Abstract

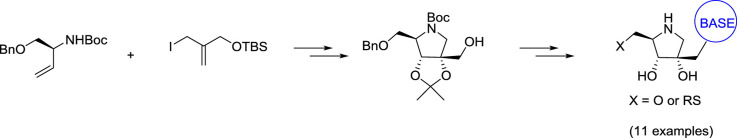

Azanucleosides, sugar-modified nucleoside analogues containing a 4′ nitrogen atom, have shown a lot of therapeutic potential, e.g. as anti-cancer and antiviral agents. We report the synthesis of a series of 2’-homoazanucleosides, in which the nucleobase is attached to the 2’-position of the pyrrolidine ring via a methylene linker. A suitable orthogonally protected iminosugar was synthesized by ring closing metathesis and dihydroxylation as key steps and further converted to a series of 8 nucleoside analogues through Mitsunobu reaction with suitably protected nucleobases. The 5′ position of the adenine analogue was then further derivatized with thiols to afford 2 additional compounds. The final compounds were evaluated for biological activity.

Keywords: Nucleoside, Azanucleoside, Homonucleoside, Iminosugar, Transition state analogue

Graphical abstract

1. Introduction

Azanucleosides, a class of sugar-modified nucleoside analogues in which the 4’-oxygen of the ribose is replaced by a nitrogen atom, have recently attracted considerable attention.1, 2 The Immucillins, a series of aza-sugar-C-nucleosides, show potential for the treatment of leukemia, auto-immune disorders, bacterial infections, etc.3 The pyrrolidine nitrogen atom allows these nucleosides to function as transition state analogue inhibitors of several nucleoside-processing enzymes such as human purine nucleoside phosphorylase (PNP),4 5’-methylthioadenosine nucleosidase (MTAN) & 5’-methylthioadenosine phosphorylase (MTAP).5 Due to the diverse essential functions of these enzymes among several organisms and species, inhibitors may exhibit various biological activities. The most notable are inhibition of quorum sensing (through MTAN) and anticancer activity (through MTAP and PNP).6, 7, 4 Other noteworthy effects include antiparasitic and antibacterial activity.8, 9, 10 Immucillin A (1), also shows broad-spectrum antiviral activity (Fig. 1 ). It is an RNA polymerase inhibitor and functions as a non-obligate chain terminator. It is currently in clinical trials for the treatment of Ebola virus infection under the name galidesivir®.11, 12, 13

Fig. 1.

Immucillin A (1), DADMe-Immucillin A (2), 1′-N-homoazanucleoside (3), 2′-N-homoazanucleoside (4).

The synthesis of azanucleosides is not trivial. The core iminosugar often requires a long multi-step synthesis, and attachment of the nucleobase poses a second challenge, due to the unstable hemi-aminal linkage that would hydrolyze spontaneously upon contact with water. Several strategies have been investigated to overcome this liability. Apart from synthesizing C-nucleosides, where most of the research has been focusing on, enhanced stability can also be obtained by substituting the nitrogen. Chiacchio et al., for example, reported an N-Boc-protected 3’-deoxyazaribonucleoside that displays highly potent anti-HCV activity in a replicon assay.14 A third strategy is the synthesis of N-homoazanucleosides, in which a methylene linker is inserted between the carbohydrate mimic and the base. Although this formal insertion of a CH2 unit in the glycosidic bond lengthens the separation between the base and the pyrrolidine ring relative to that in the natural substrate, this bond is likewise elongated in transition states. 1’-homoaza-adenosine 3 is an inhibitor of protozoan nucleoside hydrolases, although less potent than the corresponding C-nucleoside.15, 16 Furthermore, several second-generation Immucillins, for example the femtomolar MTAP/MTAN inhibitor 2, also possess an extra methylene linker between the pyrrolidine and the surrogate nucleobase.17, 18, 19 In addition, homonucleosides are resistant towards nucleases, may still be phosphorylated by cellular enzymes and are able to pair with natural nucleosides through Watson-Crick interactions.20 1′-Homonucleosides were recently reviewed by Wróblewski et al.21

In this work we report the synthesis of a series of 2’-homoazanucleosides, regioisomers of the 1’-homoazanucleosides (e.g. 3), in which the nucleobase is attached to the 2’-position of the pyrrolidine ring via a methylene linker. This transposition of the nucleobase affords analogues with the same number of bonds between the nucleobase and carbons 2′, 3′ and 4′ of the pyrrolidine ring as in the natural nucleosides and therefore might more closely mimic the spatial arrangements of natural nucleosides. A series of 2’-homo-azanucleosides was synthesized containing the natural and some closely related nucleobases, as well as two 5’-thio analogues, inspired by the potent methylthioadenosine-mimicking aza-C-nucleosides (e.g. 2).

2. Results and discussion

2.1. Scaffold synthesis

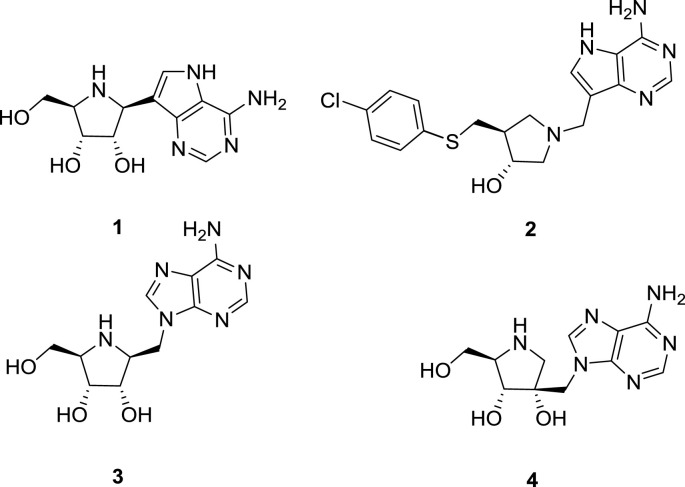

We envisioned a convergent synthetic approach wherein the protected polyhydroxylated pyrrolidine scaffold is synthesized first, subsequently coupled with a variety of nucleobases. The desired 2′-C-hydroxymethyl iminosugar has, contrary to several of its stereoisomers,22 not been reported yet. Its retrosynthesis comprises ring-closing metathesis and subsequent dihyroxylation as key steps (Fig. 2 ), based on the observation that this strategy has already been successfully applied in the synthesis of a number of analogous iminosugars.23

Fig. 2.

Retrosynthesis of the 2′-N-homoazanucleoside scaffold. (FGI = functional group interconversion, RCM = ring closing metathesis).

Several syntheses for the vinylglycinol precursor of 10 have been reported,24, 25 but we opted for the method of Van den Nieuwendijk et al. using an Ellman tert-butylsulfinamide because of its 100% enantiopurity.26, 27 Rac-Solketal 12 was first protected as benzyl ether, after which the isopropylidene acetal was hydrolyzed (Scheme 1 ). Oxidative cleavage of the resulting diol and condensation with (S)-tert-butanesulfinamide led to sulfinimine 14. Addition of vinylmagnesium bromide resulted in a mixture of diastereoisomers in a 9:1 ratio in favor of the desired diastereoisomer 15, as determined by 1H NMR. We found that the addition of hazardous AlMe3, as described by Van den Nieuwendijk et al., could be omitted without a significant drop in diastereoselectivity. The two diastereoisomers could be separated by column chromatography, affording enantiopure 15. Removal of the sulfinamine chiral auxiliary with HCl in MeOH and subsequent Boc-protection of the resulting amine furnished 10 in 45% yield over 6 steps.

Scheme 1.

Synthesis of (S)-O-benzyl-N-Boc-vinylglycinol 10. Reagents and conditions: a) (i) BnBr, NaH, THF/DMF, 0 °C to rt, 3 h; (ii) AcOH/H2O, rt, 24 h, 97% (2 steps); b) (i) NaIO4, CH2Cl2/H2O, 0 °C, 6 h; (ii) (S)-tert-butylsulfinamide, CuSO4, CH2Cl2, rt, overnight, 77% (2 steps); c) vinylMgBr, toluene, −78 °C, 3 h, 71%; d) (i) HCl, MeOH, rt, 1.5 h; (ii) aq. NaOH, rt, 94% (2 steps); e) Boc2O, Et3N, CH2Cl2, rt, 4 h, 90%.

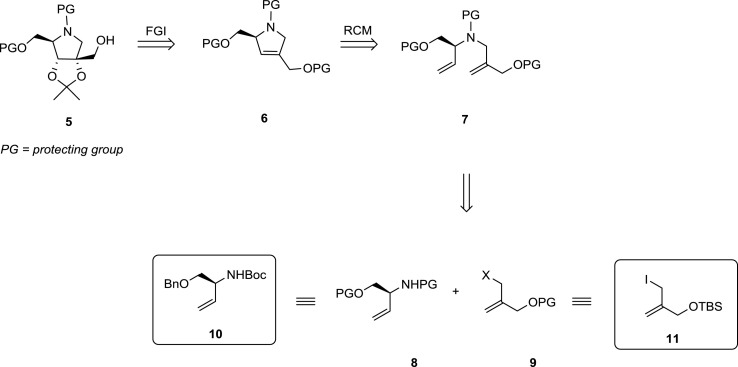

The second building block was synthesized from commercially available 2-methylene-1,3-propanediol 17 (Scheme 2 ). Selective monoprotection as TBS-ether and subsequent iodination yielded 11, which required purification prior to use in the alkylation reaction with 10 in order to get reproducible results.

