Abstract

One of the goals of biomaterials science is to reverse engineer aspects of human and nonhuman physiology. Similar to the body’s regulatory mechanisms, such devices must transduce changes in the physiological environment or the presence of an external stimulus into a detectable or therapeutic response. This review is a comprehensive evaluation and critical analysis of the design and fabrication of environmentally responsive cell-material constructs for bioinspired machinery and biomimetic devices. In a bottom-up analysis, we begin by reviewing fundamental principles that explain materials’ responses to chemical gradients, biomarkers, electromagnetic fields, light, and temperature. Strategies for fabricating highly ordered assemblies of material components at the nano to macro-scales via directed assembly, lithography, 3D printing and 4D printing are also presented. We conclude with an account of contemporary material-tissue interfaces within bioinspired and biomimetic devices for peptide delivery, cancer theranostics, biomonitoring, neuroprosthetics, soft robotics, and biological machines.

Keywords: Cell-material constructs, biofabrication, bioprinting, biomimetic materials, intelligent hydrogels, molecular machines, drug delivery, theranostics, tissue engineering

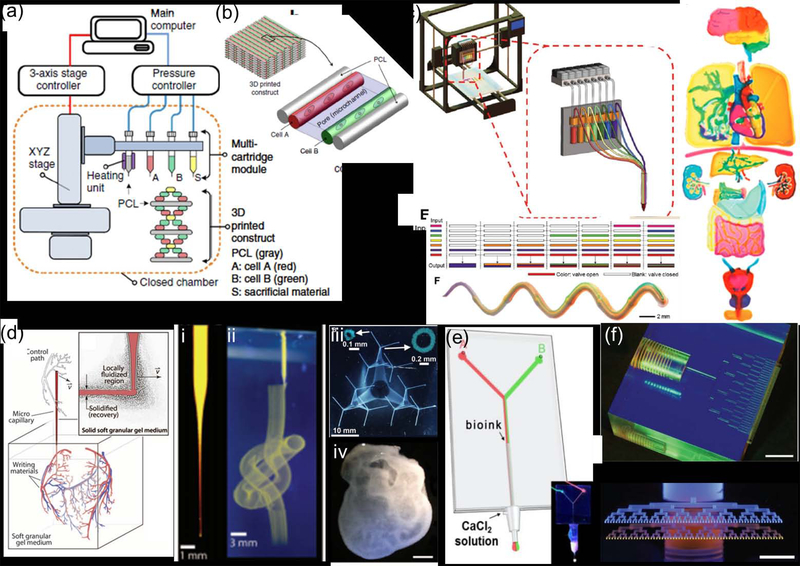

I. Introduction

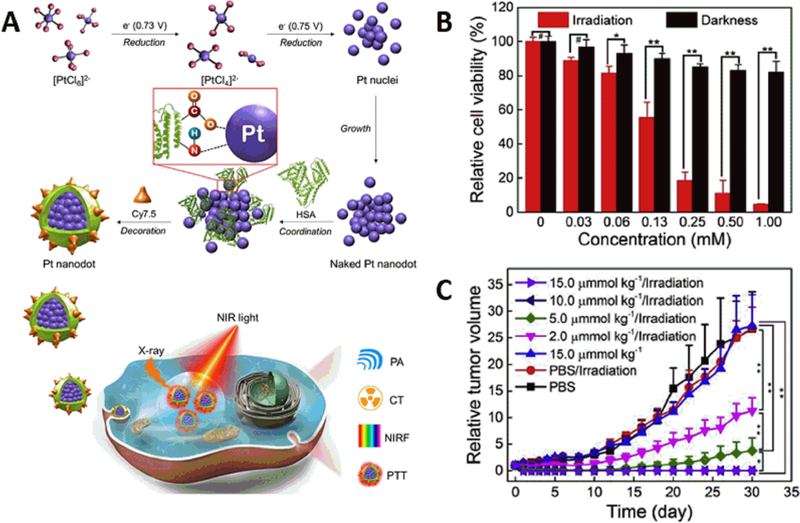

1.1. Rationale and Relevant Definitions for Bioinspired Actuators and Biomimetic Devices

Recent advances in the rational design and synthesis of intelligent materials, especially polymers, for medical, biological and other applications have led to systems that are uniquely capable of responding to a dynamic surrounding environment such as a biological or physiological fluid. Research on formulating precise chemical architectures that recognize target molecules or ions from an ensemble of closely related entities in the surrounding environment has resulted in new classes of intelligent polymers for numerous applications. These environmental interactions can be general (e.g. temperature, pH, ionic strength, thermodynamic compatibility of the solvent, nature of co-analyte) or specific (e.g. molecular recognition) in nature. The composition and supramolecular assembly of material components drives the sensitivity and physical nature of a response.

A major research goal is to engineer new formulations and chemical architectures of polymeric or biohybrid material that ‘communicate’ with their surrounding environment. By ‘communication’, we refer to the ability of a material to act as an intelligent actuator – integrating biological stimuli and transducing a response (i.e. a mechanical output). Here, we define an ‘actuator’ as a control system component that converts a stimulus into an output. Biomedical actuators convert biological stimuli into useful outputs. Biomedical applications that require intelligent polymeric actuators include biosensors, intelligent and/or triggerable drug delivery systems, closed-loop devices that respond to physiological stimuli with therapeutic intervention, and scaffolds for biological machinery.

Such systems can be adapted to respond to environmental conditions by emitting a signal or intervening therapeutically. Closed-loop devices integrate biochemical stimuli and therapeutic intervention through controller function, which is either a component of a complex actuation system or a property of the actuator material itself. Intelligent materials that transduce perturbations in the environment into mechanical outputs are particularly useful as auto-control elements, which deliver drugs, monitor physiological conditions, or modulate embedded cells.

Researchers are also integrating cellular and molecular components with intelligent material scaffolds to construct novel biohybrid machines that solve elusive medical and biological problems. These applications include continuous monitoring of analytes for diagnostic purposes, identification of tumors in vivo, regeneration of diseased or damaged tissue (e.g. skeletal muscle, cardiac muscle), and recapitulation of highly-ordered biological activity within advanced devices (i.e. biomimetic design). The integration of biomedical material actuators with native (or non-native) tissue offers promise to restore disease-induced, aberrant control systems in the body. Creative constructs of intelligent biomaterial and embedded cells have found utility as a class of ‘biomimetic machines’ that perform unique mechanical functions beyond the capability of purely mechanical elements, for medical and non-medical purposes.

1.2. A Framework for the Design, Fabrication, and Evaluation of Biomedical Actuators

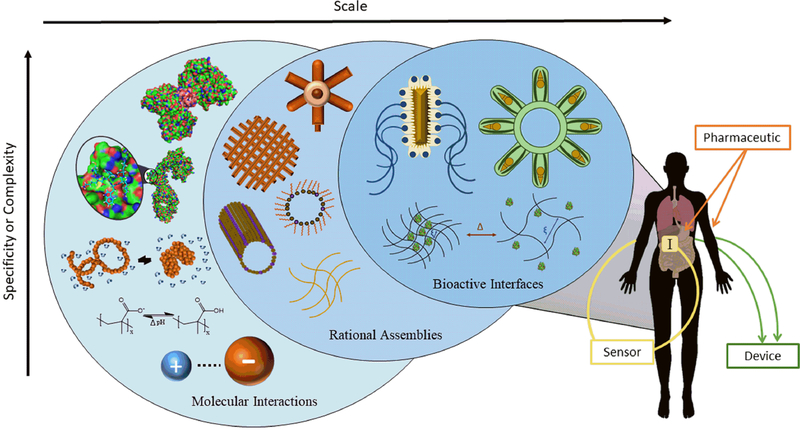

A schematic capturing the lineages of design inquiry for bioinspired therapeutic devices and biomimetic machines is presented in Figure 1.1. This schematic provides not only a useful guide for organizing one’s critical evaluation of a new biomedical actuator (as we will throughout this manuscript) but also a framework for designing new bioinspired and biomimetic devices for medical purposes. We therefore hope that you will find it useful for contextualizing existing work and informing innovative designs.

Figure 1.1:

Intelligent polymers can serve as actuators to transduce a signal from the biological environment into a mechanical output or detectable signal. These advanced material platforms function as novel biosensors, vehicles for protein and peptide delivery, and scaffolds for tissue growth. When interfacing novel biomaterials with embedded and/or genetically engineered cells, cell-laden hybrids can mimic the activity and function of a biological system.

Starting with the biomaterial, engineering intervention is informed by a desired function, or outcome. In a typical therapeutic case, in order to design a useful biomaterial actuator, you must first identify an area of deficiency, disease, or need; determine the stimuli or signals that characterize the disease; and select a corrective action that provides benefit to the patient.

By the example of type I diabetes, the area of deficiency is insufficient insulin production. This deficiency manifests as an elevated blood glucose level, which can cause significant detriment for the patient if untreated. However, overcorrection (hypoglycemia) also presents a significant danger. Therefore, the deficiency is insulin presentation to tissue, the relevant biological signal is blood glucose level according to specified thresholds, and the necessary corrective action is insulin release. A suitable engineering intervention must turn the biological signal of glucose level into a switch or trigger for tunable and calibrated insulin release.

