Abstract

Objectives:

Most previous work conducted on the wear behavior of dental materials has focused on wear rates and surface damage. There is, however, scarce information regarding the subsurface damage arising from sliding contact fatigue. The aim of this study was to elucidate the wear mechanisms and the subsurface damage created during sliding contact fatigue in 5 contemporary CAD/CAM materials against a zirconia indenter.

Methods:

Forty discs (ø12 mm, 1.55 mm thick) were cut out of IPS e.max CAD (e.CAD), Suprinity PC (SUP), Enamic (ENA), Vitablocs Mark II (VMII) and Lava Ultimate (LU) blocks and mirror polished. After cementation onto a dentin-like composite, off-axis mouth-motion cycling was conducted with a spherical zirconia indenter (r = 3.175 mm) in water (200 N load, 2 Hz frequency) for 5 different cycling periods (102, 103, 104, 105, 106 cycles, n = 8). Analysis of the wear scars was conducted using light-microscopy, scanning-electron-microscopy and optical profilometry. Subsurface damage was assessed using sagittal and transverse sections of the samples.

Results:

Fatigue wear mechanisms predominated in glassy materials (e.CAD, SUP, VMII), accompanied by extensive subsurface damage, whereas abrasive wear mechanisms were responsible for the large wear craters in the resin composite (LU) with an absolute absence of subsurface fracture. A combination of both mechanisms was observed in the polymer-infiltrated reinforced-glass (ENA), displaying large wear craters and severe subsurface damage.

Significance:

Well-controlled laboratory simulation can identify wear and subsurface damage susceptibility of various classes of restorative materials. Both wear and subsurface fracture are determining factors for the long-term success of restorations.

Keywords: Dental ceramics, composites, sliding contact, wear mechanism, wear rate

1. Introduction

Computer-aided-design and computer-aided-manufacturing (CAD/CAM) technologies have revolutionized the fabrication of dental restorations, not only by an immense reduction in the laboratory working times, but also by opening the door to a wide spectrum of new materials. Originally designed for the machining of hard ceramics, computer assisted technologies have expanded to almost every restorative material in modern dentistry, encompassing feldspathic ceramics and glass-ceramics and, more recently, also resin composites. Parallel to this strong industrial development, intensive research has been done by dental material’s scientists in order to better characterize and predict the mechanical behavior of these newly introduced materials. This is reflected by the vast amount of literature published in the field over the last few years focusing on their microstructure [1,2], strength [3–6], fracture toughness [7,8] and wear behavior [9–13]. This latter property has been considered as a clinical predictor of the material’s resistance to masticatory forces and oral attrition. Still, a direct correlation of in vitro results to clinical data has shown to be strongly dependent upon the material in question and the testing method employed [14]. Therefore, data from the literature tend to be difficult to assess, preventing a direct comparison of their findings and limiting the application of their conclusions in clinical scenarios.

Wear is defined as a gradual loss of material originated by the mechanical interaction between two contacting surfaces that are in relative motion under a given load [15]. Physical separation during the process occurs mainly due to microfracture and chemical dissolution [16], creating telltale marks on the worn surface characteristic to the wear mechanisms that originated them. Accordingly, four main types of wear have been described: adhesive-, abrasive-, fatigue- and corrosive wear [16,17]. Abrasive wear is the most commonly observed wearing type in dental restorative materials, generally occurring under plastic contacts. Its main mechanism is ploughing [18], with material removal by the indentation of asperities or hard particles into the softer surface of the antagonist [17]. As a consequence, abrasive grooves are formed in the direction of sliding. These wear marks depend on the nature of the indented material and the ploughing mechanism, varying from microcutting in ductile surfaces, to microfracture in brittle materials [16]. Fatigue wear, on the other hand, occurs under repeated elastic contacts, with crack propagation from microdefects in the sliding path of the indenter as the main mechanism. The friction force caused by sliding introduces shear stresses at the contact interfaces, whereas compressive stresses are generated ahead of the motion and tensile stresses develop at the trailing edge of the sliding indenter [16]. Thus, nucleation and propagation of cracks is favored by the cyclic motion, eventually causing the cracks to reach the surface and leading to delamination and material loss or spallation in the surrounding areas [17].

In the subsurface of the material, repeated cycling favors the development and growth of partial cone cracks, which are generated by tensile stresses at the trailing edge of the indenter and further driven by hydraulic pumping of water into the cracks [19,20]. Their morphology, density and crack-to-surface angles are closely related to the coefficient of friction at the interface [21,22], as well as to the fracture toughness of the indented material [19]. Hence, materials with higher toughness will exhibit enhanced resistance to propagation of partial cone cracks during sliding contact fatigue. On the other hand, higher coefficients of friction lead to steeper penetration angles, as well as higher crack densities [21]. The continuous growth of this type of cracks into the bulk of the material, especially at high penetration angles, can seriously jeopardize the final strength of the restoration by acting as stress concentrators and ultimately as fracture origins [23].

Most literature published over the years on the wear behavior of CAD/CAM materials has been focusing on the wear rates and the surface damage caused by different indenters (natural teeth, steatite, metals, oxide ceramics, etc.) under diverse testing conditions (i.e. two- or three-body wear). There is, however, scarce information regarding the underlying damage arising from sliding contact fatigue, which seems to be a determining factor for the long-term success of these restorative materials [19]. Moreover, only limited descriptions of the subsurface damage modes and the resistance against crack propagation of newly introduced materials, such as polymer-infiltrated reinforced-glass networks (PIRGN) or lithia-based glass-ceramics, is available. Therefore, the goal of the present study was to characterize the surface and subsurface damage mechanisms in five contemporary CAD/CAM materials subjected to cyclic sliding contact fatigue against a spherical zirconia indenter. Tests were conducted in water at a relatively high load in order to allow a complete development of partial cone cracks at the trailing edge of the indenter. Their growth, as well as the concomitant surface degradation, was successively followed up to 1 million cycles.

2. Materials and Methods

2.1. Sample preparation

Five ceramic-containing dental materials currently in use for milling CAD/CAM restorations were selected from a wide range of material classes. They include two lithia-based glass-ceramics (IPS e.max CAD, Ivoclar-Vivadent, Schaan, Lichtenstein; and Suprinity PC, Vita Zahnfabrik, Bad Säckingen, Germany), a feldspar-reinforced aluminosilicate glass (Vitablocs Mark II, Vita Zahnfabrik), a polymer-infiltrated reinforced-glass network, PIRGN (Enamic, Vita Zahnfabrik), and a pre-polymerized nanoparticle/nanocluster resin composite (Lava Ultimate, 3M, St. Paul, MN, USA). The blocks with initial dimensions 14 × 12 × 18 mm3 (e.g. C14, I14) were ground round (Ø = 12 mm) using diamond lapping and subsequently cut with a precision diamond saw (IsoMet 1000, Buehler, Lake Bluff, IL, USA) into 1.80 mm thick slices under constant water irrigation. Obtained discs were then ground parallel and fine polished down to 1 μm diamond lapping plates and diamond suspensions on a power head polisher (Ecomet 4, Buehler). Forty specimens, with final thicknesses of 1.50 ± 0.05 mm, were prepared for each material. One of the sample’s surfaces was etched using 5% hydrofluoric acid (Ceramic Etch, Vita Zahnfabrik) for 20 s (IPS e.max CAD and Suprinity) or 60 s (Vitablocs Mark II and Enamic), except for Lava Ultimate samples, which were sandblasted with 30 μm Al2O3 particles at 2 bar for 15 s. A silane coupling agent (Monobond Plus, Ivoclar-Vivadent) was applied onto the etched surfaces, while a universal adhesive (Scotchbond Universal, 3M) was used for Lava Ultimate. The specimens were cemented onto previously hydrated (30 days storage in distilled water) glass-fiber reinforced epoxy resin rods (Ø25 × 15 mm, Epoxyglass G10, Acculam, Accurate Plastic, Yonkers, NY, USA) using one of two resin-based dual polymerizing luting agents: Multilink Automix (Ivoclar-Vivadent) for silanized surfaces and RelyX Ultimate (3M) for Lava Ultimate. Photopolymerization of the luting agent was carried out by exposing the ceramic/cement interface to a LED curing light with an irradiance of 850 mW/cm2 for 40 s for 4 consecutive times from different directions (Ultra Lume LED 5, Ultradent, South Jordan, UT, USA). After cementation, the ceramic/cement/G10 assemblies were stored in distilled water at 37°C for 7 days for continued polymerization and hydration of the cement.

2.2. Sliding contact fatigue

Frictional sliding testing was conducted in an electrodynamic biaxial mouth-motion simulator (Elf-3300, EnduraTEC, TA Instrument, Minnetonka, MN, USA) using a spherical 3Y-TZP indenter (r = 3.18 mm) at 200 N load and 1.5 – 2.0 Hz frequency in distilled water. The test set-up is displayed in Figure 1. Specimens were mounted onto a tilted block (30°) in order to generate off-axis loading of the indenter. The sliding cycle consisted of an initial contact of the indenter with the specimen’s surface at which the maximum load was transferred while sliding down for about 1 mm. Following unloading, the indenter lifted off from the specimen’s surface while the specimen returning to its original position. Specimens of each material where randomly divided into 5 subgroups (n = 8) and subjected to fatigue testing for a different number of cycles: 102, 103, 104, 105 or 106, after which the specimen was removed from the machine and the G10 was carefully cut, leaving a thin layer of G10 attached to the ceramic/cement disc.

