Abstract

The current analytical techniques for characterizing printing and graphic arts substrates, particularly those used to date and authenticate provenance, are destructive. This limits the amount of data that can be captured from an individual sample. For samples being evaluated in forensic and archeological investigations, any loss or degradation of the materials is undesirable. Furthermore, it is difficult to produce statistically relevant data for such analytes. We have shown elsewhere that a contactless microwave resonant cavity dielectric spectroscopy technique can discriminate between paper samples made from different plant fiber species based on their lignin content. In this publication, we demonstrate the utility of the contactless resonant cavity dielectric spectroscopy (RCDS) technique in the characterization of naturally and artificially aged paper samples. Based on our experimental results, we suggest that the technique could be used in forensic and archeological investigations of unique paper products.

Keywords: Fiber analysis, relative age of paper, nondestructive, writing and graphics arts substrates, paper, cellulose, cellulose degradation, resonant cavity dielectric spectroscopy

Introduction

Cellulose, the polymeric foundation of printing, writing, and graphic arts substrates, is not inert and subject to degradation; consequently, the aging of cellulosic materials is of great economic and scientific interest (Carter 1996a). The degradation of paper is a multi-dimensional problem; both the long-term natural and accelerated aging of cellulosic papers are influenced by a myriad of environmental conditions such as light flux, light spectrum, temperature, humidity, and the presence of atmospheric pollutants producing a number of degradation products (Area and Cheradame 2011). The average molecular size for cellulosic materials decreases with age, ranging from about 1000 for as-processed to less than 200 for very aged materials (Griffin et al. 1995).

The chemical end products formed by paper aging are essentially the same, whether aged very rapidly in the accelerated process or slowly, over a century or so, by natural processes (Arnold 2003). Subjecting naturally aged paper to additional accelerated aging did not alter the end products, irrespective of the original paper fabrication process (Arnold 2003). Chemical additives, including metal ions from the paper fabrication process, and other naturally occurring constituents, such as lignin, also impact the degradation products and kinetics of cellulose (Arnold 2003; Area and Cheradame 2011). The degradation products are not all labile; some accumulate in the substrate which result in altered physico-chemical and mechanical properties of cellulosic artifacts (Dupont et al. 2007; Ostlund et al. 2010).

There are several different analytical techniques for estimating the age of paper, but the utility of each technique is dictated by the study’s objectives (Area and Cheradame 2011). For example, the quantity of degradation by-products in paper has been used to assess the degraded state of the analyte, but more research is needed to firmly support the relationships between degradation product concentration and the chronological age of the sample (Emsley and Stevens 1994). By and large, the current analytical methods to study the degradation of cellulose are complex and often destructive and include. Such techniques include, but are not limited to, viscometry, gel permeation chromatography, saccharide determination, nuclear magnetic resonance (NMR), infrared spectroscopy (IR), and 14C-based radiocarbon dating (van der Plicht and Mook 1987; Area and Cheradame 2011).

For sheeted samples, such as paper, it is not uncommon to obtain conflicting results from the analyses of the same sheet due to sampling along different sides of the sheet and/or locations along the sheet (Causin et al. 2012). If the sample is not mutilated or destroyed during analysis using one of these techniques, then direct contact with the substrate is required, which may result in damage or contamination of the analyte (Blumich et al. 2003). It is well established that paper and pulp materials, like other biomaterials, have characteristic dielectric profiles which can be used to identify and differentiate between specimens (Joshi et al. 2015; Roig et al. 2017).

Dielectric spectroscopy (DS) offers a non-contact, nondestructive means to quantify and detect degradation products of the cellulose polymer. By employing a resonant cavity, DS interrogates both sides of the sheet simultaneously, thus eliminating the need to perform duplicate measurements (Orloff et al. 2014). Historically, the dielectric characterization of paper and pulp has focused on the testing of moisture content and fiber orientation of industrial paper (Metaxas and Driscoll 1974; Sundara-Rajan et al. 2005), as well as paper used as insulators in electrical transformers (El Omari et al. 2016). Water is frequently used as an indicator molecule in the study of paper (Perkins and Batchelor 2012).

