Supply disruptions of imported mineral commodities pose significant risk to U.S. manufacturers of emerging technologies.

Abstract

Trade tensions, resource nationalism, and various other factors are increasing concerns regarding the supply reliability of nonfuel mineral commodities. This is especially the case for commodities required for new and emerging technologies ranging from electric vehicles to wind turbines. In this analysis, we use a conventional risk-modeling framework to develop and apply a new methodology for assessing the supply risk to the U.S. manufacturing sector. Specifically, supply risk is defined as the confluence of three factors: the likelihood of a foreign supply disruption, the dependency of U.S. manufacturers on foreign supplies, and the ability of U.S. manufacturers to withstand a supply disruption. The methodology is applied to 52 commodities for the decade spanning 2007–2016. The results indicate that a subset of 23 commodities, including cobalt, niobium, rare earth elements, and tungsten, pose the greatest supply risk. This supply risk is dynamic, shifting with changes in global market conditions.

INTRODUCTION

Together, population growth, economic development, and the accelerating pace of technological innovation are driving the demand for natural resources to unprecedented levels. This is especially the case for nonfuel mineral commodities that are increasingly used in emerging and low-carbon technologies, including cobalt in rechargeable batteries (1), tellurium in certain thin-film solar photovoltaics (2), and rare earth elements in permanent magnets (3). It is these and other mineral commodities that will be required in greater quantities to fulfill the needs and desires of an increasingly affluent, growing global population (4).

While demand for mineral commodities will likely continue to grow, the reliability of their supply is not necessarily assured. A number of trends, including the concentration of production in a few countries (5), declining mineral ore grades (6), in-use dissipation (7), and limited end-of-life recycling (8), raise concerns regarding the reliability of supplies. These concerns are compounded by the fact that many of the mineral commodities used in emerging technologies are produced mainly or solely as by-products and may have inelastic supply (9). Moreover, the potential for material substitution is often limited (4, 10), especially as manufacturers strive for smaller, faster, lighter, and smarter technologies by using each commodity for its particular properties that are uniquely suited for the desired function.

While several of the aforementioned factors may affect availability of mineral commodities in the long term (i.e., >10 years), recent trade tensions, geopolitical instability, conflict-associated artisanal and small-scale mining [e.g., (11)], persistent mine labor strikes [e.g., (12)], as well as calls for resource nationalism [e.g., (13)] have served to underscore concerns for the short to medium term (i.e., 5 to 10 years), especially for countries that are highly import reliant (14). Concerns regarding access to and availability of natural resources are not new. Industrialized nations have been concerned with the security of mineral supplies and “mineral independence” since at least the early 1900s (15, 16). These concerns have waxed and waned throughout most of the 20th century [e.g., (17)]. A 2008 report by the U.S. National Research Council (18), which coincided with China’s growing role as both a supplier and a consumer of a large number of mineral commodities, heightened awareness of these underlying issues and concerns. These concerns were realized in 2010 when a territorial dispute between China and Japan threatened to disrupt the supply of the rare earth elements and have since reemerged over the past few months with rising trade tensions between the United States and China.

These developments have renewed interest in assessing the supply risk (SR) of mineral commodities among governmental agencies [e.g., (19)], nongovernmental organizations [e.g., (20)], academic researchers [e.g., (21)], and corporations [e.g., (22)] who have developed their own assessment of “criticality.” These assessments vary in purpose, scope, and methodology (23, 24). Some focus on specific countries or regions [e.g., (25)], while others assess the global situation [e.g., (26)]. Some focus on a specific issue [e.g., renewable energy (27)], while others examine only a narrow set of commodities or a single commodity [e.g., (28)].

In the United States, existing and new efforts to address concerns regarding critical minerals were recognized and accelerated in December 2017 when the President issued Executive Order 13817 (29). This Order highlighted U.S. foreign reliance as a strategic vulnerability and directed the publication of a list of critical minerals, which were defined as follows:

“(i) a non-fuel mineral or mineral material essential to the economic and national security of the United States, (ii) the supply chain of which is vulnerable to disruption, and (iii) that serves an essential function in the manufacturing of a product, the absence of which would have significant consequences for our economy or our national security.”

Using the work of the Subcommittee on Critical and Strategic Mineral Supply Chains at the U.S. National Science and Technology Council (NSTC), a list of 35 critical mineral commodities and commodity groups was issued in the Federal Register on 18 May 2018 (30).

The analysis presented here builds upon the NSTC’s work by addressing a very specific question: which nonfuel mineral commodities pose the greatest SR to the U.S. manufacturing sector? Our analysis focuses on the U.S. manufacturing sector because it is the sector of the economy that would be most directly affected by a mineral commodity supply disruption. To address this question, we use a conventional risk-modeling framework. Specifically, risk is defined as the confluence of three factors: a hazard (i.e., the likelihood of a disruptive event of a certain severity to occur), the degree of exposure to the said hazard, and the vulnerability to it. From the U.S. perspective of mineral commodity SR, the hazard is a foreign (i.e., non-U.S.) mineral commodity supply disruption, exposure is the U.S. manufacturing sector’s dependence on foreign supplies, and vulnerability is the U.S. manufacturing sector’s ability (or lack thereof) to withstand a supply disruption. This “risk triangle” (31)—consisting of hazard, exposure, and vulnerability—indicates that the combination of these factors is necessary, but each alone is an insufficient condition for risk. The U.S. manufacturing sector may, for example, be vulnerable to a supply disruption, but if the likelihood of that supply disruption is low, then the overall risk is low. Similarly, if the likelihood of a supply disruption is high but the U.S. manufacturing sector is not reliant on foreign supplies or is not vulnerable to supply disruptions, then the overall risk to the U.S. manufacturing sector would also be low.