Synthesis, selection, fabrication, and processing of intelligent materials is necessary to achieve the complex structure, network, or assembly capable of transducing the biological signal (e.g. glucose) into a therapeutic response (e.g. insulin release). These responsive biomaterials can be natural or synthetic in origin, possess pH, ion, or otherwise responsive chemical moieties, have labile functional groups or crosslinks, and interact with differential affinity to biomacromolecules. Co-polymerization, blending, and interconnectivity can yield combinations of, and interactions between, material-environment interactions. Precise supramolecular and macroscopic assembly of these intelligent materials results in the formation of dynamic, bioactive materials. We provide a fundamental analysis and critique of environmentally responsive materials in Chapter 2, and a review of material fabrication and bioprinting methods in Chapter 3.

Again using the example of continuous glucose monitoring, we can use advanced materials science and fabrication to generate glucose-responsive networks. An example of a glucose-responsive network is poly(methacrylic acid) (P(MAA)) with orthogonal, conjugated, enzymatic units (i.e. glucose oxidase), and insulin. Glucose oxidase (GOx) catalyzes the conversion of glucose to gluconic acid, resulting in a dip in the local pH that corresponds to the pKa of MAA. The polymer network responds by collapsing, facilitating insulin release. The combination of P(MAA) and GOx achieves molecular recognition (i.e. signal detection) and mechanical response (i.e. pH-responsive swelling). Consequently, the rational assembly of the two, applied in the context of type I diabetes, is a biomedical actuator. Therapeutic and theranostic applications of environmentally responsive polymers are presented in Chapter 4.1. Additional medical devices for continuous analyte monitoring are discussed in Chapter 4.2.

Actuation:

In the bolded box, we present the types of intelligent responses typically exhibited by biomedical actuators. The most common biomaterial responses to physiological stimuli are swelling, assembly, or disassembly. Molecular mobility and electrical conductivity are also possible, and are discussed in the later sections of this report. As was the case in the glucose biosensor example, many biomedical actuators couple their physical output with a molecular recognition event (e.g. antibody-antigen, enzyme-substrate, or other highly specific interaction).

The initial physical response of biomedical actuators can frequently accomplish the entirety of the initial design specification. This is the case in most diffusion-controlled drug delivery systems and biosensors. However, in scaffolds for tissue regeneration or biomimetic machines, biomedical material actuators must additionally integrate with cellular components to produce complex behavior.

Cellular Actuators provide additional activity, responsiveness, and design potential. Certain cell lineages, such as cardiac muscle, will respond to an electrical stimulus with contraction and can therefore convert an external signal (i.e. delivered by a conducting polymer) into mechanical work. The incorporation of cells as actuators into implants and devices requires an additional engineering intervention (i.e. selection and differentiation of cells, fabrication of scaffolds that achieve necessary cell density and alignment, modification of genome and gene expression, etc.). The major advantage of generating cell-laden devices is to achieve complex environmentally responsive behavior that non-living elements cannot generate.

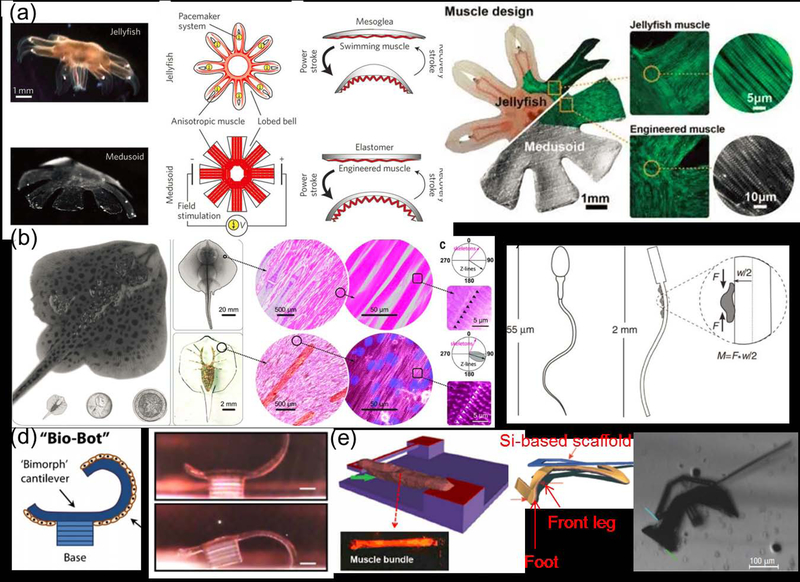

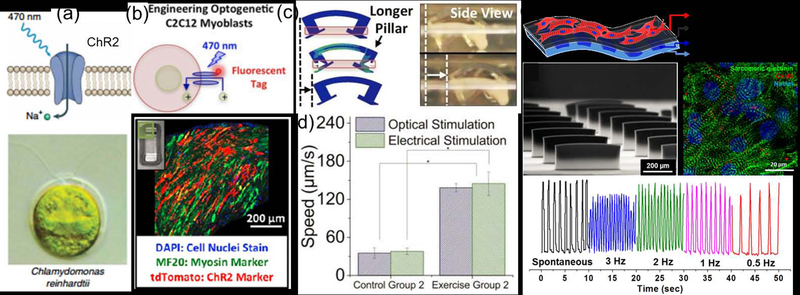

By example, in Chapter 4.3 we describe a jellyfish bioinspired machine. The material for this hybrid bioactuator was fabricated with precise geometric constraints to capture the jellyfish geometry and facilitate the necessary alignment of cardiomyocytes. The research team modified the cardiomyocytes genetically (an additional level of engineering control) so that stimulation with visual light (blue light at 10 mW) would activate the muscle cells. Upon final preparation of the cell-laden construct, the biomimetic jellyfish machine could swim with the characteristic undulations of the native fish, with precise external control over the swim trajectory (i.e. through light). We discuss this example, and many other novel biological machines, in Chapter 4.3.

As illustrated in these brief examples, researchers are using biologically responsive polymers to construct therapeutic devices, biosensors, and biological machines. Recent efforts in the field have addressed fundamental scientific inquiry and the development of translational technology. Fundamental advancements have included refined thermodynamic theories to explain the behavior of biopolymers in physiological solutions; new chemistries for synthesizing diverse, environmentally responsive polymers; nano- and micro-fabrication technology for forming ordered assemblies of natural and synthetic device components; and bioprinting technology for generating cell-laden constructs. Recent contributions to translational science include novel controlled release devices that deliver drugs, peptides, and proteins in response to changing physiological conditions; new diagnostic systems that minimize patient discomfort and maximize efficacy; and implantable cardiovascular devices.

1.3. Intelligence of Molecules, Materials, and Biomedical Devices: Relevancy across Molecular Complexity, Length Scale, and Application Space

A pictorial representation of this review’s scope, sequence, and structure is presented in Figure 1.2. The image has three interlocking, cascading circles, where each circle represents a subsection of our review. Within each circle exists a continuum of scale and complexity. All three seemingly disparate units coincide in the design of advanced pharmaceutical formulations, biosensors, and biomimetic devices that interface with, or enhance, human physiology. Analyzing the graphical depiction in Figure 1.2 in a bottom-up manner, we start with molecular interactions.

Figure 1.2:

Next-generation material-tissue interfaces function through the synergy of multiple material-environment interactions. These interactions range from simple (anion-cation) to complex (protein-protein). Biomaterials are fabricated into rational assemblies by chemical crosslinking, self-assembly, patterning, or printing. The resulting cell-material or material-tissue interfaces can navigate the physiological environment and/or mimic native bioactivity as components of pharmaceutical formulations, biosensors, and bioinspired machinery.

Molecular interactions span along a continuum from general to specific. At the most general, there is the attraction or repulsion between two atoms or molecules (e.g. an anion and cation, as shown). The strength of these general interactions depends on a number of parameters, including the identity of the molecules, distance or molecular orientation, and solvent condition. These interactions are ‘general’ because they exist between classes or groups of molecules, rather than single, specific ones (e.g. anions and cations exhibit attractive forces for one another, Na+ attracts Cl−, but Na+ does not exclusively interact with Cl−). At increased scales, these intramolecular forces govern the conformational state of a polymer and its interactions with solutes in the environment. Biopolymers with specific sequences and three-dimensional (3D) structure can achieve specific interactions (i.e. orders of magnitude greater affinity for a single analyte or solute) because of multiple complementary, spatially oriented functional moieties.

Intermolecular forces, chemical equilibria, and thermodynamic laws govern the dynamic polymer-environment interactions necessary for actuation. Therefore, in order to design next-generation bio-actuators for bioinspired and biomimetic devices, one must first appreciate and understand the corresponding fundamental principles. This critical background, as well as relevant examples from research in materials engineering and biomaterials science, are given in Chapter 2.