Scheme 2.

Synthesis of 1-iodo-2-methylenepropanol 11. a) TBS-Cl, NaH, THF, rt, 2 h, 85%; b) I2, imidazole, PPh3, Et2O/MeCN, rt, 30 min, 48%.

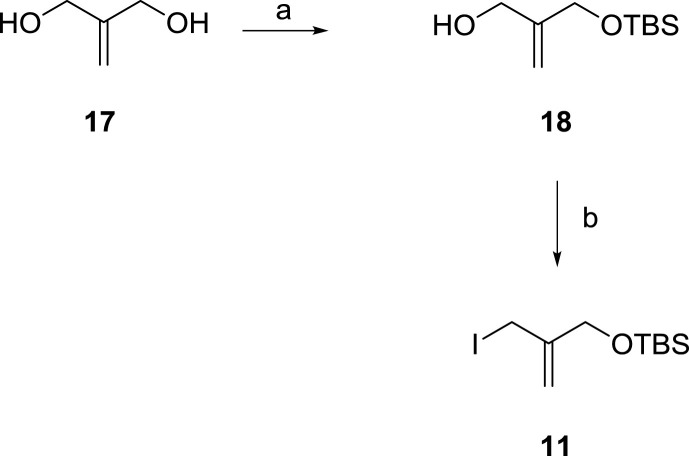

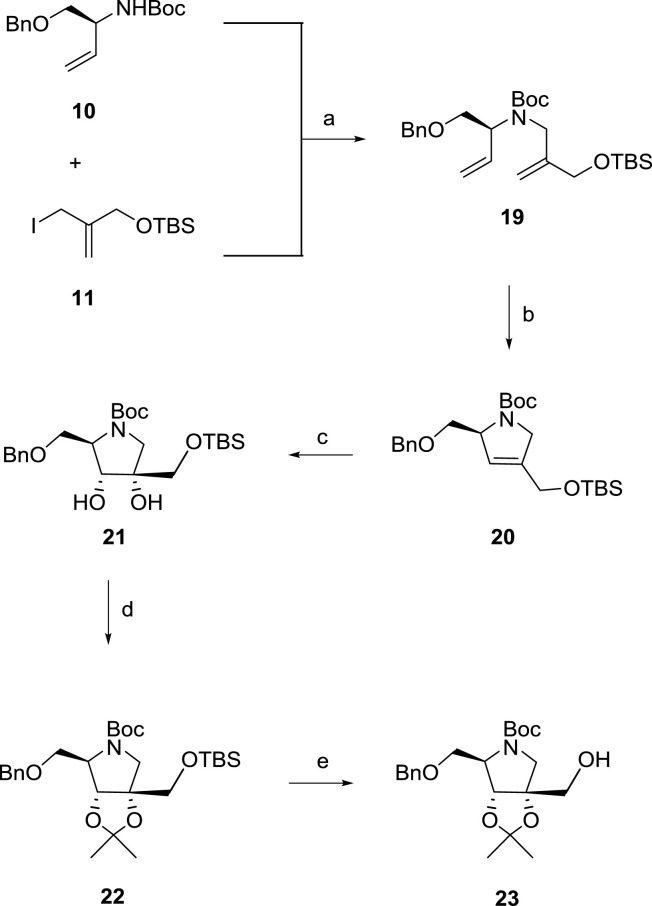

Carbamate 10 was alkylated with 1.1 eq. of iodide 11 using sodium hydride as base (Scheme 3 ). Product 19 was then cyclized by ring closing metathesis, which proceeded smoothly with only 1.5 mol% Grubbs II catalyst. Ring-closed product 20 was then dihydroxylated with OsO4 to yield diastereomerically pure 21. The stereocenter already present apparently provides enough stereoinduction to have dihydroxylation selectively on the opposite face, rendering the reaction stereospecific. The stereochemistry was proven by X-ray analysis of compound 21 (see Supporting Information), which shows the product to be the expected diastereoisomer (Fig. 3 ). Isopropylidene protection of 21 was first tried with 2,2-dimethoxypropane and catalytic TsOH, but resulted in significant amounts of TBS-deprotected compound. This could be circumvented by using 2-methoxypropene and 2 mol% camphersulphonic acid (CSA), affording 22 in almost quantitative yield. Final TBS-deprotection with TBAF provided the orthogonally protected central scaffold 23 in 43% yield over 5 steps from 10.

Scheme 3.

Synthesis of protected iminosugar scaffold 23. Reagents and conditions: a) NaH, DMF, rt, 1 h, rt, 80%; b) 1.5 mol% Grubbs II, DCE, 50 °C, 4 h; c) OsO4, NMO, acetone/H2O, rt, overnight, 92%; d) 2-methoxypropene, CSA (cat.), THF, rt, 24 h, 98%; e) TBAF, THF, rt, 1 h, 98%.

Fig. 3.

Molecular X-ray structure of 21, showing thermal displacement ellipsoids at the 50% probability level.

2.2. Nucleobase coupling and deprotection

Introduction of the desired nucleobase in 23 was accomplished by a Mitsunobu reaction. Two possible issues (i.e. the solubility of the nucleobases in organic solvents and the alkylation site selectivity) were avoided by prior protection of the nucleobases.28

We chose protecting groups that are cleavable under the same conditions as the protecting groups on the pyrrolidine scaffold. Adenine was protected as its N-6-Boc2 derivative, and almost exclusively yielded the desired coupling product 24 (Scheme 4 ).29 N-3-BOM-protected uracil and thymine readily afforded 30 and 31.30 We first tried to deprotect the resulting nucleosides in 2 steps using hydrogenolysis with Pd/C and subsequent acidic hydrolysis. However, hydrogenolysis proved to be difficult and afforded only small amounts of debenzylated product, presumably due to the coordinating effects of the different nitrogen atoms of the nucleobase to the palladium.31 Fortunately, deprotection with the Lewis acid BCl3, provided the completely deprotected nucleosides in one step.32 Purification by column chromatography and acidification yielded the desired nucleoside analogues as their HCl salts.

Scheme 4.

Nucleobase alkylation and deprotection. Reagents and conditions: a) protected nucleobase, PPh3, DIAD, THF, dioxane or acetonitrile, 0 °C to rt, overnight; b) i) Ms-Cl, Et3N, CH2Cl2, 2 h, 0 °C to rt; ii) protected nucleobase, K2CO3, 18-crown-6, DMF, Δ, overnight; c) i) BCl3, CH2Cl2, -78 °C, 2 h; ii) MeOH, 5 min, −78 °C to rt; iii) HCl, H2O; d) i) NaN3, DMF, 60 °C, overnight; ii) Pd(OH)2, H2, EtOH, rt, 24 h, 74%; iii) conc. HCl, THF/H2O, reflux, 1 h; e) i) 7 N NH3 in MeOH, MeOH, rt, overnight, 98%; ii) BCl3, CH2Cl2, -78 °C, 2 h, 53%; iii) HCl, H2O.

The guanine and hypoxanthine analogues 28 and 29 were synthesized from the corresponding 6-chloropurines. The chloride was substituted for a hydroxy function during the BCl3-mediated deprotection, by dropwise quenching with MeOH at low temperature. Substitution can be avoided by adding Et3N prior to quenching with MeOH.33

Mitsunobu reaction of 23 with 7-deaza-6-chloropurine to synthesize 34 was not possible due to the less acidic pyrrole NH. Hence, 23 was first mesylated and then substituted in a classical SN2 fashion, to afford 34. The chloride was then substituted with NaN3. Reduction of the azide and simultaneous removal of the 5′-O-benzyl with Pd(OH)2 and H2, followed by acidic hydrolysis of the remaining protecting groups afforded 7-deazadenine analogue 35. 5-Fluorouracil was introduced as its N-3-benzoyl protected derivative.34 Deprotection of 36 was realized in 2 steps: first basic removal of the benzoyl group, then treatment with BCl3. Lastly, substitution of the mesylate of 23 with N-4-acetylcytosine, afforded an acceptable amount of N-1-alkylated 38.

The regiochemistry of the nucleobase alkylation reactions was verified on the final compounds via NMR data, which were in agreement with those found in literature.20, 35, 36, 37 The deprotected compounds were purified by column chromatography and converted to the corresponding mono- or bis-HCl salts.38

2.3. 5’-derivatization

Pd(OH)2-catalyzed hydrogenolysis of 24 yielded alcohol 40, which was then converted to the mesylate and subsequently substituted with sodium thiomethoxide or 4-chlorothiophenol to yield 41 and 42, respectively (Scheme 5 ). Deprotection with BCl3 and HCl-salt formation yielded 43 and 44.

