Abstract

Various types of single-cell analyses are now extensively used to answer many biological questions, and with this growth in popularity, potential drawbacks to these methods are also becoming apparent. Depending on the specific application, workflows can be laborious, low throughput, and run the risk of contamination. Microfluidic designs, with their advantages of being high throughput, low in reaction volume, and compatible with bio-inert materials, have been widely used to improve single-cell workflows in all major stages of single-cell applications, from cell sorting to lysis, to sample processing and readout. Yet, designing an integrated microfluidic chip that encompasses the entire single-cell workflow from start to finish remains challenging. In this article, we review the current microfluidic approaches that cover different stages of processing in single-cell analysis and discuss the prospects and challenges of achieving a full integrated workflow to achieve total single-cell analysis in one device.

INTRODUCTION

The application of single-cell analysis to answer biological questions has expanded over the past few decades. The conventional bulk approach usually requires a relatively large quantity of sample, and only an average snapshot of the biological state is captured; using the single-cell approach offers an exceptionally high resolution of molecular profile down to each cell, with a small sample size requirement. Single-cell analysis becomes a more promising approach than bulk when subpopulations of cells and rare biomolecules are the targets of investigation.

Despite the versatility and utility of modern single-cell analyses, challenges and obstacles remain. Single-cell approaches often suffer from low throughput. Typically, each cell occupies one reaction chamber; thus preparation time scales up when the sample size increases, which results in a laborious workflow and also risks the precious sample being degraded or contaminated in the process. Traditional microtube formats, even when successfully adapted to allow single-cell applications, consume a large volume of reagents, and as the desired sample size for single-cell applications is generally on the scale of 103–104 cells, performing them in microliter volumes becomes prohibitively expensive. Although liquid handlers can be used to minimize the workload and reduce the sample preparation time and reagent consumption, this type of costly equipment may not be accessible to every laboratory. Hence, the demand is rising for a method to reach higher throughput, while reducing the sample preparation time and cost for single-cell applications.

Incorporating single-cell workflows into microfluidics has been a widely adopted approach to tackle the low-throughput problem, making use of microscale channels and wells in bio-inert materials to easily enable all four stages of cellular and molecular manipulation. As such, microfluidics holds promises to facilitate single-cell applications and their processes, and there are many reports outlining the practical use of microfluidic devices in all four stages for single-cell analysis. However, most of these describe devices addressing one, or at most two, out of all stages of single-cell analysis, such as a chip designed specifically for performing cell lysis or a chip specifically for sorting and enriching a certain cell type. The remaining processes are performed off-chip or not at all. While these devices are certainly technically novel and significant, they are not able to fully address the key challenges in single-cell analysis for the following reasons: When sample transfer is required from on-chip processes to off-chip processes, additional sample contamination risk is introduced; often the volume mismatch between on-chip and off-chip processes can also compromise the accuracy and sensitivity of single-cell analyses; finally, the transition from on-chip to off-chip also prevents automation and, therefore, restricts scaling of throughput.

To fully exploit the strengths of microfluidics in single-cell applications, workflow integration (i.e., the combination of all functional units essential to complete a given workflow) on a single microfluidic platform is a potential solution. A fully integrated and enclosed analysis system would reduce the risk of contamination due to the absence of a reversible external connection between functional parts. This helps yielding better signals for low copy number species, which are common in single-cell studies. In integrated systems, in addition to the inclusion of multiple components, the connections between built-in components would also be more efficient. The increased efficiency can be attributed to the elimination of dead volume in external tubing and calculations pertaining to linkage across unit operations during the design of all-in-one devices. Bypassing the need to transfer reagents and samples between discrete instruments mitigates sample loss and dilution, which leads to benefits such as lower reagent consumption and sample input, reduction of detection limit, and increased assay sensitivity. Smoother transitions between functional components also entail shorter analysis time and thus higher throughput. In addition, by omitting human intervention, such as manual injection of reagents across devices, workflow integration enables a higher degree of automation, which would ultimately translate into greater experimental reproducibility. With these considerations in mind, an integrated device where the entire single-cell workflow can be performed on-chip would offers tremendous advantages. Here, we review the current state of microfluidic designs toward the full single-cell analysis workflow, the bottlenecks of achieving such integrated design, as well as potential designs and approaches in which modules are compatible with each other. Since nucleic acid-based single-cell analyses have gained popularity, this review will focus on these rather than on protein-based analyses.

AN OVERVIEW OF THE DIFFERENT STAGES IN A TYPICAL SINGLE-CELL ANALYSIS WORKFLOW

Single-cell analysis can be subdivided into genomic, transcriptomic, epigenomic, and proteomic analysis; collectively, these analyses are able to probe all the major stages in the central dogma, from DNA to RNA to protein, providing detailed views of various cellular processes. Various protocols and technology platforms have been invented to measure the abundance of these biomolecules-of-interest at the single-cell level, and most of these protocols share the same general experimental workflow stages. There are five main stages that are commonly found in most approaches: cell enrichment/selection, single-cell isolation/encapsulation, cell lysis, molecular processing, and molecular quantification/readout (Fig. 1). In this section, we summarize what each stage entails and set the stage for discussing the challenges of integrating them in a single device.

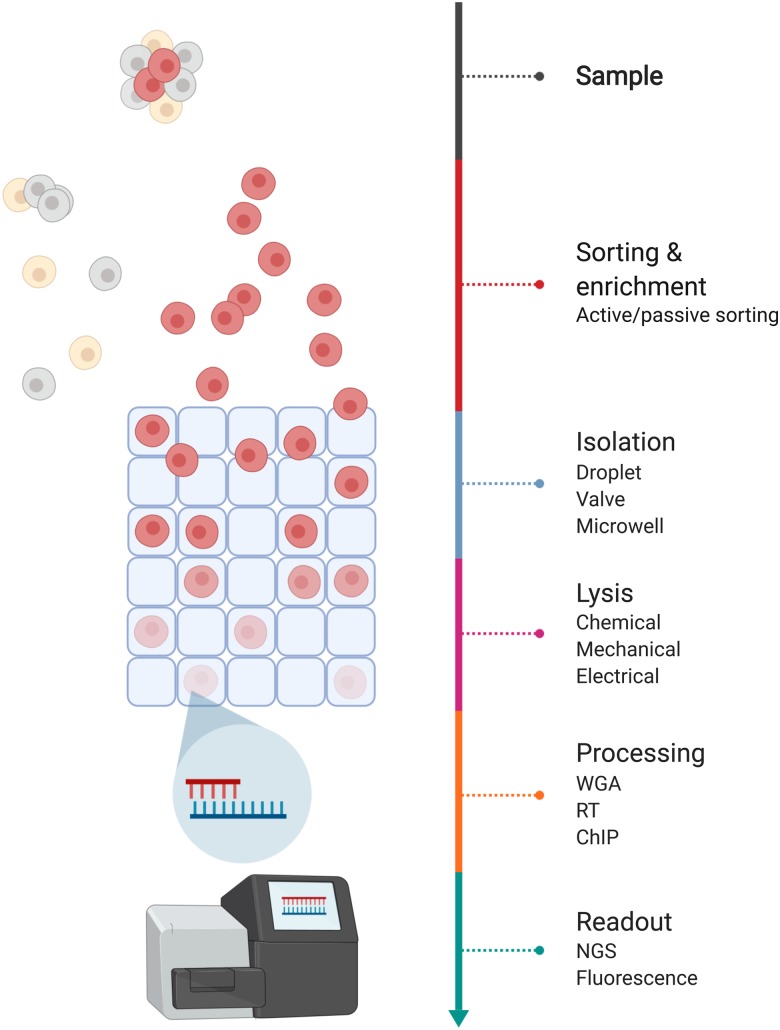

FIG. 1.

Workflow of single-cell analysis. The biological sample is first sorted and enriched for the population of interest at the single-cell level. Each cell is then isolated in individual reaction chamber, followed by cell lysis to release biological materials. The materials, such as gDNA, mRNA, or expressed proteins, are processed depending on the target analysis, to downstream readouts, such as next-generation sequencing, or fluorescent signal as reporter.

Cell enrichment or selection

Although not always necessary or desired, cell enrichment/selection is often used to target specific cells-of-interest within a large population; performing cell enrichment can lower sequencing cost by removing cells that are not of interest and is almost necessary at times for researchers to establish statistical power when studying rare yet heterogeneous cellular subpopulations. Currently, researchers employ conventional cell biology methods to enrich or select cells, either based on biophysical properties such as size or protein markers on the cell surface. The most commonly used methods are density gradient separation, antibody-bound magnetic bead-based separation, and fluorescence-activated cell sorting (FACS). Often, due to the large volume of the starting material, microfluidic solutions may not be ideal for this workflow. Yet paradoxically, the final sorted population of rare cells may be so few in number that transferring them from large volumes into microfluidic volumes for the next stage could result in severe or total loss of the sample. Thus, integrated solutions bridging this step to the next would be highly desirable.

