Abstract

Unlike other tissue types, the nervous tissue extends to a wide and complex environment that provides a plurality of different biochemical and topological stimuli, which in turn defines the advanced functions of that tissue. As a consequence of such complexity, the traditional transplantation therapeutic methods are quite ineffective; therefore, the restoration of peripheral and central nervous system injuries has been a continuous scientific challenge. Tissue engineering and regenerative medicine in the nervous system have provided new alternative medical approaches. These methods use external biomaterial supports, known as scaffolds, to create platforms for the cells to migrate to the injury site and repair the tissue. The challenge in neural tissue engineering (NTE) remains the fabrication of scaffolds with precisely controlled, tunable topography, biochemical cues, and surface energy, capable of directing and controlling the function of neuronal cells toward the recovery from neurological disorders and injuries. At the same time, it has been shown that NTE provides the potential to model neurological diseases in vitro, mainly via lab-on-a-chip systems, especially in cases for which it is difficult to obtain suitable animal models. As a consequence of the intense research activity in the field, a variety of synthetic approaches and 3D fabrication methods have been developed for the fabrication of NTE scaffolds, including soft lithography and self-assembly, as well as subtractive (top-down) and additive (bottom-up) manufacturing. This article aims at reviewing the existing research effort in the rapidly growing field related to the development of biomaterial scaffolds and lab-on-a-chip systems for NTE applications. Besides presenting recent advances achieved by NTE strategies, this work also delineates existing limitations and highlights emerging possibilities and future prospects in this field.

Keywords: Amniotic membrane, Biofabrication, Neural tissue engineering, Lab-on-a-chip, Central nervous system, Peripheral nervous system, Neural regeneration, Scaffolds

1. Introduction

The nervous tissue consists of the central nervous system (CNS) and the peripheral nervous system (PNS) and is the most complex system in the body. Injuries to the human nervous system affect more than 1 billion people around the world, with 6.8 million dying as a result of them each year [1], and have been associated with a wide variety of disorders including neurodegenerative diseases, as well as brain and spinal cord (SC) traumatic injuries and stroke [2]. The central nervous tissue does not regenerate under normal conditions, and to date, there is no treatment modality with clinically documented efficacy to actively improve CNS repair. Current medical approaches focus primarily on stabilization and prevention, e.g., orthopedic fixation of an unstable spine, and consequently on rehabilitation and the preparation of prosthetics. On the contrary, the management of a PNS injury is much simpler. The currently applied treatments involve nerve autografts and allografts; however, there are many difficulties, including shortage of donor nerves, donor-site morbidity, aberrant regeneration, infectious diseases, and immunological issues [3]. It is therefore understood that there is a vital need for engineered alternatives to autograft application [4].

In view of the ineffectiveness of current therapeutic methods, the restoration of the damaged PNS and CNS has been a continuous challenge for neurologists and neurobiologists. As a result, novel treatment strategies for the injured nervous system have been pursued. Tissue engineering and regenerative medicine in the nervous system have provided new medical approaches as alternatives to traditional transplantation methods. These methods use external biomaterial supports, known as scaffolds, to create a platform for the cells to migrate to the injury site and repair the tissue. Three-dimensional (3D) scaffold models have been found to be critical for mimicking the exact microcellular environment and cell-cell interactions. Pioneering works in this domain have identified and characterized 3D matrices as vital for cell anchorage and precise replication of the cellular microenvironment and have enabled the creation of living tissues from a source of cells. Such scaffolds are often loaded with cells and/or growth factors to hasten the differentiation of cells to preferred types of lineage to promote new tissue formation.

In recent years, neural tissue engineering (NTE) has significantly contributed to the research efforts devoted toward the identification of suitable strategies for recovery from neurological disorders and injuries. Based on these efforts, it has been realized that the nervous tissue is undoubtedly the most complex system of human anatomy, comprising a complex multilayer environment in which topographical features display a large spectrum of morphologies and size scales. As a result, it demands far more intricate tissue-engineered scaffolds and architectures [5,6]. At the same time, the physicochemical characteristics of NTE constructs are critical for neuronal cell function and viability. Besides this, it has been shown that NTE provides the potential to model neurological diseases in vitro, mainly via lab-on-a-chip systems, especially in cases in which it is difficult to obtain suitable animal models. As a consequence of the intense research activity in the field, a variety of synthetic approaches and 3D fabrication methods have been developed for the fabrication of NTE scaffolds, including soft lithography and self-assembly, as well as top-down (subtractive) and bottom-up (additive) manufacturing.

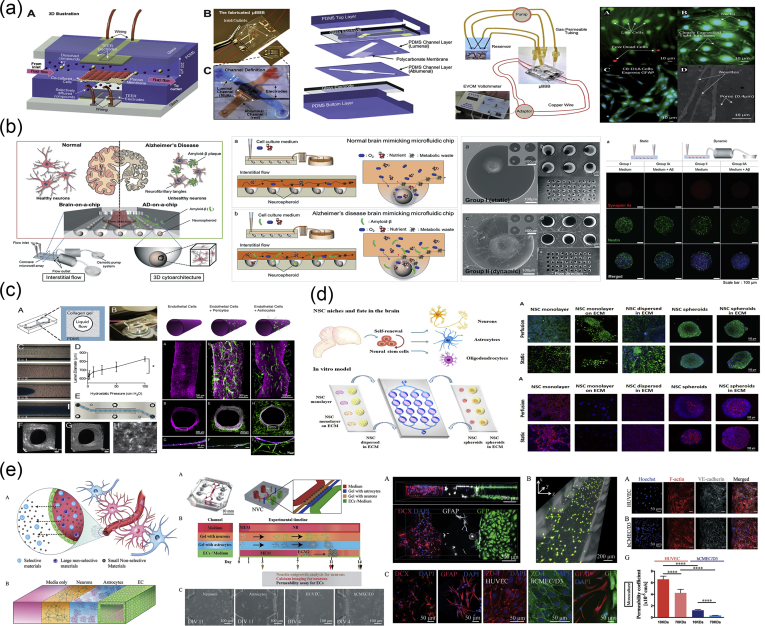

The present review article aims at reviewing the existing body of literature in the rapidly growing field related to the development of biomaterial scaffolds and lab-on-a-chip systems for NTE applications (Fig. 1). In particular, the first part reviews the various methods used for the fabrication of NTE constructs of various sizes, shapes, and physicochemical characteristics. The second part is devoted to the most important reports used to address CNS and PNS injury issues, via the application of NTE scaffolds and lab-on-a-chip systems. Besides presenting recent advances achieved by NTE strategies, this work also delineates existing limitations and highlights emerging possibilities and future prospects in this field.

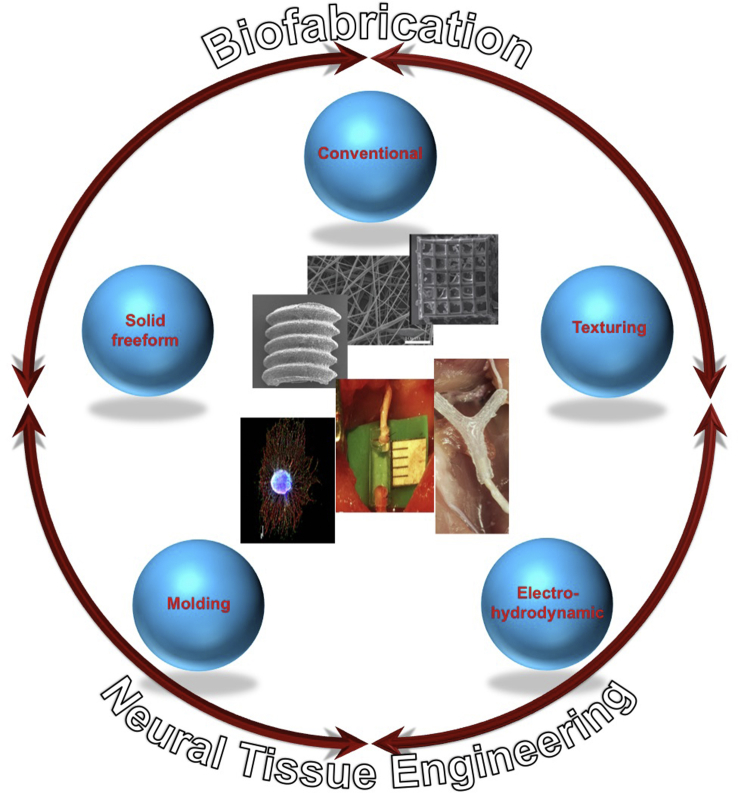

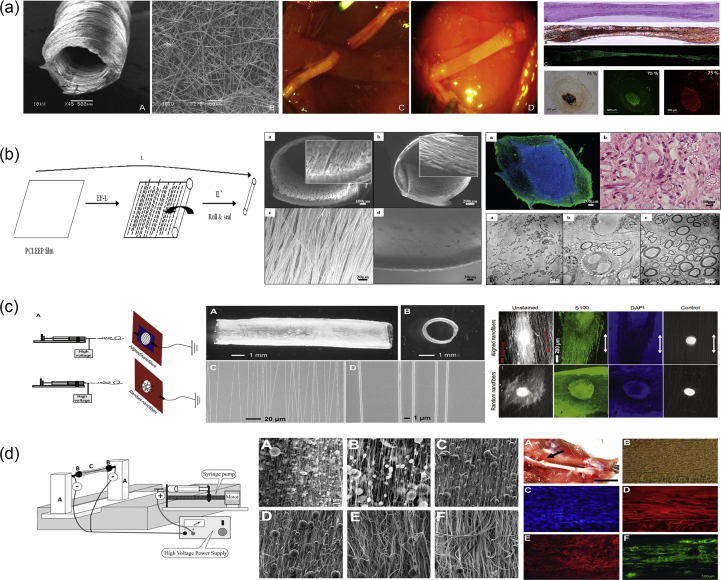

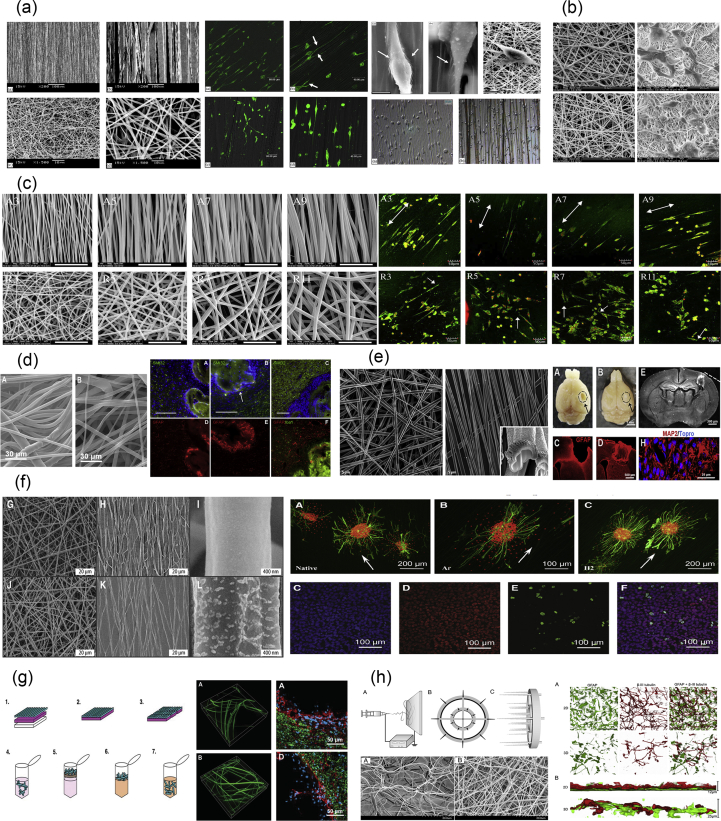

Fig. 1.