Overall, the analysis includes 52 nonfuel mineral commodities (with several commodities being delineated at multiple supply chain stages) and spans the years 2007–2016. While the scope of commodities and time period covered was selected, in part, due to data availability, it provides an opportunity to examine trends and insights across a wide breadth of commodities—ranging from industrial minerals to precious metals and from base metals to their by-products—and over a period of time that includes various market and geopolitical dynamics including the aforementioned 2010 rare earth crisis.

MATERIALS AND METHODS

SR was calculated as the geometric mean of three indicators: disruption potential (DP), trade exposure (TE), and economic vulnerability (EV) (Eq. 1)

| (1) |

These indicators aim to capture the three complementary aspects of risk, respectively: hazard, exposure, and vulnerability. For ease of comparability, each indicator was normalized on a common 0 to 1 scale, with higher scores indicating a greater degree of risk.

The following sections explain the calculation of each indicator, with details regarding data sources and assumptions for each commodity provided in the Supplementary Materials. There are eight commodities (aluminum, cobalt, copper, lead, nickel, tin, titanium, and zinc) for which data are available for multiple production stages. For these eight commodities, the highest indicator score among the production stages in a given year was used. This “bottleneck” approach allows for the identification of commodities that may have issues at different supply chain stages. Further information on the analysis of multiple production stages is also provided in the Supplementary Materials. For a few commodities, namely, dysprosium, neodymium, praseodymium, samarium, and tellurium, data are not available to complete the analysis for all years.

Disruption potential

A variety of factors can trigger a supply disruption including those that are caused by nature (e.g., earthquakes) and those that are man-made (e.g., labor strikes) (32, 33). Furthermore, man-made disruptions may be deliberate (e.g., trade disputes), while others may be involuntary or accidental (e.g., mine accidents). This analysis focuses on man-made supply disruptions and therefore addresses a producing country’s ability and willingness to supply the United States. From this perspective, “ability” encompasses factors such as a producing country’s political stability, infrastructure, and availability of skilled labor that may affect its ability to continue to supply raw materials, while “willingness” encompasses factors such as a producing country’s trade ties, shared values, and military cooperation with the United States that may affect the likelihood that it would deliberately disrupt supplies to the United States. All other things being equal, the likelihood of a supply disruption is greater for a commodity whose production is concentrated in a few countries that are more likely to become unable or unwilling to supply the United States than a commodity with production that is highly distributed among many willing and able producing countries. The following equation calculates the DP for a given commodity in a given year

| (2) |

where for commodity i in year t, PS is the share of world production attributable to country c, ASI is a country-specific Ability to Supply Index, and WSI is a country-specific Willingness to Supply Index. The squaring of the production share simulates the Herfindahl-Hirschman Index (HHI). HHI, a metric that was developed to provide a measure for market concentration (34), is most commonly known for its use by the U.S. Department of Justice to assess horizontal mergers and acquisitions. It has since been used by most criticality assessments (23). Whenever possible, both primary and secondary (i.e., postconsumer or old scrap) country-level production quantities were used in the calculation of HHI. However, for many commodities, only primary production data are available at the country level. Prompt or “new” scrap, as well as “home” scrap, was excluded from the analysis because it does not, on a net basis, provide additional supply. Because the analysis was conducted from the perspective of a supply disruption to the United States, production in the United States was excluded from the HHI calculation. Table S1 provides details regarding data sources for primary and secondary production used in this analysis.

To assess ASI, the Fraser Institute’s Policy Perception Index (PPI) was used (35). PPI was selected in this analysis over other country-level indicators that have been used in other criticality assessments, such as the World Bank’s Worldwide Governance Indicators, because it encompasses factors that are more directly related to a country’s ability to continue to perform mining activities. Specifically, PPI is part of an annual survey of mining and exploration executives that rates jurisdictions on 15 different policy factors including availability of skilled labor, access to infrastructure and power, level of security and political stability, taxation regime, and uncertainties regarding laws and regulations. Responses that best describe each jurisdiction on a five-tiered scale across each policy factor were aggregated to provide a single score on a 100-point scale. As illustrated in Eq. 3, PPI scores for each country c and year t were normalized in this analysis by reversing the scores, such that higher scores indicate a higher DP, and linearly scaling the scores to a maximum of 1

| (3) |

Note that in 2016, the Fraser Institute revised its methodology for calculating PPI. Previously, the PPI was calculated by examining only the top 2 response categories, while the new methodology accounts for all five response categories. To avoid the impact of this methodological change on the results, the new PPI methodology has been applied to all years by using the raw data in the reports provided by the Fraser Institute. In addition, PPI scores that are provided at the subnational level for several countries, namely, Canada, Australia, and Argentina, were aggregated by averaging all subnational jurisdiction scores provided.

To assess WSI, three new indicators have been developed: trade ties (TT), shared values (SV), and military cooperation (MC). The rationale underlying WSI is that the stronger the relations (be they trade, ideological, or military) between a country and the United States, the less likely it is for that country to deliberately disrupt its supplies to U.S. manufacturers. Specifically, TT refers to the amount of trade that a country has with the United States and is measured as the monetary sum of its imports and exports with the United States relative to its gross domestic product (GDP) in a given year; SV refers to the extent to which the ideological values of a country align with those of the United States and is measured as the Euclidean “distance” between the country in question and the United States across indicators of political rights and civil liberties (electoral process, political pluralism and participation, functioning of government, freedom of expression and belief, associational and organizational rights, rule of law, and personal autonomy and individual rights), as quantified by Freedom House’s Freedom in the World (FIW) index (36); and MC refers to whether the country has a current collective defense arrangement with the United States. Details regarding the calculation of each WSI indicator, as well as the country-level annual results from 2007 to 2016, are presented in the Supplementary Materials. Overall, WSI was calculated as the average of TT and SV, both of which have a maximum score of 1 for the “least willing” countries (i.e., those with greatest DP), and was reduced by 0.1 for countries that have a collective defense arrangement with the United States (MC).

