Abstract

Introduction

The 2.5 hour Foundations for Safety Leadership (FSL) training program teaches construction supervisors the leadership skills they need to strengthen jobsite safety climate and reduce adverse safety-related outcomes.

Methods

Using a quasi-experimental prospective switching replications study design, we examined (1) if FSL-trained jobsite safety leaders would report improved understanding and practice of the FSL leadership skills, safety practices and crew reporting of safety related conditions, and (2) if their crew perceived a change in (a) their supervisors’ practices, (b) their own safety practices and reporting of safety-related conditions, and (c) overall jobsite safety climate.

Twenty construction sub-contracting companies were recruited and randomly assigned to either an early or lagged-control training group. Participating supervisors and workers completed surveys at multiple time points before and after the FSL training. We used linear mixed modelling to test changes over time.

Results

Only supervisors in the early group reported a statistically significant improvement in their understanding and practice of the leadership skills as well as safety practices from before to 2- and 4-weeks post-training. Overall, no significant change was detected in crew-reported outcomes from before to after their supervisors’ participated in the FSL training.

Conclusions

These results provide evidence that the FSL training can, at least in the short-term, improve construction frontline leaders’ jobsite leadership skills. Future research could include an evaluation of FSL refresher activities and a longer-term follow-up.

Practical applications

The Foundations for Safety Leadership (FSL) program fills an identified need for construction frontline supervisors to learn and practice critical safety leadership skills on the jobsite. It has already reached over 10,000 leaders and has the potential to reach over 100,000 each year during either an OSHA 30-hour or a stand-alone course.

Keywords: safety culture, intervention, training, occupational health and safety, transformational leadership, safety climate, construction foremen

INTRODUCTION

Safety leadership, conceptualized as a multidimensional construct reflecting a value for safety, is demonstrated through actions and practices that can directly influence worksite safety (Barling, Loughlin, & Kelloway, 2002). Recent research across multiple industry sectors, including construction, has shown that there is a relationship between safety leadership, safety climate (i.e., employee perceptions of company commitment to jobsite safety), and other safety outcomes (Clarke, 2013; Hoffmeister et al., 2014). Despite the evidence, few training interventions have been created and implemented to improve frontline supervisors (henceforth called safety leaders) leadership skills and evaluate the effectiveness of such training to improve safety leadership practices and jobsite safety climate in the construction industry.

Fifteen years ago, Zohar et al. (2003) developed a feedback-based training program to increase the frequency of safety communication (one dimension of safety leadership) between supervisors and workers employed in a manufacturing setting. After implementing the program they observed an increase in supervisor-worker safety communication and improved worker safety climate perceptions. Kines et al. (2010) tested a similar intervention amongst construction supervisors and their crews and found comparable results. Mullen and Kelloway (2009) evaluated the impact of a 1-day training program provided to Canadian healthcare industry leaders that covered general and safety-specific transformational leadership theory and goal setting. Compared to a control group, those receiving the training showed a positive change in safety attitudes, self-efficacy, and intentions to promote safety and employee reports of improved safety leadership practices and safety climate.

More recently, von Thiele Schwarz et al. (2016) evaluated the effectiveness of a twenty-day leadership training program with Swedish forestry leaders and their workers that included 360 degree feedback, didactics, goal setting, and on-the-job practice. Their findings showed a positive change in leader safety leadership practices and worker reported safety climate. In a recent process evaluation article (i.e., no outcome data were collected), Jeschke et al. (2017) described the successful implementation of a 22-hour training program for construction site supervisors in Denmark that included topics such as communication, conflict management, and safety. Finally, Bronkhorst et al. (2018) evaluated a six-month, multi-faceted intervention in which senior management in five healthcare companies conducted safety walk-arounds, supervisors’ completed safety leadership training, and all team members participated in an online platform where they could discuss safety issues. Findings showed evidence of a positive change in safety climate and safety participation in the intervention group only.

Beyond this empirical evidence, construction industry stakeholders attending a 2013 CPWR/NIOSH sponsored safety climate/culture workshop identified ‘Improving Supervisory Leadership’ as a key leading indicator of a strong jobsite safety climate (CPWR: The Center for Construction Research and Training, 2013). The stakeholders remarked that to improve safety climate, companies need to distribute safety responsibilities to frontline leaders who have the skills to (a) communicate their own values and the company’s values and expectations for safety, (b) coach and teach crew members about safety, (c) motivate all employees to participate in the safety program, and, most importantly, to (d) lead by example. This feedback, along with the empirical evidence reported above, led our research team to develop the Foundations for Safety Leadership (henceforth referred to as FSL) training program (see Goldenhar et al. (provisionally accepted) in this issue for more detail on the FSL).

The two overarching goals of this study were to assess if after FSL training: 1. frontline construction company supervisors would report a greater understanding and increased practice of the learned safety leadership skills, improve their own safety practices, and report improved crew reporting of safety related conditions and 2. their crew members (henceforth referred to as workers) would perceive an improvement in their leaders’ use of safety leadership skills, their own safety practices and reporting of safety related conditions, as well as a stronger jobsite safety climate.

METHODS

FSL Training Intervention

The FSL is a 2.5-hour training program designed to address the construction industry’s stated need to improve foremen and frontline leaders’ safety leadership practices, strengthen overall jobsite safety climate, and ultimately reduce the incidence of adverse health and safety outcomes. Creating the program was a collaborative effort carried out by a 17-member curriculum development team that included Occupational Safety and Health Administration (OSHA) 30-hour trainers, safety and health professionals from small and large construction companies (both union and non-union), as well as researchers from CPWR and 4 universities. The training materials cover the direct and indirect costs of ineffective safety leadership, the benefits of effective safety leadership, and how to practice the five critical safety leadership skills on the jobsite. The five safety leadership skills emphasized during the training include: Leading by example, Engaging and empowering team members, Actively listening and Practicing 3-way communication, Developing team members through teaching, coaching and feedback, and Recognizing team members for a job well done. These skills closely align with the four core factors of safety-specific transformational leadership (Barling et al., 2002; Mullen & Kelloway, 2009). After learning the didactic material presented in section 1 of the module, students have the opportunity to apply the concepts by working through a number of real-world construction scenarios. On January 1, 2017, the Occupational Safety and Health Administration (OSHA) approved the FSL as an official 2.5-hour elective in their 30-hour course and all FSL training materials and other related resources were uploaded to CPWR’s website so the FLS can also be used as a stand-alone training and educational activity (CPWR: The Center for Construction Research and Training, 2018). Since the official roll-out well over 10,000 leaders have received the training. A full description of how the FSL evaluation instruments were developed and pilot-tested can be found in this issue (Goldenhar et al. (provisionally accepted).