Scheme 5.

5’-derivatization of 24. Reagents and conditions: a) Pd(OH)2, H2, MeOH, 40 °C, overnight, 56%; b) Ms-Cl, Et3N, CH2Cl2, 0 °C to rt, 2 h; c) 4-chloro-thiophenol, NaH, DMF, 50 °C, 4 h, 97% or NaSMe, DMSO, 50 °C, overnight; d) i) BCl3, CH2Cl2, -78 °C, 2 h, ii) HCl, H2O.

2.4. Biological evaluation

The synthesized nucleosides were screened against a panel of viruses (HSV-1, HSV-2, Vaccinia virus, Adenovirus-2, Human Coronavirus) and microorganisms (Staphylococcus aureus, Escherichia coli, Candida albicans, Trypanosoma brucei) in cell cultures, but no activity was found in concentrations up to 64 μM. The effect on signaling molecule (AI-2, AHL/CAI-1) production in Vibrio harveyi was also investigated, but no activity was found in concentrations up to 100 μM.

3. Conclusions

A convenient synthetic approach was developed to prepare a series of 2’-homoazanucleosides. The unprecedented orthogonally protected iminosugar scaffold was synthesized first, involving a ring closing metathesis and dihyroxylation as key steps. All steps proceeded in high yield, highlighting the practical use of this synthesis. From this scaffold a series of 9 nucleoside analogues with different nucleobases, as well as two 5’-thio modified adenine analogues was synthesized. The nucleoside analogues were evaluated broadly for antiviral, antibacterial, and antiprotozoal activity, but failed to show activity.

4. Experimental section

4.1. General

All reactions described were performed under argon atmosphere and at ambient temperature unless stated otherwise. All reagents and solvents were purchased from Sigma–Aldrich (Diegem, Belgium), Acros Organics (Geel Belgium), TCI Europe (Zwijndrecht, Belgium) or Carbosynth Ltd (Compton Berkshire, United Kingdom) and used as received. NMR solvents were purchased from Eurisotop (Saint-Aubin, France). Reactions were monitored by TLC analysis using TLC aluminium sheets (Macherey–Nagel, Alugram Sil G/UV254) with detection by UV or by spraying with a solution of (NH4)6Mo7O24 × 4H2O (25 g/L) and (NH4)4Ce(SO4)4 × 2H2O (10 g/L) in H2SO4 (10%) followed by charring or an aqueous solution of KMnO7 (20 g/L) and K2CO3 (10 g/L) followed by charring. Silica gel column chromatography was performed manually using Grace Davisil 60 Å silica gel (40–63 lm) or automated using a Grace Reveleris X2 system and the corresponding flash cartridges. High resolution spectra were recorded with a Waters LCT Premier XE Mass spectrometer. 1H and 13C NMR spectra were recorded with a Varian Mercury-300BB (300/75 MHz) spectrometer. Chemical shifts are given in ppm (d) relative to tetramethylsilane as an internal standard (1H NMR) or the NMR solvent (13C NMR). In 19F NMR, signals have been referred to CDCl3 or DMSO-d 6 lock resonance frequency according to IUPAC referencing with CFCl3 set to 0 ppm. Coupling constants are given in Hz. The correct regiochemistry of the nucleobase alkylation reactions was verified via HMBC NMR experiments of the final compounds. Optical rotations were recorded on a PerkinElmer 241 polarimeter, using a sodium-vapor lamp (D-line; λ = 589.3 nm).

4.2. Synthesis

4.2.1. General procedure 1: mitsunobu reaction

Diisopropylazodicarboxylate (2.3 eq.) was added dropwise to a solution of triphenylphosphine (2.3 eq.) in THF, dioxane or acetonitrile (indicated in individual procedures) at 0 °C. After 15 min, alcohol 23 was added and the reaction was allowed to warm to room temperature. The appropriate protected nucleobase was added and the reaction mixture stirred overnight. When TLC indicated the disappearance of the starting material, the mixture was concentrated in vacuo, absorbed onto celite® and purified by flash column chromatography to afford the protected nucleoside analogue.

4.2.2. General procedure 2: BCl3-mediated deprotection

BCl3 (1.0 M in CH2Cl2, 10 eq.) was added to a solution of protected nucleoside (0.1 M) in CH2Cl2 at −78 °C. When TLC analysis indicated disappearance of the starting material and the presence of a single lower-running spot, MeOH (5 mL) was added dropwise and the mixture warmed to room temperature. Then it was concentrated in vacuo and co-evaporated with MeOH 3 times. The residue was dissolved in MeOH, absorbed onto celite® and purified by flash column chromatography (MeOH/NH4OH/CH2Cl2 20:1:79 and then 45:5:50).

4.2.3. General procedure 3: HCl-salt formation

The purified compound was dried under high vacuum overnight, and dissolved in MeOH (10 mL). Concentrated HCl (0.5 mL) was added, and the mixture concentrated in vacuo. The residue was dissolved in 10 mL H2O, transferred to a separation funnel, and washed with 2 × 5 mL CHCl3. The water phase was then lyophilized overnight to afford the final nucleoside as its HCl salt.

4.2.4. 3-(benzyloxy)propane-1,2-diol (13)

Sodium hydride (60% wt. in mineral oil, 15.4 g, 117 mmol, 1.3 eq.) was added portionwise to a solution of rac-solketal in a mixture of DMF (50 mL) and THF (150 mL) at 0 °C. When gas evolution had ceased, benzyl bromide (23.9 g, 140 mmol, 1.2 eq.) was added dropwise. After 3 h, TLC analysis (Hexanes/EtOAc 1:1) indicated disappearance of the starting material. 150 mL water was added and the mixture was extracted with 3 × 200 mL Et2O. The combined organic layers were washed with brine, dried over Na2SO4 and concentrated in vacuo. The residue was dissolved in AcOH/H2O 4:1 and stirred 24 h at room temperature. The mixture was concentrated in vacuo, and purified by flash column chromatography (hexanes/EtOAc, 7:3 and 0:10). The product was obtained as a transparent oil in 97% yield (2 steps). 1H NMR (300 MHz, DMSO-d 6) δ ppm 3.30–3.42 (3 H, m), 3.47 (1 H, s), 3.64 (1 H, dt, J = 16.1, 5.6 Hz), 4.49 (2 H, s), 4.52 (1 H, t, J = 5.9 Hz), 4.69 (1 H, d, J = 5.0 Hz), 7.21–7.42 (5 H, m). 13C NMR (75 MHz, DMSO-d 6) δ ppm 62.9, 70.3, 71.7, 72.0, 127.0, 127.1, 127.9, 138.4. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C10H15O3 +: 183.10212; found 183.10184.

4.2.5. (S,E)-N-(2-(benzyloxy)ethylidene)-2-methylpropane-2-sulfinamide (14)

3-(benzyloxy)propane-1,2-diol 13 (8.70 g, 47.7 mmol) was dissolved in CH2Cl2 (90 mL) and cooled to 0 °C. A solution of NaIO4 (15.3 g, 71.6 mmol, 1.5 eq.) in H2O (90 mL) was added and the reaction mixture was stirred for 6 h. The mixture was then transferred to a separation funnel and extracted with 3 × 150 mL CH2Cl2. The organic phases were dried over Na2SO4 and concentrated in vacuo under medium pressure at 35 °C. The residue was dissolved in CH2Cl2 after which anhydrous CuSO4 (15.2 g, 95.4 mmol, 2.0 eq.) was added, followed by (S)-2-methyl-2-propane-sulfinamide (6.94 g, 57.3 mmol, 1.2 eq). The reaction mixture was stirred overnight, filtered over celite® and concentrated in vacuo. The residue was purified by flash column chromatography (Hexanes/EtOAc 9:1 to 7:3) to afford 14 as a yellow oil in 77% yield. 1H NMR (300 MHz, CDCl3) δ ppm 1.13 (9 H, s), 4.32 (2 H, dd, J = 3.4, 1.0 Hz), 4.55 (2 H, s), 7.26–7.38 (5 H, m), 8.05 (1H, t, J = 3.2 Hz). 13C NMR (75 MHz, CDCl3) δ ppm 22.4, 56.9, 71.2, 73.3, 127.8, 128.0, 128.5, 137.2, 166.7. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C13H20O2S+: 254.12148; found 254.1209.

