Abstract

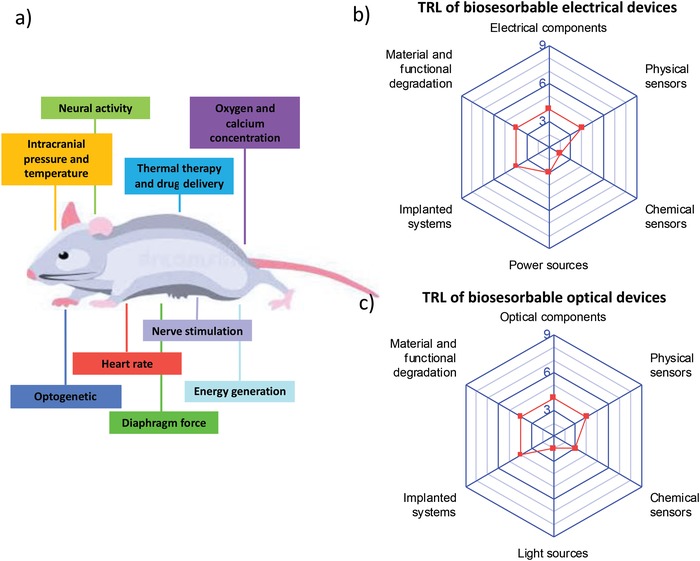

Over the last decade, scientists have dreamed about the development of a bioresorbable technology that exploits a new class of electrical, optical, and sensing components able to operate in physiological conditions for a prescribed time and then disappear, being made of materials that fully dissolve in vivo with biologically benign byproducts upon external stimulation. The final goal is to engineer these components into transient implantable systems that directly interact with organs, tissues, and biofluids in real‐time, retrieve clinical parameters, and provide therapeutic actions tailored to the disease and patient clinical evolution, and then biodegrade without the need for device‐retrieving surgery that may cause tissue lesion or infection. Here, the major results achieved in bioresorbable technology are critically reviewed, with a bottom‐up approach that starts from a rational analysis of dissolution chemistry and kinetics, and biocompatibility of bioresorbable materials, then moves to in vivo performance and stability of electrical and optical bioresorbable components, and eventually focuses on the integration of such components into bioresorbable systems for clinically relevant applications. Finally, the technology readiness levels (TRLs) achieved for the different bioresorbable devices and systems are assessed, hence the open challenges are analyzed and future directions for advancing the technology are envisaged.

Keywords: biodegradable sensors, bioresorbable materials, implanted devices, material dissolution, transient electronics

Bioresorbable materials that fully dissolve in the body with biologically benign byproducts provide a unique opportunity to engineer new electrical, optical, and sensing components into implantable biomedical systems with direct access to organs, tissues, and biofluids, without need of secondary device‐retrieving surgery. Herein, the current picture and future direction of bioresorbable devices and systems are presented, with specific attention to challenges that still need to be addressed toward real‐word applications.

1. Introduction

Bioresorbable materials that fully dissolve in the body with biologically benign byproducts provide a unique opportunity to engineer new electrical, optical, and sensing components into implantable biodegradable systems that eliminate any boundary with the human body, granting direct access to organs, tissues, and biofluids without the need of secondary device‐retrieving surgery that may cause tissue lesion or infection.1

Traditional medical devices designed to be implanted in the human body to treat either acute or chronic diseases (e.g., cardiac pacemakers, cochlear implants, coronary stents, articular prostheses) are made of (or coated with) inert biocompatible materials and optimized to warrant the organ functionality from days to years, depending of the targeted problem/disease, before surgical retrieval/replacement (when needed).2, 3 While for some specific cases (e.g., heart stimulation, hearing loss, coronary heart disease) implanted devices ideally working/operating over the whole patient life are required, in many other cases (e.g., muscle stimulation, bone growth stimulation, neuro stimulation, wound healing) the devices are required to work/operate only for a prescribed amount of time, so that surgical retrieval is eventually needed, which could be potentially dangerous for patient health.4

Bioresorbable medical devices designed to be implanted in the human body and operate for a prescribed time, before they undergo spontaneous dissolution in patient body, would therefore represent a new paradigm in patient care.

Besides, the continuous diffusion of noninvasive and minimally invasive sensor systems for personalized medicine and sport&wellness activities envisages an ever‐growing electronic waste that poses serious environmental hazards, given the pervasive presence and rapid turn‐over of electronic devices in everyday life.5, 6, 7, 8, 9 The development of biodegradable electronic components and systems that facilitate disposal by natural dissolution in ambient or mild conditions without environmental threats could mitigate electronic waste problems.10, 11, 12

Bioresorbable components and biodegradable electronics would greatly benefit one from each other findings, both pursuing the same goal of developing high‐quality devices that operate for a prescribed time and then vanish under well‐defined conditions. In both cases, mechanisms for triggering and tuning the dissolution of these devices by using different physico‐chemical conditions, such as, acidic13, 14 or basic15, 16 solutions, light exposure,17 and low18 or high temperatures,19, 20 are envisaged to provide a more accurate on‐demand control over dissolution.

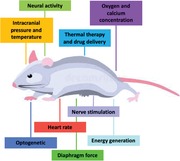

Summarizing, an ideal bioresorbable system is required to monitor physio‐pathological parameters of clinical interest (e.g., intracranial pressure), transmit the acquired data to an external receiver, and produce a feedback action on the relevant organs/tissues aimed at improving the clinical status of the patient. If implanted, the materials that compose the system are required to be biocompatible and degradable in physiological conditions, further resulting in biocompatible degradation byproducts. Eventually, the system operation and performance are required to be stable until programmed (or even better, externally triggered) dissolution occurs, to ensure correct monitoring and effective caring of the patient throughout the healing process, and the degradation products need to be rapidly resorbed and/or drained by the patient organism to avoid the risk of foreign body reactions both at local and systemic levels, especially for a chronic implant. For instance, imagine an infection sentinel system being implanted in a surgical site, able to continuously monitor bacterial charge, releasing antibiotics and sending alerts to physicians in case of infection risk, and that after complete surgical wound healing totally and safely dissolves within days. It would be a groundbreaking achievement for patient life quality and health safety.

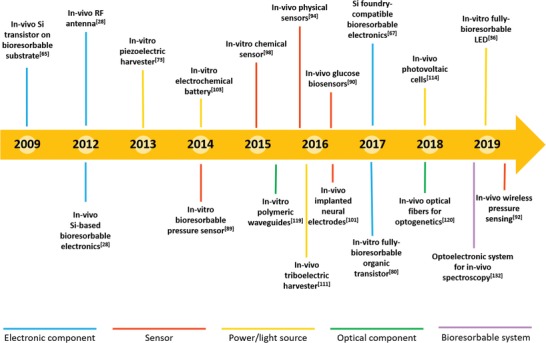

In spite of the huge research effort paid over the latest years on this subject, many important issues remain open and have still to be addressed toward the achievement of such a bioresorbable medical system, including lifetime of electronic and optical components, stability and lifetime of power sources, on‐demand triggering of material dissolution, development of chemical sensors operating in vivo, and long‐term material biocompatibility in vivo. A summary of the milestones achieved over the last decade on this field is given in Figure 1 .

Figure 1.

Milestones on bioresorbable devices and systems. Milestones achieved over the last decade on bioresorbable devices and systems for in vitro and in vivo applications, highlighting the impressive outcomes of the research field in the last few years.

In this Review, differently from recent reviews on transient, degradable, and bioresorbable materials and devices mainly focusing on material preparation and fabrication processes,21, 22, 23, 24, 25, 26, 27 we will focus on functional operation and physiological dissolution of bioresorbable devices and systems, aimed at assessing the TRL achieved by the different facets of the bioresorbable technology. We will first discuss the dissolution chemistry and kinetics, as well as the biocompatibility of the main bioresorbable materials, including inorganic semiconductors, oxides, and metals, as well as organic polymers, systematically grouping material class and dissolution rate. Next, we will review the state‐of‐the‐art bioresorbable devices and systems, including electronic components, sensors and actuators, power sources, and optical devices. Eventually, we will draw the current picture and envisage future direction on bioresorbable devices and systems, with specific attention to the challenges that still need to be overcome toward real‐word applications.

2. Bioresorbable Materials and Dissolution Chemistry

In this section we will review dissolution chemistry and kinetics, and biocompatibility (when available) of the main bioresorbable materials both in vitro and in vivo, namely: inorganic semiconductors (e.g., silicon (Si), germanium (Ge), and zinc oxide (ZnO)), oxides and nitrides (e.g., silicon oxides and silicon nitrides), metals (e.g., magnesium (Mg), zinc (Zn), tungsten (W), and molybdenum (Mo)), and polymers and organic materials (e.g., polyesters, waxes, cyclic poly(phtalaldehyde) (cPPA), and silk). Figure 2 summarizes the etching rates of these materials in physiological conditions (i.e., pH 7.4 and 37 °C), with organic and inorganic semiconductors being mostly used as active part of bioresorbable transistors, metals mainly used as electrodes and for interconnections, polymers typically employed as supporting substrate and flexible coating, and oxides/nitrides being used as encapsulation layer.

Figure 2.