The main biofabrication methods for the development of biomaterial scaffolds for neural tissue engineering applications.

2. Biofabrication of NTE components

The creation of tissue engineering components, including scaffolds and integrated systems, has gone through a lengthy process, with several techniques being developed to create complex structures from a variety of natural and synthetic components. From the beginning, the aim has been the fabrication of ideal scaffolds to match the physical, chemical, and mechanical properties of the tissue. These scaffolds should bear several desirable characteristics such as pores, fibers, and channels, which are crucial for applications in NTE.

In this section, we will present the most important biofabrication methods that have been used for the creation of NTE constructs and explain the principles on which they are based [7,8]. Each of these methods is able to produce a different range of shapes and structures to fulfill the needs and the requirements of the corresponding application and has its own advantages and disadvantages. With the term ‘biofabrication,’ we refer to all methods used to produce constructs with biological function for use in tissue engineering and regenerative medicine applications [8]. As such, we have started from the older and more ‘traditional’ conventional methods and continued with the advanced technologies that have been developed over the last few decades. Table 1 summarizes the characteristics of the fabrication methods that have been applied in NTE, the structural characteristics of the resulting scaffolds, the advantages and the disadvantages of each method, and their potential impact in the future of NTE.

Table 1.

Methods of fabrication of tissue engineering systems, particularly applied for NTE.

| Techniques | Structural characteristics | Advantages | Disadvantages | Potential impact in NTE |

|---|---|---|---|---|

|

Conventional methods | ||||

| Solvent casting/particulate leaching [9] | Through the control of the amount of porogen added, as well as its size and shape, these scaffolds usually have an average pore size of ∼500 μm with ∼95% porosity. |

|

|

Fabrication of biocompatible scaffolds for peripheral nerve injury repair, in combination with molding techniques |

| Phase separation (non-solvent–induced phase separation [NIPS] [10] and thermally induced phase separation [TIPS] [11]) | Porous scaffolds with possible integration of bioactive molecules |

|

|

Fabrication of scaffolds, in conjunction with molding techniques |

| Self-assembly [12] | Nanofibers with amino acid residues that can be modified by the addition of bioactive molecules |

|

|

Formation of injectable materials for nerve regeneration |

| Freeze-drying [13] | Porous scaffolds without the presence of potentially harmful solvents |

|

|

Design of scaffolds for nerve repair using biocompatible and biodegradable materials |

| Gas foaming [14] | Creation of porous scaffolds with pore sizes ranging from 100 to 500 μm |

|

|

Fabrication of scaffolds, in conjunction with other techniques (i.e., molding, phase separation) |

| Hydrogel formation [15] |

Hydrogels can have a range of different properties that depend on the type of polymeric material used and the method of cross-linking used. |

|

|

Fabrication of scaffolds using bioprinting methods and design of bioinks for brain delivery and regeneration |

|

Molding and texturing methods | ||||

| Compression molding/injection molding [9] | Scaffolds with controllable porosity through the use of porogens with different sizes and chemical properties |

|

|

Construction of in vitro brain models for drug screening and efficacy testing (such as lab-on-a-chip devices). Should be used in combination with other methods |

| Photolithography [16] | Scaffolds with details in the nanometer and micrometer scale printed on photoresists |

|

|

– |

| Soft lithography [17] | Scaffolds with details in the nanometer and micrometer scale that have been transferred onto a range of polymers with different properties |

|

|

Fabrication of components for microfluidic systems and lab-on-a-chip devices. Like compression molding, should be used in combination with other methods. |

| Laser texturing [18] | Structuring/texturing of the material surface can be localized without affecting the surrounding areas and is in the region of nanometers and micrometers |

|

|

Precise and controllable micropatterning/nanopatterning of scaffolds for nerve regeneration |

| Fiber mesh/fiber bonding [19] |

Fibrous scaffolds with large surface areas |

|

|

– |

| Electrohydrodynamic techniques | ||||

| Electrospraying [20] | Highly charged droplets are formed. Their charge prevents their coagulation and promotes their self-dispersion. |

|

|

Fabrication of carriers for drugs and therapeutic molecules for brain delivery. |

| Electrospinning [21] |

Continuous microscale and nanoscale fibers from a rich variety of materials. By blending different polymers, nanofibers with internal morphology, and secondary structures, e.g., porous, hollow, or core-sheath structure can be fabricated. In addition, fibers can be organized into ordered arrays or hierarchical structures by modulating their stacking, arrangement, and folding. |

|

|

Synthetic nerve conduits to facilitate axonal guidance and to enhance nerve regeneration |

|

Solid freeform fabrication/rapid prototyping | ||||

| Photolithography-based techniques [22] | Precise internal architectures and external geometries, which match those of human tissue (structures with ≥50-μm features) |

|

|

Fabrication of complex 3D tissue structure with high resolution for brain regeneration as long as biocompatible hydrogels are used |

| Selective laser sintering/selective laser melting [23] | Fabrication of complex geometries with intricate and controllable internal architectures |

|

|

– |

| Microsphere sintering (subcategory of sintering) [24] | Microspheres are fused together to create a single macroscopic unit, with complex shapes and architectures. |

|

|

Fabrication of macroporous, 3D shape–specific constructs, conductive to infiltration and with controlled release of bioactive molecules for nerve regeneration |

| Fused deposition modeling [25] | Scaffolds with honeycomb-like pattern, fully interconnected channel network, and controllable porosity and channel size |

|

|

New biocompatible and biodegradable filament materials must be formulated to use fused deposition modeling for nerve regeneration applications. |

| 3D bioprinting [26,27] | Precise layering of cells, biologic scaffolds, and growth factors to create bioidentical tissue for a variety of uses. |

|

|

Construction of brain-like structures to serve as in vitro 3D models and custom-made platforms for personalized medicine |

NTE, neural tissue engineering; PGA, polyglycolic acid; PLLA, poly-l-lactic acid; 3D, three-dimensional.

2.1. Conventional methods

2.1.1. Solvent casting/particulate leaching

Solvent casting/particulate leaching (Fig. 2a) is a popular, traditional method used for porous scaffold fabrication and is based on a relatively simple technique. A homogeneous polymer solution that contains some type of porogen is cast into a mold, and the solvent is allowed to evaporate. The resulting composite material contains the polymer and the porogens. For final scaffold fabrication, this composite material is submerged in a bath so that the porogens can dissolve to reveal a porous structure that can be used in various tissue engineering applications [9].

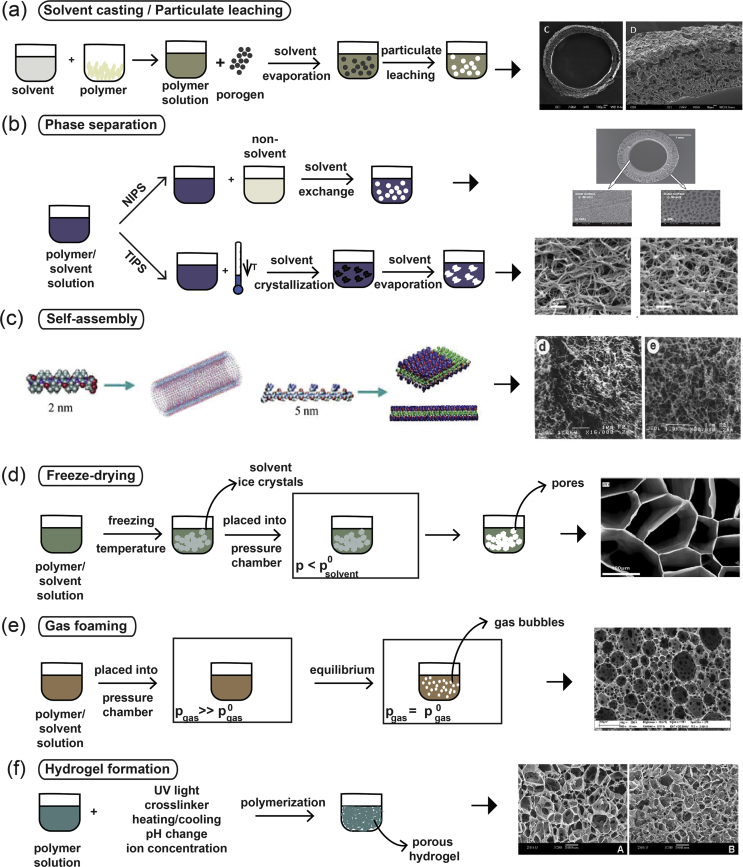

Fig. 2.

(a) Solvent casting/particulate leaching fabrication method. The polymer powder is dissolved in a solvent to create a polymer solution, to which a porogen is added. The polymer hardens through the evaporation of the solvent, and the final network within the scaffold is created by leaching the porogen out of the structure [42]. (b) Phase separation processes depicting the differences between NIPS [43] and TIPS [44]. (c) Example of the structure of a peptide amphiphile that is used in the self-assembly fabrication technique. The chemical structure and the molecular model of peptide amphiphiles are shown [45]. Fabrication processes of (d) freeze-drying [46], (e) gas foaming [47], and (f) hydrogel formation [48]. Scaffold images reprinted with permission from (a) Kokai et al. [42], (b) Oh et al. [43] and Sun et al. [44], (c) Zhao and Zhang [45] and Holmes et al. [49] (Copyright (2000) National Academy of Sciences), (d) Stokols and Tuszynski [46], (e) Barbetta et al. [47], and (f) Zhang et al. [48]. NIPS, non-solvent–induced phase separation; TIPS, thermally induced phase separation.

A variety of different materials can be used as porogens, with salt, sugar, and wax being the most common candidates [[28], [29], [30]]. Through this fabrication method, it is possible to create scaffolds with controlled porosity as the method allows for optimization both through the use of porogens of different types, shapes, and sizes as well as through the concentration of porogens added to the polymeric solution [31]. In addition, by using various types of pretreatments (such as prefusing porogen particles or using more than one type of porogen), scientists have been able to control the porosity even further and improve pore interconnectivity [32].

2.1.2. Phase separation

Phase separation (Fig. 2b) can be split into two distinct subcategories depending on the method of fabrication followed: non-solvent–induced phase separation (NIPS) and thermally induced phase separation (TIPS).

NIPS requires three components: a polymer, a solvent, and a non-solvent. A homogeneous polymer solution that contains at least one solvent is first cast on a suitable support structure, exposed to the air for a short amount of time, and then immersed in a bath containing the non-solvent solution. The exchange between the solvent and the non-solvent leads to the formation of two phases that are created owing to the precipitation of the polymer: the polymer-rich and the polymer-lean phase. As the polymer-rich phase becomes more enriched in the non-solvent, the porous structure is created [10,33,34]. Used mostly for the preparation of membranes, NIPS-generated scaffolds usually have heterogeneous pore structures and, as such, have limited applications in tissue engineering.