Study Participants

Companies

A power analysis indicated that at least 200 leaders and 1000 workers needed to participate in the study to detect any change in safety climate perceptions from before to after the FSL training. To meet this goal, we used a purposeful sampling strategy (Patton, 2015) to identify sub-contracting companies that employed at least 10 foremen who supervised at least 5 workers and would participate in the training. To maximize the generalizability of the study’s results, we recruited companies that were diverse in union status, geographic location, and trade risk based on Bureau of Labor of Statistics injury and fatality data (Bureau of Labor Statistics, 2018). We also recruited small, medium, and large companies as defined by the number of full-time equivalents.

The company contact, typically the owner or safety director, identified and provided names and jobsite location of potential leaders and workers to participate in the study. The research team obtained permission from the contact to visit jobsites during morning/afternoon huddles or scheduled meetings to explain the study objectives to the work crews, describe the logistics of participation, and obtain their consent. The majority of leaders and workers chose to participate. Each who did was given a unique identifier, which we used to track survey responses over time.

Leaders and Workers

We recruited leaders, defined as foremen or other frontline lead workers, as well as their crew members, defined as someone in a non-supervisory role who worked directly for the leaders, to participate in the study. At the initial jobsite visit, leaders who consented to participate completed a baseline survey, were reminded that there would be follow-up surveys and were asked to attend an FSL training which would be conducted at a convenient time identified by the company contact. There was no cost to attend the training and a meal was always provided. Workers who consented also completed a baseline survey, were informed of follow-up surveys, and received a five-dollar gift card for each survey completed.

Trainers

In each geographic location (detail below), we identified and recruited instructors to conduct the FSL sessions who did not work for the participating company and had previously conducted occupational health and safety training programs with construction workers. All trainers attended a train-the-trainer session during which they participated in the full FSL and were instructed not to deviate from the procedures outlined in the FSL instructor guide when they conducted the training. Trainers were compensated for the time spent preparing for and delivering the training. At least one member of the research team was present at each FSL training session and was responsible for collecting immediate pre and post-training surveys.

Study Design & Data Collection

Design

Our industry partners informed us that companies would be less inclined to participate in the study if there was a chance they would be assigned to a control group in which their leaders would not receive the training. Therefore, rather than a randomized controlled trial, we used a quasi-experimental prospective switching replications study design to evaluate the FSL training (Sadish, Cook, & Campbell, 2002). The design includes an early and lagged-control group and four waves of data collection (Table 1). Specifically, leaders in the early group completed surveys immediately before and after the training as well as approximately 2- and 4-weeks after the training. Their workers were asked to complete a survey 1-week before as well as 2- and 4-weeks after the training. The 4-week post-training data gathered from the early group was used to assess sustained training impact. Leaders in the lagged-control group completed surveys 4-weeks prior and immediately before the training, as well as immediately after and 2-weeks post training. Since we asked lagged-control group participants to complete a survey 4-weeks prior to the training, which we used as control data, we limited their survey burden by not asking them to complete another one 4 weeks post-training. This design is strong with respect to internal as well as external validity or generalizability and is one of the most ethically feasible designs as it assured that leaders from all companies eventually participated in the FSL training. All study procedures and materials were approved by the University of Colorado Boulder Institutional Review Board.

Table 1 -.

Data collection time points by intervention group

| Intervention group | |||

|---|---|---|---|

| Early | Lagged-Control | ||

| Survey data collection before and after FSL training | Leaders | Immediately before (Pre_T0) | 4-weeks before (T-2) |

| FSL TRAINING | Immediately before (Pre_T0) | ||

| Immediately after (Post_T0) | FSL TRAINING | ||

| 2-weeks after (T+l) | Immediately after (Post_T0) | ||

| 4-weeks after (T+2) | 2-weeks after (T+l) | ||

| Workers | 1-week before (T-l) | 4-weeks before (T-2) | |

| LEADERS’ FSL TRAINING | 1-week before (T-l) | ||

| 2-weeks after (T+l) | LEADERS’ FSL TRAINING | ||

| 4-weeks after (T+2) | 2-weeks after (T+l) | ||

Surveys

To assess the impact of the FSL, we developed pre- and post-training surveys to collect data from the trained leaders and the workers they oversee. In addition to demographics, the surveys included items to measure the outcome variables presented in Table 2. A full description of survey development, including items, scales, and reliability testing can be found in Goldenhar et al. (provisionally accepted).

Table 2 -.

Outcome Variables (All measured using 1–5 Likert response scales)

| Leaders | Workers |

|---|---|

| • Understand leadership skills • Use leadership skills • Use safety practices • Crew’ reporting safety-related conditions |

• Leader’s use leadership skills • Safety climate • Use safety practices • Self-reporting of safety-related conditions |

Data Analysis

To assess the effectiveness of the FSL, we conducted linear mixed modeling analyses with Stata version 14.2 (StataCorp, 2015) to test the following hypotheses:

H1: Compared to the leaders in the lagged-control group (Pre_T0, ref = T-2), the leaders in the early group will show an increase in their:

Understanding of the leadership skills (Post_T0, ref = Pre_T0)

Use of leadership skills (T+1, ref = Pre_T0)

Use of safety practices (T+1, ref = Pre_T0)

Crew reporting of safety-related conditions (T+1, ref = Pre_T0)

H2: Compared to workers of leaders in the lagged-control group (T-1, ref = T-2), workers in the early group will report:

An increase in their leader’s use of the leadership skills (T+1, ref = T-1)

An enhanced safety climate (T+1, ref = T-1)

An increase in their use of safety practices (T+1, ref = T-1)

An increase in their reporting of safety-related conditions (T+1, ref = T-1)

We used a two-stage model building strategy to test the first two hypotheses. In model 1, we included a binary variable representing time of survey (see listed hypotheses above for detail on which time points were compared). In model 2, we added a binary variable representing intervention group (0 = Lagged-control group, 1 = Early group) and an interaction term between the time and group variables to test if the responses over time were different in the two groups. To test these hypotheses, we compared the goodness of fit of the simpler model with just time (model 1) to the more complex model with time and group variables (model 2) using the likelihood ratio test. In both models, we accounted for the fact that we repeatedly measured leaders as well as their work crews via survey by nesting all outcome variable scores within participant at each data collection time point. We also included a random intercept to allow scores to vary across participants prior to the training. Finally, we controlled for ethnicity (Hispanic vs. Non-Hispanic), survey language (Spanish vs. English), and leaders’ self-report learning goal orientation, which has been linked to learning during training (Johnson et al., 2018).