Dissolution rates of the principal bioresorbable materials in physiological conditions. Summary of the dissolution rates of the different materials used in bioresorbable devices and systems at pH 7.4 and 37 °C, namely, a,b) semiconductors,30, 31, 33, 35, 36 c) metals,43 d) oxides and nitrides,39 and e) polymers.52, 53, 54, 55, 56, 57, 58

2.1. Inorganic Semiconductors

Among the different bioresorbable materials, monocrystalline silicon in the form of nanomembranes (Si NMs) represents an emerging choice for the fabrication of high‐performance transient electronics and bioresorbable devices.28, 29

Hwang et al.30 studied the kinetics of hydrolysis of monocrystalline Si NMs with different dopants (type and concentration) in different solutions (buffers and biofluids), evaluating in vitro and in vivo cytotoxicity. The dissolution of single‐crystalline Si NMs in aqueous media is governed by Equation (1), namely

| (1) |

Si NMs (B‐doped 1016 cm−3, 100 nm thick) were fully and uniformly dissolved in 24 h upon immersion in 1 m phosphate buffered saline (PBS) (at pH 7.4 and 37 °C) and in bovine serum (at pH ≈ 7.4 and 37 °C), with a comparable dissolution rate r (by definition, thickness of dissolved material per day) of ≈100 nm day−1. By changing type (P‐ and B‐doped) and concentration (1017 through 1020 cm−3) of dopants, the dissolution rate was found to be more sensitive to concentration rather than type of dopants, at least for 70 nm thick Si NMs in PBS (0.1 m, pH 7.4 and 37 °C). For instance, dopant concentrations of 1017 cm−3 and 1019 cm−3 resulted in r ≈ 3 nm day−1 regardless of the type of dopants, whereas at concentration of 1020 cm−3 the etching rate was ≈0.8 and ≈0.3 nm day−1 (roughly a factor 3) for P and B dopants, respectively. In vitro cytotoxicity tests were carried out on metastatic breast cancer cells (MDA‐MB‐231) cultured on Si NMs subjected to continuous dissolution for consecutive days. Although the Si NMs were fully dissolved in 4 days in the culture medium, the cell viability was excellent after ten days (93 ± 4%). In vivo studies were performed by subcutaneous implantation of Si NMs in mice dorsal skin. Biodegradability and biocompatibility (no cytotoxicity and no weight loss in mice) of the implant over 5 weeks were assessed using high‐density polyethylene (HDPE) as Food and Drug Administration (FDA)‐approved control material. After 5 weeks, no residues of degradation were visible at the implant sites by stereomicroscopic analysis, while immunohistochemistry of the skin sections and hematoxylin and eosin (H&E) staining proved similar levels of immune cells to those of HDPE (i.e., no cytotoxicity).

Expanded studies on dissolution kinetics of semiconductors for transient electronics were reported by Kang et al.31 The authors correlated the dissolution rates of 100 nm thick NMs of polycrystalline silicon (p‐Si), amorphous silicon (a‐Si), silicon–germanium alloy (SiGe), and germanium (Ge) in aqueous solutions with different pH (7–10) and temperature (room temperature and 37 °C) values. Equation (2) applies to germanium dissolution in aqueous media, namely

| (2) |

Dissolution rates at physiological temperature (37 °C) were higher than those at room temperature for all the tested materials, which is in agreement with the Arrhenius equation.32 The increase of pH significantly increases the dissolution rate of p‐Si, a‐Si, and Ge NMs. For instance, at physiological conditions (37 °C and pH 7.4) r was 2.8, 4.1, and 3.1 nm day−1, respectively, while at pH = 10 the NMs were completely dissolved in a few hours, regardless of the material. Conversely, the SiGe alloy (Si8Ge2 (100)) showed higher stability with pH than the other materials, and no significant dissolution was recorded until pH = 8 after 16 days, while only 25 nm were dissolved at pH = 10. Biocompatibility was evaluated by culturing two different cell types (L929 mouse fibroblast and whole splenocytes harvested from mouse spleen) over 72 h onto the NMs for cytotoxicity studies. Cell viability suggested the nontoxic nature of the four dissolved materials, compared to HDPE used as control.

Two years later, the same research group deepened the understanding on dissolution kinetics of Si NMs in ground‐water and biofluid media.33 The authors investigated the dissolution rate of Si NMs (B‐doped, 1015 cm−3, 200 nm thick) in PBS (1×) spiked with different concentrations of albumin (0.01–35 g L−1), Si(OH)4 (0–300 mg L−1) and cations (Na+, Mg2+ and Ca2+, 1 × 10−3 m) at 37 °C. The increase of the protein concentration slowed down the dissolution rate due to augmented protein adsorption onto the NM surface; moreover, regardless of the concentration (and presence) of proteins, the dissolution rate reduced by increasing the concentration of Si(OH)4, consistently with the chemical equilibrium reported in Equation (1). Conversely, the presence of cations in the aqueous medium (i.e., PBS at pH 7.4, with 35 g L−1 of proteins at 37 °C) led to an accelerated dissolution rate, which was greater for divalent cations (namely, Ca2+ and Mg2+) with respect to monovalent cations (Na+). For instance, the presence of 1 × 10−3 m Ca2+ increased the dissolution rates of a factor ≈1.5, from 35 nm day−1 (in absence of cations) to 51 nm day−1. This result was explained with the ability of divalent cations to deprotonate surface silanol groups, formed by absorption of water on Si surface, and to enhance, in turn, the reactivity of water and siloxane groups, as suggested for SiO2 dissolution.34 The Si NMs were eventually investigated as water barrier for encapsulation of bioresorbable electronics. Two different strategies were examined to decrease the dissolution rate in the presence of Ca2+: the use of heavily doped Si NMs (B‐doped, 1020 cm−3), for which a decrease of the dissolution rates of ≈40‐fold was achieved; and nanometric superficial oxidation with UV ozone (UVO, 3 nm thick) or O2 plasma (20 nm thick) of Si NMs, for which a delay of the Si dissolution of 10 and 30 days, respectively, was demonstrated.

Yin et al.35 further reported that in aqueous media the dissolution kinetics of Si NMs was affected by the presence of cations (e.g., Na+, Ca2+, and Mg2+) and anions (Cl−, HCO3−, HPO4 2−) which are commonly available in biologic and environmental fluids at concentrations ranging from 0.1 to 50 g L−1. The study reported that the dissolution rate of Si NMs (B‐doped, 1017 cm−3) was ≈1 nm day−1 at low ionic concentrations (e.g., 0.05 m K2HPO4/KH2PO4), and increased up to 65 nm day−1 at high concentrations (e.g., 1 m K2HPO4/KH2PO4). Density functional theory (DFT) simulations showed that the presence of anions could weaken the interaction between Si atoms and nearby Si–Si backbones, thus accelerating the dissolution kinetics.

Dissolution of ZnO in physiological conditions was recently investigated by Lu et al.,36 who used ZnO as semiconductor in the fabrication of bioresorbable light‐emitting diodes (LEDs). ZnO samples (200 µm × 200 µm squares, thickness ≈200 nm) immersed in PBS at pH = 7.4 and 37 °C completely dissolved in 48 h, with a dissolution rate of about 4.1 nm h−1 (≈100 nm day−1). The Zn2+ concentration, measured at the end of the dissolution tests using a fluorescent chelating agent, namely, zinquin, was estimated to be 33 ng mL−1, confirming a full and direct degradation of ZnO according to hydrolysis reaction reported in Equation (3), namely

| (3) |

without formation of insoluble precipitates of Zn(OH)2 (solubility ranging from 3.2–21 µg mL−1, experimentally observed at 25–50 °C, pH 7.4). Further, possible precipitates of Zn(OH)2, formed at concentrations exceeding Zn2+ solubility, could dissolve via formation of elementary Zn2+ ions and 2OH− hydroxides according to the equilibrium reaction Zn(OH)2 ↔ Zn2+ + 2OH− (with solubility constant K ps = 3 × 10−17), driven by the continuous excretion of the dissolved ions (i.e., Zn2+) from the organism (Le Chatelier's principle).37 The biocompatibility of ZnO and, in turn, of its byproducts was assessed by monitoring the dissolution of ZnO nanostructures in horse blood and serum.38

2.2. Silicon Oxides and Nitrides

In the field of transient electronics, silicon oxides and nitrides have also key significance for digital and analog circuits and thin film displays, due to their use as gate and interlayer dielectrics, passivation coatings, and barriers against water penetration.39, 40

Kang et al.39 studied the hydrolysis kinetics of thin films of silicon oxides and nitrides in diverse aqueous solutions at different pH levels, ion concentrations, temperatures, and for different deposition methods. Silicon oxides dissolve in aqueous media according to Equation (4), namely

| (4) |

The reaction is initiated and kinetically influenced by OH− concentration (i.e., pH of solution). At this purpose, the authors investigated the dependence of dissolution rate on pH (i.e., range 7.4–12), temperature (i.e., room temperature and 37 °C), and type of oxide (i.e., thermal oxide, grown in O2 (tg‐dry) or H2O vapor (tg‐wet), and deposited oxide, obtained through plasma‐enhanced chemical vapor deposition (PECVD) and electron‐beam evaporation (E‐beam)). The dissolution rate increased with temperature (according to Arrhenius equation)32 and with pH for all the tested oxides. Once temperature and pH values were given, the different oxides were etched at different rates r tg‐dry < r tg‐wet < r PECVD < r E‐beam. In particular, r tg‐dry ranged from 6.3 × 10−4 to 1 nm day−1, r tg‐wet from 4.7 × 10−4 to 1.4 nm day−1, r PECVD from 2.2 × 10−2 to 14 nm day−1, and r E‐beam from 3.5 to 282 nm day−1, at pH 7.4 and room temperature, and at pH 12 and 37 °C, respectively. The different etching rates were explained in terms of different physico‐chemical properties of oxides grown/deposited with different methods, namely: thermal oxide is uniformly dense and has a homogeneous stoichiometry; PECVD oxide has different densities and nonhomogeneous stoichiometry; E‐beam oxide can be affected by nanoscale fragmentation.