On the other hand, TIPS (Fig. 2b) can occur with solutions of polymers and solvents that are homogeneous at elevated temperatures. Through the cooling of these homogeneous solutions, they tend to separate into polymer-lean and polymer-rich phases. The latter phase solidifies, creating the scaffold matrix, whereas the polymer-lean phase creates the pores owing to the removal of the solvent. TIPS can be further split into two categories: solid-liquid (S-L) phase separation and liquid-liquid (L-L) phase separation. S-L phase separation uses the lowering of the temperature to induce solvent crystallization, with the removal of these crystals leading to pore formation. L-L phase separation takes advantage of an upper critical temperature at which both phases (polymer-rich and polymer-lean) coexist, and the temperature and concentration at which their demixing occurs leads to the formation of the porous structure [9,11]. More specifically, the separation between the two phases can occur owing to binodal demixing and/or spinodal decomposition. Binodal demixing is characterized by nucleation and growth, takes place in the metastable region (between the binodal and spinodal curves), and tends to create a porous structure with a poorly interconnected network. On the other hand, spinodal decomposition takes place within the spinodal curve (unstable region) and leads to the formation of a well-interconnected network. As a result, the way in which the phase separation happens and the thermodynamic region in which it occurs are of critical importance in the determination of the morphology attained [35].

2.1.3. Self-assembly

Self-assembly (Fig. 2c) is the autonomous organization of well-defined components into ordered structures without external instruction. It has been widely used for the fabrication of various nanofibers using biological molecules and is based on the presence of both non-covalent and weak covalent interactions (e.g., van der Waals interactions, hydrophobic interactions, hydrogen bonds) [36]. Although the individual interactions are quite weak, the fact that there are a large number of them leads to the formation of the assembled scaffold/structures. The process of self-assembly is directly inspired by nature, in which viral proteins are able to self-assemble to create the viral capsids and phospholipids—which are naturally amphiphilic molecules—and are able to assemble into different types of higher order structures, including lipid bilayer membranes, vesicles, micelles, or even tubules.

Two types of natural materials are widely used in the self-assembly fabrication process: collagen and elastin. Both these molecules are extremely abundant in vivo because they are components of all connective tissues and the extracellular matrix (ECM). These natural molecules have been used as the basis for the design of new materials that are collagen- and elastin-like, as well as paved the way for the de novo design of synthetic peptides [12].

A large number of the molecules used in this fabrication method are amphiphilic peptides and can contain a variety of features essential for the self-assembly process to take place. Such examples are as follows: (1) long hydrophobic tails that aggregate in aqueous solutions, (2) consecutive cysteine residues to enable the formation of disulphide bonds, (3) glycine residues to provide flexibility to the peptide, (4) phosphorylated serine residues to enable interactions with calcium ions, and/or (5) RGD ligands to enhance cellular adhesion. The RGD (arginine-glycine-aspartic acid tripeptide) sequence is a well-known bioactive motif found in ECM proteins such as fibronectin [37], and as part of the design strategy, incorporation of this motif into peptide and protein scaffolds is used to convey cell adhesion properties.

Amphiphilic peptides usually start to self-assemble based on the adjustment of certain parameters of the solution they are in. The main parameters are light, pH, temperature, salt ion concentration of the solution, and the presence/absence of a reducing/oxidizing agent [11,12,38]. Self-assembling peptides can also be modified to become tissue specific through the integration of different signaling peptide sequences into the peptides or even through the addition of growth factors specific for each cellular environment [39]. Understanding all the different characteristics and elements that can be incorporated into these peptides gives researchers the ability to precisely design and fine-tune the morphological features of the scaffold they desire. Changing the amino acidic composition of the self-assembling peptides enables the creation of a variety of different structures, including vesicles, micelles, monolayers and bilayers, fibers, and tapes [40], while also allowing the more precise mimicking of the extracellular environment. Furthermore, recent developments have proposed that novel computationally engineered self-assembling peptides can offer open-ended capabilities to future multifunctional tissue engineering scaffolds [41].

Self-assembling peptides usually form hydrogels with various types of nanofibers and nanoscale networks and, as such, have poor mechanical stability, making it quite difficult to create stable 3D structures [11]. This can result in the fragmentation of the engineered nanofibers, which are more susceptible to endocytosis. Owing to the high cost of synthesis for the biomaterials used in this type of fabrication method, the applications in tissue engineering and regenerative medicine are quite limited, although there are ongoing efforts to improve the fabricated scaffold properties.

2.1.4. Freeze-drying

Freeze-drying (Fig. 2d) is a method that is used to produce highly porous scaffolds, without the need for a porogen. It is a relatively simple technique in the sense that it requires a polymer solution to be cooled down to a low temperature (−70 °C to −80 °C), a process which leads to the formation of ice crystals from the solvent. This results in the polymer aggregating in all the spaces left around the ice crystals. The latter are subsequently removed through the application of pressure at a level that is lower than the equilibrium vapor pressure of the frozen solvent, leading to the formation of dry scaffolds with interconnected pores through sublimation. Any residual water (H2O) that was not in a frozen state is removed in a secondary drying process through desorption [11,50]. Scaffold porosity can be controlled to an extent through the use of different polymeric material solutions and by controlling the freezing temperatures that are used during the freeze-drying process [50,51]. Scaffolds that have been prepared through freeze-drying have been widely used in NTE as the good interconnectivity of the pores achieved through this fabrication method has been found to promote cellular infiltration and tissue growth when used in situ [50].

2.1.5. Gas foaming

Gas foaming (Fig. 2e) is a technique that requires the formation of a gas in a polymer solution. The first way in which this can occur requires a molded polymer together with a gas-foaming agent, such as carbon dioxide (CO2), nitrogen (N2), or H2O. The polymers are pressurized using the gas-foaming agents until they become saturated, to achieve nucleation—the formation of gas bubbles within the polymer. Through this process, the size of the bubbles that are formed range from 100 μm to 500 μm, essentially forming pores of the same size within the polymer [47,51]. Another way to induce gas foaming is to cause a reaction during the mixing process. Through the addition of two chemicals that, upon reaction, causes the release of a gas (e.g., N2), foaming is rapidly induced, leading to the formation of a highly porous network [14]. However, despite the fact that it is a relatively easy technique that does not require the use of a solvent, it has one major drawback. Because of the way in which the bubbles are formed, most of the scaffolds fabricated through this process have poorly connected pores with a non-porous outer surface [52]. Such scaffolds are very difficult to use in tissue engineering owing to the necessity for both a porous outer surface that will facilitate cell infiltration and a well-interconnected porous network that will allow the elongation of axons during the repair process. As such, its applications in NTE are extremely limited.

2.1.6. Hydrogel formation

Hydrogels are highly hydrophilic polymers that can incorporate very large amounts of H2O into their structures. The material that is used to create the hydrogel structures is a liquid solution of polymer chains of varying sizes, which also contains unreacted monomers or cross-linking compounds [53,54]. For the formation of porous hydrogel structures, the components of this material need to be cross-linked. This process can occur in various ways, ranging from UV photopolymerization and ionic concentration–dependent cross-linking to changes in the temperature or pH of the material (Fig. 2f) [15,55]. Depending on the type and the properties of the polymeric material, as well as the cross-linking method used, the hydrogels can acquire different properties and can range from being soft and flexible (mimicking soft tissues such as the brain) to rigid (mimicking cartilage or bone) or elastic (mimicking the skin). Essentially, the changes that can occur in the porosity and stiffness/flexibility of the resulting hydrogel play a crucial role in how hydrogels interact with cells [53].

The polymeric materials that are used for the formation of hydrogels can be of natural or synthetic origin. Naturally occurring molecules able to form hydrogels include collagen, gelatin, chitosan, agarose, hyaluronate, and alginate, whereas synthetic molecules that are commonly used include poly(acrylic acid) and its derivatives [with one of the most well-known ones being poly(2-hydroxyethyl methacrylate) (PHEMA), poly- (ethylene oxide) (PEO) and its copolymers, and poly(vinyl alcohol) (PVA)] [53,56]. The materials that will be chosen for any given application are always dependent on the specific requirements of the application, and the potential adverse effects must always be taken into consideration. Natural biomaterials are more reminiscent of the ECM environment but can often have disadvantages such as high variability between batches, as well as high immunogenicity. On the other hand, synthetic biomaterials may be more consistent between batches and have very low immunogenicity but may not always be compatible with the tissue of interest [57].

2.2. Molding and texturing methods

2.2.1. Compression/injection molding

Compression/injection molding (Fig. 3a) is a fabrication process very similar to solvent casting/particulate leaching. With the particulate leaching component of the process being the same in all cases, the way in which it differs is related to the way in which the polymer is prepared. The process of melt molding requires three separate components: a mold, a polymer powder, and a porogen. Similar to the methodology described previously for solvent casting, a polymer solution is prepared, wherein the polymer is dissolved in a solvent and poured into a mold, to allow the solvent to evaporate and create the scaffold structure. In this fabrication method, there are two ways to prepare the polymer and porogen used for scaffold creation. In the first method, the polymer is melted and becomes mixed with the porogen through an extruder or a mixing machine, creating a polymer matrix with an even distribution of the porogen. Then, the molding can take place either through compression or injection. In the second method, the polymer powder becomes physically mixed with the porogen in solid form and is added to the mold. The scaffold is created through the use of compression [9,51]. The porosity of the sample can be controlled through the different chemical compositions and sizes of the porogens and the method that is used to prepare the scaffold as the use of the melting process in the first method nearly always leads to porogen shrinking in size [9].

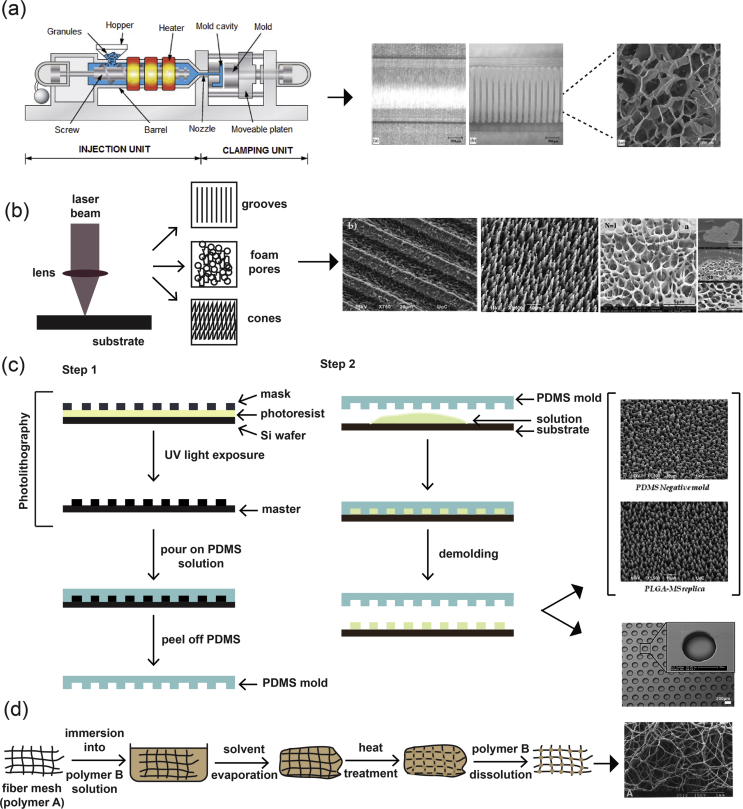

Fig. 3.