Rational Assemblies:

Certain materials possess chemical properties that enable the formation of stable 3D architectures. At the general level, crosslinking creates network polymers. Networks are insoluble, but can respond to environmental conditions with swelling conditions and/or degrade in response to biological stimuli in a formulation-dependent manner. At higher orders of engineering control, self-assembled structures (i.e. micelles, vesicles, tubes) form out of chemically ordered molecules (i.e. lipids, peptides, surfactants) under certain environmental conditions. Lithographic techniques, 3D printing, and bioprinting enable the generation of amenable materials with precise geometric control.

Intermolecular forces, and polymer-solvent compatibility drive the formation (i.e. self-assembled structures) and environmental responsiveness (self-assembled and crosslinked structures) of rationally assembled materials. Photoinitiated chemistries enable the formation of precise and repeatable microstructures by two-photon lithography and PRINT. This is why it was critical to analyze molecular interactions first. Molecular interactions explain the behavior of polymers in physiological solutions. Therefore, one cannot design rationally assembled polymeric materials without first addressing the fundamentals of intermolecular forces and environmental response. Rational and/or creative assemblies of such biopolymers translate fundamental findings in materials chemistry into supramolecular biomaterials that improve human health. These fabrication strategies are discussed in detail in Chapter 3.

Bioactive interfaces involve the interaction between natural, synthetic, or hybrid materials and biological systems (i.e. bioactive proteins, cells, tissues, organs). In most cases, bioactive interfaces either recapitulate biology (i.e. biomimetic devices and technology) or respond to biological cues (i.e. bioinspired pharmaceuticals or sensors). In Chapter 4, we review diverse applications of bioactive interfaces in the design of next-generation vehicles for oral and transdermal drug delivery, theranostic systems for cancer therapy, closed-loop sensors for glucose monitoring, wearable electronics, neural prostheses, bacteriobots, and skeletal muscle-laden devices.

Proper molecular architectures are required to interface material systems with biological components productively. For example in drug delivery, an application may require environmentally responsive, pulsatile, or sustained elution of a payload. To achieve the desired release profile, engineers must employ the combination of supramolecular assemblies or optimized networks. In constructing a bioactuator with cardiac muscle, proper cell alignment is crucial to generating coordinated, cyclic contraction. Bioconjugation and biofabrication technology allow for presentation of adhesion ligands to promote the adhesion of cardiomyocytes. Additionally, 3D printing and bioprinting technologies enable the fabrication of materials with proper geometric constraints for mimicking muscle fibers.

Interactions between chemical moieties, biological fluids, and solutes drive the environmental sensitivity of biomaterials. Creative and rational assemblies of biomaterials are necessary in bioactive interfaces. Furthermore, as we discuss throughout this review, spatiotemporal distributions of cues (i.e. mechanical, chemical) significantly alter the behavior of embedded cells, and subsequently the function of the cell-material construct. While a fundamental understanding of materials chemistry was necessary for generating new complex biomaterial constructs, a knowledge of biofabrication or bioprinting is a prerequisite for engineering bioinspired and biomimetic devices.

Returning to Figure 1.2, we now see why molecular interactions, rational assemblies, and bioactive interfaces interlock and progress in sequence. The current and future outcomes of synergy in all three research areas are novel pharmaceutical formulations, biosensors, and devices that solve pressing medical issues. After all, addressing these problems, designing devices and products as solutions, and improving the quality-of-life of patients are the motivations for our work.

1.4. Intelligent Materials for Next-Generation Material-Tissue Interfaces:

In this introduction, we have provided a useful engineering framework for the conceptualization and critique of biomimetic and bioinspired medical devices. Using the illustrative examples of closed loop glucose monitoring and cardiac muscle-laden cell actuators, we discussed the cascading structure-function relationships at the molecular, material, and device scales.

In the following sections, we highlight fundamental concepts and recent progress in the areas of environmentally responsive materials, biofabrication, and biomimetic/bioinspired device development. This comprehensive analysis highlights both the recent progress and opportunities for further development in each area.

2. Advanced Functional Materials for Dynamic and Intelligent Systems

Response to a stimulus is one of the most basic processes found in living systems. The desire to engineer dynamic and functional materials is becoming more prevalent in an effort to precisely detect changes in an environment, which can be transduced through an actuator into a signal or therapeutic intervention. Environmentally responsive biomaterials are unique because each material response is purposefully engineered at the molecular level to communicate with physiological processes through complex structure-property relationships and produce a macroscopic functional behavior. When joined together via modular or hierarchical assembly, these responsive components form intelligent devices that simultaneously respond to multiple stimuli and perform complex functions.

Functional intelligent materials recognize a specific environmental stimulus and respond in a predetermined and predictable manner. The degree of response is controlled by the intensity of applied stimuli, and these materials return to the original state when the stimuli is discontinued. To engineer environmentally responsive biomaterials for various applications, researchers have looked to nature for inspiration. By biomimetic design, they have reverse engineered the molecular responsiveness and complex structure-property relationships necessary to transduce biological stimuli into useful mechanical outputs.

Environmental stimuli are divided into three main categories: chemical, physical, and biological. Chemical stimuli are those that stimulate intermolecular interactions such as pH, solvent, and ionic strength. Physical cues include mechanics (stress/strain), temperature, light, magnetic fields, and electric fields. Biological stimuli include enzymatic reactions, membrane permeating peptides, and receptor-ligand recognition. A response can take many forms, from a simple shift in solubility to a series of complex biochemical reactions that transduce minute signals into an optical output. The choice of stimuli and response is driven by the device’s therapeutic or diagnostic application, which will be covered in a later section (Chapter 4).

Understanding the intricacies of a stimulus-response relationship is essential to achieve kinetic, thermodynamic, and spatial control in a useful biomaterial actuator within the device-tissue interface. The following section provides the reader with a fundamental basis for how materials and stimuli interact, and offers engineering considerations to enable the rational design of next-generation materials.

2.1. Thermodynamics of Polymer-Solvent and Polymer-Solute Interactions:

Dynamic material-tissue interfaces rely on materials that recognize shifts or perturbations in the surrounding environment. At the molecular level, this means that a shift in the environmental conditions (e.g., pH, temperature, presence of an analyte) must alter the polymer-polymer, polymer-solvent, or polymer-solute interactions with sufficient vigor to alter the bulk materials’ conformation and/or bioactivity. In this section, we highlight the relevant fundamental principles that explain dynamic material interfaces in physiological buffers. A robust understanding of these principles is crucial to engineering novel biomimetic and bioinspired materials.

2.1.1. Polymer-Solvent Interactions within Hydrogel Biomaterials

In dilute solutions, polymers act as large macromolecular chains and can display a wide variety of possible conformation states (1–3). Typically, they exhibit a random coil or globular conformation to varying degrees rather than existing in an elongated or fully stretched state. A polymer will present itself in a more elongated form in a good solvent, as there is a significant increase in the flexibility of the polymer chains. In non-solvents, there is a loss of chain flexibility and a polymer will aggregate or shrink to varying degrees.

The polymer-solvent affinity determines how energetically preferred polymer-solvent interactions are over polymer-polymer interactions (1–4). This particular behavior allows attractive forces between polymer segments to become stronger or weaker than polymer-solvent interactions. Stronger attractive forces between polymer segments result in random coil or globular states, and weaker forces result in elongated or stretched conformation states. A greater polymer-solvent affinity corresponds to a lower chemical potential within the polymer aggregate or matrix network than that of the surrounding environment. In turn, the polymer-solvent mixing pulls the surrounding fluid into the matrix network and leads to an increase in the osmotic pressure,.

The change in total Gibbs energy (ΔGtotal) and the energy associated with mixing (ΔGmixing) at constant temperature and pressure are governed by the thermodynamic formulas described here:

In the first expression, the total Gibbs energy of the system is presented as the sum of the free energy associated with stretching or compressing chemical bonds (i.e. elastic) and the energy associated with mixing two compatible phases (i.e. mixing). The changes in enthalpy and entropy associated with the mixing process are represented in the second equation by ΔHmixing and ΔSmixing, respectively. T represents the absolute temperature in Kelvin. It is important to note that Flory-Rehner theory, presented here, is valid for nonionic gels and that direct use it to explain the behavior of ionic hydrogels is incorrect (3). In this case, the theory must be adapted to account for additional ionic interactions and forces within the hydrogel network and between the hydrogel and surrounding environment.

As the vital studies of Flory and Huggins have demonstrated, the contribution of the polymer-solvent affinity to the free energy (ΔGmixing) depends on several factors including: (i) the polarity of the solvent, and (ii) the hydrophobic-hydrophilic character of the groups attached to the polymer backbone (1). This is detailed by the Flory-Huggins solution theory:

where the total moles of the solvent and polymer are represented by n1 and n2, respectively, and the respective volume fractions are represented by v1 and v2, respectively. The introduction of a mixing parameter, χ12, is present to account for the increase of energy due to the interspersing and contacts between polymer and solvent molecules. T represents the absolute temperature in Kelvin, and R is the universal gas constant. It is important to consider that the polymer equilibrium properties are highly dependent upon several key physicochemical parameters, including the type of solvent, pH, type of salts present, total ionic strength of the surrounding solution, and temperature (3, 5).