Stability of thermal silicon oxide as biofluid barrier was further investigated by Lee et al.,40 who examined the effect of various ionic species present in biofluids, revealing the dependence of the dissolution rate on both cation (Na+, K+, Mg2+, and Ca2+) and anion (Cl− and HPO4 2−) concentrations, near neutral pH values. The authors found that the presence of Ca2+ accelerates the dissolution rate more effectively than Mg2+ and Na+, regardless of pH value. For instance, at pH 7.5 the dissolution rates were 34, 56, and 110 nm day−1 with 30 × 10−3 m NaCl, 10 × 10−3 m MgCl2, and 10 × 10−3 m CaCl2 solubilized in the aqueous solution, respectively. This was explained with the enhanced ability of Ca2+ in Si—O bonding polarization and, in turn, in making it more prone to hydrolysis. These findings were in agreement with former reports on the role of alkali metals in quartz dissolution.41 Further, the dissolution rate was higher in the presence of HPO4 2− rather than Cl−: for instance, for 1 m ionic strength and pH = 6.8 the dissolution rates were 146 ± 9 and 64 ± 7 nm day−1, respectively. The anionic‐specific increase of dissolution rate with phosphate was explained in terms of strong hydrogen bonding with the silica surface.

Similar studies on dissolution kinetics were also carried out for silicon nitride.39 Silicon nitride dissolves in aqueous media in two chemical steps: 1) oxidation to silicon dioxide, according to Equation (5), namely

| (5) |

and 2) hydrolysis of silicon oxide, according to Equation (4). The overall reaction is reported in Equation (6), namely

| (6) |

Being the silicon dioxide an intermediate byproduct of the reaction, the dissolution rate of silicon nitride also increased with temperature and pH, as previously reported for silicon dioxide. Two different silicon nitride deposition techniques were considered: low pressure chemical vapor deposition (LPCVD) and PECVD. The dissolution rate of LPCVD nitride resulted lower than that of PECVD nitride (at pH 7.4 and 37 °C dissolution rates were 0.16 and 0.83 nm day−1, respectively), due to better stoichiometry and higher density of the former. Stacked layers of SiO2 and Si3N4 were employed in the encapsulation of a magnesium serpentine resistor (300 nm thick) as a proof‐of‐concept application in transient electronics. In particular, it was shown that, by using a triple bilayer of PECVD‐deposited SiO2 and Si3N4 (single material layer thicknesses of 200, 200, and 100 nm, respectively, resulting in a total thickness about 1 µm) for the encapsulation, a lifetime of roughly 10 days was guaranteed for the resistor in deionized water (DIW) at room temperature.

The biocompatibility of SiO2 and Si3N4 was demonstrated by subcutaneous implantation of both the materials in rodents using a stainless steel wire mesh cage as carrier. Exudates were sampled after 4, 7, 14, and 21 days, and inflammatory response and leukocyte concentrations (leukocytes mL−1) were evaluated. The inflammatory response generated by SiO2 and Si3N4 was not significantly different from that produced by the empty cage used as control, monitored over the experiment duration.42

2.3. Metals

Metals are interesting in bioresorbable (and implantable) devices for their peculiar mechanical and electronic properties.43

Mg was successfully used for electrical contacts and interconnections in silicon‐based transient electronics by Hwang et al., due to its ease of processing, fast dissolution rate in aqueous media, and full biocompatibility.28 Yin et al.43 later reported on chemistry and mechanism of dissolution of Mg in deionized water. Mg dissolves in aqueous media according to Equation (7), namely

| (7) |

Although Mg dissolution macroscopically exhibited high uniformity, scanning electron microscope (SEM) analysis revealed that dissolution occurred with the formation of micropores and needle‐like structures. In addition, X‐ray photoelectron spectroscopy (XPS) analysis showed that the main product of the dissolution was Mg(OH)2, with MgO and MgCO3 as byproducts due to the presence of oxygen and CO2 in ambient atmosphere, respectively. The outer surface was mainly composed of a Mg(OH)2 layer that featured an increased thickness as the dissolution proceeded, according to experimental results carried out in DIW (r = 7.2 nm day−1) and Hanks's balanced saline solution (HBSS) (r = 115 nm day−1) as a simulated body fluid.

Other metals, including W, Mo, and Zn, showed similar dissolution chemistries and transient behaviors both in DIW and HBSS.43 Zn (comparably to Mg) showed a fast transient mechanism both in DIW (1.7 nm day−1) and in biofluids (7.2 nm day−1), while W and Mo showed a slower and better tunable degradation both in DIW and HBSS (in the range of 10−2 nm day−1 ). For this reason, the latter two materials should be preferred for medical devices that require metals to have direct contact with biological tissues, for instance, for physiological electrical signal sensing.

The biocompatibility of Mg and its alloys,44 Fe,45 and Zn46 was already largely assessed in vivo (with materials and devices implanted in animal models or humans), through evaluation of inflammatory response, and histological and immunofluorescence analysis. Mo and W, although of considerable interest for bioresorbable devices, have less comprehensive data on biocompatibility related to the concentration of byproducts released.43

All the discussed metals were deposited via vacuum‐based technologies, such as, chemical vapor deposition and sputtering. However, a huge interest is nowadays directed toward the development of new and low‐cost methods to reliably fabricate bioresorbable metal films, such as laser printing and metal nanoparticle‐filled conductive inks.47, 48, 49

2.4. Polymers and Organic Materials

Bioresorbable polymers are mostly employed as substrate support for degradable devices and systems.50 Compared to all the above‐discussed materials, polymeric materials offer higher flexibility in tuning the dissolution timescale. Indeed, polymer dissolution can be triggered by using external signals,14 and its rate can be tailored by varying molecular weight, material crystallinity, chemical structure, hydrophilic/hydrophobic character, and exploiting bulk/surface erosion mechanisms.51

Commonly used bioresorbable polymers are poly(lactide) (PLA/PLLA) and poly(lactide‐co‐glycolide) (PLGA),52 poly(caprolactone) (PCL),53, 54 poly(octanediol‐co‐citrate) (POC),55 poly(glycerol sebacate) (PGS),56 poly(hydroxybutyrate) (PHB),57 silk,58 and, recently reported, candelilla wax.49 All these polymers are polyesters (or polyamide, silk), and their depolymerization mechanism in aqueous solution is based on acid or basic hydrolysis of the ester (or amide) bond. As an example, Equation (8) reports the hydrolysis of PLGA

The dissolution rates (expressed as polymer mass% dissolved per day in PBS at pH 7.4 and 37 °C) ranged from a minimum value of 0.22% day−1 for a blend of PCL and PLA (5/95) to a maximum value of 8.6% day−1 for PGS copolymer (50/50).

The biocompatibility of these polymers was largely assessed, as reported in former scientific studies.59, 60, 61, 62, 63, 64 For instance, PLA and PLGA biocompatibility was demonstrated in vivo through histological and immunologic tests after implantation of microspheres in rats;59 PCL biocompatibility was assessed through evaluation of the viability of L929 mouse fibroblasts cultured on films of the polymer;60 biocompatibility of POC was assessed by monitoring form and phenotype of porcine chondrocytes cultured on POC scaffolds;61 PGS biocompatibility was demonstrated using human cardiac mesenchymal stem cells and rat cardiac progenitor cells cultured on PGS membrane through evaluation of viability after staining with DAPI;62 biocompatibility of PHB was assessed by subcutaneous implantation in rats and evaluation of the inflammatory response on tissue after 4 and 12 weeks;63 silk biocompatibility was widely demonstrated both in vitro and in vivo for applications in wound healing and in tissue engineering of bone, cartilage, tendon, and ligament tissues.64

Won et al.49 reported on the use of natural waxes as materials for long‐time and hydrophobic encapsulation in bio/ecoresorbable electronics. Soy, myrtle, and candelilla waxes, derived from soybeans (via soybean oil), myrica cerifera (myrtle), and candelilla shrubs, respectively, were tested. Waxes are known to be environmentally and biologically degradable (hydrolysis of ester and anhydride bonds in aqueous solution), conversely to their petroleum‐derived counterparts. Biodegradation tests carried out on candelilla wax (800 µm thick foil) subcutaneously implanted in the dorsal region of rats revealed a thickness reduction of roughly 28 µm after three months. Further, candelilla wax was used as biodegradable matrix for the preparation of conductive pastes, e.g., loaded with tungsten microparticles (C‐Wax, 800 µm thick foil). Biocompatibility of both candelilla and C‐wax were investigated through subcutaneous implantation in the abdominal region of mice for two months. No remarkable histological changes were recorded after staining of the skin tissue section with H&E (compared to sham surgery skin). In addition, no adverse immunological response was verified after staining with antibody CD45, a pan‐immune cell marker.

In 2014, Lopez Hernandez et al.14 reported an innovative photodegradable or photo‐triggerable transient electronic device using cPPA as substrate. cPPA is a metastable polymer that depolymerizes into monomers once triggered by acidic conditions. The authors developed a transient system based on a film of cPPA and a photoacid generator, namely, 2‐(4‐methoxystyryl)‐4,6‐bis(trichloromethyl)‐1,3,5‐triazine (MBTT), linked to the backbone of cPPA. When the device was exposed to UV light (379 nm), the MBTT generated a highly reactive Cl• radical rapidly forming hydrochloric acid (HCl), that reacted with cPPA triggering its depolymerization. As a proof‐of‐concept, a free‐standing 2.5% MBTT/cPPA film featuring an array of transistors was fabricated. The MBTT/cPPA film was initially robust under ambient conditions (in air) but the continuous exposition to a UV lamp activated the depolymerization process, transforming the film in an oily and shapeless agglomerate. The whole degradation process lasted about 4 h, though degradation rates could be tuned by modifying the photoacid generator concentration and the irradiance of the UV source. No biocompatibility studies of the material, byproducts, or device were reported by the authors.

