 9.3 | 23 | 0.58 | 68.4 | 132 | |

| ZIF‐68 | [Zn(bim)(2‐nim)] | Hbim, 2‐Hnim | 7.5 | 10.3 | 30 j) | 0.52 | 133, 134 | |||

| ZIF‐71 | [Zn(4,5‐dcim)2] | 4,5‐Hdcim | 1183/1350 | 0.385 | 4.2 | 16.5 | 4.5 | 0.3 | 79, 133, 135, 136 | |

| ZIF‐90 | [Zn(2‐cim)2] | 2‐Hcim | 1280/1466 | 0.485 | 3.5 | 11.2 | 331 | 0.35 | 79, 137 | |

| ZIF‐300 | [Zn(2‐mim)0.86(5‐bbim)1.14] | 5‐Hbbim, 2‐Hmim | 420/490 | 6 | 0.58 | 138 | ||||

| ZIF‐301 | [Zn(2‐mim)0.94(5‐cbim)1.06] | 5‐Hcbim, 2‐Hmim | 680/825 | 5.8 | 0.52 | 138 | ||||

| ZIF‐302 | [Zn(2‐mim)0.67(5‐mbim)1.33] | 5‐Hmbim, 2‐Hmim | 240/270 | 4.5 | 0.53 | 138 | ||||

| MAF‐5 | [Zn(2‐eim)2] | 2‐Heim | 2.2–4.9 | 7–10 | ≈0 | 139 | ||||

| MAF‐6 | [Zn(2‐eim)2] | 2‐Heim | 1343/1695 | 0.61 | 7.6 | 18.4 | 16.2 | ≈0.5 | 143 | 78 |

| [Ni8(L3)6] | [Ni8(OH)4(H2O)2(1,4‐bdp)6] | 1,4‐H2bdp | 1770/– | 990 | 0.65 | 140 | ||||

| [Ni8(L4)6] | [Ni8(OH)4(H2O)2(bpdy)6] | H2bpdy | 1920/– | 936 | 0.5 | 140 | ||||

| [Ni8(L5)6] | [Ni8(OH)4(H2O)2(bpeb)6] | H2bpeb | 2215/– | ≈24 | 1129 | 0.7 | 140 | |||

| [Ni8(L5‐CH3)6] | [Ni8(OH)4(H2O)2(bpdm)6] | H2bpdm | 1985/– | ≈24 | 720 | 0.7 | 140 | |||

| [Ni8(L5‐CF3)6] | [Ni8(OH)4(H2O)2(bpdf)6] | H2bpdf | 2195/– | ≈24 | 862 | 0.83 | 140 | |||

| Cu‐tebpz | [Cu2(tebpz)] | H2tebpz | 576/– | 0.37 | 4.6–13 | 6 | 0.5 | 141 | ||

| Zn(NDI–SEt) | [Zn(ndi–SEt)] | H2ndi–SEt | 888/– | 237 | 0.4 | 142 | ||||

| MOFF‐3 | [Cu(bptz‐F8)(H2O)] | H2bptz‐F8 | 37 | 0.3 | 135 | 112 | ||||

| MAF‐2 | [Cu(3,5‐etz)] | 3,5‐Hetz | 1.5–4.2 | 9 | 7.4 | 0.5 | 143 | |||

| MAF‐7 | [Zn(3‐mtz)2] | 3‐Hmtz | –/1870 | 0.67 | 3.4 | 11.2 | 443 | 0.33 | 77 | |

| MAF‐X5 | [Zn(3,5‐dmtz)F] | 3,5‐Hdmtz, F− | 155/195 | 3.6 | 144 | |||||

| MAF‐52 | [Cu7Cl(fmtz)6] | Hfmtz | 1023/848 | 0.365 | 7.2 × 8.2, and 7.4 × 8.3 | 10.6 | 0.81 | 148 | 145 | |

| SCUTC‐18 | [Zn2(1,4‐bdc)2(2,2′‐dmbpy)] | 1,4‐H2bdc, 2,2′‐dmbpy | 523/– | 8.0 | 146 | |||||

| SCUTC‐19 | [Zn2(1,4‐bdc)2(3,3′‐dm‐bpy)] | 1,4‐H2bdc, 3,3′‐dm‐bpy | 458/– | 6.5 | 146 | |||||

| oCB‐MOF‐1, | [Zn4O2(1,4‐bdc)2(oCB‐L)2(DMF)2] | 1,4‐H2bdc, oCB‐L | 296/– | 3.2 × 6.4 | 8.6 | 50 | 0.5 | 140 | 147 | |

| CID‐1 | [Zn2(ip)2(4,4′‐bpy)2] | Hip, 4,4′‐bpy | 300/– | 5 × 6 | 64k) | 0.61 | 148 | |||

| [Cu(bpbtp)(L)(DMF)] | [Cu(bpbtp)(dbbpy‐F18)(DMF)] | H2bpbtp. dbbpy‐F18 | 149 | |||||||

| [Cd(NO2‐bdc)(azbpy)] | [Cd(1,4‐NO2‐bdc)(azbpy)] | 1,4‐H2bdc‐2‐NO2, 4,4′‐azbpy | 149 | 0.32 | 150 | |||||

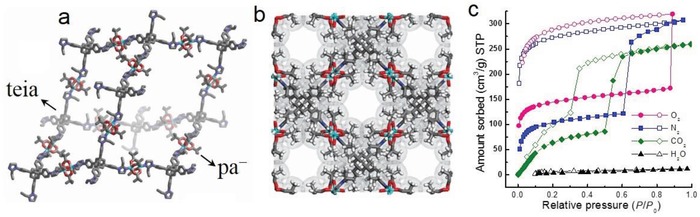

| SNU‐80 | [Cu4(pa)8(teia)] | Hpa, teia | 1035/1167 | 0.43 | 10 | 0.5 | 151 | |||

| [Cu(bpy)2(otf)2]‐3D | [Cu(4,4′‐bpy)2(otf)2] | 4,4′‐bpy, Hotf | 740/– | 0.27 | 152 | |||||

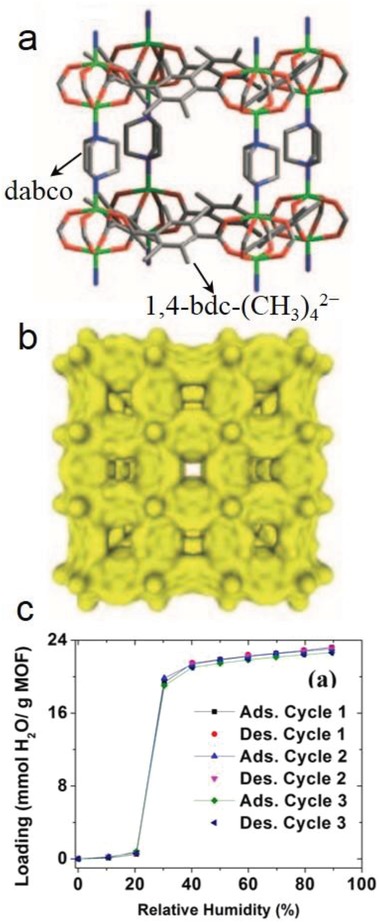

| DMOF‐TM2 | [Zn2(1,4‐bdc‐(CH3)4)2(dabco)] | 1,4‐H2bdc‐(CH3)4, dabco | 1050 | 0.51 | 3.5 | 412 | 0.26 | 153 | ||

| MOFF‐2 | [Cu2(bpdc‐F8)2(dabco)] | H2bpdc‐F8, dabco | 444/– | 11 | 0.53 | 151 | 112 | |||

| DUT‐30(Zn) | [Zn2(adb)2(dabco)] | H2adb, dabco | 960/– | 0.43 | 366 | 0.95 | 154 | |||

| Zn‐dmpc | [Zn4O(dmpc)3] | H2dmpc | 840/– | 0.45 | 4 × 4 | 6 | 437 | 0.83 | 155 | |

| MAF‐X8 | [Zn(mpba)] | H2mpba | 1161/1306 | 0.47 | 6.7–8.8 | 156 | ||||

| MAF‐X10 | [Zn4O(tmbpz)2(1,4‐bdc)] | 1,4‐H2bdc, H2tmbpz | 2032/– | 0.80 | 6.6 × 5.8 | 9.4 × 9.9 × 13.2 | 157, 158 | |||

| MAF‐X12 | [Zn4O(tmbpz)2(1,4‐ndc)] | 1,4‐H2ndc, H2tmbpz | 1787/– | 0.71 | 3.0 × 5.8 | 9.4 × 9.9 × 13.2 | 157 | |||

| MAF‐X13 | [Zn4O(tmbpz)2(bpdc)] | H2bpdc, H2tmbpz | 2742/– | 1.01 | 6.6 × 10.0 | 9.4 × 9.9 × 15.9 | 157 | |||

