Summary

This paper presents results of large-scale experiments with varying levels of fire severity on lateral force-resisting systems commonly used in cold-formed steel framed buildings. Gypsum-sheet steel composite panel sheathed walls, oriented strand board sheathed walls, and steel strap-braced walls are examined. Postflashover fire conditions of two different intensities as well as 1 hour of fire exposure similar to that in a standard furnace qualification test are studied. Additionally, a full-scale furnished kitchen fire experiment is conducted for comparison. The results highlight differences in the thermal response and subsequent performance of the walls as well as differing sensitives of the walls to pre-damage, eg, that might occur during an earthquake. The results are part of a larger effort to provide fragilities for these wall systems in response to realistic fires for performance-based design.

Keywords: cold-formed steel, fire, fire following earthquake, gypsum-sheet steel composite panel, oriented strand board, performance-based design, strap-braced walls

1 |. INTRODUCTION

Cold-formed steel (CFS) framing is widely used to construct nonstructural elements (eg, interior partitions and exterior cladding support) in buildings; however, it is also common to find CFS serving as structural elements in single and multi-storey construction.1 Together with timber-framed structures, lightweight framing systems comprise the majority of housing in the United States.2 CFS structural elements are made of relatively thin steel (0.455 to 2.997 mm thick)3 and typically rely on one or more layers of gypsum board for fire protection. As CFS is increasingly used in taller buildings, fire resistance plays an important role as the structure needs to withstand the fire for longer times, ensuring safe occupant egress and suppression activities.

Gypsum board, also referred to as wallboard, sheetrock, or drywall, is primarily composed of calcium silicate dihydrate,4,5 which undergoes a two-step calcination reaction releasing its free and chemically bound water when heated. The duration of the water release is critical for the fire protection provided by the gypsum board and depends strongly on the heating rate.6 The fire resistance of CFS structural assemblies, eg, walls including gypsum board, is commonly assessed using standardized fire resistance tests such as those in the American Society of Testing and Materials (ASTM) standard ASTM E1197 or the International Organization for Standardization (ISO) standard ISO 834–1.8 While standardized tests provide common ground to compare assembly performance, the relationship between results obtained from standard fires and realistic fire conditions is tenuous.9–11 Therefore, it is valuable to augment standard fire tests with tests using realistic fire exposures, particularly for use with performance-based design approaches.12

The work presented in this paper is part of a larger study conducted at the National Fire Research Laboratory (NFRL) at the National Institute of Standards and Technology (NIST) to characterize the influence of fire on the capacity of CFS lateral force resisting systems. Shear walls (walls with structural sheathing) and strap-braced walls are structural systems intended to resist lateral (horizontal) forces, such as the ones that occur due to wind and earthquakes. The first phase of the study investigated the performance of gypsum-sheet steel composite panel sheathed shear walls under a specific fire exposure.13,14 The results showed that the failure mode shifted from local to global buckling of the sheathing as a consequence of the fire exposure and highlighted the relevance of the gypsum boards on the performance of the walls.15 The second phase of the study extended the work to two additional types of CFS walls and various levels of fire severity.16 In the second phase, 22 wall specimens were subjected sequentially to various combinations of cyclic shear deformation and fire load. This paper focuses on the fire response of gypsum-sheet steel composite panel sheathed walls, oriented strand board (OSB) sheathed walls, and steel strap-braced walls; the structural response of the walls is reported separately.17 Most the experiments were conducted using natural gas-fuelled fires of varying severity. Two of the fire loads represented characteristics of actual fires of mild and severe intensity, and the third fire load approximated a standard fire test. A final experiment was performed on an OSB sheathed wall in which the fire load was provided by real kitchen furnishings.

2 |. WALL SPECIMENS

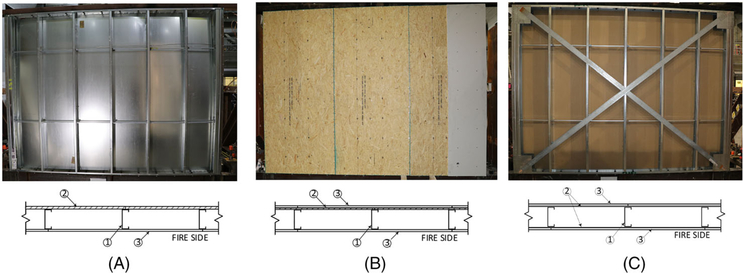

Figure 1 shows cross-sections and photographs of the test specimens. They are Type I shear walls* designed using allowable stress design (ASD) nominally following American Iron and Steel Institute (AISI) standards S100–1618 and S400–15/S1–16.19 All wall specimens were 2.7 m tall by 3.7 m long. The CFS studs and track were 152 mm wide and had material thickness of 1.37 mm or greater. The gypsum-sheet steel composite panels were a proprietary product that consisted of 0.686-mm thick sheet metal adhered to 16-mm thick Type X gypsum board. The OSB sheathing elements were 11 mm thick wood structural panels. All other gypsum boards were 16 mm thick Type X. The walls were designed to achieve a 1-hour fire-resistance rating per ASTM E119. On the fire-exposed side of the walls, the gypsum board joints were sealed using a base coat of drywall joint compound and paper tape, and the seams and fastener heads then covered with a skim coat of drywall joint compound. No joint compound or paper tape was used on the unexposed side of the wall. The measured moisture content of specimens from three randomly sampled gypsum boards was (18.9 ± 0.1) percent by mass. The structural design and detailing of the walls is provided in the NIST report Influence of Fire on the Lateral Resistance of Cold-Formed Steel Shear Walls–Phase 216; hereafter “NIST report.”