Compared to the previously reported bioresorbable polyester polymers, silk‐based natural peptide fibers (naturally produced by Bombyx mori larvae) have been reported as a more attractive alternative for the design of bioresorbable sensors and electronics because of the robust mechanical properties, the ability to tailor dissolution and biodegradation rates (from hours to years), the formation of noninflammatory amino acid degradation products, and the option to prepare the materials at ambient conditions to preserve sensitive electronic functions.58, 65, 66 From the chemical point of view, silk consists of two main proteins, namely, sericin and fibroin, the latter being the structural center of the silk, while the former being the sticky material surrounding it. In vitro dissolution tests of raw silk and of fibroin and sericin filaments (PBS at 37 °C) showed that dissolution occurred with weight losses of 0.12 and 0.08% day−1, respectively.58

3. Bioresorbable Electrical Devices

In this section we will review the main electrical components made out, either in total or partially, of bioresorbable materials, namely, active (e.g., transistors) and passive (e.g., resistors) components, sensors (e.g., physical and chemical), and power sources (e.g., batteries and energy harvesters), paying specific attention to their performance versus biodegradability and biocompatibility in vitro and/or in vivo, where reported.

From now on, for those components in which biodegradability and/or biocompatibility of some of the materials were not explicitly investigated with the component itself, the reader should refer to Section 2 of this Review.

3.1. Electrical Components

Several inorganic and organic bioresorbable materials have been used as active semiconductors, gate dielectrics, electrical interconnections, and supporting substrates for the fabrication of degradable electrical components, toward the achievement of more complex electronic circuits and (in perspective) small microprocessors.

3.1.1. Inorganic Transistors

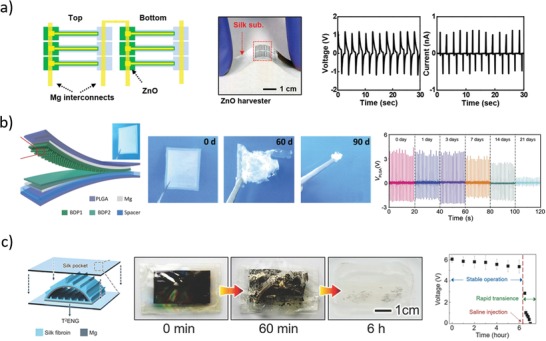

A great impulse to bioresorbable electronics came from the discovery that implanted silicon nanomembranes dissolve in vivo under physiological conditions,28 allowing the use of already mature silicon integrated circuit (IC) technology for the fabrication of transient electronic devices.67

In 2009, Kim et al.65 proposed silk as a bioresorbable substrate for silicon‐based n‐channel metal‐oxide‐semiconductor field effect transistors (MOSFETs). The transistors were fabricated leveraging silicon technology, i.e., silicon dioxide as dielectric and gold for electrical contacts deposited and patterned on crystalline silicon NMs (200 nm thick, p‐type) by using photolithography, reactive ion etching, plasma enhanced chemical vapor deposition, and electron beam evaporation. After fabrication, the transistors were transfer‐printed on a silk freestanding membrane using a poly(dimethylsiloxane) (PDMS) stamp. Silk was chosen as substrate because of its excellent biocompatibility and tunable dissolution, which can be tailored by modification of its chemical structure. Threshold voltage and electron mobility of the transistors were around 0.2 V and 500 cm2 V−1 s−1, respectively, which were comparable to those of traditional silicon MOSFETs. When immersed in water, the 25 µm thick silk substrate dissolved within 3 min, releasing the transistors in water. Electrical characteristics of the transistors after silk dissolution showed only small variations compared to as‐prepared transistors (threshold and electron mobility of 0.5 V and 440 cm2 V−1 s−1, respectively). In vivo studies were carried out by subcutaneously implanting the transistors laying on silk substrate in mice and retrieving them after 2 weeks. The results showed only partial dissolution of both silk film and transistors in this time frame, as well as the lack of any inflammation around the implant site. Although additional studies were required, these initial in vivo experiments suggested promising developments for this form of biodegradable electronics.

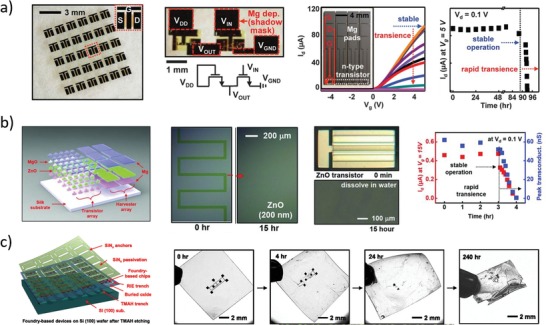

In fact, three years later (2012) the same research group reported28 the groundbreaking invention of transient electronic devices made of silicon, allowing facile fabrication of bioresorbable electronic components (Figure 3 a). In particular, silicon nanomembrane‐based transistors were fabricated using silicon (300 nm thick, p‐type) as active material, SiO2 (100 nm) as gate dielectric, Mg (300–400 nm) for electrical contacts, MgO (400 nm) and silk (70 µm) as encapsulant layers. The disintegrable n‐channel MOSFETs exhibited threshold voltage and electron mobility of about 0.6 V and 500 cm2 V−1 s−1, respectively. In vitro dissolution in DIW at room temperature resulted in stable operation for about 4 days, followed by rapid performance degradation in 30 min (due to Mg electrode disintegration). NAND and NOR logic ports were fabricated and tested in similar ways, as well.

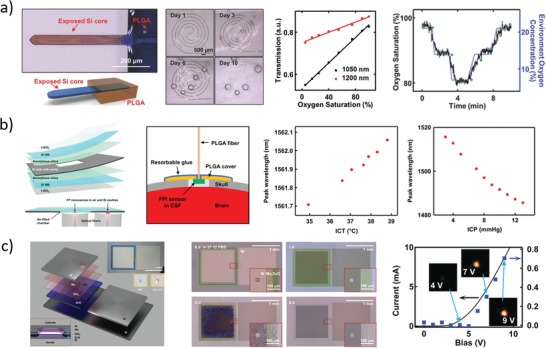

Figure 3.

Representative examples of inorganic transistors. a) Left: Photographs of an array of completely bioresorbable silicon transistors on silk substrate.28 Middle‐left: Optical micrograph of a transient silicon nMOSFET inverter on silk substrate, and respective circuit scheme. Middle‐Right: Electrical characteristic of a nMOSFET during in vitro degradation experiment in deionized water at room temperature; inset: optical micrograph of the device configuration used for the degradation experiment. Right: Functional degradation of the silicon transistor. Reproduced with permission.28 Copyright 2012, American Association for the Advancement of Science. b) Left: Sketch of the ZnO‐based bioresorbable transistor array.73 Middle: Representative optical microscope images during dissolution experiments of a ZnO trace (left) and a complete transistor (right) immersed in deionized water at room temperature. Right: Functional degradation of a MgO‐encapsulated ZnO transistor during immersion in deionized water. Reproduced with permission.73 Copyright 2013, John Wiley and Sons. c) Left: Sketch of the foundry‐compatible bioresorbable Si transistor.67 Right: Representative photographs during device dissolution in buffer at pH 7.4 and 70 °C. Reproduced with permission.67 Copyright 2017, The Authors, Published by National Academy of Sciences.

One year later, Hwang et al.68 reported on silicon‐based bioresorbable n‐type MOSFETs and nMOS inverters fabricated on a custom silicon on insulator (SOI) wafer. The transistors were fabricated with standard IC processes on a 100 nm thick p‐silicon layer, using SiO2 as gate and interlayer dielectrics, and Mg for electrical contacts. Additional SiO2 (100 nm, PECVD) and Si3N4 (400 nm, PECVD) layers were used as encapsulating and masking materials, respectively. Etching of the silicon on the back‐side was carried out in tetramethyl ammonium hydroxide (TMAH) to release the transistors, which were then transfer‐printed on a silk substrate, before removal of the Si3N4 layer. The fabricated bioresorbable nMOSFETs exhibited threshold voltage and electron mobility around 0.6 V and 530 cm2 V−1 s−1, respectively. In vitro experiments in PBS at pH 7.4 and 37 °C were performed to monitor both kinetics and mechanisms of the transistor dissolution. Magnesium was completely dissolved in 36 h, silicon dioxide in 2 weeks, and silicon in 4 weeks. Monitoring of the transistor performance in PBS at pH 7.4 and 37 °C was carried out using an additional magnesium dioxide layer (800 nm thick) for encapsulation. A stable operation was recorded for 8 h, followed by performance degradation in the subsequent 45 min. In vivo experiments were carried out with an array of transistors transfer‐printed on a silk substrate and subcutaneously implanted in mice. The results showed full transistor dissolution and no inflammation response after 2 weeks (verified through histological examination of the tissue surrounding the implant), while substrate dissolution was not yet complete. Using similar approaches, silicon transistors were successfully fabricated on different bioresorbable polymeric substrates, such as PLGA,69 poly(octanediol‐co‐citrate),70 levan polysaccharide,71 as well as on metal foils.72

In the same year, Dagdeviren et al.73 reported on a fully bioresorbable ZnO FET (Figure 3b). Magnesium oxide was used as gate dielectric, magnesium for electrical contacts, and zinc oxide as semiconductor. Silk fibroin was used both as substrate and as encapsulation layer. The threshold voltage of the transistors was 1 V, and carrier mobility was 0.95 cm2 V−1 s−1. Dissolution experiments were performed in deionized water at room temperature: the silk substrate immediately dissolved when immersed in water, while the other components slowly dissolved in 15 h without visible flaking or cracking. To demonstrate functionality in aqueous solution, the transistors were fabricated on glass substrate and encapsulated with magnesium oxide (500 nm thick), resulting in a stable operation over 3 h, followed by a rapid functional degeneration in the next 45 min. All the materials used in this work spontaneously dissolved in water, producing hydroxides (e.g., Mg(OH)2 and Zn(OH)2) or polypeptides that were environmentally and biologically benign (as discussed in Section 2).