Since the sorbed water is partitioned between the cellulose and other hydrogen-bonding capable constituents in paper, we should expect the polarization dynamics of bound water in aged paper to change as a function of the aging process as the chemistry of the material domains change with the production of the associated by-products. At least in theory, we should be able to differentiate between samples containing different amounts of degradation products using the resonant cavity technique (Joshi et al. 2015). We recently demonstrated the application of contactless resonant cavity dielectric spectroscopy in the testing of paper by leveraging the relaxation dynamics of water molecules adsorbed within the cellulose polymer matrix in the paper analytes as indicators (Kombolias et al. 2018). Specifically, we correlated reduction in the rate of depolarization of sorbed water molecules in paper with the fiber species content of a variety of papers.

In this publication, we demonstrate the ability of the microwave resonant cavity technique to differentiate between new and aged paper (both naturally and artificially) based on the polarization dynamics of bound water in the microwave spectra region. We use data collected in this work to discuss various aspects of paper aging as well.

Materials and methods

Analyte sample preparation

Paper samples were obtained from commercial office supply vendors or from the Testing and Technical Services Laboratory of the United States Government Publishing Office, Washington, D.C. Paper strips were cut out of large sheets of analyte, using a rotary cutter, to fit the particular cavity used in this work. Paper strips of width 0.5 cm and 8 cm in length were cut at different angles, with the basis of the machine direction set to 90°, while the cross direction is set to 0°. The sample strips were stored between glass microscope slides in a nitrogen-filled dry box but were equilibrated with ambient humidity before measurements in the resonant cavity. The thickness of the paper was determined through an average of ten caliper measurements. Strips of the specimens for accelerated aging were cut out of random sheets taken from reams of store-bought office paper.

Naturally aged paper samples

Naturally aged paper samples of varying cotton content (25% cotton and 100% cotton) and varying dates of manufacture were provided by the United States Government Publishing Office. Samples were housed in the dark in warehouse conditions.

Accelerated paper fade testing

For these tests, we used whole sheets of commercially produced colored office paper [24-lb(i.e., 90 gms) office papers] of two different compositions: virgin and 30% recycled fibers[i.e., 0% and 30% post-consumer waste (PCW) recycled fiber content, respectively]. Paper samples were optically aged under ultraviolet-light at elevated temperature and laboratory ambient humidity in a weathering chamber equipped with 340 nm UVA bulbs, at an irradiance of 0.72 W/m2 at 50°C for 169 hours (QUV 10-0791-78-se weathering chamber, Q-Lab Corporation, Westlake, OH*). The color changes of the paper samples were evaluated by color space measurements (L*a*b*) using a portable spectrophotometer (X-Rite eXact,X-Rite, Inc., Grand Rapids, MI*), the results of which are presented in Table 1. Sample strips were cut out of the aged paper to fit the resonant cavity after the aging studies.

Table 1.

Comparisons of color parameters (L*, a*, b*) with the dielectric loss (ε′′) in 0% and 30% PCW recycled 24 lb office papers.

| % PCW | Aging time / (h) | L* | a* | b* | ε″ |

|---|---|---|---|---|---|

| 0% | 0 | 69.98 ± 0.21 | −27.25 ± 0.11 | −25.51 ± 0.17 | 0.295 ± 0.005 |

| 30% | 0 | 70.78 ± 0.21 | −27.12 ± 0.10 | −24.82 ± 0.21 | 0.262 ± 0.04 |

| 0% | 169 | 74.59 ± 0.17 | −21.09 ± 0.10 | −13.04 ± 0.25 | 0.228 ± 0.005 |

| 30% | 169 | 74.55 ± 0.30 | −21.40 ± 0.37 | −13.39 ± 0.44 | 0.211 ± 0.013 |

Resonant cavity measurement

Background to contactless resonant cavity dielectric spectroscopic measurements

In the following, we utilize the concept of dielectric loss, ε′′, as an index to represent the cavity’s quality dependence on analyte volume. This index could be related to the dielectric permittivity, surface conductivity, or dielectric loss depending on the properties of the material under test (MUT) and the intrinsic phenomenon of interest. The dielectric loss associated with the specimen is represented as the rate of change of the cavity’s quality factor (Q-factor) as a function of the volume of air displaced by the analyte inserted into the cavity, as described by Eq. (1):

| (1) |

where represents the difference of the reciprocal of the Q-factor of the specimen from the Q-factor of the empty cavity, and is the ratio of the volume of the inserted specimen to the volume of the empty cavity. The intercept b′′ accounts for the non-uniform field in the specimen (Obrzut et al. 2016). By monitoring the decrease in the cavity’s Q-factor while inserting the MUT, in this case, paper samples, into the otherwise empty cavity, the dielectric loss ε′′ may be extracted from the slope of (1).