Single-cell isolation and lysis

Compartmentalization of individual cells and its contents forms the basis of single-cell analysis, setting it apart from bulk assays. Individual cells are isolated in an enclosed reaction chamber to separate them and to confine their cellular contents after they are lysed. Almost all existing single-cell analysis methods use the same lysis approach, which is to introduce surfactant chemicals into each compartment to chemically disrupt the cell membrane. The main consideration for integration with other workflows is the chemistry and buffer compatibility, because surfactants that disrupt the cell membrane if at sufficiently high concentrations can also have detrimental effects on enzyme activity. Another key consideration for integration is how to maintain cell-to-cell compartmentalization as workflows progress to avoid cross-contamination.

Molecular biology and biochemistry of target biomolecules

Since biomolecules from single cells are usually extremely low in quantity, further processing is often necessary to prepare for quantification and readout. The target molecular species usually need to be converted biochemically into a measurable or accessible format, and this conversion is dependent on the molecular of interest and the type of analysis being done. When the genomic content at the single-cell level is of interest, multiple displacement amplification (MDA) or new methods such as MALBAC1 or LIANTI2 are employed for whole-genome amplification (WGA) to obtain sufficient genomic DNA (gDNA) for analysis. For single-cell transcriptomic profiling, RNA is typically first converted into complementary DNA (cDNA) via reverse transcription (RT), followed by PCR amplification to obtain sufficient quantities for analysis. Stemming from the very first single-cell RNA-seq method by Tang et al.,3 methods such as CEL-seq,4,5 Quartz-seq (Sasagawa et al., 2013, 2018), and Smart-seq26,7 were designed to improve the library preparation pipeline. Apart from nucleic acid-based assays, the investigation of epigenetics and proteomics at the single-cell level is also possible, and with the exception of proteomics, they all use some form of the enzymatic process. To integrate these biochemistries with other stages of the workflow, buffer compatibility is a big challenge, as well as the need to maintain stable incubation or cycling temperatures for each reaction. If multiple steps are involved, such as for RNA-seq, where RT and PCR need to take place consecutively, buffer compatibility and the potential for enzymes from different steps to interfere with each other also need to be carefully considered when designing integrated platforms.

Quantification and readout

After molecular processing, materials are then ready to be quantified and reported. There are two widely used readouts for nucleic acid-based single-cell analyses: quantitative PCR (qPCR), which reports the abundance of specific target sequences via fluorescently labeled probes, and next-generation sequencing (NGS), which provides genome-wide profiling for all cells without having to select specific targets, but requires further molecular biology and more complex bioinformatic analysis.

THE CURRENT STATE OF MICROFLUIDICS INTEGRATION FOR SINGLE-CELL ANALYSIS

Existing microfluidic platforms for single-cell analysis can be considered partially integrated, as they usually cover more than one stage in the five-step single-cell analysis workflow described above. In this section, we discuss existing platforms, in particular those that have gained broad usage, and discuss the current extent of workflow integration for each platform. The discussion is categorized by droplet-based, valve-based, microwell-based, and others.

Droplet microfluidics

Droplet microfluidics is now commonly used in many single-cell analysis approaches by isolating cells along with reagents in water-in-oil droplets. Each individual droplet is a microreactor isolated by a continuous stream of inert carrier oil, which prevents chemical crosstalk between droplets.8 Apart from cell isolation by droplet generation, cells in each droplet are also lysed in parallel by detergents or surfactants that have been incorporated in the aqueous phase. Evident from the variety of operations that can be easily carried out in droplets, droplet microfluidics is versatile. The lineup of operations includes splitting, merging, addition and extraction of reagents, and thermocycling.9 Despite the diverse toolset available, operations, such as washing and buffer exchange, remain challenging to implement at scale and is one major bottleneck for integrating more stages of the workflow.

Using droplets for single-cell analysis greatly increases the throughput of each experiment, making it an excellent choice for experiments involving a huge number of samples. To profile gDNA, SiC-seq by Lan et al. and sd-MDA by Hosokawa et al. were both microfluidic devices capable of high-throughput library preparation up to 50 000 per run and 21 000 cells per hour with droplet fusion, respectively.10,11 Both of these cover two stages of single-cell analysis: cell isolation, as well as lysis and some biochemistry processing. Droplets are also extensively used for transcriptomic profiling. Klein et al. and Macosko et al. developed inDrop and Drop-seq; both similarly utilize water-in-oil droplets to compartmentalize barcodes and single cells and then lyse the cell for RT and barcoding of the cDNA,12,13 thus performing cell isolation, lysis, and molecular processing all at once. For epigenetic studies, Rotem et al. developed a droplet microfluidic chip that can perform chromatin immunoprecipitation (ChIP) on barcoded chromatin by lysing single cells isolated in droplets, followed by merging of DNA tags emulsified into droplets as well.14 For single-cell proteomic study, Shahi et al. presented Abseq for single-cell protein profiling that could barcode individual cells and profile their protein expression.15 In this approach, cells are isolated and lysed on-chip before a series of droplet merging and splitting steps to incorporate barcode drops into cell drops.

For single-cell RT-PCR or qPCR workflows, more stages can be integrated. Mary et al. described a single-cell qPCR microfluidic design for 100 samples that first encapsulates cells in droplets with lysis reagents, followed by thermal cycling directly on-chip, in droplets. Given the transparent property of Polydimethylsiloxane (PDMS), the fluorescent signal from each droplet, representing each cell, can be observed directly over the chip. Kim et al. have also presented a design with higher throughput that can prepare 47 078 cells in 120 min, in which droplet-containing cells are lysed inside the microfluidic chip and then merged with qPCR buffer. Droplets are then extracted out of the chip for thermal cycling and fluorescence measurements.16,17

Partly due to the number of droplets needed to achieve experiment scale and the large collective volume of these droplets, almost all commercial implementations of droplet-based single-cell analysis platforms use off-chip thermocycling to complete the molecular biology and the readout.

Valve microfluidics

In valve-based systems, microfluidic chambers are coupled with valves for flow control and cell confinement, with pressure-controlled valves having the broadest application.18 These valves execute flow control when the soft elastomeric membrane of the valve is deflected by the pressure exerted by an orthogonal control layer, and the deflected membrane obstructs the flow channel (REF). The incorporation of valves enables facile adding and removing of reagents, cell capture, mixing, partitioning, incubation, and transfer of analytes for various treatments across a series of chambers.19 Valve-based approaches feature more complex manipulation of the cells and reagents. As each cell is individually processed inside microfluidic chambers, a mechanism to barcode the biomolecules of each cell separately from another is optional. Furthermore, valve opening and closing can be actuated automatically with computer-controlled programs, allowing precise timing of reagent and sample handling, as well making experiments less labor intensive.

Valve-based microfluidics have been widely adopted for single-cell analysis, including genomic and transcriptomic applications. Fan et al. presented a chip for single-cell whole-genome haplotyping of individuals, in which individual cells are captured and lysed, followed by amplification, downstream genetic interrogation, and haplotyping.19 The same design was later used by Wang et al. for genome-wide analysis of recombination and mutation rates in a single human sperm.20 Yu et al. reported a device design that parallelized the MALBAC genome amplification protocol to process eight samples per run21 by first manually loading single cells into each inlet, followed by cell lysis in individual chambers. Amplified products were collected at the outlet for NGS sequencing. Recently, Li et al. presented a device capable of isolating rare circulating tumor cells (CTCs) from patients’ blood sample each run. Compared to other microfluidic devices, this design is capable of identifying CTC within the sample, demonstrating “whole blood in, WGA product out” in a chip.22 Single CTCs are captured in individual chambers, followed by lysis and WGA in subsequent chambers, then amplified products are retrieved for off-chip sequencing. The first microfluidic device designed for single-cell mRNA analysis was reported by Marcus et al., where cDNA was synthesized in a valve-controlled microfluidic chip, capable of cell isolation, lysis, RT, and cDNA synthesis are all carried out on-chip.23 A device for single-cell whole-transcriptome sequencing was reported by Streets et al., in which cells were isolated and lysed in chambers for cDNA synthesis, then taken off the chip to perform downstream amplification and sequencing library preparation.24 Some other valve-based devices even allow a complete single-cell workflow, including a signal readout such as fluorescence measurements directly on-chip, taking advantage of the optical transparency of PDMS. For instance, White et al. and VanInsberghe et al. performed RT-qPCR from start to finish, including cell loading and lysis, reverse transcription, cDNA synthesis, and fluorescence readout of qPCR probe signals.25,26 Single-cell proteomic analysis as demonstrated by the SCBC protocol from Shi et al. and Deng et al.27,28 can complete the entire workflow from single-cell capture, lysis, to protein modification, tagging with intracellular fluorescent probes, and readout on-chip.

Evidently, with valving, there can be more versatility in terms of the addition of reagents and buffer concentration adjustments; therefore, with valved designs, there has been more integration, where most of the biochemistry steps such as pre-amplification and PCR can be integrated on-chip with the aid of the external component for thermal cycling. There are fewer examples of single-cell analysis chips that have integrated thermal elements on-chip. This is partly due to the challenges and higher cost of mixing fabrication processes for PDMS and for silicon-based integrated circuits, partly because other than the very few applications where the device needs to be portable, there is no compelling advantage of integrating the thermal elements. Integrated optical readout is another advantage, but the trade-off is parallelization and throughput, which for valved devices is typically an order of magnitude lower than droplet-based systems since chambers are not generated on-demand and scalable like droplets are.