| CALF‐25 | – | optp | 385/– | 4.6 × 3.9 | 76.9 | 0.73 | 85 | |||

| CALF‐30 | [Cu3(btp‐iPr)2] | H3btp‐iPr | 244/300 | 3.57 | 159 | |||||

| CALF‐33‐Et3 | [Cu3(L1‐Et3)2] | H3L1‐Et3 | 842/1030 | 7.2 × 16.1 | 160 |

1,4‐H2bdc‐2‐NO2, 2‐nitro terephthalic acid; 1,4‐H2bdc‐(C2H5)2, 2,5‐diethylterephthalic acid; 1,4‐H2bdc‐C2F5, 2‐pentafluoroethylterephthalic acid; H2ma, propanedioic acid; 1,4‐H2bdc‐(CF3)2, 2,5‐bis(trifluoromethyl)terephthalic acid; 1,4‐H2bdc‐CH3, 2‐methyl‐terephthalic acid; 1,4‐H2bdc‐(CH3)2, 1,4‐H2bdc‐(CH3)4, 2,3,5,6‐tetramethylterephthalic acid; 2,5‐dimethyl‐terephthalic acid; 1,4‐H2bdc‐CF3, 2‐trifluoromethyl‐terephthalic acid; 1,4‐H2bdc‐F4, 2,3,5,6‐tetrafluoroterephthalic acid; 2,6‐H2ndc, 2,6‐naphthalenedicarboxylic acid; H2bn, 1,1′‐binaphthyl‐4,4′‐dicarboxylic acid; 3‐Hmtz, 3‐methyl‐1,2,4‐triazole; 2‐Hmim, 2‐methylimidazole; 2‐Hmim‐F3, 2‐trifluoromethylimidazole; 2‐Hvim, 2‐vinyl‐imidazole; 2‐Hmimc, 4‐methyl‐5‐imidazolecarboxaldehyde; H2hfipbb, 4,4′‐(hexafluoroisopropylidene)bis(benzoic acid); 1,4‐H2bdp, 1,4‐bis(4‐pyrazolyl)benzene; H2bpdy, 4,4′‐buta‐1,3‐diyne‐1,4‐diylbis(1H‐pyrazole); H2bpeb, 1,4‐bis((1H‐pyrazol‐4‐yl)ethynyl)benzene; H2bpdm, 4,4′‐(2,5‐dimethyl‐1,4‐phenylene)bis(ethyne‐2,1‐diyl)bis(1H‐pyrazole); H2bpdf, 4,4′‐(2,5‐bis(trifluoromethyl)‐1,4‐phenylene)bis(ethyne‐2,1‐diyl)bis(1H‐pyrazole); H3btmb, 1,3,5‐tris(3‐carboxyphenyl)benzene; pbdc, polymeric bdc‐acid; oCB‐L, 1,2‐bis{(pyridin‐3‐yl)methanol}‐1,2‐dicarba‐closo‐dodecarborane, Hip, isophthalic acid; 4,4′‐bpy, 4,4′‐bipyridine; 2,2′‐dm‐bpy, 2,2′‐dimethyl‐4,4′‐bipyridine; 3,3′‐dm‐bpy, 3,3′‐dimethyl‐4,4′‐bipyridine; H2bpdc‐F8, 2,2′,3,3′,5,5′,6,6′‐octafluorobiphenyl‐4,4′‐dicarboxylic acid; H2bptz‐F8, 5,5′‐(perfluorobiphenyl‐4,4′‐diyl)bis(1H‐tetrazole); dabco, 1,4‐diazabicyclo[2.2.2]octane; H2bpbtp, 2,5‐bis(perfluorobutyl)terephthalic acid, dbbpy‐F18, 2,5‐bis(perfluorobutyl)‐1,4‐bis(4‐pyridyl)benzene; 4,4′‐azbpy, 4,4′‐azobipyridine; H3btc, 1,3,5‐benzenetricarboxylic acid; H3mbtc, methyl‐1,3,5‐benzenetricarboxylic acid; H3ebtc, ethyl‐1,3,5‐benzenetricarboxylic acid; H3NH2btc, 2‐aminobenzene‐1,3,5‐tricarboxylic acid; H4tptc‐onhex, 2′,5′‐di‐n‐hexyloxy‐[1,1′:4′,1′‐terphenyl]‐3,3″,5,5″‐tetracarboxylic acid; teia, 1,3,5,7‐tetrakis(4‐(2‐ethyl‐1H‐imidazol‐1‐yl)phenyl)‐adamantane; Hpa, pivalic acid; H2tpda, 4,4′‐(3,5‐bis(trifluoromethyl)phenylazanediyl)dibenzoic acid; H2ope‐C18, 4,4′‐(2,5‐bis(octadecyloxy)‐1,4‐phenylene)bis(ethyne‐2,1‐diyl)dibenzoic acid; H2mpba, 4‐(3,5‐dimethylpyrazol‐4‐yl)benzoic acid; H2glu, glutaric acid; H2abdc‐(CF3)2, 2,2′‐bistrifluoromethyl‐4,4′‐azobenzenedicarboxylic acid; H2tmbpz, 3,3′,5,5′‐tetramethyl‐4,4′‐bipyrazole; H2bpdc, biphenyl‐4,4′‐dicarboxylic acid; 3,5‐Hdmtz, 3,5‐dimethyl‐1,2,4‐triazole; Hfmtz, 3‐methyl‐5‐trifluoromethyl‐1,2,4‐triazole; H2adb, 4,4′‐(anthracene‐9,10‐diyl)dibenzoic acid; H3btp‐iPr, isopropyl benzene‐1,3,5‐triyltris(hydrogen phosphonate); optp, octaethyl pyrene‐1,3,6,8‐tetraphosphonate; H2tmbpd, 3,3′,5,5′‐tetrakis(methylthio)biphenyl‐4,4′‐dicarboxylic acid; H2CH3PhTDC, 3‐methyl‐4‐phenylthieno[2,3‐b]thiophene‐2,5‐dicarboxylic acid; H2tbip, 5‐tert‐butyl isophthalic acid; 3,5‐Hetz, 3,5‐diethyl‐1,2,4‐triazole; H2bbpdc, 4′‐tert‐butyl‐biphenyl‐3,5‐dicarboxylic acid; Hotf, trifluoromethanesulfonic acid; H2dmpc, 3,5‐dimethyl‐1H‐pyrazole‐4‐carboxylic acid; H4pptc, pentiptycene‐based tetracarboxylic acid; 2‐Hnim, 2‐nitroimidazole; Hbim, benzimidazole; 2‐Heim, 2‐ethylimidazole; H2tebpz, 3,3′,5,5′‐tetraethyl‐4,4′‐bipyrazole; 3,5‐Htftz, 3,5‐bis(trifluoromethyl)‐1,2,4‐triazole; 4,5‐Hdcim, 4,5‐dichloroimidazole; 1,3‐H2bdb, 1,3‐di(4‐carboxyphenyl)benzene; 2,7‐H2ndb, 2,7‐di(4‐carboxyphenyl)naphthalene; H3ctta, 5′‐(4‐carboxyphenyl)‐2′,4′,6′‐trimethyl‐[1,1′:3′,1″‐terphenyl]‐4,4″‐dicarboxylic acid; H3ttna, 6,6′,6″‐(2,4,6‐trimethylbenzene‐1,3,5‐triyl)tris(2‐naphthoic acid); H8tdhb, 3,3′,5,5′‐tetrakis(3,5‐dicarboxyphenyl)‐2,2′,4,4′,6,6′‐hexamethylbiphenyl; 2‐Hcim, imidazole‐2‐carboxaldehyde; 5‐Hbbim, 5‐bromobenzimidazol; 5‐Hcbim, 5‐chlorobenzimidazole; 5‐Hmbim, 5‐methylbenzimidazole; Hbtz, 1H‐benzotriazole; RR‐H2cam, (1R,3R)‐1,2,2‐trimethyl‐1,3‐cyclopentanedicarboxylic acid; H2bim, 1,2‐bis((5H‐imidazol‐4‐yl)methylene)hydrazine; 2‐H2bmim, 1,2‐bis((2‐methyl‐1H‐imidazol‐4‐yl)methylene)hydrazine; DIFP, diisopropylfluorophosphate; DES, diethylsulfide; H4tcpp, tetrakis(4‐carboxyphenyl)porphyrin

S BET and S L stand for the BET and Langmuir surface areas, respectively

V p stands for the pore volume

d a stands for the size of the aperture or channel

d p stands for the size of the cavity

stands for the water adsorption capacity near saturation pressure and room temperature unless otherwise specified

α stands for the relative pressure at which half of the water adsorption capacity at saturation pressure is reached; and α are obtained by reference values or by scanning the reported adsorption isotherm with the software ScanIt

CA stands for the water contact angle

Qualitative data were not provided

at 0.7 P/P 0

k) at 0.63 P/P 0.

3.1. Presynthetic Ligand Design and Functionalization

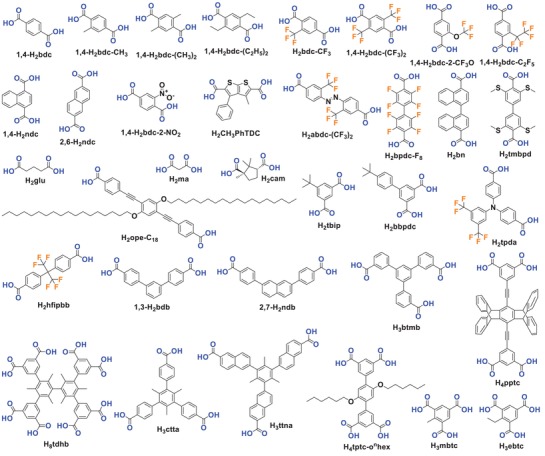

3.1.1. Carboxylic Acids

The carboxylic acid ligands used for constructing reported hydrophobic MOFs are summarized in Scheme 1. The ligand 1,4‐benzenedicarboxylic acid (1,4‐H2bdc), a representative ditopic carboxylic acid ligand, is one of the most frequently used ligands for the construction of MOFs. Many MOFs, including the well‐known [Zn4O(1,4‐bdc)3] (MOF‐5), [M(OH)(1,4‐bdc)] (MIL‐53, M = Cr, Al, Fe), MIL‐101(Cr), [Zr6O4(OH)4(1,4‐bdc)6] (UiO‐66), [ZrO(1,4‐bdc)] (MIL‐140A), and [In(OH)(1,4‐bdc)] (MIL‐68(In)), are synthesized from this ligand. Although built from the same ligand, these MOFs show quite different degrees of hydrophobicity. MOF‐5 and MIL‐53 are commonly regarded as hydrophilic MOFs, according to the sensitivity of MOF‐5 to water161 and the water adsorption isotherm of MIL‐53.103 From their water adsorption isotherms,102, 104, 162 which all show relatively gradual increasing uptakes at low‐P/P 0 ranges, MIL‐101(Cr) and UiO‐66 are regarded to be slightly hydrophobic, regardless of the presence of some hydrophilic sites (OH− or F−) on their inorganic secondary building units (SBUs). Similar to UiO‐66, MIL‐140A is synthesized by the solvothermal reaction of ZrCl4 with 1,4‐H2bdc, except that the reaction temperature is higher. Surprisingly, the structure of MIL‐140A has been found to be very different from that of UiO‐66. There are less hydrogen‐bond acceptor or donor sites on the pore surface of MIL‐140A, and it is thus regarded as a hydrophobic MOF.71 This conclusion is supported by the water adsorption isotherms, where the uptakes nearly linearly increase with the increasing of P/P 0. In contrast, the pores of UiO‐66 are almost fully occupied by water at 0.5 P/P 0 according to its water adsorption isotherm.104, 162 A typical type V water adsorption isotherm at room temperature has been observed for MIL‐68(In).103 Almost no water is adsorbed below 0.55 P/P 0, at which pore filling starts to occur. This type of water adsorption isotherm is commonly found for hydrophobic carbon‐based adsorbents.

Scheme 1.

Carboxylic acid ligands used for constructing hydrophobic MOFs.

