Abstract

Cattle are responsible more injuries and fatalities than any farm animal, and cattle-related nonfatal injuries are some of the costliest, requiring more time off work than other injuries. Though research has improved our understanding of cattle behavior, developed low-stress handling practices, and determined how facilities can be safer, injury rates remain high. This project identified the types of equipment commonly used on farms and assessed farmer perceptions of safety and barriers to implementing changes.

Methods:

A mixed methods study design was used for this research. The study was comprised of a survey (N=66) and four site visits conducted at operations focusing on different types of beef production in Iowa, U.S. Information collected included descriptive characteristics of the operator and operation, tasks carried out on the farm, handling facility components and design, and incidents of handling-related injuries.

Results:

Most farms cited that they utilized equipment like alleyways, a manual headgate, a sorting/diverter gate, and a manual squeeze chute. Farmers cited the cost of equipment, lack of necessity (their setup worked well already), and lack of time as being the main reasons they have not implemented changes on their operations. However, qualitative responses provided additional details and nuance to these responses, illuminating farmers’ anxieties related to farm transitions, knowledge, and trust of equipment sales personnel.

Conclusion:

This study provides health and safety professionals with additional details about why beef cattle producers may choose not to invest in safer handling equipment, even when they recognize the safety benefits of doing so.

Keywords: agricultural safety, cattle handling, mixed methods research

Introduction

The agriculture, forestry, fishing and hunting sector consistently ranks as having one of the highest occupational fatality rates of all industry sectors. In 2017, the fatality rate among U.S. farmers and ranchers was 24 per 100,000 full-time equivalent workers and about 100 agricultural workers per day suffered a lost-work-time injury.1 There are several types of injury risks to which those involved in agriculture are exposed, one of these is livestock. An evaluation of studies pertaining to injuries and fatalities associated with livestock handling reported that livestock handling activities were the second or third leading cause of on-farm injuries in most years, with machinery and fall-related injuries comprising other leading causes.2 Livestock handling injuries also tend to be more costly and result in more time off work than injuries stemming from other causes.2,3

Cattle are responsible for the most injuries and fatalities on farms of any animal.2,4 There are several mechanisms through which cattle can injure workers. These include kicking, trampling, goring, dragging, biting, pinning or crushing victims into fixed structures, striking an object and propelling it into the victim, and striking the victim and propelling them into another object.4–7 In addition, certain tasks have been found to be associated with higher rates of injury, including working cattle in enclosed areas, moving cattle between pens or pushing them (walking behind to encourage forward movement) through a facility, loading on and unloading from trailers, vaccinating and other processing, castrating, dehorning, and calving.3 Additional factors identified influencing the risk and the severity of injury while working around cattle include size of operation, layout of working facilities and types (or lack) of equipment used, the degree of experience a worker has, and whether a worker completes tasks alone.2,3,8,9

Equipment & Handling Facilities

Many cattle handling injuries are directly related to equipment, building structures, or the design of a working facility. Hubert et al. found that the most common locations for handling injuries tend to be pens, alleyways, and squeeze chutes and posed that 25% of cattle-handling injuries are associated with equipment used and the design of working facilities.10 Thus, efforts that aim to prevent handling injuries should be directed toward facility and equipment design, and should attempt to limit direct interaction between workers and cattle.2,3 Working pen construction, especially pen size and shape, is an important consideration, recognizing that pens are often used for multiple purposes.2,11 Pens that are too small for a task may put workers at risk because of overcrowding, but pens that are too large require more workers interacting with livestock.2

Safe alleyway construction should also be factored into the design of facilities and researchers have proposed various ideal alley shapes. These include curved alleyways leading up to a chute, or circular alleys that facilitate turning.12 There is general agreement that there should be no sharp right-angle turns in an alley because animals may lose sight of the stock ahead and become anxious. In addition, having solid-walled alleyways, pens, and ramps also contributes to calmer cattle during handling because their vision is obstructed, minimizing distractions from outside the handling area.12