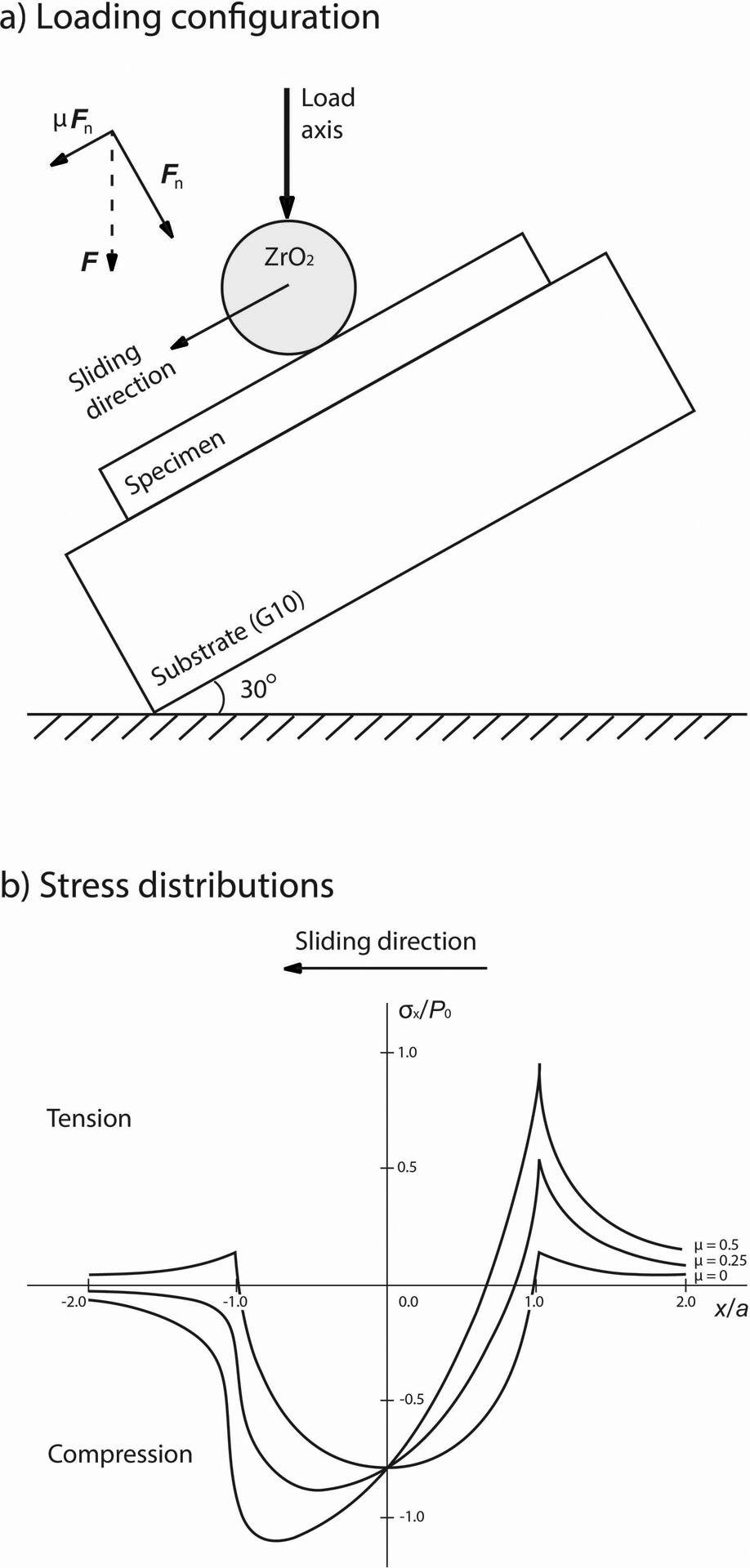

Figure 1.

(a) Schematic of the loading configuration used in the present study. The test material was cemented onto a compliant substrate (G10) and subjected to cyclic indentation with a spherical ZrO2 indenter (r = 3.18 mm). In order to facilitate the sliding motion, a 30° inclination was used (off-axis loading). The indenter first contacted the test material with an initial load of 5 N and then slid over the surface for about 1 mm while increasing to a maximum load of F = 200 N at a 1000 N/s rate. (b) Normalized stress in the ceramic surface for coefficient of friction μ = 0, 0.25, and 0.5 (after ref [52]). Note: a and P0 are the Hertzian contact radius and pressure, respectively.

2.3. Light microscopy and SEM analysis

The surface appearance and dimensions of the generated wear scars were analyzed under the light stereomicroscope (MZ-APO, Leica, Wetzlar, Germany) using reflected light. The presence of a polished surface surrounding the wear crater allowed a neat observation of its boundaries, as well as the surface features of the partial cone cracks. One specimen of each material tested for 104 cycles was selected for SEM analysis of the wear crater (TM4000Plus Tabletop Microscope, Hitachi, Tokyo, Japan). An additional sample of these subgroups was carefully removed from the remaining G10 and fine polished on the cementation surface. The wear scar was then analyzed under transilluminated light in the stereomicroscope and the characteristics of the subsurface damage (crack systems) where highlighted by varying the direction and incidence angle of the light source.

Two further samples of each material at 104 cycles were selected and embedded in clear epoxy resin and then sectioned saggitally or transversally (i.e. parallel or normal to the direction of sliding), slightly away from the wear scar [24]. The cross-sectioned samples were polished up until the half of the fatigue scar was reached and then fine polished down to 1 μm diamond suspension. The features of the partial cone cracks in both planes were assessed using the stereomicroscope under transilluminated light.

2.4. Optical Profilometric analysis

The dimensions of the wear scars at each cycling interval were examined using a high-resolution confocal optical profilometer (CT 100, CyberTechnologies, Eching, Germany), with a vertical resolution of 0.02 μm and measuring with XY step sizes of 5 μm. The width, length and maximum depth of the wear scars, as well as the volume loss of five samples per cycling interval per material were measured. One-way analysis of variance (ANOVA) was used to analyze the data (Minitab 17, Minitab Inc., State College, PA, USA). Statistical differences between groups at 5% significance level were determined using the Tukey’s post-hoc test.

3. Results

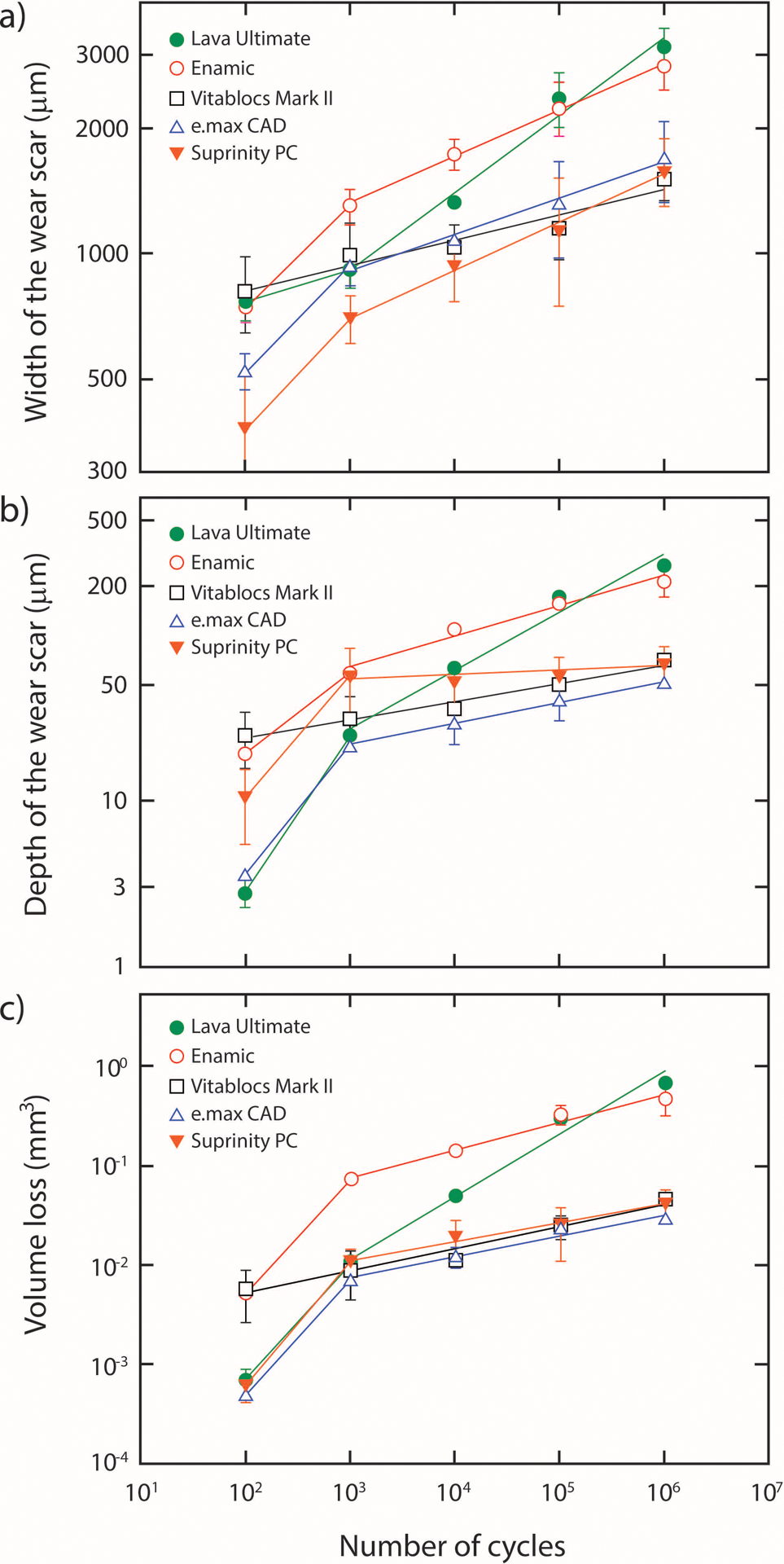

Results for the wear behavior of the different tested materials are displayed in Figures 2 and 3, as well as in Table 1. In general, the 3 ceramic materials (Mark II, e.max CAD and Suprinity PC) exhibited similar wear patterns with significantly smaller wear scars relative to Enamic (PIRGN) and Ultimate, especially following prolonged cyclic sliding contact (Fig. 2). Interestingly, an initial run-in stage, with higher wear rates, was observed between the first two measurement intervals, i.e. 102 to 103 cycles for all materials, with the exception of Vitablocs Mark II (Fig. 3). Indeed, a closer examination of Figure 2 revealed a strong increase in the width of the wear scars between these two intervals, corresponding well with the measured increment in all wear parameters (width, depth and volume loss) shown in Figure 3 and Table 1. In addition, despite marked differences in microstructure, strength and toughness among the 3 ceramic materials [1–8], the overall volume loss in these materials was similar, being an order of magnitude less than that of the PIRGN and Ultimate (Table 1). Although the initial volume of PIRGN was far greater than that of Ultimate, the latter exhibited a much higher steady-state wear rate, leading to similar long-term volume losses in the 2 materials.