Microwell

Well-based systems make use of arrays of coverless miniature containers to isolate single cells. Irrelevant to “device” design, the execution of different steps typically relies on the functionalization of glass covers, with antibodies for immunoassay29 for example, or the presence of barcoded beads for mRNA capture30,31 co-encapsulated in wells. Similar to valve-based systems, the drawback compared to droplets is the reduced throughput, but due to its simple design and fabrication procedure, scalability can be achieved through simply running more arrays or plates for each experiment.32 Automation and parallelization would still be problematic for very large sample sizes; therefore, microwells are most suitable for protocols with simple, prolonged incubation steps and few reagent exchanges. More automated reagent exchange can be carried out by using liquid handlers or coupling microfluidic channels with well arrays.33

For genomic analysis, MIDAS by Gole et al. features the use of microwells to lyse and amplify genomic content by MDA in ultra-low reaction volume down to 12 nl.34 Amplified products were then collected by pipet for off-chip analysis. The very first reported microwell platform for single-cell RNA-seq was described by Fan et al., known as Cytoseq.35 Later, more methods based on microwells, such as the automated microwell platform by Yuan and Sims,36 Seq-Well by Gierahn et al. that passively loads cells into microwells together with one bead that carry oligos to capture mRNA after lysing cells,30 and STRT-seq-2i by Hochgerner et al., have been reported.37 These methods share a similar workflow: a solution of cells, together with beads for mRNA capture, is placed on the array or well surface and passively settle into wells by gravity, and then cells are lysed in the microwells. Almost all microwell-based approaches only perform biomolecular capture in the device; molecular processing such as RT and amplification are carried out in the conventional format after capture beads are retrieved, with the exception of STRT-seq-2i, where cDNA synthesis occurs in the well. For proteomic analysis, Hughes et al. reported a microwell platform for single-cell western blotting that integrates passive cell loading, lysis, biochemistry processing, and fluorescent readout directly on a polyacrylamide gel chip.53

Although an integrated microwell platform appears to be feasible and a good compromise between the droplet-based and valve-based systems in terms of scalability, versatility, and automation, it is not without drawbacks. Due to the open structure of microwells, this platform is more at risk of sample cross-contamination and evaporation, which are precisely the problems that integration tries to solve. Studies have also shown that for single-cell RNA-seq applications, microwell formats also tend to have lower sensitivity and accuracy compared to other systems.38

Microposts

Unlike valve, droplet, and microwell microfluidics, devices that consist of microposts or micropillars could be an alternative approach for those single-cell analyses with specific needs. Microposts, in microfluidic devices, are usually narrowly spaced for retaining materials that need further processing. For instance, they can be used to reduce amplification bias in genomic assays during WGA. Tian et al. incorporated micropillars in their device to physically spread gDNA such that reagents and enzymes can be distributed evenly on linearized gDNA, thereby reducing amplification bias.39 Microfluidic designs that use microposts for assays are uncommon and often suffer from low throughput.

THE ABSENCE OF COMPLETELY INTEGRATED MICROFLUIDIC SINGLE-CELL WORKFLOWS

Microfluidic designs discussed so far can perform at least two steps in any single-cell analysis workflow, and depending on the assay being implemented, there have even been some demonstrations of complete workflow integration from sample to readout. The aforementioned applications with relatively simple biochemistry and that use optical analysis, such as qPCR, often can be adapted to a microfluidic format that integrates the complete single-cell workflow. However, such fully integrated systems remain elusive for most protocols, and in particular, many popular protocols for single-cell sequencing, be it genomic or transcriptomic, are not fully integrated. Even with the steady growth of single-cell analysis in microfluidics, steps that involve enzymatic reaction and incubation are not always performed on-chip. Off-chip processing is often necessary in high-throughput methods such as droplets and microwells. Different from qPCR, NGS requires additional material processing to construct the sequencing library, and a completely separate sequencer for readout. To date, no chip can cover entire workflow: from isolation, lysis, to sequencing library preparation and sequencing. Droplet microfluidics usually require off-chip processes for processes such as reverse transcription and PCR,12,13 steps beyond hybridization of mRNA to barcoding beads in microwells are all carried out off-device,30,35,40 limiting its possibilities to perform the entire workflow on-chip. Since amplified biomolecules from single cells cannot be pooled together without cell barcoding,11–15 extra steps for barcode synthesis and incorporation are needed in the workflow. Valve microfluidics are able to usually integrate up to the cDNA amplification on-chip, yet sequencing library construction is hindered by the requirement of even more reagents. Although these additional reagent handling steps could potentially be addressed by adding even more control circuits and valves, the design of these circuits and their fabrication using multi-layer soft lithography is laborious and time-consuming, often involving massive circuit redesign for even slight variations in the flow layer design. Furthermore, as designs become increasingly complex, fabrication becomes challenging and of low-yield, leading to high costs. Though its simple architecture expedites design and fabrication, microwells are lacking in the ability to manipulate fluids. In general, reagent exchange in wells is done manually through pipeting, which is laborious and time-consuming.32 Based on the microfluidic designs reviewed here, we believe a bottleneck for complete workflow of single-cell sequencing analysis in microfluidics exists.

Overall, there are several main challenges in the development of fully integrated single-cell analysis microfluidic devices. First, as -omic studies become more and more popular, workflows with NGS as readout require additional sample processing steps compared to targeted approaches like qPCR that can use optical measurements, and currently, there are very few approaches for direct sequencing on-chip. Second, as a consequence of the increasing complexity needed in microfluidic designs to accommodate these additional steps and reagents, the design, fabrication, and operation of these more sophisticated devices become somewhat limited by the currently available technology. Finally, the mismatch in scale between the sample volume and microfluidic device has persisted as an engineering challenge, as strategies for increasing the sample concentration in microfluidics are limited.

Device fabrication and operation technologies are bottlenecks to integration

In droplet microfluidics, an additional number of fluid components for material processing means additional syringe pumps would be necessary to drive these fluids at their respective flow rates, thus requiring more peripheral equipment. On-chip incubation of droplets is difficult to achieve since a large incubation chamber is required to store all the droplets, which is easier to circumvent by harvesting droplets off chip. While on-chip incubation is possible, its implementation remains a challenge. Whereas short-term incubation (<1 h) necessitates lengthy delay lines resulting in pressure drop adverse to throughput,41 incubating for prolonged periods would require storing droplets in built-in reservoirs, such that droplet generation must cease upon reaching full capacity, effectively ruling out the possibility to operate continuously. Besides obstacles in maintaining throughput, there have also been considerable difficulties when designing for droplet incubation. Due to the aforementioned complications to incubate on-chip, the majority of droplet microfluidics protocols to date have opted for incubation off-chip to ensure continuous operation of upstream processes, thereby preserving the inherently high throughput of droplet-mediated systems.12,42,43

In valve-based microfluidics, having at least two layers consisting of a flow layer for the reagent and cell flow and a control layer for valve control increases the complexity of chip design. Additional peripherals for controlling valves add another layer of operational complexity as control software and electronics could be a barrier for biologists.44 Limited by the number of chambers, microfluidic devices utilizing valves have relatively lower throughput than other approaches. Shrinking the size and scaling up the number of chambers could possibly increase its throughput, yet the device would rely even more heavily on peripherals, as well as increasing design difficulties.

Without having way to actively manipulate them, microwells within an array are often treated collectively entity during reagent change since it is challenging to address individual wells separately, while keeping track of each one. Thus, this platform should be avoided when different treatments are required for different cells. It is worth mentioning, however, that among all these platforms, microwells are operationally the simplest and usually have the lowest peripheral equipment required to operate.

New technologies are needed to integrate sequencing on-chip

Other than the difficulties of conducting enzymatic reactions on-chip, the challenges to sequence DNA on the microfluidic chip to achieve a complete integrated workflow remain. Assays that rely on next-generation sequencing usually have sequencing libraries constructed off-chip due to the dependence on reagents and chemistries specifically designed for commercialized sequencers. Efforts to develop a microfluidic sequencing platform have employed nanopore-based technology: When single-stranded DNA passes through a nanopore in a membrane, the ionic current flowing through the pore changes depending on the combination of DNA bases passing through, and these current changes can be measured and deconvoluted to give DNA sequence information.45,46 Rofeh et al. reported a microfluidic system comprised of a block copolymer with a nanopore protein array in which DNA was successfully translocated.47 Commercial platforms such as the Oxford Nanopore system show the feasibility of perform NGS in a portable microfluidic format, but to incorporate such a platform into a fully integrated single-cell analysis device is non-trivial. Polymer-based devices are generally more biocompatible and lower cost for industrial manufacturing and are currently the most commonly employed for single-cell analysis devices, while silicon-based semiconductors are required for nanopore sequencing; hence, materials and fabrication process compatibility, as well as cost, are two of the major considerations and challenges that need to be resolved before full integration with NGS can be achieved.47 Achieving this will likely depend on the emergence of new technologies, such as new materials or processes that enable cost-effective manufacturing—novel and versatile 3D printing-based fabrication methods that print circuits on various surfaces comes to mind as a potential future solution—or new NGS or proteomics measurement modalities that can be done in polymer-based devices.