FIGURE 1.

Photographs of partially constructed test specimens and cross-sections: A, gypsum-steel sheet composite panel sheathed walls; B, OSB sheathed walls; C, steel strap-braced walls. (1, steel stud; 2, structural sheathing or diagonal bracing; 3, gypsum board) [Colour figure can be viewed at wileyonlinelibrary.com]

We limited this investigation to interior walls. Consequently, fire-resistance requirements for exterior walls and gravity-load bearing walls were not considered, nor were the effects of supplemental vertical (gravity) loads. Furthermore, the influence of insulation material in the wall cavity on the thermal and mechanical behavior of the walls was not examined.

3 |. FIRE SCENARIOS

Lateral force-resisting structural walls on the interiors of buildings are often placed along corridors, which provide long, straight runs. In multifamily residential buildings, a typical use for CFS framed structures, kitchens are often located adjacent to these corridors. The scenario of a postflashover kitchen fire in a room adjacent to a corridor was used as a prototype for these investigations.

The wall specimens were subjected to three fires referred to here as Severe Fire, Mild Fire, and Standard Fire. Additionally, one OSB sheathed wall was tested in a compartment fire with kitchen furnishing. The design fires are depicted in Figure 2 as target upper layer gas temperature versus time curves. The Severe Fire and Mild Fires were intended to encompass a range of postflashover fire conditions that could occur in modern residential kitchens. A combination of statistical data,20,21 empirical formulations, and engineering judgement was used to define these scenarios. The duration of the fire was estimated using typical North American kitchen fire load densities and dimensions20 with different opening factors. The target temperatures were based on statistical analysis of compartment fire data.21

FIGURE 2.

Target temperature-time curves for the natural gas-fuelled design fires [Colour figure can be viewed at wileyonlinelibrary.com]

Severe Fire is a postflashover fire of relatively long duration (35 minutes) and a peak upper layer gas temperature of 1100°C.

Mild Fire is a postflashover fire of relatively short duration (15 minutes) and a peak upper layer gas temperature of 900°C.

Standard Fire is a 1-hour temperature-time exposure similar to ASTM E119.

The Standard Fire does not fulfil all requirements in ASTM E119; however, the upper gas layer temperatures approximate those specified in the standard. Ventilation conditions, pressure, and oxygen content were different than those achieved in a standard furnace test. In terms of the radiative heat flux from the hot gas layer (ie, area under the σ · T4 curve, where σ is the Stefan-Boltzmann constant and T is the gas temperature in the compartment), the Severe Fire represents 2.2 times the demand compared with 1 hour of the Standard Fire. The Mild Fire represents 0.62 times lower demand than the Standard Fire. While oversimplified, this quantification of fire severity provides a useful indication of the relative fire severity that incorporates implicitly the compartment characteristics (eg, geometry, ventilation, and boundary heat transfer).

For kitchens in multifamily dwellings in Canada, Bwalya reported20 a mean floor area of (9.8 ± 3.6) m2 and an average fire load density (FLD) of (807 ± 123) MJ/mfloor,2 where the reported uncertainty is the standard deviation for 515 housing units. To obtain the time to burnout, Kawagoe’s formulation22 was used to estimate the heat release rate (HRR) of the fully developed fire (Equation 1). The room was assumed to have a ceiling height of 2.7 m and opening height of 2 m. The width of the opening varied to obtain an opening factor of 0.04 m1/2 or 0.08 m1/2. It was assumed that the fire was ventilation-controlled, had predominantly wood fuel, and that all the combustion took place in the compartment. To determine the time to burnout, the authors assumed that 20% of the fuel was consumed during the decay phase (Equation 2). A maximum of 1100°C upper layer gas temperature is the 95th percentile of the 146 fully developed compartment fire tests used in the Society of Fire Protection Engineers (SFPE) report titled Evaluation of Enclosure Temperature Empirical Models,21 and a maximum of 900°C is the 50th percentile. In Equations 1 and 2, Qflashover is the HRR (kW), A0 and H0 are the area (m2) and height (m) of the opening, and At is the total area (m2) of the compartment interior boundary surfaces.

| (1) |

| (2) |

The primary goal of the furnished kitchen compartment fire was to provide a comparison with the design fire scenarios. The compartment FLD and floor area were selected to match the mean values reported by Bwalya.20 An opening factor of 0.08 m1/2 was used to provide similar time to burnout as in the Mild Fire. Table 1 summarizes the compartment dimensions, fire loads, and time to burnout for the investigated fire scenarios.

TABLE 1.

Parameters for the design fires

| Fire | Floor Area (m2) | Fire Load Density (MJ/m2) | Opening Factor (m1/2) | Time to Burnout (Min) |

|---|---|---|---|---|

| Standard fire | - | - | - | - |

| Severe fire | 9.8 | 807 | 0.04 | 35 |

| Mild fire | 0.08 | 15 | ||

| Kitchen fire | 0.08 | 15 |

4 |. TEST PROGRAM

Table 2 provides an overview of all tests performed. The fire tests included tests to assess repeatability (designated with an “R”). The influence of earthquake pre-damage to the specimens was investigated for the OSB sheathed and steel strap-braced walls; the gypsum-sheet steel composite walls were studied previously.15 This paper presents results related to the fire performance of the walls. For information about other aspects of the wall performance as well as details about the measurement uncertainty, the reader is referred to the NIST report.16

TABLE 2.