Because the leader is the unit of analysis for Hypotheses H2a-d, we combined and averaged their workers’ survey responses for each outcome variable at each data collection point. The within-group homogeneity as measured by the intraclass correlation coefficient (ICC,1) was acceptable for workers’ perceptions of leader’s use of leadership skills (0.28 [95% CI = 0.21 – 0.37]), safety climate (0.11 [95% CI = 0.06 – 0.19]), safety practices (0.11 [95% CI = 0.06 – 0.18]), and self-reporting of safety-related conditions (0.16 [95% CI = 0.10 – 0.24]). Other safety climate and safety leadership researchers have observed similar ICC(1)s (Dov Zohar & Polachek, 2014).

To assess the near-term sustained impact of the FSL training we analyzed the post-training data gathered only from the early intervention group to assess the degree to which leader and worker outcome variables changed from 2- to 4-weeks after the FSL training (T+2, ref = T+1). Specifically, we tested the following hypotheses by including a binary variable representing time of survey in the model and accounted for repeated measures, included a random intercept, and controlled for ethnicity, survey language, and leaders’ self-report learning goal orientation:

H3: Compared to 2-weeks, at 4 –weeks post training, leaders will report maintained or improved:

Use of leadership skills

Use safety practices

Crew-reporting of safety-related conditions

H4: Compared to 2-weeks, at 4 –weeks post training, workers will report maintained or improved:

Leader’s use of leadership skills

Safety climate

Use of safety practices

Self-reporting of safety-related conditions

RESULTS

Study sample

We successfully recruited a diverse sample of 20 construction sub-contracting companies in 3 geographic US locations; 14 in the west, 3 in the mid-west, and 3 in the east. The companies in each location were randomly assigned to either the early or lagged-control group (see Table 3). The majority were medium-sized (50%). Eleven (55%) identified as union contractors and eleven (55%) specialized in high-risk trades as defined by Bureau of Labor of Statistics injury and fatality data. The most common trades represented were heavy civil (n = 5), drywall (n = 5), electrical (n = 4), labor (n = 4) and mechanical (n = 3).

Table 3 -.

Company characteristics

| Early (#) | Lagged-control (#) | Total N (%) | |

|---|---|---|---|

| Geographic location | |||

| West (Denver area) | 7 | 7 | 14 (70%) |

| Midwest (Pittsburgh, PA/Morgantown WV) | 1 | 2 | 3 (15%) |

| Northeast (Boston area) | 2 | 1 | 3 (15%) |

| Size (self-reported) | |||

| Small (0 – 75 FTEs) | 2 | 3 | 5 (25%) |

| Medium (76–200 FTEs) | 4 | 6 | 10 (50%) |

| Large (201+ FTEs) | 4 | 1 | 5 (25%) |

| Union status | |||

| Non-union | 6 | 5 | 11 (55%) |

| Union | 4 | 5 | 9 (45%) |

| Trade risk level | |||

| Low risk | 7 | 2 | 9 (45%) |

| High risk | 3 | 8 | 11 (55%) |

Note. FTEs - Full time equivalents

The study participants were primarily white males between 38 and 45 years old. More than 70% of the leaders reported having worked with their current company for more than 4 years and a majority were in a foremen/lead person role. Less than 42% of workers had worked with their current company for more than 4 years and a majority said they were an experienced worker or apprentice/trainee. Twelve percent of leaders and 20% of workers choose to complete the Spanish language survey (Table 4).