Although it would be technically interesting and represent a tour-de-force of engineering to combine total single-cell analysis with NGS into one integrated device, it is arguably not critical to include NGS readout as part of the workflow, but rather just the library construction to make biomolecules NGS-ready. The reason is that by the time a sample is NGS-ready, it is usually in sufficiently high quantities and concentrations such that they are less susceptible to sample transfer-associated loss or minor contamination. Therefore, for practical application purposes, researchers and engineers in the near-term can focus instead on the full integration of stages up to and including NGS library construction on-chip.

INTEGRATED ON-CHIP CELL ISOLATION, ENRICHMENT, AND LYSIS ALTERNATIVES

Of the workflow stages that are more easily integrated, cell isolation, enrichment, and lysis are among the most helpful to the microfluidic workflow, since performing this step off-chip conventionally is often labor intensive or sometimes in the case of very rare cell populations could be impossible due to transfer-associated sample loss. For example, CTCs are present in the tens per milliliter of blood, and sorting them using conventional FACS, for example, would result in at most hundreds of cells in several milliliters of buffer or media, making it impossible to load them into a commercial system like the 10X genomics single-cell RNA-seq system. Being able to sort labeled cells on-chip means that prior cell enrichment off-chip by other means is not necessary, and could not only make the single-cell analysis workflow more manageable but could also additionally open up single-cell analysis to new sample types.

Conventional cell enrichment

Conventional methods to manipulate single cells are versatile but have downsides. A few examples of commonly used sorting methods include fluorescence-activated cell sorting (FACS), mouth pipeting, and laser-assisted capture microdissection (LCM) (Fig. 2). Cell sorting by FACS requires samples to pass through sheath fluid with high speed and pressure, and sorting is achieved by using a strong electric field generated by high voltage to deflect cells, such that desired cells are sorted to another tube. Although this approach is routinely used, high pressure causes stress to cell samples and may affect cell physiology and viability. It was previously reported that flow cytometry has an impact on cellular metabolome and the cell redox state,48–50 effectively altering cell physiology. Additionally, the volume of the resulting cell solution can often be too large, making the concentration of cells too low to transfer into microfluidic devices for the next step. Mouth pipeting uses suction force of the operator's mouth through a fine pulled glass pipet to pick up cells from a dish, and although very accurate, it is time-consuming and low-throughput. LCM can be used to cut cells directly from tissue, but maintaining specificity can be challenging: a liberal dissection might include neighboring cells, but a conservative cut might not encompass the entire cell.51 It is low throughput when operated manually, and although automated lasers are available and can reduce the hands-on time, they are extremely expensive.

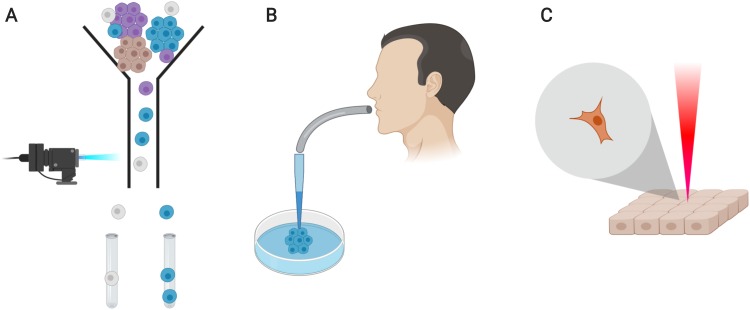

FIG. 2.

Illustration of methods to achieve single-cell sorting. (a) Fluorescence-activated cell sorting (FACS) sorts cells to desired location, individual tubes for single-cell application, with the use of laser detectors. (b) Mouth pipeting uses suction force from mouth to pick individual cells. (c) Laser-assisted microdissection cuts tissues around single cell for isolation.

Microfluidic-assisted cell sorting

Microfluidic enrichment and sorting offer advantages for cell viability, accuracy and specificity, speed, and throughput compared to conventional methods. Many aspects post-sorting would need to be taken into consideration when integrating currently available microfluidic cell sorting and enrichment techniques to downstream single-cell assay workflow, as to replace typical cell loading. The ideal sorting technique for single-cell application should be able to (1) detect cell-type specific markers to identify populations-of-interest, (2) sort cells at single-cell resolution with high specificity to minimize the occurrence of cell doublets or clusters downstream, while (2) maintaining high cell viability to minimize biological noise from cell fragments or free biological molecules that could hinder sample quality.

Active sorting manipulates cells by external force, usually from an actuator, to move them to desired locations to achieve sorting. When coupled with a detector, cells that are labeled with a reporter such as a fluorescent molecule can trigger the actuator to sort specific target cells, although label-free active sorting is also possible. Many reports have demonstrated the use of active sorting strategies to enrich and sort cells that are of their interest, with excellent cell viability, accuracy, speed, and throughput. These strategies include acoustophoresis, dielectrophoresis (DEP), and optics.

Acoustophoresis uses acoustic pressure wave to migrate cells or particles. Cells can be manipulated to either the pressure nodes (minimum pressure amplitude) or antinodes (maximum pressure amplitude), depending on the relative density and compressibility between cells and the aqueous phase52 [Fig. 3(a)]. Typical surface acoustic wave (SAW) approach has little impact on cell viability, integrity, and functionality.53–55 This strategy can be combined with a detector for labeled cell sorting to enrich cells-of-interest. Ma et al. reported a fluorescence-activated cell sorting system by laser detection of fluorescence signal from cells and sorting by SAW that achieved high viability of 95%, as well as high purity of 86% of MCF-7 cells.56 Schmid et al. reported another fluorescent-activated cell sorter that can achieve 3000 cells/s with good viability.57 Although acoustophoresis system can maintain cell viability and high speed, while being accurate and high-throughput, optimization is still required when it is used for single-cell analysis and downstream integration. For instance, SAW device requires AC input to generate acoustic forces, which will eventually generate heat that might affect downstream enzymatic reactions. A solution to remove heat from device is needed when integrating the acoustophoresis system to downstream workflow.

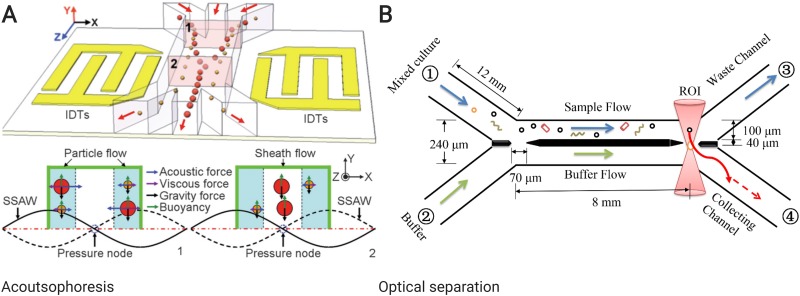

FIG. 3.

Schematic illustration of different microfluidic cell sorting mechanisms. (a) Cell sorting utilizing acoustophoresis. Standing surface acoustic wave (SSAW) is generated by two parallel interdigital transducers (IDTs) across the channel for cell manipulation.52 Reproduced with permission from Shi et al., Lab Chip 9, 3354 (2009). Copyright 2009 Royal Society of Chemistry. (b) Optical separation of cells by optical trap to achieve cell sorting.61 Reproduced with permission from Qi et al., Biomed. Opt. Express 8, 934 (2017). Copyright 2017 The Optical Society.

Dielectrophoresis (DEP) refers to a phenomenon in which a particle displacement is caused by an external force when it is in a non-uniform electric field. Direction and magnitude of displacement by DEP force depend on the properties of cells, solutions, and the electric field. Given that the electrical field can potentially cause harm to the viability of cells, it is possible to apply DEP force on emulsified droplets containing cells, maintaining cell viability. Sciambi and Abate reported a dielectrophoretic droplet sorting system that can achieve sorting speed up to 30 k cell/s with high accuracy.58 While DEP shows great promises in efficiently sorting single cells with good viability, accuracy, speed, and throughput, a power source is needed to generate the electric field, which will also generate heat and electricity that could interfere with the workflow followed by cell sorting.

Cell sorting with an optical beam is an alternative approach other than acoustic force and electric fields [Fig. 3(b)]. Optical actuators have three main characteristics: size-matching, which the laser beam diameter is tunable for different scenarios; force-matching, which the force to manipulate cells is adjustable for slight or strong push; and biocompatibility, in which the effect of laser beam on cell viability is low.59,60 An optical cell sorting system designed by Qi et al. uses optical tweezer to sort cells with 830 cell/s at maximum speed, in which the cells sorted with laser beam are still viable after 420 days of culturing.61 A 3D microfluidic laser-triggered FACS by Chen et al. also makes the use of laser beam to generate cavitation bubbles with hot plasma and sorts cells at a speed of 230 k cell/s with 90% purity and high viability.62 Optical approaches can meet the criteria for single-cell analysis; however, the need for laser equipment poses as a limitation when considering device design, especially for integration.