More recently (2017), Chang et al.67 developed foundry‐compatible bioresorbable MOSFETs, inverters, and logic ports (Figure 3c). The transistors were fabricated on standard 6‐inch SOI wafers by an external foundry using common IC processes and materials, and then (in laboratory) they were transfer‐printed on a PLGA substrate and encapsulated in a further PLGA layer. Eventually, tungsten electrical connections were patterned between different single transistors as needed. Typical nMOSFET voltage threshold and electron mobility were reported to be about 1.2 V and 630 cm2 V−1 s−1, respectively. Accelerated dissolution experiments on wafer‐attached transistors were performed in PBS at pH 7.4 and 96 °C. Encapsulation layers, interlayer dielectrics, and connection layer dissolved within 5 days, while buried thermal oxide dissolved in the subsequent 10 days. The only insoluble (yet biocompatible) components were adhesion layers (100 nm thick) made of titanium and titanium nitride, whose disintegration happened through delamination, peeling, and flake formation. Device integrity when transferred on PLGA substrate was tested in PBS at pH 7.4 and 70 °C: transistors and interconnections fractured within a few hours, due to PLGA swelling and buckling. PLGA total degradation time was estimated to be around 20 days in the tested conditions (pH 7.4 and 70 °C). Summarizing, bioresorbable silicon‐based transistors have been successfully fabricated with performance comparable to that of standard silicon devices, and the process has been demonstrated to be scaled up to wafer level using industrial IC processes. Although biocompatibility and dissolution of these devices have not always been assessed both in vitro and in vivo (in animal models), the biocompatibility of materials used for transistor fabrication was formerly assessed in independent studies, as discussed in Section 2; performance of isolated devices was only tested in vitro to date.

3.1.2. Organic Transistors

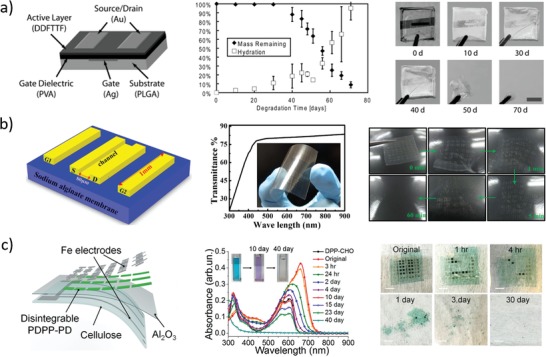

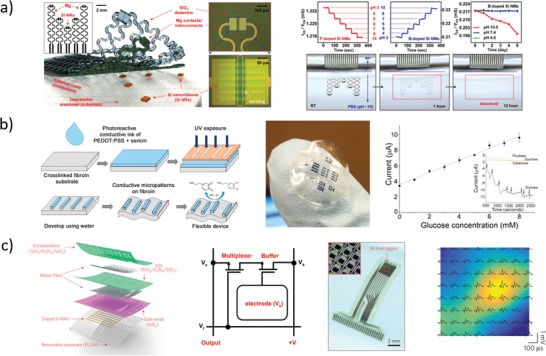

Following the work of Kim et al.65 (2009) on silicon‐based n‐channel MOSFETs on a silk bioresorbable substrate, organic bioresorbable transistors have been also proposed, exploiting well‐known degradable materials commonly used in food, textile, and cosmetic industry (Figure 4 ).

Figure 4.

Representative examples of organic transistors. a) Left: Sketch of the organic transistor with biodegradable substrate and gate dielectric.74 Middle: In vitro degradation experiments, performed in citrate buffer at pH 4 and 37 °C. Right: Representative photographs of in vitro device degradation; scale bar is 5 mm. Reproduced with permission.74 Copyright 2010, John Wiley and Sons. b) Left: Sketch of the biodegradable Electric Double Layer transistor.79 Middle: Transmittance spectrum and photograph of a fabricated transistor array, showing transparency and flexibility. Right: Representative photographs of in vitro device degradation in DIW. Reproduced with permission.79 Copyright 2015, IEEE. c) Left: Sketch of the ultralightweight and biodegradable synthetic polymer transistor.80 Middle: Monitoring of PDPP‐PD degradation in aqueous solution at pH 4.6 by absorbance spectroscopy. Right: Representatives photographs of in vitro device degradation in pH 4.6 solution containing 1 mg mL−1 cellulase enzyme. Reproduced with permission.80 Copyright 2017, The Authors, Published by National Academy of Sciences.

Bettinger and Bao in 2010 reported on a FET74 making use of crosslinked poly(vinyl alcohol) (PVA) as gate dielectric, 5,5'‐bis‐(7‐dodecyl‐9H‐fluoren‐2‐yl)‐2,2′‐bithiophene (DDFTTF) as p‐channel semiconductor, and silver and gold for electrical contacts, both of which were not biodegradable, though having good biocompatibility (Figure 4a); PLGA 85:15 was used as substrate. Threshold voltage and mobility of the transistor were about −15 V and 0.2 cm2 V−1 s−1, respectively. Upon immersion in citrate buffer (pH 4.0) at 37 °C, transistor performance immediately started to deteriorate because of DDFTTF delamination from the dielectric, and the device ceased functioning within hours. PLGA structurally started degrading in one month, and the near‐total device resorption occurred approximately in 70 days.

Capelli et al.75 proposed silk fibroin as a gate dielectric in n‐type and p‐type FETs, making use of N,N′‐ditridecylperylene‐3,4,9,10‐tetracarboxylic diimide (P13) as n‐type semiconductor, α,ω‐dihexyl‐quaterthiophene (DH4T) as p‐type semiconductor, and indium tin oxide (ITO) and gold for electrical contacts; glass was used as substrate. The p‐type FET had a threshold voltage of −17 V and a mobility of 1.3 × 10−2 cm2 V−1 s−1, while the n‐type FET had a threshold voltage of 2 V and a mobility of 4 × 10−2 cm2 V−1 s−1. For n‐type FET, deep‐red (700 nm) light emission was also achieved at V gs = V ds = 90 V.

Jeon et al.76 proposed chicken albumen as potentially biodegradable gate dielectrics of n‐type FET, further using amorphous In–Ga–Zn–O (IGZO) as semiconductor, alumina as passivation layer, and ITO and aluminum as electrical contacts. Transistors were fabricated using either glass or paper as substrate. The FETs fabricated on glass substrate had threshold voltage and electron mobility of 2.25 V and 5.64 cm2 V−1 s−1, respectively, while the ones on paper substrate exhibited 1.73 V and 6.48 cm2 V−1 s−1, respectively.

Irimia‐Vladu et al.77 reported on both p‐ and n‐type semiconductor FETs exploiting glucose, caffeine, or adenine‐guanine bilayers as gate dielectrics (possibly in conjunction with inorganic alumina to increase performance), indanthrene yellow G and indanthrene brilliant orange RF (known in textile and food industry as Vat yellow 1 and Vat orange 3, respectively), β‐carotene, or indigo as semiconductors, and aluminum for electrical contacts. Caramelized glucose and gelatin were used as substrates. Operational voltages and electrical mobilities were in the ranges of 4–20 V and 10−4–10−2 cm2 V−1 s−1, respectively. Indigo pigment was further investigated by Irimia‐Vladu et al.78 in a following work, using anodized aluminum passivated with tetratetracontane (a biodegradable long‐chain alkane commonly found in nature) as gate dielectric, and aluminum for electrical contacts; shellac resin was used as bioresorbable substrate. Indigo showed ambipolar semiconductor properties, enabling the fabrication of both p‐type and n‐type FETs, as well as of complementary MOSFET (CMOS) inverters. The FET threshold voltages were between −1.5 and −3 V for p‐type, and between 4.5 and 7 V for n‐type transistors, while carrier mobilities were around 10−2 cm2 V−1 s−1 in both cases. Indigo performance in n‐type FET degraded upon exposure to air, so that encapsulation with polyimide was used to avoid oxygen‐related degradation.

Although the organic materials employed in the fabrication of these transistors were all potentially biodegradable, no degradation, dissolution, or biocompatibility tests were reported for the studies discussed above. Further, the inorganic materials used were not biodegradable, at least under physiological conditions.

In 2015 Guo et al.79 proposed an electric double layer transistor with aluminum‐zinc oxide electrodes directly deposited on a sodium alginate membrane acting as both bioresorbable substrate and active layer (Figure 4b). Threshold voltage and carrier mobility were −0.05 V and 6.19 cm2 V−1 s−1, respectively. Upon immersion in DIW at room temperature, sodium alginate rapidly dissolved within 5 min, followed by electrode hydrolysis in 1 h.

In 2017 Lei et al.80 reported on pseudo‐CMOS inverters, NAND, and NOR logic ports fabricated using alumina as die‐lectric, a synthetic conjugated polymer as p‐type semiconductor, namely, poly(diketopyrrolopyrrole)‐phenylenediamine (PDPP‐PD), and gold or iron (Fe) for electrical contacts (Figure 4c). Ultrathin regenerated cellulose was used as substrate. The threshold voltage and carrier mobility with gold electrodes were about −4.67 V and 0.21 cm2 V−1 s−1, whereas iron electrodes resulted in slightly poorer performance, namely, about −5.75 V and 0.12 cm2 V−1 s−1, respectively. Upon immersion in acetate buffer at pH 4.6, PDPP‐PD, alumina, and iron spontaneously dissolved; conversely, the use of cellulase enzyme (1 mg mL−1) was necessary to degrade the cellulose substrate. The entire device was completely dissolved within 30 days in cellulase‐containing buffer at pH 4.6. PDPP‐PD degradation was further investigated via absorbance spectroscopy in acetic acid solution 1% v/v in water, showing complete depolymerization in 10 days, and total disintegration in 40 days. The biocompatibility of PDPP‐PD was proved through in vitro cell culture with HL‐1 cardiomyocytes on a glass slide coated with the polymer. No significant difference in cell viability was observed after 6 days, compared to cell cultured on a control surface.