Table 4 –

Participant Demographics

| Leaders (N=286) | Workers (N= 1173) | |||

|---|---|---|---|---|

| Early (n=169) | Lagged (n=117) | Early (n=809) | Lagged (n=364) | |

| n(%) | n(%) | n(%) | n(%) | |

| Gender | ||||

| Male | 163 (99%) | 100(100%) | 607 (99%) | 300 (100%) |

| Female | 1(1%) | 0(0%) | 9 (1%) | 1 (0%) |

| Age - Mean (SD) | 43(9) | 45 (10) | 39(13) | 38(12) |

| Ethnicity | ||||

| White | 110 (67%) | 79 (79%) | 295 (49%) | 164 (56%) |

| African American | 3 (2%) | 1(1%) | 23 (4%) | 12 (4%) |

| Hispanic | 44 (27%) | 19 (19%) | 270 (44%) | 100 (34%) |

| Asian | 0(0%) | 0(0%) | 2 (0%) | 0(0%) |

| Native American | 2 (1%) | 0(0%) | 4(1%) | 3(1%) |

| Mixed | 4 (2%) | 1(1%) | 11 (2%) | 11 (4%) |

| Other | 1(1%) | 0(0%) | 3 (0%) | 3(1%) |

| Years in construction - Mean (SD) | 21(9) | 23 (9) | 13(11) | 15 (11) |

| Current position | ||||

| Supervisor/manager | 5(3%) | 4 (4%) | - | - |

| Superintendent | 16 (10%) | 20 (20%) | - | - |

| Foreman/lead person | 140 (85%) | 73 (72%) | - | - |

| Experienced worker | - | - | 413 (69%) | 219 (75%) |

| Apprentice/trainee | - | - | 144 (24%) | 50(17%) |

| Laborer | - | - | 20 (3%) | 9(3%) |

| Other | 3 (2%) | 4 (4%) | 20 (3%) | 13 (4%) |

| Tenure with company | ||||

| <1 year | 19 (12%) | 6(6%) | 291 (50%) | 88 (30%) |

| 1–3 years | 29 (18%) | 13 (13%) | 161 (27%) | 84 (29%) |

| 4–6 years | 32 (20%) | 13 (13%) | 80(14%) | 41 (14%) |

| 7–10 years | 27 (17%) | 14 (14%) | 23 (4%) | 23 (8%) |

| 10+ years | 54 (34%) | 54 (54%) | 32 (5%) | 57 (20%) |

| Wks w/current supervisor - Mean (SD) | - | - | 39 (109) | 56 (106) |

| Location in the US | ||||

| West | 128 (76%) | 82 (70%) | 593 (73%) | 254 (70%) |

| Mid-west | 15 (9%) | 17 (15%) | 32 (4%) | 38(10%) |

| Northeast | 26(15%) | 18 (15%) | 184 (23%) | 72 (20%) |

| Company size | ||||

| Small | 26(15%) | 23 (20%) | 184 (23%) | 58(16%) |

| Medium | 46 (27%) | 70 (60%) | 164 (20%) | 265 (73%) |

| Large | 97 (57%) | 24 (21%) | 461 (57%) | 41 (11%) |

| Union Status | ||||

| Non-Union | 110 (65%) | 67 (57%) | 487 (60%) | 185 (51%) |

| Union | 59 (35%) | 50 (43%) | 322 (40%) | 179 (49%) |

| Trade risk level | ||||

| Low risk | 114 (67%) | 49 (42%) | 620 (77%) | 181 (52%) |

| High risk | 55 (33%) | 68 (58%) | 189 (23%) | 173 (48%) |

Of the 286 leaders who received the training (169 early and 117 lagged-control) we collected 247 surveys (86%) to test Hypotheses 1 a-d. In the early intervention group, we collected 133 out of 169 (80%) leader surveys to test Hypothesis 3 a-c. Of the 1,173 total number of workers who participated in the study (809 early and 364 lagged-control), we collected surveys from 706 (60%) of them to test Hypotheses 2a-d. In the early intervention group we collected surveys from 458 out of 809 (57%) to test Hypotheses 4a-c.

Before and after the FSL training (H1 and H2)

In the following sections, we present the results of the linear mixed modelling analysis for hypotheses 1–4 in which we compared data collected from the early group before to after their FSL training to data collected from the lagged-control group at two time points before their FSL training. We present the results of model 2 in the text below. The results of model 1 as well as more detailed statistical results can be found in Supplementary Table S1.

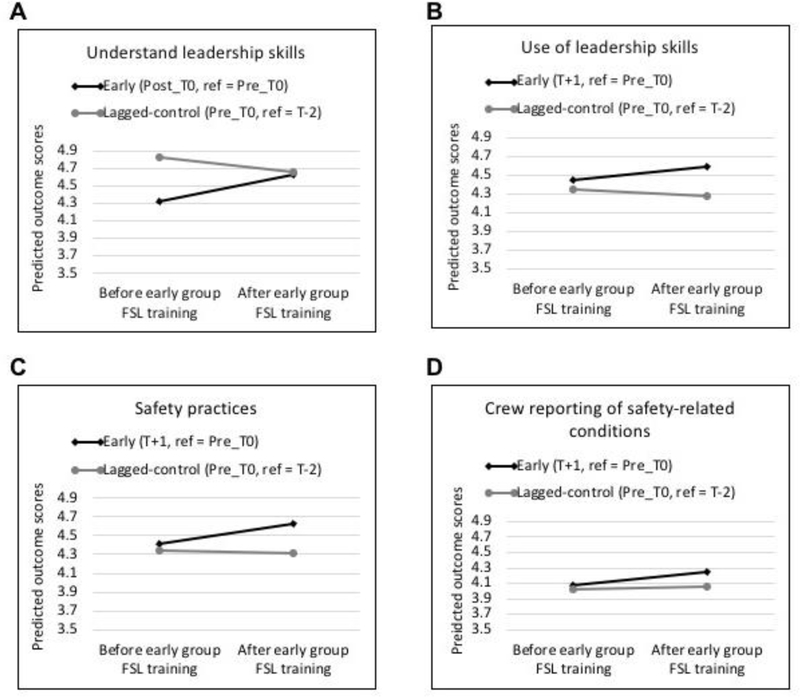

Leaders

The only significant difference observed between lagged-control and early groups in the mean scores of the four outcome variables immediately prior to the training was understanding of leadership skills; with the early group scoring lower (β= −0.49 (SE = 0.19), p < 0.01) (see Figure 1a).

Figure 1 –

Results of linear mixed models - predicted average scores for early and lagged-control group leader outcome variables (1–5 Likert response scales)

In terms of within group mean scores only, leaders in the early group reported a significant improvement in one outcome variable immediately before to immediately after their training and two outcome variables at two-weeks after their training. These variables included their understanding of leadership skills (β = 0.46 (SE = 0.07), p < 0.01) immediately after their training and their use of leadership skills (β = 0.21 (SE = 0.05), p < 0.01) and safety practices (β = 0.22 (SE = 0.05), p < 0.01) two-weeks after their training (see Figures 1a-c).

Leaders in the lagged-control group showed a slight decline in their understanding of leadership skills (β = −0.16 (SE = 0.06), p < 0.01) and showed no significant change in use of leadership skills (β = −0.06 (SE = 0.04), p = 0.14) or safety practices (β = −0.01 (SE = 0.04), p = 0.71) from 4-weeks before to immediately before their training (see Figures 1a-c).

Leaders in the neither group reported a significant improvement in crew-reporting of safety-related conditions (Early (Pre_T0 to T+1): β = 0.14 (SE = 0.09), p = 0.14; Lagged-control (T-2 to Pre_T0): β = 0.02 (SE = 0.07), p = 0.76) (see Figure 1d).

The likelihood ratio tests used to examine Hypotheses 1 a-d indicated that for three of the four outcome variables in model 2, containing both time and group effects, fit the data significantly better than model 1 containing time effects only: H1a – understanding of leadership skills (χ2 (2) = 33.6, p < 0.01), H1b – use of leadership skills (χ2 (2) = 28.9, p < 0.01), and H1c - safety practices (χ2 (2) = 22.9, p < 0.01). The likelihood ratio test for crew-reporting of safety-related conditions (H1d) indicated that model 2 did not fit the data significantly better than model 1 (χ2 (2) = 0.26, p > 0.10). Together, these findings partially confirm Hypothesis 1.