A micro-electro-mechanical system (MEMS) can use electronic technologies and mechanical forces to manipulate cells to the desired location. MEMS such as piezoelectric actuators and vapor bubble actuators are two examples that were used to sort cells with high throughput when coupled with a detector. Cheng et al. took advantage of the pushing and pulling forces generated by piezoelectric actuators on PDMS to manipulate sheath flow and isolate HeLa cells with high throughput and separation efficiency.63 de Wijs et al. utilized vapor bubble jet flow by heating up certain spots to ultimately manipulate cells for enrichment and sorting. Although the heating process is as short as 100 μs with no detrimental effect on cell viability,64 the effect on temperature-sensitive enzymes was not investigated.

Cell lysis in microfluidic device

Even though most microfluidic protocols utilize chemical lysis for biomolecule access, other cell lysis methods could be potentially useful when designing new devices. Lysis ideally should not interfere with the rest of the workflow to avoid undermining the performance of other steps. Simplicity in design and operation of the lysis unit is desired; specifically, there should be little to no reliance on peripherals or additional treatments to enable downstream reactions. Contamination should be minimized through selective lysis of biological membranes that are essential for the intended analysis. Depending on the workflow, there may be specific requirements for lysis speed or post-lysis state of molecules of interest. In addition, in integrated platforms, sample dilution should also be minimized for effective coupling between functional units.43 To complement this effect, techniques with high lysis speed are favored to avoid dilution too much by limiting the extent of diffusion. Efficient interfacing with downstream events is ideal and possible when reaction conditions for lysis and subsequent reactions are compatible. Other than chemical lysis, thermal, mechanical, electrical, and optical lysis are available and previously reported in microfluidic chips.

Thermal lysis disrupts cell by denaturing proteins on the cell membrane with high temperature.65,66 Generally speaking, this approach is not compatible with continuous flow mode in droplet-based devices for instance, since it takes time to reach a desired temperature. In both microwell and valve formats, heat can be supplied to the device by built-in heating elements67 [Fig. 4(b)] or from external sources29 [Fig. 4(a)]. Unless taken off-chip, cells in droplets cannot be effectively lysed using this method.68

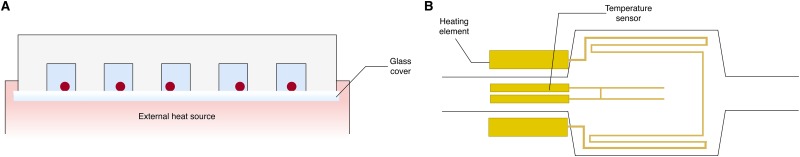

FIG. 4.

Example setup of thermal lysis conducted with heat supplied on-chip and by an external source, respectively. (a) When heat is provided by an external source, no extra component has to be added to chip design. Possible external heat source includes thermocycler and heating block. (b) For on-chip heat supply, device configuration typically includes heating elements to generate heat and a temperature sensor for regulation.

As the required temperature of reactions in different workflow stages varies, heating for lysis may hinder the efficiency of other reactions, restricting the entire system to batch operation and undermining throughput. To address this, Ke et al. built insulation channels around microchambers to reduce thermal crosstalk and enable each chamber to operate at different temperatures.69 An alternative solution by Privorotskaya et al. is to shrink the heating element into a microcantilever such that the energy delivered is highly localized.70 In the same paper, the nuclear membrane was lysed 10 s following the disruption of the plasma membrane, demonstrating that selective lysis is achievable by fine-tuning the duration of heating. Despite these strategies to overcome thermal inhibition, they complicate the device design and fabrication and have not been widely adopted. Too many temperature changes also predispose the system to bubble formation, which would disrupt downstream operations.

Looking into requirements specific to workflow, since RNA is heat sensitive, heat lysis should be avoided whenever transcriptional analysis is of interest.68 The method also has limited utility in studies probing dynamic events in cells since it is usually slow, taking minutes to reach full lysis.71 Long lysis duration would also result in considerable lysate dilution, such that a synergistic effect in reducing sample dilution is absent.

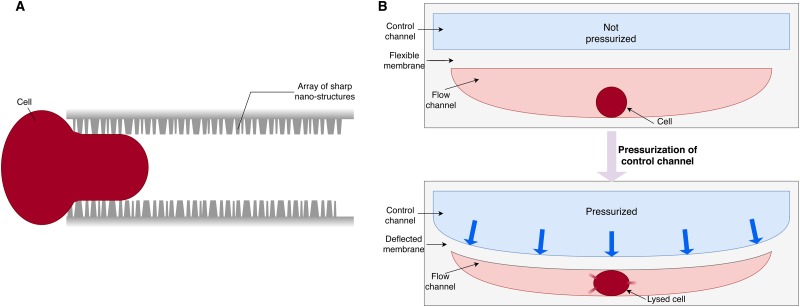

Mechanical lysis involves tearing or puncturing of cell membranes using mechanical forces such as shear stress, friction forces, and compressive stress.72,73 Possible mechanisms include membrane disruption by sharp nanostructures [Fig. 5(a)] and compressive forces [Fig. 5(b)]. Pioneering in cell disruption by sharp features, Di Carlo et al. reported a silicon-based microfluidic device consisting of a mechanical filter covered with sharp nanoknive tips.74 Similarly, Kim et al. fabricated a nanowire-integrated device in which cells are ruptured, as they are driven through the nanowires by continuous flow, due to the strong interaction with the wire bundles.75

FIG. 5.

Schematic illustrating different mechanical lysis mechanisms. (a) Lysis by sharp nanofeatures. To enable lysis using this mechanism, the channel size has to be slightly smaller than the cell diameter. Cells are punctured by sharp features lining the walls as they are driven by flow and squeezed into the channel. (b) Lysis by compression. Devices leveraging this approach are equipped with a flow channel and a control channel segregated by a flexible membrane. When the control channel is pressurized, single cells sitting in the flow channel is compressed by the deflected membrane and finally lysed.

In general, nanostructure-assisted cell lysis is only compatible with valve-based systems since fluid velocity from continuous flow is necessary. Although continuous flow is used in droplet-based systems, encapsulation in droplets prevents cells from having direct contact with sharp features. In an alternative mechanism, compressive force is leveraged to lyse cells. It has been combined with valve-based systems. Kim et al. confined cells in a microchamber flanked by valves and applied compressive force by loading pressurized water to deflect a membrane above the chamber.76

As a whole, mechanical lysis would pose problems to downstream separation and purification since cells lysed this way generate large sized debris that are sticky and difficult to remove later and could cause clogging problems and increase non-specific adsorption of biomolecules. On-chip integration of filtration units, such as the use of internal structures like porous membranes or pillars to try and catch debris, often complicates the device operation, since constant monitoring is needed to avoid or resolve device blockage and clogging.77

Applying shear force can cause macromolecules, including DNA and proteins, to degrade. This approach also does not provide the selectivity to discriminate between different membranes.78 This is especially true when continuous flow is needed such that subcellular components may be subjected to ongoing disruptive forces. However, recently, Hsiao et al. reported the extraction of functional mitochondria by breaking cells with blades features made of soft PDMS, instead of hard silicon employed in previous studies.79

While most mechanical approaches require additional features, their complexity varies. Silicon-based nanoknives necessitate complex microfabrication techniques, such as DRIE.74 PDMS-based methods like nanowires necessitate the growing of nanowires in addition to device fabrication.75 For the compression approach, when integrating with valve-based systems, one can make use of the existing bilayer flow control structure to incorporate a lysis module. Overall, the control of lysate dilution is poor since mechanical lysis typically takes seconds to minutes to complete.80

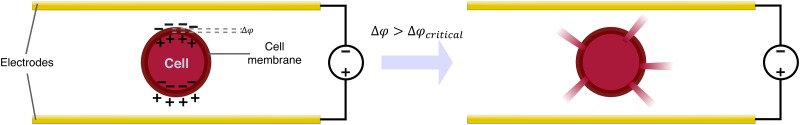

Electrical lysis occurs when cells are exposed to an external electric field such that its transmembrane potential exceeds a certain stability threshold, resulting in extensive pore formation81 (Fig. 6). In general, electrical lysis is incompatible with droplets due to low conductivity of the carrier oil sheath which significantly hinders lysis efficiency. Exceptions do exist as demonstrated by de Lange et al. who electrically lysed single cells prior to droplet encapsulation.82 However, this approach is only applicable to cells with the cell wall such that its shape can be maintained for effective encapsulation. Implementation of electrical lysis in valve- and microwell-based systems typically necessitates a built-in electrode to provide an electrical field.83,84

FIG. 6.

Schematic of electrical lysis. A transmembrane potential is generated in the presence of an external electric field. When the transmembrane potential exceeds a certain critical value , the cell membrane is disrupted and pores start to form.