The dielectric loss of the paper, ε′′, is a characteristic property of the material and indicates how much energy is dissipated by the specimen from the applied microwave electric field. In the case of paper materials, ε′′ at microwave frequencies arises primarily from the dielectric relaxation of adsorbed water molecules. The adsorbed water in papers is confined and therefore has a lower dielectric constant than free water (Saukkonen et al. 2015). It is this confined water that is probed in order to understand the physico-chemical differences of papers of different ages, fiber furnishes and differing degradation by-products per effective medium theory (Steeman and van Turnhout 2003). In addition, moisture hysteresis is not a factor as previous work has shown that below 10% moisture content the dielectric loss measured in paper is attributable to the dipolar mechanism of water bound to cellulose and within the cellulose polymer (Driscoll 1976).

Resonant cavity fixture

The resonant cavity fixture used in this work consisted of an air-filled standard rectangular waveguide (R100, Agilent Technologies, Keysight, Santa Rosa, CA;a = 10.16 mm, b = 22.86 mm, lz = 127.0 mm) with an operating microwave frequency range of 6.700 to 13.000 GHz. The cavity was connected to a network analyzer (Agilent N5225A, Keysight, Santa Rosa, CA) with semi-rigid coaxial cables and coaxial to the waveguide coupling adapters. The coupling adapters were nearly cross polarized with respect to the waveguide polarization angle of about 87° to achieve optimal power loading into the cavity while maximizing the quality factor. The specimen is inserted into the cavity through a slot machined in the center of the cavity, where the electric field, Ex, attains a maximum value at each odd TE10n mode.

The Q-factor, Q0, and the resonant frequency, f0, of the empty cavity at the third odd resonant mode TE103 at which we make the measurements are 3.200 and 7.435 GHz, respectively. During measurements, the specimen is partially inserted into the cavity in steps to a certain volume, Vx, while the quality factor, Qx, and the resonant frequency, fx, are recorded. Dielectric permittivity of the paper samples was obtained by plotting the measured Vx, fx, and Qx data and solving the two linear perturbation equations for complex permittivity as described in references (Orloff et al. 2014; Obrzut et al. 2016; IEC 2016). The measurements were performed in ambient laboratory conditions. The dielectric loss values shown take into account the relative humidity of the laboratory, as that is a determinant of the value of the quality factor of the empty cavity, Q0. Whereas the techniques described in this paper involved harvesting test coupons to fit into the resonant cavity, these measurements are also readily replicated with free space microwave non-contact measurements.

Results and discussion

Natural aging of paper

Figure 1 compares the time evolution of the dielectric loss measured for two blends (100% and 25% cotton) of cotton-containing papers with differing years of manufacture stored under identical environmental conditions (i.e., ambient temperature and humidity with little to no exposure to light) for over a 40-year period. Under these conditions, we expect the paper to age naturally. Considering that the storage ambient has not changed substantially over the 40-year period, it is reasonable to assume that the observed changes in the dielectric loss are real consequences of the paper degradation occurring naturally through the passage of time.

Figure 1.

Comparison of the time evolution of dielectric loss of two blends of cotton papers stored under the identical environmental conditions. The square symbols represent the measurements for 100% cotton, and the circular symbols represent the data for 25% cotton papers. The error bars represent the standard deviation of the mean of at least three replicates.

In such low light conditions, cellulose degradation results in a decrease in the amount of bound water (Capitani et al. 2012; Teodonio et al. 2016). Thus, the differences in the dielectric loss in these samples may be a measure of the extent of cellulosic degradation and the quantity of accumulated degradation by-products in the samples. Inspection of Figure 1 shows that the dielectric loss of the pure cotton and the cotton blend bond paper are different, with lower dielectric loss values for the pure cotton paper samples. The difference may be attributed to the impact of lignin on the distribution of sorbed water in the blended papers (Atalla et al. 2000; Arnold 2003; Kombolias et al. 2018).

Since cellulosic degradation through hydrolytic depolymerization could be acid catalyzed (Zou et al. 1996; Zervos 2010), we readily accept that comparisons of these paper samples may not be rigorous since we do not explicitly account for the changes in paper manufacturing methods over the past half-century. We did not measure the surface nor the bulk pH of the paper since the measurement process results in modification of the analyte, and the results are subject to experimental artifacts such as the concentration of atmospheric CO2 (Strlic et al. 2004). However, we do not expect the interaction of bound water with the degradation by-products to be sensitive to the details of the paper manufacturing process. Thus, the following discussion assumes the analytes are fabrication process agnostic. Also, since this work did not start off as a long-term study of paper aging, we do not have the corresponding data from fresh samples.