Test matrix

| Loading |

||||

|---|---|---|---|---|

| Wall Type | Specimen Name | Cycling (Before Fire) | Fire | Cycling (After Fire) |

| Gypsum-sheet steel composite | SB01 | Cycle to failure | - | - |

| SB02 | - | Severe Fire | Cycle to failure | |

| SB03 | - | Mild Fire | Cycle to failure | |

| SB03R | - | Mild Fire | Cycle to failure | |

| SB04 | - | Standard Fire | Cycle to failure | |

| Oriented strand board | OSB01 | Cycle to failure | - | - |

| OSB01R | Cycle to failure | - | - | |

| OSB02 | - | Severe Fire | Cycle to failure | |

| OSB03 | - | Mild Fire | Cycle to failure | |

| OSB03R | - | Mild Fire | Cycle to failure | |

| OSB04 | - | Standard Fire | Cycle to failure | |

| OSB05 | Drift Level 2 | Mild Fire | Cycle to failure | |

| OSB06 | Drift Level 1 | Mild Fire | Cycle to failure | |

| Steel strap braced | S01 | Cycle to failure | - | - |

| S01R | Cycle to failure | - | - | |

| S02 | - | Severe Fire | Cycle to failure | |

| S03 | - | Mild Fire | Cycle to failure | |

| S04 | - | Standard Fire | Cycle to failure | |

| S05 | Drift Level 2 | Mild Fire | Cycle to failure | |

| S06 | Drift Level 1 | Mild Fire | Cycle to failure | |

| Additional | OSB01NG | Cycle to failure | - | - |

| OSB Kitchen | - | Real furnishings | - | |

Abbreviations: OSB, oriented strand board.

5 |. EXPERIMENTAL SETUP

5.1 |. Natural gas-fuelled fire compartment

During the Mild, Severe, and Standard fires, the thermal load was applied using a natural gas burner in a three-sided movable compartment adjacent to the test specimen (Figure 3). The interior dimensions were 3.2 m long × 1.2 m deep × 2.9 m high. The compartment had vents located at each side 1.7 m tall × 1.2 m wide. The compartment was lined with two layers of thermal ceramic blanket each 25mm thick. A window made of fused silica glass was place in the back wall of the compartment to allow observation of the test specimen and video recording.

FIGURE 3.

Compartment for natural gas-fuelled fires: A, photograph; B, cross-section [Colour figure can be viewed at wileyonlinelibrary.com]

The burner was 1.4 m long × 0.8 m wide. The gas entered near the bottom of the burner and percolated up through a 25-mm thick layer of thermal ceramic fiber blanket. A positive displacement rotatory flowmeter, pressure gauge, and thermistor were used to measure the mass flow rate of the gas to the burner. The composition of the gas was determined using in-line gas chromatography. The calculated HRR of the burner was rapidly increased to 1.7 MW for 15 minutes for the Mild Fire, 2.3 MW for 35 minutes for the Severe Fire, and increased more slowly up to 1.4 MW for the Standard Fire. The HRR levels for the burner were based on modeling of the test compartment using the The Consolidated Model of Fire and Smoke Transpor (CFAST) fire zone model.23 Additionally, shakedown tests were performed to verify the achieved upper layer gas temperatures. The HRR versus time curves remained unchanged throughout the test series regardless of the temperatures achieved in a specific experiment in order to keep the thermal loading similar between test specimens.

As shown in Figure 4, the natural gas fuelled compartment was instrumented as follows:

FIGURE 4.

Compartment sensors for gas fueled fires: A, looking east; B, looking north [Colour figure can be viewed at wileyonlinelibrary.com]

two thermocouple (TC) arrays each with five Inconel-sheathed Type K grounded junction TCs of 3.175 mm outside diameter. The measurement range was −200°C to 1250°C with an expanded uncertainty of ±2.8% of the reading. The top TC was placed 2.5 cm away from the ceiling, and the four remaining TCs were spaced 61 cm from each other. These TCs were not corrected for radiative heating and have a manufacturer-specified response time of about 12 seconds;

one additional Inconel-sheathed Type K grounded junction TC was placed 2.5 cm from the ceiling at the center of the compartment; and

nine plate TCs were placed 10 cm from the back wall of the compartment facing the test specimen. Each plate TC probe plate was 100 mm × 100 mm and was specified to operate up to 1200°C. A manufacturer-reported standard uncertainty was not available.

5.2 |. Kitchen furnishings fire compartment

For the kitchen furnishings fire, a three-sided compartment 3.6 m long × 2.8 m wide × 2.8 m high with a 1.6 m wide × 2.0 m high opening was constructed (Figure 5). The compartment was lined with two layers of 16 mm thick Type X gypsum board.

FIGURE 5.