Summarizing, biodegradable organic transistors have shown poor electrical performance with respect to bioresorbable inorganic semiconductor FETs, and in most cases device degradation was only postulated and concerned with single elements of the whole devices, such as, semiconductor, substrate, or dielectric layers. Only in few cases degradation has been tested in vitro, and never in vivo, and stability of the performance of such transistors upon immersion in aqueous media has been mostly overlooked.

3.1.3. Passive Components

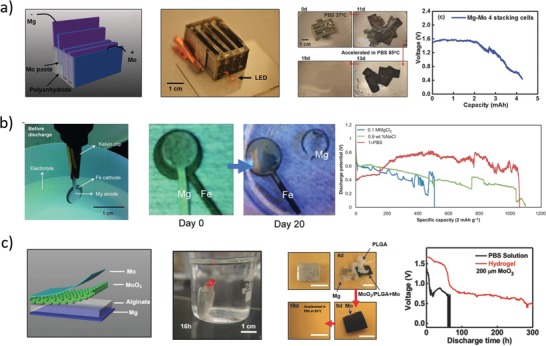

Bioresorbable passive components (e.g., resistors, inductors, antennas, capacitors, diodes) have also been proposed28, 81, 82, 83, 84, 85, 86, 87, 88 either to complement active components (i.e., transistors) toward the realization of more complex circuits (e.g., antennas in radio frequency (RF) circuits), or to be used as transducers (e.g., heaters) in biomedical applications (e.g., antibacterial therapy).

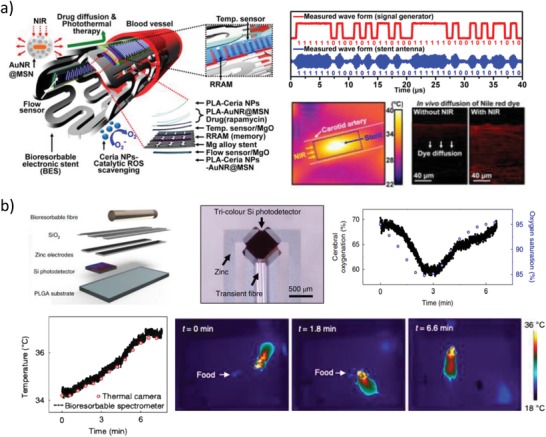

In 2012, Hwang et al.28 reported on the fabrication of inductive coils, resistive serpentines, and capacitive electrodes using Mg for electrical contacts and conductive traces, MgO or SiO2 as encapsulation layers, dielectric materials for capacitors and MOSFET gates, and interlayer insulators, Si as active semiconductor in diodes and transistors, and silk as substrate (Figure 5 a). Single components were fabricated and tested in vitro, demonstrating functionality and lifetime tunability with encapsulation layer type and thickness: for example, a 300 nm thick Mg serpentine with stable resistance over a time interval tunable from 3 h (400 nm MgO) to 100 h (crystallized silk) in DIW at room temperature was reported. A magnesium coil connected to a silicon resistor was demonstrated as an effective in vitro thermal bactericidal device for an Escherichia coli colony in a Petri dish: namely, an external coil was fed with 2 W at 80 MHz for 30 min, causing inductively coupled current flow in the disintegrable circuit and, in turn, resistor heating up to 50 °C. The coil‐resistor circuit was implanted in mouse, resulting in a local temperature increase of about 5 °C upon activation. A metamaterial Mg (400 nm) antenna coated by MgO (600 nm) and encapsulated in silk (100 µm) was implanted in rat and used to monitor biofluid infiltration‐related biodegradation, showing continuous resonance quality factor degradation (Q decreasing from 7 to 2) along 15 days. After this time, the device was retrieved from the animal, showing faint disconnected Mg residues.

Figure 5.

Representative examples of electronic passive components. a) Left: Photograph of various bioresorbable discrete circuital elements on silk substrate.28 Middle: Representative photographs of circuit dissolution in deionized water at room temperature. Right: Metamaterial magnesium antenna transmission peak measured during 15 days of implantation in rat. Reproduced with permission.28 Copyright 2012, American Association for the Advancement of Science. b) Left: Photograph (scale bar: 5 mm) of four wirelessly actuated heaters and sketch of the device materials and structure.82 Middle: Thermographic camera images (inset: optical micrographs) of activated devices during dissolution in PBS at pH 7.4 and 37 °C. Right: Doxorubicin release with and without device activation, showing drug retention in the lipid bilayers for several days if device is not activated. Reproduced under the terms of the CC BY license.82 Copyright 2015, Springer Nature. c) Left: Sketch of the double‐coil antenna with half‐wave rectifier circuit for nerve electrical stimulation.83 Middle: Representative photographs during device degradation in PBS at pH 7.4 and 37 °C. Right: Somatosensory evoked potentials in rat with and without nerve electrical stimulation via bioresorbable coil and electrodes. Reproduced with permission.83 Copyright 2018, Springer Nature.

In 2014, Tao et al.81 used magnesium resistors (200 nm thick) and coils (2 µm thick) on silk substrate (50 µm) to demonstrate thermal effects for direct antibacterial activity and potential on‐demand drug release. The device was characterized in vitro to overheat a bacterial culture on a Petri dish, effectively killing Staphylococcus aureus in the heated zone. In vitro degradation of nonencapsulated devices in deionized water resulted in disintegration after 5 min and complete dissolution within 150 min. In vivo implants in rats infected with S. aureus resulted in sanitizing the wound with two sets of 10 min activations of the wireless resistor at 49 °C (500 mW input power of the external coil, at 80 MHz). After 7 days from implantation, only few traces of the magnesium coil and silk substrate were visible, which were completely resorbed at day 15. In vitro release of bactericidal drug was also demonstrated by coating the device with an ampicillin‐soaked silk layer, and accelerating its dissolution through resistor‐induced heat.

One year later, Lee et al.82 used a very similar approach to fabricate bioresorbable coils for frequency‐addressable drug releasing devices. Molybdenum coils and serpentines were deposited on PLGA substrate, and thermally responsive lipid bilayers were assembled on top, to encapsulate hydrophobic drugs such as antitumoral doxorubicin (Figure 5b). The number of coil turns defined the circuit resonance frequency, while activation time and power (100–1300 mW) modulated the temperature increase to tune lipid bilayer destabilization and, in turn, drug release. In vitro degradation experiments were conducted in PBS at pH 7.4 and 37 °C, resulting in stable operation for 7 days, with significant performance loss occurring on day 8. Complete molybdenum dissolution and PLGA resorption were estimated in several months. Ex vivo experiments with porcine skin showed no doxorubicin leak at 24 h from implantation, and significant drug release after 3 h from device activation at 43 °C. In vivo biocompatibility studies carried out on mice for 5 weeks resulted in immune‐inflammatory response comparable to FDA‐approved HDPE (similar levels of inflammatory cytokines and percentages of immune cells in blood), thus suggesting good biocompatibility of both materials and device.

Very similar coils were also reported by Koo et al.83 and Guo et al.84 for wireless energy transfer via electromagnetic coupling. In particular, Koo et al.83 used a wireless RF receiver to stimulate peripheral nerves in injured rodents (Figure 5c). The device consisted in a magnesium double‐coil antenna (50 µm thick), a silicon RF diode (320 nm silicon with 300 nm Mg electrodes) and a magnesium/silicon oxide/magnesium capacitor (50 µm/600 nm/50 µm), connected so as to form a half‐wave rectifier on a PLGA substrate (30 µm), with magnesium electrodes (50 µm) for contacting the nerves with a wrapping cuff. In vitro dissolution tests in PBS at pH 7.4 and 37 °C showed component disintegration within one month, while in vivo implant residuals were still visible after 8 weeks. The device was tested on living rodents to wirelessly stimulate muscular contraction and accelerate healing of peripheral nerve injury, using the wireless bioresorbable stimulator for 1 h per day, for 6 consecutive days after nerve cut and device implantation.

In 2014, Huang et al.85 reported on a transient printed circuit board (PCB) for the assembling of both active and passive components fabricated using rapidly biodegradable materials. The PCB (23 mm × 23 mm) consisted of stacked layers of transient metal traces and dielectric interlayers on a flexible support. Specifically, sodium carboxymethyl cellulose (Na‐CMC, 50 µm thick) was used as substrate, and Mg, W, and/or Zn (2 µm thick) were used for electrical traces. A layer of poly(ethylene oxide) (PEO) (1 µm thick) between the different Na‐CMC layers of the stack bonded them together. A transient metal paste, consisting of either W or Zn microparticles (4 to 12 µm in average diameter) dispersed in PEO in an organic solvent, was used to mount commercial‐off‐the‐shelf (COTS) components onto contact pads located on the PCB. Evaporation of the solvent at room temperature resulted in a solidified metal/polymer composite with good conductivity properties (up to 40 kS m−1), which acted as a conductive glue between the pins of the COTS components and the PCB. Dissolution tests of the PCB were carried out in water at room temperature, with polymeric materials completely dissolving in 10 min, and transient metals dissolving on timescales of hours to days. As a proof‐of‐concept application, a RF circuit that sensed the ambient temperature and transmitted the measured data through a frequency‐modulated wireless signal was assembled on a PCB with two stacked layers. A transmission antenna located 30 cm away from the circuit was used as power source. The frequency of the wireless signal transmitted by the circuit increased from 2.47 to 2.49 GHz as the temperature changed from 35 to 18 °C.