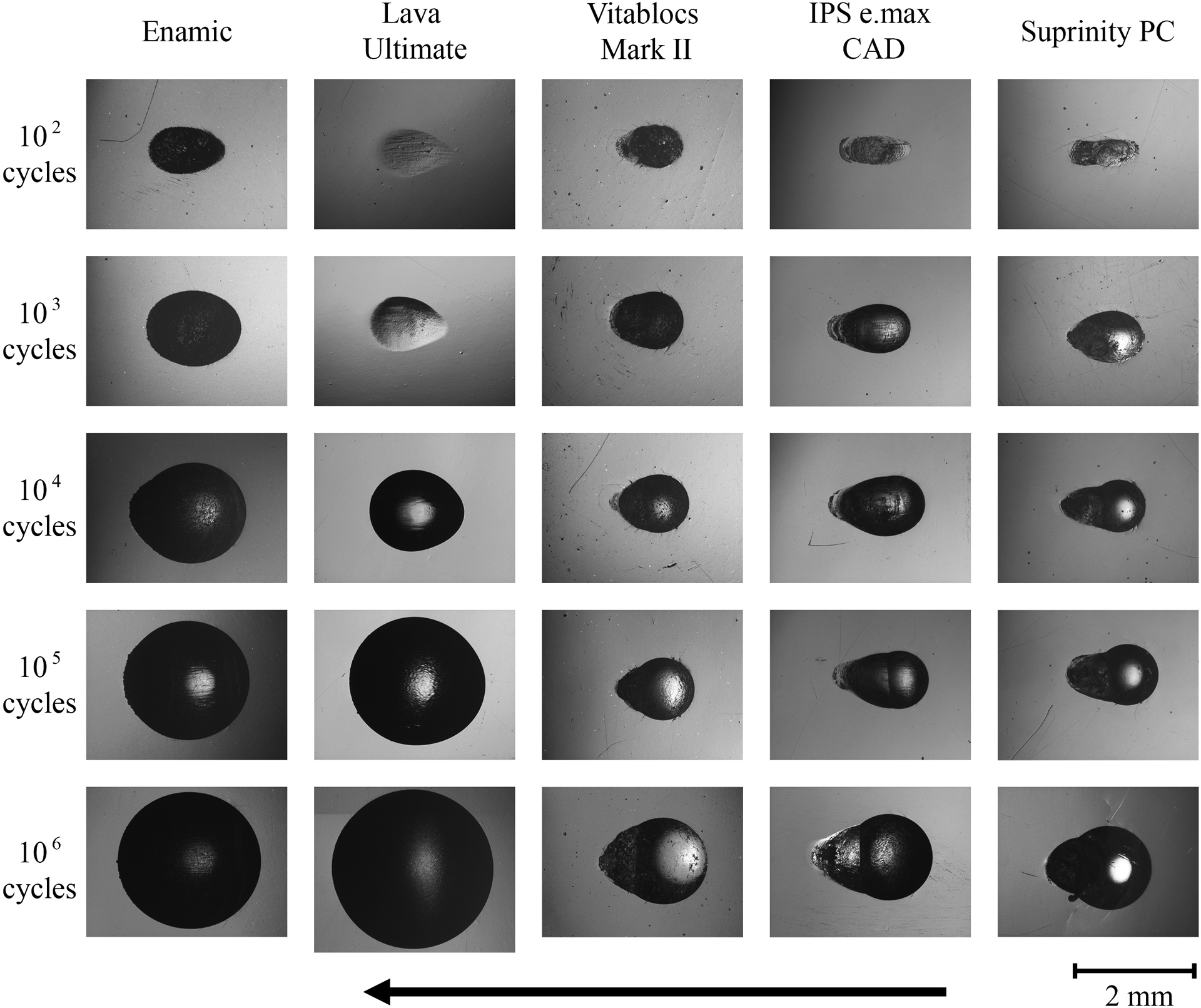

Figure 2.

Wear scars of the different materials tested and their evolution with repeated sliding contact. The same magnification was used for all images. The sliding direction was from right to left, as indicated by the black arrow. Brittle materials (Vitablocs Mark II, IPS e.max CAD and Suprinity PC) showed wear scars with similar dimensions and evolutionary sequences, having a small increment in their length, but a sustained increase in its width at the tail of the indenter’s path. Partial cone cracks extending outside the wear crater along the sliding path were observed at each cycling interval, already starting after 102 cycles. Materials comprising polymers (Enamic and Lava Ultimate) had a similar evolutionary behavior with cycling, with an important increment in the width of the wear scar, which led to a final round crater. Akin to the brittle materials, partial cone cracks emanating from the crater boundaries were observed for Enamic at each cycling interval, whereas no cracks were seen in the surface of Lava Ultimate samples at any period.

Figure 3.

Evolution of wear scars as a function of number of sliding cycles. The width (a) and maximum depth (b) of the wear scars, as well as the volume loss (c) measured using optical profilometry. Note: the unit of the y-axis is micron (μm) for (a) and (b) but millimeter (mm3) for (c). Individual curves of all 3 dimensions measured seem to agree well, giving an account of the wear rate during the sliding fatigue process. A high initial wear was observed for most materials, as shown by the steep slopes until 103 cycles. Further material loss after this point occurred at lower but steady rates, especially for the glass-ceramic materials Suprinity PC and IPS e.max CAD, which display relatively flat slopes. An exception to this behavior was observed for Vitablocs Mark II, which had a sustained increment of material loss during the complete sliding period, not evidencing differences in the wear rate during the process. Its curve matched those displayed by the glass-ceramics after 103 cycles. A larger increase in width, depth and volume loss was observed for polymer comprising materials, with Lava Ultimate having slightly steeper slopes than Enamic. It is noteworthy the low volume loss of Lava Ultimate at the first two intervals (102 and 103 cycles), being at the same level of the glass-ceramics.

Table 1.

Mean volume loss due to wear (in mm3) for the studied materials at different cycling intervals. Standard deviation in parenthesis. Values followed by the same superscript within the columns are not statistically different (p < 0.05)

| Material | 102 cycles | 103 cycles | 104 cycles | 105 cycles | 106 cycles |

|---|---|---|---|---|---|

| Enamic | 0.005 A (0.0007) | 0.044 A (0.002) | 0.138 A (0.012) | 0.319 A (0.066) | 0.463 A (0.155) |

| Lava Ultimate | 0.0007 B (0.0002) | 0.0053 B (0.0003) | 0.049 B (0.001) | 0.311 A (0.019) | 0.68 A (0.034) |

| Vitablocs Mark II | 0.006 A (0.003) | 0.009 B (0.005) | 0.011 C (0.002) | 0.025 B (0.007) | 0.046 B (0.009) |

| IPS e.max CAD | 0.0005 B (0.00005) | 0.007 B (0.0004) | 0.012 C (0.003) | 0.024 B (0.013) | 0.029 B (0.005) |

| Suprinity PC | 0.0006 B (0.0002) | 0.011 B (0.004) | 0.019 C (0.009) | 0.024 B (0.013) | 0.042 B (0.015) |

To shed some light on the wear mechanisms, damage sustained in each class of material has been examined in detail and the results are shown in Figures 4 through 8. An important surface degradation was observed for the feldspar reinforced glass, with material spalling and large herringbone cracks at the trailing edge of the indenter (Fig. 4a–c), whereas surface damage in the PIRGN showed a combination of resin matrix abrasion and fracture and partial removal of the feldspathic reinforced glass network (Fig. 5a–b). Degradation in the resin composite samples was limited to abrasive wear patterns, displaying smooth surfaces crossed by plough marks and worn off of the nanoparticles and clusters (Fig. 6a–b). Fatigue wear mechanisms dominated in the glass-ceramics, with surface damage arising predominantly from subsurface herringbone cracks at the tail of the indenter’s path and fully developed cone cracks at the arresting point (Figs. 7a–c and 8a–c). More severe fracture features were observed at the surface of Suprinity PC samples, than in their IPS e.max CAD counterparts.

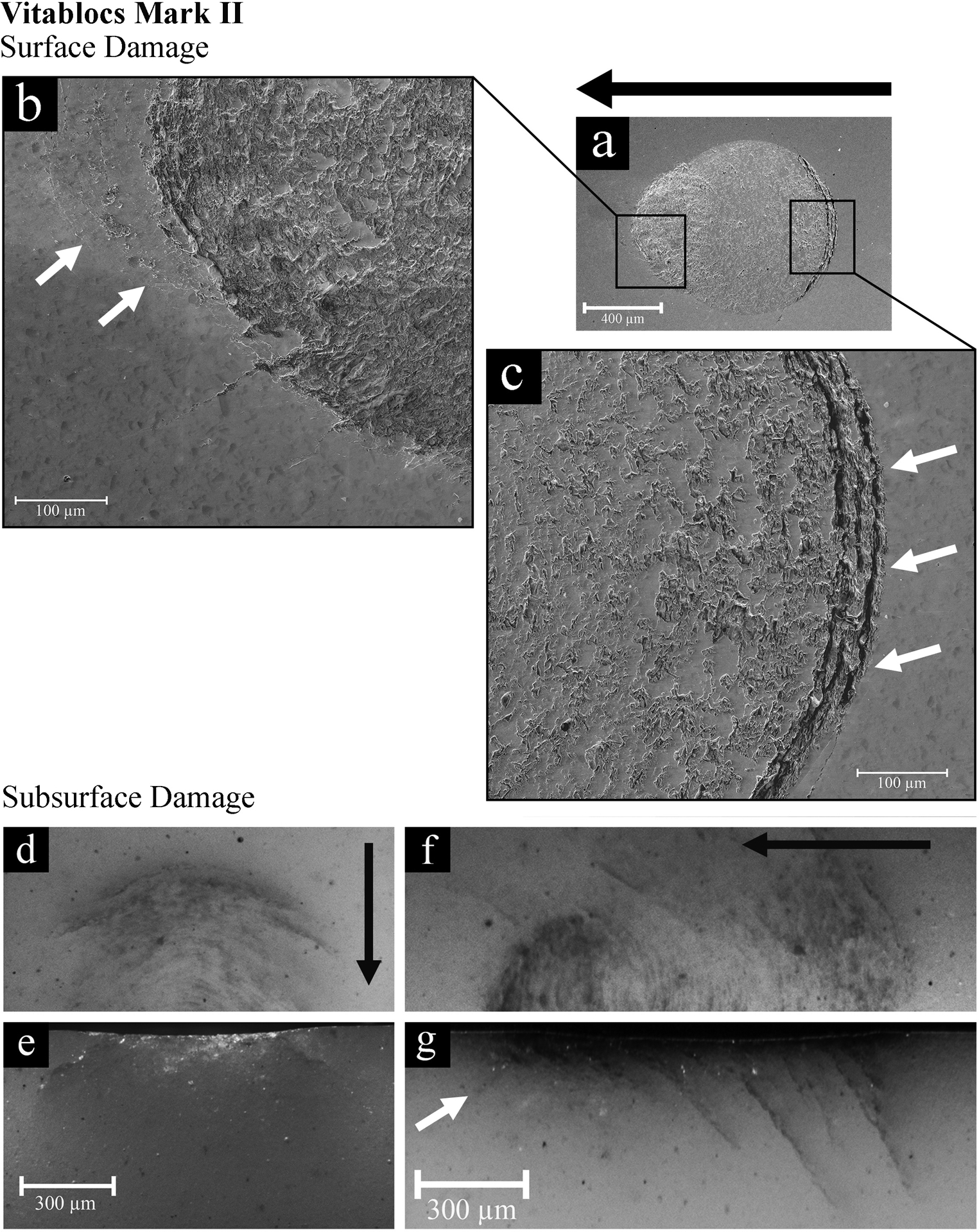

Figure 4.