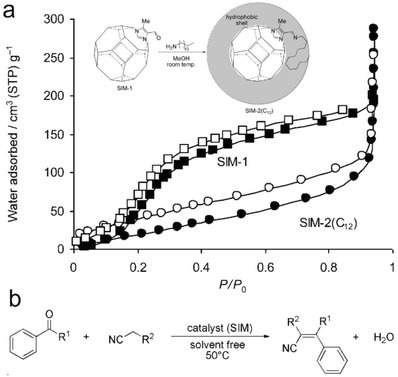

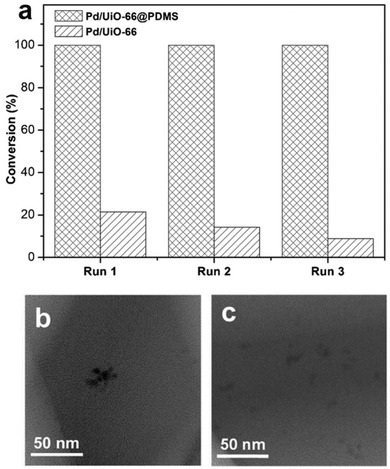

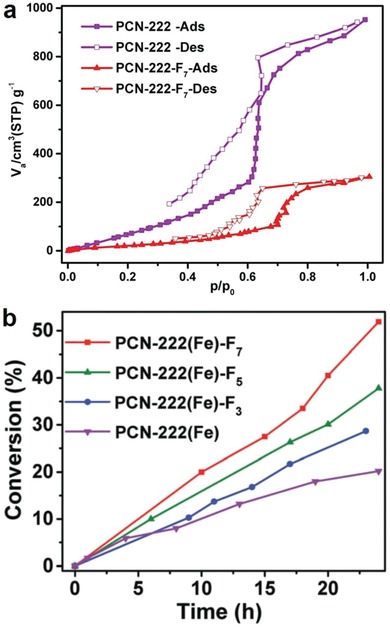

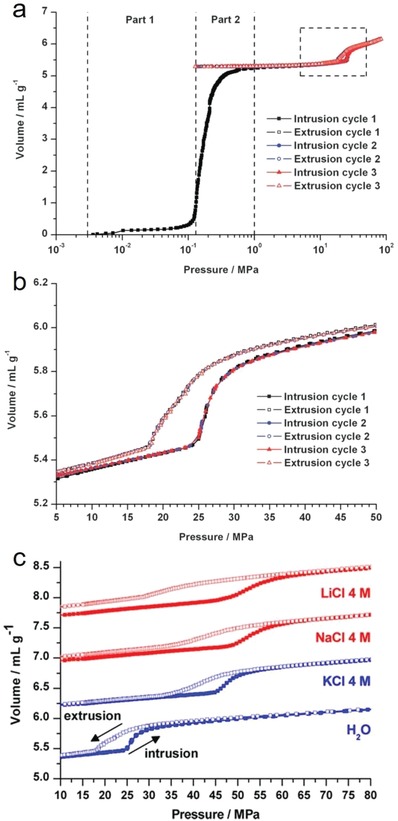

Many 1,4‐H2bdc‐derived ligands with one or more hydrophobic substituents have been used to construct MOFs.163, 164, 165, 166, 167 Wu et al. reported a MOF‐5 analogue, Banasorb‐22, built from the ligand 2‐trifluoromethoxy terephthalic acid (1,4‐H2bdc‐2‐CF3O).72 It was expected that the introduction of the strongly water‐repelling trifluoromethoxy groups (CF3O—) into the MOF would enhance its stability toward water. After MOF‐5 was treated by the steam of boiling water for several minutes, its BET surface area decreased from 2365 to 50 m2 g−1; however, the BET surface area of Banasorb‐22 only decreased from 1113 to 210 m2 g−1 after one week under the same treatment conditions.

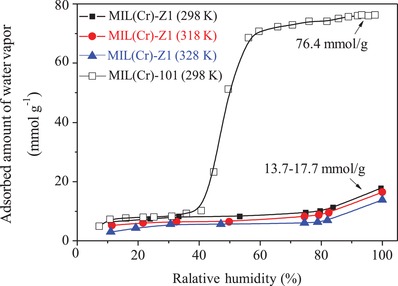

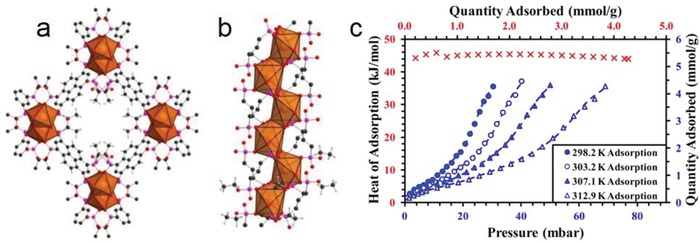

Akiyama et al. investigated the water sorption properties of MIL‐101(Cr) and three analogues, MIL‐101‐NO2, MIL‐101‐NH2, and MIL‐101‐SO3H, obtained by —NO2, —NH2, and —SO3H substituted 1,4‐H2bdc ligands.102 In the water adsorption isotherm of MIL‐101(Cr), the uptake gradually increases at low pressures below 0.4 P/P 0 and abruptly increases from 0.4 to 0.6 P/P 0 in two steps, which were assigned to the pore filling of its 29 and 34 Å cages, respectively. The water uptake of MIL‐101(Cr) at 0.6 P/P 0 reached up to 1200 mg g−1. The water adsorption isotherm profiles of MIL‐101‐NO2, MIL‐101‐NH2, and MIL‐101‐SO3H are similar to that of MIL‐101(Cr). However, the pore filling pressures of MIL‐101‐NH2 and MIL‐101‐SO3H shifted to lower P/P 0, and the uptakes of MIL‐101‐NO2 were lower than those of MIL‐101(Cr) in the whole range of pressures tested. The isosteric heats of water adsorption for the four tested MOFs were in the order of MIL‐101‐NO2 < MIL‐101(Cr) < MIL‐101‐NH2 ≈ MIL‐101‐SO3H, suggesting that the hydrophobicity (hydrophilicity) of MIL‐101(Cr) could be tuned by introducing —NO2 (—NH2, —SO3H) groups onto its pore surface (although its pore size and surface area were reduced). Zhu et al. reported a MIL‐101(Cr) analog, [Cr3O(H2O)2F(1,4‐ndc)3] (MIL(Cr)‐Z1), obtained by using the ligand 1,4‐naphthalenedicarboxylic acid (1,4‐H2ndc).105 The water adsorption isotherm of MIL(Cr)‐Z1 showed an uptake of 17.7 mmol g−1 (318.6 mg g−1) at 0.99 P/P 0 and 298 K (Figure 5), substantially lower than that of MIL‐101(Cr) (76.4 mmol g−1, 1375 mg g−1) under similar conditions,76 indicating that the framework hydrophobicity was significantly improved by replacing the ligand 1,4‐bdc2− with 1,4‐ndc2−.

Figure 5.

Water adsorption isotherms for MIL(Cr)‐Z1 and MIL(Cr)‐101. Adapted with permission.105 Copyright 2017 Elsevier.

Cmarik et al. investigated the water adsorption properties of UiO‐66 and four analogues, UiO‐66−NH2, UiO‐66−2,5‐(OMe)2, UiO‐66−NO2, and UiO‐66−1,4‐Naphyl, which were obtained from 1,4‐H2bdc ligands substituted with —NH2, —OMe, —NO2, and naphthyl (—Naphyl) groups, respectively.104 Compared to that of UiO‐66, the water adsorption isotherms of for UiO‐66—NH2, UiO‐66—2,5‐(OMe)2, and UiO‐66—NO2 showed similar uptakes at 0.9 P/P 0, and increased uptakes below 0.3 P/P 0, indicating that the introduction of —NH2, —OMe, —NO2 groups enhanced the affinity between the MOFs and water. The water uptakes of UiO‐66—1,4‐Naphyl were significantly lower than those of UiO‐66−NH2, UiO‐66—2,5‐(OMe)2, and UiO‐66—NO2 at all pressures, but slightly higher than those of UiO‐66 only at pressures below 0.2 P/P 0. This observation was explained by the pore size of UiO‐66−1,4‐Naphyl being reduced compared to that of UiO‐66, which increased the adsorption potential; however, full pore filling was depressed at higher P/P 0 due to the introduction of hydrophobic naphthyl groups. UiO‐66−1,4‐Naphyl was thus regarded as a promising adsorbent for gas separations under humid conditions. Yu et al. studied the water adsorption properties of 6 UiO‐66 analogues, UiO‐66D‐(CF3)2, UiO‐66‐(C2H5)2, UiO‐66‐C2F5, UiO‐66‐(CF3)2, UiO‐66‐CH3, UiO‐66‐(CH3)2, and UiO‐66‐CF3, obtained by alkyl‐ and perfluoroalkyl‐functionalized 1,4‐H2bdc ligands.87 The authors also showed that the water adsorption behaviors were affected by both the hydrophobicity of the functional group and the effect of pore reduction.

As extended versions of 1,4‐H2bdc, some long, linear dicarboxylic acid ligands have been used to construct hydrophobic MOFs, such as H2tmbpd,109 H2abdc‐(CF3)2,87 H2ope‐C18,110 H2CH3PhTDC,111 and H2bpdc‐F8.112 Many angular dicarboxylic acid ligands have also been reported for use in hydrophobic MOFs.88, 113, 114, 115, 116, 117, 118, 119, 120 As early as 2004, Pan et al. reported a Cu2 paddle‐wheel SBU based MOF, [Cu(hfipbb)(H2hfipbb)0.5], with the angular ligand H2hfipbb.116, 117 In this MOF, there are irregular‐shaped small hydrophobic channels with alternating large chambers (7.3 Å) and small necks (3.2 Å) between the chambers. It was demonstrated that [Cu(hfipbb)(H2hfipbb)0.5] favored the adsorption of propane and butane but not pentane or other higher normal and branched hydrocarbons. The same research group also reported a hydrophobic MOF, Zn(tbip), by the angular ligand H2tbip.113 The 1D channels of Zn(tbip) are lined with butyl groups at a size of 4.5 Å, accounting for 17.7% of the crystal volume. The material's hydrophobicity was confirmed by water adsorption, which showed a very low uptake (less than 1 mg g−1) at 0.65 P/P 0 and 298 K, lower than that for pure silica ZSM‐5 (7 mg g−1) under similar conditions.

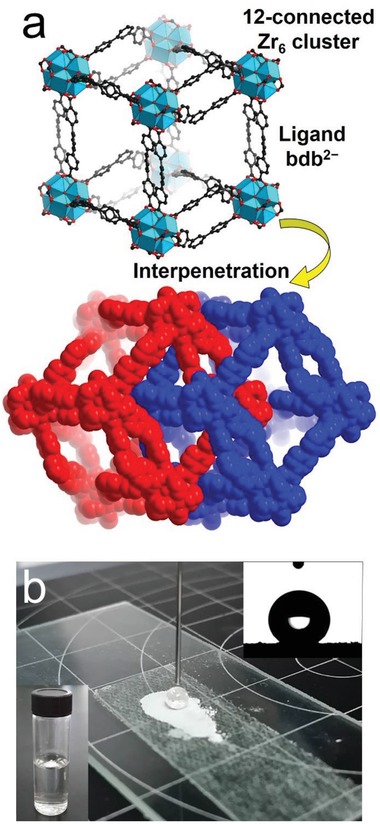

Xie et al. recently reported two zirconium‐based MOFs, [Zr6O4(OH)4(1,3‐bdb)6] (BUT‐66) and [Zr6O4(OH)4(2,7‐ndb)6] (BUT‐67), by using the angular dicarboxylic acid ligands 1,3‐H2bdb and 2,7‐H2ndb, respectively.88 The MOFs contain 1D channels with a size of 6–7 Å, the wall of which is predominately made of the aromatic rings of ligands. The water adsorption studies at 298 K for BUT‐66 and BUT‐67 showed uptakes of 5.7 mmol g−1 (103 mg g−1) and 6.9 mmol g−1 (124 mg g−1) at 0.95 P/P 0, lower than the predicted water uptakes (420 and 380 mg g−1) assuming that their pore volumes (determined from N2 adsorption at 77 K) are fully filled with crystallized water (density: 0.9168 g cm−3). The MOFs were thus regarded as adsorbents with moderately hydrophobic channels. The authors proposed that a 2‐fold network interpenetration of their structures contributed to the hydrophobicity of the channel surfaces of the MOFs (Figure 6a), where some hydrophilic surfaces in one network were covered by the hydrophobic phenyl groups of ligands in the other network. In addition, it was found that BUT‐66 and BUT‐67 could float on the surface of water, although their densities calculated from single‐crystal structures were higher than the density of water (1 g cm−3), suggesting a high hydrophobicity of the external crystal surface of the MOFs. The external hydrophobicity was verified by water contact angle measurements, which gave 143° and 138° water contact angles (Figure 6b).