Photograph of (A) exterior and (B) interior of the kitchen compartment [Colour figure can be viewed at wileyonlinelibrary.com]

The thermal load in the compartment was provided by typical kitchen furnishings, mostly untreated spruce, pine or fir and particle board. The design fire load was 807 MJ/m2floor based on values reported by Bwalya et al.20 The opening factor was selected to be 0.08 m1/2 to achieve the desired burn duration of 15 minutes. The fire load and opening factor correspond those used to develop the Mild Fire (Table 1). Figure 6A shows the distribution of the fuel within the compartment. The measured total mass of combustible material was (411 ± 0.1) kg. The estimated energy for each item was determined using calorific values from literature.24 The total estimated energy was 8100 MJ, thus the achieved FLD was 804 MJ/m2. The fire started by auto-ignition of 500 mL of corn oil in a 203-mm diameter cast iron pan left unattended on a stove. To ensure the spread of the fire to the cabinets, the doors on the cabinet above the stove were left ajar and a small wood crib and paper towels were placed in the cabinet (Figure 6B).

FIGURE 6.

(A) Model of the installed fuel (axes units in centimeters) and (B) ignition source and objects of first ignition [Colour figure can be viewed at wileyonlinelibrary.com]

The Kitchen Fire compartment instrumentation consisted of the following:

two Type K TCs welded to the inside bottom of the pan to measure the oil temperature;

twoTC arrays with five Inconel-sheathed Type K TCs each as in the natural gas-fuelled compartment. The TC arrays were placed equidistant between the cabinet edge and the centerline of the compartment;

five plate TCs: one 50.8 cm above the pan, two above the opening, and two in front of the test specimen 45.7 cm from bottom and top of the wall;

bare bead TCs placed through the cross section of the ceiling and on top of the vent behind the first and second layer of the gypsum board;

two bidirectional probes and co-located TCs placed in the compartment opening 65 cm from top and bottom;

gas sampling (O2, CO, CO2) performed in the upper gas layer at the center-top of the compartment;

a photoelectric smoke detector place on the ceiling 60 cm away from the opening; and

water-cooled video and 360° cameras placed in the opening.

5.3 |. Wall specimen instrumentation

Figure 7 shows the locations of the instrumentation in the wall specimens. All walls were instrumented with TCs through the cross-section at four locations, eight TCs on the unexposed side, and two TCs in the chord studs (an axial load-bearing stud located at the ends of shear wall segments or strap-braced walls). Most TCs were 24-gauge Type K bare bead. The TCs were attached to the surfaces by clamping them between materials or compressing against the material using a screw. Self-adhering TCs were used for unexposed side measurements. Velocity probes were placed at the knockout holes 91 cm from the bottom and 61 cm from the top of the chord studs, measuring the air flow into and out of the cavity. The pressure inside the cavity was measured 61 cm from the top of the wall.

FIGURE 7.

Instrumentation in the wall specimens [Colour figure can be viewed at wileyonlinelibrary.com]

6 |. RESULTS

6.1 |. Fire exposure

The average upper gas layer temperatures measured in all tests are plotted in Figure 8A as the average of the top threeTCs of the twoTC arrays. The Mild Fire showed the largest variation in gas temperatures; however, it had the largest number of test repeats: nine tests versus three for the Severe and Standard fires. The measured gas temperatures are close to the design values (compare Figure 8 with Figure 2) up to the decay phase. For the decay phase, in the experiments, the burners were shut off and the compartment cooled as dictated by the geometry and materials in the compartment. This led to faster cooling than in the design fires. Additionally, the Standard Fire had a slower heating rate at the beginning and slightly lower maximum temperatures than the ones in the design fire. Figure 8B plots the upper gas layer temperature for OSB sheathed wall tests with various fire loads. The Kitchen Fire had similar duration to the Mild Fire with a slightly higher peak temperature. In the Severe Fire, the increase in temperature after 20 minutes is caused by the burning of the OSB.

FIGURE 8.

(A) Temperature-time curves for the investigated fires plotted as the mean value (line) and one standard deviation (shaded area) for the standard, severe, and mild fires and (B) comparison of the upper layer gas temperatures for individual tests of the oriented strand board (OSB) sheathed walls [Colour figure can be viewed at wileyonlinelibrary.com]

Figure 9 plots incident heat fluxes obtained from the plateTC temperatures (TPT, in K) and adjacent gas temperatures (Tgas, in K) at each time step (i) using Equation 3.25

| (3) |

where is the incident heat flux in Watts, σ is the Stefan-Boltzmann constant (5.670E-8 W/m2/K4), h is the convective heat transfer coefficient assumed26 to be 10 W/m2/K, KPT is a heat transfer coefficient due to heat losses of the plateTC assumed25 as 8 W/m2/K, CPT is the lumped heat capacity of the plate TCs assumed25 as 4200 J/m2/K, t is time (s), and εPT is the emissivity of the plate assumed to be 0.9. The incident heat fluxes plotted indicate that the highest values are at the top of the compartment and at the center directly above the burner. The incident heat fluxes are higher for the Mild Fire and Severe Fire than for the Standard Fire and are closer to the peak values obtained in the Kitchen Fire (Figure 10). The Standard Fire exposes the specimens to a lower incident heat flux for a longer period than the more realistic fire scenarios.

FIGURE 9.

Heat flux (mean and standard deviation) in compartment for mild, standard, and severe fires [Colour figure can be viewed at wileyonlinelibrary.com]

FIGURE 10.