Despite the prevalence of research outlining how to reduce injuries in cattle operations, injury rates remain high. In 2015, the nationwide incidence rate of total reportable cases of nonfatal injuries for livestock production was 6.9 injuries per 100 full-time workers, surpassing the crop sector’s incidence rate for the same year at 5.7 injuries per 100 full-time workers.13 According to the Bureau of Labor Statistics’ industry data on injuries and illnesses, not only do the incidence rates for the number of reportable cases of livestock injuries consecutively rank higher than those of the crop production sector, the incidence rates for the total number cases with days away from work, job transfer, or restriction do as well.14

Given the relationship of equipment and facilities with injury rates, this study used a mixed methods approach to identify the current equipment and facilities in use on Iowa beef cattle operations and illuminate the barriers faced by producers of adopting safer equipment and facilities on those operations.

Methods

Study Design

The goals of this study were to identify the types of handling equipment commonly used on Iowa beef farms and to more fully identify obstacles to implementing changes. A sequential, mixed methods study design was used for this research; an initial survey was followed up with an in-depth interview of a smaller sample of respondents. The survey collected both qualitative and quantitative data, including descriptive demographic characteristics of the operator and operation. Respondents also indicated tasks carried out on the farm, handling facility components and design, and incidents of handling-related injuries. For these questions, a list of options was developed based on the existing literature, respondents could “select all that applied” as well as provide additional comments. Operators were also asked to classify the type of beef production carried out on their farms. Options included cow/calf, backgrounding/stocker, feedlot, or other. If more than one option was selected, the farm was categorized as a multiple enterprise operation. The survey was developed and administered online through Qualtrics software.

The initial survey was followed by in-depth interviews with a one respondent from each type of operation: cow-calf, backgrounding/stocker, feedlot, and multiple enterprise.15 During the follow-up site visit interviews, the survey questions were used as a semi-structured interview guide as participants walked through their operation with the interviewer. The interviewer took detailed notes and photographs during the site visits. These interactions provided more in-depth information than the survey, enhancing our understanding of the nuances associated with identified “barriers” to safer facilities.

The survey was designed to be completed in 20 minutes or less, and the site visit interview and walk-through of the operation were estimated to take less than an hour but was ultimately at the discretion of the primary operator. The overall study protocol was approved by the University of Iowa’s Institutional Review Board. Consent for interview participation was verbal, consent for survey participation was indicated by completing the first page of the online survey.

Participants

Survey participants were recruited through the Iowa Farm Bureau16 and agriculturally-related Facebook communities. A letter of recruitment was emailed to Farm Bureau District 7 members registered in Des Moines, Henry, Jefferson, Lee, Van Buren and Wapello County via a district manager who expressed interest in the project. The letter of recruitment was also included in the Farm Bureau Spokesman, an agricultural newspaper, as part of an insert exclusive to the same counties listed above. A variety of agriculturally-related Facebook communities were utilized to recruit potential participants, and had the potential to reach participants not living in the targeted Farm Bureau district. These communities included buy, sell, and trade pages for everything farm-related and some pages exclusively used for cattle marketing. Cattle-related communities exclusively used for information-sharing between producers and those involved in the cattle industry were also targeted. Finally, members of Practical Farmers of Iowa (PFI) were contacted via email list serve asking for their participation in the study. PFI is an organization comprised of a diverse group of farmers that emphasizes farmer-led investigation and information sharing.

Farmers were eligible to participate in the study based on the following inclusion criteria: the respondent was at least 18 years old, they were the primary operator of the farm’s beef enterprise, and the farm they were representing was currently producing beef cattle. Screening questions at the beginning of the survey were used to ensure that these inclusion criteria were met.

Potential site visit participants were identified through the first author’s professional network of beef producers who reside in Farm Bureau District 7. One candidate who represented each of four different types of cattle enterprises was sent an informational letter and was asked to contact the first author if they were interested in participating in a site visit and interview. All candidates responded to the initial request, except for the first feedlot candidate, so a second feedlot producer was contacted. Interested primary operators contacted the researcher, verified that they met the inclusion criteria of the project, which was the same as for the online survey portion, and then approved a meeting time.