In 2015, Hwang et al.86 reported on the use of bioresorbable Mg resistors and antennas, and Si NM p–n diodes for the fabrication of bioresorbable passive circuits that changed functionality over time. In a first example, a serpentine Mg resistor was connected in parallel with a Si NM p–n diode, the latter of which was encapsulated with a layer of MgO whereas the Mg resistor was unprotected. At low electrical biases (up to 1 V) most of the current flowed through the resistor, being its resistance much lower than that of the diode. Upon immersion in water, dissolution of Mg occurred, thus changing the electrical response of the circuit from that of a resistor to that of a diode. In a further example, a Mg resistor was connected to a Mg antenna, where specific regions of the antenna were encapsulated with 400 (region 1) and 800 nm (region 2) thick layers of MgO. The other regions of the passive system were encapsulated with bilayers of MgO (800 nm) and SiO2 (2 µm). Upon immersion of the system in water, regions 1 and 2 of the antennas progressively dissolved with different times, thus changing length and, in turn, resonance frequency of the antenna from 1.8 GHz (before immersion) to 1.9 GHz (regions 1 dissolved), and eventually to 2.2 GHz (regions 2 dissolved).

In 2017, Lee et al.87 reported on a fully biodegradable micro‐supercapacitors (MSCs) with high electrochemical performance. Fe, Mo, or W (about 300 nm thick) were used as electrode materials and current collectors, agarose gel with NaCl salt as hydrogel electrolyte (150 µm), PLGA (about 15 µm thick film) was used as supporting substrate, and polyanhydride as encapsulating material. MSCs with Mo interdigitated electrodes offered an areal capacitance of 1.6 mF cm−2 at a current density of 0.15 mA cm−2, and areal energy density and power density of 0.14 µW h cm−2 and 61 µW cm−2, respectively. These values were comparable to those of recently reported nontransient supercapacitors. The electrochemical performance of the supercapacitors was measured up to 10 000 charge/discharge cycles. The capacitance of Mo MSCs increased dramatically during the first 3000 cycles when charged at 0.1 mA cm−2, reaching a maximum value of 4 mF cm−2 (20 times larger than the initial value), and then decreased. This effect was ascribed to additional redox reactions occurring at the metal oxide growing during the capacitor charge/discharge cycles, until the oxide thickness hindered electronic exchange. The performance of Mo MSCs encapsulated in PLGA (about 15 µm) was also studied upon immersion in PBS 10 × 10−3 m at pH 7.4 and 37 °C. The MSCs showed stable performance for 6 h after immersion in PBS, then quickly and completely dissolved afterward (at 10 h). To increase lifetime, an Mo MSC was encapsulated and sealed using polyanhydride (150 µm thick), thus extending stable operation time of the MSC up to 36 h.

3.2. Sensors

There is today an increasing demand for biodegradable and bioresorbable sensors to be used in sport&wellness and/or healthcare applications. In this section we will review the main achievements on physical (e.g., pressure, force, temperature) and chemical (e.g., ions, pH, biomolecules) bioresorbable sensors. In the aforementioned milestone work of Roger's group,28 silicon strain gauges (gauge factor near 40) and silicon diodes and magnesium thermoresistive sensors (sensitivity of −2.23 mV °C−1 and 0.23% °C−1, respectively) had been proposed, along with Si photodiodes in a 2D array configuration, opening great possibilities for following developments.

3.2.1. Physical Sensors

Pressure and temperature sensors represent the most studied bioresorbable physical sensors to date. The former exploit variable capacitors, piezoelectric crystals, and strain gauges; the latter mainly exploit thermoresistive materials (Figure 6 ).

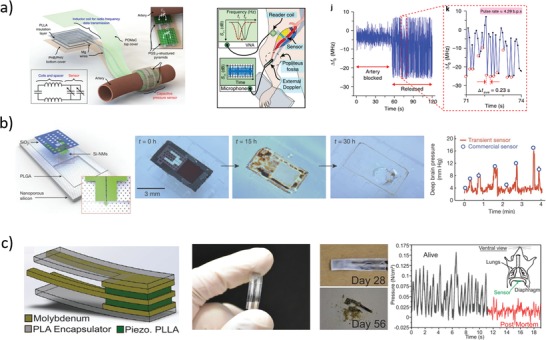

Figure 6.

Representative examples of physical sensors. a) Left: Sketch of the structure and functional principle of the wireless‐readable capacitive pressure sensor.92 Middle: Sketch of the in vivo inductively coupled measurement setup. Right: In vivo rat heart rate measurement. Reproduced with permission.92 Copyright 2019, Springer Nature. b) Left: Sketch of the piezoresistive Si NM pressure sensor.94 Middle: Representative photographs of device dissolution during immersion in aqueous buffer at pH 12. Right: Calibration of device performance in artificial cerebrospinal fluid. Reproduced with permission.94 Copyright 2016, Springer Nature. c) Left: Sketch of the piezoelectric pressure sensor.96 Middle: Photographs of a fabricated device before degradation (left) and after (right) immersion in PBS at 74 °C. Right: In vivo measurement of diaphragm pressure in mouse. Reproduced with permission.96 Copyright 2018, The Authors, Published by National Academy of Sciences.

Luo et al.89 fabricated fully bioresorbable capacitors using a PLLA substrate sealed with PCL, with metal connections and electrodes made of iron (adhesion promoter) and zinc. Namely, iron (5–10 µm thick) and zinc (50 µm) were electroplated through a mask in order to fabricate a coil (inductor) connected to two disks (capacitor electrodes); the obtained metal traces were then laminated on a poly(l‐lactide) (PLLA) substrate (200–300 µm), and the assembly was folded so as to obtain a plane capacitor with the metal disks separated by a 30 µm PLLA O‐ring, and sealed with 40 µm PCL spacer. The capacitor was thus enclosed in a passive inductor, capacitor, and resistor (LCR) circuit, and the shift of the resonant frequency of the circuit induced by changes of the capacitance value upon application of a pressure was monitored with an external antenna. The system was characterized in the pressure range 0–20 kPa, showing a sensitivity of about −39 MHz kPa−1 (relative capacitance sensitivity 0.05 kPa−1) in air. In vitro stability tests were performed on the LCR sensing circuit immersed in aqueous saline solution (NaCl 0.9%) without an external applied pressure, resulting in an increased performance during the first 107 h (sensitivity of −54 MHz kPa−1), then followed by rapid performance degradation until hour 170. In vitro degradation of the metal traces was tested using freestanding iron/zinc electroplated electrodes immersed in saline solution at room temperature, resulting in disintegration within 24 h, and almost complete dissolution in roughly 300 h.

Boutry et al.90 fabricated a capacitive pressure sensor using iron (2 nm thick, used as adhesion promoter) and magnesium (100 µm) as capacitor electrodes, printed on polyhydroxybutyrate/polyhydroxyvalerate (PHB/PHV, 25 µm) substrates, separated by a PGS (150 µm) dielectric spacer. To improve device recovery time after pressure application and reduce hysteresis, the PGS surface was patterned with micropyramids. The relative capacitive sensitivity was 0.76 kPa−1 until 2 kPa, and 0.11 kPa−1 from 2 to 10 kPa. A 5 × 4 bidimensional grid of sensors was obtained using orthogonal electrical connections in the top and bottom layers. Blood pulse wave from radial, femoral, and carotid arteries was successfully measured on human volunteers by application of the device on the skin. Material degradation was tested by immersing the device in PBS at pH 7.4 and 37 °C for seven weeks, showing rapid metal dissolution, and rather slow polymeric dissolution, which lasted a few months (after seven weeks, the device retained about 85% of its initial weight). Further, mechanical characteristics of PGS cylinders did not vary significantly during seven weeks of incubation in PBS, due to slow material surface erosion mechanism (instead of rapid bulk erosion, typical in many water‐swelling polymers, like PLGA), suggesting device functional characteristic stability over time.

The same group recently reported a hybrid sensor for simultaneous strain and pressure measurement.91 It was composed by a capacitive pressure sensor (similar to that previously described90 with Mg electrodes separated by PGS micropyramids) and a capacitive strain sensor (two comb Mg electrodes (100 nm thick) patterned on top of PLLA substrates (50 µm thick) and stacked so that a 50 µm thick PLLA acted as dielectrics). The entire device was encapsulated in poly(octamethylene maleate (anhydride) citrate) (POMaC) and PGS. In‐plane strain caused changes in Mg comb alignment, and, consequently, capacitance variations. The capacitive strain sensor was tested in laboratory environment, showing a sensitivity of about −0.23 pF %−1, with a capacitance percentage change of 50% at strain of 15%, with fast response time (within milliseconds), good stability to cycling (capacitance drift about 10% after 20 000 cycles between 5% and 10% strains), and no crosstalk between pressure and strain measurements. The device was tested in vitro by immersion in PBS at pH 7.4 and 37 °C, showing stable performance for 2–3 weeks, with much longer degradation time (after 7 weeks most of the device was still not degraded). In vivo subcutaneous implantation of the sensor in the back of rats resulted in good pressure and strain signal detection after 3.5 weeks, thanks to POMaC and PGS slow surface erosion mechanism. In vivo biocompatibility studies (both immunohistochemistry and H&E staining) carried out over 8 weeks from implantation showed inflammatory response comparable to that of silicone patch used as control.

In another recent work of the same group,92 a miniaturized capacitive pressure sensor with slightly different geometry was implanted in rat around the femoral artery, and heart rate was wirelessly measured on‐demand, exploiting RF coupling to monitor LCR resonant circuit frequency shift.89, 93 Namely, PHB/PHV and POMaC (thickness of 10 µm each) were used as bottom and top substrate, respectively, laser‐cut magnesium foil (50 µm) was used for inductive coil antenna and fringe‐field capacitor metal traces, PLLA (40 µm) was inserted as coil spacer, and micropatterned PGS (40 µm) acted as dielectric (Figure 6a). The sensor was characterized in vitro with both contact and noncontact experiments: for contact measurements, a PDMS slab was pressed (up to 20 kPa) on the device, while in noncontact measurements the PDMS slab was only approached to the device without touching it. In vitro sensor characterization was carried out using an LCR meter directly wired to the device, resulting in a relative sensor sensitivity of about 2.2% kPa−1 for contact pressure experiments (in the 0–6 kPa range) and 2.5% nm−1 for noncontact experiments. Noncontact mode was of chief importance because a tight wrapping of the device around blood vessel could hinder blood flow inside it. The device was implanted in rat, wrapping femoral artery with softer POMaC layer facing blood vessel wall, and harder PHB/PHV facing outside, in order to reduce pressure interferences due to respiration movements. Rat heart rate was successfully measured by inductive coupling between the internal coil and an external antenna connected to a vector network analyzer, monitoring real‐time resonance frequency shifts. One week after implantation, the signal had a poorer quality, but it was still recognizable. Partial bioresorption (only PHB/PHV left) was observed after 12 weeks without severe inflammation signs, through immunohistochemistry analysis with CD68, a surface marker of macrophages.