To obtain scores that range from 0 to 1, the raw DP scores (Eq. 2) were normalized on the basis of the observed minimum and maximum scores across all commodities and years

| (4) |

Note that ASI and WSI scores are available for most, but not all, countries. For producing countries without either an ASI or WSI score, the available index was instead used twice (i.e., the available index is squared in Eq. 2). There were no instances in the analysis in which both ASI and WSI were not available for a producing country.

Trade exposure

U.S. manufacturers that can obtain their supplies of a commodity completely from domestic sources are, to a considerable degree, insulated from supply disruptions that occur in other countries. Conversely, manufacturers that must obtain all their supplies of a commodity from abroad have full exposure to foreign supply disruptions. The TE indicator thus measures the degree of exposure to foreign supply disruptions by calculating the U.S. net import reliance as a percentage of apparent consumption for each commodity

| (5) |

where for commodity i in year t, I and E are the U.S. import and export quantities, respectively, of the applicable Harmonized Tariff Schedule trade codes, ΔS is the adjustments of U.S. industry and government stocks, and AC is the U.S. apparent consumption. AC was calculated as follows

| (6) |

where for commodity i in year t, PP and SP are the primary and secondary (old scrap) production quantities of the United States. Most of the commodities analyzed use this method to calculate TE. For a few commodities, including several of the rare earth elements, a reported consumption (RC) quantity was used in combination with (or instead of) apparent consumption due to limited specific trade data for that commodity. In those cases, TE was calculated as follows

| (7) |

Table S2 presents specifics regarding the data, data sources, and assumptions for U.S. primary and secondary production, trade codes, and stock changes. Net imports can be negative if exports are greater than imports (i.e., the United States is a net exporter). However, TE is limited to range from 0 to 1 such that commodities with net exports receive a score of zero.

Economic vulnerability

Faced with a supply disruption that increases the price of their mineral commodity inputs, manufacturers can undertake one or more actions: They can absorb the price increase; reduce their use via either enhanced manufacturing techniques, “thrifting,” or substitution; secure supplies through long-term contracts or strategic inventories; or pass part or all of the price increase to their customers. While circumstances vary by the individual manufacturer and commodity, in general, many of these options are undesirable and often have real and substantial limitations and costs. For example, substitution may be possible if an alternative technology is readily available but will often require manufacturers to pay higher prices or accept lower performance (4, 10, 37). Committing to long-term contracts reduces flexibility, while maintaining large inventories increases costs and ties up working capital. Manufacturers with market power may be able to pass commodity price increases to their customers but that may erode demand over time.

All other things being equal, manufacturers that are less profitable are less able to use any of these options and are thus less able to withstand a commodity price shock that may result from a supply disruption compared to manufacturers that are more profitable. Similarly, manufacturers that have large expenditures on a given commodity (either due to its high price or large quantities required) are more vulnerable than those that expend very little on that commodity. The ratio of an industry’s expenditure on a given commodity relative to that industry’s profitability thus provides a useful metric for assessing an industry’s relative vulnerability. Summing the industry-specific vulnerabilities across applicable industries generates a commodity-specific assessment. Given that not all industries are of equal importance to the U.S. economy, industries that provide a greater contribution to the economy are weighted more heavily. Taking these factors into account, the following equation assesses the EV of the U.S. manufacturing sector for each commodity

| (8) |

where EXPi,t,j is industry j’s expenditure on commodity i in year t, OP is that industry’s operating profit, and VA is the industry’s value added (i.e., its contribution to GDP). The ratio of EXP to OP provides a measure of each industry’s vulnerability, while that of VA to GDP provides a measure of that industry’s economic importance to the economy.

The United States defines economic industries by the North American Industry Classification System (NAICS) in a hierarchical structure at the two-digit sector (e.g., 31-33 manufacturing), three-digit subsector (e.g., 334 computer and electronic product manufacturing), four-digit industry group (e.g., 3341 computer and peripheral equipment manufacturing), and five- and six-digit NAICS and national industry (e.g., 334112 computer storage device manufacturing) levels, with more digits signifying a more narrowly defined industry. Wherever possible, the most detailed level applicable (typically six-digit NAICS) was used in this analysis. Data regarding specific economic conditions of each NAICS-defined industry were obtained from the U.S. Census Bureau’s Economic Census, which occurs every year that ends with 2 and 7 (38). For interim years, the U.S. Census Bureau provides similar data in its Annual Survey of Manufactures (ASM) (39). These surveys are mandatory and provide statistics on all manufacturing establishments with one or more paid employees. To estimate an industry’s operating profitability (OP), the following costs were subtracted from its total value of shipments and receipts for services: payroll, fringe benefits (e.g., employee health insurance), cost of materials and energy, rental or lease payments, changes in inventories (including finished goods, work in progress, and materials and supplies), and other operating expenses.

Multiplying a commodity’s total apparent or reported consumption quantity by the fraction that is associated with a specific industry and an appropriate commodity unit price generates industry-specific EXP estimates for that commodity. In most cases, consumption fractions (i.e., the fraction of demand associated with a given use) are available on an application basis rather than being industry specific (e.g., approximately 8% of aluminum is used in electrical applications). These consumption fractions by application are thus linked to an appropriate set of industries, with OP and VA of the individual industries being aggregated across the set. Table S4 presents details on the demand fractions for each application and the associated NAICS codes, while table S1 presents details on the commodity prices used.