Similarly, the change in osmotic pressure from polymer and solvent mixing can calculated using the formula below:

In the equation, the molar volume of the solvent is represented as V1. The formula was further simplified using the known identity:

One relevant example of dynamic biomaterial-solvent interaction is that of a non-ionic hydrogel and water. Hydrogels are 3D, insoluble water-swollen structures composed of hydrophilic homopolymers or co-polymers. They are crosslinked either chemically or physically and swell in aqueous solutions (5, 6). They can absorb as little as 20%, and up to 90% water by total weight when submerged in biological fluids or water. Hydrogels represent a very important and broad class of biomaterials, can be prepared using a wide variety of techniques, and can exhibit a range of behaviors. Due to the significant water content, hydrogels offer a degree of flexibility akin to natural tissue, which has garnered significant attention in biomedical applications and tissue engineering.

The 3D polymeric networks can be prepared using chemical or physical crosslinking techniques (5, 6). Chemical crosslinks entail covalent attachment of the polymer chains and are stable mechanically and thermally. Physical crosslinks may be incorporated into the network through molecular entanglement of the polymer chains or crystalline segments. These hydrogels are not homogeneous, but rather are clusters of polymer chain entanglements or clustered domains governed by attractive hydrophobic forces.

A non-ionic hydrogel will start to swell when in contact with water due to the favorable thermodynamic state of the polymer chains and solvent molecules. This phenomenon has been studied extensively by Peppas et al., and is the subject of many comprehensive reviews (5–9). Swelling in non-ionic hydrogel systems is driven primarily by a gain in entropy of the system through the mixing of the solvent molecules and polymer chains (1, 2, 5, 6). The elastic, retractile forces imparted by the polymer crosslinks counterbalance the forces of fluid intake and network expansion. Hydrogel swelling reaches an equilibrium condition when the two opposing forces are equal.

In order to define the structure of a hydrogel network, three important parameters should be considered: (i) the polymer volume fraction in the swollen state, (ii) the number average molecular weight between crosslinks, and (iii) the corresponding network mesh size (5, 6). The equilibrium volume fraction of the polymer phase is calculated as the ratio of polymer volume to the volume of the fully swollen hydrogel network. It is also the reciprocal of the polymer network volume ratio between the collapsed and fully swollen states, which can be determined experimentally through equilibrium swelling studies.

As mentioned above, the swelling behavior can be influenced by environmental (pH, temperature, ionic strength, etc.) and internal factors (polymer composition, hydrophobicity, etc.). Additionally, the swelling behavior is significantly affected by the nature of the crosslinks (covalent vs. physical) and crosslinking density (5, 6). The density directly influences the network mesh size and should be considered significantly depending on the application. For example in drug delivery applications, network porosity is a critical characteristic in defining the structure as it directly correlates to the ability of an entrapped solute or molecule to diffuse out through the network (5, 6). With higher crosslinking densities, the permeability and ability to diffuse out drastically decreases. This is especially true in the case of high molecular weight solutes such as growth factors, proteins, and antibodies.

2.1.2. Dynamics of Material-Solute Interfaces:

It is critical to understand the magnitude, length scale, and governing properties of biomolecule-biomaterial interactions in order to discuss their implications in bioactive devices and interfaces. In particular, electrostatic interactions, hydrogen bonding, and hydrophobic interactions are critical to the affinity of a material surface for biomolecules of all sizes.

Electrostatic Interactions:

A simple approximation of the force of electrostatic interaction between charged biomolecules and biomaterials according to Coulomb’s law(10, 11):

where ε0 is the permittivity of free space, D is the dielectric constant, q1 and q2 are the charges of the two interacting molecules, and r is the distance separating them. In water, this expression can be simplified to:

Electrostatic interactions are extremely enthalpically favorable. Additionally, even though the length of an electrostatic interaction is shielded in physiological salt solutions, this length is much greater than that of other intermolecular interactions (i.e. hydrogen bonding, van der Waals forces). Considering the charged state of nearly all biomacromolecules (DNA, RNA, protein), electrostatic interactions are critical in natural biomolecule interactions, are common targets in the development of inhibitory compounds, and, in the greatest relevancy to this review, are a critical design criterion in synthesizing bio-interfacial materials(12).

Electrostatic Interactions in Physiological Solutions:

In typical biological solutions, such as those present in vitro or in vivo, however, the presence other ionic species (salts, etc.) results in a charge-screening cloud. At a characteristic length, called the Debye length, the charged species and screening cloud together are effectively neutral. Therefore, electrostatic protein-material interactions occur at a closer proximity than the Debye length, which is calculated:

where kB is the Boltzmann constant, T is temperature, z is the valency of the ion, e is the elementary charge, and cinf is the counter-ion concentration in the screening cloud(11). A reasonable simplifying assumption is that this concentration is not significantly different from that of the solution at equilibrium. A typical Debye length in biological solutions is approximately 0.7 nm.(13)

Hydrogen Bonding:

Hydrogen bonding, another critical intermolecular interaction between biomolecules, materials, ligands, and water, is far more dependent on distance and orientation than electrostatic interactions (14). The average distance between a hydrogen bond donor and acceptor varies depending on the identity of each species, but ranges from approximately 1.54 to 2.79 angstroms(15). Hydrogen bonding interactions are extremely favorable when the spatial orientation of the species is appropriate. However, at distances that are closer than optimum, hydrogen bond interactions act in a repulsive manner, and at distances greater than the optimum the interaction strength declines rapidly (Figure 2.1). As shown in the figure, the repulsion force between hydrogen bond donors and acceptors increases sharply (scales with r−12) as they are brought in closer proximity than the optimal position. As the donor and acceptor are separated from their ideal orientation, the bond energy decreases (scales with r−6)(14).

Figure 2.1:

Distance-dependent bond potential of a hydrogen bond. Hydrogen bonds can be stabilizing or destabilizing, depending on the donor and acceptor. Few hydrogen bonds deviate substantially from the optimal distance Reprinted with permission from (14) published by Wiley.

Hydrogen bonding is critical to proper biological function, as it is responsible for complementary base pair formation in DNA and plays a significant role in the 3D folding of proteins (16). The precise spatial constraints of hydrogen bonding make it ideal for maintaining specific biomolecule interactions, and thus it is a commonly exploited molecular interaction in the design of biomimetic devices.

Hydrophobic Interactions:

Hydrophobic interactions are widely believed to be the driving thermodynamic forces behind high affinity ligand-receptor interactions in vivo(17). Hydrophobic ligand-receptor interactions are thermodynamically favorable in a number of ways. In an unbound state, hydrophobic binding pockets within a macromolecular receptor must interact with the solvent environment (water). As this interaction between hydrophobic residues and water is unfavorable, immediate water molecules will assemble into fixed orientations that maximize hydrogen bonding between the fixed water molecules and minimize contact with the hydrophobic material. This coordinated orientation is very entropically unfavorable(18, 19).

Proper ligands, which engage in hydrophobic interactions with the receptor’s binding pocket, liberate the fixed water molecules from this bound conformation. These water molecules, now expelled from the binding cavity, can then engage in hydrogen bonding with neighboring water in solution, but can also explore many spatial orientations, resulting in a higher entropy state(20).

As applied in a molecular and materials engineering context, properly aligned hydrophobic interactions are a critical tool. Modulation of hydrophilicity, evidenced through water contact angle, was one of the early methods for increasing the biocompatibility of medical implants(21). To this day, coating biomaterials with hydrophilic polymers such as poly(ethylene glycol) (PEG) is the primary approach for ‘passivation’ or prevention of immune recognition of adsorbed molecules(22). In drug delivery, regenerative medicine, and biosensing, proper design is necessary to provide complementary hydrophobic interactions between material carriers and tissue biomarkers, loaded therapeutic cargo, or regenerative factors. These interactions are used to impart material-protein affinity leading to lower dissociation constants, increased loading capacities, extended drug retention, and ideal release profiles(23).

2.1.3. Molecular Recognition:

A molecular recognition event occurs when a multiplicity of intermolecular interactions coincide productively to generate a binding environment with specificity for a particular analyte. Nature has mastered the art of molecular recognition, with antibody-antigen binding as a classic example of high affinity and specificity recognition. The engineering of biomaterials with molecular recognition properties has recently emerged as a materials science research area, particular for bio-separations, molecular sensing, and pharmaceutical applications. In the following section, we review the thermodynamic principles that explain molecular recognition in natural biological systems, biomaterials, and at the interfaces of the two.

Free Energy of Binding:

Minimization of the relevant systems’ free energy state drives material-protein and protein-ligand interactions. The first relevant contributor to free energy is the enthalpic gain or loss attributed to protein-material-solvent interactions. Electrostatic interactions, hydrogen bonds, and van der Waals forces each contribute directly to the systems’ enthalpy:

Here, ΔH represents the enthalpy off the system, which is the sum of the enthalpic contributions (favorable and deleterious) of electrostatic interactions, hydrogen bonding, van der Waals forces, and other intermolecular forces (i.e. polar interactions) between molecules within the system (i.e. ligand, receptor, and solvent).