Data Collection

Once provided with the link to the survey, participants were able to complete the survey online through the Qualtrics website on their own time and wherever they chose. Participants were first prompted with an informational page providing details about the study, inclusion criteria, and consent. The respondent’s consent to take the survey was implied if they continued on to the survey items after reading the informational page. However, they could end the survey at any point after it began, and some chose to do so. In addition to the survey, four primary operators were interviewed in person at the site visits. During these visits, the survey instrument was used to collect quantitative and demographic data. The open-ended questions were used as a semi-structured interview guide with follow-up questions asked by the interviewer1 during a walk-through of each farm. These responses were recorded on paper at the time of the interview and were later typed up and entered into the Qualtrics survey. Additional comments, and detailed descriptions of the respondents’ farms were typed up as field notes.17

Data Analysis

Quantitative analysis was conducted using SPSS 24 and included generating descriptive statistics (ranges, means, standard deviations, and frequency counts and percentages) to characterize demographics of the primary operator and several aspects of the operation, including production type, herd size, and equipment and facility designs used. Risk estimates were analyzed and a bivariate analysis was conducted using Pearson’s Chi Square tests and Pearson Correlations to evaluate the relationship between demographic variables and the number of injuries.

The purpose of the mixed-methods approach for this study was to collect qualitative data that would provide more depth and nuance than simple survey response selections.18 The qualitative data collected from the survey and interviews were manually coded and analyzed by two members of the research team to identify themes. Codes were a priori, based on the survey questions and focusing in particular on the most frequently indicated barriers to implementing change.19 For example, because “cost of equipment” was a frequently noted barrier to making changes, all qualitative responses and interview notes were read and coded for references to cost. Contextual data were then extracted for analysis and comparison with other responses to better understand respondents’ perceptions related to “cost of equipment,” as described below.

Quantitative Results

Sixty-six participants began the survey; because respondents could decline to answer any questions, not all questions had a response rate of 66. Sixty provided demographic information, of those, 42 (70%) were male and 18 (30%) were female. Twenty-seven (45%) respondents reported that they were within the age 30–49 category. Seventeen (28.33%) identified as between ages 50–64, 14 (23.33%) were between 18–29 category, and two (3.33%) were age 65–79. The majority of the operations (72.41%) had produced cattle 16 years or more, ranging anywhere from 18 to 165 years, with a mean of 62.08 years.

Fifty-eight individuals responded to the questions about the type of operation, 91.40% reported that they were a cow/calf operation, 13.80% were a backgrounding/stocker operation, 36.20% were a feedlot operation, and 10.30% considered themselves to be a different type of operation. These percentages do not add up to 100%, as respondents could select multiple responses, and were therefore considered a multiple enterprise operation. Overall, 41.38% of farms could be classified as multiple enterprise operations.

Equipment and Facilities

Fifty-two participants indicated where they most frequently work with their cattle, and on what type of surface. The highest proportion (40.38%) work their livestock inside a barn, shed, or other building exclusively. Others (36.54%) utilize both indoor and outdoor space, and some (23.08%) work stock exclusively outside. With the varying locations that tasks are completed also comes a variety of ground surface conditions. Most operators (63.46%) indicated that they worked stock only on dry, non-slip floor surfaces. Dirt was a commonly mentioned surface, both indoors and out. For those working on dirt outside, many elaborated (using “other” as a response) that they would work around weather conditions to avoid working in muddy conditions. Twenty one percent of operations reported their facilities had both dry, non-slip and wet, slippery floor surfaces.

Respondents also selected all the types of equipment that were used on their farm, shown in Figure 1. Most farms (over 50%) reported at least having an alley, a manual headgate, a sorting/diverter gate, and a manual squeeze chute to work stock. Hydraulic headgates and chutes were less prevalent, with 24.49% and 10.20% of farms reporting their use respectively. Six farms indicated having a bud box2, but this was not a pre-determined option provided to them in the question and the option was written in under the “other” category. Along with identifying the types of equipment used on the operation, respondents also were asked whether the piece was a recent purchase within the past five years.