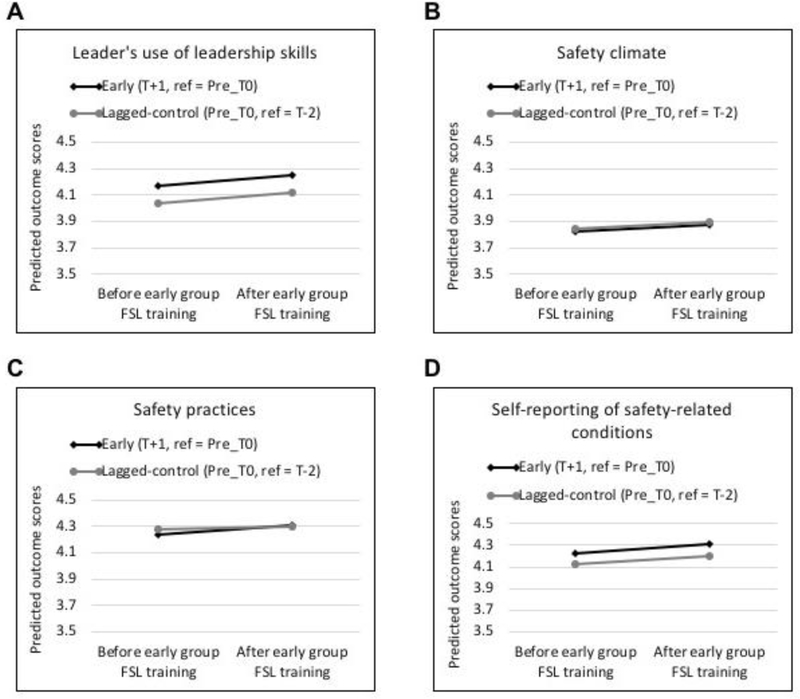

Workers

Prior to the FSL training, there were no significant group differences in workers perceptions of their leader’s use of leadership skills (β = 0.13 (SE = 0.08), p = 0.11), safety climate (β = −0.02 (SE = 0.06), p = 0.72), safety practices (β = −0.04 (SE = 0.06), p = 0.54), or self-reporting of safety-related conditions (β = 0.11 (SE = 0.08), p = 0.16) supporting the idea that randomization worked in creating worker groups with similar outcome variable scores prior to the training.

We observed slight improvements during the intervention period for the early group and during the control period for the lagged-control group (see Figure 2a-d). However, this change was not statistically significant for all outcomes in the early group: leader’s use of leadership skills (β = 0.01 (SE = 0.07), p = 0.91), safety climate (β = 0.00 (SE = 0.06), p = 0.98), safety practices (β = 0.06 (SE = 0.06), p = 0.32), or their own reporting of safety-related conditions (β = 0.00 (SE = 0.07), p = 0.96) from 1-week before to 2-weeks after their leaders participated in the FSL training. It was also not statistically significant for all outcomes in the lagged-control group: leader’s use of leadership skills (β = 0.08 (SE = 0.05), p = 0.16), safety climate (β = 0.05 (SE = 0.05), p = 0.30), safety practices (β = 0.01 (SE = 0.05), p = 0.76), or their own reporting of safety-related conditions (β = 0.08 (SE = 0.05), p = 0.15) from 4-weeks before to 1-week before their training.

Figure 2 –

Results of linear mixed models - predicted average scores for early and lagged-control group worker outcome variables (1–5 Likert response scales)

The likelihood ratio tests of the worker data indicated that for all outcome variables, model 2 with time and group effects did not fit the data significantly better than model 1 with the time variable only: H2a – leader’s use of leadership skills (χ2 (2) = −1.5, p > 0.10), H2b - safety climate (χ2 (2) = −5.28, p > 0.10), H2c - safety practices (χ2 (2) = −4.5, p > 0.10), and H2d – self-reporting of safety-related conditions (χ2 (2) = −2.48, p > 0.10). Thus, we cannot confirm Hypothesis 2 a-d.