The second major contributor to free energy state is entropic gain or cost, associated with the number of physical arrangements the material-ligand-solvent system can sample. By argument of statistical mechanics, the entropy is calculated by:

where kB is the Boltzmann constant and W is the number of equally-probably states (i.e. orientations and arrangements) that the system can explore(24). The following relation approximates the change in entropy of a ligand-receptor interaction.

Extending this expression to a protein-material-solvent system:

where ΔS is the change in entropy for either the system, solvent (i.e. bound or liberated molecules), the molecular ligands/receptors, and other species (i.e. associated or liberated ions, physiological molecules).

The Gibbs free energy expression, therefore, contains the above contributions:

where the system’s enthalpic and entropic contributions are the sum of all components, and the temperature is expressed in absolute units (Kelvin)(25). As applied to recognitive material systems, these expressions describe a favorable binding event as one that leads to additional enthalpically favorable molecular interactions, so long as the enthalpic gain overcomes the entropic loss of a fixed conformation. However, binding events are not always entropically unfavorable, as protein-material interactions can also liberate alternative ligands, molecules of solvent, or adsorbed ions. These outcomes can subsequently increase the total system entropy.

Equilibrium Adsorption Constants:

The equilibrium adsorption constant expression takes into account the binding free energy:

The standard binding free energy (ΔG°) is an expression that describes the free energy of association under an idealized system (i.e. 1M ligand and receptor concentration, 1 atmosphere of pressure, 298K). In the expression, R is the universal gas constant, T is the absolute temperature, and ka is the equilibrium adsorption constant. Frequently dissociation constants (kd), rather than association constants, are employed to compare the affinity of different ligand-receptor systems:

where [L] and [R] describe the concentration of ligand and receptor, and [LR] describes the concentration of the bound ligand-receptor complex. It is standard practice in the field to quantify affinity interactions by presenting the magnitude of the dissociation constant (e.g., micromolar). Many typical dissociation constants for protein-protein interactions are in the micromolar range, although high-affinity or super-affinity partners (e.g., antibody-antigen interactions, avidin-biotin binding) can reach nanomolar, picomolar, or even femtomolar affinity.

Upon deviation from an equilibrium condition, the Gibbs free energy of the system can be described by the following relation;

taking note that as the system approaches an equilibrium condition (ΔG→0) the expression simplifies back to the standard binding energy (17).

Multiplicity:

High affinity protein-protein and protein-material interactions are achieved through the productive sum of multiple intermolecular interactions. The important thermodynamic aspect of this reality is the concept of multiplicity(26). If a receptor can productively engage a ligand at two epitopes that provide similar enthalpic gains, for example, the total enthalpic gain of the ligand-receptor interaction will effectively double. As the ligand-receptor complex is held in a fixed orientation from the first interaction, there is minimal entropic loss from engagement in a second epitope-binding event. This will decrease the Gibbs free energy of binding significantly, shifting the equilibrium further toward the bound complex. Antibodies achieve high functional affinity (or avidity) for their antigen through multiplicity, and mimicking multiplicity within synthetic biomaterials using spatial composition control has been a research goal for several decades(27).

Super Affinity:

Molecular dynamic simulations have been utilized to explore the concept of ‘super affinity’, which is a term commonly used to describe affinity between binding proteins and other biomolecules (e.g., other proteins, peptides, or sugars) that are higher than anticipated based on the magnitude of individual intermolecular interactions(28, 29). Super affinity appears to emerge where the formation of hydrophobic contacts or enclosures coordinate with hydrogen bonding. These super affinity interactions are unique to certain properties of the protein receptor, as the specific hydrophobic ligand cavity must be naturally present, but nonetheless demonstrate the incredible specificity that can be achieved by synergistic intermolecular forces in confined geometries(30). Super affinity interactions are of particular interest to engineers designing next-generation biosensors, as well as scaffolds for tissue engineering that retain necessary growth factors.

2.2. Engineering Materials that Respond to Chemical Stimuli

With a fundamental understanding of the principles underlying polymer-polymer, polymer-solvent, and polymer-solute interactions, it is possible to design material systems that respond predictably to biological stimuli. To achieve the design goal of engineering devices that respond to dynamic physiological environments, researchers have employed a diverse repertoire of chemically-active natural and synthetic materials.

It is most practical to guide the design of advanced biomaterials that recognize and respond to changes in the physiological environment by characteristics of native physiology or a pathological state. The medical application and necessary transformation (e.g., change in protonation state, interaction with solvent, adsorption events, or cleavage of crosslinks) will guide researchers’ selection of material architecture and chemical stimulus. The following section details recent developments, challenges, and limitations in biomaterials that respond to several chemical stimuli, including pH, salts, ionic strength, oxidation, and reduction.

2.2.1. Switchable Polymer Brushes

In recent years, there has been great interest in engineering materials with solvent-responsive surface properties. This has been important in generating advanced devices and implants, such as those with anti-fouling and self-healing properties to more complex signaling systems that adaptively control the permeability and flow through nano/micro-pores. To this extent, there have been extensive studies on polymer films with switchable properties through a change the conformation of surface grafted chains (31–35).

Polymers such as poly(methyl methacrylate) (PMMA), poly(styrene) (PS), PEG, poly(butyl acrylate), and poly(dimethylaminoethyl methacrylate) (PDMAEMA) have been extensively researched in the fabrication of solvent responsive polymers (31–34). When treated with different solvents, the polymer brushes can exhibit a degree of deformation or change in orientation. As described in the previous section, the exact response is dependent upon the solvent environment and the thermodynamic nature of the polymer segments (i.e. the relative strength of the polymer/polymer vs. polymer/solvent interactions). Good solvent environments will yield an extended, stretched brush-like regime due to swelling, maximized solvent contacts, and increased flexibility of the macromolecular chains. When exposed to poor or non-solvent environments, the polymer brush deforms to yield more aggregated mushroom-like regimes.

Mixed polymer brush systems are those consisting of two or more homopolymer segments with different characteristics (32). The system are more complex, but have generated a lot of interest as they can display an amplified response when exposed to external solvents or proteins. This is due to the combination of a change in the network conformational state with the immiscibility and subsequent phase separation of the specific network domains.

For example, a mixed polymer brush can be comprised of a distinct hydrophilic homopolymer segment and hydrophobic homopolymer segment. If the polymer brush is in an aqueous environment, polymer/solvent interactions with the hydrophilic segment are more energetically favorable. Thus, the hydrophilic portion orients itself outward, and the surface becomes hydrophilic. If exposed to a hydrophobic environment, the same polymer system will instead preferentially segregate the hydrophobic homopolymer outward.

Control of the polymer brush architecture and morphology is critical for determining its performance in the end application. To this extent, nanoscale patterning of solventresponsive polymer brushes has opened up the ability to generate films or particle surfaces of varying controlled morphology, as illustrated in Figure 2.2. The structure and the surface roughness of the brushes can be controlled by varying the solvent quality during sequential surface reactions. The length scale between neighboring chains (low or high density grafting) influences the type of brush produced, and the brushes will naturally stretch away from the surface at high densities in order to reduce neighboring interactions (i.e. steric repulsion). Self-healing films can be generated by designing a system with hidden tethers that are exposed upon the rearrangement of externally grafted polymers at the interface. In more complex systems, direct patterning after grafting the polymer brushes has been demonstrated to fabricate nanochannels or pores in the system via electron beam lithography (36).

Figure 2.2.

Polymer brushes can be utilized to synthesize responsive films or surfaces. (a) Simple methods can be utilized to generate polymer brush surfaces with smooth or rough nanoscale morphology. Here, the degree of roughness can be controlled by varying the solvent quality during subsequent polymerizations. Reprinted with permission from (33) published by Elsevier. (b) The morphology and design can impart switchable anti-fouling and self-healing properties. Here, the additional self-healing aspect of the antifouling film is due to the rearrangement of internally grafted polymers to the interface (marked as dark blue chains). Reprinted with permission from (37) published by Wiley.

The reversible deformation with a change in solvent has been of particular importance in designing switchable surfaces for electronics (microactuators), microfluidic devices (lab on a chip, organ on a chip), and biosurfaces (biosensors and implants). Further, it has opened up many new possibilities in surface engineering concepts for improved wettability and adhesion at biological interfaces, mechanical actuation, chemical sensing, cell growth and separation, and micro- and nano-fluidics (31–33, 37). These applications will be covered in detail in Chapter 4.

2.2.2. pH-Responsive Polymers

pH-responsive polymers, commonly known as polyelectrolytes, contain functional moieties that are capable of accepting or donating protons as a response to pH changes in the surrounding environment (5, 6). The groups are often utilized as pendant groups or in side chains, but may be present in the polymer backbone. The extent of ionization depends on the environment pH. When a homopolymer is in an ionized state, the moieties carry a charge (all positively or negatively) and the chains repel one another due to electrostatic repulsion. The change ionization state may also cause the polymer to alternate between hydrophobic and hydrophilic behavior. Within the class of charged materials, polymers can be divided and characterized as anionic or cationic. Both anionic and cationic polymers can have a characteristic pKa between pH 1 and 14, and the underlying mechanism of the environmental response is the same for both species.