Surface and subsurface damage in Vitablocs Mark II after 104 cycles. Black arrows indicate the direction of sliding. The SEM images of the material inside the wear scar (images a and insets b and c) show an important degradation of the surface, with material spalling off and the development of large herringbone cracks, especially at the tail of the indenter path (white arrows in inset c). Partial cone cracks are observed throughout the sliding path. In inset b, fully developed cone cracks are formed at around the arresting point of the indenter (white arrows). The surface shows here an even higher degradation than that observed at the tail of the indenter path, with extensive microcracking and material loss. The surface and subsurface features of the cracks can be observed in images d through g. A high density of partial cone cracks is visible throughout the indenter path, having penetration angles between 50° and 60°, as shown in the sagittal section depicted in g. The subsurface appearance of the fully developed cone cracks of inset b is indicated by the white arrow in g. In the transversally sectioned sample shown in e, the subsurface damage at the center of the wear scar compromises quasi-plastically deformed zone up to 100 μm in depth and the partial cone crack extending several hundred microns into the bulk of the material. A higher magnification was used for images f and g, than for d and e.

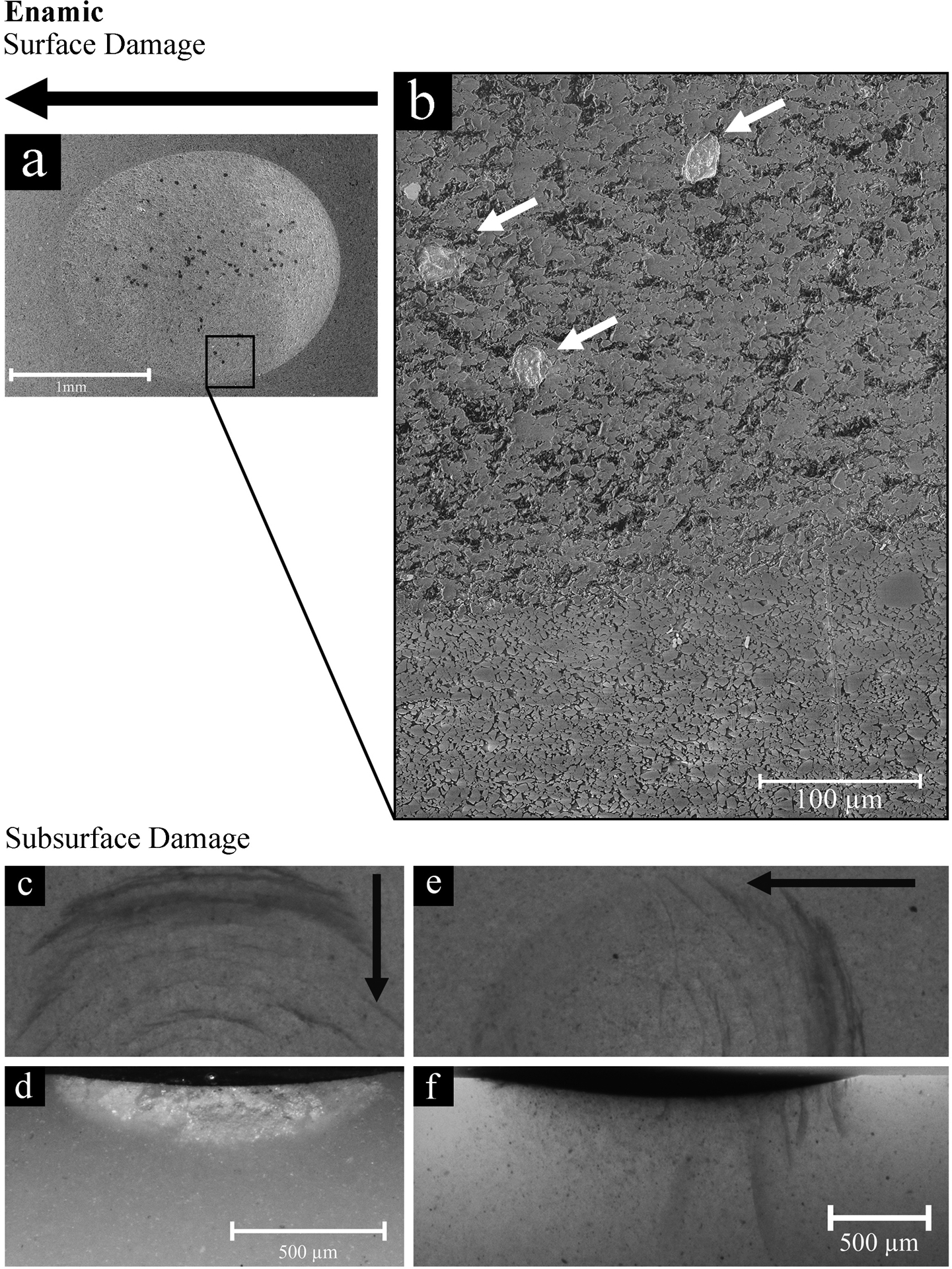

Figure 5.

Surface and subsurface damage in Enamic after 104 cycles. Black arrows indicate the direction of sliding. An important surface degradation is observed inside the wear scar as observed in the SEM image a and its inset b. Partially removed feldspathic particles can be observed inside the crater (white arrows) still embedded in the polymer network. The fracture and removal of the glassy matrix leaves a porous and rough surface, which contrasts strongly with the compact and polished appearance of the material surrounding the crater. The same surface features are observed throughout the crater. Partial cone (herringbone) cracks were visible in the direction of sliding under transilluminated light in the stereomicroscope, as depicted in c and e. A higher density of cracks is observed at the tail of the indenter path. In d, a transversal section of one of this partial cone cracks is presented. The sagittally-sectioned sample depicted in f shows the series of partial cone cracks penetrating deep into the material. Note the steep penetration angles of the cracks, ranging between 75° and 85°. A higher magnification was used for images c and d, than for e and f.

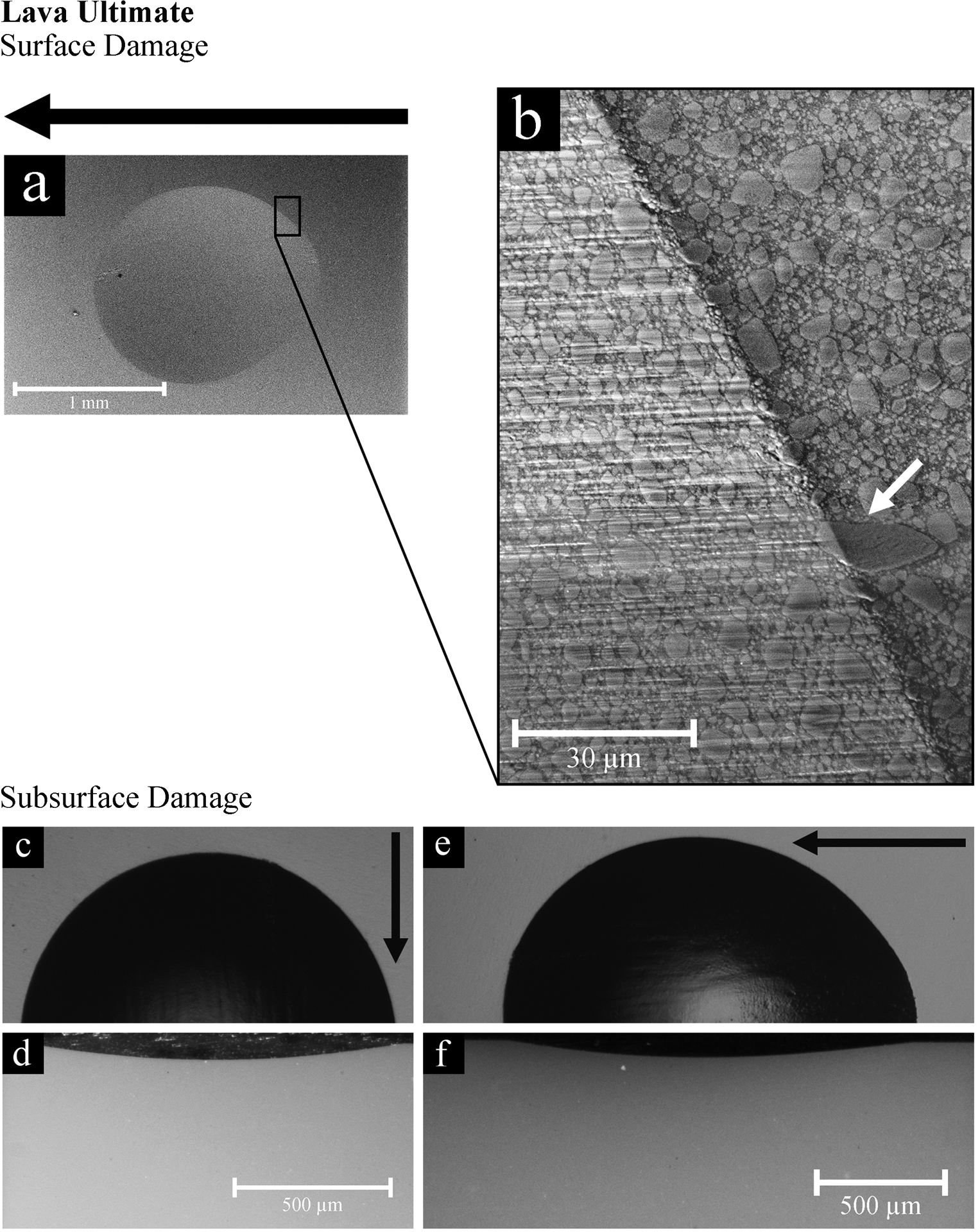

Figure 6.