(a) Schematic representation of an injection molding machine [71] and SEM images of representative structures [72]. (b) Laser texturing [68,73]. (c) Photolithography and soft lithography. Step 1: Photolithography and the process for the creation of the negative PDMS mold for use in soft lithography techniques [73,74]. Step 2: Process for the transfer of the pattern of the negative PDMS mold onto another material. (d) Fiber bonding [19]. Reprinted with permission from (a) Svečko et al. [71] and Freier et al. [72], (b) Babaliari et al. [73] and Daskalova et al. [68], (c) Babaliari et al. [73] and Leijten et al. [74], and (d) Mikos et al. [19]. PDMS, polydimethylsiloxane; SEM, scanning electron microscopy.

2.2.2. Soft lithography and photolithography

Soft lithography (Fig. 3c) is a family of techniques that are used for the fabrication and/or replication of structures through the use of molds, stamps, and photomasks, and it includes methods such as microcontact printing (μCP), replica molding, microtransfer molding, micromolding in capillaries, and solvent-assisted micromolding [58]. It was developed as a way to enable microfabrication at the nanometer and micrometer scale, to partly replace photolithography as the main fabrication method. The use of the word ‘soft’ refers to the materials that are used in these fabrication techniques, which are planar, flexible, curved, and soft substrates, as opposed to the more rigid ones used in other lithographic techniques, such as polystyrene (PS)-based polymers [17]. Photolithography is routinely used for the manufacturing of microelectronic structures using a projection-printing system. It is the main tool used in the semiconductor industry and is used to produce all integrated circuits. The way in which this method works is by projecting the image of a reticle through a high-numerical-aperture lens system onto a thin film of photoresist that has been spin-coated on a wafer.

The application of this technique in biology and biotechnology comes with several limitations owing to factors such as its very high cost, the limited amount of control over the properties of the surface, and being compatible with a limited number of materials [16]. As a result, soft lithography techniques were developed to overcome these limitations. In each one of the techniques that make up the soft lithography technique family, an elastomeric stamp or mold is used to transfer a pattern to the substrate. First, the pattern is designed, followed by the fabrication of the mask and the master. Once these are made, they are used to make the polydimethylsiloxane (PDMS) stamps/molds, which are then used in the printing/molding/embossing stage of each individual protocol [58].

2.2.3. Laser texturing

To create various structures on surfaces and tailor their morphology for a variety of different applications, there have been several approaches that have been developed, including photolithography and plasma treatment. One of the most recently developed techniques that belong to the subtractive manufacturing approaches is surface texturing through the use of ultrafast lasers (Fig. 3b) [59,60]. This particular technique is based on the principle of laser ablation and has found a large number of applications owing to its advantage to locally excite certain areas of a material, with minimal damage to the surrounding ones. This is due to the short duration of the pulse, which allows for a higher excitation threshold intensity to be attained, without increasing laser beam intensity. As a consequence, precise structuring/texturing on the material surface at both the nanometer and the micrometer scales can be attained [18].

Additional advantages of the laser texturing method include the fact that it is non-contact, can be applied to a variety of different materials (including metals, ceramics, and polymers), and can be used to texture materials on their surface, as well as etching deeper regions within the bulk of the material to create structures with complex geometries [61]. Materials that have been laser patterned with structures such as grooves, pillars, microcones and nanocones [62], and channels have been widely used as cell culture platforms to investigate the effect of topographical cues on various cellular responses [63].

Another phenomenon that can occur as a result of laser irradiation is foaming. This can be induced superficially on the surfaces of biopolymers, such as gelatin, collagen, and chitosan, through the application of single pulses in the nanosecond to femtosecond domains. More specifically, the single pulse that is delivered to the surface of the biopolymer creates a transient acoustic wave that eventually leads to nucleation and the creation of bubbles [[64], [65], [66]]. Through controlling the number, duration, wavelength, and fluence of the pulses, the foaming process can be fine-tuned and can lead to the creation of differentially nanostructured biomaterial scaffolds [65,67,68]. As a consequence, this method provides us with a tool to create scaffolds with micrometer precision [69].

2.2.4. Fiber mesh/fiber bonding

The fiber mesh fabrication technique (Fig. 3d) requires the formation of fibers made out of polymeric materials, which are then used in the same way as threads would be and are woven into 3D patterns to create meshes with a range of pore sizes [70].

The scaffolds obtained via this method have quite a large surface area and allow the rapid diffusion of nutrients essential for growth and survival. However, because they are not stable enough for use in vivo, this technique was further developed into fiber bonding, in which the scaffold created as part of the fiber mesh fabrication technique was placed into a second polymer/solvent solution. Once the solvent has been evaporated, the scaffold is heated to a temperature higher than the melting temperature of both polymers, and after cooling, the second polymer is removed through selective dissolution. The result is a scaffold made out of one polymer that has been physically bonded at the intersections between the fibers [19,75]. This fabrication method does not offer fine control over scaffold porosity, and the scaffolds have limited use owing to the types of polymers that can be used and the use of a solvent during the fabrication process.

2.3. Electrohydrodynamic techniques

Electrohydrodynamic methods of fabrication are based on the electrostatic attraction of a liquid which, while coming out of a nozzle, is subjected to an electric field and subsequently collected on a plate. The typical setup (Fig. 4a) for these fabrication methods consists of three primary components: (i) a high-voltage power supply (usually in the kilovolt range), (ii) a syringe with a metallic needle (spinneret), and (iii) a grounded collector. In a typical electrohydrodynamic process, a viscoelastic solution is placed in the syringe, and as a small droplet is forced out of the tip, it becomes charged by applying an electrical potential difference between the droplet and the plate. The electrical field is created by connecting the positive electrode of the high-voltage power supply to the metallic needle and the negative electrode to the grounded conductive collector. As voltage increases, electrostatic repulsion starts to overcome the surface tension of the fluid, and the pendant droplet deforms into a conical droplet, known as the Taylor cone. When electrostatic repulsion finally overcomes the surface tension, a fine, charged jet of solution is ejected from the tip of the needle toward the grounded collector [76]. On the way to the collector, the solvent is evaporated, and nanostructures/microstructures are obtained once the process is complete.

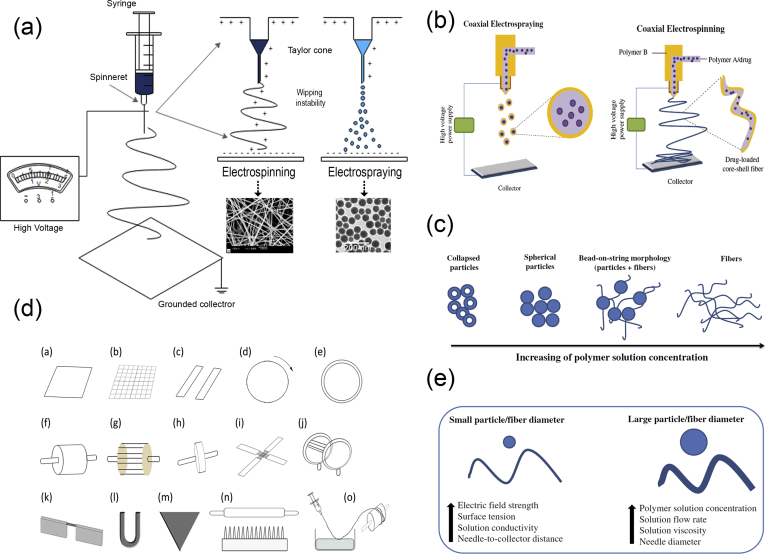

Fig. 4.

Electrohydrodynamic techniques. (a) Schematic representation of an electrospinning/electrospraying setup, (b) coaxial nozzles, (c) the resulting electrospun structures depending on the concentration of the solution, (d) different types of collectors used in electrospinning, and (e) factors affecting the diameter of particles/fibers created by electrohydrodynamic methods. SEM images in (a) have been reprinted with permission from Yang et al. [78] and Eaton et al. [79], and images in (b), (c), and (e) have been reprinted with permission from Nikolaou and Krasia-Christoforou [21]. SEM, scanning electron microscopy.

One critical parameter of the process that affects the morphology of the resulting structure is the concentration of the solution (Fig. 4c) [77]. At lower solution concentrations, spherical particles are observed. As the concentration increases, fibers also begin to be formed, resulting in bead-on-string morphologies (i.e., electrospun fibers with particulates). At concentrations higher than the critical solution concentration, continuous, uniform fibers can be generated. Finally, when the solution concentration is too high, helix-shaped microribbons are formed instead of smooth fibers. Hence, two different electrohydrodynamic approaches have been developed: (a) electrospraying and (b) electrospinning. Electrospinning and electrospraying are two highly versatile and scalable electrohydrodynamic methods for fabrication of nanoscale and microscale fibers and particles, respectively.

2.3.1. Electrospraying

Electrospraying (Fig. 4a) is a process of liquid atomization by electrical forces. As mentioned previously, its main difference from electrospinning is the concentration of the solution. In electrospraying, the low-concentration of the solution destabilizes the jet due to varicose instability, and hence, fine droplets are formed. These highly charged droplets self-disperse in space, thereby preventing droplet agglomeration and coagulation. Furthermore, solvent evaporation over time promotes the contraction and solidification of the droplets, resulting in solid particles deposited on the grounded collector.

During the electrospraying process, the jet deforms and disrupts into droplets mainly owing to electrical force as no additional mechanical energy is needed for liquid atomization. The charge and size of the droplet can easily be controlled to some extent by adjusting the flow rate and voltage applied to the nozzle. Consequently, electrospraying has some advantages over conventional mechanical spraying systems, in which droplets are charged by induction: (i) it produces droplets of a smaller size, (ii) their size distribution is usually narrow with low standard deviation, (iii) the charged droplets are self-dispersing, and no droplet agglomeration and coagulation occurs, (iv) the motion of charged droplets can easily be controlled by electric fields such as deflection or focusing, and (v) the deposition efficiency of the charged spray is much higher than that of uncharged droplets [80].

For small-scale processes, electrospraying with a single capillary is used; however, for traditional industrial spraying approaches, multinozzle or slit-nozzle systems have been established. An alternative coaxial electrospraying approach has been developed for the formation of multilayered particles for biomedical applications (Fig. 4b). Coaxial electrospraying is based on conventional microencapsulation/nanoencapsulation processes and modifies the single-axial electrospray process by using a coaxial capillary needle to deliver two liquids independently. The key component in the setup is a coaxial nozzle that consists of an outer and an inner needle and two immiscible liquids, one in each needle (Fig. 4b). Two pumps control the flow rates in the respective needles creating two-layer droplets using an electric field.