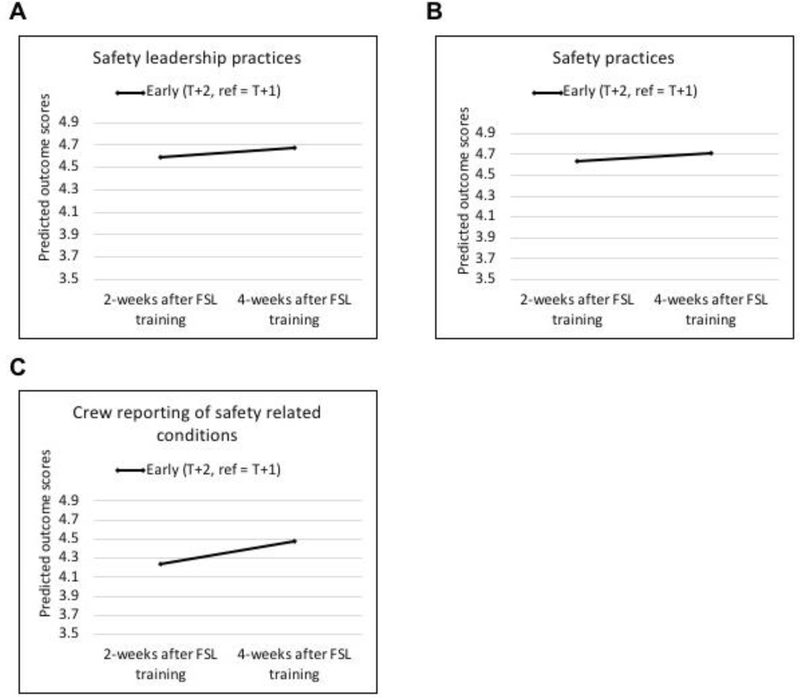

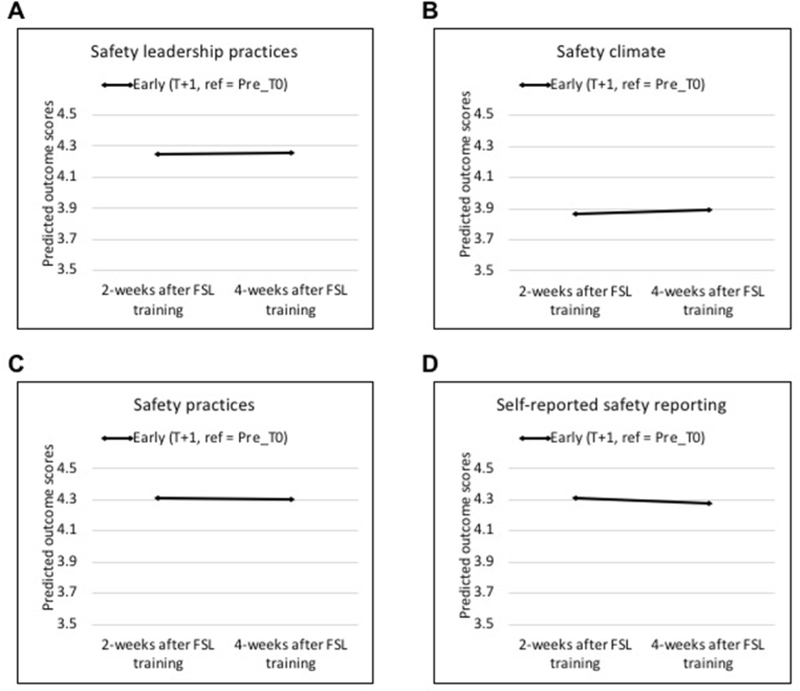

Sustained impact of the FSL training (Early group only)

As described above, a post-training survey (4 weeks later) was completed in the “early” group only. All leader-reported outcome variables improved significantly from 2- to 4- weeks after the training, including crew-reporting of safety-related conditions (see Figure 3 and Supplemental Table S3). These findings confirm hypothesis 3 a-c. In contrast, the worker-reported outcomes did not significantly change (see Figure 4 and Supplemental Table S4). Thus, hypothesis 4 a-c is not confirmed.

Figure 3 –

Results of linear mixed models - predicted average scores for leader reported outcomes from 2- to 4-weeks after the early group leader’s FSL training (1–5 Likert response scales)

Figure 4 –

Results of linear mixed models - predicted average scores for worker reported outcomes from 2- to 4-weeks after the early group leader’s FSL training (1–5 Likert response scales)

DISCUSSION

The goal of this study was to assess the degree to which the Foundations for Safety Leadership (FSL) training affected construction leader and worker-reported outcomes. We found that the FSL training helped to increase leaders’ understanding of the FSL safety leadership skills as well as positively change their use of the safety leadership skills and their safety practices. However, there were no statistically significant changes in worker-reported outcome variables.

The results reported here are supported by findings from earlier research studies conducted in other industries and in other countries, which found that providing safety leadership training to those in management or supervisory positions can have a positive impact on a variety of safety-related outcomes (Mullen & Kelloway, 2009; von Thiele Schwarz et al., 2016). Our study adds to this literature as it demonstrated that when compared to control group data, construction foremen and frontline leaders in 3 geographic locations across the US reported a greater understanding and increased practice of safety leadership skills and improved safety practices at both 2- and 4-weeks after participating in the Foundations for Safety Leadership (FSL) training program.

Approximately three months after the final survey data were collected, we conducted 30-minute structured phone interviews with each company contact to learn the degree to which they had observed any change in leaders’ use of the FSL leadership skills on the jobsite. The resulting quotes gave us a deeper insight of the FSL training effects beyond what we could collect in the surveys. For example, one sub-contractor told us: “I would have to say just the participation in the class lets the foremen know that the owners and upper management are on-board with safety, by actually giving them the time to do what they have to do to perform the job safely.” Others commented that after the FSL training, they observed their frontline leaders being more likely to engage crews in safety-related discussions. These two quotes exemplify their observations:

“I think they’re more aware when they do their morning huddle…. I also see them take a little more time when they’re talking about the work that they also cover the safety implications of that work. [They] try to get more input from the employees on their crew instead of just giving instructions.”

“It’s a rare occurrence that construction [frontline] leaders thank us for training, but that’s what we received from our supervisors after the FSL training. What’s even better is that they have been able to improve their communication and engagement with their team.”

We also interviewed a sample of frontline leaders who participated in the FSL training to learn how they were applying the FSL lessons learned on the jobsite. Practicing 3-way communication and recognizing team members for going above and beyond were the two skills most often mentioned as exemplified in these quotes:

“I never took it as seriously as I do now … You know, having the people explain back to you what you told them. I mean, that really really has helped a lot. Instead of just giving somebody some information, sending them off blindly to do the job, and then you know, getting mad ‘cause they didn’t do it right. That way you know, they can explain to you back exactly what you said to them and if they didn’t get it the first time, you know, you can talk about it, have an opportunity to get it right.”

“It also makes them feel like they’re, part of the, you know, the planning. So for the specific task, I think that it is a great tool. Something I’ve done a little bit of but really try to do a lot more of ‘cause of the training.”

The following quote illustrates practicing the skill of recognizing workers:

“…somebody walking by, picking up a rebar cap and putting it on instead of just walking right by it. It only takes a couple of seconds but telling them thank you and good job and recognizing that they did that, it makes them feel like they should do that more…my crew has been doing that more and more.”

Prior research has demonstrated that managements’ leadership style can influence workers’ health, safety, and wellbeing (Mullen & Kelloway, 2011). When compared to other leadership styles, leaders who use transformational leadership skills in particular are more likely to have stronger positive safety climate perceptions and better safety outcomes (Clarke, 2013). Recall that the leadership skills taught in the FSL are grounded in transformational leadership principles. While the worker findings reported from this study did not show an improvement in workers’ perceptions of their leaders’ safety leadership practices, in safety climate, or of their own safety practices and safety reporting, contractor interview data showed that they had observed an increase in worker engagement and jobsite safety-related communication after the training. This quote exemplifies comments made by a majority of contractors we interviewed: “I think the crew is more willing to bring up items to the foreman…I know that we have had guys bring stuff up that matters, and we’ve actually made changes on site or brought it to the attention of people who can make changes because of what our guys are bringing up.”