Surface and subsurface damage in Lava Ultimate after 104 cycles. Black arrows indicate the direction of sliding. The SEM images of the wear scar, a and its inset b, show a smooth surface crossed by thin plough marks caused by the dislodgement of fine particles and fragments of nanoclusters from the material. Larger clusters of nanoparticles were worn off together with the resin matrix, as exemplarily shown by the white arrow in b. The microstructure of the material was not altered during the sliding process. Images c through f show the different planes of the wear scar under the stereomicroscope. A relatively smooth surface inside the crater is observed with reflected light in c and e, not showing any sign of cracking. This is confirmed in the cross-sectioned samples, where an absolute absence of cracks is observed in the transversal (d) and sagittal (f) sections. A higher magnification was used for images c and d, than for e and f.

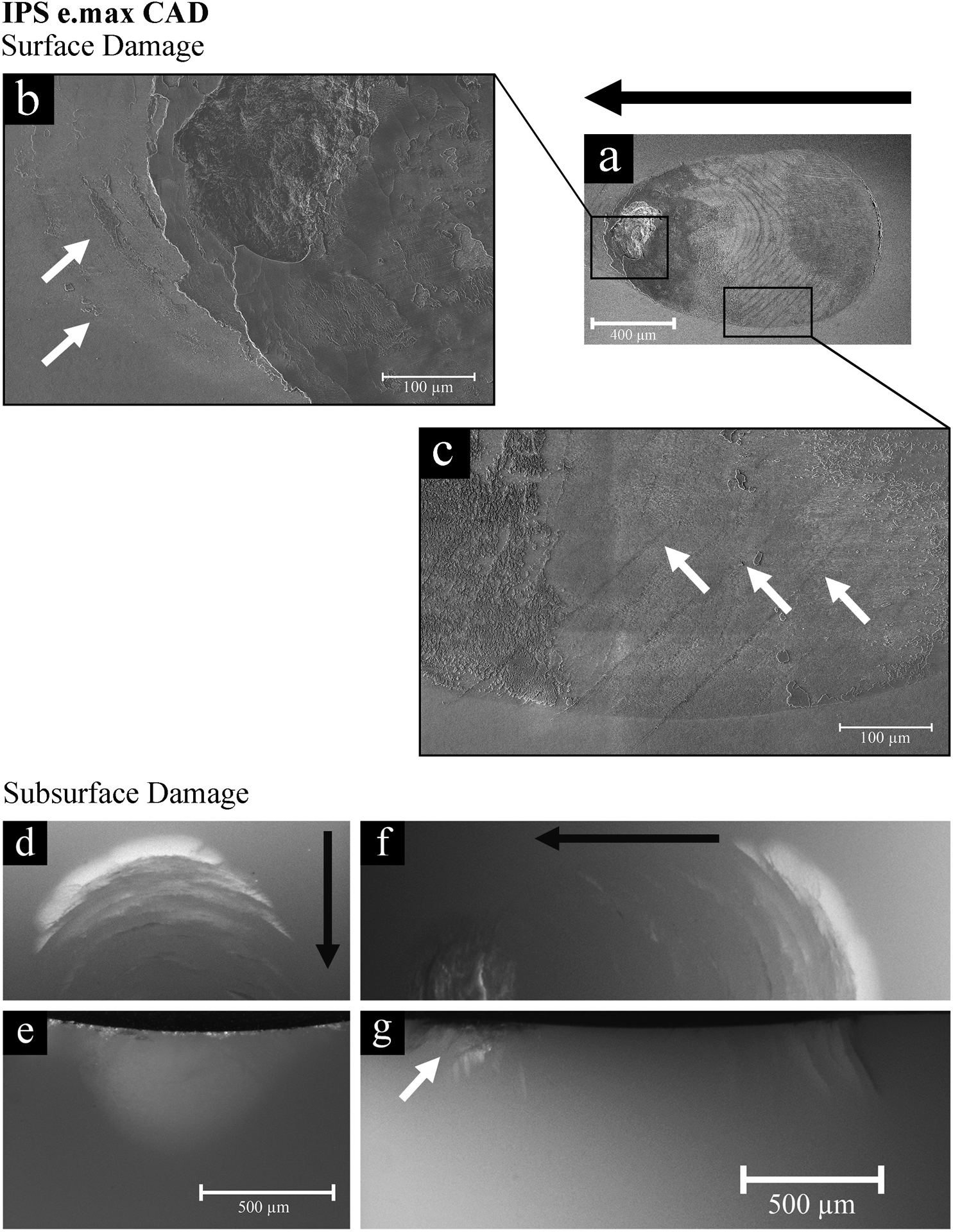

Figure 7.

Surface and subsurface damage in IPS e.max CAD after 104 cycles. Black arrows indicate the direction of sliding. A series of partial cone cracks are visible in the wear scar in the SEM image a, having a higher density at the tail of the indenter’s path (white arrows in inset c). The surface appears relatively smooth, having an increased roughness and material damage at the arresting point of the indenter’s path (inset b), where cone cracks fully developed (white arrows). The stereomicroscope images corroborate an extensive subsurface damage, with partial cone cracks concentrating at the tail of the indenter’s path (images f and g). As observed in g, the cracks have a deep penetration angle, ranging between 80° and 85°. The white arrow points out the fully developed cone cracks at the arresting area of the indenter’s path. In the transversally sectioned sample of image e the deep appearance of the partial cone crack can be observed, penetrating about 500 μm into the bulk of the material. No important surface damage (material spalling) inside the crater is observed. A higher magnification was used for images d and e, than for f and g.

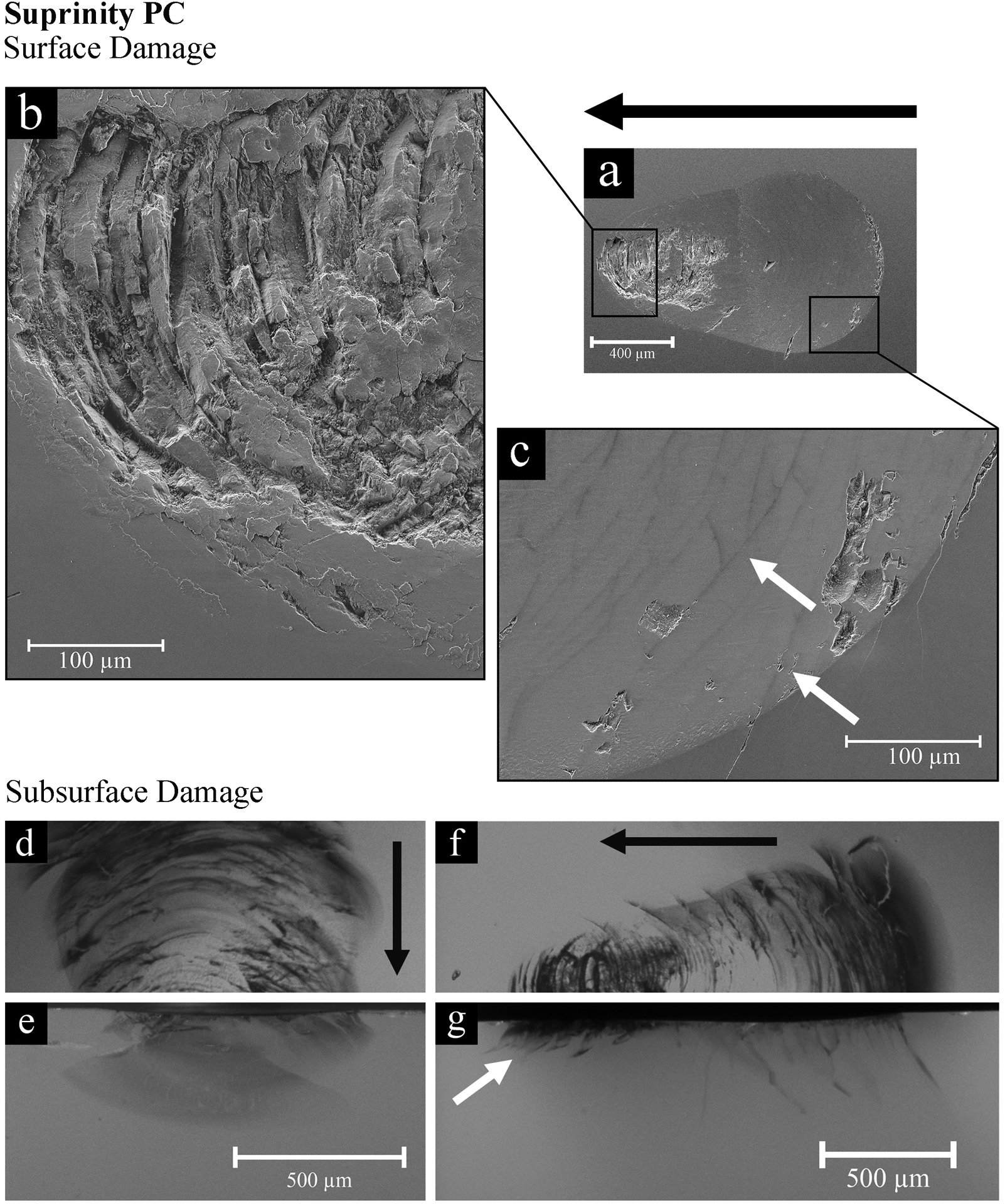

Figure 8.

Surface and subsurface damage in Suprinity PC after 104 cycles. Black arrows indicate the direction of sliding. Partial cone cracks are visible inside the wear scar (white arrows in inset c) throughout the entire sliding path of the indenter. The surface of the crater appears smooth except at the arresting area of the indenter’s path, where important material spallation and microcracking is observed (inset b). This extensive surface damage zone follows a circular geometry (image a), closely related to the fully developed cone cracks in this area. The full extent of the subsurface damage is appreciable in the stereomicroscope images, especially under transilluminated light (d and f). In the main portion of the crater a high density of herringbone cracks follow the direction of sliding, penetrating deep into the bulk of the material (image g). These partial cone cracks have a less steeper penetration angle than the other glassy materials in this study, ranging between 50° and 60°. Merging of several of these cracks is observed as they grow, mainly due to the high crack density. The white arrow in g points out the fully developed cone cracks at the arresting area of the indenter’s path. In the transversally sectioned sample depicted in e the large subsurface area encompassed by one of the partial cone cracks is presented, covering several hundred microns in depth and width. In the immediate subsurface region interaction and merging of smaller cracks is observed. A higher magnification was used for images d and e, than for f and g.