Figure 6.

a) Twofold network interpenetration in the structure of BUT‐66. b) An optical photo of a water drop on BUT‐66 powder; inset: the water contact angle of BUT‐66 (upper right) and a photo of BUT‐66 crystals floating on the surface of water (bottom left). Adapted with permission.88 Copyright 2018 Elsevier.

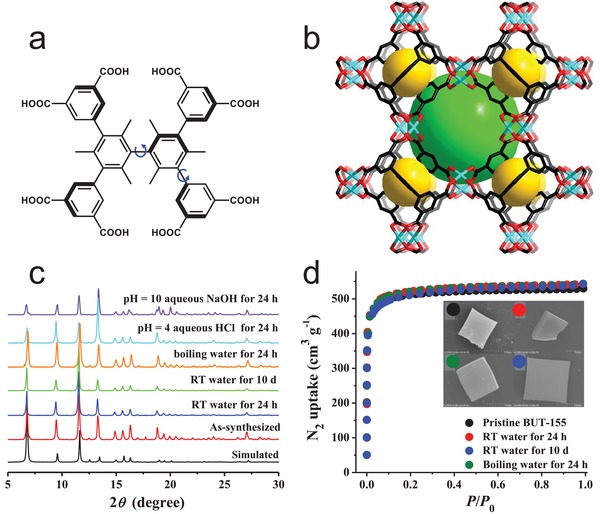

MOFs synthesized from some tritopic, tetratopic, and octatopic carboxylic acid ligands have also shown characteristics of hydrophobicity.121, 122, 123, 125, 126, 127, 128 Cai et al. reported two Cu2 paddle‐wheel SBU based MOFs, [Cu3(mbtc)2] (CuMBTC) and [Cu3(ebtc)2] (CuEBTC), which were obtained from methyl‐ and ethyl‐ group‐functionalized H3btc ligands, H3mbtc and H3ebtc, respectively.121 The assembly of H3btc and Cu2 paddle‐wheel SBUs produces the well‐studied MOF [Cu3(btc)2] (HKUST‐1, also called CuBTC or MOF‐199). However, due to the steric impact of the alkyl groups, the carboxyl groups in H3mbtc and H3ebtc are not coplanar. As a result, both CuMBTC and CuEBTC are not isostructural to HKUST‐1 but still highly porous. Although the difference in pore volumes for the three MOFs (0.83, 0.79, and 0.65 cm3 g−1 for HKUST‐1, CuMBTC, and CuEBTC, respectively) is not significant, the water adsorption isotherms show an uptake of 184 mg g−1 for both CuMBTC and CuEBTC at 0.9 P/P 0 and 298 K, considerably lower than that of HKUST‐1 (587 mg g−1) under the same conditions. It was pointed out that hydrophobic functional groups on pore surface could depress the strong adsorption preference of water for the MOFs, even there were open metal sites (coordinatively unsaturated metal sites). However, similar to HKUST‐1, CuMBTC and CuEBTC still degraded after exposure to water, according to powder X‐ray diffraction (PXRD) patterns. Recently, Chen et al. reported a Cu2 paddle‐wheel SBU based MOF, [Cu4(tdhb)] (BUT‐155), which was synthesized by an octatopic carboxylic acid ligand, H8tdhb.128 There exist six methyl groups, compelling the ligand to adopt a rigid tetrahedral backbone geometry (Figure 7a,b). Surprisingly, BUT‐155 showed a high porosity (BET surface area: 2070 m2 g−1 and pore volume: 0.82 cm3 g−1), as well as exceptional stability against water (even boiling water), which was verified by PXRD patterns, N2 adsorption studies, scanning electron microscopy (SEM) images and single‐crystal X‐ray diffraction (SXRD) studies for the BUT‐155 crystals after treatment in water for 10 days at room temperature or in boiling water for 24 h (Figure 7c,d). The authors proposed that a combined effect of the high connectivity and constrained geometry of the ligand, the hydrophobicity of the pore surface, and the electron donation contribution of the six methyl substituents of the ligand to Cu—O coordination bonds led to the unexpectedly high hydrolytic stability of BUT‐155, although copper(II) paddlewheel‐based MOFs were commonly considered to be intrinsically unstable in water.

Figure 7.

a) Molecular structure of the octatopic carboxylic acid ligand H8tdhb. b) The framework structure of BUT‐155 built from Cu2 paddle‐wheel SBUs and tdhb4−. c) PXRD patterns, d) N2 adsorption isotherms recorded at 77 K, and SEM images (d, inset) for BUT‐155 samples after being treated under different conditions. Adapted with permission.128 Copyright 2017 American Chemical Society.

Zhang et al. also reported a hydrophobic and water stable copper(II) paddlewheel‐based MOF, [Cu2(pptc)] (UPC‐21), obtained by a pentiptycene‐based tetratopic carboxylic acid ligand, H4pptc.126, 127 Due to the high hydrophobicity of the pentiptycene moieties in the ligands, UPC‐21 showed a high water contact angle (145°), and it could float on the surface of water for a long time without the collapse of its crystalline structure. However, the water adsorption isotherm for UPC‐21 was not reported. UPC‐21 was also highly porous (BET surface area: 1725 m2 g−1) when it was prepared by a so‐called “diauxic growth” method, whereby large pure crystals of UPC‐21 were formed in a filtrate after the reaction mixture was first reacted in an oven at 75 °C for 25 h, and the resultant small crystals were filtered off.

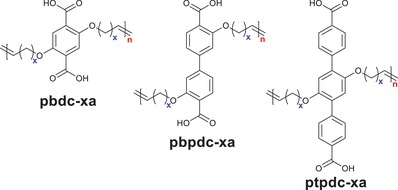

Commonly, MOFs are prepared by small molecular ligands. Recently, Cohen and co‐workers demonstrated that certain linear organic polymers with aromatic dicarboxylic acids in their backbones could be used as ligands to synthesize highly crystalline and porous MOFs, called polyMOFs.129, 168, 169, 170 A series of polymer ligands were synthesized (Figure 8) and used to prepare polyMOFs with crystalline structures isostructural to MOF‐5, [Zn2(bdc)2(dabco)], [Zn2(bdc)2(4,4′‐bpy)], UiO‐66, UiO‐67, and UiO‐68, respectively. The polyMOFs showed a permanent porosity, as their parent MOF structures do, and some of these polyMOFs inherited the hydrophobicity of their polymer ligands. Moreover, compared to the parent MOFs, the polyMOFs exhibited an enhanced stability against water. For example, Zn‐pbdc‐8a showed a BET surface area of 856 m2 g−1 and a water contact angle of 112°. After being exposed in open air for 3 days, Zn‐pbdc‐8a retained its crystalline structure. In contrast, MOF‐5 degraded into another phase (MOF‐69c)161 after exposure in air for 1 day.

Figure 8.

Polymer ligands used to prepare polyMOFs. The “x” in the names of the polymer ligands represents the number of methylene spacers between each H2bdc, H2bpdc or H2tpdc unit, while “a” denotes the acid form of the polymer ligands.129

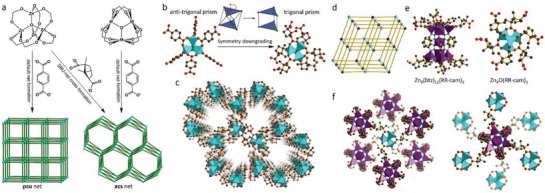

Polytopic carboxylic acids used for the construction of hydrophobic MOFs are mostly ligands with aromatic backbones, and examples constructed from aliphatic carboxylic acid ligands are rare. As early as 2003, Vaidhyanathan et al. reported a cadmium malonate [Cd(O2C‐CH2‐CO2)(H2O)] and a manganese glutarate [Mn(O2C‐(CH2)3‐CO2)], both possessing 1D hydrophobic channels with sizes of 6.95 and 6.64 Å, respectively. However, neither gas nor water vapor adsorption study was performed to confirm their permanent porosity and hydrophobicity. Recently, Zhao et al. reported two hydrophobic MOFs, [Zn4O(RR‐cam)3] (CPM‐300) and [Zn4O(RRcam)3][Zn9(btz)12(RR‐cam)3] (CPM‐301), synthesized from a pentane‐ring‐based chiral dicarboxylic acid, RR‐H2cam.101 CPM‐300 was a 6‐connected framework with the acs topology constructed by 6‐connected [Zn4O]6+ clusters and RR‐cam2− ligands, and CPM‐301 was a binodal 6‐connected framework with the pcu topology constructed by 6‐connected [Zn4O]6+ and 6‐connected [Zn9(btz)12]6+ (with btz− serving as terminal ligands) clusters bridged by RR‐cam2− ligands (Figure 9). The N2 sorption study at 77 K revealed a moderate porosity for CPM‐300 with a BET surface area of 310.5 m2 g−1 and a Langmuir surface area of 429.9 m2 g−1. The hydrophobic natures of CPM‐300 and CPM‐301 were confirmed by water contact angle measurements, which gave contact angles of 138.7° and 145.0° for compressed pellets of the MOFs, respectively. In contrast, an initial contact angle of ≈17.0° was observed for MOF‐5, and the water droplet completely wet the MOF‐5 sample in less than 10 s. The water contact angle was also recorded for the ligand RR‐H2cam, which showed a high initial contact angle (114.5°), but the water droplet gradually wet the ligand sample within 1 min. Noteworthily, the [Zn4O]6+ cluster is well‐known for its poor stability toward water in MOF‐5; however, CPM‐300 and CPM‐301, built from the same cluster, show high stabilities, even in boiling water for 1–2 days. The authors proposed that small methyl groups on the chiral ligand RR‐cam2− shielded the [Zn4O]6+ clusters from degradation by water, even at high temperatures.

Figure 9.

a) SBU‐net cross formation in CPM‐300. b) A comparison of the Zn4O(CO2)6 SBU in MOF‐5 and that in CPM‐300 showing a symmetry reduction from antitrigonal prism (octahedron) to trigonal prism, when the geometry of the ligands is taken into account. c) A perspective view of CPM‐300, showing the chiral hexagonal channels along the c axis. d) In CPM‐301, by introducing the [Zn9(btz)12]6+ cluster, the 6‐connected [Zn9(btz)12]6+ and [Zn4O]6+ clusters are arranged alternatingly to form a pcu net of CPM‐301. e) The [Zn9(btz)12]6+ and [Zn4O]6+ clusters in CPM‐301. f) The connection between the [Zn4O]6+ and [Zn9(btz)12]6+ clusters. Adapted with permission.101 Copyright 2018, American Chemical Society.