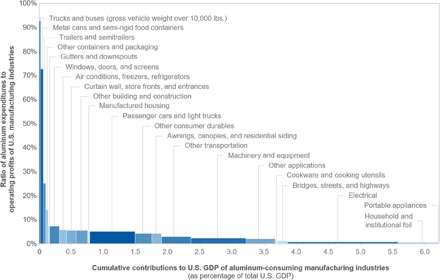

Figure 1 provides an example of the EV calculation for aluminum in 2008. Each aluminum application is linked to either an individual NAICS manufacturing industry or a set of industries (see table S4). Aluminum’s consumption in these applications is multiplied by aluminum’s annual average price to provide an estimate of EXP, while the OP and VA of the associated industries are derived from Economic Census or ASM data and, where applicable, aggregated on an application basis. In the figure, each application is represented as an individual column, with the ratio of EXP to OP plotted as the height of each column on the vertical axis and the ratio of VA to GDP plotted as the width of each column on the horizontal axis. The 21 identified applications that use aluminum are plotted cumulatively in descending order of their EXP-to-OP ratio. The area of each column (i.e., EXP/OP × VA/GDP) represents the EV of each application (presented with darker shading indicating greater vulnerability). The sum of the areas for all applications across the entire figure represents the overall EV of aluminum.

Fig. 1. Assessing the EV of aluminum by application for the year 2008.

Each of the 21 aluminum applications is represented by an individual column, with height depicting the ratio of EXP to OP and width representing the ratio of VA to GDP. The area of each column represents the application’s vulnerability, with darker shades indicating a greater contribution to aluminum’s overall vulnerability.

Note that, on the vertical axis, a column with a height of 100% specifies that EXP equals OP, indicating that the expenditure on this specific commodity by that industry (or set of industries) was equal to that industry’s operating profit. Another way to interpret the vertical axis is that its numerical inverse indicates the percentage increase in a commodity’s price that would be necessary to eliminate the industry’s profits for the year. For example, an EXP-to-OP ratio of 50% indicates that a commodity price increase of 200% (i.e., a tripling of price of this specific commodity) would effectively eliminate the industry’s operating profits for the year, while an EXP-to-OP ratio of 100% suggests that a price increase of 100% (i.e., a doubling of the commodity’s price) would eliminate the industry’s operating profits.

In this aluminum example, the width of the column for passenger cars and light trucks is large in comparison to that of metal cans and semi-rigid food containers. In contrast, the height of the metal cans column is notably taller than that of passenger cars. This indicates that the industries associated with passenger cars provide a larger contribution to GDP than the industries associated with metal cans, but the metal cans industries are much more vulnerable to aluminum price shocks because the ratio of their expenditures on aluminum to operating profits is greater than that of the passenger cars industries. Overall, these two applications contribute the most to aluminum’s total vulnerability (as indicative of their areas and their darker shading), with passenger cars providing a slightly greater contribution than metal cans for this particular year (2008). Notably, the sum of VA across applications on the horizontal axis indicates that more than 6% of U.S. GDP (or just under $917 billion) was associated with aluminum in the manufacturing sector in 2008. For comparison, the entire manufacturing sector accounted for approximately 12% of U.S. GDP that year.

The raw EV scores were normalized to range from 0 to 1, with higher scores indicating greater vulnerability, based on the observed minimum and maximum scores across all commodities and years using the following equation

| (9) |

RESULTS AND DISCUSSION

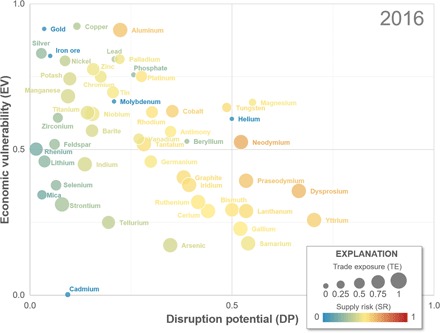

The results are presented in Fig. 2 for 2016, with similar figures for years 2007–2015 presented in the Supplementary Materials. Figure 2 is a scatterplot, with each point’s location representing a commodity’s DP (horizontal axis) and EV (vertical axis), its size representing a commodity’s TE, and its shade representing a commodity’s overall SR. An initial observation of the two-dimensional space (DP and EV) indicates that commodities extend from the top left corner (low DP, high EV) to the bottom right (high DP, low EV). This general trend makes sense given that commodities that are used extensively throughout the economy are those that have been used by societies for millennia and are produced by a diverse set of countries, while mineral commodities used in niche applications are typically produced by only a small number of countries.

Fig. 2. Assessment of SR for year 2016.

DP (horizontal axis), EV (vertical axis), TE (point size), and SR (point shade) are shown. For some commodities, indicator scores are rounded to avoid disclosing company proprietary data.

In three-dimensional space, with TE as the third dimension, the situation is more complex and less intuitive to decipher visually. A hierarchical cluster analysis—a statistical mechanism for grouping objects based on similarities in their attributes—based on the Euclidean distance across the three indicators is used to help interpret the results and identify natural groupings (see the Supplementary Materials for details). One cluster includes arsenic, indium, strontium, and tellurium. These commodities have moderate to low DP (0.1 to 0.3) and EV (0.2 to 0.4) but very high TE (0.9 to 1.0), thereby resulting in moderate overall SR (0.3 to 0.4). These scores reflect the relative diversity of countries that produced these commodities, the lack of significant domestic production, and their use in a limited number of specialized applications.

A nearby cluster with similarly moderate EV (0.3 to 0.6) but notably lower DP (<0.1) and TE (0.5 to 0.8) includes feldspar, lithium, mica, rhenium, selenium, and zirconium. Greater production diversity and a significant amount of domestic production distinguish commodities in this cluster from those in the previous one. Their overall SR scores are thus lower (0.2 to 0.3).

On the upper end of the EV scale are copper, gold, iron ore, lead, molybdenum, and phosphate. These commodities have very high EV (0.7 to 0.9) but low DP (0 to 0.3) and TE (0 to 0.3) because they are used extensively throughout the U.S. manufacturing sector and are produced by a large number of countries, including the United States. The United States is a net exporter for several of these commodities. Their overall SR scores are thus also low (0 to 0.3).