Figure 1 -.

Type of Equipment and Recent Purchases on Respondents’ Farms

Operators were asked to describe additional changes that were made to handling facilities within the past five years. Responses (N=28) included descriptions of increasing the stability and secureness of gates and fences, complete redesigns and updates of facilities, and also an increased focus on low-stress handling and other efforts conscious of the health of the stock.

Barriers

Operators were asked whether they felt that their handling facility was optimal for safely working cattle and whether they would like to change anything about the existing setup to make it safer. Of the 53 who responded, 57.69% of the operators felt that their setup was safe, as opposed to 42.31% who felt theirs were not. When asked if they would like to change their operations to improve safety, 71.15% (of 52 responses) indicate they would, and 28.85% said that they would not. Seventeen respondents who described their facility as being safe still expressed a desire to make changes to improve safety. Conversely, two respondents who did not feel that their facility was safe for handling livestock still said that they would not make changes to increase its safety.

Of the 37 operators who said they would make changes to increase the safety of their handling facility, 30 provided comments indicating what they would like to improve. The most commonly cited change was to purchase new equipment to integrate into the facility (46.67%). New head gates and squeeze chutes were frequently listed. Other commonly indicated changes were to redesign one element or all of the facility (40.00%) and to make fixtures, particularly gates and fencing, more permanent (40.00%). Less frequently, respondents indicated a desire to improve the stability of existing permanent gates and fences (20.00%), reduce contact between workers and cattle (20.00%), improve floor surfaces (13.33%), and design and implement worker escape routes (10.00%).

Regardless of whether participants responded that they would change anything to make their setup safer, all were asked to identify the reasons why they have not made changes to their operation. In other words, respondents were asked what barriers prevented them from implementing safe equipment and facility designs. Multiple choices could be selected, and a text box was provided for narrative responses.