The fiber content of the 25% cotton analytes is, by definition, inhomogeneous, as opposed to the 100% cotton samples. Thus, the larger variability seen in dielectric loss values of the 25% cotton samples compared to the 100% cotton samples may be explained by the inhomogeneity of their fiber content.

Accelerated aging of paper

To understand the utility and sensitivity of the resonant cavity technique in studying paper aging, we conducted accelerated photoaging on readily available commercial office copier papers of the same hue, basis weight, and manufacturer but differing recycled fiber content. In these accelerated light aging studies we assumed that accelerated photoaging results in changes that are commensurate with natural aging phenomena (Porck 2000; Zervos 2010). In fact, several international standards specify methods for accelerating the aging of paper through exposure to an elevated light irradiance and for assessing the effect of aging on optical properties for the purpose of predicting stability to long-term natural aging that occurs due to exposure to light (ISO 2014).

In these studies, we obtained the best dielectric loss sensitivity and resolution with test samples cut at 60° relative to the cross direction of the paper analyte. This is probably due to the natural orientation of cellulose polymers in the fibers used in making the paper. It has been shown through in vivo studies of live plants that the preferred orientation of the cellulose polymer is non-orthogonal, deviating between ca. 30° to 45° from the normal within the cellulose microfibril structure. This disorientation of cellulose fibers in live plants translates to about the 60° orientation in sheeted paper as we have designated here (Anderson et al. 2010; Thomas et al. 2017).

In the current studies, the paper photoaging was monitored in-situ through color change by measuring the values of L*, a*, and b*, which correspond to three separate axes in CIELAB color space. The L* axis corresponds to lightness-darkness, whereas the a* and b* values express color along the green-red and blue-yellow axes, respectively. The color difference, which is represented by the term ΔE* (delta Empfindung, sensation in German), is the calculated linear distance between two sets of L*a*b* color coordinates within three-dimensional color space (Tong 2013). As the value of ΔE* approaches zero, the disparity between the two hues being compared also becomes negligible. The just noticeable difference (JND) value for ΔE* that the average human eye can perceive is between 1 and 3 (Tong 2013).

Table 1 compares the average color measurement and average dielectric loss data of the paper samples with respect to UV exposure time and post-consumer waste (PCW) recycled fiber content to illustrate the impact of paper composition furnishes on the measurands. Prior to the accelerated aging, one could not distinguish between the 0% PCW and 30% PCW samples as-received by optical inspection; the calculated color difference of ΔE* = 1.06 between these two sets of analytes confirms that they are virtually indistinguishable by color to the human eye. After 169 hours of accelerated aging, the calculated color difference between the virgin and recycled analytes is even less perceptible to the human eye at ΔE* = 0.47.

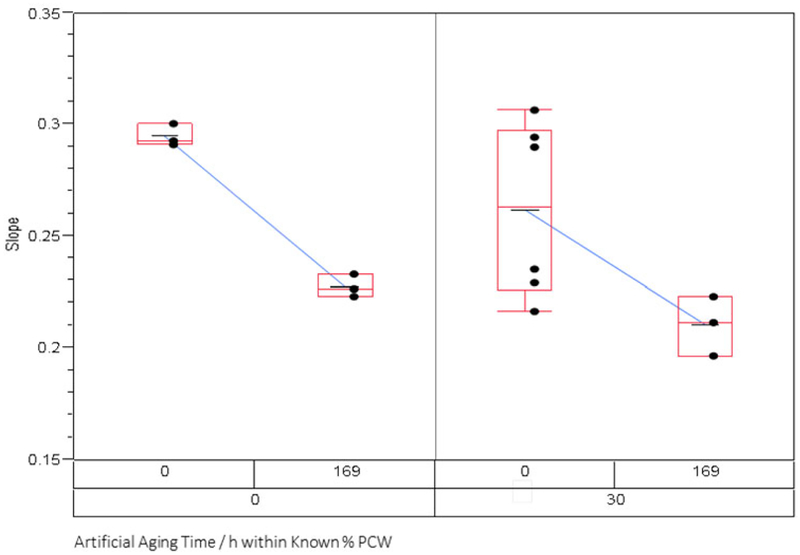

Figure 2 compares the dielectric loss profiles of paper samples with 0% (virgin) and 30% PCW recycled fiber office paper; the pre-and post-aging dielectric loss profiles are statistically different. While the virgin material was dielectrically uniform, as shown by the compact box plots, the “as-received” 30% recycled material was non-uniform (i.e., the wider range of dielectric loss values). Interestingly, the dielectric profiles of the aged materials appear to be more uniform and closely related to each other. This suggests that the aging process produced chemically similar end products and is consistent with the literature (Atalla et al. 2000). The virgin sample elicits a higher average ε′′ value than the recycled sample, and the difference (Δε′′ in the average dielectric loss of these samples is 0.033. In other words, the sorbed water in the 30% PCW recycled sheet is approximately 10% less polarizable compared to the 0% PCW virgin sample.