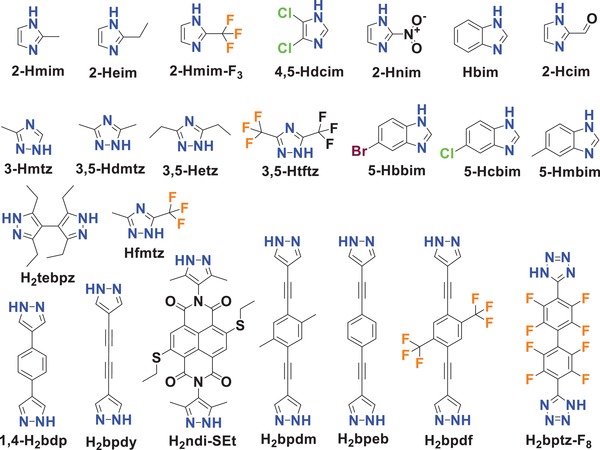

3.1.2. Azoles

Azole ligands, mostly imidazoles, polypyrazoles, triazoles, and tetrazoles, have been extensively used for the construction of MOFs,15, 171, 172 some of which are shown in Scheme 2. Many metal azolates are extremely hydrophobic with a high porosity. A representative example is ZIF‐8, also called MAF‐4,173, 174 which is also one of the most well‐known MOFs. ZIF‐8, a 3D zinc 2‐methylimidazolate with the SOD zeolitic topology, shows both a high porosity (BET surface area: 1870 m2 g−1 and pore volume: 0.67 cm3 g−1)77 and high stability under nonacidic conditions.174, 175, 176 Moreover, ZIF‐8 is highly hydrophobic, which was confirmed by water adsorption studies. Kaskel et al. first reported the water adsorption isotherm for ZIF‐8 at 25 °C, which showed a very low uptake of 10 cm3 g−1 (8 mg g−1) at P/P 0 = 0.8, and a final steep increase to 150 cm3 g−1 (121 mg g−1) at P/P 0 = 0.97.76 Several other works have also reported water adsorption isotherms for ZIF‐8. The water adsorption isotherm for ZIF‐8 at 25 °C reported by Zhang et al. showed a very low water uptake at P/P 0 < 0.9 and an uptake of 32 cm3 g−1 (26 mg g−1) at P/P 0 = 0.99.77 Chance and coworkers reported the water adsorption isotherm for ZIF‐8 at 35 °C, which indicated a low uptake of 10 mg g−1 at P/P 0 = 0.98.79 These results all demonstrated the high hydrophobicity of the internal pore surface of ZIF‐8, although, there were some differences among the water vapor adsorption isotherms, which should originate from the differences in those ZIF‐8 samples obtained by distinct synthesis and/or activation methods. However, it should be mentioned that most ZIF‐8 samples reported in the literature have hydrophilic exterior crystal surfaces, as indicated by their water contact angles (0°–56°).78, 176, 177

Scheme 2.

Azole acid ligands used for constructing hydrophobic MOFs.

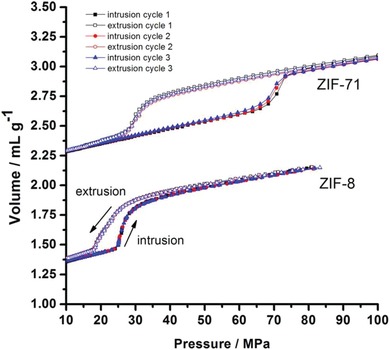

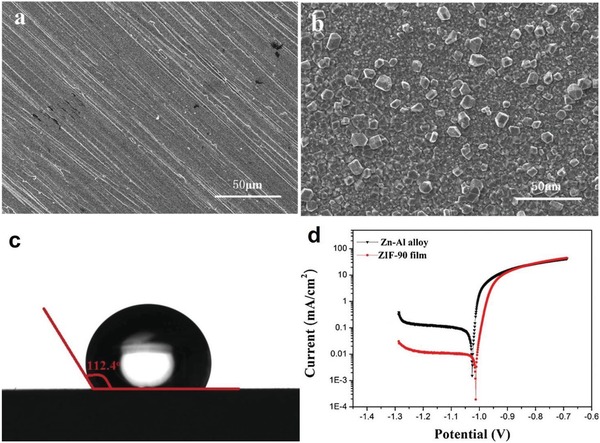

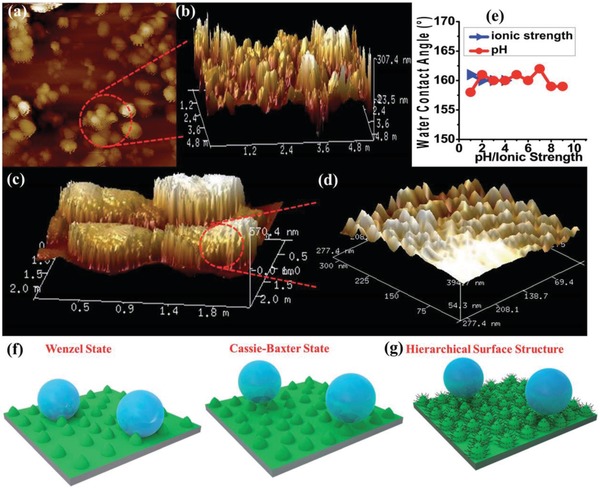

Some other reported metal imidazolates have also been proven highly hydrophobic. Lively et al. found that ZIF‐71 (RHO topology, formulated as [Zn(4,5‐dcim)2]) synthesized in methanol at room temperature shows a high porosity and high hydrophobicity.136 The BET surface area of the ZIF‐71 sample was 1186.5 m2 g−1, evidently higher than that of the ZIF‐71 sample synthesized from DMF by a solvothermal reaction (652 m2 g−1).135 The water adsorption isotherm of ZIF‐71 revealed a very low uptake of 0.3 mmol g−1 (5.4 mg g−1) at P/P 0 = 0.95 and 35 °C. Later, the same team reported the water adsorption isotherms of ZIF‐8, ZIF‐71, and ZIF‐90 (formulated as [Zn(2‐cim)2]).79 Type III isotherms with low water uptakes, even at near saturation pressure, were observed for ZIF‐8 and ZIF‐71. At high P/P 0, the water uptakes of ZIF‐8 were slightly higher than those of ZIF‐71, indicating the stronger affinity toward water of the former. This result is not surprising because the cages in ZIF‐71 (16.5 Å) are larger than those in ZIF‐8 (11.6 Å). The water adsorption isotherm of ZIF‐90 showed low uptakes below 0.3 P/P 0 and pore filling at higher pressures, with an uptake of 18.6 mmol g−1 (335 mg g−1) at P/P 0 = 0.98. The authors suggested that ZIF‐90 was less hydrophobic than ZIF‐8 and ZIF‐71 due to the existence of the more‐hydrophilic carbonyl group in the ligands of ZIF‐90, which was also a SOD‐type zeolitic framework like ZIF‐8.

He et al. reported a zinc 2‐ethylimidazolate with the RHO zeolitic topology, MAF‐6, showing a large surface area (Langmuir surface area: 1695 m2 g−1), high pore volume (0.61 cm3 g−1), large pore (d = 18.4 Å), and aperture size (d = 7.6 Å), and highly hydrophobic internal pore and external crystal surfaces.78 The water uptake of MAF‐6 at P/P 0 = 0.97 and 298 K was only 0.90 mmol g−1 (16.2 mg g−1). It was also found that powder samples of MAF‐6 could float on the water surface. The MOF's hydrophobic external crystal surface was confirmed by water contact angle measurement, which showed a large contact angle of 143°. Surprisingly, MAF‐5,139 an isomer of MAF‐6 with the ANA zeolitic topology, showed a highly hydrophilic external crystal surface with a contact angle of 0°.

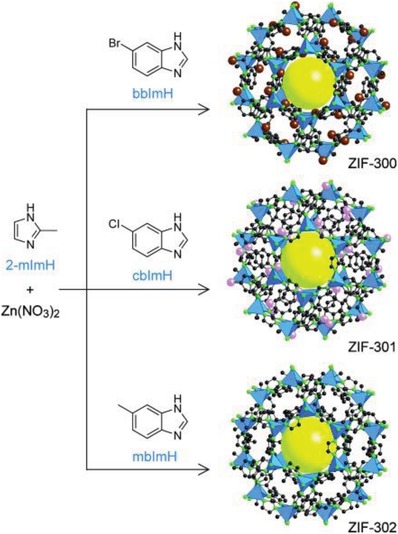

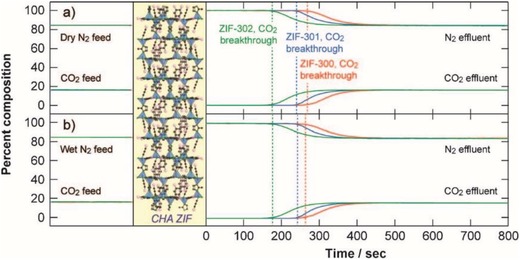

Nguyen et al. reported three hydrophobic zinc imidazolates, [Zn(2‐mim)0.86(5‐bbim)1.14] (ZIF‐300), [Zn(2‐mim)0.94(5‐cbim)1.06] (ZIF‐301), and [Zn(2‐mim)0.67(5‐mbim)1.33] (ZIF‐302), acquired by using two distinct imidazole ligands for each (2‐Hmim/5‐Hbbim, 2‐Hmim/5‐Hcbim, and 2‐Hmim/5‐Hmbim), which are 3D framework structures with the chabazite (CHA) zeolite topology (Figure 10).138 Ar gas‐adsorption measurements at 87 K showed the moderate porosities of the three ZIFs with BET surface areas of 420, 680, and 240 m2 g−1. PXRD patterns confirmed the high stability of ZIF‐300, ZIF‐301, and ZIF‐302 in boiling water for 7 days. Water adsorption measurements at 298 K were carried out and gave type III isotherms for all three ZIFs with low uptakes (6, 5.8, and 4.5 mg g−1) at P/P 0 ≈ 0.8.

Figure 10.

The ligands and crystal structures for ZIF‐300, ZIF‐301 and ZIF‐302. Adapted with permission.138 Copyright 2014, John Wiley and Sons.