Subsurface damage in the different materials is revealed in its orthogonal planes in 3-dimensional space: a plane parallel to the wear surface as well as planes parallel and perpendicular to the direction of sliding, respectively (Figs. 4d–g, 5c–f, 7d–g and 8d–g). Partial cone cracks formed in the subsurface having a perpendicular orientation relative to the specimen surface and propagated downwards, with their inclination angles being dependent upon the tested material. At the arresting point of the indenter’s path, fully developed cone cracks were observed (Figs. 4g, 5f, 7g and 8g), being more evident in the glassy materials. No subsurface damage of any type was present in Lava Ultimate samples.

4. Discussion

4.1. Sliding contact fatigue testing

In vitro results on the wear behavior of dental materials are influenced by a large amount of variables, including applied load, length of the sliding movement, number of cycles, type, size and surface finishing of the antagonist, testing environment, etc. [25]. Most studies in the literature use steatite or enamel from extracted teeth as antagonist, in an effort to mimic the wear conditions of the materials in the oral environment. However, the use of softer antagonists often leads to their simultaneous wear during sliding, which in turn changes the contact area and introduces additional wear debris to the process. In the present study, a hard zirconia spherical indenter with a highly polished surface was selected in order to limit the antagonist wear [11], following clinical recommendations for this material [26]. This facilitated an independent examination of the material’s variables influencing the process, while at the same time standardized the effect of the indenter, favoring a direct comparison among materials. Another important difference with most published data on the wear behavior of dental materials is the high load used here during sliding contact fatigue. Whereas commonly “physiological loads” in the range of 0.4 to 75 N are used in vitro [25], the 200 N load applied here resembled more closely a worst case scenario, such as that observed in clenching and bruxism [27]. This allowed on the one hand to analyze the wear behavior and degradation mechanisms under extreme loading conditions and on the other hand ensured the onset and propagation of partial cone cracks [21]. Further, experimental conditions (such as the use of a wet testing environment, the 1 mm length of the sliding movement, the examination intervals, etc.) were defined in order to create ideal conditions for the development and characterization of this subsurface type of damage and its implications on the wear process.

4.2. Wear behavior and surface damage

The higher initial wear phase (run-in stage) observed for all materials tested here (Fig. 3) has been previously described in vitro for enamel [28] and more recently for glass-ceramics [25] and PIRGN materials [29]. It seems to be related with the formation of the wear scar itself and the high contact stresses generated by the antagonist in the unworn surface [29]. As the area of the wear scar increases, the contact stresses are reduced, resulting in a steady-state stage of wear, represented by the lower slope of the curves observed after 103 cycles (Fig. 3). From here on, the increase in width and depth, as well as the overall volume loss followed a constant rate, governed by the different wear mechanisms of each material.

Vitablocs Mark II specimens showed an accelerated initial wear, having larger crater formation after 102 cycles (Fig. 2) and significantly higher material loss than the glass-ceramics and resin composite material (Table 1). No run-in stage was observed (Fig. 3), as it probably concluded before 102 cycles were reached, with the wear mechanisms of the steady-state stage already operating when the first measurement was undertaken. This is confirmed by the optical profilometry measurements of its wear scars, revealing the highest initial width, depth and volume loss among all materials tested here (first data point, at 102 cycles in Fig. 3). The higher initial wear is related to the wear mechanisms observed for this material, with the softer glassy phase abrading fast and exposing the feldspathic crystals, which, upon removal, act as abrasive particles for further material removal (i.e. 3-body wear). Similar surface features for the wear scar of this material have been observed after wear testing against enamel [10] and zirconia [12], displaying a partially broken-off glass matrix with extruded feldspathic crystals. This wear mechanism seemed to govern over the entire cycling period studied here, resulting in constant slopes for all three measured parameters (Fig. 3) and accounting for similar surface damage features across the wear scar (Fig. 4). The greater accumulation of damage and microcracking at the arresting area of the indenter path (Fig. 4b) seems to be related to the subsurface damage introduced to the material by the indenter, as further discussed in section 4.3.

The wear behavior of Enamic showed some resemblances to that observed for Vitablocs Mark II, owing to the similar composition of this latter material and the reinforced-glass phase of the PIRGN [1]. Accordingly, both materials displayed the highest initial volume loss, being statistically similar at 102 cycles (Table 1), with the size of the wear scars being also comparable (Fig. 2). The presence of the polymer network in Enamic, however, seemed to be responsible for the extension of the run-in stage up to 103 cycles, resulting in a similar wear rate of Enamic relative to the glass-ceramics Suprinity PC and IPS e.max CAD (similar slopes between 102 and 103 in Fig. 3). After this point, a steady-state stage is observed, defined by a lower wear rate in all three measured parameters. A similar reduction in the wear rate of Enamic after 5 × 103 cycles was described by Xu et al. using an analogous set-up with a silicon nitride antagonist [29]. An important degradation of the material’s microstructure is appreciable in the SEM images of the worn surface (Fig. 5a and b), with the preferential wear of the soft polymer matrix and subsequent exposure of the reinforcing glass network to microfractures and particle dislodgement (Fig. 5b). These wear mechanisms correspond well with the observations by other authors on Enamic wear against a hard zirconia [12] or silicon nitride [29] antagonist, with an important particle exfoliation and ceramic-network protrusion, accompanied by considerable polymer peel off [29]. The sever surface damage, in addition to the important volume loss displayed by Enamic (being statistically comparable to that observed for Lava Ultimate after 104 cycles, Table 1), are in strong contrast to the good wear performance against enamel reported for this material in the literature [9,10,30]. Such a large discrepancy manifests the effect of relative hardness between the mating surfaces on wear and wear mechanism. In light of the outcomes of the present study, the polymer network seems to provide only a moderate to weak resistance against abrasive wear caused by the zirconia sphere, leaving the glassy network unprotected against fatigue wear and microfracture (Fig. 5). Therefore, little advantage in wear resistance is gained by the interpenetration of the glass and polymer networks, when compared to conventional particle-reinforced polymers, such as Lava Ultimate. Moreover, the presence of a brittle glass phase seems to account for an accelerated initial wear (Fig. 3) and to be responsible for the extensive subsurface damage observed in this material (Fig. 5c-f).

Lava Ultimate displayed a significantly lower initial wear than Enamic, with volume loss and scar depths being statistically similar to the glass-ceramics at the first two cycling intervals (Fig. 3 and Table 1). Despite these low initial values, this material developed the highest wear rate among all materials studied here, reaching and surpassing the volume loss observed for Enamic at higher number of cycles. The high filler content (up to 80 wt.%) of dispersed and clusters of nanometric colloidal silica and ZrO2 spherical particles present in Lava Ultimate [1] leads to an increased initial hardness [31] and a reduced exposition of the resin matrix to the antagonist [32], which explains the lower wear rate observed during the first 102 cycles. The benefit of utilizing nanoparticles and nanoclusters in a resin composite is the higher retention of polishing and long-term gloss relative to a conventional hybrid composite material; upon abrasive wear, nanoclusters break down into small fragments rather than the dislodgement of a large particle [33]. However, as the interparticle resin starts to abrade, exfoliation of particles from the surface takes place, leading to a sustained increase in wear as a consequence of the abrasive action of these loosen particles and clusters on the material’s surface. Highly filled resin composites are more prone to particle dislodgment during wear due to an increased filler agglomeration and a higher proportion of filler-filler interfaces, which oppose a weaker adhesive resistance than resin-filler interfaces [31]. This is further aggravated by the large size of an important portion of the filler particles and clusters encountered in Lava Ultimate [1], which are more susceptible to be exposed and lost [30,34]. The SEM image in Fig. 6b corroborates the wear processes described above, with the surface of the wear crater covered with plough marks in the direction of sliding, caused by dislodged particles and small fragments of the nanoclusters. Finally, the absence of cracks inside the wear crater and in the subsurface of the material contrasts with findings by other authors [9,34], suggesting that abrasive wear (more specifically, 3-body abrasion) is the dominating mechanism.

The glass-ceramics IPS e.max CAD and Suprinity PC displayed a similar wear behavior (Fig. 3). Following a steep run-in stage, both materials entered the steady-state phase after 103 cycles, with flat curves close to that of Vitablocs Mark II. The slightly narrower initial scar sizes displayed by Suprinity PC (Fig. 3a) were counterbalanced by the shallower craters of IPS e.max CAD samples (Fig. 3b), leading to a statistically comparable volume loss (Table 1). The morphology of the worn surfaces in these materials is highly dependent upon the size and shape of the crystals. According to Zhang et al., crystal sizes smaller than 5 μm will lead to abrasive wear, whereas fatigue wear and delamination predominate in materials with larger crystal size [35]. Thus, the 1-2 μm large lithium disilicate crystals found in IPS e.max CAD and the even smaller lithium metasilicate crystals present in Suprinity PC (0.5 μm) [1] should have led to abrasive wear patterns, as previously observed in the literature [9,36,37]. However, no features commonly found in abrasively worn surfaces, such as plough marks or furrows, were distinguishable in the SEM images of the wear scars (Figs. 7a–c and 8a–c). On the contrary, the presence of microcracking and material spallation suggest fatigue wear as the main surface degradation process. The use of a smooth zirconia sphere, instead of enamel or steatite as an antagonist, may have influenced this distinct wear behavior. During sliding contact fatigue, the weaker glassy matrix is worn away first, exposing the crystals, which in turn increases the roughness and the friction coefficient of the surface [36]. This causes rapid abrasive wear of softer antagonists, such as steatite or enamel, generating wear debris that plough the glass-ceramic surface [11]. In contrast, the harder surface of the zirconia indenter was not seriously compromised by the extruded crystals, maintaining its initial contact area and promoting fatigue wear damage in the glass-ceramic surface. Still, the smaller crystal size of Suprinity PC seemed to be responsible for a smoother wear scar surface (Fig. 8c) than its lithium disilicate counterpart (Fig. 7c). On the other hand, the higher fracture toughness of this latter material [8] suppressed the occurrence of microcracking, especially at the arresting area of the indenter path (Fig. 7b). The more brittle Suprinity PC had severe destruction of the surface in this area (Fig. 8b), a direct consequence of the initiation and propagation of subsurface cone cracks (Fig. 8g, white arrow).