Another cluster includes beryllium, helium, magnesium, and tungsten. These commodities have moderate DP (0.4 to 0.6) and EV (0.5 to 0.7) and either very low (for helium and beryllium) or moderate (for tungsten and magnesium) TE. While the United States is the largest global producer of both beryllium and helium, it is not a major producer of tungsten or magnesium (metal). In the case of tungsten, U.S. production is exclusively secondary (i.e., recycling). This dissimilarity in TE causes these two sets of commodities within this cluster to have notably different overall SR scores, with magnesium and tungsten at around 0.5 and beryllium and helium at less than 0.3.

Commodities with high DP (0.4 to 0.7), very high TE (0.9 to 1.0), and moderate EV (0.2 to 0.5) form yet another cluster. Commodities in this cluster, which includes bismuth, cerium, dysprosium, gallium, natural graphite, iridium, lanthanum, neodymium, praseodymium, ruthenium, samarium, and yttrium, generally have the highest overall SR for this specific year (0.5 to 0.6). These commodities are mainly produced in one or two countries (of which the United States is not one) and often have niche or specialized applications.

The remaining commodities (aluminum, antimony, barite, chromium, cobalt, germanium, manganese, niobium, nickel, palladium, platinum, potash, rhodium, silver, tantalum, tin, titanium, vanadium, and zinc) form another cluster also with high TE (0.5 to 0.9), but in contrast to the previous cluster, their DP is low (0 to 0.4) and their EV is high (0.5 to 0.9). Their SR scores have a wide range (0.2 to 0.6), reflecting the diversity of commodities within this group that includes both high-volume commodities such as aluminum and low-volume precious metals such as rhodium.

Aside from these six clusters stands cadmium with exceptionally low scores in all three dimensions. These low scores reflect cadmium’s limited use by U.S. manufacturers, a lack of a single dominant global producer, and the ability of domestic suppliers to provide sufficient quantities for domestic consumption.

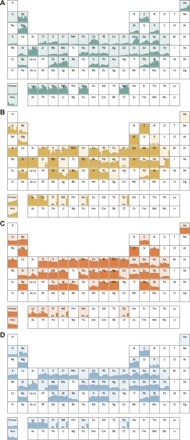

The SR of a commodity can and does change with market dynamics. Figure 3 presents these changes for each of the indicators and the overall SR for the years 2007–2016. From this figure, several interesting trends emerge. In Fig. 3A, for example, the DP of several commodities, including aluminum, arsenic, bismuth, cobalt, gallium, germanium, helium, molybdenum, phosphate, tantalum, and tungsten, has increased over the years 2007–2016. This is mainly due to an increase in global production concentration. Despite the overall increase in DP, there is also a notable decline in DP in the latter years for several of these commodities. For some commodities, such as molybdenum, this is mainly attributable to a decrease in global production concentration stemming from a decline in production from one or more major producers. For other commodities, such as tantalum, the decline in production concentration is instead due to an increase in production in countries that are not the dominant producers. Increased production diversification is also the reason DP for the rare earth elements decreased in the past few years, as production outside of China ramped up. For most commodities, DP has remained relatively constant or has changed only modestly.

Fig. 3. SR by indicator for years 2007–2016.

DP (A), TE (B), EV (C), and SR (D) scores for all commodities examined for the years 2007–2016 are shown. For each box, the vertical axis represents scores ranging from 0 to 1, while the horizontal axis represents the years 2007–2016. No results are available for tellurium (Te) before 2011 or neodymium (Nd), praseodymium (Pr), samarium (Sm), and dysprosium (Dy) before year 2015, as indicated by “NA” in their box. For some commodities, indicator scores are rounded to avoid disclosing company proprietary data.

As illustrated in Fig. 3B, some commodities have seen sporadic changes in their TE due to the dynamics of domestic production, trade, consumption, and stock releases. However, TE for most commodities has remained relatively or completely constant. Throughout the decade, TE for helium, iron ore, molybdenum, and gold has been 0 (i.e., the United States was a net exporter of these commodities), while TE for 12 other commodities including natural graphite (listed under C), indium, and gallium has been 1 (i.e., the United States was 100% net import reliant for these commodities). There are, however, a few noteworthy trends. For lanthanum and cerium, the decline and subsequent increase in TE reflect the shifting operations of the Mountain Pass mine in California over the decade. The mine has since restarted operations but currently ships the concentrate to China for processing.

As displayed in Fig. 3C, EV for most commodities have also been relatively constant throughout the decade, with some commodities including aluminum, copper, gold, iron ore, lead, and silver having consistently high EV, while others including arsenic, iridium, strontium, and tellurium having consistently low EV. A few exceptions include bismuth, ruthenium, and rhodium for which EV has decreased notably. In each of these cases, EV declined mainly because of a decline in the commodity’s price and (or) a decrease in its consumption. The price spike of rare earths in 2011 and subsequent decline are also evident in the EV peak for lanthanum, cerium, and yttrium.

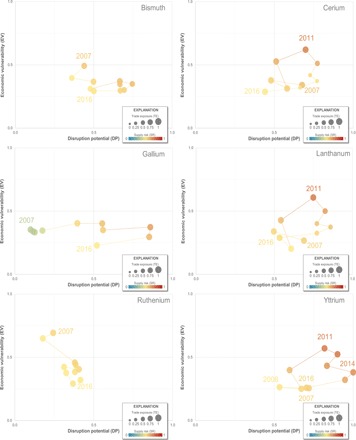

Some commodities have notable movements in more than one indicator. The movements for several of these commodities are displayed in Fig. 4. For bismuth, the increases and subsequent decreases in DP are driven by the production outside of China, which has fluctuated throughout this period. Decreases in bismuth’s price and its consumption by the U.S. manufacturing sector explain the decreases in its EV. For ruthenium, a notable decline in its price and domestic consumption drove EV significantly lower, while an estimated increase in production concentration in South Africa increased DP modestly. For gallium, DP increased significantly from 2007 to 2014 because of the rapid increase in production in China. In 2016, Chinese production decreased notably because of an effort to reduce excess supply, which has also been driving down the price of low-purity (≤99.99%) gallium. Consumption of gallium by U.S. manufacturers also decreased notably from 2015 to 2016, especially in laser diodes and light-emitting diodes, possibly because of a shift of production of these optoelectronic devices overseas. As a result, both DP and EV for gallium declined significantly in 2016. For the rare earth elements cerium, lanthanum, and yttrium, scores moved in a clockwise direction in the DP and EV space, reaching a peak EV score in 2011 at the height of the rare earth crisis when prices spiked before reaching a peak DP in 2014. The 2016 scores returned to nearly the same position they were at in 2007 (especially in the case of yttrium) as countries outside of China ramped up their production.