Measured heat flux to specimen for the kitchen fire [Colour figure can be viewed at wileyonlinelibrary.com]

6.2 |. Thermal response of the walls

The temperature measurements in the wall specimens include temperatures on the side of the wall opposite to the fire exposure (unexposed side), cross-section temperatures at an interior stud and halfway between studs, chord stud temperatures, and temperatures between the gusset plates and the straps in the strap-braced walls (Figure 7). A complete listing of the thermal measurements can be found in the NIST report.16

The temperatures relevant to the thermal behavior of the structural elements include chord stud temperatures, interior stud temperatures, sheathing panel temperatures (sheathed walls), and the temperatures between the gusset plates and straps (braced walls). The top interior stud temperature (TC_T_IS) was generally a good overall indicator of the thermal damage to the wall.

Figures 11–13 plot the cross-section temperatures 46 cm from the top of the wall at an interior stud for the Mild, Standard, and Severe fires. All figures show a plateau in temperatures occurring around 100°C. This plateau is due to the calcination reaction of the gypsum board as it releases its chemically free and bound water in a two-step endothermic reaction. This reaction is critical in providing fire protection for the wall. The length of the plateau depends on the incident heating; for fires with a faster heating rate, the plateau is shorter. The variation of the plateau length can be more easily seen in Figure 14, which compares just the interior stud temperatures. Although the interior studs experience lower peak temperatures during the Mild Fire than during the Standard Fire, the plateau is shorter due to the higher rate of heating and larger heat flux amplitudes.

FIGURE 11.

Temperatures through the specimen at an interior stud 46 cm from the top of gypsum-sheet steel composite panel sheathed walls: A, mild fire; B, standard fire; C, severe fire [Colour figure can be viewed at wileyonlinelibrary.com]

FIGURE 13.

Temperatures through the specimen at an interior stud 46 cm from the top of steel strap-braced walls: A, mild fire; B, standard fire; C, severe fire [Colour figure can be viewed at wileyonlinelibrary.com]

FIGURE 14.

Interior stud temperatures 46 cm from the top the walls: A, gypsum-sheet steel composite panel sheathed walls; B, OSB sheathed walls; C, strap-braced walls [Colour figure can be viewed at wileyonlinelibrary.com]

For the gypsum-sheet steel composite panel sheathed walls, a puddle of water formed at the bottom of the walls (Figure 15A) coincident with the two-step calcination reaction. The water that evaporated from the gypsum boards condensed on the steel sheet and ran to the ground. After the calcination reaction had completed, the temperatures increased rapidly through the cross-section. The insulation criteria in ASTM E119 limits the temperature raise on the unexposed side of the walls or partitions to 250°F (139°C) above its initial temperature. The unexposed side temperatures (eight TCs) remained less than 139°C above the initial wall temperature (Figure 16A) in all cases except for the Severe Fire, where the paper on the unexposed side of the wall started to burn and temperatures increased locally near the top of the wall. However, the presence of the sheet steel prevented flame spread to the unexposed side of the wall even during the most severe fire investigated.

FIGURE 15.

Photographs of unexposed side (Severe Fire): A, gypsum-sheet steel composite panel sheathed wall after the fire test; B, oriented strand board (OSB) sheathed wall 24 minutes and 59 seconds after ignition; C, strap-braced wall after the fire test [Colour figure can be viewed at wileyonlinelibrary.com]

FIGURE 16.

Temperatures (mean and standard deviation) on unexposed side: A, gypsum-sheet steel composite panel sheathed walls; B, oriented strand board (OSB) sheathed walls; C, strap-braced walls [Colour figure can be viewed at wileyonlinelibrary.com]

Similar behavior was observed for the OSB sheathed walls with regard to the length of the plateau and the rapid heating following the calcination reaction. However, once the exposed gypsum board was sufficiently damaged by the fire, the OSB inside the wall ignited and continued to burn until the fire was supressed or until all of the OSB was consumed. Burning of the OSB occurred during the Severe Fire and the Standard Fire. Figure 15B shows an image of the OSB burning during the Severe Fire. Figure 16B summarizes the temperatures on the unexposed side of the OSB walls. Although the unexposed side temperature generally remained less than 139°C above the initial wall temperature, the gypsum detached from the OSB and fell from the wall preventing higher temperatures from being measured.

For the strap walls, during the Mild Fire and Standards Fire, all temperatures on the unexposed side of the wall remained less than 139°C above the initial wall temperature (Figure 16C) in all cases except for the Severe Fire. During the Severe Fire, a hole opened on the unexposed side of the wall (Figure 15C) that affected the fire dynamics within the compartment. The heating during the Severe Fire caused severe oxidation of the strap braces toward the south end of the wall.