4.3. Fracture mechanisms and subsurface damage

The off-axis loading configuration used in the present study was specifically designed to favor the initiation and propagation of partial cone cracks. Thus, normal and tangential load components are superposed (Fig. 1), with the tangential component being directly dependent upon the applied load and the generated friction coefficient μ during sliding [22]. As the indenter slid over the surface, tensile stresses concentrated at its trailing edge (Fig. 1), which facilitated the formation of a series of partial cone cracks [38]. Further crack growth was driven by hydraulic pumping [39], causing a deep crack penetration that even surpassed one third of the sample thickness in Vitablocs Mark II and Enamic specimens (Figs. 4g and 5f).

In the glassy ceramics, the fracture process was controlled by the interrelation of the imposed load, the friction coefficient and the material’s properties (i.e. fracture toughness KIc, elastic modulus and Poisson’s ratio) [21]. As both lithia-based glass ceramics and the reinforced aluminosilicate glass tested here share very similar elastic constants [1], the differences in the penetration depth of the cracks can be mainly attributed to the different fracture resistance of the materials. Consequently, shorter cracks developed in the tougher IPS e.max CAD (KIc = 2.04 MPam0.5 [8]), whereas deeper cracks were observable in the more brittle Suprinity and Vitablocs Mark II specimens (KIc respectively 1.52 MPam0.5 and 1.23 MPam0.5 [8]). On the other hand, steeper partial cone cracks developed in IPS e.max CAD (80 – 85°, Fig. 7g), than in Suprinity and Vitablocs Mark II (50 – 60°, Figs. 4g and 8g). This difference is related to the coarser microstructure of IPS e.max CAD [1], where protrusion and extrusion of the interlocked lithium disilicate microstructure during the wear process [36] increased frictional stresses. The morphology and penetration angles of the cone cracks has shown to be strongly dependent upon the friction coefficient [21,38], as it affects the intensity of the tensile component in the near field of the sliding contact area [40]. Accordingly, the finer crystalline microstructure of Suprinity and the glassy nature of Vitablocs Mark II [1] would anticipate reduced friction coefficients and thus, explain the sharper angles observed.

The arresting area of the indenter path warrants especial attention. Here, ring cracks formed within the contact area (white arrows in Figs. 4b and g; 7b and g; and 8g), and exhibited a similar crack morphology (i.e. inclination angles) to the inner cone cracks observed in uni-axial fatigue loading [41]. Unlike the classical outer cone cracks, which form outside the contact area where the tensile stresses reach their maximum value, inner cone cracks form inside the contact area and propagate downward at a relatively steep angle [42]. It is important to note that the driving force for the outer cones is moisture-assisted slow crack growth whereas that for inner cones consists of an addition yet more deleterious mechanical fatigue mechanism (i.e. hydraulic pumping). As a result, inner cones propagate much faster and deeper than outer cones [43]. The subsurface damage in this region of the wear scar coincides with extensive microcracking and material spallation in the specimen surface, especially for IPS e.max CAD and Suprinity PC (Figs. 7b and 8b). This type of surface damage is characteristic for severe wear regimes [17,21] and is originated by the nucleation of the cone cracks in the subsurface, intensified in this region of the wear scar by their higher density (especially in Suprinity, as shown Fig. 8). In contrast, the larger spacing between partial cone cracks reduced the occurrence of material spallation in the surface of the remaining portions of the wear scar, giving a smoother appearance in both glass-ceramics tested here. The rougher surface of the crater in Vitablocks Mark II specimens, on the other hand, is mainly caused by the 3-body wear mechanisms described in section 3.2, being further aggravated by the lower fracture toughness of this material. Thus, the contribution of the subsurface damage is masked by the abrasive wear patterns, where the smeared surface materials and wear debris give a homogeneous appearance throughout the wear scar. Surface opening of the cracks was only visible at the trailing edge of the indenter (white arrows in Fig. 4c) and to a lesser extent its arresting area (Fig. 4b).

Similar damage patterns were observed in the subsurface of the PIRGN material. The infiltration of a polymer into a reinforced-glass scaffold has been claimed to significantly enhance the mechanical properties of the resulting material [44]. This has been related to the toughening effect of the interpenetrated resin, being able to bridge growing cracks in the glassy phase [45] and thus, to increase the overall fracture resistance of the material. On the other hand, incorporation of the polymer has shown to significantly reduce the elastic modulus of the material [1,45], increasing the energy dissipation capacity through elastic-plastic deformation and thus, to a raise in the critical load for cone crack initiation [46]. However, the results in the current study differ from most published data on this new type of materials, as an important subsurface damage was observed after sliding contact fatigue. Under the high load applied here, the polymer network was unable to prevent the onset and propagation of partial cone cracks at the trailing edge of the indenter, as clearly depicted in Figs. 5c–f. The extension of these cracks and their density was comparable to that observed for the Vitablocs Mark II samples, evidencing the dominating role of the glass-phase in the fracturing process of the PIRGN material. A noticeable difference with Vitablocs Mark II, however, was observed for the crack-to-surface angles of the partial cone cracks (Fig. 5f), which lied in the range of 75° to 85°, very close to those observed in IPS e.max CAD. The exposure of the reinforced-glass network, as a consequence of polymer wearing away during sliding (Fig. 5b), seemed to increase the frictional forces and hence, the friction coefficient of the material.

A similar type of subsurface damage was observed by El-Zhawi et al. in Enamic molar crowns submitted to accelerated sliding-contact step-stress fatigue [47], developing even deeper partial cone cracks as the loading forces increased. Coldea et al. also observed ring cracks when a 190 N load was applied to the PIRGN material using a 0.5 mm radius tungsten carbide indenter [46]. In their study, however, application of lower loads or the use of a larger indenter caused plastic deformation in the absence of cone crack development.

In contrast with the PIRGN material, crack propagation in resin composites occurs mainly through the polymer matrix, with the fillers promoting toughening mechanisms such as crack deflection and bridging [48,49]. A similar crack propagation mechanism has been recently described for Lava Ultimate [50]. The presence of a discontinuous inorganic phase (in the form of nanometric silica and zirconia particles, as well as nanometric zirconia/silica clusters), instead of a continuous glass/ceramic-matrix, account for a lower elastic modulus of this material when compared to Enamic (12.7 GPa vs. 37.4 GPa, respectively [1]). This higher compliance of Lava Ultimate helped in dissipating the mechanical energy and reduced, therefore, the stress intensity at critical defects. The large filler content and the high conversion rate of the polymer fraction, on the other hand, have shown to increase the mechanical properties of this material and to provide an enhanced resistance to subcritical crack propagation [51]. Accordingly, an absolute absence of cracks was observed here (Figs. 6c–f). This outcome was not completely unexpected, considering that most previous work addressing contact damage in this indirect resin composite has shown none [12] or only minor [9,10] microfracture in the worn surfaces. To the best of the authors’ knowledge, only one in vitro study investigated before the subsurface damage of Lava Ultimate after cyclic contact fatigue [50]. In this study, conducted on molar crowns, development of partial cone cracks was observed at the trailing edge of the indenter, whereas inner cone cracks developed at the impact area of the tungsten carbide sphere. Crack propagation during mouth-motion fatigue, however, occurred at substantially higher loads (up to 1.7 kN) than those applied here. The results in the current study highlight the higher load threshold for the onset of crack propagation under cyclic contact fatigue in Lava Ultimate (certainly above 200 N), compared to Enamic and the glass-ceramics. This also raises the question of whether the continuous inorganic phase is a better reinforcement mechanism than conventional particle fillers for contemporary resin CAD/CAM materials.

5. Conclusions

A close relation between the wear mechanisms and the material loss was evidenced by the results of the present study. Whereas fatigue wear in the brittle glass-ceramics and reinforced glass lead to lower wear rates and a moderate material loss, abrasive wear was responsible for the large wear craters observed in the nano-particulate resin composite. A combination of these mechanisms in the PIRGN caused both, a higher wear rate and extensive material removal. The presence of severe damage in the subsurface of the glassy materials confirmed their susceptibility to crack initiation and propagation under sliding contact fatigue. In the polymer-containing materials, the interpenetration of a resin matrix into a glass ceramic network proved to be less efficient against the onset of partial cone cracks than the conventional particle-filled resin composite. This latter material offers an interesting alternative for high-load bearing areas, as well as for patients with bruxism and clenching.

Acknowledgements

All materials were kindly donated by the manufacturers. This work was supported by the U.S. National Institutes of Health / National Institute of Dental and Craniofacial Research (Grant Nos. R01DE026279 and R01DE026772).

Footnotes

Disclosures

All authors declare that there is no conflict of interest regarding the publication of this article.

References

- 1.Belli R, Wendler M, de Ligny D, Cicconi MR, Petschelt A, Peterlik H, Lohbauer U. Chairside CAD/CAM materials. Part 1: Measurement of elastic constants and microstructural characterization. Dental Materials 2017; 33:84–98. [DOI] [PubMed] [Google Scholar]

- 2.Hussain B, Thieu MKL, Johnsen GF, Reseland JE, Haugen HJ. Can CAD/CAM resin blocks be considered as substitute for conventional resins? Dent Mater 2017; 33:1362–1370. [DOI] [PubMed] [Google Scholar]

- 3.Wendler M, Belli R, Petschelt A, Mevec D, Harrer W, Lube T, Danzer R, Lohbauer U. Chairside CAD/CAM materials. Part 2: Flexural strength testing. Dent Mater 2017; 33:99–109. [DOI] [PubMed] [Google Scholar]

- 4.Elsaka SE, Elnaghy AM. Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent Mater 2016; 32:908–914. [DOI] [PubMed] [Google Scholar]

- 5.Homaei E, Farhangdoost K, Tsoi JK, Matinlinna JP, Pow EH. Static and fatigue mechanical behavior of three dental CAD/CAM ceramics. J Mech Behav Biomed Mater 2016; 59:304–313. [DOI] [PubMed] [Google Scholar]

- 6.Stawarczyk B, Liebermann A, Eichberger M, Güth J-F. Evaluation of mechanical and optical behavior of current esthetic dental restorative CAD/CAM composites. J Mech Behav Biomed Mater 2016; 55:1–11. [DOI] [PubMed] [Google Scholar]