2.3.2. Electrospinning

Electrospinning (Fig. 4a) is the method of drawing thin fibers out from a viscoelastic fluid using electrostatic forces. During this process, as the charged jet is ejected toward the collector, it is forced to a whipping or bending motion owing to the unevenly distributed charges and the high concentration of the solution. As a result, after the elongation of the jet and the rapid evaporation of the solvent, a solid, thin fiber is deposited on the grounded collector. The final structure is usually a randomly oriented, non-woven mat. However, electrospinning offers the possibility of the production of fibers with different orientation and hierarchical structures. To obtain aligned orientation in electrospinning, the type of the collector plays a crucial role. In the past decades, to achieve aligned electrospun fibers, several special designed collectors have been used, such as rotating drums, metal frames, or two conductive substrates separated by an insulating gap (Fig. 4d) [81]. The shape of the collector also influences the resulting nanofiber structure. The deposited patterns include shapes such as circles, triangles, squares, crosses, rectangles, and more and can be made out of different materials such as copper, aluminum, gold, wood, and so on [81]. In addition, a liquid system with a coagulation bath can be used instead of a collector or can be combined with a rotating mandrel, to obtain a continuous yarn made from electrospun fibers. In general, the necessary fiber alignment can be obtained by mechanical, magnetic, or electrostatic means [82,83]. In the mechanical approach [[84], [85], [86]], it is usually the use of a rotating mandrel that aligns the fibers along the direction of the rotation. Alignment can also be achieved by magnetic forces [87]. In this case, a small number of magnetic nanoparticles are incorporated in the polymer solution to magnetize it, and the solution can be electrospun into nanofibers in the presence of a magnetic field. In this way, the magnetized fibers are stretched into essentially parallel fibers, across a gap, to generate a uniaxially aligned array between the two magnets. In the electrostatic approach, the collector typically consists of a pair of electrodes with an insulating gap between them, which forces the fibers to be stretched and align themselves perpendicular to each edge of the gap [88].

In recent years, hierarchical nanofiber structures, including core-shell, hollow, and porous structures, can be obtained by electrospinning. Typically, the nanofibers produced using electrospinning have a solid structure; however, two strategies have been explored for generating porous nanofibers: (i) selectively removing one of the components from the fibers and (ii) inducing polymer-solvent phase separation by rapidly cooling the fibers before complete solidification [82]. Both approaches have been used and can be extended to obtain porous nanofibers from a variety of polymers. A coaxial electrospinning setup (Fig. 4b) can be used to create tubular fibers. Electrospinning of two immiscible solutions through a coaxial spinneret can generate core-sheath and hollow nanofibers with controllable dimensions by selective removal of the core after electrospinning. By adjusting the experimental parameters, the wall thickness and the inner diameter of the tubular nanofibers can be tuned from tens to several hundred nanometers.

Electrospun and electrosprayed products possess several structural advantages such as high surface-to-volume ratio, porosity, tailored morphology, and submicron and nanoscale size. Furthermore, the size and the final structure can be controlled by manipulating critical factors such as the solution as well as instrumental and ambient parameters. The solution parameters include the molecular weight, the type, and concentration of the polymer, the solvent used, and the solution properties (i.e., pH, conductivity, viscosity, and surface tension). The instrumental parameters include the applied electrical potential, the flow rate of the solution, the distance between the tip of the needle and the collector, and occasionally the nature of the collector material and the shape. Finally, the ambient conditions in the process chamber, such as the temperature, humidity, and air velocity, can collectively determine the rate of evaporation of the solvent from the electrospun or electrosprayed product and affect the characteristics of the final structure. Regarding the size of the particle/fiber diameter, a general rule that applies is that it is decreased when electric field strength, surface tension, solution conductivity, and needle-to-collector distance are increased. On the contrary, any increase in the solution concentration, viscosity, flow rate, and needle diameter results in particles and fibers with larger diameters (Fig. 4e) [21].

Apart from the particle/fiber size and structure, which can be fine-tuned by adjusting the electrospraying/electrospinning parameters, postprocessing of the final products may be required to produce functionalized structures for several applications [89]. The most frequent functionalization strategies that can facilitate a better cell response for biomedical applications are surface treatment by chemical and physical means and the coating or binding of bioactive molecules. Methods for surface modification include plasma treatment, poly(dopamine) treatment, layer-by-layer technique, coating with blends and emulsions, grafting of natural polymers, and so on [89].

Besides the independent use of nanoparticles/microparticles or nanofibers/microfibers, electrospraying and electrospinning have also been combined together for the generation of hybrid particle/fiber composite materials [90,91]. For the generation of these hybrid structures, a simultaneous electrospinning and electrospraying process can be performed using the same collector, or the electrospraying process can take place on the same collector after the completion of the electrospinning procedure [91]. Both of the aforementioned processes result in the deposition of electrosprayed particles onto the surfaces of the electrospun fibers, generating advanced composite materials useful in the field of biomedical research for tissue engineering.

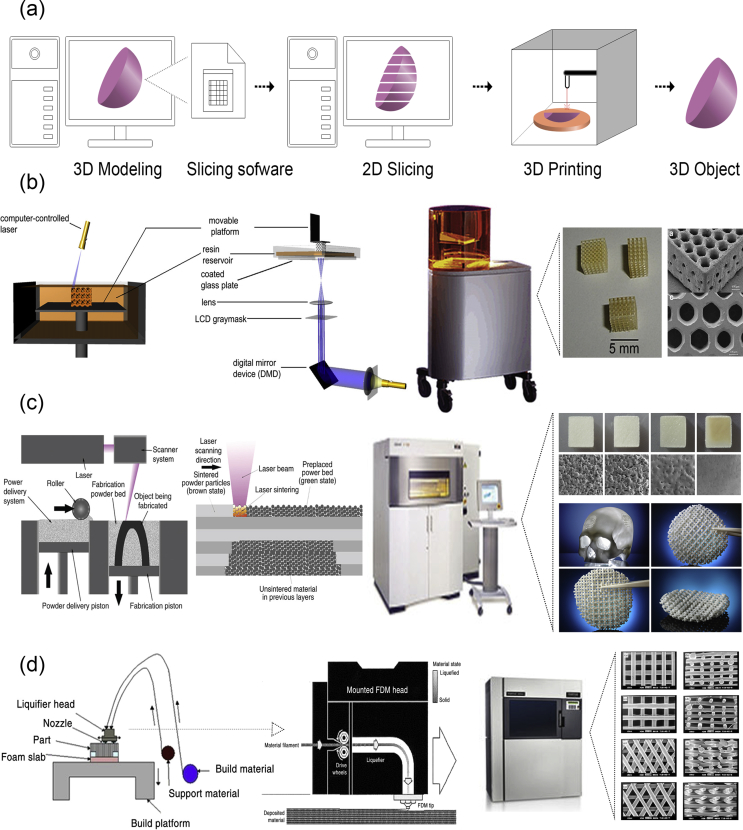

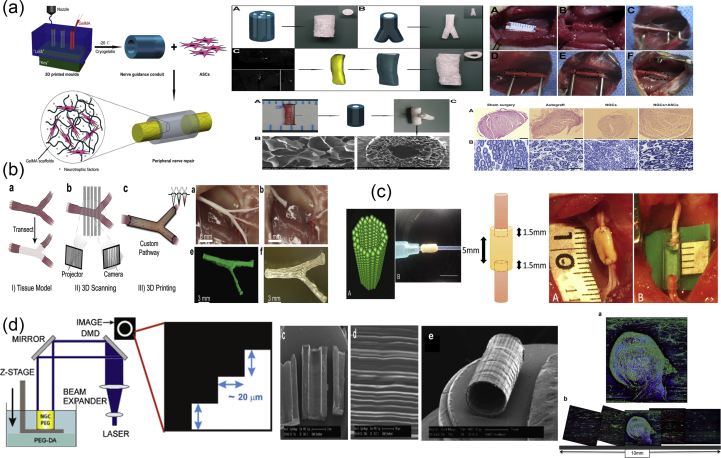

2.4. Solid freeform fabrication/rapid prototyping

Rapid prototyping or additive manufacturing is a group of techniques that are used to quickly fabricate physical models and prototypes using 3D computer-aided design (CAD) data (Fig. 5a). The first step in rapid prototyping is the creation of a 3D computer model using software, which builds spatial image models. The 3D images are corrected or modified and are subsequently cut into sequences of layers using slicer software. These are then used during the second step of the process, to generate complex objects layer by layer via the solidification of melts, layer photopolymerization, or the bonding of particles using either laser beam–induced sintering or special binders. The final step is related to postprinting procedures such as curing, sintering, or final finishing. Irrespective of the technology used for the creation of a 3D model, all the methods in additive manufacturing are based on the same principle: the laying down of material in a layer-upon-layer fashion to create a whole object. In other words, the successive addition of 2D layers of material continues until a complete 3D object is fabricated.

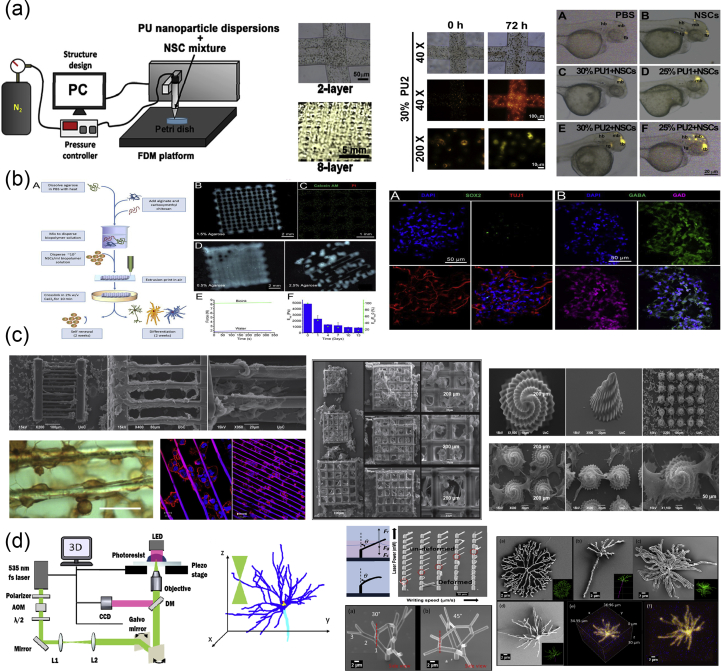

Fig. 5.

Principles and methods of rapid prototyping/solid freeform fabrication. (a) Schematic representation of the rapid prototyping process. A 3D computer model is created, sliced into layers, and printed in a layer-by-layer fashion. Schematic representation of the printing processes of (b) stereolithography as a representative example of the photolithography-based techniques, (c) selective laser sintering, and (d) fused deposition modeling. For each method, we also show its corresponding equipment and representative examples of fabricated scaffolds. Images were adapted with permission from (b) Melchels et al. [93], (c) Molitch-Hou [103] and Gayer et al. [104], (d) Masood [105] and Zein et al. [25] for SEM images. Scale bar in (c) 500 μm x/y/z. 3D, three-dimensional; SEM, scanning electron microscopy; FDM, fused deposition modeling; LCD, liquid crystal diode.

A variety of additive manufacturing techniques have been developed, with the most common methods being selective laser sintering (SLS) and selective laser melting (SLM), stereolithography (SLA), fused deposition modeling (FDM), and 3D plotting/printing. All these bottom-up approaches can be used with various forms of materials such as liquids, solids, or powders and offer the ability to create highly organized 3D structures with architectures that cannot be attained via traditional manufacturing processes. They additionally address issues such as internal porosities, lack of residual stress, and interlocking shapes without connection [92]. However, the most important advantage of additive manufacturing is the capability of the approach to produce customized structures that can serve as surgical prototypes, prostheses, or scaffolds in biomedicine.