The absence of intense heat and chemical treatment prevents biomolecules from deteriorating. Ohmic heating during lysis can be minimized through a number of strategies, including the use of AC field in combination with DC field in place of entirely DC fields and modification of channel geometry to amplify the electric field in a highly localized manner.85,86 Electrical lysis is highly efficient, normally completing in milliseconds,77 effectively suppressing lysate dilution. Also worth mentioning is the method's ultra-high selectivity originating from the variation of critical transmembrane potential across different biological membranes.87

The collective use of AC and DC fields during electrical lysis would give rise to a voltage gradient useful for electrophoretic separation. McClain et al. fabricated a fully automated integrated device which transports cells to an electrical lysis location via a focusing flow of emulsifier and subsequently injects the cell lysate into a separation channel for the electrophoretic separation of lysate contents prior to LIF detection.88

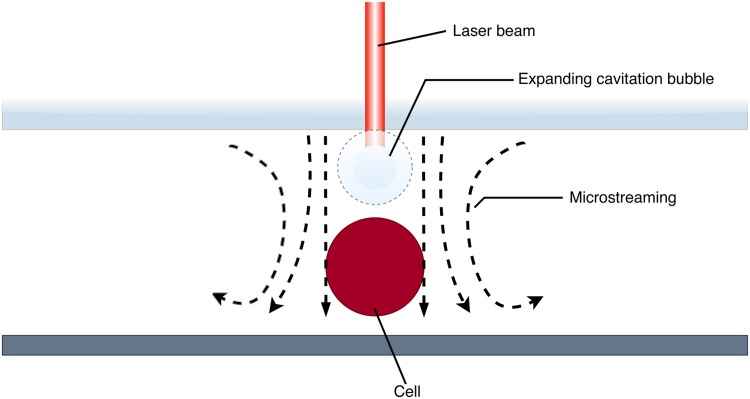

Optical lysis encompasses a collection of cell lysis mechanisms actuated by light. The bubble cavitation approach involves focusing of laser pulses on the physiological buffer to generate bubbles that give rise to shockwaves upon expansion and collapse77 (Fig. 7). This method can be used in conjunction with all major isolation strategies since it imposes no restriction on flow conditions. The only requirement is the provision of optical access to the zone of lysis,89 which can be easily fulfilled using transparent materials, such as glass and PDMS, for device construction. However, when applied on non-adherent cells, the cell may be displaced by flow induced by the bubble, instead of being lysed.90 Undesired cell movements can be eliminated by fixing the cell location with cell traps or tweezers. Lysis by cavitation is suitable for a diverse range of downstream operations since photodegradative effects are kept minimal.91 Though the presence of persistent bubbles may disrupt fluid flow, it can be readily remedied by applying gas-impermeable coating to channel walls and degassing buffers before use. The process typically takes place in milliseconds and lysate dilution is, thus, minimized. During the process, intracellular contents of the cell targeted would be temporarily carried away by flow induced by bubble expansion and relocalized afterward,90 such that the involvement of bubble cavitation would not exacerbate lysate dilution, making it an attraction option toward sensitive detection of low copy species. Selectivity in this approach can be achieved by modulating the size and site of the cavitation bubble such that only the desired portion of membrane is disrupted as a direct contact with bubbles is important for efficient lysis.92,93 Laser-mediated lysis is especially suitable when fluorescence readout is desired. By coupling the lysis laser to lasers for optical tweezer and fluorescence, it is possible to position and lyse cells, and detect signals with the least hardware possible.

FIG. 7.

Schematic of optical lysis by bubble cavitation. Laser irradiation produces a cavitation bubble in the medium near the target cell. As the bubble expands and comes into contact with the cell, the cell is disrupted. Microstreaming induced by oscillations in bubble size introduces shear stress to the cell, which enhances lysis performance.

Sorting and lysis technique considerations

Even as there are many options for cell lysis available, additional considerations need to be taken when integrating these approaches with cell sorting and enrichment. Interference, both physical and chemical, could hamper the performance of the integrated workflow, because enzymatic reaction and reagent composition are essential for the analysis. Hence, it is important for the previous steps of cell processing to provide an inert reaction environment to avoid an unwanted chemical reaction that could affect the processing of biomolecules. On the other hand, good and stable encapsulation is also necessary to prevent exchange of biomolecules between two different cells such that the biological information from cell encapsulation to processing remains the same.

PROMISES AND CHALLENGES OF FULLY INTEGRATED MICROFLUIDICS FOR SINGLE-CELL ANALYSIS

So far, techniques and methods for each procedure in single-cell assays have not been truly optimized to transit seamlessly into the next step for the purpose of integration. Device designs for cell sorting focus on separating cells only, while current single-cell assays assume cell input is in single-cell suspensions. From the perspective of integration, a microfluidic device that can perform cell isolation, lysis, material processing, and produce final readout is the ultimate goal, with optional cell enrichment or sorting. Here, we discuss some potential combinations of microfluidic workflows that could be integrated into a one-chip solution for single-cell analysis.

An optimal approach yields productive experiments and results, and it is obvious that some microfluidic approaches are more compatible with other previous single-cell steps. Droplet- or microwell-based microfluidic devices could help process large number of cells in an instance, making it optimal when the sorting step could enrich a large number of single cells. Microwell, on the other hand, can be used without additional peripherals. Still, these high-throughput methods require additional barcoding as to identify each cell and its contents after processing and at readouts, which adds another layer of complexity when integrating multiple steps altogether. The valve-based approach is best used when quality is favored over quantity—which can be used when visualization and precise manipulation of cells are desired, without the use of high-throughput sorting method. The use of microposts is specifically seen in genomic analysis and could be possibly combined with valve designs to allow more specific control of cell movement, whether for reducing amplification bias, or to capture rare cell populations.

Achieving high throughput in integrative microfluidics

For many applications, the goal is to profile as many cells as possible, and a high-throughput workflow is preferred. Single-cell transcriptomic analysis studies the global mRNA profile of individual cells of the population. One highlight of this assay is that it could potentially discover rare subpopulations that have a different expression profile than the other cells. When a larger number of cells is processed, it would statistically increase the chance of profiling these rare populations. Hence, it is reasonable to apply a high-throughput cell sorting approach into transcriptomic assay to increase the possibility of capturing cells that would either be masked or missed by conventional bulk or single-cell sequencing techniques. If desired, genomic analysis could also benefit from high-throughput cell sorting and enrichment followed by parallelized WGA to identify the genome of the samples which would be amplified to saturation.11 Cell viability is another important factor to capture the true expression profile of single cells. If a known cell surface protein is available in the cell-of-interest, it can be utilized as a surface marker for further enrichment with an actuator for active sorting. Yet, the use of a detector and actuator makes the device dependent on peripherals, putting constraints on the microfluidic design. It is also worth noting that the operation of steps after cell sorting and enrichment might also be subjected to the availability of peripherals, which could be an operational burden to users.

A large number of sorted cells would then be isolated into single-cell encapsulations. Based on currently demonstrated approaches, droplet and microwell techniques are suitable candidates to accommodate such input. Both being able to minimize contamination across compartments, water-in-oil droplet could be generated quickly and scaled to match the number of cells for individual capture, whereas the simplicity of microwell arrays could trap cells into each compartment by gravity pull. Valves microfluidics, however, would require either the number of reaction chambers to be adequate to accommodate all single cells, which would give rise to a large device footprint, or serial performance of downstream reactions, which would dramatically lengthen the workflow time.

Lysing cells without damaging the biomolecules would be the very next step after isolation. Among the lysis methods reviewed here, chemical lysis is the most popular due to its simplicity. Reports that utilize droplet and microwell for single-cell analysis applied chemical lysis by mixing lysis detergents with reverse transcription enzyme in droplets or flushing wells with detergents.12,13,30,35,40 While other lysis methods are effective, not all of them are appropriate for transcriptomic analysis. In particular, thermal lysis may interfere with enzymatic function when the temperature is too high. Mechanical, optical, and electrical lysis require specific designs to function, again posing challenging constraints to the device design. Right after cells are lysed, sequencing libraries could be constructed with cell materials as templates.

Integrated microfluidic systems with high precision

In a scenario where high throughput is not absolutely necessary, but the quality of genomic amplification is desired, which could be attained by unbiased genome amplification using microposts,39 the combination of workflows would be very different. After manipulating sorted cells into individual chambers, different lysis methods could be applied. In contrast to transcriptomic analysis which necessitates great speed, for genomic studies, chemical lysis might not be the only option available. Thermal lysis, for instance, becomes a viable approach if DNA is entangled and linearized on microposts, given that reagents can be flushed into the chamber after lysis completes, without denaturing enzymes for amplification. Other lysis options such as mechanical, optical, and electrical lysis are also available when combined with precise cell and reagent flow control offered by valve microfluidics. Once MDA is finished, amplified products from the individual single cell can be harvested with valve controls. Similar approaches can also be found for single-cell qPCR in microfluidics.25,26

Assessing compatibility of microfluidic modules in the view of single-cell analysis

As such, the compatibility of different methods can be classified by their throughput. Generally, in cell sorting and enrichment (Table I), most microfluidic approaches are designed for high-throughput cell sorting, though the number of cells sorted could be adjusted based on demand. When high throughput is favored, however, active sorting methods could be more beneficial as these designs make use of detector and actuator that could minimize cell doublets or debris when sorting. Enrichment can also be carried out if cell labeling is available. Even if cell surface markers are not in use, a live/dead cell stain could improve downstream workflow by eliminating poor quality cells.