For all the walls, the Standard Fire and Severe Fire yielded temperatures in the structural elements (studs, chords, gussets, sheaths) capable of affecting the structural capacity of the walls. Even the Mild Fire affected the postfire load bearing capacities of the walls by reducing contributions from the gypsum board on the lateral load-bearing capacity. For further discussion of the influence of the fires on the load-bearing capacities of the walls, the reader is referred to the NIST report16 and related publication.17 Velocities and pressure profiles inside the cavity of the walls can be found in the NIST report.16

6.3 |. Influence of pre-damage to the walls

In select tests, the authors pre-damaged OSB sheathed and strap-braced walls† by subjecting them to reversed cyclic lateral deformation before the fire to study the influence on the thermal and postfire mechanical performance. The levels of pre-damage—defined by storey drift ratios (SDRs)—of approximately 0.5% and 1.5% correspond to the damage levels that might occur in a design earthquake (DE) and maximum considered earthquake (MCE), respectively. As mentioned above, the interior stud temperature near the top of the wall was generally a good indicator of the thermal damage through the wall. Hence, Figure 17A plots the top interior stud temperature of OSB sheathed walls that are undamaged, pre-damaged to 0.45% SDR, and pre-damaged to 1.5% SDR then exposed to the Mild Fire. Figure 17B provides similar plots‡ for the strap-braced walls. The results showed that the smaller drift level (Drift Level 1) did not affect the thermal response of the wall. However, for larger drift level (Drift Level 2), which tore the drywall joint compound and tape covering the joints of the gypsum boards, the temperatures achieved in the interior stud were notably higher. This increase of the temperature through the cross-section had limited effect on the strap-braced walls; however, for the OSB sheathed wall, the increase in temperature was sufficient to cause the OSB to ignite.

FIGURE 17.

Interior stud temperatures for pre-damaged and undamaged walls exposed to the Mild Fire: A, oriented strand board (OSB) sheathed walls; B, steel strap-braced walls [Colour figure can be viewed at wileyonlinelibrary.com]

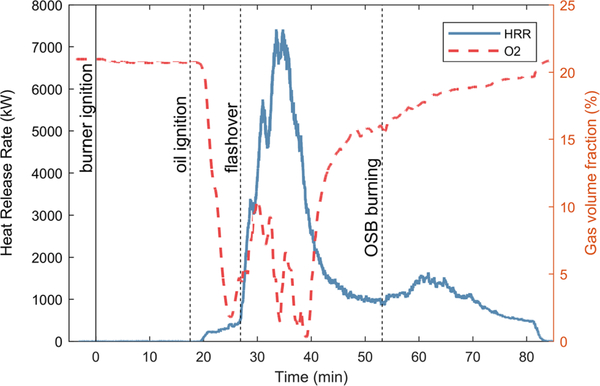

6.4 |. Furnished kitchen compartment fire

The furnished kitchen compartment fire provides a comparison with the natural gas-fuelled fires. The fire development is illustrated in Figure 18 by HRR measured in the exhaust hood.§ The fire was started by auto-ignition of the oil in pan on a gas stove 17 minutes and 31 seconds after the burner was turned on (Figure 19A). The fire spread to the cabinets above the stove in about 2 minutes (Figure 19B). Around 26 minutes, flashover of the compartment occurred (Figure 19C). Thirty-five minutes after burner ignition, there were indications of pyrolysis of the OSB inside the wall cavity (darker smoke emitted from holes in chord studs), but no flaming combustion of the OSB was observed. Most of the room furnishings were consumed by 40 minutes after burner ignition (Figure 19D), and the oxygen content started to raise in the compartment, reaching 15% 45 minutes after burner ignition. Flaming combustion of the OSB was clearly visible by 54 minutes after burner ignition (Figure 19E). A local peak in the HRR occurred between 60 minutes coincident with the flaming combustion of the OSB. The OSB continued to burn until it was consumed and the gypsum board on the unexposed side fell off. Remaining fire was suppressed using water 80 minutes after burner ignition when almost all the OSB had been consumed (Figure 19F).

FIGURE 18.

Heat release rate and compartment oxygen concentration during the kitchen fire [Colour figure can be viewed at wileyonlinelibrary.com]

FIGURE 19.

Photographs of growth and decay of kitchen fire: A, oil ignition; B, flame spread to cabinets; C, compartment flashover; D, furnishings consumed; E, burning of combustible sheathing; F, end of experiment [Colour figure can be viewed at wileyonlinelibrary.com]

Figure 18 also plots the oxygen concentration sampled at the center of the compartment 30 cm from the ceiling. Starting around 20 minutes, as the fire grew and flashover occurred, the oxygen content in the compartment rapidly decreased. Around 40 minutes after ignition of the burner, when most of the content in the compartment had burnt, the oxygen concentration increased. After returning to an oxygen concentration of approximately 15%, the OSB inside of the wall exhibited flaming combustion. The results highlight the importance of considering oxygen concentration when studying the fire performance of building elements that include combustible materials. The times until flaming combustion of the OSB was visible is summarized in Table 3. For the Kitchen Fire, the times are provided relative to the time when compartment flashover occurred, which is the most direct comparison for the Mild and Severe Fires, and relative to the oil ignition. Temperatures through the cross-section 46 cm from the top of the wall at an interior stud during the Kitchen Fire are shown in Figure 20.

TABLE 3.

Time until flaming combustion of OSB was visible

| Fire | Time (min) |

|---|---|

| Mild (from burner ignition) | No ignition |

| Severe (from burner ignition) | 19 |

| Standard (from burner ignition) | 42 |

| Kitchen (from flashover) | 26 |

| Kitchen (from oil ignition) | 35 |

Abbreviations: OSB, oriented strand board.

FIGURE 20.