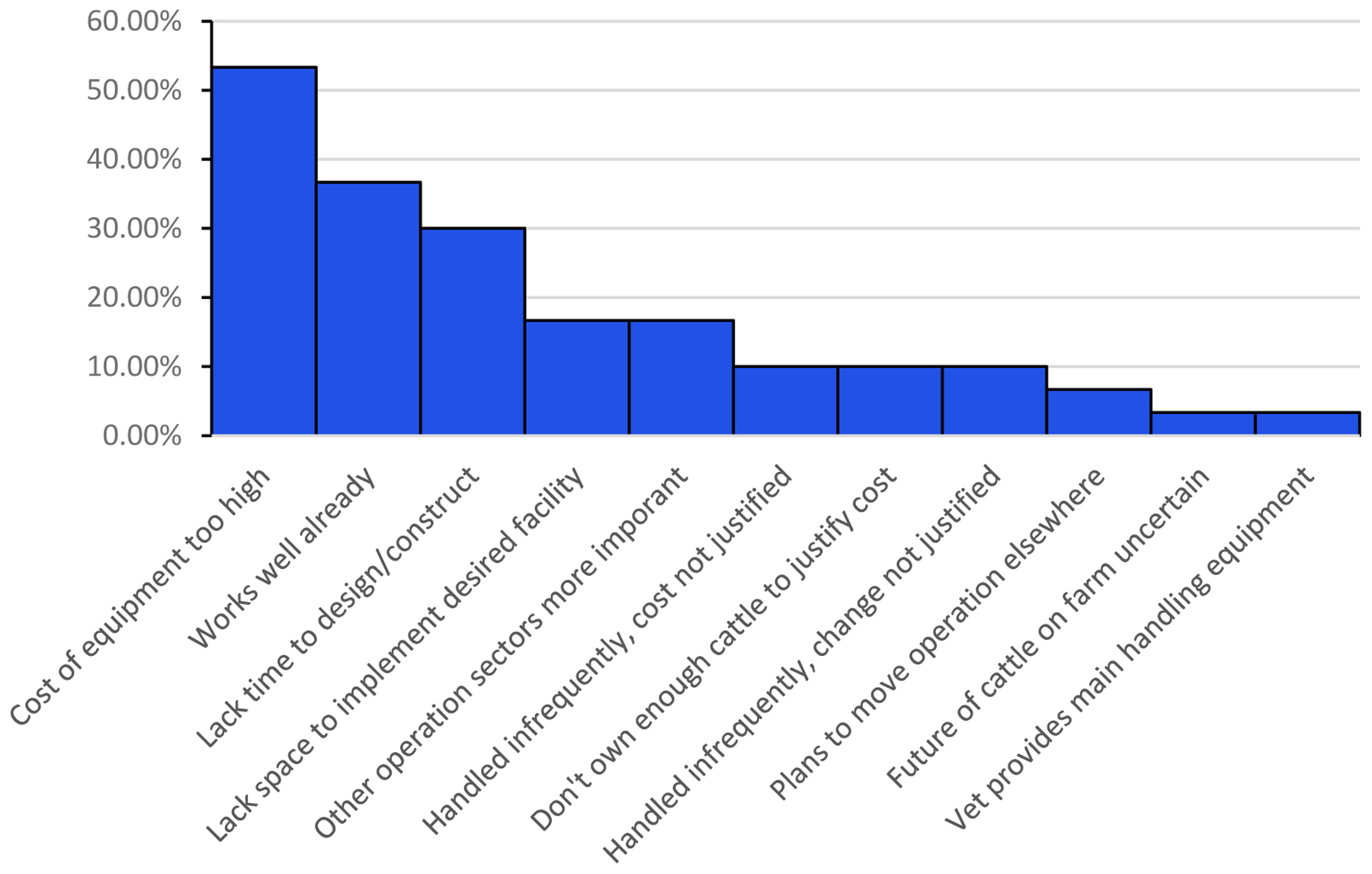

Figure 2 shows how frequently different barriers were selected.

Figure 2 -.

Overall Barriers to Making Changes on Operations

After selecting all of the barriers to implementing changes on their operations, operators were asked to select the three they felt to be most important or influential. Figure 3 below shows the barriers that were most often cited by respondents as being within their top three.

Figure 3 -.

Barriers Identified as Most Influential

Qualitative Results

In addition to identifying their top three reasons for not implementing changes, respondents were asked to provide additional details about how they made those selections. The qualitative components of the survey as well as the on-site interviews with four producers provided additional nuanced detail not captured by the check box selections, particularly relating to issues of priority or other factors of farm life.

Cost of Equipment Too High

In relation to financial priorities, one respondent noted, “A squeeze chute alone, that is not of the quality or has the features we desire, is around $6,000. Equipment depreciates in value, so my $6,000 would be better spent investing in breeding stock and return money to my operation.” Another noted, “cattle are not worked enough to justify purchase and money better spent elsewhere.” A third wrote:

Cost is really what prevents us from doing anything. Aside from cattle, we also have other livestock and raise our own hay. Extra money goes towards what is most important at the time. We are also trying to grow, which has been an effort over the past few years, so we have made investments in other areas and this one as we can. But we just have to use what we can to get by.

These comments place the priority of safety investments in the context of the rest of the farm operation. Another commented on family life as a competing factor:

Up until last year, the family had not been getting along very well. Because of this, we were unsure of what impacts this would have on the farm. Things are still on edge at times, so it has kind of been a trial run around here with this generation. I just don’t know whether I want to put forth the time, effort and money since I’m not even sure if there’s going to be a farm in the coming years.

Others also noted the larger economic context, such as this example: “Money! The market fluctuates to [sic] often to know if you can afford to make changes, so the only time something new is bought is when the old breaks or no longer functions properly.”