The interview data helped us to explore why workers reported that they did not witness nor experience their leaders using the skills from the FSL training program. For example, one company safety director told us: “The training by itself I think had a very positive influence, but it’s fairly short-lived…A two-and-a-half-hour training is great…but to continue that I need to continue to reinforce those skills.” Another indicated that her leaders who participated in the training may not feel supported by their senior management saying, “There seems to be a disconnect between the foremen and superintendent where communication is not happening as frequently as it should…I think there’s an issue with trust.”

Strengths & limitations

The FSL Training addressed a stated need within the construction industry to explore methods to improve safety climate and safety outcomes, and construction industry stakeholders provided extensive input into the content and design. While some large construction companies and labor unions are starting to provide leadership training for employees, the FSL program provides safety leadership skills to all frontline construction leaders regardless of their affiliation. The FSL training program had face validity to the end-users. Data collected from OSHA Education Centers and construction company safety directors since January 1, 2017 show that over 10,000 foremen/lead workers and others in the industry have already participated in the training even without quantitative evidence of effectiveness. Furthermore, a number of General Contractors and other companies are now requiring that the FSL module be a required part of the OSHA 30-hour course for their foremen, and not merely an elective. This is a testament to the need and its’ observed usefulness to promote job site leadership skills.

Our evaluation study has a number of strengths. First, the wide range of trades, geographical locations, sizes, and union membership status of participating companies in this evaluation study suggests that our findings are generalizable. Additionally, the switching-replications study design allowed us to compare intervention and control group data and still provide the training to leaders in the comparison group, which strengthened our relationship with company partners.

A limitation of our study is that the reliance on self-reported survey data. The initial intent to conduct safety audits on each jobsite as an additional and more objective outcome measure proved infeasible. However, many of the self-reported metrics have been validated in the construction and other industries within theoretical and behavioral frameworks supporting their use here. Another constraint is the difficulty in collecting prospective data due to the dynamic and constantly changing flow of workers on and off job sites (Sparer et al., 2015). This challenge resulted in a notable amount of missing worker follow-up data, and may have resulted in an inability to accurately assess changes in worker-reported outcomes from before to after the FSL training. We anticipated that the strategy of following companies and rather than jobsites would maximize our ability to collect follow-up data because we would be able to find the workers through our company contact. To maximize success we put a significant amount of effort into coordinating with each company to determine where and when each worker would be. Nevertheless, participating companies were retained in the study between 6 and 9 weeks, and many workers left the study group at various points due to relocation to other jobsites, layoffs, or other types of absences. To address this challenge, we averaged worker responses within the work crews, which was supported by the ICC descriptive statistics.

Also, as Kelloway and Barling (2010) note, leadership development interventions are difficult to evaluate as their effects are often indirect and delayed. Ideally, we would like to have collected data several months after the FSL training to allow leaders time to integrate the key concepts presented in the FSL training into their workday practices, and also for their workers to observe the changes (Bronkhorst et al., 2018; Mullen & Kelloway, 2009; von Thiele Schwarz et al., 2016). This is particularly true for safety climate, as perceptions related to this outcome take time to be internalized and expressed.

Possible future FSL-related activities

To achieve our goals, various design-decisions related to length and content had to be made during development of the FSL and activities such as goal setting, 360-degree feedback, and on the job guided practice were not included. Mullen and Kelloway (2009) suggest combining training with personalized ongoing feedback for a year to facilitate maintenance of safety leadership practices. It may be valuable to create a longer training module that includes extensive coaching components (Kines et al., 2010; von Thiele Schwarz et al., 2016; D Zohar & Luria, 2003). However, there are number of downsides to having a longer program. First, OSHA trainers on our curriculum development team told us that it had to be less than 3 hours or they, as trainers, would not select it as one of their electives to teach. Relatedly, it is highly likely that had it been longer OSHA would not have agreed to include it in their 30-hour course, which reaches hundreds of thousands of workers each year. Also, even given the fast-paced nature of construction, with time being a critical and often defining element, many companies may not find it feasible to implement a longer module into their on-going training efforts. This may not be the case had the FSL been a longer training program.

In the time since the FSL was rolled out, we have been developing resources to address the concern raised about needing to reinforce the learned leadership skills after the training is over. Specifically, we created a 16-page handbook that provides users with a brief synopsis of the leadership skills, how to implement the skills, a self-assessment to determine what skills they are currently practicing, and a personal leadership skill improvement plan. We created 6 tool box talks covering the critical safety leadership skills, which leaders can use during morning huddles or as part of new employee orientation. To further enhance the training program, one of the participating contractors suggested we create a “Create your own Scenario” worksheet that companies, leaders, and trainers can use to develop new scenarios based on their own trade and/or experiences. As a next step, researchers could evaluate the benefit of combining the FSL training module with these additional resources in improving safety leadership and jobsite safety climate. All FSL teaching materials and additional resources can be downloaded on CPWR’s website for free at https://www.cpwr.com/foundations-safety-leadership-fsl (CPWR: The Center for Construction Research and Training, 2018).

Additional training interventions with similar safety leadership messages could be designed that draw upon shared or distributed leadership theory, which has been linked to safety outcomes (Bienefeld & Grote, 2014). Shared leadership theory posits that leadership can emanate from multiple members of a team when there is a shared purpose, social support, and voice (Carson, Tesluck, & Marrone, 2007). An integrated safety training that targets leaders at all levels could be designed to address conflicting role demands, production pressures, and unsupportive environments that can affect one’s ability to be an effective safety leader (Conchie, Moon, & Duncan, 2013).

Finally, additional evaluation metrics such as safety audit data, injury data, and workers’ compensation costs could be used to expand our understanding of the FSL training’s effect on both leading and lagging indicators of worker health and safety.

Conclusions

In 2013, construction industry stakeholders identified a need for their foremen and other frontline leaders to acquire the knowledge and skills to become more effective jobsite safety leaders. The Foundations for Safety Leadership (FSL) was designed to meet that need. This is also the first safety leadership training intervention study to be completed in the US construction industry. While there are a number of study limitations, we were able to provide evidence that leaders report using and improving the skills they learned 4-weeks after participating in the FSL training and the industry has found it to be valuable.