Temperatures through the specimen at an interior stud 46 cm from the top of an oriented strand board (OSB) sheathed wall during the kitchen fire [Colour figure can be viewed at wileyonlinelibrary.com]

7 |. CONCLUSIONS

This paper presented results of experiments on CFS framed shear walls subjected to various levels of fire severity. The investigated wall types were (a) gypsum-sheet steel composite panel sheathed walls, (b) OSB sheathed walls, and (c) steel strap-braced walls. The investigation is limited to interior walls, without considering gravity loads and the effect of insulation materials in the cavity. The study was part of a larger project undertaken at NIST to characterize the impact of fire on the resistance of CFS lateral force-resisting systems. The investigated fires included one that followed a standard temperature-time curve such as that in ASTM E119 or ISO 834–1 (Standard Fire) and realistic scenarios that represented a range of temperatures and durations of typical kitchen compartment fires (Mild Fire and Severe Fire). An additional test was performed with a furnished kitchen (Kitchen Fire) for comparison and to better understand the interaction between the fire dynamics in the compartment and the wall response.

The results from this limited set of experiments showed that while the Severe Fire critically damaged the integrity of all the wall typologies, the impact of the Standard Fire on the different walls varied. The OSB sheathed wall was severely damaged by the Standard and Severe fires because in both cases, the OSB ignited after a certain time of exposure. Whereas the influence of the Standard Fire on the gypsum-sheet steel composite panel sheathed wall and steel strap-braced wall was less pronounced. During the Mild Fire, the thermal insulation criteria of a maximum temperature raise of 139°C on the unexposed side of the wall was fulfilled in all cases, as long as no pre-damage to the wall before the fire was present.

Comparison plots of the upper layer gas temperatures showed how a furnished compartment with dimensions and fuel loads representative of typical kitchens in North America provided similar temperatures to the investigated Mild Fire and Severe Fire. However, measured upper layer gas temperatures and calculated incident heat fluxes for the Standard Fire were notably lower. The incident heat fluxes in the furnished compartment fire peaked above 200 kW/m2, while the Standard Fire provided values below 100 kW/m2 at 1 hour. The results from this limited series of tests also highlight that a 1-hour rated wall assembly based on a standard furnace test may or may not be able to withstand the realistic fire exposure used in this test series. While this does not imply that the construction is unsafe, it reinforces the need to evaluate the adequacy of the fire performance using anticipated fire loads and safety objectives.

Pre-damaging of the walls using various intensities of simulated earthquakes showed how a small level of pre-damage (approximately 0.5% SDR) had little influence on the performance of the walls for this limited series of experiments. However, a larger level of pre-damage (approximately 1.5% SDR), which damaged the fire protection of the joints, accelerated ignition of the OSB sheathed walls during fire testing.

The presented results are step toward developing fragility curves (representations of the probability of exceeding a given damage state as a function of an engineering demand parameter) for these systems and is essential for performance-based design for fire. Further work needs to be done to relate standard fire test to realistic fire conditions.

FIGURE 12.

Temperatures through the specimen at an interior stud 46 cm from the top of oriented strand board (OSB) sheathed walls: A, mild fire; B, standard fire; C, severe fire [Colour figure can be viewed at wileyonlinelibrary.com]

ACKNOWLEDGEMENTS

This work was funded by the National Institute of Standards and Technology (NIST). We thank Carleton Elliott (Sure-Board), Fernando Sesma (CEMCO), Jim DesLaurier (Marino/WARE), Brian Mucha (Panel Systems, Inc.), Larry Williams (SFIA), Benjamin Schafer (Johns Hopkins University), and Rob Madsen (Devco Engineering) for their expert consultation. We also thank the NIST Fire Research Division staff including Brian Story, Laurean DeLauter, Anthony Chakalis, Philipp Deardorff, Michael Selepak, Marco Fernandez, William Grosshandler, and Artur Chernovsky whose efforts and expertise made these experiments possible.

Funding information

National Institute of Standards and Technology (NIST)

Footnotes

Walls with no openings that have anchorage at each end of the wall.

The influence pf pre-damage on the behavior gypsum-sheet steel composite panel sheathed walls was investigated previously by Hoehler.15

Slightly larger pre-damage drift ratios were used for the strap braced walls due to differences in the cyclic loading protocol arising from the differing load-displacement behavior of the wall types.

There is a time delay between the events in the compartment and the measured heat release rate (HRR) due to the time it takes for the combustion products to travel from the compartment to the exhaust hood where the HRR is measured. This delay is largest when the fire is small.

REFERENCES

- 1.Madsen RL, Castle TA, Schafer BW. Seismic Design of Cold-Formed Steel Lateral Load-Resisting Systems: A Guide for Practicing Engineers. Gaithersburg, MD: NEHRP Seismic Design; Technical Brief No.12; 2016. 10.6028/NIST.GCR.16-917-38 [DOI] [Google Scholar]

- 2.Steel Framing Industry Association. Market Share and Comparative Report: Cold-Formed Steel Framing and Project Specification Trends. VA: Falls Church; 2016. [Google Scholar]

- 3.American Iron and Steel Institute (AISI). AISI S201–12 North American Standard for Cold-Formed Steel Framing—Product Data. Vol 07; 2012. [Google Scholar]

- 4.Rahmanian I Thermal and Mechanical Properties of Gypsum Boards and their Influences on Fire Resistance of Gypsum Board Based Systems. 2011. PhD Thesis, School of Aerospace, Mechanical and Civil Engineering, University of Manchester, UK. [Google Scholar]