Some highly hydrophobic MOFs have been prepared from 3‐substituted or 3,5‐substituted 1,2,4‐triazoles. In 2008, Zhang and Chen reported a cuprous 3,5‐diethyl‐1,2,4‐triazolate, [Cu(3,5‐etz)] (MAF‐2), having a 3D framework with the nbo topology and so‐called “kinetically controlled” hydrophobic channels.143 The large cages in MAF‐2 are interconnected by small windows defined by six pendant ethyl groups (Figure 11a). Those windows are blocked by the ethyl groups below a critical or onset adsorption temperature and are tuned to be open at higher temperatures (Figure 11b–e). The water adsorption isotherm of MAF‐2 at 298 K showed a very low uptake (3 mg g−1) at P/P 0 = 0.97, which was attributed to particle surface adsorption on uncoordinated defects. Although the pores in MAF‐2 were closed for water, they could adsorb large amounts of small organic molecules such as MeOH, EtOH, and MeCN. It was also found that MAF‐2 could adsorb benzene, but cyclohexane could not diffuse into its “kinetically controlled” pores. The authors recently reported a partially fluorinated Cu triazolate, MAF‐52, containing the ligand Hfmtz.145 MAF‐52 is a 5‐connected 3D framework (bnn topology) consisting of Cu5(µ5‐Cl) clusters interconnected by fmtz− ligands. It was demonstrated that MAF‐52 was porous (Langmuir surface area: 1023 m2 g−1, and pore volume: 0.365 cm3 g−1), highly chemically stable (tolerant to water and aqueous solutions with pH ranging 2–13), and highly hydrophobic, as suggested by its water contact angle (148°) and low water uptake (0.8 mg g−1) at P/P 0 = 0.95 and 25 °C. The same group also reported a zinc 3‐methyl‐1,2,4‐triazolate, [Zn(3‐mtz)2] (MAF‐7), which was an SOD‐type zeolitic framework structure similar to MAF‐4/ZIF‐8 but with one uncoordinated triazolate N on the pore surface. The authors determined that MAF‐7 was also stable in water, similar to MAF‐4/ZIF‐8, and the N2 adsorption measurements showed the close porosity of MAF‐7 to that of MAF‐4/ZIF‐8 (Langmuir surface area: 1870 m2 g−1, and pore volume: 0.67 cm3 g−1). The water adsorption isotherm of MAF‐7 was a type V isotherm, where low uptakes (<20 mg g−1) observed at P/P 0 < 0.24 were followed by pore filling at higher P/P 0 (with an uptake of 380 mg g−1 reached at P/P 0 = 0.98). Clearly, MAF‐7 is more hydrophilic than MAF‐4 due to the presence of uncoordinated triazolate N atoms on its pore surface.

Figure 11.

a) The framework of MAF‐2 with large cages (large yellow spheres) interconnected by small windows (green columns). The window size is kinetically controlled by the rotation/swing motions of the pendant ethyl groups. b−e) A perspective view of four representative channel states: double closed, double open, closed‐open, and open‐closed (the ethyl groups are colored in red and green to highlight the two different gates). Adapted with permission.143 Copyright 2008, American Chemical Society.

Yang et al. reported a highly hydrophobic Ag(I)‐based MOF named FMOF‐1 (formulated as {Ag2[Ag4(3,5‐tftz)6]}) obtained by the perfluorinated ligand 3,5‐Htftz.80, 130 The fluorous MOF has a 3D framework consisting of 6‐connected tetranuclear [Ag4(3,5‐tftz)6] clusters linked by 3‐coordinated Ag(I) centers with cylindrical channels in a semirectangular shape (≈12.2 Å × 7.3 Å) and diamond‐shaped small cavities (≈6.6 Å × 4.9 Å). The hydrophobic —CF3 groups of the perfluorinated ligand 3,5‐tftz− are pointed into the channels. The N2 adsorption study revealed a BET surface area of 810.5 m2 g−1 and a pore volume of 0.324 cm3 g−1 for FMOF‐1. The high hydrophobicity of FMOF‐1 was confirmed by a water adsorption study, which showed a negligible uptake at P/P 0 = 0.9, regardless of its large channel size. The negligible water adsorption of FMOF‐1 was further confirmed by the single‐crystal X‐ray diffraction analysis of a water‐soaked single crystal of FMOF‐1, which showed a unit cell volume (6999 Å3) comparable to that of a guest‐free FMOF‐1 crystal (7063.0 Å3). The authors also confirmed the absence of water in the channels of FMOF‐1 by IR measurement, which showed no O–H stretches from H2O molecules for a water‐treated sample, as observed for the guest‐free FMOF‐1 sample. Moreover, the authors found that FMOF‐1 possessed a superhydrophobic external surface, as indicated by the high water contact angle up to 158° of a pellet sample of FMOF‐1.131

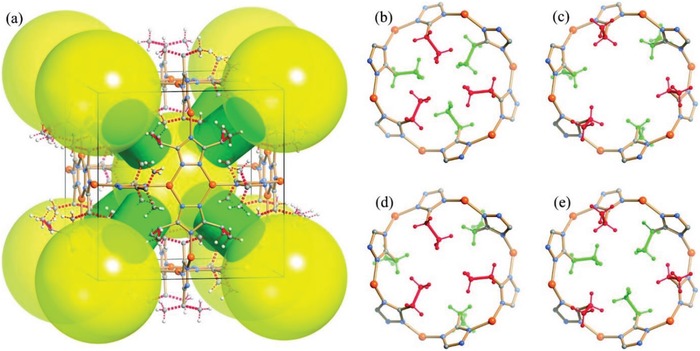

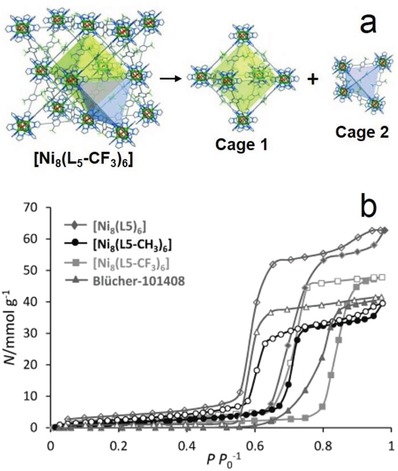

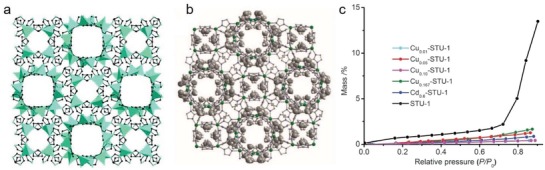

Padial et al. reported a series of MOFs named as [Ni8(L)6] (L stands for ligand) obtained by using the bipyrazole ligands 1,4‐H2bdp (L3 in the reference), H2bpdy (L4), H2bpeb (L5), H2bpdm (L5‐CH3), and H2bpdf (L5‐CF3).140 [Ni8(L)6] are isoreticular 12‐connected frameworks of the fcu topology with [Ni8(OH)4(H2O)2] as 12‐connected SBUs, which are bridged by the bipyrazole ligands (Figure 12a). The framework structures of the [Ni8(L)6] series are analogous to the well‐known UiO series with 12‐connected [Zr6O4(OH)4] SBUs.178 The [Ni8(L)6] series exhibited high porosities (BET surface areas: 205–2215 m2 g−1) and high stabilities in water and basic media at room temperature for 24 h. In contrast, two isoreticular MOFs, [Ni8(L1)6] and [Ni8(L2)6], synthesized from mixed pyrazolate/carboxylate linkers (H2L1 = 1H‐pyrazole‐4‐carboxylic acid, and H2L2 = 4‐(1H‐pyrazole‐4‐yl)benzoic acid) were not stable to moisture. Type V water adsorption isotherms were observed for [Ni8(L3)6], [Ni8(L4)6], [Ni8(L5)6], [Ni8(L5‐CH3)6], and [Ni8(L5‐CF3)6], with partial pressures corresponding to the beginning of water vapor condensation in the range of 0.30 to 0.80 P/P 0 (Figure 12b). Especially, [Ni8(L5‐CF3)6], containing fluorinated methyl groups, was considered to be more hydrophobic than prototypical mesoporous MOFs such as MIL‐100(Fe) and MIL‐101(Cr) and even the highly hydrophobic, commercially available, activated carbon Blücher‐101408, which was employed in the state‐of‐the‐art Saratoga filtering systems.

Figure 12.

a) The 3D framework of [Ni8(L5‐CF3)6] with two types of cages: octahedral (yellow polyhedron) and tetrahedral (gray polyhedron) cages. b) H2O adsorption isotherms at 298 K for the isoreticular [Ni8(L5‐R)6] series and the activated carbon Blücher‐101408. Solid symbols denote adsorption, and open symbols denote desorption. Adapted with permission.140 Copyright 2013, John Wiley and Sons.

Wang et al. also reported a bipyrazole‐ligand‐based hydrophobic MOF, [Cu2(tebpz)] (Cu‐tebpz), which is a rare (3,4)‐connected framework structure built from triangular Cu3(tebpz)3 and tetrahedral Cu4(tebpz)4 SBUs.141 There are three types of 1D channels with sizes of 4.6 × 4.7, 6.5 × 6.5, and 6.3 × 13.2 Å2, and dangling tetraethyl groups are located on the interior surface of the channels. The MOF showed a moderate porosity with a BET surface area of 576 m2 g−1 and a pore volume of 0.37 cm3 g−1. Like many other stable metal bipyrazolate MOFs,179, 180, 181, 182, 183 Cu‐tebpz was proven stable in boiling solvent (THF, toluene, hexane, or DMSO), water, and even acidic (1 × 10−3 m HCl) and basic (1 × 10−3 m NaOH) aqueous solutions for 24 h by PXRD patterns. The hydrophobicity of Cu‐tebpz was confirmed by its water adsorption isotherm, which showed almost negligible uptakes, even at high humidity up to 0.9 P/P 0 at 298 K, but an abundance of benzene and n‐hexane could be adsorbed by the MOF under the same conditions.

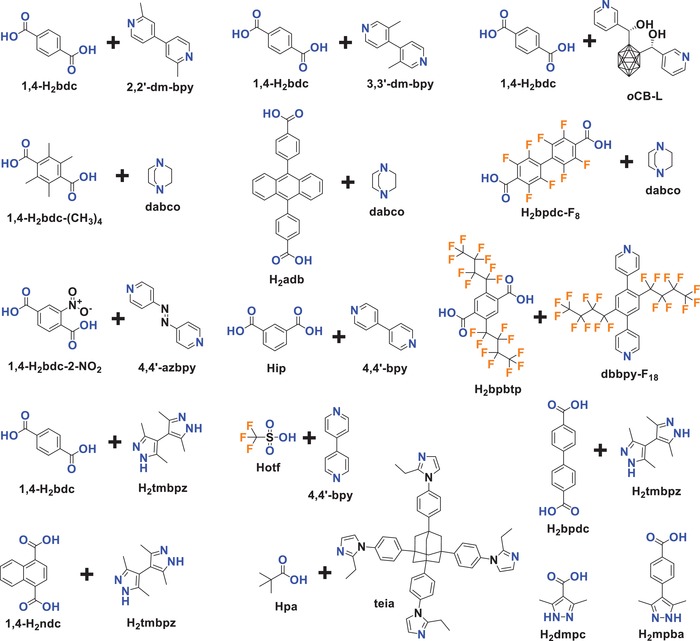

3.1.3. Mixed Ligands and Ligands with O and N Donors

Some hydrophobic MOFs have been synthesized from more than one type of ligand or by one type of ligand with different coordination donors, mostly O and N atoms, as shown in Scheme 3.112, 148, 149, 150, 152, 154, 184

Scheme 3.

Mixed ligands and ligands with O and N donors used for constructing hydrophobic MOFs.