Anionic polymers, commonly known as polyacids, are polymers containing acidic functional moieties. Function groups used typically include carboxylic acid (−COOH), sulfonic acid (−SO3H), boronic acid (−B(OH)2), and phosphonic acid (−PO(OH)2). Under acidic conditions (below the pKa), the functional groups on polyacids will accept protons to yield a neutral polymer. The protonation enables hydrogen bonds to form with accepting groups in the polymer network and contributes to structural deformation or the formation of complexes (5, 6). At neutral or basic conditions (above the pKa value), the moieties release protons to form a negatively charged polymer. The charged state results in electrostatic repulsion, an increased solubility of the polymer, and maximized solvent contacts to yield an extended or stretched conformation. If in a crosslinked network, the Coulomb repulsion will result in a swelling or expansion.

Cationic polymers, on the other hand, contain basic functional groups and display an inverse behavior to anionic polymers. Common examples include tertiary amines (−NR2), pyridine (−C5H4N), pyrrolidine (−C4H8N), imidazole (−C3H3N2), and piperazines (−C4H4N2R). As with polyacids, cationic polymers will accept protons under acidic conditions below the pKa (5, 6). However, the functional moieties will now carry a positive charge. The positive charge results in the same electrostatic repulsion and conformation change as described above. At higher pH values (above the pKa value), the groups release the protons to yield a neutral polymer.

Amphiphilic polymers, or polyampholytes, are comprised of both acidic and basic functional groups (5, 6). The groups used to create amphiphilic polymers are the same as described above. Specific examples may include naturally occurring polymers (e.g., gelatin), synthetic polymers (e.g., P(MAA)-b-P(DMAEMA)), and hybrid semi-synthetic or modified natural polymers (e.g., modifications of chitosan, cellulose esters, alginate). As a significant portion of research has focused on creating biomimetic materials, these polymers have generated great interest. A portion of the increased interest stems from the discovery that many biomacromolecules are amphoteric in nature, including amino acids and nearly all proteins. Polyampholytes can also contain a hydrophilic and hydrophobic domain simultaneously across a range of solvents and pH values, making them very useful as surfactants.

Compared to simply anionic and cationic homopolymers, polyampholytes display a much more complex behavior to changes in pH due to competition between the acid-base equilibria of each unit. With weak acidic and basic groups, the polymer will likely have a net charge a certain pH values. However, it is possible for both groups to be charged throughout the entire pH range, yielding a net zero charge on the polymer. This is highly dependent upon the nature of the functional moieties used. Further, the conformation state in solution is highly dependent upon the charge distribution and location (not only the average composition). The acidic and basic moieties are commonly located in separate monomer units, but may be located on the same chain. For example, polybetaines are a subclass of polyampholytes that carry both a positive and negative species in each monomer unit.

The “pH critical point” of a polymer is a term used to represent the pH value where the polymer displays an inflection in the ionization state and/or solvent interaction (5, 6). As described above, a pH-responsive polymer typically displays a more compact, folded state in the unionized state. When the polymer is ionized, the moieties carry a charge and the chains move away from one another due to the Coulomb repulsion. However, it is important to note that the ionization process and subsequent structural change reflects deformation of the polymer or a change in the conformation state. The process does not involve breaking of bonds and is reversible.

The interplay between hydrophobicity and electrostatic repulsion dictates the extent and character of pH-responsive behavior. Repulsion between proximal anions or cations results in an increase in the hydrodynamic volume of the polymer. Additionally, osmotic pressure exerted by mobile counterions neutralizing the network charges explain polymer chain transition from a coiled to an expanded state. To this extent, network swelling is influenced by any condition that modifies the ionization state or electrostatic repulsion (e.g., type of counter ions, ionic strength, temperature) (5).

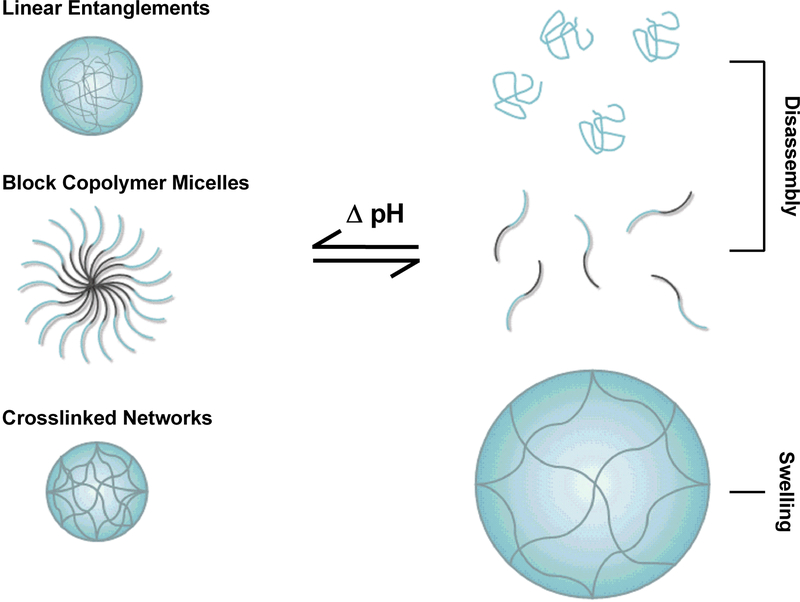

As detailed above, swelling in hydrogel networks is driven by a balance of thermodynamic and physical forces. In the case of simple linear or complexation polymers, the pH-dependent hydrogen bonding and electrostatic interactions result in a transition from an aggregated state to complete or partial dissociation (Figure 2.3). With crosslinked polymer networks, the swelling behavior is still governed by hydrogen bonding and electrostatics. However, the osmotic pressure of the counterions results in a swelling or deswelling behavior with the crosslinks serving as tie points to maintain 3D network structure.

Figure 2.3.

pH-responsive polymers may be comprised from linear entanglements, block copolymer micelles, and crosslinked networks.

A well-studied, pH-responsive hydrogel is crosslinked poly(acrylic acid), or P(AA) (5, 6). The solubility of P(AA) as a function of pH defines the conformation of the 3-dimensional network in an environment. At pH values below the pKa, the ionizable carboxylic acid pendant groups are neutral (−COOH). Electrostatic repulsion is absent, hydrogen bonding is favorable, and the polymer network is in a collapsed conformation state. At high pH (above the pKa of the carboxylic group), the functional groups are deprotonated and carry a negative charge (−COO−). In this salt form, there is a rapid influx of mobile counterions, the polymer network adsorbs water, and it rapidly swells.

In addition to P(AA), synthetic monomers commonly used to impart pH-responsive behavior include those with carboxylic acid (−COOH), sulfonic acid (−SO3H), boronic acid (−B(OH)2), amine (−NH2), and imidazole (−C3N2H4) groups. For example, MAA, itaconic acid (IA), ethylene imine (EI), DMAEMA, and diethylaminoethyl methacrylate (DEAEMA), and β-amino esters are widely studied in the literature (5, 6, 38–40). In certain cases, a polymer may also undergo multiple ionization processes. For example, a polymer comprised with phosphonates or phosphonic acid (H3PO3) functional groups will pass through each ionization state and gradually reach a fully dissociated form.

There are also a breadth of natural polymers that display reversible pH-responsive behavior. Common natural polyacids and polybases studied in the biomedical literature include chitosan, alginate, hyaluronic acid, and dextran (38, 41, 42). Natural amphoteric molecules are also prevalent in the literature and include collagen and albumin (43–46). Natural polymers are appealing because they offer low antigenicity and high biocompatibility - making them an ideal choice for biomedical and tissue engineering applications. Further, natural polymers are often derived from renewable sources and can display biomimetic properties (e.g., hydroxyapatite, collagen).

However, natural polymers have several disadvantages, which may be significant depending on the desired application (5, 6). Natural polymers are often derived using methods that can result in inconsistent production, batch-to-batch variability, and potential contamination. Additionally, they may degrade too rapidly in vivo or lack sufficient mechanical strength for a specific site in the body. In that regard, synthetic polymers may offer increased control over the structure-property relationship. A summary of common pH-responsive natural, synthetic, and hybrid biomedical polymers is given in Figure 2.4.

Figure 2.4.

Schematic with representative structures for common synthetic, hybrid semi-synthetic and natural pH-responsive polymers.

Modulation of pH Critical Point:

The pH range of the network phase transition can be modified using two common strategies. In a first strategy, the pKa of the ionizable group is selected to closely match the desired pH range in the ultimate application (6, 7, 47). This strategy requires careful selection of the acidic and/or basic functional groups with respect to the characteristic pH range of and the biocompatibility necessary for the intended application. By definition, the pKa of pH-responsive polymers is a function of the ionizable groups. To this extent, changing the characteristic nature of the functional groups (e.g., electronegativity, steric hindrance, hybridization, induction, resonance) can efficiently modulate the pKa. Thus, the pH-induced, reversible transition can be adapted to meet requirements of the desired application.