Fig. 4. Dynamic SR indicators for selected commodities.

DP (horizontal axis), EV (vertical axis), TE (point size), and SR (point shade) for the years 2007–2016 for selected commodities are shown. For some commodities, indicator scores are rounded to avoid disclosing company proprietary data.

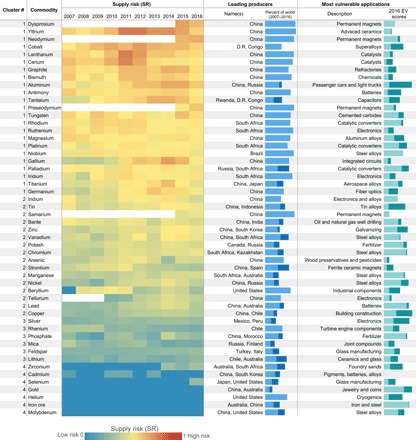

The movements of these individual indicators are reflected in the trends of the overall SR in Fig. 3D. Some commodities including aluminum, gallium, germanium, and tantalum have generally increasing SR, while commodities including magnesium, mica, and strontium have generally decreasing SR. Aside from these and a few other notable movements, SR for most commodities has remained relatively consistent such that commodities with generally high SR and those with generally low SR maintained those levels throughout the decade. This is best illustrated in Fig. 5, which displays a heat map for SR (with orange to red shades indicating a greater degree of risk) for all the commodities analyzed over this period. The commodities are listed in descending order based on their average SR across the decade.

Fig. 5. Heat map displaying the SR for all commodities examined for years 2007–2016.

Warmer (i.e., orange to red) shades indicate a greater degree of SR. Commodities are listed in descending order of their 2007–2016 average SR and identified by cluster based on a hierarchical cluster analysis. Leading producing countries, based on primary production, are identified, and their share of world production from 2007 to 2016 is displayed in the stacked blue bars. The most vulnerable applications in 2016 are identified, and their contribution and the contribution of all other applications to a commodity’s overall EV are depicted in the stacked teal and dark teal bars, respectively.

A second hierarchical cluster analysis, this time on the 2007–2016 average SR for each commodity (see the Supplementary Materials for details), identifies four clusters as indicated in the first column of Fig. 5. Cluster 1 consists of 23 commodities with the highest SR scores and thus poses the greatest SR to the U.S. manufacturing sector. These commodities include rare earth elements, platinum-group elements, cobalt, tungsten, and tantalum. Figure 5 also identifies the largest producing country (or top 2 countries if the largest producer produced less than half of world production from 2007 to 2016). China is the largest producer for 16 of the 23 commodities identified as having the greatest SR. This is, perhaps, not surprising given China’s increasing role over the past few decades as a major producer of numerous mineral commodities. In addition, 15 of these 23 commodities are produced mainly or solely as by-products. This is aligned with previous criticality assessments (24) and is not unexpected given that by-product commodities typically have highly concentrated production (9). Moreover, despite differences in methodological approaches and scopes of previous assessments, 21 of the 23 commodities identified in this analysis as having the greatest SR have previously been designated as “critical” in at least 71% of studies in which they were examined (24). Aluminum and titanium are the two exceptions having been identified as critical in only 22 and 26% of previous studies in which they were examined, respectively (24). The reason for this divergence stems primarily from the use of the bottleneck approach in this assessment in which indicator scores for a commodity with data at multiple production stages are derived from the production stage that yields the highest scores. In the case of both aluminum and titanium, different production stages provide higher indicator scores for different indicators. Specifically, the high TE scores for aluminum and titanium are driven by bauxite and titanium mineral concentrate production, respectively, while the high DP and EV scores are driven by aluminum smelter and titanium metal production. This bottleneck approach thus appropriately identifies risks that reside at different supply chain stages that would otherwise be overlooked if examined separately.

The applications that are most vulnerable to a supply disruption for each commodity are also displayed in Fig. 5. Specifically, these applications contributed the most to the overall EV score of that commodity for year 2016. The contributions of the most vulnerable applications and the contributions of all other applications are depicted in the teal and dark teal colors, respectively. Notably, for many commodities, the vulnerability is driven by a single application (e.g., permanent magnets for dysprosium, neodymium, praseodymium, and samarium; catalytic converters for rhodium; and cemented carbides for tungsten), while for others, the vulnerability stems from many different applications (e.g., aluminum).

CONCLUSIONS

For the decade spanning 2007–2016, these results identify a subset of mineral commodities, including rare earth elements, platinum-group elements, cobalt, niobium, tantalum, and tungsten, that pose the greatest SR for the U.S. manufacturing sector. This subset includes commodities that have a high degree of production concentration in countries that may become unable or unwilling to supply to the United States, are mainly imported from other countries, and are consumed in economically important manufacturing industries that may be less able to withstand a price shock that may result from a supply disruption. It is this subset of commodities for which further investigations are necessary.

No set of indicators alone can perfectly capture the complex set of issues that are unique to each commodity and the manufacturing industries that consume it. Moreover, SR is dynamic, increasing and decreasing with changing global market conditions that are specific to each commodity and industry. A commodity with supply that is not at high risk today may become at high risk in the future as production and consumption patterns shift. Nevertheless, the analysis indicates that significant changes in SR over short periods of time are rare, seeming to have occurred for only a few commodities examined in this analysis over the past decade. Moreover, although SR scores can and do change markedly, the subset of commodities with the highest SR has been largely consistent throughout the time period examined. This is noteworthy given that both policies and corporate actions cannot be driven by year-to-year fluctuations.