TABLE I.

Compatibility level of the cell sorting method in high/low throughput. AP: acoustophoresis; ++/+/−: Highly compatible/compatible/not compatible.

| Throughput | AP | DEP | MEMS |

|---|---|---|---|

| High | ++ | ++ | ++ |

| Low | + | + | + |

The approach selected for isolating cells can be very different depending on the desired throughput (Table II). The most efficient way to isolate cells from high-throughput sorting is either by droplet emulsions or microwells, as the former could be rapidly generated when encapsulating cells, while the latter are compact arrays of wells with confined space, in which both are very easy to scale up to suit the number of cells sorted prior to isolation. In the context of system integration, droplet microfluidics can be deemed a direct beneficiary due to the bypass of repeated injections into separate chips that predispose droplets to undesired coalescence.16 Valve-based isolation, however, is not a good choice for large numbers of cells due to being constructed in a more complex device structure. In this case, not only is the total number of chambers per device constrained by physical size limits, but also the increased fabrication complexity introduces additional difficulties in scalability. On the flip side, valve devices are well-suited for applications involving lower cell number, given that each cell can be assessed and managed independently through valve control, whereas droplet and microwell offer no degree of control over individual cells. The valve approach also opens up a variety of lysis methods, while droplet and microwell might be limited based on their design.

TABLE II.

Compatibility level of the isolation method in high/low throughput. ++/+/−: Highly compatible/compatible/not compatible.

| Throughput | Droplet | Valve | Microwell |

|---|---|---|---|

| High | ++ | − | ++ |

| Low | + | ++ | + |

The choice of cell lysis method heavily depends on the cell isolation approach (Table III). Cell lysis methods for high-throughput approaches like droplet microfluidics and microwells are limited due to their respective mechanisms. In particular, thermal lysis and mechanical lysis are incompatible to droplet and microwell isolation methods; thermal lysis interferes with the enzymatic reaction by denaturing proteins, while the use of external force in mechanical lysis might break the droplet that encapsulates cell. The use of electrical field to break cell membrane could be applicable to cells isolated by microwell, but not for droplet due to ineffectiveness of electric field to lyse cells in droplets. Methods for cell lysis are more compatible in a valve-based approach, giving it more options for lysis. Unlike droplets and microwells, cells are enclosed in chambers, in which fluid flow can be manipulated, meaning that designs for mechanical lysis are applicable to cells. Thermal lysis becomes a viable option too due to possible segregation of enzymes and reagents before lysis. Electrical lysis is also effective when the cells are static in their own chambers. Both chemical and optical lysis are compatible with all isolation methods. Many microfluidic designs have demonstrated the versatility of chemical lysis, as it requires only the incorporation of chemical reagents into fluidic flow or reagent mix, instead of extra microfluidic design to achieve, as well as compatible to many types of microfluidic designs herein discussed, such as droplets and valve microfluidics, and microwells.24,40 Although optical lysis requires additional apparatuses and components, it is the fastest lysis method compared to all. It is also more advantageous than chemical lysis since samples are not diluted by the addition of reagents for lysis.

TABLE III.

Compatibility level of the lysis method in high/low throughput. ++/+/−: Highly compatible/compatible/not compatible.

| Throughput | Chemical | Thermal | Mechanical | Electrical | Optical |

|---|---|---|---|---|---|

| High | ++ | − | − | + | ++ |

| Low | ++ | + | + | ++ | ++ |

OPPORTUNITIES FOR NEW APPROACHES

Besides providing a framework for common analysis workflow, integration could also open up new solutions for challenges previously difficult to tackle. For instance, the combination of valve and micropost microfluidics might allow single-cell multi-omic analysis by amplifying entangled DNA for genomic analysis while reverse transcribing RNA or collecting proteins in lysate for genomic, transcriptomic, and proteomic analysis. This could be achieved when the device is capable of directing reagents and amplified products for different analyses to designated outlets and coupled with micropost for keeping DNA in one separated chamber. Another possible combination would be droplet sorting after cell lysis. Transcript-specific reporters could be utilized after cell lysis to report droplets that contain the cell-of-interest, leveraging transcripts as markers for sorting, aside from the conventional cell surface markers. This approach could reduce sequencing cost spent on cells that are not targeted, as well as reagent usage for droplets that contain no cells.

CONCLUSION AND FUTURE REMARKS

Today, genomes, transcriptomes, and epigenomes can all be profiled at the single-cell level, reflecting the versatility of single-cell analysis for answering biological questions at unprecedented resolution. As the number of cells being profiled per study increases, throughput and cost become major concerns, and conventional experimental workflows for single-cell analysis are not able to rise to the challenge. Traditional single-cell workflows suffer from low throughput with a disproportionate reaction volume such that cost per cell becomes considerably high. Moreover, lengthy and laborious manipulation results in an increased risk of contamination, degradation, and chemical crosstalk between samples. Owing to its compact and enclosed form factor, coupled with design flexibility, microfluidic technologies have brought dramatic improvement to the single-cell analysis workflow. It reduces reagent consumption and minimizes contamination risk while enabling extremely high throughput. Microfluidic designs and methods that address different stages of single-cell applications and studies range from devices for cell sorting, lysis, isolation, to those for processing and readouts. Each device has its unique strengths and advantages, yet, most of them encompass only one or two stages. Incompatibility between experimental methods and biochemistries of different stages remains an unresolved issue in realizing full integration of single-cell workflows into a single device. We remain optimistic, however, that the active development in the microfluidics field will not only make great strides in workflow integration, but also promises of more compact and versatile labs-on-chips with untapped research and clinical potential.

AUTHORS’ CONTRIBUTIONS

C.W.F. and S.N.C. contributed equally to this work.

ACKNOWLEDGMENTS

We thank all the members of the Wu Research Group for their ongoing support during this work, in particular Ms. Ying Xu and Dr. Liane Slaughter for their administrative assistance and Ms. Sin Yen Tan for her suggestion in figure preparation. This work was funded by HKUST's start-up and initiation grants (Hong Kong University Grants Committee) and the Hong Kong Research Grants Council Theme-based Research Scheme (No. RGC TBRS T12-704/16R-2), as well as the HKUST VPRGO matching support (No. VPRGO17SC02). The corresponding author is also supported by the Hong Kong RGC Early Career Support Scheme (No. RGC ECS 26101016), the Hong Kong RGC General Research Fund (No. RGC GRF 16101118) and Collaborative Research Fund (Nos. RGC CRF C4001-18G and C6002-17G), the Hong Kong Epigenomics Project (No. LKCCFL18SC01-E), and the HKUST BDBI Labs.

REFERENCES

- 1.Zong C., Lu S., Chapman A. R., and Xie X. S., Science 338, 1622 (2012). 10.1126/science.1229164 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Chen C., Xing D., Tan L., Li H., Zhou G., Huang L., and Xie X. S., Science 356, 189 (2017). 10.1126/science.aak9787 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Tang F., Barbacioru C., Wang Y., Nordman E., Lee C., Xu N., Wang X., Bodeau J., Tuch B. B., Siddiqui A., Lao K., and Surani M. A., Nat. Methods 6, 377 (2009). 10.1038/nmeth.1315 [DOI] [PubMed] [Google Scholar]

- 4.Hashimshony T., Wagner F., Sher N., and Yanai I., Cell Rep. 2, 666 (2012). 10.1016/j.celrep.2012.08.003 [DOI] [PubMed] [Google Scholar]

- 5.Hashimshony T., Senderovich N., Avital G., Klochendler A., de Leeuw Y., Anavy L., Gennert D., Li S., Livak K. J., Rozenblatt-Rosen O., Dor Y., Regev A., and Yanai I., Genome Biol. 17, 77 (2016). 10.1186/s13059-016-0938-8 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Picelli S., Faridani O. R., Björklund ÅK, Winberg G., Sagasser S., Sandberg R., Björklund A. K., Winberg G., Sagasser S., and Sandberg R., Nat. Protoc. 9, 171 (2014). 10.1038/nprot.2014.006 [DOI] [PubMed] [Google Scholar]

- 7.Picelli S., Björklund ÅK, Faridani O. R., Sagasser S., Winberg G., and Sandberg R., Nat. Methods 10, 1096 (2013). 10.1038/nmeth.2639 [DOI] [PubMed] [Google Scholar]

- 8.Guo M. T., Rotem A., Heyman J. A., and Weitz D. A., Lab Chip 12, 2146 (2012). 10.1039/c2lc21147e [DOI] [PubMed] [Google Scholar]

- 9.Shembekar N., Chaipan C., Utharala R., and Merten C. A., Lab Chip 16, 1314 (2016). 10.1039/C6LC00249H [DOI] [PubMed] [Google Scholar]