Jasuja et al. reported that a zinc‐base MOF with a pillared‐layer structure, [Zn2(1,4‐bdc‐(CH3)4)2(dabco)] (DMOF‐TM2), was synthesized from the dicarboxylic acid ligand 1,4‐H2bdc‐(CH3)4 and the neutral ligand dabco and possessed a high porosity, hydrophobicity and stability toward water.153 DMOF‐TM2 was first reported by Kim and coworkers.185 It is a mixed‐ligand MOF in which paddle‐wheel‐shaped dimeric zinc clusters are connected by 1,4‐bdc‐(CH3)4 2− ligands, forming 2D layers, and the 2D layers are pillared by the neutral dabco ligands, resulting in an open framework with 1D channels of 3.5 Å (Figure 13a,b). The N2 adsorption measurement at 77 K revealed the high porosity of DMOF‐TM2, showing a BET surface area of 1050 m2 g−1 and a pore volume of 0.51 cm3 g−1. DMOF‐TM2 was proven stable toward moisture (90% RH), as confirmed by the PXRD patterns and BET surface areas measured before and after water exposure. The authors confirmed that DMOF‐TM2 maintained its crystallinity after exposure to lab air for approximately one year. When the dicarboxylic ligand 1,4‐bdc‐(CH3)4 2− in DMOF‐TM2 was replaced by 1,4‐bdc2− and/or its fluorine‐ or methyl‐substituted derivatives, 1,4‐bdc‐CH3 2−, 1,4‐bdc‐(CH3)2 2−, and 1,4‐bdc‐F4 2−, six isostructural pillared‐layer MOFs were obtained, and they almost completely lost their crystallinity after exposure to moisture. DMOF‐TM2 showed type V water adsorption isotherms with low uptakes below 0.2 P/P 0 and pore filling at higher partial pressures (e.g., 412 mg g−1 at 0.9 P/P 0), indicating the moderately hydrophobic nature of the MOF. Three cycles of water adsorption/desorption measurements were performed, and no change in the isotherms (Figure 13c) was noted. While PXRD patterns and BET surface area measurements also confirmed no change in the crystal structure after the three adsorption/desorption cycles. According to experimental results and molecular simulations, the authors concluded that the improved moisture stability of DMOF‐TM2 over that of the other isostructural MOFs originated from the shielding of the carboxylate oxygen in the structure by nearby hydrophobic methyl groups, which prevented hydrogen‐bonding interactions and subsequent structural transformations occurring, and as a result, the electrophilic zinc atoms in this structure became inaccessible to the nucleophilic oxygen atoms in water, thus, preventing any ligand displacement hydrolysis reactions occurring.

Figure 13.

a) The framework structure, b) 1D small channels, and c) cyclic water adsorption isotherms at 298 K and 1 bar for DMOF‐TM2. Adapted with permission.153, 185 Copyright 2005, John Wiley and Sons for panels (a) and (b); and Copyright 2013, American Chemical Society for panel (c).

Ma et al. reported the two MOFs, [Zn2(1,4‐bdc)2(2,2′‐dmbpy)] (SCUTC‐18) and [Zn2(1,4‐bdc)2(3,3′‐dm‐bpy)] (SCUTC‐19),146 isostructural to [Zn2(1,4‐bdc)2(4,4′‐bpy)] (MOF‐508),186 a pillared‐layer MOF built from layers of 1,4‐bdc2−‐bridged paddle‐wheel Zn2 clusters with neutral 4,4′‐bpy ligands as pillars. In SCUTC‐18 and SCUTC‐19, the pillars involve 4,4′‐bpy that are methyl‐substituted at ortho‐ and meta‐positions with respect to the pyridine atoms, namely, 2,2′‐dm‐bpy, 3,3′‐dm‐bpy, respectively. The three MOFs are all 2‐fold interpenetrated structures with 1D channels of 6.4, 6.5, and 8.0 Å. N2 sorption measurements showed the moderate porosity of the MOFs, and the BET surface areas were 398, 523, and 458 m2 g−1 for MOF‐508, SCUTC‐18, and SCUTC‐19, respectively. The authors determined that MOF‐508 was unstable in air and that its structure fully collapsed after moisture exposure for one week; however, SCUTC‐18 and SCUTC‐19 showed improved stabilities in ambient air. After exposure to air for 7 days, no new peaks appeared for SCUTC‐19, but all the peak intensities of SCUTC‐19 decreased. For SCUTC‐18, no new peaks or apparent loss in peak intensity of PXRD patterns was observed after being exposed to air for up to 30 days. N2 sorption measurements were also carried out after the MOFs were exposed to air for one week, and the BET surface areas of MOF‐508 and SCUTC‐19 deceased significantly (87% and 55% reduction, respectively). However, only a slight change was observed for SCUTC‐18 (from 523 to 506 m2 g−1, maintaining 97%). This result was interpreted as the hydrophobic methyl groups at the ortho‐positions of the coordinating nitrogen atoms of the pillar ligands were close to the Zn centers in SCUTC‐18, which shielded the Zn ions from attack by water molecules; however, the methyl groups at the meta‐positions are far from the metal centers in SCUTC‐19, which resulted in a weak protection effect.

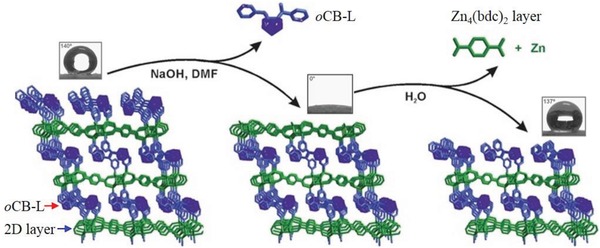

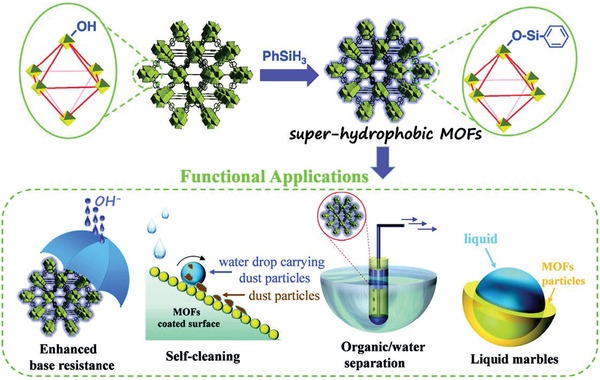

Rodríguez‐Hermida et al. reported a unique pillared‐layer MOF, [Zn4O2(1,4‐bdc)2(oCB‐L)2(DMF)2] (oCB‐MOF‐1),147 which was synthesized by mixed ligands of 1,4‐H2bdc and a neutral hydrophobic carborane‐based linker, oCB‐L. The 3D framework of oCB‐MOF‐1 consists of square‐grid‐like Zn4(1,4‐bdc)2 layers, which are pillared by the neutral oCB‐L ligands. There are 1D channels with small apertures (3.2 × 6.4 Å) and larger cavities with a diameter of 8.6 Å (Figure 14), and the carborane moieties of oCB‐L ligands are located on the pore surface. The N2 adsorption measurement at 77 K for oCB‐MOF‐1 showed no uptake of N2 at 77 K; however, evident CO2 adsorption at 195 K with a type I isotherm and a saturated uptake of 69.4 cm3 g−1 was noted. The BET surface area of oCB‐MOF‐1 was estimated to be 296 m2 g−1. The authors explained that the small pore aperture in oCB‐MOF‐1 should be responsible the adsorption selectivity of CO2 over N2. It was found that oCB‐MOF‐1 was stable in aqueous solutions with a wide range of pH (2–12) for at least 15 h at room temperature. The high stability was attributed to the high hydrophobicity of oCB‐MOF‐1, which was suggested by the water adsorption and water contact angle measurements. A type III water adsorption isotherm was observed for oCB‐MOF‐1, and the water uptake at 0.95 P/P 0 and 298 K was 50 mg g−1. The water contact angles for a hand‐packed powder sample on a glass surface and for a pellet sample (formed under a pressure of 10 tons for 5 min) with a roughness factor of 1.7 were 140° and 108°, respectively. Interestingly, a reversible transformation between hydrophobic and superhydrophilic (water contact angle: 0°) surfaces was found when oCB‐MOF‐1 was immersed in a solution of NaOH in DMF and subsequently in a slightly acidic aqueous solution. By 1H‐ and 11B‐{1H}‐NMR spectroscopy, mass spectrometry and ICP‐MS analyses, the switching of the surface hydrophobicity/hydrophilicity of the oCB‐MOF‐1 crystals was attributed to the selective removal of hydrophobic oCB‐L linkers from the crystal surface under basic conditions and the selective removal of hydrophilic Zn4(bdc)2 layers under slightly acidic aqueous conditions (Figure 14). When the layers of hydrophobic oCB‐L linkers were removed, the hydrophilic Zn4(bdc)2 layers were exposed to the crystal surface, and when the hydrophilic Zn4(bdc)2 layers were removed, the crystal surface recovered hydrophobicity, as the oCB‐L linkers were exposed on the crystal surface. The authors proposed that this type of material with a switchable hydrophobic/hydrophilic surface would be useful for myriad applications.

Figure 14.

The proposed mechanism for the switchable surface hydrophobicity–hydrophilicity of oCB‐MOF‐1. Pillaring oCB‐L linkers are represented in blue, and Zn4(bdc)2 layers in green. Inset: water contact angles for the oCB‐MOF‐1 samples. Adapted with permission.147 Copyright 2016, John Wiley and Sons.

Xie and Suh reported a flexible and hydrophobic MOF, [Cu4(pa)8(teia)] (SNU‐80), which was synthesized by mixed ligands of the monocarboxylic acid Hpa and a tetrahedral shaped neutral ligand, teia.151 The MOF is a 3D framework with 6‐fold interpenetrated diamondoid nets, which consist of [Cu2(Me3CCOO)4] paddle‐wheel units interconnected by the tetrahedral teia ligands (Figure 15a). There are 1D channels with a diameter of ≈6.5–7.0 Å, the surfaces of which are predominantly covered by the hydrophobic tert‐butyl groups of pivalate ligands and by the ethyl groups of teia ligands (Figure 15b). Due to the structural transformation after activation, SNU‐80 showed stepwise adsorptions of N2, O2, and CO2 gases at 77, 77, and 195 K, respectively (Figure 15c). It was believed that SNU‐80 underwent a structural transformation due to pore expansion during the gas adsorption processes. The Langmuir and BET surface areas and the pore volume of the expanded‐pore phase of SNU‐80 were estimated as 1167 m2 g−1, 1035 m2 g−1, and 0.43 cm3 g−1 from the desorption branch of the N2 adsorption isotherm at 77 K. Additionally, according to the adsorption branch of the N2 adsorption isotherm, the Langmuir and BET surface areas and the pore volume for the shrunken‐pore phase of SNU‐80 were 456 m2 g−1, 398 m2 g−1, and 0.18 cm3 g−1. The highly hydrophobic nature of SNU‐80 was confirmed by the water adsorption experiment, TGA and elemental analysis (EA). The water adsorption isotherm at 298 K showed a low uptake of 12 cm3 g−1 (9.6 mg g−1) at 0.97 P/P 0. TGA also confirmed only a 1.0% weight loss at 25–150 °C for adsorbed water after a SNU‐80 sample was exposed at saturated water vapor at room temperature for one week. The EA data of the saturated water vapor sample of SNU‐80 were almost identical to those of a fresh activated sample of SNU‐80. In addition, the PXRD patterns suggested that SNU‐80 was stable in saturated water vapor and liquid water for one week; however, it was also found that the as‐synthesized phase of SNU‐80 (with n‐propanol as guest) turned amorphous after being immersed in water for just 6 h and degraded to a colorless powder of teia ligands after 2 days. The authors believed that the structural shrinkage from the as‐synthesized phase to the activated phase of SNU‐80 after guest removal enhanced the hydrophobicity of the pore surface and hydrolytic stability of the MOF.