Once identified as having high SR, it is then important to determine how best to reduce that risk for that commodity. As noted in Introduction, risk arises at the confluence of three factors: hazard, exposure, and vulnerability. The combination of these three factors is necessary, but each alone is insufficient. In turn, reducing the risk of a supply disruption can be achieved by reducing any one of these three factors. As indicated by a recent report from the U.S. Department of Commerce in response to Executive Order 13817 (40), diversifying supply, securing supplies through trade relationships, developing domestic primary and secondary resources and capabilities, using less of a material through improved or alternative manufacturing techniques and recycling, and stockpiling are all means by which the risk can be reduced. The degree to which any one of these strategies can be successful at minimizing the risk to an acceptable level depends on the specific commodity and the industries involved, as well as what is deemed to be an acceptable level of risk.

Supplementary Material

Acknowledgments

We would like to thank the specialists at the National Minerals Information Center at the U.S. Geological Survey for input and feedback. All authors are U.S. government employees or contractors for the U.S. government. This work was conducted as part of the authors’ regular duties. No funding was received from sources external to the U.S. government. Author contributions: N.T.N. and S.M.F. conceived the research. N.T.N. designed the research and developed the methodology with input from the other authors. All authors contributed to the analysis. N.T.N. created the figures and wrote the manuscript with input from the other authors. Competing interests: The authors declare that they have no competing interests. Data and materials availability: All data needed to evaluate the conclusions in the paper are present in the paper, the Supplementary Materials, or the referenced data sources. A full list of references cited in this Supplementary Materials can be found on the following website: https://doi.org/10.5281/zenodo.3595382.

SUPPLEMENTARY MATERIALS

Supplementary material for this article is available at http://advances.sciencemag.org/cgi/content/full/6/8/eaay8647/DC1

Supplementary Materials and Methods

Fig. S1. WSI and constituent components by year.

Fig. S2. SR, DP, EV, and TE scores for years 2007–2015.

Fig. S3. Hierarchical cluster analysis based on 2016 DP, EV, and TE scores.

Fig. S4. Hierarchical cluster analysis based on 2007–2016 average SR scores.

Table S1. Description of data for world primary and secondary production and prices for each commodity.

Table S2. Description of data for U.S. apparent consumption calculation by component for each commodity.

Table S3. Estimated elemental content of various steel alloys.

Table S4. Description of applications, associated NAICS codes, and U.S. demand fractions for each commodity.

Table S5. Rare earth oxide distribution (in percent of total) for various world regions.

Table S6. Rare earth oxide distribution (in percent of total) for various regions in China.

REFERENCES AND NOTES

- 1.Tisserant A., Pauliuk S., Matching global cobalt demand under different scenarios for co-production and mining attractiveness. J. Econ. Struct. 5, 4 (2016). [Google Scholar]

- 2.Nassar N. T., Wilburn D. R., Goonan T. G., Byproduct metal requirements for U.S. wind and solar photovoltaic electricity generation up to the year 2040 under various Clean Power Plan scenarios. Appl. Energy 183, 1209–1226 (2016). [Google Scholar]

- 3.Alonso E., Sherman A. M., Wallington T. J., Everson M. P., Field F. R., Roth R., Kirchain R. E., Evaluating rare earth element availability: A case with revolutionary demand from clean technologies. Environ. Sci. Technol. 46, 3406–3414 (2012). [DOI] [PubMed] [Google Scholar]

- 4.Graedel T. E., Harper E. M., Nassar N. T., Reck B. K., On the materials basis of modern society. Proc. Natl. Acad. Sci. U.S.A. 112, 6295–6300 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Subcommittee on Critical and Strategic Mineral Supply Chains, “Assessment of critical minerals: Screening methodology and initial application” (U.S. National Science and Technology Council, 2016); https://obamawhitehouse.archives.gov/sites/default/files/microsites/ostp/NSTC/csmsc_assessment_of_critical_minerals_report_2016-03-16_final.pdf.

- 6.Mudd G. M., The environmental sustainability of mining in Australia: Key mega-trends and looming constraints. Resour. Policy 35, 98–115 (2010). [Google Scholar]

- 7.Ciacci L., Reck B. K., Nassar N. T., Graedel T. E., Lost by design. Environ. Sci. Technol. 49, 9443–9451 (2015). [DOI] [PubMed] [Google Scholar]

- 8.Graedel T. E., Allwood J., Birat J.-P., Buchert M., Hagelüken C., Reck B. K., Sibley S. F., Sonnemann G., What do we know about metal recycling rates? J. Ind. Ecol. 15, 355–366 (2011). [Google Scholar]

- 9.Nassar N. T., Graedel T. E., Harper E. M., By-product metals are technologically essential but have problematic supply. Sci. Adv. 1, e1400180 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Nassar N. T., Limitations to elemental substitution as exemplified by the platinum-group metals. Green Chem. 17, 2226–2235 (2015). [Google Scholar]

- 11.Nassar N. T., Shifts and trends in the global anthropogenic stocks and flows of tantalum. Resour. Conserv. Recycl. 125, 233–250 (2017). [Google Scholar]

- 12.T. R. Yager, Y. Soto-Viruet, J. J. Barry, Recent Strikes in South Africa’s Platinum Group Metal Mines: Effects Upon World Platinum Group Metals Supplies (U.S. Geological Survey, 2013). [Google Scholar]

- 13.G. W. Lederer, Resource Nationalism in Indonesia—Effects of the 2014 Mineral Export Ban (U.S. Geological Survey, 2016). [Google Scholar]