4.2.6. (S)-N-((S)-1-(benzyloxy)but-3-en-2-yl)-2-methylpropane-2-sulfinamide (15)

Compound 14 (9.28 g, 36.6 mmol, 1.0 eq.) was dissolved in dry toluene and cooled to −78 °C. Vinylmagnesium bromide (1.0 M in THF, 54.9 mL, 54.9 mmol, 1.5 eq.) was added dropwise (0.5 mL/min). After 3 h, 7 mL of a saturated solution of Na2SO4 in H2O was added slowly and the mixture was warmed to room temperature. The mixture was further dried over Na2SO4 and concentrated in vacuo. The residue was purified twice by column chromatography (5–25% EtOAc in hexanes) to afford diastereomerically pure 15 as a yellow oil in 71% yield.

1H NMR (300 MHz, DMSO-d 6) δ ppm 1.07–1.20 (9 H, m), 3.46 (1 H, dd, J = 9.7, 6.4 Hz), 3.50 (1 H, dd, J = 9.7, 6.4 Hz), 3.79–3.97 (1 H, m), 4.51 (2 H, s), 4.92 (1 H, d, J = 6.2 Hz), 5.14 (2 H, dt, J = 10.5, 1.2 Hz), 5.28 (2 H, dt, J = 17.3, 1.8 Hz), 5.78 (1 H, ddd, J = 17.0, 10.5, 7.0 Hz), 7.24–7.46 (5 H, m). 13C NMR (75 MHz, DMSO-d 6) δ ppm 22.4, 55.0, 57.1, 72.0, 72.5, 116.9, 127.4, 127.5, 128.2, 137.2, 138.2. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C15H24O2S+: 282.15278; found 282.1521.

4.2.7. (S)-1-(benzyloxy)but-3-en-2-amine (16)

10 mL concentrated HCl was added to a solution of 15 (18.7 g, 66.4 mmol) in MeOH at room temperature. After 90 min, TLC analysis indicated completion of the reaction and the mixture was concentrated in vacuo. The residue was purified by column chromatography (Hexanes/EtOAc 1:1 to remove a higher-running impurity and then CH2Cl2/MeOH 9:1 to elute the title compound as its HCl salt). The purified HCl salt was then dissolved in 200 mL 0.5 M NaOH solution and extracted with 3 × 100 mL CH2Cl2. The organic phases were dried over Na2SO4 and concentrated in vacuo to give the title compound as a yellow oil in 94% yield. 1H NMR (300 MHz, CDCl3) δ ppm 1.48 (2 H, br. s), 3.31 (1 H, dd, J = 9.1, 7.9 Hz), 3.51 (1 H, dd, J = 9.1, 4.1 Hz), 3.63 (1 H, br. s.), 4.56 (2 H, s), 5.11 (1 H, dt, J = 10.4, 1.2 Hz), 5.24 (1 H, dt, J = 17.3, 1.5 Hz), 5.84 (1 H, ddd, J = 17.1, 10.6, 6.0 Hz), 7.24–7.43 (5 H, m). 13C NMR (75 MHz, CDCl3) δ ppm 53.8, 73.3, 75.1, 115.2, 127.7, 128.4, 137.9138.9. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C11H16NO+: 178.12319; found 178.1211.

4.2.8. tert-butyl (S)-(1-(benzyloxy)but-3-en-2-yl)carbamate (10)

Et3N (6.01 mL, 43.1 mmol, 2.0 eq.) and Boc2O (6.44 mL, 28.0 mmol, 1.5 eq.) were added to a solution of 16 (3.82 g, 21.6 mmol) in CH2Cl2 (150 mL) at room temperature. After 4 h of stirring, the mixture was transferred to a separation funnel. 70 mL saturated NH4Cl solution was added and the mixture was extracted with 3 × 100 mL CH2Cl2. The organic phases were washed with brine, dried over Na2SO4 and concentrated in vacuo. The residue was purified by flash column chromatography (Hexanes/Et2O 9:1) to afford 10 as a colourless oil in 90% yield. 1H NMR (300 MHz, DMSO-d 6) δ ppm 1.36–1.44 (9 H, m), 3.46 (2 H, d, J = 6.4 Hz), 4.13–4.28 (1 H, m), 4.50 (2 H, s), 5.09 (1 H, dt, J = 10.5, 1.5 Hz), 5.18 (1 H, dt, J = 17.6, 1.8 Hz), 5.74–5.91 (1 H, m), 6.48 (1 H, d, J = 7.6 Hz), 7.19–7.42 (5 H, m). 13C NMR (75 MHz, DMSO-d 6) δ ppm 27.8, 52.1, 71.5, 71.7, 77.4, 114.7, 126.8, 126.9, 127.6, 136.6, 138.1, 154.6. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C16H24NO3 +: 278.17517; found 278.1750.

4.2.9. 2-(((tert-butyldimethylsilyl)oxy)methyl)prop-2-en-1-ol (18)

Sodium hydride (60% wt. in mineral oil, 0.800 g, 20.0 mmol, 1.0 eq.) was dispersed in dry THF (70 mL). 2-methylene-1,3-propanediol (1.67 mL, 20.0 mmol, 1.0 eq.) in dry THF (10 mL) was added dropwise. A precipitate was formed. After 45 min, TBS-Cl (3.01 g, 20.0 mmol, 1.0 eq.) was added. After 2 h of stirring, 100 mL H2O was added and the mixture was extracted with 3 × 100 mL EtOAc. The combined organic fractions were washed with brine, dried over Na2SO4 and concentrated in vacuo. Purification by flash column chromatography (0–15% EtOAc in hexanes) yielded 18 as a colourless oil in 85%. 1H NMR (300 MHz, CDCl3) δ ppm 0.05–0.12 (6 H, m), 0.87–0.96 (9 H, m), 2.08 (1 H, br. s.), 4.17 (2 H, s), 4.21–4.27 (2 H, m), 5.05–5.15 (2 H, m). 13C NMR (75 MHz, CDCl3) δ ppm −5.5, 18.3, 25.6, 25.8, 64.6, 65.1, 111.1, 147.4. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C11H16NO+: 203.14629; found 203.1462.

4.2.10. tert-butyl((2-(iodomethyl)allyl)oxy)dimethylsilane (11)

Compound 18 (3.456 g, 17.08 mmol) was dissolved in Et2O/MeCN 4:1 (200 mL). PPh3 (6.27 g, 23.9 mmol, 1.4 eq.), and imidazole (1.63 g, 23.9 mmol, 1.4 eq.) were added, followed by I2 (6.07 g, 23.9 mmol, 1.4 eq.). A white precipitate started to form. After 30 min, TLC analysis indicated completion of the reaction, and 100 mL 2 M Na2S2O3 solution was added. The mixture was extracted 3 times with 100 mL Et2O, washed with brine, dried over MgSO4 and concentrated in vacuo. The residue was purified by flash column chromatography (100% hexanes and 10% EtOAc in hexanes) to afford 11 as an orange oil in 48% yield. 1H NMR (300 MHz, CDCl3) δ ppm 0.07–0.16 (6 H, m), 0.93 (9 H, s), 3.96 (2 H, s), 4.31 (2 H, s), 5.20 (1 H, d, J = 1.5 Hz), 5.32 (1 H, d, J = 0.6 Hz). 13C NMR (75 MHz, CDCl3) δ ppm −5.4, 5.7, 18.3, 25.9, 63.9, 113.3, 145.8. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C10H22IOSi+: 313.04791; found 313.0478.

4.2.11. tert-butyl (S)-(1-(benzyloxy)but-3-en-2-yl)(2-(((tert-butyldimethylsilyl)oxy)methyl)allyl)carbamate (19)

NaH (60% in mineral oil, 0.309 g, 7.74 mmol, 1.3 eq.) was added to an ice-cold solution of compound 10 (1.65 g, 5.95 mmol) in DMF (25 mL). After 30 min, a solution of compound 11 (2.60 g, 8.33 mmol, 1.4 eq.) in DMF (5 mL) was added and the mixture warmed to room temperature. After 1 h, TLC analysis (Hexanes/EtOAc 8:2) indicated completion of the reaction. 50 mL water was added and the mixture was extracted with 3 × 50 mL Et2O. The combined organic phases were dried over MgSO4, concentrated in vacuo and purified by flash column chromatography (0–10% Et2O in hexanes). The product was retrieved in 80% yield as a colourless oil. 1H NMR (300 MHz, DMSO-d 6, 80 °C) δ ppm 0.05 (6 H, s), 0.89 (9 H, s), 1.39 (9 H, s), 3.65 (2 H, ddd, J = 29.9, 9.7, 7.0 Hz), 3.79 (2 H, dd, J = 16.7, 6.7 Hz), 4.08 (2 H, s), 4.41 (1 H, d, J = 6.7 Hz), 4.48 (2 H, dd, J = 11.7, 3.5 Hz), 4.99 (2 H, s), 5.11–5.19 (2 H, m), 5.82–6.00 (1 H, m), 7.22–7.42 (5 H, m). 13C NMR (75 MHz, DMSO-d 6,, 80 °C) δ ppm −5.9, 17.5, 25.3, 27.6, 47.2, 58.2, 63.5, 70.0, 71.7, 78.6, 108.9, 116.4, 126.8, 127.6, 134.8, 137.9, 145.4, 154.3. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C26H44NO4Si+: 462.30342; found 462.3055.