Figure 2.

Comparison of the dielectric loss (ε′′) of 0% and 30% post-consumer waste (PCW) recycled fiber content in 24 lb office papers cut at a 60° strip angle before and after fading. The error bars represent the variability in multiple measurements on at least six samples and are attributable to the heterogeneous nature of the paper products.

Similar trends in dielectric behavior were maintained between the virgin and recycled samples after 169 hours of accelerated aging: the 0% PCW sample retained a higher average ε′′ value than the 30% PCW recycled sample. Inspection of the measurands as a function of time reveals that the UV light accelerated aging process affords lower dielectric loss values. Relative to the as received samples, accelerated aging resulted in about 23% decrease in the dielectric loss in the 0% PCW analyte, while the 30% PCW sample suffered about 20% decrease in the dielectric loss, relative to the as-received samples, respectively.

The ability to differentiate between paper manufactured exclusively from virgin fiber from one that contains only 70% virgin fiber after artificial aging is consistent with our previous work on speciation on the basis of lignin content (Kombolias et al. 2018). The broader distribution of the dielectric loss (ε′′ values in the sample with 30% recycled content in Figure 2 suggests that there is greater variability present in the materials tested. This is anticipated, as the portion of recycled fiber present in this product has undergone further processing, resulting in additional structural changes due to iterative cycles of repulping, bleaching, and drying which would not have occurred in 100% virgin furnish (Sahin and Arslan 2008; Chen et al. 2015). The artificial aging of the virgin and 30% PCW recycled sheets likely resulted in polymer chain fragmentation through the development of free radicals and the creation of new functional groups due to photooxidation, which adjusts the degree of substitution of the cellulose polymer and of any dye molecules (Carter 1996b). Dielectric spectroscopy studies comparing native (plant/bacterial origin) celluloses and other starches to bleached cellulose pulps and to regenerative celluloses and the derivatized variants of each have shown that not only do the dielectric properties of each cellulose type change with different chemical substituents (e.g., acetyl, carboxymethyl, tosyl, etc.) present, but also with the same substituent, degree of substitution influences the dielectric behavior (Einfeldt et al. 2000, 2002).

The variability observed in the 30% PCW samples could also suggest that the fractions of virgin and recycled fiber in this paper may not completely miscible, leading to changes in polarizability at the interfaces of the recycled and virgin fibers within the 30% PCW product (Landauer 1978; Bergman and Stroud 1992). Given the sensitivity of sorbed water to the changing chemical environment, it should be possible to use dielectric spectroscopy to study the kinetics of cellulose degradation.

Clearly the information yielded from the contactless resonant cavity dielectric spectroscopy technique as described in this work is substantially greater than that which can be captured from traditional fiber analysis protocols (TAPPI 2015). The data presented here suggest that the comparison of the dielectric loss measurements provides a more sensitive, and insightful, in-situ estimation of durability and composition prior to performing any physical tests. To our knowledge, there are no other test methods that correlate and corroborate the very slight differences within color space (and, therefore, relative age in addition to the concentration of colorant) with dielectric behavior and can distinguish between recycled and virgin paper furnishes.

For example, a recent extensive study on paper permanence using traditional measurement techniques was unable to statistically account for the observed differences between paper with no recycled fiber content and 30% recycled content (Recycled Paper Research at the Library of Congress 2014). Other techniques which are similarly limited to purely elemental or isotopic analysis have been unable to produce a correlation between fiber type among recycled and virgin white office papers (Trejos et al. 2010; Jones et al. 2013, 2016). Thus, an examination of the virgin and 30% PCW papers relying on color measurements and traditional fiber analysis protocols such as TAPPI T 401 alone is unlikely to statistically and definitively distinguish between these two varieties.