Works Well Already

This is the second most frequently checked reason for not making changes and one respondent reinforced it by writing “If it’s not broke why fix it” in the text box. Others provided more details, again placing the change in the context of their specific operation. One noted, “I set it up to work for me ‘a mostly one-man operation.’ I haven’t had any problems, so why change something that is working?”

Others put the decision in the context of future plans, noting that, even though they see room for improvement, they want to wait until they had made all final decisions. The producer wrote, “The set-up also hasn’t changed because we have kicked around the idea of putting up a new facility for a while, so we didn’t want to invest much if it was just going to change entirely.” Another reported, “Plans to move elsewhere—debates over moving the main handling facility to a different property closer to where we live and maintained another herd.”

Lack of Time

Lack of time was the third most frequently indicated barrier to change. As with the first and second ranked reasons, respondents provided in some depth the context of this barrier. Some put the issue of time into the context of other work. One noted, “Lack of time-work part time off farm.” Other work is relevant on the farm too: “Don’t work cattle enough to really make it a priority to re-do or change.” Another explained:

Time is the main reason; herdsmen work many hours a week. When the farm boss tries to lessen our workload by not having us do certain tasks, he finds more things for us to do instead. We really would need someone from a different enterprise on this farm to come do it, but I would prefer to do it myself so I know it’s done right

In addition, some pointed out that the installation of new facilities or adoption of new equipment was only one step in a longer process. One noted, “If we were to implement something, it would take time to tweak it to get it where we wanted it.” Ongoing changes to facilities were also emphasized. During one interview, a cow-calf operator described numerous small changes over the past five years. At this farm, the tub, alley, and chute were all rotated to reverse the flow of cattle and make the process much smoother for both the handlers and the cattle. Gates were moved around to change paths to other pens and the load-out area, and some temporary gates were replaced by more permanent steel pipe fencing. The lanes on the outside edges of the staging pen that lead up to the barn were also narrowed over time to about ten feet wide, but the primary operator explained that they intend to narrow them even more to prevent cattle from turning back towards the pen.

Another survey respondent described the time required to implement the initial design:

Don’t really know how to get started. I’m not sure entirely what I would envision a re-design to look like on the operation, so I need to do some thinking on that…I also don’t know who to go through about designing. I can build it myself, but would just like to consult with someone about how to design it. I can kind of get an idea by looking at existent and suggested layouts, but I of course have to adapt that to my needs and resources. I also don’t really want to talk with a salesman because I will always question their motives; are they trying to help me or are they just trying to make a buck?

Discussion

More than half of the study participants indicated a desire to improve the safety of their livestock handling facilities. They most commonly indicated a need for new pieces of equipment, redesigning some or all of the handling facilities, and to make existing facilities more permanent. The high percentage of responses indicating a desire for change suggest that livestock producers are well aware of the safety deficits of their existing facilities.

Participants selected “high cost,” “current system works well already,” and “lack of time to redesign or construct new facilities” as the three top barriers to making change in their current system. These responses are consistent with other literature.20–22 However, the qualitative results provided both in the survey and during the walk-through interviews illuminate additional nuance in decision making processes not captured by the survey.

Notably, those who indicated that the cost of equipment was too high put that cost in the context of their overall operation. Respondents described the competing priorities on their farms, pointing out that any equipment purchased would depreciate in value over time, and that they had to balance an investment in livestock facilities with other areas of their farm operation. Thus, these responses indicate that the cost of improved handling facilities is not objectively out of financial reach for these farmers; rather, that it is not a high enough priority in the context of the overall farm operation. In addition, some participants alluded to additional anxieties and challenges related to overall family stress and farm transition. A sense of economic precarity, or the fear that the next generation would not take over the farm, also contribute to the response that cost is a barrier to making change.

Those who indicated that their current set up “works well already” also provided more contextual information that provides insight into producers’ decision making process. In most cases, they indicated that, although their system works, they recognize that it could be improved. However, any changes would need to fit in with other potential operational changes. Some were anticipating moving facilities to different areas on their farms, and wanted to ensure that any facility changes were appropriate for a new location. Thus, the statement “works well already,” may include the caveat “for now.” Those producers who are anticipating other changes in their operation wanted to ensure that livestock facility upgrades would be compatible with other parts of the system.