4.2.12. tert-butyl (S)-2-((benzyloxy)methyl)-4-(((tert-butyldimethylsilyl)oxy)methyl)-2,5-dihydro-1H-pyrrole-1-carboxylate (20)

Compound 19 (6.60 g, 14.3 mmol) was dissolved in dry degassed 1,2-dichloroethane (10 mL). The reaction was warmed to 50 °C and Grubbs II catalyst (0.121 g, 0.143 mmol, 1 mol%) in 2 mL DCE was added. After 1 h of stirring, a second portion of Grubbs II catalyst (0.060 g, 0.071 mmol, 0.5 mol%) in 2 mL DCE was added. After 3 more hours, TLC analysis indicated that most of the starting material reacted and further progression of the reaction had ceased. The reaction mixture was concentrated in vacuo and the residue purified by flash column chromatography (0–10% Et2O in hexanes). The obtained material was not pure enough for NMR analysis and was used as such in the next reaction. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C24H40NO4Si+: 434,27012; found 434.2725.

4.2.13. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(((tert-butyldimethylsilyl)oxy)methyl)-3,4-dihydroxypyrrolidine-1-carboxylate (21)

To a stirred solution of 20 (4.70 g, 10.8 mmol, 1.0 eq.) in acetone/water (3:1, 100 mL was added K2OsO4·2H2O (0.041 g, 0.11 mmol, 0.01 eq.), followed by NMO monohydrate (2.13 g, 15.7 mmol, 1.5 eq.). The mixture was stirred overnight, after which Na2SO3 (3.96 g, 31.4 mmol, 3.0 eq.) was added and the mixture stirred for another hour. The mixture was concentrated in vacuo to remove the acetone, diluted with water (50 mL) and extracted with 3 × 100 mL EtOAc. The organic phases were washed with brine, dried over Na2SO4 and concentrated in vacuo. The residue was purified by flash column chromatography (0–40% EtOAc in hexanes) to afford 21 in 70% yield as a white solid. 1H NMR (300 MHz, DMSO-d 6, 80 °C). δ ppm 0.05 (6 H, s), 0.87 (9 H, s), 1.39 (9 H, s), 3.24 (1 H, d, J = 12.3 Hz), 3.40 (1 H, d, J = 11.4 Hz), 3.43–3.57 (3 H, m), 3.65 (1 H, dd, J = 10.0, 1.8 Hz), 3.90 (1 H, dd, J = 9.8, 4.0 Hz), 4.20 (2 H, br. s.), 4.50 (2 H, s), 4.68 (1 H, br. s.), 7.17–7.39 (5 H, m). 13C NMR (75 MHz, DMSO-d 6, 80 °C). δ ppm −6.0, 17.4, 25.3, 27.8, 52.9, 61.9, 63.0, 67.6, 71.1, 72.2, 76.0, 77.9, 126.6, 126.7, 127.6, 138.3, 153.6. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C24H40NO4Si+: 468.27759; found 468.2796.

4.2.14. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(((tert-butyldimethylsilyl)oxy)methyl)-3,4-isopropylidene-pyrrolidine-1-carboxylate (22)

Camphersulphonic acid (0.029 g, 0.125 mmol, 0.02 eq.) was added to a solution of 21 (2.94 g, 6.28 mmol, 1.0 eq.) in THF (180 mL). 2-methoxypropene (5.80 mL, 62.8 mmol, 10.0 eq.) was added and the mixture was stirred for 24 h 200 μL Et3N was added and the mixture was concentrated in vacuo. The residue was purified by flash column chromatography (0–20% EtOAc in hexanes) to afford 22 as a colourless oil in 98% yield. 1H NMR (300 MHz, DMSO-d 6, 80 °C) δ ppm 0.04 (6 H, s), 0.88 (9 H, s), 1.33 (3 H, s), 1.34 (3 H, s), 1.39 (9 H, s), 3.31 (1 H, d, J = 12.3 Hz), 3.46–3.61 (3 H, m), 3.70 (2 H, s), 4.04 (1 H, dd, J = 6.4, 4.4 Hz), 4.48 (1 H, s), 4.50 (2 H, s), 7.20–7.43 (5 H, m). 13C NMR (75 MHz, DMSO-d 6, 80 °C) δ ppm −5.9, 17.5, 25.3, 26.9, 27.6, 27.6, 54.1, 64.3, 68.3, 72.1, 78.5, 111.0, 126.9, 127.0, 127.8, 137.7, 152.9. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C27H45NO6Si+: 508.30889; found 508.3120.

4.2.15. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-hydroxymethyl-3,4-isopropylidene-pyrrolidine-1-carboxylate (23)

TBAF (1.0 M in THF, 10.8 mL, 10.77 mmol, 1.2 eq.) was added to a solution of 22 (4.56 g, 8.98 mmol, 1.0 eq.) in THF. After 1 h, TLC analysis showed completion of the reaction. The mixture was concentrated in vacuo, and the residue purified by flash column chromatography (0–30% EtOAc in hexanes) to afford 23 in 98% yield as a colourless oil. 1H NMR (300 MHz, DMSO-d 6, 80 °C) δ ppm 1.33 (3 H, s), 1.34 (3 H, s), 1.39 (9 H, s), 3.33 (1 H, d, J = 12.3 Hz), 3.49–3.61 (6 H, m), 4.04 (1 H, t, J = 5.8 Hz), 4.48 (1 H, s), 4.51 (2 H, s), 4.84 (1 H, t, J = 5.8 Hz), 7.23–7.42 (5 H, m). 13C NMR (75 MHz, DMSO-d 6, 80 °C) δ ppm 27.0, 27.6, 27.7, 54.0, 62.8, 63.2, 67.9, 72.0, 78.4, 83.9, 110.8, 126.9, 127.7, 137.8, 153.0. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C21H32NO6 +: 394.22242; found 394.2132.

4.2.16. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(N-9-methyl-N-6-bis-tert-butyloxycarbonyl-adenine)-3,4-isopropylidene-pyrrolidine-1-carboxylate (24)

Compound 23 (0.596 g, 1.51 mmol) was subjected to general procedure 1, using N-6-Boc2-adenine as nucleobase and THF as solvent. The residue was purified by flash column chromatography (5 → 40% EtOAc in hexanes) to afford 24 as a white foam in 65% yield. 1H NMR (300 MHz, DMSO-d 6, 80 °C) δ ppm 1.00 (3 H, s), 1.30 (3 H, s), 1.37 (9 H, s), 1.38 (18 H, s), 3.58 (2 H, dd, J = 12.6, 2.9 Hz), 3.62–3.70 (2 H, m), 4.61 (2 H, dd, J = 12.0, 2.9 Hz), 4.69 (2 H, s), 4.75 (1 H, s), 7.21–7.46 (5 H, m), 8.47 (1 H, s), 8.82 (1 H, s). 13C NMR (75 MHz, DMSO-d 6, 80 °C) δ ppm 21.1, 26.5, 26.9, 27.3, 27.6, 46.6, 55.6, 63.5, 69.0, 72.4, 78.8, 82.7, 111.7, 127.1, 127.2, 127.8, 137.7, 147.2, 149.0, 149.4, 151.1, 152.7, 153.2. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C36H51N6O9 +: 711,37121; found 711.3737.

4.2.17. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(N-9-methyl-6-chloropurine)-3,4-isopropylidene-pyrrolidine-1-carboxylate (25)

Compound 23 (0.261 g, 0.66 mmol) was subjected to general procedure 1, using 6-chloropurine as nucleobase and THF as solvent. The residue was purified by flash column chromatography (10–40% EtOAc in hexanes) to afford 25 as a white powder in 58% yield. 1H NMR (300 MHz, DMSO-d 6, 80 °C) δ ppm 1.03 (3 H, s), 1.31 (3 H, s), 1.37 (9 H, s), 3.52–3.68 (4 H, m), 4.03 (1 H, t, J = 3.8 Hz), 4.58 (2 H, dd, J = 12.3, 3.8 Hz), 4.69 (2 H, s), 4.74 (1 H, s), 7.23–7.42 (5 H, m), 8.55 (1 H, s), 8.77 (1 H, s). 13C NMR (75 MHz, DMSO-d 6, 80 °C) δ ppm 27.4, 28.1, 28.5, 47.8, 56.4, 64.4, 69.9, 73.2, 79.7, 110.0, 112.7, 127.9, 128.0, 128.0, 128.7, 138.5, 152.8. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C26H33ClN5O5 +: 530.21648; found 530.2158.

4.2.18. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(N-9-methyl-2-amino-6-chloropurine)-3,4-isopropylidene-pyrrolidine-1-carboxylate (26)

Compound 23 (0.300 g, 0.76 mmol) was subjected to general procedure 1, using 2-amino-6-chloropurine as base and 1,4-dioxane as solvent. The residue was purified by flash column chromatography (10–45% EtOAc in hexanes), but 26 could not be separated from Mitsunobu byproducts. The residue was used as such in the next reaction. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C26H34N6O5 +: 545.22738; found 545.2316.