2.4.1. Photolithography-based techniques

In photolithography-based techniques, the solidification of liquid photosensitive polymers takes place by exposure to light to build 3D models. These techniques include SLA, digital light processing (DLP), continuous liquid interface production (CLIP), two-photon polymerization (2PP), and multiphoton polymerization (MPP) [22]. Both SLA and DLP work by selectively exposing liquid resin to a light source, with their difference being in the light source: a laser in the case of SLA and a projector in the case of DLP. During the process of SLA (Fig. 5b), a built platform is lowered in a vat filled with a liquid photopolymer resin [93]. UV or visible light is focused on the resin-platform interface in a precise pattern and solidifies the resin to create the first layer. Once this layer is solidified, the platform is lowered for the polymerization of the subsequent layer, and this process is repeated until the whole 3D structure is complete. Although SLA originally used UV light for photocuring, the visible light has been explored as an alternative to UV radiation which is harmful for live cells, in order for SLA to be used for bioprinting. In DLP, just like in SLA, a resin tank with a transparent bottom and a built platform that descends into a resin tank are used, and the objects are built upside down, layer by layer. The difference here is that a digital screen is used as a projector and flashes an image of a layer across the entire platform, curing all points simultaneously. This makes DLP much faster than SLA. DLP has been used for the fabrication of 3D constructs with high spatial resolution, excellent structural stability, and reliable biocompatibility, which mimic the complex architecture of biological tissues [[94], [95], [96]]. CLIP, also known as Digital Light Synthesis (DLS), is based on SLA, but the process does not pause after each layer. Instead, the resin continuously flows, and the objects are built upside down. Due to this continuous process, the parts have smother surfaces and are printed much faster. 2PP differs from other laser-based additive manufacturing techniques because it applies the principle of two-photon absorption for the generation of microstructures and nanostructures inside a polymerizable solution [97]. This can be achieved by the use of a tightly focused, femtosecond pulsed laser beam (with wavelengths in the near-infrared range), which penetrates the solution and confines the polymerization to the focal point instead of the entire area. Thus, 2PP does not operate in a layer-by-layer fashion and as a result has virtually no geometrical restrictions when producing a structure. Compared with other conventional additive manufacturing techniques, 2PP provides higher resolution 3D scaffolds [[98], [99], [100]] and is therefore able to mimic the ECM to a greater extent, which is beneficial for cell attachment and proliferation [101,102].

2.4.2. Selective laser sintering/selective laser melting

SLS and SLM (Fig. 5b) belong to the powder-based additive manufacturing techniques because they induce consolidation of a powdered material using high-energy light sources [23]. The powders that can be used must be materials that can be melted by lasers. During the process, a layer of powder is deposited and melted using a laser, which creates a precise pattern dictated by CAD data. Next, a new layer of powder is deposited on top and melted, and the process is repeated as many times as necessary to complete the whole structure. SLS and SLM are very similar methods. The main difference between them is that in the former, the powder does not fully melt, but it is heated to a degree at which it can be fused together on a molecular level. As such, sintering allows for controlled porosity of the material. SLM uses the laser to achieve a full melt of the powder into a homogeneous liquid, creating stronger structures with fewer or no voids as long as a single metal powder is used.

A special case of sintering is microsphere sintering [24], in which microspheres of the polymer are used instead of powder. Prefabricated polymeric microspheres are poured into a mold and heated to a specific temperature (usually higher than the glass transition temperature of the polymeric matrix) for several hours. This causes the melting of the surface layer of the microspheres, which are fused with adjacent microspheres, creating a 3D porous scaffold with excellent mechanical properties. Besides heat sintering, which is the most used method for microsphere sintering, other techniques can be used such as solvent-based sintering and subcritical CO2 sintering.

2.4.3. Fused deposition modeling

Fused deposition modeling (Fig. 5c) belongs to the material extrusion additive manufacturing techniques and uses a small temperature-controlled extruder to force out a thermoplastic filament material [105,106]. The polymer filaments are deposited onto a platform under semimolten conditions, in a shape as per a computer-designed model and in a layer-by-layer process. Once a layer is completed, the base platform is lowered and the next layer is deposited. Fused deposition modeling offers the capability of creating highly porous scaffolds with a fully interconnected channel network, as well as controllable porosity and channel size. Owing to the nature of the materials processed in FDM (e.g., thermosensitive plastics and polymers), this method has been widely used in medicine for the fabrication of customized patient-specific medical devices, such as implants, prostheses, anatomical models, and surgical guides, as well as customized platforms for personalized medicine.

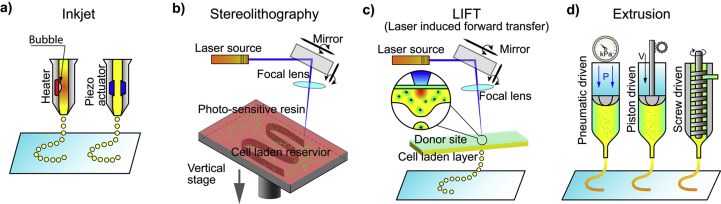

2.4.4. Three-dimensional bioprinting

Three-dimensional printing includes several flexible techniques for the direct manufacturing of complex shapes with high resolution, as well as for the processing of highly customized medical products combined with image reconstitution techniques. As an additive manufacturing technique, 3D printing is based on the deposition of biomaterials in a layer-by-layer manner. In most cases, a computer-controlled three-axis mechanical platform drives the movements of the printhead in the required algorithm and shape. Bioprinting differs from conventional 3D printing in that a bioink with living cells and growth factors is used to create tissue-like structures that imitate natural tissues [107]. Bioink usually consists of a carrier material in which living cells have been enveloped; however, it can be composed only of cells, or the cells can be loaded later on. The carrier material in most cases is a polymeric gel that supports cell attachment and function but also provides protection to the cells during the printing process.

The most commonly used methods of bioprinting for tissue engineering applications are the inkjet-based, the extrusion-based, the SLA-based, and the laser-assisted printing (Fig. 6) [26,108].

Fig. 6.

Illustration of 3D printing processes: inkjet-based 3D printing (a), stereolithography-based 3D printing (b), laser-assisted 3D printing (c), and extrusion-based 3D printing (d). Image reprinted with permission from Jiang et al. [108]. 3D, three-dimensional.

In inkjet-based printing (Fig. 6a), droplets of biomaterials are selectively placed on the platform in a layer-upon-layer fashion for the creation of a complete structure. Droplets can be formed either by thermal, piezoelectric, or electrostatic forces. The main limitation of the procedure is the inherent inability of the printhead to provide continuous flow and the low cell densities in the ink (only bioinks with viscosities lower than 10 mPa are printable via inkjet). Thermal inkjet printing is not common in tissue engineering owing to the loss of activity of the macromolecules from the very high temperatures used (potentially higher than 200 °C).

In SLA-based bioprinting (Fig. 6b), visible light can be used as an alternative to harmful UV light, for the curing of biocompatible hydrogels and biopolymer blends. Two modifications have been described: the ‘top-down’ approach, which is similar to conventional SLA but with the platform being lowered into a tank filled with bioink (this usually consists of a prepolymer solution with living cells), and the ‘bottom-up’ approach, in which the prepolymer solution with the cells is pipetted into the container one layer at a time from the bottom to the top [109]. This ‘bottom-up’ setup is suitable for cell encapsulation applications. The advantages of SLA-based bioprinting are high resolution and velocity, the high cell concentrations that can be used, and the absence of problems due to nozzle clogging. The main disadvantages are the high cost of the devices and the cytotoxicity of the lights and photoinitiators.

Laser-assisted bioprinting (Fig. 6c) is a non-contact, nozzle-free technique, which allows high-resolution deposition of biomaterial in a solid or liquid state [110]. It is based on the laser-induced forward transfer technique, and the typical setup includes the laser and two parallel laser-transparent glass slides: the donor and the receiver. The printed cells are spread onto a donor slide, embedded in a biological polymer, or suspended in a culture medium or hydrogel. The receiving slide is usually coated with a hydrogel to enhance cell adhesion and proliferation. The hydrogel on the receiver slide also offers protection and minimizes cell damage upon impact. A laser pulse induces the propulsion of cells from the donor slide toward the collector slide in a computer-controlled manner. In some cases, an absorbing layer is interposed between the donor slide and the bioink to avoid the direct interaction of the laser with the living cells in the bioink. This technique was previously used for printing/patterning of a variety of biomolecules, such as proteins and DNA for engineering of biosensors, diagnostics, or cell culture platforms [[111], [112], [113]].

In extrusion-based printing (Fig. 6d), biomaterials are extruded out of the printhead due to mechanical or pneumatic pressure. This method allows the incorporation of cells and biomolecules because it does not involve any heating processes. When compared with inkjet bioprinting, extrusion-based bioprinting offers higher cell densities but lower speed and resolution. (Bioinks with viscosity in the range of 306–107 mPa are printable with extrusion-based printing.)

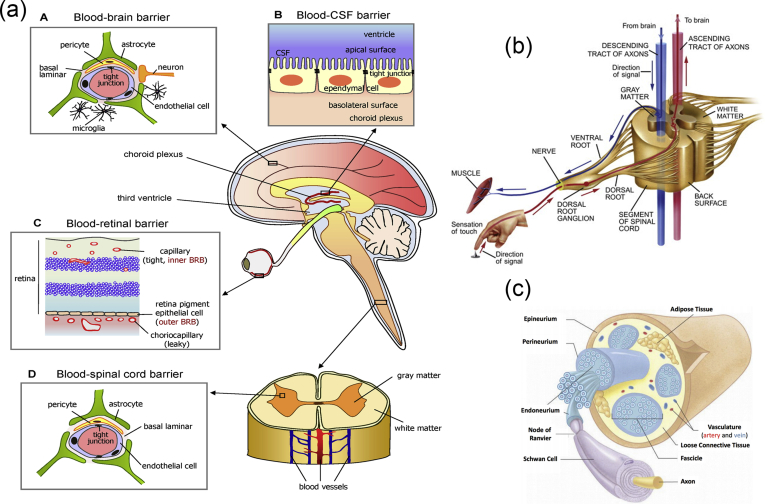

3. Applications in NTE

As mentioned previously, the vertebrate nervous system (Fig. 7) is subdivided into the CNS and the PNS. The main components of the CNS are the brain and the SC, but it includes also the optic, olfactory, and auditory systems owing to the fact that they are connected directly to brain tissue without intermediate nerve fibers. The PNS consists of cranial nerves that branch out from the brain, spinal nerves that branch out from the SC, and sensory nerve cell bodies (dorsal root ganglia - DRGs) and their processes.

Fig. 7.

Schematic representation of the major components of the human nervous system. (a) Anatomy of the brain and the blood-brain barrier [114], (b) cross section of the spinal cord [115], and (c) anatomy of the peripheral nerve [116]. Images reprinted with permission from (a) Choi and Kim [114], (b) McDonald et al. [115], and (c) Kuliasha et al. [116]. CSF, cerebrospinal fluid; BRB, blood-retinal barrier.