Finally, those who indicated that there is a lack of time to implement changes also suggested that anxieties about knowledge and resources contribute as well. These respondents recognized that the time and effort involved in new facilities or equipment are not limited to the time it takes to install and/or build the new physical structures. Several pointed to the time in planning and designing, as well as the anxiety that is associated with their lack of knowledge about how to proceed. In addition, some expressed concern about finding a person they could trust to help them make these decisions. Some were skeptical of sales people and felt unsure about who to contact to help them through the process.

Taken together, these responses provide suggestions for health and safety professionals who are interested in encouraging investment in safer livestock handling facilities. Such consultants should be prepared to ask more questions when producers cite common barriers to making changes for safety. General concerns about cost may actually reflect how producers prioritize costs, not indicate a lack of ability to pay for improvements. This suggests that safety professionals should be ready to articulate how investments in safety have economic value and offset the risk of purchasing equipment that may depreciate in value. Those producers who suggest that their facilities work well enough may be planning other changes; safety professionals should be prepared to consult with producers on all aspects of their farm management, not just isolated livestock facilities. Finally, those who are concerned about a lack of time may be indicating that they lack knowledge about how to go about redesigning facilities. They may also lack trust in salespeople or other potential advisors. This provides an opportunity for health and safety professionals to provide valuable consultation and input not driven by sales motives.

Limitations

Although this study provides nuanced information not captured in prior research on cattle handling safety, it suffers from some limitations. The sample size was very small and calculating a precise response rate was impossible because the online distribution of the survey link did not allow for identification of all potential participants. The focus on Iowa beef producers may not be representative of all beef producers and the small number of responses limits the generalizability of the results. In addition, selection bias is a concern with this research, as respondents may be individuals with a higher interest in safety than the general population of beef producers. Ultimately, this study may provide avenues for further investigation, rather than generalizable results.

Conclusion

Most of the producers in this study had long-term (more than 16 years) experience handling cattle. Their farm operations included a combination of equipment, in many cases with homemade structures, for cattle handling. Most also expressed a desire to improve the safety of their operations. However, they noted several barriers to making changes, most commonly that the cost of upgrades is too high, that their current set-up worked well already, and that they lacked the time to design or build a new system. Qualitative data collected in the online survey and during the interview provided more nuanced discussions of these basic categories of cost, function, and time, revealing how producers prioritize safety in their operations and the anxieties that they may feel with regard to farm succession, integrating livestock facility changes with other production strategies, and their own lack of knowledge about how to go about designing and purchasing new equipment. These results provide guidance for health and safety professionals, who should be ready to consult on a range of topics beyond isolated livestock equipment, recognizing that decisions about livestock handling equipment are ultimately related to many other factors on the farm.

Funding information

National Institute for Occupational Safety and Health, Grant/Award Number: T42OH008491

Footnotes

Interviews were conducted by the first author, who has experience with beef cattle production and received guidance on qualitative data collection from the research team.

A bud box system utilizes a rectangular pen with an attached alley. Cattle are brought into the pen past the opening to the alley, and a gate is shut behind them so that they cannot see from whence they came. Cattle are then worked from the opposite corner of the pen from the alley. They will turn back towards the gate and see that it is closed, and seek the next route of escape, which is the alley leading to a chute or load-out

References

- 1.National Census of Fatal Occupational Injuries in 2017. In: Statistics BoL, ed. Washington, DC2018. [Google Scholar]

- 2.Dogan K, Demirci S. Livestock-Handling Related Injuries and Deaths In: Javed K, ed. Livestock Production. 1 ed.: Intech; 2012:81–116. [Google Scholar]