4.2.19. (2R,3R,4R)-2-((hydroxy)methyl)-4-(N-9-methyladenine)-3,4-dihydroxy-pyrrolidine (27)

Compound 24 (0.143 g, 0.20 mmol) was subjected to general procedure 2 and general procedure 3. white powder, 85% yield (2 steps). 1H NMR (300 MHz, D2O) δ ppm 3.28 (1 H, d, J = 12.9 Hz), 3.55 (1 H, d, J = 12.9 Hz), 3.69 (1 H, ddd, J = 9.1, 5.6, 3.5 Hz), 3.86 (1 H, dd, J = 12.6, 5.6 Hz), 3.98 (1 H, dd, J = 12.7, 3.4 Hz), 4.26 (1 H, d, J = 9.1 Hz), 4.46 (2 H, s), 8.08 (1 H, s), 8.09 (1 H, s). 13C NMR (75 MHz, D2O) δ ppm 47.3, 51.5, 57.7, 62.3, 72.2, 77.0, 117.7, 142.9, 148.9, 151.7, 154.6. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C11H17N6O3 +: 281.13567; found 281.1374. .

4.2.20. (2R,3R,4R)-2-(hydroxymethyl)-4-(N-9-methylhypoxanthine)-3,4-dihydroxy-pyrrolidine (28)

Compound 25 (0.094 g, 0.177 mmol) was subjected to general procedure 2 and general procedure 3. White powder, 44% yield. 1H NMR (300 MHz, D2O) δ ppm 3.33 (1 H, d, J = 12.9 Hz), 3.54–3.72 (2 H, m), 3.83 (1 H, dd, J = 12.9, 5.6 Hz), 3.95 (1 H, dd, J = 12.6, 3.2 Hz), 4.30 (1 H, d, J = 9.1 Hz), 4.66 (2 H, m, J = 1.0 Hz), 8.28 (1 H, s), 8.81 (1 H, br. s.). 13C NMR (75 MHz, D2O) δ ppm 48.7, 51.4, 57.6, 62.3, 72.3, 76.3, 148.0, 155.9. (3 quaternary carbons missing). HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C11H16N5O4 +: 282.11968; found 282.1188. .

4.2.21. (2R,3R,4R)-2-(hydroxymethyl)-4-(N-9-methylguanine)-3,4-dihydroxy-pyrrolidine (29)

Compound 26 was subjected to general procedure 2 and general procedure 3. White solid, 11% yield (3 steps). 1H NMR (300 MHz, D2O) δ ppm 3.36 (1 H, d, J = 13.2 Hz), 3.58–3.71 (2 H, m), 3.84 (1 H, dd, J = 12.9, 5.6 Hz), 3.96 (1 H, dd, J = 12.6, 3.5 Hz), 4.29 (1 H, d, J = 9.1 Hz), 4.52 (2 H, d, J = 2.6 Hz), 8.88 (1 H, br. s.). 13C NMR (75 MHz, D2O) δ ppm 48.6, 51.5, 57.6, 62.2, 72.2, 76.1, 155.2, 155.4. (3 quaternary carbons missing). HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C11H17N6O4 +: 297.13058; found 297.1295. .

4.2.22. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(N-3-benzyloxymethyluracil)-3,4-isopropylidene-pyrrolidine-1-carboxylate (30)

Compound 23 (0.253 g, 0.64 mmol) was subjected to general procedure 1, using in N-3-BOM-uracil as nucleobase and THF as solvent. The residue was purified by flash column chromatography (10–45% EtOAc in hexanes), affording 30 as a colourless oil in 52% yield. 1H NMR (300 MHz, DMSO-d 6, 80 °C) δ ppm 1.25 (3 H, s), 1.32 (3 H, s), 1.38 (9 H, s), 3.44 (1 H, d, J = 12.3 Hz), 3.59 (2 H, d, J = 4.7 Hz), 3.66 (1 H, d, J = 12.6 Hz), 3.97–4.26 (4 H, m), 4.55 (2 H, s), 4.61 (2 H, s), 4.68 (1 H, s), 5.39 (2 H, s), 5.71 (1 H, d, J = 8.0 Hz), 7.20–7.38 (10 H, m), 7.54 (1 H, d, J = 8.0 Hz). 13C NMR (75 MHz, DMSO-d 6, 80 °C) δ ppm 22.5, 27.6, 28.3, 28.5, 51.6, 56.2, 64.2, 69.6, 70.7, 71.7, 73.1, 79.6, 100.6, 112.5, 127.7, 127.8, 127.9, 127.9, 128.6, 128.6, 138.6, 146.6, 152.4, 153.6, 162.6. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C33H42N3O8 +: 608.29665; found 608.2994.

4.2.23. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(N-3-benzyloxymethylthymine)-3,4-isopropylidene-pyrrolidine-1-carboxylate (31)

Compound 23 (0.275 g, 0.70 mmol) was subjected to general procedure 1, using N-3-BOM-thymine as nucleobase and THF as solvent. The residue was purified by flash column chromatography (10–45% EtOAc in hexanes), but 31 could not be separated from Mitsunobu byproducts. The residue was used as such in the next reaction. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C34H44N3O8 +: 622.31230; found 622.3138.

4.2.24. (2R,3R,4R)-2-((hydroxy)methyl)-4-(N-1-methyluracil)-3,4-dihydroxy-pyrrolidine (32)

Compound 30 (0.177 g, 0.29 mmol) was subjected to general procedure 2 and general procedure 3. white powder, 32% yield (3 steps). 1H NMR (300 MHz, D2O) δ ppm 3.39 (1 H, d, J = 13.2 Hz), 3.50 (1 H, d, J = 13.2 Hz), 3.67 (1 H, ddd, J = 9.1, 5.9, 2.8 Hz), 3.80–4.01 (3 H, m), 4.14 (1 H, d, J = 14.9 Hz), 4.19 (1 H, d, J = 9.1 Hz), 5.81 (1 H, d, J = 7.9 Hz), 7.59 (1 H, d, J = 7.9 Hz). 13C NMR (75 MHz, D2O) δ ppm 51.6, 51.7, 57.8, 61.9, 72.2, 77.3, 101.4, 147.9, 152.5, 166.7. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C33H42N3O8 +: 258,10845; found 258.1086..

4.2.25. (2R,3R,4R)-2-((hydroxy)methyl)-4-(N-1-methylthymine)-3,4-dihydroxy-pyrrolidine (33)

Compound 31 was subjected to general procedure 2 and general procedure 3. light yellow powder, 37% yield (3 steps). 1H NMR (300 MHz, D2O) δ ppm 1.85 (3 H, s), 3.39 (1 H, d, J = 12.9 Hz), 3.49 (1 H, d, J = 13.2 Hz), 3.67 (1 H, ddd, J = 9.0, 5.6, 3.5 Hz), 3.81–4.14 (4 H, m), 4.18 (1 H, d, J = 9.1 Hz), 7.44 (1 H, d, J = 1.0 Hz). 13C NMR (75 MHz, D2O) δ ppm 11.3, 51.3, 51.6, 57.8, 61.9, 72.1, 77.3, 110.5, 143.7, 152.5, 166.8. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C11H18N3O5 +: 272,12410; found 272.1245. .

4.2.26. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(4-chloro-7H-pyrrolo[2,3-d]pyrimidin-7-yl)methyl)-3,4-isopropylidene-pyrrolidine-1-carboxylate (34)

Compound 23 (0.524 g, 1.33 mmol, 1.0 eq.) and DMAP (0.024 g, 0.2 mmol, 0.1 eq.) were dissolved in CH2Cl2 (15 mL) and cooled to 0 °C. Et3N (0.279 mL, 2.00 mmol, 1.5 eq.) and Ms-Cl (0.155 mL, 2.0 mmol, 1.5 eq.) were added and the mixture was stirred for 2 h 25 mL saturated NaHCO3 solution was added, and the mixture was extracted with 3 × 50 mL CH2Cl2. The combined organic phases were washed with brine, dried over Na2SO4, and concentrated in vacuo. The residue was dissolved in 7 mL DMF and added to a previously stirred (30 min) mixture of 6-chloro-7-deazapurine (0.511 g, 3.33 mmol, 2.5 eq.) and NaH (60% wt. in mineral oil, 0.106 g, 2.66 mmol, 2.0 eq.). The temperature was raised to 85 °C and the mixture stirred overnight. The mixture was filtered over celite®, rinsed with EtOAc and transferred to a separation funnel. 30 mL saturated NaHCO3 solution was added and the mixture was extracted with 3 × 50 mL EtOAc. The organic phases were dried over Na2SO4, concentrated in vacuo and purified by flash column chromatography (10–50% EtOAc in hexanes) to yield 34 as a colourless oil in 14% yield (2 steps). 1H NMR (300 MHz, DMSO-d 6, 80 °C) δ ppm 1.08 (3 H, s), 1.31 (3 H, s), 1.36 (9 H, s), 3.45–3.67 (4 H, m), 3.98–4.06 (1 H, m), 4.50–4.75 (5 H, m), 6.66 (1 H, d, J = 3.5 Hz), 7.25–7.39 (4 H, m), 7.65 (1 H, d, J = 3.5 Hz), 8.62 (1 H, s). 13C NMR (75 MHz, DMSO-d 6, 80 °C) δ ppm 27.4, 28.2, 28.5, 48.8, 56.3, 64.3, 69.7, 73.1, 79.6, 85.7, 99.1, 112.6, 117.1, 127.9, 128.0, 128.7, 133.0, 138.5, 150.8, 151.3, 151.8, 153.6. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C27H33ClN4O5 +: 529.22123; found 529.2209.