Conclusion and perspective

The contactless resonant cavity dielectric spectroscopy technique simultaneously provides chemical and structural information in a rapid and nondestructive manner. This technique can be used to estimate the accumulated amount of aging-related degradation by-products in the analyte. We have also demonstrated that the technique has enough resolution to distinguish between samples of varying composition and may be used to distinguish between present day paper substrates and those manufactured only a few years apart within the past half-century. These results cannot be determined via any other methods of analysis that we are currently aware of.

More reliable means of studying the performance and durability of printing and graphics arts substrates can be developed by harnessing dielectric profiles to produce more realistic simulated test samples. There is immediate applicability of the contactless resonant cavity technique for the color and composition quality assurance and quality control testing in paper manufacturing. This technique also holds promise toward improving the development of secure printing products which are typically manufactured in lots and must be updated and redesigned on regular intervals to frustrate counterfeiters. Contactless resonant cavity dielectric spectroscopy has broad utility and is readily adaptable to meet the needs of the paper and pulp industries, secure credential manufacturers, forensic scientists, archeologists, and conservators, especially in investigations where samples are unique or rare.

References

- Recycled Paper Research at the Library of Congress. 2014. Edited by Preservation Research and Testing Division Library of Congress. Washington, DC: Library of Congress; Accessed February 8, 2019 URL: https://www.loc.gov/preservation/scientists/projects/rec_paper%20report_2015.pdf. [Google Scholar]

- Anderson CT, Carroll A, Akhmetova L, and Somerville C. 2010. Real-time imaging of cellulose reorientation during cell wall expansion in arabdopsis roots. Plant Physiology 152(2): 787–796. doi: 10.1104/pp.109.150128. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Area MC, and Cheradame H. 2011. Paper aging and degradation: recent findings and research methods. BioResources 6(4):5307–5337. [Google Scholar]

- Arnold RB 2003. ASTM’s Paper Aging Research Program. Accessed February 8, 2019 URL: http://cool.conservation-us.org/byauth/arnold/astm-aging-research/index.html. [Google Scholar]

- Atalla R, Bond J, Hunt C, and Agarwal U. 2000. Quantification and prediction of aging of printing and writing papers exposed to light In ASTM research program into the effect of aging on printing and writing papers. Madison, WI: USDA Forest Service, Forest Products Laboratory. [Google Scholar]

- Bergman DJ, and Stroud D. 1992. Physical properties of macroscopically inhomogenous media. Solid State Physics 46:147–269. [Google Scholar]

- Blumich B, Anferova S, Sharma S, Segre AL, and Federici C. 2003. Degradation of historical paper: Nondestructive analysis by the NMR-MOUSE. Journal of Magnetic Resonance 161: 204–209. doi: 10.1016/S1090-7807(03)00034-X. [DOI] [PubMed] [Google Scholar]

- Capitani D, Di Tullio V, and Proietti N. 2012. Nuclear magnetic resonance to characterize and monitor cultural heritage. Progress in Nuclear Resonance Spectroscopy 64:29–69. [DOI] [PubMed] [Google Scholar]

- Carter HA 1996. The chemistry of paper preservation: Part 1. The aging of paper and conservation techniques. Journal of Chemical Education 73(5):417–420. doi: 10.1021/ed073p417. [DOI] [Google Scholar]

- Carter HA 1996. The chemistry of paper preservation: part 2. the yellowing of paper and conservation bleaching. Journal of Chemical Education 73(11):1068–1073. doi: 10.1021/ed073p1068. [DOI] [Google Scholar]

- Causin V, Casamassima R, Marruncheddu G, Lenzoni G, Peluso G, and Ripani L. 2012. The discrimination potential of diffuse-reflectance ultraviolet-visible-near infrared spectrophotmetry for the forensic analysis of paper. Forensic Science International 216(1–3):163–167. doi: 10.1016/j.forsciint.2011.09.015. [DOI] [PubMed] [Google Scholar]

- Chen Y, Wan J, Ma Y, Dong X, Wang Y, and Huang M. 2015. Fiber properties of de-inked old newspaper pulp after bleaching with hydrogen peroxide. BioResources 10(1):1857–1868. doi: 10.15376/biores.10.1.1857-1868. [DOI] [Google Scholar]

- Driscoll JL 1976. The dielectric properties of paper and board and moisture profile correction at radio frequency. Paper Technology and Industry 17(2):71–75. [Google Scholar]