- 5.Park S, Manzello S, Bentz DP, Mizukami T. Determining thermal properties of gypsum board at elevated temperatures. Fire Mater. 2009;n/a. 10.1002/fam.1017 [DOI] [Google Scholar]

- 6.Andres B, Livkiss K, Hidalgo JP, et al. Response of stone wool insulated building barriers under severe heating exposures. J Fire Sci. 2018;36(4): 315–341. 10.1177/0734904118783942 [DOI] [Google Scholar]

- 7.ASTM E119. Standard test methods for fire tests of building construction and materials. Am Soc Test Mater. 2016;18ce1:1–36. 10.1520/E0119-16A [DOI] [Google Scholar]

- 8.ISO 834–1 Fire Resistance Tests-Elements of Building Construction - Part 1: General Requirements. Vol 1999 Genève, Switzerland: International Organization for Standardization; 1999. [Google Scholar]

- 9.Craft S, Isgor B, Mehaffey J, Hadjisophocleous G. Modelling heat and mass transfer in wood-frame floor assemblies exposed to fire. Fire Saf Sci. 2008;9:1303–1314. 10.3801/IAFSS.FSS.9-1303 [DOI] [Google Scholar]

- 10.Ariyanayagam A, Mahendran M. Development of realistic design fire time-temperature curves for the testing of cold-formed steel wall systems. Front Struct Civ Eng. 2014;8(4):427–447. 10.1007/s11709-014-0279-1 [DOI] [Google Scholar]

- 11.Jones BH. Performance of Gypsum Plasterboard Assemblies Exposed to Real Building Fires; 2002.

- 12.ASCE/SEI 7–16. Minimum Design Loads and Associated Criteria for Buildings and Other Structures. Reston, VA: American Society of Civil Engineers; 2017. 10.1061/9780784414248 [DOI] [Google Scholar]

- 13.Hoehler MS, Smith CM. Influence of Fire on the Lateral Load Capacity of Steel-Sheathed Cold-Formed Steel Shear Walls - Report of Test (NISTIR 8160). Gaithersburg, MD; 2016. 10.6028/NIST.IR.8160 [DOI] [Google Scholar]

- 14.Hoehler MS, Smith CM. Dataset from Influence of Fire on the Lateral Resistance of Cold-Formed Steel Shear Walls - Phase 1. 10.18434/T4/1422515 [DOI]

- 15.Hoehler MS, Smith CM, Hutchinson TC, Wang X, Meacham BJ, Kamath P. Behavior of steel-sheathed shear walls subjected to seismic and fire loads. Fire Saf J. 2017;91:524–531. 10.1016/j.firesaf.2017.03.021 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Hoehler MS, Andres B, Bundy M. Influence of Fire on the Lateral Resistance of Cold-Formed Steel Shear Walls – Phase 2: Oriented Strand Board, Strap Braced, and Gypsum-Sheet Steel Composite (NIST Technical Note 2038). Gaithersburg, MD; 2019. 10.6028/NIST.TN.2038 [DOI] [Google Scholar]

- 17.Hoehler MS, Andres B, Bundy MF. Experiments on the Lateral Resistance Reduction to Cold-Formed Steel Framed Shear Walls under Various Fire Scenarios. J Struct Eng. [PMC free article] [PubMed] [Google Scholar]

- 18.American Iron and Steel Institute. AISI S100–16 North American Specification for the Design of Cold-Formed Steel Structural Members. Washington, DC: American Iron and Steel Institute (AISI); 2016. [Google Scholar]

- 19.American Iron and Steel Institute. AISI S400–15 w/S1–16, North American Standard for Seismic Design of Cold-Formed Steel Structural Systems (with Supplement 1). Washington, DC: American Iron and Steel Institute (AISI); 2016. [Google Scholar]

- 20.Bwalya AC, Lougheed GD, Kashef A, Saber HH. Survey Results of Combustible Contents and Floor Areas in Multi-Family Dwellings; 2008.

- 21.Hunt SP, Cutonilli J, Hurley M. Evaluation of Enclosure Temperature Empirical Models. Bethesda; 2010. [Google Scholar]

- 22.Kawagoe K Fire Behaviour in Rooms, Report 27. Tokio, Japan; 1958. [Google Scholar]

- 23.Peacock RD, McGrattan KB, Reneke PA, Forney GP. CFAST – Consolidated Model of Fire Growth and Smoke Transport (Version 7) Volume 1: Technical Reference Guide. Gaithersburg, MD; 2015. 10.6028/NIST.TN.1889v1 [DOI] [Google Scholar]

- 24.Society of Fire Protection Engineers. In: Hurley MJ, Gottuk D, Hall JR,et al. , eds. SFPE Handbook of Fire Protection Engineering. New York, NY: Springer New York; 2016. 10.1007/978-1-4939-2565-0 [DOI] [Google Scholar]

- 25.Häggkvist A, Sjöström J, Wickström U. Using plate thermometer measurements to calculate incident heat radiation. J Fire Sci. 2013;31 (2):166–177. 10.1177/0734904112459264 [DOI] [Google Scholar]

- 26.Inganson H, Wickström U. Measuring incident radiant heat flux using the plate thermometer. Fire Saf J. 2007;42(2):161–166. [Google Scholar]