4.2.27. (2R,3R,4R)-2-((hydroxy)methyl)-4-(4-amino-7H-pyrrolo[2,3-d]pyrimidin-7-yl)methyl)-3,4-dihydroxy-pyrrolidine (35)

NaN3 (0.029 g, 0.45 mmol, 3.0 eq.) was added to a solution of compound 34 (0.080 g, 0.15 mmol, 1.0 eq.) in 5 mL DMF. The solution was warmed to 85 °C and stirred for 24 h 10 mL water was added, and the mixture was extracted with 3 × 25 mL EtOAc. The organic phases were dried over Na2SO4, concentrated in vacuo and purified by flash column chromatography (5–40% EtOAc in hexanes). The residue was dissolved in 5 mL EtOH, Pd(OH)2 (0.016 g, 20% wt.) was added and the reaction mixture was stirred under H2 atmosphere for 24 h. The mixture was filtered over celite®, concentrated in vacuo, and used crude in the next reaction. The residue was dissolved in a mixture of THF & H2O (1:1, 4 mL) and 1 mL concentrated HCl was added. After 1 h of stirring, the mixture was concentrated in vacuo and purified by flash column chromatography (MeOH/NH4OH/CH2Cl2 20:1:9 and 45:5:55). The residue was then subjected to general procedure 3 to afford 35 in 54% yield (3 steps) as a white solid. 1H NMR (300 MHz, D2O) δ ppm 3.23 (1 H, d, J = 12.9 Hz), 3.54 (1 H, d, J = 13.2 Hz), 3.67 (1 H, ddd, J = 9.0, 5.6, 3.2 Hz), 3.83 (1 H, dd, J = 12.9, 5.6 Hz), 3.95 (1 H, dd, J = 12.6, 3.2 Hz), 4.22 (1 H, d, J = 9.1 Hz), 4.52 (2 H, d, J = 3.2 Hz), 6.81 (1 H, d, J = 3.8 Hz), 7.37 (1 H, d, J = 3.5 Hz), 8.23 (1 H, s). 13C NMR (75 MHz, D2O) δ ppm 48.4, 51.5, 57.7, 62.1, 72.0, 77.6, 101.5, 101.8, 129.3, 141.7, 147.2, 150.6. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C12H18N5O3 +: 280.14042; found 280.1403..

4.2.28. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(N-3-benzoyl-5-fluorouracil)-3,4-isopropylidene-pyrrolidine-1-carboxylate (36)

Compound 23 (0.281 g, 0.71 mmol) was subjected to general procedure 1, using N-3-benzoyl-5-fluorouracil as nucleobase and MeCN as solvent. The residue was purified by flash column chromatography (5–40% EtOAc in hexanes), but 36 could not be separated from Mitsunobu byproducts. The residue was used as such in the next reaction. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C32H37FN3O8 +: 610.22592; found 610.2605.

4.2.29. (2R,3R,4R)-2-((hydroxy)methyl)-4-(N-1-methyl-5-fluorouracil)-3,4-dihydroxy-pyrrolidine (37)

Compound 36 (0.075 g, 0.12 mmol) was dissolved in 3 mL MeOH. A 7 N solution of NH3 in MeOH (2 mL) was added and the mixture was stirred overnight. The mixture was concentrated in vacuo and purified by flash column chromatography (10–40% EtOAc in hexanes). The residue was subjected to general procedure 2 and general procedure 3. White powder, 52% yield. 1H NMR (300 MHz, D2O) δ ppm 3.39 (1 H, d, J = 13.2 Hz), 3.49 (1 H, d, J = 12.9 Hz), 3.67 (1 H, ddd, J = 8.9, 5.6, 3.1 Hz), 3.80–4.16 (5 H, m), 4.19 (1 H, d, J = 9.1 Hz), 7.80 (1 H, d, J = 5.9 Hz). 13C NMR (75 MHz, D2O) δ ppm 51.6, 51.8, 57.8, 61.9, 72.1, 77.2, 131.6, 132.0, 138.6, 141.7, 151.0, 159.9. 19F NMR (282 MHz, D2O) δ ppm −168.09. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C10H15FN3O5 +: 276.09903; found 276.0985..

4.2.30. tert-butyl (2R,3R,4R)-2-((benzyloxy)methyl)-4-(N-1-methyl-N-4-acetylytosine)-3,4-isopropylidene-pyrrolidine-1-carboxylate (38)

Compound 23 (0.275 g, 0.70 mmol, 1.0 eq.) and DMAP (0.08 g, 0.07 mmol, 0.1 eq.) were dissolved in CH2Cl2 (8 mL) and cooled to 0 °C. Et3N (0.146 mL, 1.05 mmol, 1.5 eq.) and Ms-Cl (0.081 mL, 1.05 mmol, 1.5 eq.) were added and the mixture was stirred for 1 h 25 mL saturated NaHCO3 solution was added, and the mixture was extracted with 3 × 50 mL CH2Cl2. The combined organic phases were washed with brine, dried over Na2SO4, and concentrated in vacuo. The residue was dissolved in 6 mL DMF. N-4-acetylcytosine (0.129 g, 0.84 mmol, 1.2 eq.), K2CO3 (0.145 g, 1.05 mmol, 1.5 eq.) and 18-crown-6 (0.030 mL, 0.14 mmol, 0.2 eq.) were added and the mixture was warmed to 75 °C. After 18 h, the mixture was filtered over celite® and purified by flash column chromatography (0–5% MeOH in CH2Cl2) to afford 38. 38 could not be obtained pure enough for NMR analysis and was used as such in the next reactions. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C27H37N5O7 +: 529.26568; found 529.2678.

4.2.31. (2R,3R,4R)-2-((hydroxy)methyl)-4-(N-1-methylcytosine)-3,4-dihydroxy-pyrrolidine (39)

Compound 38 (0.098 g, 0.185 mmol) was subjected to general procedure 2 and general procedure 3. Off-white solid, 15% (2 steps). 1H NMR (300 MHz, D2O) δ ppm 3.39 (1 H, d, J = 13.2 Hz), 3.50 (1 H, d, J = 13.2 Hz), 3.65 (1 H, ddd, J = 11.8, 5.6, 3.1 Hz), 3.83 (1 H, dd, J = 12.7, 5.7 Hz), 3.96 (1 H, dd, J = 12.7, 3.4 Hz), 4.03 (1 H, d, J = 15.5 Hz), 4.16–4.25 (2 H, m), 6.16 (1 H, d, J = 7.6 Hz), 7.79 (1 H, d, J = 7.9 Hz). 13C NMR (75 MHz, D2O) δ ppm 51.6, 52.4, 57.7, 61.9, 72.2, 76.9, 94.3, 149.3, 150.3, 159.5. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C10H17N4O4 +: 257,12444; found 257.1256. .

4.2.32. tert-butyl (2R,3R,4R)-2-((hydroxy)methyl)-4-(N-9-methyl-N-6- bis-tert-butyloxycarbonyl -adenine)-3,4-isopropylidene-pyrrolidine-1-carboxylate (40)

Pd(OH)2 (0.107 g, 20% wt.) was added to a solution of compound 24 (0.537 g, 0.76 mmol) in MeOH. The reaction mixture was warmed to 40 °C and stirred under H2 atmosphere for 3 days. The mixture was filtered over celite®, concentrated in vacuo, and purified by flash column chromatography (10–50% EtOAc in hexanes) to afford 40 as a white foam in 56% yield. 1H NMR (300 MHz, DMSO-d 6, 80 °C) δ ppm 1.02 (3 H, s), 1.30 (3 H, s), 1.35–1.41 (27 H, m), 3.57 (2 H, s), 3.60–3.69 (2 H, m), 3.92 (1 H, t, J = 4.1 Hz), 4.67–4.81 (3 H, m), 4.93 (1 H, t, J = 5.0 Hz), 8.51 (1 H, s), 8.84 (1 H, s). 13C NMR (75 MHz, DMSO-d 6, 80 °C) δ 26.6, 26.9, 27.3, 27.7, 46.9, 55.8, 60.5, 65.4, 78.6, 82.7, 111.6, 127.2, 147.1, 149.0, 149.4, 151.1, 152.8, 153.2. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C29H45N6O9 +: 621,32426; found 621.3249.