Neural tissue in both the CNS and PNS is composed of neurons and glial cells. Neurons are specialized cells that can receive and transmit chemical or electrical signals and consist of a cell body (soma) and its extensions (axons and dendrites). Clusters of sensory nerve somata are located just outside the spinal column and are known as ganglia. Dendrites transmit electrical signals to the neuron cell body, and the axon conducts impulses away from it. Glial cells provide support and protective functions for the neurons and include Schwann cells in the PNS and astrocytes and oligodendrocytes in the CNS. Although neurons and glial cells are found in both divisions of the nervous system, a large variation concerning the basic cell types and tissue organization can be observed between the two. One of the major differences between the CNS and PNS lies in their potential for regeneration. Peripheral nerves can spontaneously regenerate if the injury is small; therefore, suturing together the ends of the damaged nerves is sufficient to repair the defect. For larger injuries, transplantation using an autograft (tissue harvested from elsewhere in the body) is the gold standard. Thus, tissue engineering applications for peripheral nerve injury (PNI) treatment aim first to facilitate nerve regeneration and guidance and, second, to prevent fibrous tissue formation that impedes the regenerating nerve. In contrast, the CNS in adults shows little to no regeneration after physical or chemical damage owing to several limiting factors. The most important of these factors are the intrinsic inability of neurons for growth, the glial scar formation which creates physical barriers, and the presence of inhibitory molecules around the lesion area. Therefore, regeneration strategies for the CNS focus on transplantation of neural stem cells (NSCs) or differentiated neural cells in combination with the incorporation of growth factors and glial cells, which can create a permissive environment to promote neuronal differentiation. Consequently, the CNS and PNS responses to injury are distinctively different, and therefore, any therapeutic approach must be specialized accordingly. In the following section, we present an overview on how the biofabrication methods presented previously have been applied to address both PNS and CNS injuries.

3.1. PNI applications

As mentioned previously, the PNS consists of two types of cells: neurons and glial cells. The main function of the neurons of the PNS is the connection of the CNS with sensory and motor targets. To achieve this, the body of each nerve cell is located close to the SC or the brain, with a long axon extending as far as required. This axon is protected by the glial cells of the PNS, the Schwann cells, which wrap around the axons and form sheaths containing a protein called myelin. The presence of these sheaths is responsible for the insulation and enhancement of the signal that is transduced through the axon. The morphology of the peripheral nerves is complex as they form cable-like bundles and are surrounded by support tissue, creating anatomically defined trunks (Fig. 7c). Individual axons are covered by the myelin sheath, and both are covered by oriented collagen fibers, which create the endoneurium. A group of axons are bundled together with many layers of flattened cells and collagen creating a fascicle, which is wrapped around with a delicate sheath and is known as the perineurium. Finally, many fascicles are bundled together with blood vessels and fatty tissue and are wrapped around with a third protective sheath of connective tissue, a structure which is known as the epineurium. During the process of PNI, parts of the axons that are connected to a peripheral nerve become severed and degrade in a process called Wallerian degradation. In this case, the Schwann cells change to a proregenerative phenotype and secrete factors that assist axon regeneration, whereas the neurons themselves focus on the process of axon regeneration by initiating protein synthesis.

PNI treatments differ depending on the length of the gap that is created during the injury process. When the gap is small, the two ends of the severed axon can be surgically reattached. When the gap is significantly longer, healthy nerve segments from elsewhere in the body are used to reconnect the two nerve edges in a surgical process that is called an autograft. To avoid the use of autografts, there have been ongoing efforts to create implantable scaffolds which can be placed in the gap that occurs after nerve injury and can facilitate the regeneration of severed axons by providing support and guidance. The majority of these scaffolds are in the form of conduits that serve as guidance channels. A variety of fabrication methods have been used to create scaffolds for peripheral nerve regeneration, and these will be analyzed in the following paragraphs.

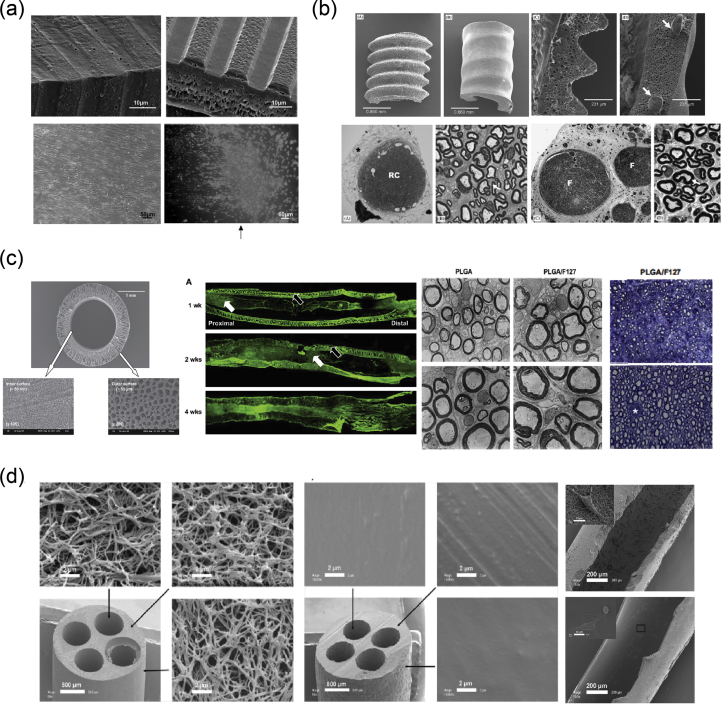

Yannas et al. [117] were the first to report that porous biodegradable collagen-glycosaminoglycan scaffolds, produced by a freeze-drying process, were able to induce regeneration of myelinated and unmyelinated axons over large distances (15 mm) between the severed ends of the adult rat sciatic nerve.

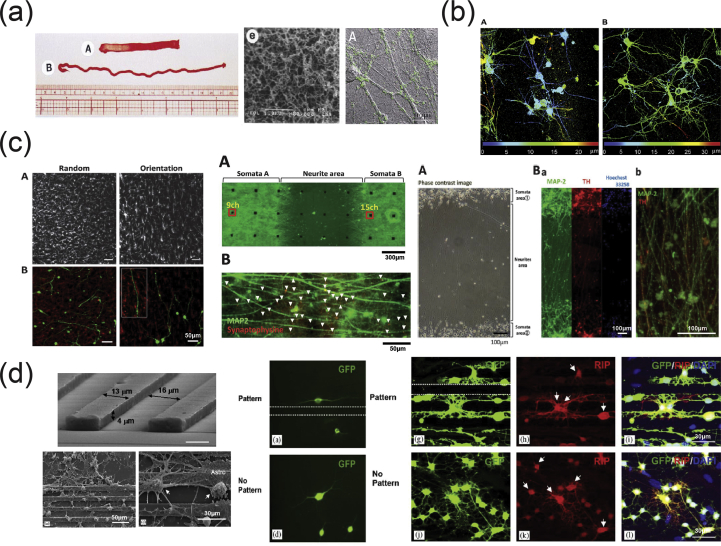

In 2001, Miller et al. [118] used both compression molding and solvent casting to produce microgrooved substrates made of poly-d, l-lactic acid (PDLA) (Fig. 8a), with the solvent casting method producing more stable substrates that exhibited lower degradation rates than the ones created through compression molding. The adsorption of laminin into the grooves and the optimization of groove width were found to be significant in promoting Schwann cell alignment, with grooves between 10 and 20 μm showing optimal results [118].

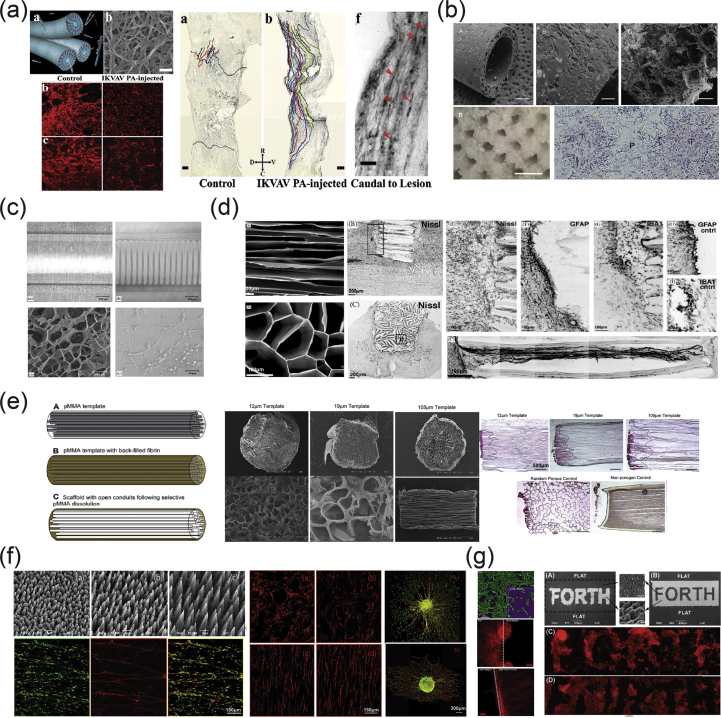

Fig. 8.

Fabrication of scaffolds for peripheral nerve regeneration applications through the use of conventional, porous, and molding methods. (a) Solvent cast, molded, microgrooved PDLA substrates were able to induce alignment in Schwann cell cultures (Miller et al. [118]). (b) Effect of reinforced PHEMA-MMA hydrogel tubes in the regeneration of a rat sciatic nerve injury model [120]. (c) PLGA/Pluronic F127 scaffold tubes were able to induce nerve regeneration in a rat sciatic nerve injury model [43], and (d) PLLA nanofibrous scaffolds were created without the use of electrospinning and showed good adherence of PC12 cells and fibroblasts [44]. Reprinted with permission from (a) Miller et al. [118], (b) Katayama et al. [120], (c) Oh et al. [43], (d) Sun et al. [44].PDLA, poly-d, l-lactic acid; PLGA, poly-lactic-co-glycolic acid; PHEMA-MMA, poly(2-hydroxyethyl methacrylate-co-methyl methacrylate); PLLA, poly-l-lactic acid.

Porogen leaching was used by Kokai et al. [42] to produce nerve guides made out of polycaprolactone (PCL). They were able to deposit a NaCl:PCL solution onto a mandrel, which, after drying and porogen leaching, created a porous nerve guide structure with 80% porosity and a pore size in the range of 10–38 μm. Although they did not directly test these scaffolds with cell cultures, they assessed their ability to be fouled as little as possible with lysozyme while also maintaining glucose permeability, which is required for cell growth within the scaffold structure.

In 2009, Chiono et al. [119] were able to produce non-porous nerve guides made out of PCL through the use of the melt extrusion technique. When tested in vivo for the repair of severed peroneal and median nerves in Wistar rats, they were found to be effective in promoting repair of small and medium nerve gaps (0.5–1.5 cm) but were ineffective when used for the bridging of longer nerve gaps (4.5 cm). As a result, further efforts were able to produce porous PCL scaffolds through the use of particulate leaching of a PCL/PEO solution, in which the PEO component was selectively dissolved by immersing in H2O to create the porous structure [13]. The obtained scaffold was then filled with a gelatin/genipin (GL/GP) solution, which upon freeze-drying forms a sponge-like structure. Cell adhesion and survival of PC12 and NOBEC cells were assessed on the GL/GP structure alone, while several NOBEC cells were also found in the gelatin of the porous nerve guides.