Figure 15.

a) A single diamondoid net formed by the interconnection of teia ligands and paddle‐wheel‐shaped [Cu2(Me3CCOO)4] units in SNU‐80. b) 1D channels in SNU‐80 formed by the sixfold interpenetrated diamondoid nets, which are lined with the hydrophobic tert‐butyl and ethyl groups of the ligands. c) Adsorption isotherms for N2 (77 K), O2 (77 K), CO2 (195 K), and H2O (298 K). Filled shapes: adsorption and open shapes: desorption. Adapted with permission.151 Copyright 2011, John Wiley and Sons.

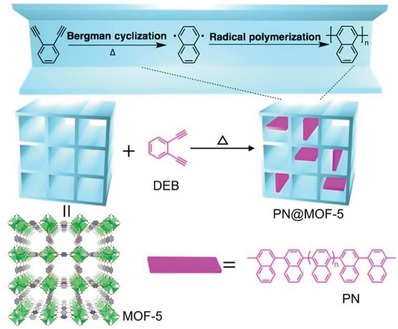

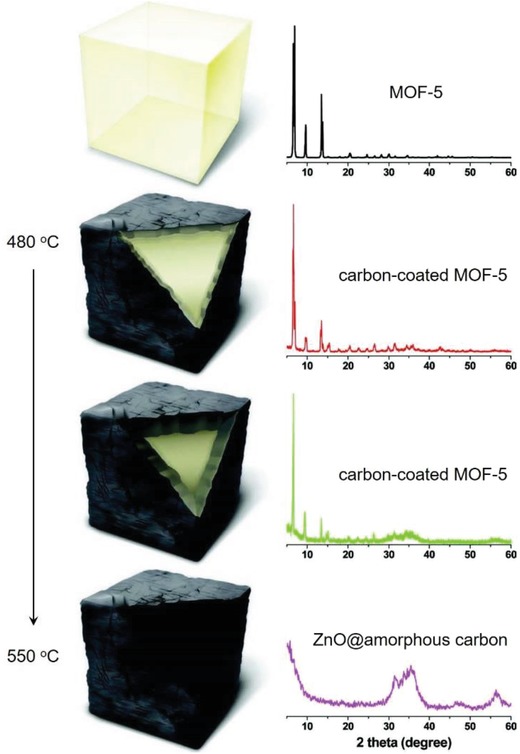

While mixed‐ligand hydrophobic MOFs are mostly constructed by the combination of an anionic ligand and a neutral ligand, there are also examples built from two types of anionic ligands. Chen and co‐workers reported a series of MOFs (MAF‐X10 formulated as [Zn4O(tmbpz)2(1,4‐bdc)], MAF‐X12 formulated as [Zn4O(tmbpz)2(1,4‐ndc)], and MAF‐X13 formulated as [Zn4O(tmbpz)2(bpdc)]) from the mixed ligands of a linear dicarboxylic acid (1,4‐H2bdc, 1,4‐H2ndc or H2bpdc) and a linear bipyrazole (H2tmbpz).157, 158 These MOFs are isostructural to the well‐known MOF‐5, consisting of 6‐connected Zn4O clusters bridged by linear ligands. Their BET surface areas range from 1787 to 2742 m2 g−1. The MOFs were regarded as hydrophobic, because their channel surfaces are lined with hydrophobic methyl groups and aromatic rings.

With some similar structural characteristics to the MOFs built from mixed ligands, some hydrophobic MOFs were synthesized by ligands with two types of coordination donors, mostly O and N atoms. Montoro et al. reported a MOF‐5‐type MOF, [Zn4O(dmpc)3] (Zn‐dmpc), created by using a mixed pyrazolate/carboxylate ligand H2dmpc.155 Zn‐dmpc showed smaller channels (4–6 Å) and a lower porosity (BET surface area: 840 m2 g−1), but a higher stability than those of MOF‐5. PXRD patterns indicated Zn‐dmpc remained crystalline after being suspended in water at room temperature for 24 h. The high hydrophobicity of Zn‐dmpc was confirmed by water adsorption measurements at 298 K, showing a type V isotherm with low uptakes below 0.7 P/P 0 and gradual pore filling at higher partial pressures (437 mg g−1 at 0.83 P/P 0). Reproducible water adsorption isotherms for two cycles were observed, further supporting the high water stability of Zn‐dmpc. He et al. obtained a pillared‐column type MOF, [Zn(mpba)] (MAF‐X8), by using a mixed pyrazolate/carboxylate ligand, H2mpba (an expanded version of H2dmpc),156 which showed large 1D channels in a size of 6.7–8.8 Å, and high BET (1161 m2 g−1) and Langmuir surface areas (1306 m2 g−1). The pores of MAF‐X8 were believed to be hydrophobic because the methyl groups of the ligand on the pore surface almost entirely blocked the Zn2+ ions and partially blocked the carboxylate O atoms.

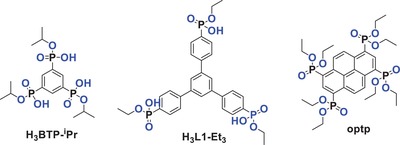

3.1.4. Phosphonate Monoesters/Phosphonic Acid Monoesters

Phosphonate monoesters (RPO2OR′−) and deprotonated phosphonic acid monoesters (H2RPO2OR′) are a type of ionic ligands offering O donors. Unlike carboxylates or azolates, phosphonate monoesters are less explored as ligands for the construction of MOFs. Three phosphonate monoester/phosphonic acid monoester ligands used for constructing hydrophobic MOFs reported in the literature are shown in Scheme 4.

Scheme 4.

Phosphonate monoester/phosphonic acid monoester ligands for constructing hydrophobic MOFs.

Shimizu's group reported a series of MOFs derived from phosphonate monoesters, some of which have been proven as hydrophobic.85, 159, 160, 187, 188 In 2012, they reported a barium tetraethyl‐1,3,6,8‐pyrenetetraphosphonate MOF, CALF‐25, from the solvothermal reaction of BaBr2 and the ligand optp, which turned into a phosphonate monoester by in situ partial hydrolysis.85 CALF‐25 is a 3D framework structure consisting of 1D barium phosphonate chains crosslinked with four neighboring chains by the ligands. There are 1D channels of size 4.59 × 3.89 Å with the ethyl ester groups lining the corners of the pores and with the pyrene backbone of ligands defining their walls (Figure 16a,b). N2 adsorption at 77 K revealed the moderate porosity of CALF‐25, and the BET surface area was estimated to be 385 m2 g−1. It was demonstrated by PXRD patterns and N2 adsorption measurements that CALF‐25 remained crystalline and porous after exposure to harsh humid conditions (90% relative humidity at 353 K). Water adsorption isotherms were recorded at 5 K intervals between 298 and 313 K and showed type III isotherms with an uptake of 4.27 mmol g−1 (76.9 mg g−1) at 0.97 P/P 0 (298 K) (Figure 16c). The heat of water adsorption was calculated to be ≈45 kJ mol−1 for the whole loading range (Figure 16c), slightly higher than the heat of vaporization of water and comparable to those of graphite and other hydrophobic MOFs, indicting the hydrophobic pore surface of CALF‐25. The authors believed that the ethyl groups of the ligands on the pore surface shielded the polar barium phosphonate chains and resulted in the hydrophobicity of CALF‐25.

Figure 16.

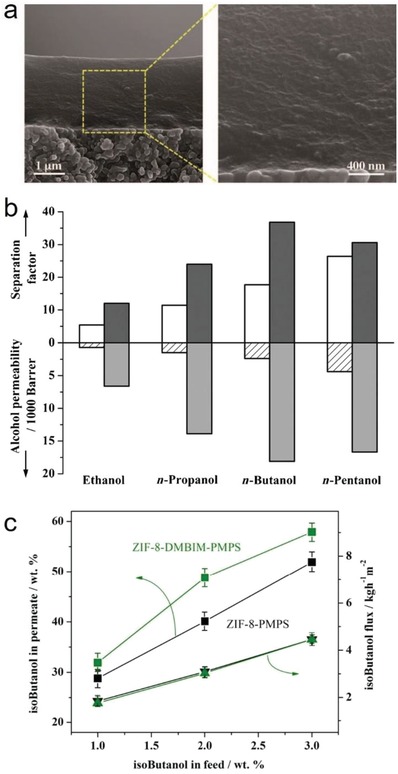

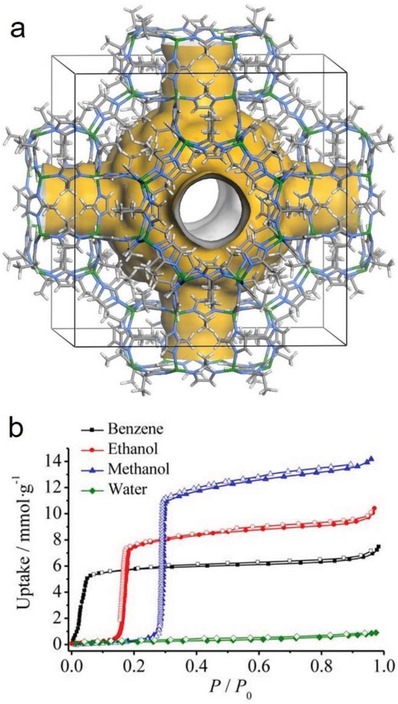

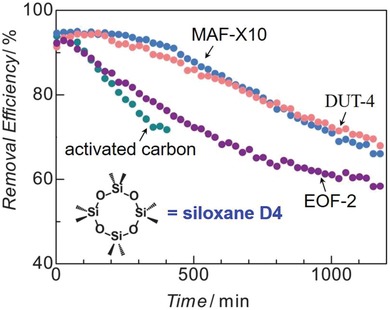

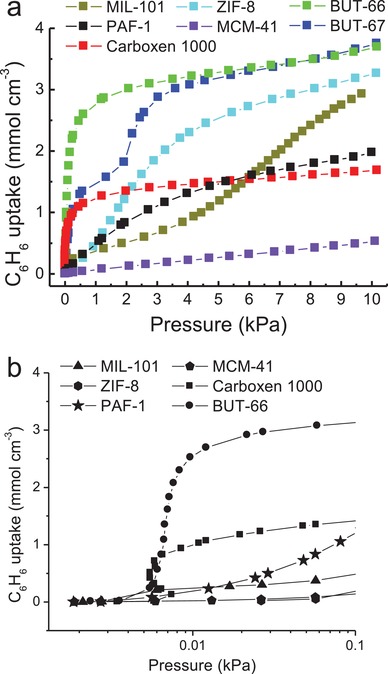

a) Framework structure of CALF‐25 with ethyl‐lined 1D channels. b) 1D barium phosphonate chain. c) Water adsorption isotherms (blue) and the isosteric heat of water adsorption (red) for CALF‐25. Adapted with permission.85 Copyright 2012, American Chemical Society.