Besides variable capacitors, piezoresistive materials that experience resistance changes when subjected to mechanical strain (piezoresistive effect) have been used for bioresorbable pressure sensors. As piezoresistive materials are also (often) sensitive to temperature changes, the same piezoresistive serpentine has been used as temperature sensor if deposited on a rigid surface, and as strain sensor if constrained on a flexible membrane.

In 2016, Kang et al.94 fabricated silicon serpentines (for both pressure and temperature monitoring) by patterning Si NMs (300 nm thick) on a SOI wafer and subsequent transfer‐printing on a flexible PLGA membrane (30 µm thick). For pressure sensing, the latter was suspended over a square cavity (about 30–40 µm deep) etched into a nanoporous silicon layer (about 60–80 µm thick, 71% porosity) used as supporting substrate (Figure 6b). Magnesium and molybdenum were used for metal traces, and SiO2 was used for electrical insulation and as encapsulating material. Silicon serpentine fabricated outside the cavity area served as temperature sensor. The pressure sensor was calibrated in vitro using artificial cerebrospinal fluid (ACSF), resulting in strain gauge resistance around 258 kΩ, and sensitivity around 0.6 kΩ kPa−1, corresponding to a gauge factor of 30. Similarly, temperature sensor in ACSF showed a sensitivity around 0.1 kΩ °C−1, with a resistance of 74 kΩ at 35 °C, corresponding to a thermal coefficient about 0.14% °C−1. Device dissolution studies were performed in vitro in buffer solution at pH 12 and room temperature, leading to complete dissolution in about 30 h. To increase the device functional time, a polyanhydride encapsulation was also used, at the cost of a decrease in pressure sensor sensitivity (0.38 kΩ kPa−1). The bioresorbable pressure and temperature sensors were implanted in living rat brain and wired to an external non‐bioresorbable power supply and communication unit fixed on the scalp, successfully proving intracranial pressure and temperature measurement for 3 and 6 days, respectively, and showing no adverse effects in the animal. Biocompatibility studies of polyanhydride were performed 2, 4, and 8 weeks after implantation through H&E staining, showing no overt adverse immune response from rat brain cells, compared to HDPE used as control. An alternative to the external wiring was proposed by using a commercial non‐biodegradable NFC chip subcutaneously fixed on a PLGA substrate with magnesium electrical connection.

Besides pressure and temperature, also acceleration, thermal conductivity, and flow rate sensors were fabricated by Kang et al.94 using serpentine sensors based on patterned Si NMs. Full dissolution, characterization, and calibration of these sensors were not detailed, though their output signals were reported to be comparable to those of commercial non‐bioresorbable control sensors. For instance, an acceleration sensor was fabricated with a piezoresistive strain gauge transfer‐printed on a PLGA cantilever suspended on a cavity etched in the porous silicon substrate. Deflection of the PLGA cantilever, upon an acceleration solicitation, resulted in change of the strain gauge resistance, that was monitored as output signal. Further, a thermal conductivity sensor was achieved using a silicon serpentine resistor. Upon injection of a current through the silicon resistor, its temperature rapidly increased; on the other hand, when the current flow ceased, the temperature of the silicon resistor returned to its initial value with a dynamic that depended on the thermal conductivity of the surrounding medium. Proof‐of‐concept demonstration was given in water, ethylene glycol, toluene, and hexane, though no calibration was reported. Eventually, a flow rate sensor was achieved using two temperature sensors with a silicon resistor in between, spatially arranged in a linear fashion. When the resistor was heated through injection of a current, a temperature gradient arose between the two sensors aligned with the flow direction of the liquid, so that the difference between the temperature sensors was directly related to the fluid flow rate. The sensor was tested in a water bath up to 3 mL s−1 showing a sensitivity around 0.15 °C s mL−1.

Shin et al.95 reported on a piezoresistive pressure sensor fabricated using silicon strain gauges on a suspended amorphous silica membrane. Two SOI wafers with a 100 nm thick top silicon layer (Si NM) were bonded together using a 3 µm thick PDMS adhesion interlayer. Before bonding, four silicon meander‐shaped resistors (defining the pressure and temperature gauge sensors) were defined on the Si NM of one the SOI wafers, and a square trench with size 200 × 200 × 10 µm (defining the pressure sensitive region) was etched on the Si NM of the other one. Two of the silicon resistors, the ones designed to work as pressure‐sensitive strain gauges, were placed in correspondence of the pressure sensitive region; the other ones, designed to work as temperature‐sensitive gauges, were placed on rigid region of the wafer. Thermal treatment at 550 °C for 2 h calcined the PDMS adhesion layer yielding an amorphous silica layer (about 200 nm thick), which acted as a flexible membrane in the pressure sensitive region, where the silica layer was suspended on the square trench. Chemical removal of the back‐side silicon of SOI wafers resulted in ultrathin, bioresorbable electronic devices encapsulated in thermal SiO2 layers. The two pressure‐sensitive strain gauges (on the suspended silica membrane) were connected with the two silicon pressure‐sensitive gauges in a Wheatstone bridge configuration, so as to obtain a bioresorbable pressure sensor chip with automatic rejection of thermal effects on pressure measurements. The pressure sensor chip was calibrated in ACSF at pH 7.4 and 37 °C, showing a pressure sensitivity around 0.13 Ω mmHg−1 (corresponding to 0.98 Ω kPa−1), and good signal stability (variation in pressure sensitivity within 1.5%) after 22 days of continuous operation. Temperature gauges were calibrated in a similar way in ACSF, resulting in a temperature coefficient of resistance (relative sensitivity) of 0.12% °C−1. Accelerated dissolution tests were performed in vitro in PBS at pH 7.4 and 95 °C, showing that the pressure sensor chip was completely dissolved within 80 h, with only the thermal SiO2 layer of the bottom SOI wafer left after this time; dissolution time in physiological conditions was estimated to be about 400 days. The pressure/temperature sensor chip was implanted in living rat skull and connected to an external digital multimeter to record voltage data. Commercial clinical pressure and temperature sensors were also implanted and used as control. In vivo pressure (while compressing and releasing the rat flank) and temperature (while applying heating blanket or ice pack to the rat) measurements recorded over a period of 25 days were consistent with clinical control sensors, though sensor accuracy degraded with time, and signals disappeared after day 25 (possibly due to dissolution of metal Mo electrodes). The authors further demonstrated wireless pressure data transmission to a personal computer (PC) from a miniaturized potentiostat wired to the implanted sensor chip and externally secured on rat skull. Insights into the physiological reactions to the proposed pressure/temperature sensor chip were achieved through implantation in rats of a miniaturized version (750 µm × 750 µm × 11 µm vs 1.3 mm × 1.3 mm × 16 µm) of the chip without thermal SiO2 encapsulation. Evaluation of the biodistribution of dissolved silicon resulted in silicon accumulation mostly in kidney, liver, and spleen after one week, and normal level recovery within 5 weeks; no adverse effects were observed in blood analysis and in histological analysis of brain, spleen, heart, and kidney tissues, by comparison between mice with and without implanted sensor.

In 2018, Curry et al.96 fabricated a bioresorbable piezoelectric pressure sensor using PLLA as piezoelectric material. The sensor structure (5 mm × 5 mm in size, 200 µm thick) consisted of two layers of piezoelectric PLLA (27 µm) sandwiched between Mo or Mg electrodes and encapsulated in normal PLA (Figure 6c). To make PLLA piezoelectric, a PLLA film was stretched at an annealing temperature of 90 °C, so as to simultaneously induce polymer chain orientation and improve material crystallinity. The PLLA film was eventually cut with an angle of 45° with respect to the stretching direction to maximize piezoelectric response. PLLA films with different draw ratios (between final stretched length and initial length) were investigated to assess piezoelectric response (through both impact and vibration testing), showing optimal piezoelectrical response of PLLA sensors with a draw ratio around 5 (for which crystallinity is about 55%). The PLLA pressure sensor was then connected to a charge amplifier circuit to convert force‐induced charge to voltage, and calibrated with predefined weights in the range 0–18 kPa. The calibration curve showed two linear regions, namely, 0–2 kPa with sensitivity of 75 mV kPa−1 and 3–18 kPa with sensitivity of 14 mV kPa−1. Performance degradation of the PLLA pressure sensor was studied both in vitro and in vivo by placing the device in PBS at pH 7.4 and 37 °C and subcutaneously implanting the device in the back of mice, respectively. In both cases, sensor output signals were comparable before and after 4 days of tests, though after 8 days from implantation there was no detectable signal. Accelerated degradation tests were then performed in PBS at pH 7.4 and 74 °C, still showing visible device fragments after 56 days. In vivo subcutaneous implantation in the back of mice showed mild immune response after 2 weeks, which reduced to normal levels after 4 weeks. Histological staining with H&E was performed to observe inflammatory cell response, while Masson's Trichrome blue staining was carried out to detect fibrosis; immunohistochemical staining with CD64 antibody was performed to reveal macrophages. As a proof‐of‐concept application, the PLLA pressure sensor was fixed to mouse abdomen and used to measure diaphragmatic contraction of the living animal during anesthesia and subsequent euthanasia via anesthetic overdose.