Belkas et al. [121] tested the capacity for peripheral nerve regeneration through the use of hydrogel nerve tubes. These tubes were created using poly(2-hydroxyethyl methacrylate-co-methyl methacrylate) (PHEMA-MMA), which is prepared by using 2-hydroxyethyl methacrylate (HEMA), methyl methacrylate (MMA) as the material to be polymerized, and ethylene dimethacrylate (EDMA) as a cross-linking agent as well as a redox-initiating system composed of ammonium persulfate and sodium metabisulfite. The final polymer blend produced was placed into custom-built disposable molds [122]. The hydrogel nerve tubes that were created through this process were measured to have an inner diameter of 1.3 mm and an outer diameter of 1.8 mm and were 12-mm long. The nerve tubes were implanted into adult male Lewis rats, which had undergone an 8-mm segment nerve excision in the sciatic nerve, and the nerve regeneration process was followed over a 16-week postimplantation period. The results were compared with the ones obtained when using the standard autograft technique, with nerve graft segments being obtained from isogenic donor rats. It is shown that although the difference between the hydrogel nerve tubes and the autografts was quite significant at 4 weeks after operation, with no axonal regeneration being seen in the PHEMA-MMA tubes, this was eliminated at 8 weeks after operation, and both categories exhibited similar regeneration rates. At 16 weeks after operation, 60% of tubes exhibited the same regenerative effects with the autografts, whereas the remaining 40% were significantly deteriorated owing to the collapse of the nerve tubes.

A follow-up study conducted in 2006 by Katayama et al [120] showed that the researchers were able to reinforce the hydrogel nerve tubes through the use of PCL coil structures within the mold (Fig. 8b). The ‘reinforced’ nerve tubes were implanted in the same way as described previously and were able to significantly improve nerve regeneration when compared with the gold standard of using autografts.

In another in vivo study, Oh et al [43] used the NIPS method to produce nerve guides made of poly-lactic-co-glycolic acid (PLGA) (Fig. 8c). Their fabrication technique included the immersion of an alginate hydrogel rod into a coPLGA/tetraglycol or PLGA/Pluronic F127/tetraglycol solution that were precipitated onto the alginate rod through the diffusion of H2O from the latter to the PLGA solutions. After washing with additional H2O, the resulting scaffolds were tubes made of PLGA and PLGA/Pluronic F127 (an additive that was used to make the PLGA more hydrophilic), respectively, with an inner diameter of ∼1.5 mm and a porous wall thickness of ∼0.4 mm. Further characterization of the tubular scaffolds was able to show that the PLGA/Pluronic F127 nerve guides had an asymmetric porous structure, with variably sized pores (∼50 nm on the inner tube surface and ∼50 μm on the outer tube surface). The in vivo tests were performed on Sprague Dawley rats and involved the severing of a 10-mm segment of the sciatic nerve and subsequent implantation of 12-mm scaffold tubes that were placed between the two severed nerve stumps. This work indicated that the addition of Pluronic F127 played an important role in the maintenance of the tubular structure of the scaffold, while also deterring the formation of fibrous scar tissue, thus resulting in better nerve regeneration behavior. This was estimated at 0.35 mm/day, with the 10-mm gap being bridged within the first 4 weeks, whereas at 12 and 24 weeks, the healed rat sciatic nerve also displayed a larger axon diameter and a thicker myelin sheath.

NIPS, in combination with microprinting, was also used to create nerve guides made of polylactic acid (PLA) [123]. More specifically, a PLA/dioxane solution was cast onto a negative PDMS microgrooved mold, and the resulting samples were placed into varying concentrations of the non-solvent ethyl alcohol (20%, 40%, and 95%) for 24 h. This process resulted in the formation of both symmetric and asymmetric porous structures, while scaffolds with the same porous structures but lacking the outer microgrooved pattern were also created. Cell alignment was tested using the BCRC-60046 glioma cell line, with the findings showing that the microgrooved pattern was able to induce alignment. The in vivo tests were along the same vein as the ones described previously, with the asymmetrically porous microgrooved scaffolds showing increased myelination rates at 4 and 6 weeks, compared with the symmetrically porous ones.

Sun et al. [44] used a combination of injection molding and TIPS to produce nanofibrous scaffolds without the use of electrospinning techniques (Fig. 8d). Through the use of a mold with varying numbers of acupuncture needles and a poly-l-lactic acid (PLLA)/tetrahydrofurane solution, they were able to create single- and multiple-channel scaffolds, by injecting the solution into the molds and inducing TIPS at −80 °C for 12 h. Control solid-walled scaffolds were also fabricated through the use of a solvent-casting method, in which a PLLA/dichloromethane (DCM) solution was placed into the same molds and placed into a fume hood to allow the evaporation of the solvent. By using different polymer concentrations, the length of the fibers forming the scaffold and its porosity could be adjusted accordingly. PC12 cells and fibroblasts that were seeded on the scaffolds showed better adherence to the nanofibrous ones than to the solid-walled ones, making the former good candidates for further optimization to facilitate the orientation of regenerating tissues.

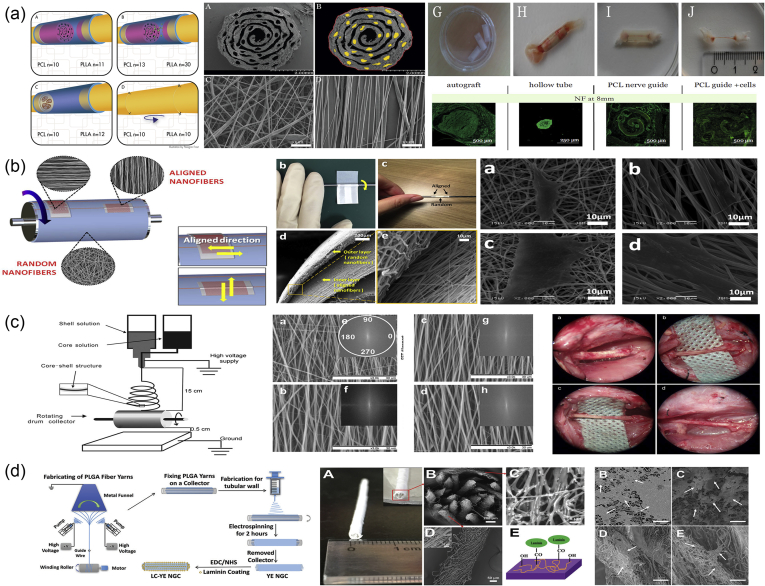

Electrospinning can produce highly aligned fibers of different diameters and, therefore, is ideal for the manufacture of nerve conduits. As a result, many scientists have used this technique for the creation of artificial grafts to replace peripheral nerve autografts (Fig. 9). In 2004, Bini et al. [124] created hollow tubes of PLGA electrospun nanofibers, which were collected using a rotating Teflon tube mandrel. The tubes were examined in the rat sciatic nerve model with a 10-mm gap, and the results showed good nerve regeneration, high tube stability, and no signs of inflammation. In a similar work, empty tubes made of biodegradable polymers (a blend of PLGA/PCL) were used for the repair of 10-mm defects in the rat sciatic nerve model (Fig. 9a) [125]. In addition, hollow tubes of electrospun fibers of a copolymer of PCL and ethyl ethylene phosphate (EEP) were rolled up and wrapped with a thin film of PCL/EEP to create conduits for peripheral nerve regeneration (Fig. 9b) [126]. For better results, scientists encapsulated human glial cell–derived neurotrophic factor (GDNF) into the electrospun fibers. The protein was randomly dispersed throughout the polymer matrix in aggregate form and released in a sustained manner for up to two months. Such conduits were tested in a rat sciatic nerve defect model and showed great regeneration in all groups and sufficient electrophysiological recovery, compared with control animals.

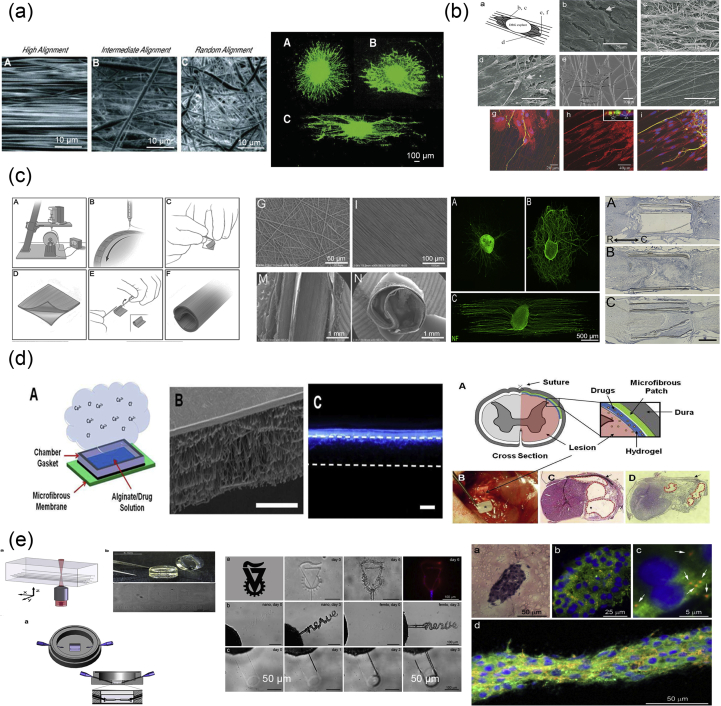

Fig. 9.

Fabrication of hollow conduits via electrospinning for peripheral nerve regeneration. (a) Hollow tubes of PLGA electrospun nanofibers used to bridge a 10-mm gap in a rat sciatic nerve [124], (b) hollow tubes made of biodegradable blend of PLGA/PCL used for the repair of 10-mm defects in the rat sciatic nerve [125], (c) a thin film of PCL/EEP was rolled up to create empty conduits for peripheral nerve regeneration [126], (d) silk fibroin conduits loaded with GDNF and NGF supported the growth of neural cells [127], and (e) ‘semisolid,’ 3D cylindrical constructs made of PCL fibers used for the reconstruction of 10-mm lesions in the rat sciatic nerve [129]. Images adapted with permission from (a) Panseri et al. [125], (b) Chew et al. [126], (c) Madduri et al. [127], and (d) Jha et al. [129]. PLGA, poly-lactic-co-glycolic acid; PCL, polycaprolactone; EEP, ethyl ethylene phosphate; GDNF, human glial cell–derived neurotrophic factor; NGF, nerve growth factor; 3D, three-dimensional.

To create conduits with adequate molecular and structural functionalities, Madduri et al. [127] developed silk fibroin (SF) conduits loaded with GDNF and nerve growth factor (NGF) (Fig. 9c). In the first step, SF films with GDNF and NGF were created through the air-drying method. Then, aligned and randomly oriented nanofibers were collected on the SF films, using two parallel electrodes or flat plates as collectors, respectively. SF films, decorated with nanofibers, were rolled around a Teflon-coated steel mandrel, and the ends were glued together to form conduits. Finally, the tubes were sprayed with PLGA to prevent release of the neurotrophic factors to the exterior of the conduit. Nerve conduits were seeded with Neuro-2A and PC12 cell lines, DRGs, and SC explants. The results showed good cell response and sustained release of neurotrophic factors for 4 weeks.