- 7.Ramos Nde C, Campos TM, Paz IS, Machado JP, Bottino MA, Cesar PF, Melo RM. Microstructure characterization and scg of newly engineered dental ceramics. Dent Mater 2016; 32:870–878. [DOI] [PubMed] [Google Scholar]

- 8.Belli R, Wendler M, Petschelt A, Lube T, Lohbauer U. Fracture toughness testing of biomedical ceramic-based materials using beams, plates and discs. J Eur Ceram Soc 2018; 38:5533–5544. [Google Scholar]

- 9.Lawson NC, Bansal R, Burgess JO. Wear, strength, modulus and hardness of CAD/CAM restorative materials. Dent Mater 2016; 32:e275–e283. [DOI] [PubMed] [Google Scholar]

- 10.Mormann WH, Stawarczyk B, Ender A, Sener B, Attin T, Mehl A. Wear characteristics of current aesthetic dental restorative CAD/CAM materials: Two-body wear, gloss retention, roughness and martens hardness. J Mech Behav Biomed Mater 2013; 20:113–125. [DOI] [PubMed] [Google Scholar]

- 11.Dupriez ND, von Koeckritz A-K, Kunzelmann K-H. A comparative study of sliding wear of nonmetallic dental restorative materials with emphasis on micromechanical wear mechanisms. J. Biomed. Mater. Res. B Appl. Biomater 2015; 103:925–934. [DOI] [PubMed] [Google Scholar]

- 12.Lauvahutanon S, Takahashi H, Oki M, Arksornnukit M, Kanehira M, Finger WJ. In vitro evaluation of the wear resistance of composite resin blocks for CAD/CAM. Dent Mater J 2015; 34:495–502. [DOI] [PubMed] [Google Scholar]

- 13.Peng Z, Izzat Abdul Rahman M, Zhang Y, Yin L. Wear behavior of pressable lithium disilicate glass ceramic. J Biomed Mater Res B Appl Biomater 2016; 104:968–978. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Heintze SD, Faouzi M, Rousson V, Ozcan M. Correlation of wear in vivo and six laboratory wear methods. Dent Mater 2012; 28:961–973. [DOI] [PubMed] [Google Scholar]

- 15.Neale M Tribology handbook. London: Butterworths; 1973; [Google Scholar]

- 16.Kato K, Adachi K. Wear mechanisms Modern tribology handbook vol 1 ed Bhushan B (Boca Raton, FL: CRC; ) pp 273–300. 2001. [Google Scholar]

- 17.Mair LH, Stolarski TA, Vowles RW, Lloyd CH. Wear: Mechanisms, manifestations and measurement. Report of a workshop. J Dent 1996; 24:141–148. [DOI] [PubMed] [Google Scholar]

- 18.Min J, Zhang Q, Qiu X, Zhu M, Yu H, Gao S. Investigation on the tribological behavior and wear mechanism of five different veneering porcelains. PLoS One 2015; 10:e0137566. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Zhang Y, Sailer I, Lawn BR. Fatigue of dental ceramics. J Dent 2013; 41:1135–1147. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Chai H Multi-crack analysis of hydraulically pumped cone fracture in brittle solids under cyclic spherical contact. Int J Fract 2007; 143:1–14. [Google Scholar]

- 21.Ren L, Zhang Y. Sliding contact fracture of dental ceramics: Principles and validation. Acta Biomater 2014; 10:3243–3253. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Kim JH, Kim JW, Myoung SW, Pines M, Zhang Y. Damage maps for layered ceramics under simulated mastication. J Dent Res 2008; 87:671–675. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Peterson IM, Wuttiphan S, Lawn BR, Chyung K. Role of microstructure on contact damage and strength degradation of micaceous glass-ceramics. Dent Mater 1998; 14:80–89. [DOI] [PubMed] [Google Scholar]

- 24.Kim JW, Liu L, Zhang Y. Improving the resistance to sliding contact damage of zirconia using elastic gradients. J Biomed Mater Res B Appl Biomater 2010; 94:347–352. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Heintze SD, Cavalleri A, Forjanic M, Zellweger G, Rousson V. Wear of ceramic and antagonist--a systematic evaluation of influencing factors in vitro. Dent Mater 2008; 24:433–449. [DOI] [PubMed] [Google Scholar]

- 26.Lohbauer U, Reich S. Antagonist wear of monolithic zirconia crowns after 2 years. Clin Oral Investig 2017; 21:1165–1172. [DOI] [PubMed] [Google Scholar]

- 27.Hidaka O, Iwasaki M, Saito M, Morimoto T. Influence of clenching intensity on bite force balance, occlusal contact area, and average bite pressure. J Dent Res 1999; 78:1336–1344. [DOI] [PubMed] [Google Scholar]

- 28.Kaidonis JA, Richards LC, Townsend GC, Tansley GD. Wear of human enamel: A quantitative in vitro assessment. J Dent Res 1998; 77:1983–1990. [DOI] [PubMed] [Google Scholar]

- 29.Xu Z, Yu P, Arola DD, Min J, Gao S. A comparative study on the wear behavior of a polymer infiltrated ceramic network (picn) material and tooth enamel. Dent Mater 2017; 33:1351–1361. [DOI] [PubMed] [Google Scholar]

- 30.Matzinger M, Hahnel S, Preis V, Rosentritt M. Polishing effects and wear performance of chairside CAD/CAM materials. Clin Oral Investig 2018; [DOI] [PubMed] [Google Scholar]

- 31.Lawson NC, Burgess JO. Wear of nanofilled dental composites at varying filler concentrations. J Biomed Mater Res B Appl Biomater 2015; 103:424–429. [DOI] [PubMed] [Google Scholar]

- 32.Gan X-q, Cai Z-b, Zhang B-r, Zhou X-d, Yu H-y. Friction and wear behaviors of indirect dental restorative composites. Tribology Letters 2012; 46:75–86. [Google Scholar]

- 33.Curtis AR, Palin WM, Fleming GJ, Shortall AC, Marquis PM. The mechanical properties of nanofilled resin-based composites: Characterizing discrete filler particles and agglomerates using a micromanipulation technique. Dent Mater 2009; 25:180–187. [DOI] [PubMed] [Google Scholar]

- 34.Tsujimoto A, Barkmeier WW, Takamizawa T, Latta MA, Miyazaki M. Influence of thermal cycling on flexural properties and simulated wear of computer-aided design/computer-aided manufacturing resin composites. Oper Dent 2017; 42:101–110. [DOI] [PubMed] [Google Scholar]

- 35.Zhang Z, Yi Y, Wang X, Guo J, Li D, He L, Zhang S. A comparative study of progressive wear of four dental monolithic, veneered glass-ceramics. J Mech Behav Biomed Mater 2017; 74:111–117. [DOI] [PubMed] [Google Scholar]

- 36.Wang L, Liu Y, Si W, Feng H, Tao Y, Ma Z. Friction and wear behaviors of dental ceramics against natural tooth enamel. J Eur Ceram Soc 2012; 32:2599–2606. [Google Scholar]

- 37.Ludovichetti FS, Trindade FZ, Werner A, Kleverlaan CJ, Fonseca RG. Wear resistance and abrasiveness of CAD/CAM monolithic materials. J Prosthet Dent 2018; 120:318.e311–318.e318. [DOI] [PubMed] [Google Scholar]

- 38.Lawn B Partial cone crack formation in a brittle material loaded with a sliding spherical indenter. Proc R Soc London 1967; 299:307–316. [Google Scholar]

- 39.Zhang Y, Song JK, Lawn BR. Deep-penetrating conical cracks in brittle layers from hydraulic cyclic contact. J Biomed Mater Res B Appl Biomater 2005; 73:186–193. [DOI] [PubMed] [Google Scholar]

- 40.Lawn BR, Wiederhorn SM, Roberts DE. Effect of sliding friction forces on the strength of brittle materials. J Mater Sci 1984; 19:2561–2569. [Google Scholar]

- 41.Kim JW, Kim JH, Thompson VP, Zhang Y. Sliding contact fatigue damage in layered ceramic structures. J Dent Res 2007; 86:1046–1050. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Zhang Y, Bhowmick S, Lawn BR. Competing fracture modes in brittle materials subject to concentrated cyclic loading in liquid environments: Monoliths. J Mater Res 2005; 20:2021–2029. [Google Scholar]

- 43.Bhowmick S, Zhang Y, Lawn BR. Competing fracture modes in brittle materials subject to concentrated cyclic loading in liquid environments: Bilayer structures. J Mater Res 2005; 20:2792–2800. [Google Scholar]

- 44.Swain MV, Coldea A, Bilkhair A, Guess PC. Interpenetrating network ceramic-resin composite dental restorative materials. Dent Mater 2016; 32:34–42. [DOI] [PubMed] [Google Scholar]

- 45.Coldea A, Swain MV, Thiel N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent Mater 2013; 29:419–426. [DOI] [PubMed] [Google Scholar]

- 46.Coldea A, Swain MV, Thiel N. Hertzian contact response and damage tolerance of dental ceramics. J Mech Behav Biomed Mater 2014; 34:124–133. [DOI] [PubMed] [Google Scholar]

- 47.El Zhawi H, Kaizer MR, Chughtai A, Moraes RR, Zhang Y. Polymer infiltrated ceramic network structures for resistance to fatigue fracture and wear. Dent Mater 2016; 32:1352–1361. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Shah MB, Ferracane JL, Kruzic JJ. R-curve behavior and micromechanisms of fracture in resin based dental restorative composites. J Mech Behav Biomed Mater 2009; 2:502–511. [DOI] [PubMed] [Google Scholar]

- 49.Wendler M, Belli R, Schachtner M, Amberger G, Petschelt A, Fey T, Lohbauer U. Resistance curves of short-fiber reinforced methacrylate-based biomedical composites. Eng Fract Mech 2018; 190:146–158. [Google Scholar]

- 50.Shembish FA, Tong H, Kaizer M, Janal MN, Thompson VP, Opdam NJ, Zhang Y. Fatigue resistance of CAD/CAM resin composite molar crowns. Dent Mater 2016; 32:499–509. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Wendler M, Belli R, Valladares D, Petschelt A, Lohbauer U. Chairside CAD/CAM materials. Part 3: Cyclic fatigue parameters and lifetime predictions. Dent Mater 2018; 34:910–921. [DOI] [PubMed] [Google Scholar]

- 52.Hamilton GM, Goodman LE. The stress field created by a circular sliding contact. J Appl Mech 1966; 33:371–376. [Google Scholar]