- 3.Douphrate DI, Rosecrance JC, Stallones L, Reynolds SJ, Gilkey DP. Livestock-Handling Injuries in Agriculture: An Analysis of Colorado Workers’ Compensation Data. American Journal of Industrial Medicine. 2009;52(5):391–407. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Drudi D Are Animals Occupational Hazards? Compensation and Working Conditions. 2000;5(3):15–22. [Google Scholar]

- 5.Browning SR, Westneat SC, Sanderson WT, Reed DB. Cattle-Related Injuries and Farm Management Practices on Kentucky Beef Cattle Farms. journal of Agricultural Safety and Health. 2013;19(1):37–49. [DOI] [PubMed] [Google Scholar]

- 6.Norwood S, McAuley C, Vallina VL, Fernandez LG, McLarty JW, Goodfried G. Mechanisms and Patters of Injuries Related to Large Animals. The Journal of Trauma: Injury, Infection, and Critical Care. 2000;48(4):740–744. [DOI] [PubMed] [Google Scholar]

- 7.Fox S Worker Injuries Involving the Interaction of Cattle, Cattle Handlers, and Farm Structures or Equipment: Animal Sciences and Industry, Kansas State University; 2011. [DOI] [PubMed] [Google Scholar]

- 8.Maltais V Risk Factors Associated with Farm Injuries in Canada. In: Statistics Canada; 2007. [Google Scholar]

- 9.Watts M, Meisel EM, Densie IK. Cattle-related trauma, injuries and deaths. Trauma. 2013;16(1):3–8. [Google Scholar]

- 10.Hubert DJ, Huhnke RL, Harp SL. Cattle Handling Safety in Working Facilities. Stillwater, OK: Oklahoma State University Extension;2017. [Google Scholar]

- 11.Stafford K Cattle Handling Skills In: Massey University Institute of Veterinary Animal and Biomedical Sciences, ed: New Zealand Accident Compensation Corporation; 2005. [Google Scholar]

- 12.Grandin T The design and construction of facilities for handling cattle In. Fort Collins, CO 80523: Animal Science Department, Colorado State University; 1997. [Google Scholar]

- 13.Statistics BoL. Employer-Reported Workplace Injuries and Illnesses-2015. United States: Department of Labor;2016. [Google Scholar]

- 14.Bureau of Labor Statistics. Injuries, Illnesses, and Fatalities. 2017; https://www.bls.gov/iif/oshsum.htm#14Summary_Tables.

- 15.Woolley CM. Meeting the Mixed Methods Challenge of Integration in a Sociological Study of Structure and Agency. Journal of Mixed Methods Research. 2009;3(1):7–25. [Google Scholar]

- 16.Iowa Farm Bureau. About. 2017; https://www.iowafarmbureau.com/About#farmersAgriculture.

- 17.Emerson RM, Fretz RI, Shaw LL. Writing ethnographic fieldnotes. Chicago: University of Chicago Press; 2011. [Google Scholar]

- 18.LeCompte MD, Schensul JJ. Analysis and interpretation of ethnographic data : a mixed methods approach. 2013. [Google Scholar]

- 19.Bernard HR. Research Methods in Anthropology: Qualitative and Quantitative Approaches, Fourth Edition Lanham, MD: AltaMira Press; 2006. [Google Scholar]

- 20.Murphy DJ, Myers J, McKenzie EA, Cavaletto R, May J, Sorensen J. Tractors and Rollover Protection in the United States. Journal of Agromedicine. 2010;15(3):249–263. [DOI] [PubMed] [Google Scholar]

- 21.Yoder AM, Murphy DJ. Using Social Marketing to Address Barriers and Motivators to Agricultural Safety and Health Best Practices. Journal of Agromedicine. 2012;17(2):240–246. [DOI] [PubMed] [Google Scholar]

- 22.Sorensen JA, Jenkins PL, Emmelin M, et al. The Social Marketing of Safety Behaviors: A Quasi–Randomized Controlled Trial of Tractor Retrofitting Incentives. American Journal of Public Health. 2011;101(4):678–684. [DOI] [PMC free article] [PubMed] [Google Scholar]