Alternatively, copolymers can be designed and synthesized to precisely tailor the pKa (6, 7, 47). Statistical copolymers comprised of multiple ionizable monomers can exhibit a pKa between those of the individual homopolymers, and fine-tuning can be achieved through variation of the monomer feed ratio. Hydrophobic moieties may also be incorporated directly into the polymer backbone. In an environment where ionizable groups are near neutral, electrostatic repulsion forces disappear within the polymer network and hydrophobic attractions dominate. The hydrophobic moiety can be varied in terms of both chain length and steric bulk. As the hydrophobic content in the network increases, greater proton activity is required to promote polymer/solvent interactions (required for dissolution or swelling) over the polymer/polymer attractive forces. For example, the enteric polymer hydroxypropyl methylcellulose acetate succinate (HPMCAS) can be tailored within a wide pKa range by changing the ratios of either the hydroxypropyl, methoxyl, acetyl, and/or succinoyl groups within the polymer functional groups. This strategy enables precise control over the structure (i.e. via the comonomer type, ratio, and distribution), and typically offers a wider variety of analogs to probe the relationship between structure and functionality.

The versatility of pH-sensitive chemistries offers many opportunities for exploiting pH variations found in native biological systems or characteristic physiological changes of diseased states (5–9, 39, 47). While the primary response to a change in pH is swelling or collapse, other possible responses are possible. pH-modulation can also induce degradation via acid-liable linkages, a sol-gel transition (from a solution to a gel), and/or the formation of micelles. These behaviors will be discussed further in Chapters 3.1 and 4.1.

2.2.3. Ion-Responsive Polymers

An ion is an atom or group of atoms carrying an electrical charge formed by the gain or loss of one or more electrons (48). In solution, ions originally present within the crystal lattice of a solid dissociate into both negatively and positively charged species (anions and cations, respectively). The species are present as electrically neutral combinations with the ability to migrate nearly independently throughout the solution. Ions in electrolyte solutions consisting of only a single atom are termed monatomic (e.g., Na+, Cl−), and those consisting of a few atoms or larger form molecular ions or polyatomic ions (e.g., NH4+, CH3COO−).

The underlying mechanism of ion-responsive polymers is that the disassociated, charged ion species will interact with the polymer or copolymers, reducing the electrostatic interactions between segments, chains, and other molecules in the surrounding environment (48). As detailed earlier in our discussion of electrostatic interactions in physiological fluids, this behavior is due to charge screening, in which the forces between any charged groups in the polymer are lowered.

Polymers containing a large number of ionizable functional groups will demonstrate increased solubility in environments where the groups carry a charge. However, the charge shielding seen with addition of salts may alter the conformation state of the polymer into a contracted coil or globular form. As a result, ionic strength and type of ion can show a strong effect on the solution behavior of many responsive polymers (e.g., pH, temperature) (48–57).

The pivotal work of Frank Hofmeister can be used to describe how ion type and concentration can alter the stability of macromolecules in aqueous solutions (58). As ranked in Hofmeister series, the order for the ability of anionic species to decrease hydrogen bond interactions between water and strengthening surface tension is generally:

and the order for cationic species is generally:

although the effect of cationic species has generally been shown to be less pronounced (59, 60). With hydrophilic macromolecules, the effect of ions on the left-hand side is characterized as decreasing the solubility or having a “salting-out effect.” In contrast, the ions to the right-hand side will increase solubility or have a “salting-in effect.” The exact order of the ion species listed should be considered qualitative (59, 60). It has been can vary with respect to the nature and structure of macromolecule being studied. Often, the effect of neighboring ions can change order. In certain cases, the effect can actually follow a reverse order of the classic Hofmeister series (53).

While experimentally useful, the fundamental mechanism of the Hofmeister series still remains poorly understood. Numerous theories to explain the effects have been suggested in literature (51, 52, 55, 60). Of those suggested, many hypothesize the ability of the different ion species to affect water structure, dividing the nature of the salts into water structure “makers” (kosmotropes) and “breakers” (chaotropes). Kosmotropes are strongly hydrated and increase the local order of water. This effect can lead to increased surface tension and increased stability of hydrophobic aggregates in solution. Using an example of a hydrophobic pH-responsive polymer, this effect can result in an apparent decrease of the pKa due to the decreased solubility of hydrophobic segments. Conversely, chaotropes are weakly hydrated anions that can break down hydrogen bonds and disrupt the local water structure. This can destabilize hydrophobic aggregates and lead to a decreased surface tension and increased solubility in solution.

In responsive materials, ion exchange describes a reversible trade between the material and its surrounding environment (48, 49, 60). Ion exchange is used in a wide variety of technical applications, including water softening, wastewater treatment, environmental remediation, chemical synthesis, and purification (61–65). In the medical field, ion exchange is well-studied for application in drug delivery, diagnostics, sensors, and a variety of other areas (44, 48, 52, 66–69).

Specifically in delivery applications, ion exchange resins are often used a drug reservoirs to enable taste-masking and sustained drug release as a function of time or exposure to counterions in the body. A variety of polymer matrices with the ability to control drug release have been reported in the literature (52, 70–77). The functional groups typically employed to generate the ion-responsive materials include quaternary ammonium, tertiary amine substitutes, sulfonic acid, and carboxylic acid.

The process and rate of ion exchange involves diffusion of the counterions through the material matrix. To this extent, porosity and particle size are critical attributes of the material. These attributes can be controlled through careful variation of the polymerization conditions and manufacturing technologies (48, 49). With polymer particles, the diffusion rate is typically under kinetic control at high concentrations. Larger length scales are slow, and smaller particle sizes typically result in improved efficiency. Conversely, the diffusion rate is kinetically controlled at low concentrations in polymer films. With both particle and film diffusion, lower polydispersity enables a more consistent kinetic performance than highly polydisperse polymers.

Outside of therapeutic delivery, the usefulness of ion exchange in the biotechnology and biomedical field is often correlated with the ability to regenerate the material for continuous use. The reaction should be reversible with no permanent change or loss of efficiency of the material as a result of ion exchange or regeneration process (48). To this extent, a variety of responsive materials have been reported in the literature for use in diagnostic sensors, self-healing hydrogels, and chromatographic separations of many biotechnology and fermentation processes such as the isolation and purification of monoclonal antibodies, proteins, and peptides (69, 78–85).

2.2.4. Oxidation – Reduction Polymers

Oxidation-reduction responsive polymers respond to environmental stimuli that can provoke a change in the oxidation state of redox sensitive groups (86). In inorganic chemistry, transition metals have historically been used to design this type of responsive material. The discovery of free radicals in biological systems occurred in 1954 (87). Over the last few decades, continued advances in our knowledge of and ability to mimic biological systems have stimulated great interest in redox-responsive polymers for potential applications in biomedical fields.

Many biomedical materials take advantage of reactive oxygen species (ROS) and reactive nitrogen species (RNS) found in the body, either by natural processes or abnormalities of diseased states (46, 88–90). Both species are characterized by a highly reactive nature, resulting as a byproduct of their unpaired electron. Common ROS include hydrogen peroxide (H2O2), hypochlorous acid (HOCl−), superoxide (O2•−), and subsequent derivatives including hydroxyl radical (•OH), hydroperoxyl radical (HO2•), peroxyl radicals (RO2•), alkoxyl radicals (RO•), and singlet oxygen. Common RNS include nitric oxide (NO•) and its derived reactive species including peroxynitrite (ONOO−), nitroxyl anion (NO−), nitroxyl cation (NO+), and nitrogen dioxide (NO2•).

Both species are produced at low levels naturally, as byproducts of healthy activity and metabolism in the human body. They can be beneficial at these low levels and are physiologically significant for complex functions such as muscle contraction, metabolism of nutrients, energy production, blood pressure regulation, and cognitive function. Additionally, they play critical roles in biological processes that are necessary to regulate life, such as cell proliferation and growth, normal apoptosis, regulatory mediators in cell signaling, and innate immunity (86, 91, 92). For example, superoxide is a natural byproduct of the immune system in response to oxygen-dependent killing mechanisms of foreign microorganisms or pathogens. Nitric acid is commonly formed as a result of the enzymatic activity of various nitric oxide synthases (NOS) with oxygen, NADPH oxidase, and L-arginine.

Overproduction of both radical species may also be induced by either external environmental stimuli or internal stimuli as a result of disease. Environmental triggers that provoke ROS/RNS production in the body can include tobacco, radiation, and air pollutants from car emissions, fossil fuels, and smoke. Internally, inflammation and inflammatory responses are associated with abnormal enzyme activity resulting in high concentrations of oxidizing agents and radical species. This state of oxidative stress is commonly associated with aging, many metabolic syndromes, and diseases such as Type 2 diabetes, cancer, muscle and tissue injuries, neurodegenerative diseases, coronary heart disease, cardiovascular disease, and hypertension. When overproduced, the stress can lead to mitochondrial and cellular dysfunction through the damage of key proteins, DNA, and RNA. This dysfunction often results in dysregulation or deactivation of certain enzymes and of polyunsaturated fatty acids in lipids (lipid peroxidation). In some cases, long term accumulation of damage from oxidative stress may lead to organism death (90).