- Dupont A-L, Egasse C, Morin A, and Vasseur F. 2007. Comprehensive characterisation of cellulose- and lignocellulose-degradation products in aged papers: Capillary zone electrophoresis of low-molar mass organic acids, carbohydrates, and aromatic lignin derivatives. Carbohydrate Polymers 68(1):1–16. doi:doi: 10.1016/j.carbpol.2006.07.005. [DOI] [Google Scholar]

- Einfeldt J, Kwasniewski A, Meißner D, Gruber E, and Henricks R. 2000. Dielectric spectroscopic results and chemical accessibility of sulfite pulps. Macromolecular Materials and Engineering 283(1):7–14. doi:. [DOI] [Google Scholar]

- Einfeldt J, Heinze T, Liebert T, and Kwasniewski A. 2002. Influence of the p-toluenesulphonylation of cellulose on the polymer dynamics investigated by dielectric spectroscopy. Carbohydrate Polymers 49(3):357–365. doi: 10.1016/S0144-8617(01)00345-9. [DOI] [Google Scholar]

- El Omari H, Zyane A, Belfkira A, Taourirte M, and Brouillette F. 2016. Dielectric properties of paper made from pulps loaded with ferroelectric particles. Journal of Nanomaterials 2016: 1–10. doi: 10.1155/2016/3982572. [DOI] [Google Scholar]

- Emsley AM, and Stevens GC. 1994. Kinetics and mechanisms of the low-temperature degradation of cellulose. Cellulose 1(1):26–26. doi: 10.1007/BF00818797. [DOI] [Google Scholar]

- Griffin PJ, Lewand LR, and Pahlavanpour B. 1995. The analysis of paper degradation by products as a tool for monitoring fault conditions in oil-filled apparatus. Second International Conference on the Reliability of Transmission and Distribution Equipment, 29–31 March 1995. [Google Scholar]

- IEC. 2016. Nanomanufacturing - Key Control characteristics - Part 6–4: Graphene - Surface Conductance Measurement Using Resonant Cavity. Geneva, Switzerland: International Electrotechnical Commission. [Google Scholar]

- ISO. 2014. ISO 5630–7:2014 In Paper and Board – Accelerated Ageing – Part 7: Exposure to Light. Geneva, Switzerland: International Organization for Standardization (ISO). [Google Scholar]

- Jones K, Benson S, and Roux C. 2016. The forensic analysis of office paper using oxygen isotope ratio mass spectrometry. Part 1: Understanding the background population and homogeneity of paper for the comparison and discrimination of samples. Forensic Science International 262:97–107. doi: 10.1016/j.forsciint.2016.02.035. [DOI] [PubMed] [Google Scholar]

- Jones K, Benson S, and Roux C. 2013. The forensic analysis of office paper using carbon isotope ratio mass spectrometry - Part 1: Understanding the background population and homogeneity of paper for the comparison and discrimination of samples. Forensic Science International 231(1–3):354–363. doi: 10.1016/j.forsciint.2013.03.048. [DOI] [PubMed] [Google Scholar]

- Joshi KH, Mason A, Shaw A, Korostynska O, Cullen JD, and Al-Shamma’a A. 2015. Online monitoring of milk quality using electromagnetic wave sensors 2015 Ninth International Conference on Sensing Technology, Auckland, New Zealand. [Google Scholar]

- Kombolias M, Obrzut J, Karl Montgomery K, Postek MT, Poster DL, and Obeng YS. 2018. Dielectric spectroscopic studies of biological material evolution and application to paper. TAPPI Journal 17(9):501–506. doi: 10.32964/TJ17.09.501. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Landauer R 1978. Electrical conductivity in inhomogeneous media. New York: American Institute of Physics Conference. [Google Scholar]

- Metaxas C, and Driscoll JL. 1974. A comparison of dielectric properties of paper and board at microwave and radio frequencies. Journal of Microwave Power 9(2):79–89. doi: 10.1080/00222739.1974.11688904. [DOI] [Google Scholar]

- Obrzut J, Emiroglu C, Kirillov O, Yang Y, and Elmquist RE. 2016. Surface conductance of graphene from non-contact resonant cavity. Measurement 87:146–151. doi: 10.1016/j.measurement.2016.03.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Orloff ND, Obrzut J, Long CJ, Lam T, Kabos P, Novotny DR, Booth JC, and Liddle JA. 2014. Dielectric characterization by microwave cavity perturbation corrected for non-uniform fields. IEEE Transactions on Microwave Theory and Techniques 62(9):2149–2159. doi: 10.1109/TMTT.2014.2336775. [DOI] [Google Scholar]