- 14.Gulley A. L., Nassar N. T., Xun S., China, the United States, and competition for resources that enable emerging technologies. Proc. Natl. Acad. Sci. U.S.A. 115, 4111–4115 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.U.S. President’s Materials Policy Commission (The Paley Commission), Resources for Freedom—Foundations for Growth and Security (U.S. Government Printing Office, 1952). [Google Scholar]

- 16.G. A. Roush, Strategic Mineral Supplies (McGraw-Hill, 1939). [Google Scholar]

- 17.E. E. Hughes, S. S. Baum, E. Just, M. D. Levine, Strategic Resources and National Security: An Initial Assessment (Stanford Research Institute, 1975). [Google Scholar]

- 18.National Research Council, Minerals, Critical Minerals, and the U.S. Economy (The National Academies Press, 2008). [Google Scholar]

- 19.Deloitte Sustainability, British Geological Survey, Bureau de Recherches Géologiques et Minières, Netherlands Organisation for Applied Scientific Research, “Study on the review of the list of critical raw materials: Criticality assessments” (European Commission, 2017).

- 20.M. Buchert, D. Schüler, D. Bleher, “Critical metals for future sustainable technologies and their recycling potential” (United Nations Environment Programme, United Nations University, 2009).

- 21.Graedel T. E., Barr R., Chandler C., Chase T., Choi J., Christoffersen L., Friedlander E., Henly C., Jun C., Nassar N. T., Schechner D., Warren S., Yang M.-y., Zhu C., Methodology of metal criticality determination. Environ. Sci. Technol. 46, 1063–1070 (2012). [DOI] [PubMed] [Google Scholar]

- 22.Duclos S. J., Otto J. P., Konitzer D. G., Design in an era of constrained resources. Mech. Eng. 132, 36–40 (2010). [Google Scholar]

- 23.Graedel T. E., Reck B. K., Six years of criticality assessments: What have we learned so far? J. Ind. Ecol. 20, 692–699 (2016). [Google Scholar]

- 24.Hayes S. M., McCullough E. A., Critical minerals: A review of elemental trends in comprehensive criticality studies. Resour. Policy. 59, 192–199 (2018). [Google Scholar]

- 25.N. Morley, D. Eatherley, “Material security—Ensuring resource availability for the UK economy” (Oakedene Hollins, C-Tech Innovation Ltd., 2008).

- 26.Graedel T. E., Harper E. M., Nassar N. T., Nuss P., Reck B. K., Criticality of metals and metalloids. Proc. Natl. Acad. Sci. U.S.A. 112, 4257–4262 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.D. Bauer, D. Diamond, J. Li, M. McKittrick, D. Sandalow, P. Telleen, “Critical materials strategy” (U.S. Department of Energy, 2011).

- 28.Rosenau-Tornow D., Buchholz P., Riemann A., Wagner M., Assessing the long-term supply risks for mineral raw materials—A combined evaluation of past and future trends. Resour. Policy 34, 161–175 (2009). [Google Scholar]

- 29.The President , Executive order 13817: A federal strategy to ensure secure and reliable supplies of critical minerals. Fed. Regist. 82, 60835–60837 (2017). [Google Scholar]

- 30.S. M. Fortier, N. T. Nassar, G. W. Lederer, J. Brainard, J. Gambogi, E. A. McCullough, “Draft critical mineral list—Summary of methodology and background information—U.S. Geological Survey technical input document in response to Secretarial Order No. 3359” (U.S. Geological Survey, 2018).

- 31.D. Crichton, “The risk triangle”, in Natural Disaster Management, J. Ingleton, Ed. (Tudor Rose, 1999). [Google Scholar]

- 32.Hatayama H., Tahara K., Adopting an objective approach to criticality assessment: Learning from the past. Resour. Policy. 55, 96–102 (2018). [Google Scholar]

- 33.Schnebele E., Jaiswal K., Luco N., Nassar N. T., Natural hazards and mineral commodity supply: Quantifying risk of earthquake disruption to South American copper supply. Resour. Policy. 63, 101430 (2019). [Google Scholar]

- 34.O. C. Herfindahl, Concentration in the steel industry, thesis, Columbia University, New York (1950). [Google Scholar]

- 35.A. Stedman, K. P. Green, Fraser Institute Annual Survey of Mining Companies 2017 (Fraser Institute, 2018). [Google Scholar]

- 36.Freedom House, Freedom in the World 2019 (Freedom House, 2018). [Google Scholar]

- 37.Smith B. J., Eggert R. G., Multifaceted material substitution: The Case of NdFeB magnets, 20104–2015. JOM 68, 1964–1971 (2016). [Google Scholar]

- 38.U.S. Census Bureau, Economic Census (2019); www.census.gov/programs-surveys/economic-census.html.

- 39.U.S. Census Bureau, Annual Survey of Manufactures (ASM) (2017); www.census.gov/programs-surveys/asm.html.

- 40.U.S. Department of Commerce, A Federal Strategy to Ensure Secure and Reliable Supplies of Critical Minerals (U.S. Department of Commerce, 2019). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material for this article is available at http://advances.sciencemag.org/cgi/content/full/6/8/eaay8647/DC1

Supplementary Materials and Methods

Fig. S1. WSI and constituent components by year.

Fig. S2. SR, DP, EV, and TE scores for years 2007–2015.

Fig. S3. Hierarchical cluster analysis based on 2016 DP, EV, and TE scores.

Fig. S4. Hierarchical cluster analysis based on 2007–2016 average SR scores.

Table S1. Description of data for world primary and secondary production and prices for each commodity.

Table S2. Description of data for U.S. apparent consumption calculation by component for each commodity.

Table S3. Estimated elemental content of various steel alloys.

Table S4. Description of applications, associated NAICS codes, and U.S. demand fractions for each commodity.

Table S5. Rare earth oxide distribution (in percent of total) for various world regions.

Table S6. Rare earth oxide distribution (in percent of total) for various regions in China.