In biomedical applications, redox-responsive materials typically use similar design principles to those described in pH-responsive materials that undergo an acid-labile cleavage or degradation. Molecularly, materials are commonly designed with functional groups with multiple oxidation states (e.g., iron, selenium, sulfur) and disulfide, diselenide, and ditellurium linkages (39, 86, 91, 92). Table 2.1 illustrates several common responsive moieties and details their oxidative states.

Table 2.1.

Commonly studied oxidation-reduction responsive moieties and their respective oxidative states. Reprinted by permission from (91) published by Wiley.

| H2O2-responsive materials | Chemical structure and oxidation |

|---|---|

| Part 1: H2O2-induced change | |

| Thioether containing materials | |

| Selenium containing materials | |

| Tellurium containing materials | |

| Phenylboronic acid/ester containing materials |  |

| Part 2; H2O2 induced degradation | |

| Diselenide groups containing materials | |

| Thioketal containing materials | |

| Phenylboronic ester capped materials | |

| Aryl oxalate ester containing materials | |

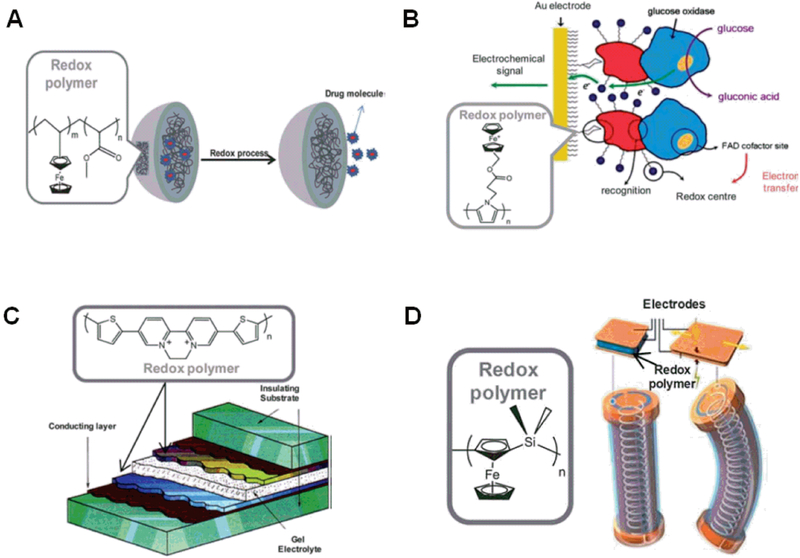

As shown in Figure 2.5, the ultimate goal of the design is typically to provoke the production of a current, controlled degradation, chain cleavage, or a conformational change in overall material structure (39, 92). This can be accomplished through either a specific bond cleavage or solubility changes at the molecular level. These responses can be useful for both sequestration/release or as bottom-up assembly approaches to nanoscale arrays and protein patterning for biosensors, bioactuators, and miniaturized diagnostic assays. Recent developments in both the manufacturing and application of these responses are reviewed in detail in Chapters 3 and 4.

Figure 2.5.

Illustration of common ROS-responsive systems utilized in biomedical applications as (a) drug delivery vehicles, (b) molecular sensors, (c)electrochromic devices, and (d) mechanical actuators Adapted with permission from (532) published by Royal Society of Chemistry.

2.3. Advanced Materials that Respond to External Signals:

In the previous section, we reviewed diverse materials that respond to changes in the physiological environment (e.g., through protonation state, interaction with solvent, adsorption events, or cleavage of crosslinks). Each of these responsive or intelligent materials transduces a biological or molecular signal into a mechanical (i.e. swelling, polymer chain extension) or conformational (i.e. assembly/disassembly) output.

In the design of next-generation biomaterials for machine-tissue interfaces, it is often productive to apply an external signal (e.g., electrical field, magnetic field, light), which the material transduces into a physical output (e.g., swelling, heat) that is productive for a diagnostic or therapeutic purpose. In the following section, we will review recent developments in biomaterials that respond to temperature, magnetic fields, electrical stimulation, or light. Each of these classes of materials will become useful for fabricating advanced molecular structures (Chapter 3) for machine-tissue interface applications (Chapter 4) in diagnostic and therapeutic medicine.

2.3.1. Temperature Responsive Materials:

Temperature-responsive polymers are an active area of research within biomedical materials, as gradients in temperature can both be natural (e.g., deviation from a normothermia in a disease state) or induced (e.g., ablation therapy)(93). Most commonly, copolymers of n-isopropyl acrylamide (NIPAAm) are applied as thermoresponsive biomaterials, as they possess a lower critical solution temperature (LCST) phase transition near body temperature (LCST ~ 32°C for the homopolymer)(94, 95). Copolymerization with alternate functional monomers can shift the LCST, so that polymer collapse coincides with a slightly hyperthermic condition(96). In addition to NIPAAm copolymers, other alkyl-substituted acrylamides have been studied as LCST thermoresponsive biomaterials (e.g., poly(N’N’-diethyl acrylamide)) (97). Poly(ethylene oxide) and poly(2-oxazoline) copolymers can also exhibit useful temperature-responsive properties, particularly upon copolymerization or end-group functionalization with hydrophobic or ionizable groups (98, 99). Many natural and synthetic polymers that exhibit LSCT-behavior, including polysaccharides (i.e. cellulose, chitosan, and dextran derivatives), polypeptides (gelatin, and elastin like peptides), synthetic homopolymers (alkyl-substituted acrylamides, Polyorganophosphazenes) and synthetic block copolymers (pluronic) (100, 101). In this section, we focus primarily on PNIPAAm gels and hybrid systems thereof to exemplify the fundamental characteristics and biomedical applications of thermoresponsive polymers.

Recent reviews have nicely summarized alternate temperature-responsive LCST hydrogels for biomedical applications(101, 102). The mechanism of swelling and/or collapse for these systems involves their unique polymer-solvent interactions (103). At low temperatures, the entropic energetic cost of holding water molecules in an arranged conformation around the hydrophobic alkyl-containing monomers is not as significant as the enthalpic gain of polymer-solvent interaction (hydrogen bonding between water and pendant amides, as well as functional groups provided by co-monomers). As temperature rises above the LCST, the entropic cost becomes too great, and a collapsed conformation that liberates the previously arranged solvent molecules becomes favorable (Figure 2.6). (103)

Figure 2.6:

P(NIPAAm) copolymers exhibit temperature behavior, where as a polymer solution is heated above the LCST, the polymeric chains collapse from a coil to a globule conformation. This collapse liberates water molecules that had adopted an ordered conformation around the alkyl-substituted amide moieties. Reprinted by permission from (103) published by Elsevier.

In contrasts with LCST-exhibiting biomaterials, a limited number of upper critical solution temperature (UCST) gels have been developed. While LCST gels collapse upon heating through the LCST, UCST materials swell with heating through the critical temperature. UCST behavior is driven by hydrogen bonding between functional moieties in the polymer chain. At temperatures above the UCST, polymer-solvent interaction breaks polymer-polymer hydrogen bonds, enables greater polymer chain mobility, and thus a more disordered polymeric state. Conversely, at temperatures below the UCST, the formation of enthalpically favorable hydrogen bonds between polymer chains achieves the lowest energy state. UCST-exhibiting biomaterials are less common in research applications than LCST gels because they are highly affected by charged impurities in the polymer backbone, or ionic species within biological media(104).

There is vibrant translational research in the area of composite systems containing thermally responsive polymers(93, 105). Such composite systems couple thermoresponsive polymers and conductive materials. For example, p(NIPAAm) copolymer shells can be synthesized on the surface of metal nanoparticles, so that heating the system via an external signal (e.g., light or magnetic stimulation) is transduced mechanically through NIPAAm collapse (106, 107). Specific processing techniques and fabrication processes for composite material systems are reviewed in Chapter 3.1. Biomedical applications of these composite systems, within biosensing and drug delivery, are reviewed in Chapter 4.1 and 4.2.

2.3.2. Electrically and Magnetically Active Materials:

Materials that respond to magnetic or electrical stimulation have found extensive applications in biosensing and tissue engineering applications. Within diagnostic applications, conductive polymers are a valuable component of next-generation sensors, including wearable electronics(108). For tissue engineering and medical device applications, composite systems that contain conductive polymers are useful for delivering electric stimuli to biological components(109).

The most common conductive polymers for biomedical applications are polypyrrole, polythiophene, polyaniline, and poly(3,4-ethylenedioxythiophene)(110). Each of these polymers has a conjugated backbone that can conduct and transduce an electrical stimulus. Because most conductive homopolymers are brittle in nature, composite systems that contain conductive polymer components are most common for proper mechanical function in biomedical applications. To diversify the bioactivity of conductive polymers, numerous research groups have adsorbed, entrapped, or covalently attached active biomolecules to conductive biomaterials for the purpose of tissue integration or drug delivery. Within tissue engineering, conductive polymers have found extensive utility for delivering electrical stimuli to neurons(111) and mimicking the mechanical activity of muscle(112, 113). These types of intelligent and/or bioactive cell-material constructs are a major focus of Chapter 5.