- 10.Lan F., Demaree B., Ahmed N., and Abate A. R., Nat. Biotechnol. 35, 640 (2017). 10.1038/nbt.3880 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Hosokawa M., Nishikawa Y., Kogawa M., and Takeyama H., Sci. Rep. 7, 5199 (2017). 10.1038/s41598-017-05436-4 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Klein A. M., Mazutis L., Akartuna I., Tallapragada N., Veres A., Li V., Peshkin L., Weitz D. A., and Kirschner M. W., Cell 161, 1187 (2015). 10.1016/j.cell.2015.04.044 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Macosko E. Z., Basu A., Satija R., Nemesh J., Shekhar K., Goldman M., Tirosh I., Bialas A. R., Kamitaki N., Martersteck E. M., Trombetta J. J., Weitz D. A., Sanes J. R., Shalek A. K., Regev A., and McCarroll S. A., Cell 161, 1202 (2015). 10.1016/j.cell.2015.05.002 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Rotem A., Ram O., Shoresh N., Sperling R. A., Goren A., Weitz D. A., and Bernstein B. E., Nat. Biotechnol. 33, 1165 (2015). 10.1038/nbt.3383 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Shahi P., Kim S. C., Haliburton J. R., Gartner Z. J., and Abate A. R., Sci. Rep. 7, 44447 (2017). 10.1038/srep44447 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Kim S. C., Clark I. C., Shahi P., and Abate A. R., Anal. Chem. 90, 1273 (2018). 10.1021/acs.analchem.7b04050 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Mary P., Dauphinot L., Bois N., Potier M.-C., Studer V., and Tabeling P., Biomicrofluidics 5, 024109 (2011). 10.1063/1.3596394 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Whitesides G. M., Nature 442, 368 (2006). 10.1038/nature05058 [DOI] [PubMed] [Google Scholar]

- 19.Fan H. C., Wang J., Potanina A., and Quake S. R., Nat. Biotechnol. 29, 51 (2011). 10.1038/nbt.1739 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Wang J., Fan H. C. C., Behr B., and Quake S. R. R., Cell 150, 402 (2012). 10.1016/j.cell.2012.06.030 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Yu Z., Lu S., and Huang Y., Anal. Chem. 86, 9386 (2014). 10.1021/ac5032176 [DOI] [PubMed] [Google Scholar]

- 22.Li R., Jia F., Zhang W., Shi F., Fang Z., Zhao H., Hu Z., and Wei Z., Lab Chip 19, 3168 (2019). 10.1039/C9LC00473D [DOI] [PubMed] [Google Scholar]

- 23.Marcus J. S., Anderson W. F., and Quake S. R., Anal. Chem. 78, 3084 (2006). 10.1021/ac0519460 [DOI] [PubMed] [Google Scholar]

- 24.Streets A. M., Zhang X., Cao C., Pang Y., Wu X., Xiong L., Yang L., Fu Y., Zhao L., Tang F., and Huang Y., Proc. Natl. Acad. Sci. U.S.A. 111, 7048 (2014). 10.1073/pnas.1402030111 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.White A. K., VanInsberghe M., Petriv O. I., Hamidi M., Sikorski D., Marra M. A., Piret J., Aparicio S., and Hansen C. L., Proc. Natl. Acad. Sci. U.S.A. 108, 13999 (2011). 10.1073/pnas.1019446108 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.VanInsberghe M., Zahn H., White A. K., Petriv O. I., and Hansen C. L., PLoS One 13, e0191601 (2018). 10.1371/journal.pone.0191601 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Shi Q., Qin L., Wei W., Geng F., Fan R., Shik Shin Y., Guo D., Hood L., Mischel P. S., and Heath J. R., Proc. Natl. Acad. Sci. U.S.A. 109, 419 (2012). 10.1073/pnas.1110865109 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Deng Y., Zhang Y., Sun S., Wang Z., Wang M., Yu B., Czajkowsky D. M., Liu B., Li Y., Wei W., and Shi Q., Sci. Rep. 4, 7499 (2015). 10.1038/srep07499 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Gong Y., Ogunniyi A. O., and Love J. C., Lab Chip 10, 2334 (2010). 10.1039/c004847j [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Gierahn T. M., Wadsworth M. H., Hughes T. K., Bryson B. D., Butler A., Satija R., Fortune S., Love J. C., and Shalek A. K., Nat. Methods 14, 395 (2017). 10.1038/nmeth.4179 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Yang L., Wang Z., Deng Y., Li Y., Wei W., and Shi Q., Anal. Chem. 88, 11077 (2016). 10.1021/acs.analchem.6b03086 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Lindström S. and Andersson-Svahn H., Biochim. Biophys. Acta 1810, 308 (2011). 10.1016/j.bbagen.2010.04.009 [DOI] [PubMed] [Google Scholar]

- 33.Bose S., Wan Z., Carr A., Rizvi A. H., Vieira G., Pe’er D., and Sims P. A., Genome Biol. 16, 120 (2015). 10.1186/s13059-015-0684-3 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Gole J., Gore A., Richards A., Chiu Y.-J., Fung H.-L., Bushman D., Chiang H.-I., Chun J., Lo Y.-H., and Zhang K., Nat. Biotechnol. 31, 1126 (2013). 10.1038/nbt.2720 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Fan H. C., Fu G. K., and Fodor S. P. A. A., Science 347, 1258367 (2015). 10.1126/science.1258367 [DOI] [PubMed] [Google Scholar]

- 36.Yuan J. and Sims P. A., Sci. Rep. 6, 33883 (2016). 10.1038/srep33883 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Hochgerner H., Lönnerberg P., Hodge R., Mikes J., Heskol A., Hubschle H., Lin P., Picelli S., La Manno G., Ratz M., Dunne J., Husain S., Lein E., Srinivasan M., Zeisel A., and Linnarsson S., Sci. Rep. 7, 16327 (2017). 10.1038/s41598-017-16546-4 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Svensson V., Natarajan K. N., Ly L.-H., Miragaia R. J., Labalette C., Macaulay I. C., Cvejic A., and Teichmann S. A., Nat. Methods 14, 381 (2017). 10.1038/nmeth.4220 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Tian H. C., Benitez J. J., and Craighead H. G., PLoS One 13, e0191520 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Han X., Wang R., Zhou Y., Fei L., Sun H., Lai S., Saadatpour A., Zhou Z., Chen H., Ye F., Huang D., Xu Y., Huang W., Jiang M., Jiang X., Mao J., Chen Y., Lu C., Xie J., Fang Q., Wang Y., Yue R., Li T., Huang H., Orkin S. H., Yuan G.-C., Chen M., and Guo G., Cell 172, 1091 (2018). 10.1016/j.cell.2018.02.001 [DOI] [PubMed] [Google Scholar]

- 41.Brouzes E., Medkova M., Savenelli N., Marran D., Twardowski M., Hutchison J. B., Rothberg J. M., Link D. R., Perrimon N., and Samuels M. L., Proc. Natl. Acad. Sci. U.S.A. 106, 14195 (2009). 10.1073/pnas.0903542106 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Cui N., Zhang H., Schneider N., Tao Y., Asahara H., Sun Z., Cai Y., Koehler S. A., De Greef T. F. A., Abbaspourrad A., Weitz D. A., and Chong S., Sci. Rep. 6, 22575 (2016). 10.1038/srep22575 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Wink K., Mahler L., Beulig J. R., Piendl S. K., Roth M., and Belder D., Anal. Bioanal. Chem. 410, 7679 (2018). 10.1007/s00216-018-1383-1 [DOI] [PubMed] [Google Scholar]

- 44.White J. A. and Streets A. M., HardwareX 3, 135 (2018). 10.1016/j.ohx.2017.10.002 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Branton D., Deamer D. W., Marziali A., Bayley H., Benner S. A., Butler T., Di Ventra M., Garaj S., Hibbs A., Huang X., Jovanovich S. B., Krstic P. S., Lindsay S., Ling X. S., Mastrangelo C. H., Meller A., Oliver J. S., Pershin Y. V., Ramsey J. M., Riehn R., Soni G. V., Tabard-Cossa V., Wanunu M., Wiggin M., and Schloss J. A., Nat. Biotechnol. 26, 1146 (2008). 10.1038/nbt.1495 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Deamer D., Akeson M., and Branton D., Nat. Biotechnol. 34, 518 (2016). 10.1038/nbt.3423 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Rofeh J., Schankweiler S., Morton D., Mortezaei S., Qiang L., Gundlach J., Fisher J., and Theogarajan L., Appl. Phys. Lett. 114, 213701 (2019). 10.1063/1.5094548 [DOI] [Google Scholar]

- 48.Binek A., Rojo D., Godzien J., Rupérez F. J., Nuñez V., Jorge I., Ricote M., Vázquez J., and Barbas C., J. Proteome Res. 18, 169 (2019). 10.1021/acs.jproteome.8b00472 [DOI] [PubMed] [Google Scholar]

- 49.Roci I., Gallart-Ayala H., Schmidt A., Watrous J., Jain M., Wheelock C. E., and Nilsson R., Anal. Chem. 88, 2707 (2016). 10.1021/acs.analchem.5b04071 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Llufrio E. M., Wang L., Naser F. J., and Patti G. J., Redox Biol. 16, 381 (2018). 10.1016/j.redox.2018.03.004 [DOI] [PMC free article] [PubMed] [Google Scholar]