- Ostlund A, Kohnke T, Nordstierna L, and Nyden M. 2010. NMR cryoporometry to study the fiber wall structure and the effect of drying. Cellulose 17(2):321–328. doi: 10.1007/s10570-009-9383-0. [DOI] [Google Scholar]

- Perkins EL, and Batchelor WJ. 2012. Water interaction in paper cellulose fibres as investigated by NMR pulsed field gradient. Carbohydrate Polymers 87(1):361–367. doi: 10.1016/j.carbpol.2011.07.065. [DOI] [PubMed] [Google Scholar]

- Porck H 2000. Rate of paper degradation - The predictive value of artificial aging tests edited by European Commission on Preservation and Access. Amsterdam: European Commission. [Google Scholar]

- Roig F, Ramanantsizehena G, Lahatra Razafindramisa F, Dantras E, Dandurand J, Hoyet H,Bernés A, and Lacabanne C. 2017. Dielectric and mechanical properties of various species of Madagascan woods. Wood Science and Technology 51(6):1389–1404. doi: 10.1007/s00226-017-0936-3. [DOI] [Google Scholar]

- Sahin HT, and Arslan MB. 2008. A study on physical and chemical properties of cellulose paper immersed in various solvent mixtures. International Journal of Molecular Sciences 9(1): 78–88. doi: 10.3390/ijms9010078. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saukkonen E, Lyytikainen K, Backfolk K, Maldzius R, Sidaravicius J, Lozovski T, and Poskus A. 2015. Effect of the carbohydrate composition of bleached kraft pulp on the dielectric and electrical properties of paper. Cellulose 22(2):1003–1017. doi: 10.1007/s10570-015-0556-8. [DOI] [Google Scholar]

- Steeman PAM, and van Turnhout J. 2003. Dielectric properties of inhomogeneous media In Broadband Dielectric Spectroscopy, ed. Kremer F and Schonhals A, 495–522. Berlin; Heidelberg: Springer-Verlag. [Google Scholar]

- Strlic M, Kolar J, Kocar D, Drnovsek T, Selih VS, Susic R, and Pihlar B. 2004. What is the pH of alkaline paper? e- Preservation Science 1:35–47. [Google Scholar]

- Sundara-Rajan K, Byrd L, and Mamishev AV. 2005. Measuring moisture, fiber, and titanium dioxide in pulp with impedance spectroscopy. Tappi Journal 4(2):23–27. [Google Scholar]

- TAPPI. 2015. TAPPI/ANSI Method T 401 om-15 Fiber Analysis of Paper and Paperboard.Atlanta, GA: TAPPI Press. [Google Scholar]

- Teodonio L, Missori M, Pawcenis D, Łojewska J, and Valle F. 2016. Nanoscale analysis of degradation processes of cellulose fibers. Micron 91:75–81. doi: 10.1016/j.micron.2016.07.013. [DOI] [PubMed] [Google Scholar]

- Thomas J, Idris NA, and Collings DA. 2017. Pontamine Fast Scarlet 4B bifluorescence and measurement of cellulose microfibril angles. Journal of Microscopy 268(1):13–27. doi: 10.1111/jmi.12582. [DOI] [PubMed] [Google Scholar]

- Tong J 2013. Quantifying color difference: a comparison between spacial frequency domain imaging to digtial color imaging in assessment of reconstructive flap occlusions. The UCI Undergraduate Research Journal XVI:45–53. [Google Scholar]

- Trejos T, Flores A, and Almirall JR. 2010. Micro-spectrochemical analysis of document paper and gel inks by laser ablation inductively coupled plasma mass spectrometry and laser induced breakdown spectroscopy. Spectrochimica Acta Part B: Atomic Spectroscopy 65(11):884–895. doi: 10.1016/j.sab.2010.08.004. [DOI] [Google Scholar]

- van der Plicht J, and Mook WG. 1987. Automatic radiocarbon calibration: illustrative examples. Palaeohistoria 29:173–182. [Google Scholar]

- Zervos S 2010. Natural and accelerated ageing of cellulose and paper: A literature review In Cellulose: Structure and properties, derivatives and industrial uses, ed. Lejeune A and Deprez T. New York: Nova Publishing. [Google Scholar]

- Zou X, Uesaka T, and Gurnagul N. 1996. Prediction of paper permanence by accelerated aging:I. Kinetic analysis of the aging process. Cellulose 3(1):243–267. doi: 10.1007/BF02228805. [DOI] [Google Scholar]