Practical applications

The Foundations for Safety Leadership (FSL) program fills an identified need for construction frontline supervisors to learn and practice critical safety leadership skills on the jobsite. It has already reached over 10,000 leaders and has the potential to reach over 100,000 each year during either an OSHA 30-hour or a stand-alone course.

Supplementary Material

Acknowledgements –

We would like to thank the many individuals who made the FSL and this project possible including: The Curriculum Development Team, the contractors, leaders, and workers who participated in the study, the FSL trainers, John Rosecrance for participating in early study-related discussions and help recruiting companies. Allison Barrera, Gus Arroyo, Janalee Thompson, Don Meglio, Ying Loo, Kang-Hung Liu, and Michelle Tran or assisting with data collection, Miranda Dally for assisting with data analysis, and Ben Amick for reviewing an early draft of the paper.

Funding: This work was made possible by a NIOSH cooperative agreement number U60-OH009762 to CPWR – The Center for Construction Research and Training. Its contents are solely the responsibility of the authors and do not necessarily represent the official view of NIOSH

References

- Barling J, Loughlin C, & Kelloway EK (2002). Development and test of a model linking safety-specific transformational leadership and occupational safety. Journal of Applied Psychology, 87, 488–496. [DOI] [PubMed] [Google Scholar]

- Bienefeld N, & Grote G. (2014). Shared leadership in multiteam systems: How cockpit and cabin crews lead each other to safety. Human Factors, 56(2), 270–286. doi: 10.1177/0018720813488137 [DOI] [PubMed] [Google Scholar]

- Bronkhorst B, Tummers L, & Steijn B. (2018). Improving safety climate and behavior through a multifaceted intervention: Results from a field experiment. Safety Science, 103, 293–304. doi: 10.1016/j.ssci.2017.12.009 [DOI] [Google Scholar]

- Bureau of Labor Statistics. (2018, Jan 12). Bureau of labor statistics: Injuries, illnesses, and fatalities. Retrieved from http://www.bls.gov/iif/

- Carson J, Tesluck P, & Marrone J. (2007). Shared leadership in teams: An investigtion of antecedant conditions and performance. The Academy of Management Review, 50(5), 1217–1234. [Google Scholar]

- Clarke S. (2013). Safety leadership: A meta-analytic review of transformational and transactional leadership styles as antecedents of safety behaviours. Journal of Occupational and Organizational Psychology, 86(1), 22–49. doi: 10.1111/j.2044-8325.2012.02064.x [DOI] [Google Scholar]

- Conchie SM, Moon S, & Duncan M. (2013). Supervisors engagement in safety leadership: Factors that help and hinder. Safety Science, 51(1), 109–117. doi: 10.1016/j.ssci.2012.05.020 [DOI] [Google Scholar]

- CPWR: The Center for Construction Research and Training. (2013). Workshop: Safety Culture and Climate in Construction: Bridging the Gap between Research and Practice. Retrieved from https://www.cpwr.com/safety-culture/workshop-safety-culture-and-climate-construction

- CPWR: The Center for Construction Research and Training. (2018). Foundations for Safety Leadership (FSL). Retrieved from https://www.cpwr.com/foundations-safety-leadership-fsl

- Goldenhar LM, Schwatka NV, & Johnson S (provisionally accepted). Leadership Skills for Strengthening Jobsite Safety Climate Journal of Safety Research. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hoffmeister K, Gibbons AM, Johnson SK, Cigularov KP, Chen PY, & Rosecrance JC (2014). The differential effects of transformational leadership facets on employee safety. Safety Science, 62(C), 68–78. doi: 10.1016/j.ssci.2013.07.004 [DOI] [Google Scholar]

- Jeschke KC, Kines P, Rasmussen L, Andersen LPS, Dyreborg J, Ajslev J, … Andersen LL (2017). Process evaluation of a Toolbox-training program for construction foremen in Denmark. Safety Science, 94, 152–160. doi: 10.1016/j.ssci.2017.01.010 [DOI] [Google Scholar]

- Kelloway EK, & Barling J. (2010). Leadership development as an intervention in occupational health psychology. Work and Stress, 24(3), 260–279. doi: 10.1080/02678373.2010.518441 [DOI] [Google Scholar]

- Kines P, Andersen LPS, Spangenberg S, Mikkelsen KL, Dyreborg J, & Zohar D. (2010). Improving construction site safety through leader-based verbal safety communication. Journal of Safety Research, 41(5), 399–406. doi: 10.1016/j.jsr.2010.06.005 [DOI] [PubMed] [Google Scholar]

- Mullen J, & Kelloway E. (2009). Safety leadership: A longitudinal study of the effects of transformational leadership on safety outcomes. Journal of Occupational and Organizational Psychology, 82(2), 253–272. doi: [DOI] [Google Scholar]

- Mullen J, & Kelloway E. (2011). Occupational health and safety leadership. In Quick JC & Tetrick LE (Eds.), (2nd ed., pp. 357–372). Washington, DC: APA. [Google Scholar]

- Patton MQ (2015). Qualitative research & evaluation methods : integrating theory and practice (Fourth edition. ed.). Thousand Oaks, California: SAGE Publications, Inc. [Google Scholar]

- Sadish W, Cook T, & Campbell D. (2002). Experimental and quasi-experimental designs for generalized causal inference. Boston: Hughton Mifflin. [Google Scholar]

- StataCorp. (2015). Stata statistical software: Release 14. College Station, TX: StataCorp LP. [Google Scholar]

- von Thiele Schwarz U, Hasson H, & Tafvelin S. (2016). Leadership training as an occupational health intervention: Improved safety and sustained productivity. Safety Science, 81, 35–45. doi: 10.1016/j.ssci.2015.07.020 [DOI] [Google Scholar]

- Zohar D, & Luria G. (2003). The use of supervisory practices as leverage to improve safety behavior: a cross level intervention model. Journal of Safety Research, 34, 567–577. [DOI] [PubMed] [Google Scholar]

- Zohar D, & Polachek T. (2014). Discourse-based intervention for modifying supervisory communication as leverage for safety climate and performance improvement: A randomized field study. Journal of Applied Psychology, 99(1), 113–124. doi: 10.1037/a0034096 [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.