4.2.33. tert-butyl (2R,3R,4R)-2-((methylthio)methyl)-4-(N-9-methyl-N-6-bis-tert-butyloxycarbonyl -adenine)-3,4-isopropylidene-pyrrolidine-1-carboxylate (41)

Compound 40 (0.119 g, 0.19 mmol, 1.0 eq.) and DMAP (0.002 g, 0.02 mmol, 0.1 eq.) were dissolved in CH2Cl2 (4 mL) and cooled to 0 °C. Et3N (0.040 mL, 0.29 mmol, 1.5 eq.) and Ms-Cl (0.022 mL, 0.29 mmol, 1.5 eq.) were added and the mixture was stirred for 1 h 10 mL saturated NaHCO3 solution was added, and the mixture was extracted with 3 × 25 mL CH2Cl2. The combined organic phases were dried over Na2SO4, and concentrated in vacuo. The residue was dissolved in DMSO (4 mL), NaSMe (0.043 g, 0.61 mmol, 3.2 eq.) was added and the temperature was raised to 50 °C. After 5 h of stirring, TLC analysis indicated completion of the reaction. The reaction mixture was diluted with EtOAc (50 mL), washed with 2 × 15 mL saturated NaHCO3 solution and 15 mL of brine, dried over Na2SO4 and concentrated in vacuo. The residue was purified by flash column chromatography (15–60% EtOAc in hexanes) to afford a mixture of 2 products, 41 and mono-Boc-protected 41. The mixture of these two compounds was used in the next reactions. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C30H47N6O8S+: 651.31706; found 651.3173. Calculated for C25H39N6O6S+: 551.26518; found 551.2678.

4.2.34. tert-butyl (2R,3R,4R)-2-(4-chloro-phenylthiomethyl)-4-(N-9-methyl-N-6- bis-tert-butyloxycarbonyl -adenine)-3,4-isopropylidene-pyrrolidine-1-carboxylate (42)

Compound 40 (0.120 g, 0.19 mmol, 1.0 eq.) and DMAP (0.002 g, 0.02 mmol, 0.1 eq.) were dissolved in CH2Cl2 (4 mL) and cooled to 0 °C. Et3N (0.040 mL, 0.29 mmol, 1.5 eq.) and Ms-Cl (0.022 mL, 0.29 mmol, 1.5 eq.) were added and the mixture was stirred for 1 h 10 mL saturated NaHCO3 solution was added, and the mixture was extracted with 3 × 25 mL CH2Cl2. The combined organic phases were washed with brine, dried over Na2SO4, and concentrated in vacuo. The residue was used crude in the next reaction. The residue was dissolved in 3 mL DMF and added to a previously stirred (30 min) mixture of 4-chloro-thiophenol (0.082 g, 0.57 mmol, 3.0 eq.) and NaH (60% wt. in mineral oil, 0.019 g, 0.48 mmol, 2.5 eq.) in 2 mL DMF. The mixture was stirred overnight and concentrated in vacuo. The residue was dissolved in CH2Cl2 (25 mL), washed with saturated Na2CO3 solution (10 mL) and brine (10 mL), dried over Na2SO4 and concentrated in vacuo. The residue was purified by flash column chromatography (10 → 50% EtOAc in hexanes) to afford 42 as a colourless oil in 97% yield (2 steps). HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C35H48ClN6O8S+: 747,29374; found 747.2935.

4.2.35. (2R,3R,4R)-2-(methylthiomethyl)-4-(N-9-methyladenine)-3,4-dihydroxy-pyrrolidine (43)

The mixture of compounds 41 and mono-Boc-deprotected 41was dissolved in a mixture of THF and H2O (1/1, 4 mL) and 1 mL concentrated HCl was added. After 2 h of stirring, the mixture was concentrated in vacuo and the residue purified by flash column chromatography (). The residue was then subjected to general procedure 3 to afford 43 as an off-white solid in 29% yield (4 steps). 1H NMR (300 MHz, D2O) δ ppm 2.09 (3 H, s), 2.58–2.88 (3 H, m), 3.10–3.26 (2 H, m), 3.75 (1 H, d, J = 8.8 Hz), 4.30 (2 H, s), 8.04 (1 H, s), 8.06 (1 H, s). 13C NMR (75 MHz, D2O) δ ppm 14.9, 35.9, 49.1, 52.8, 60.6, 77.4, 78.2, 117.7, 142.8, 149.0, 152.2, 155.2. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C12H19N6O2S+: 311.12847; found 311.1281.

4.2.36. (2R,3R,4R)-2-(4-chloro-phenylthiomethyl)-4-(N-9-methyladenine)-3,4-dihydroxy-pyrrolidine (44)

Compound 42 was dissolved in a mixture of THF and H2O (1/1, 4 mL) and 1 mL concentrated HCl was added. After 4 h of stirring, the mixture was concentrated in vacuo and the residue purified by flash column chromatography (MeOH/NH4OH/CH2Cl2 0:0:100 to 20:1:79). The residue was then subjected to general procedure 3 to afford 44 as a white solid in 66% yield (4 steps). 1H NMR (300 MHz, D2O) δ ppm 3.20–3.34 (2 H, m), 3.47–3.71 (3 H, m), 4.17 (1 H, d, J = 9.1 Hz), 4.55 (2 H, s), 7.30–7.41 (4 H, m), 8.30 (1 H, s), 8.39 (1 H, s). 13C NMR (75 MHz, D2O) δ ppm 33.0, 47.6, 51.2, 60.0, 75.2, 76.7, 117.8, 129.3, 131.6, 132.9, 144.5, 145.3, 149.7. HRMS (ESI-TOF) m/z: [M+H]+ Calculated for C17H20ClN6O2S+: 407.10515; found 407.1063..

Acknowledgements

KVH thanks the Hercules Foundation (project AUGE/11/029 “3D-SPACE: 3D Structural Platform Aiming for Chemical Excellence”) and the Research Foundation Flanders for funding.

Footnotes

Supplementary data related to this article can be found at http://dx.doi.org/10.1016/j.tet.2017.05.083.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- 1.Hernández D., Boto A. Eur J Org Chem. 2014;2014:2201–2220. [Google Scholar]

- 2.Romeo G., Chiacchio U., Corsaro A., Merino P. Chem Rev. 2010;110:3337–3370. doi: 10.1021/cr800464r. [DOI] [PubMed] [Google Scholar]

- 3.Gary B.E., Vern L.S., Peter C.T. Curr Med Chem. 2015;22:3897–3909. [Google Scholar]

- 4.Ho M.C., Shi W., Rinaldo-Matthis A. Proc Natl Acad Sci. 2010;107:4805–4812. doi: 10.1073/pnas.0913439107. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Evans G.B., Furneaux R.H., Schramm V.L., Singh V., Tyler P.C. J Med Chem. 2004;47:3275–3281. doi: 10.1021/jm0306475. [DOI] [PubMed] [Google Scholar]

- 6.Gutierrez J.A., Crowder T., Rinaldo-Matthis A., Ho M.C., Almo S.C., Schramm V.L. Nat Chem Biol. 2009;5:251–257. doi: 10.1038/nchembio.153. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Basu I., Locker J., Cassera M.B. J Biol Chem. 2011;286:4902–4911. doi: 10.1074/jbc.M110.198374. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Freitas E.O., Nico D., Guan R. PLoS One. 2015;10:e0124183. doi: 10.1371/journal.pone.0124183. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Wang S., Haapalainen A.M., Yan F. Biochemistry. 2012;51:6892–6894. doi: 10.1021/bi3009664. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Wang S., Cameron S.A., Clinch K. J Am Chem Soc. 2015;137:14275–14280. doi: 10.1021/jacs.5b06110. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Warren T.K., Wells J., Panchal R.G. Nature. 2014;508:402–405. doi: 10.1038/nature13027. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Taylor R., Kotian P., Warren T. J Infect Public Health. 2016;9:220–226. doi: 10.1016/j.jiph.2016.04.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Julander J.G., Bantia S., Taubenheim B.R. Antimicrob Agents Chemother. 2014;58:6607–6614. doi: 10.1128/AAC.03368-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Chiacchio U., Borrello L., Crispino L. J Med Chem. 2009;52:4054–4057. doi: 10.1021/jm900197j. [DOI] [PubMed] [Google Scholar]

- 15.Furneaux R.H., Schramm V.L., Tyler P.C. Bioorg Med Chem. 1999;7:2599–2606. doi: 10.1016/s0968-0896(99)00210-2. [DOI] [PubMed] [Google Scholar]

- 16.Miles R.W., Tyler P.C., Evans G.B., Furneaux R.H., Parkin D.W., Schramm V.L. Biochemistry. 1999;38:13147–13154. doi: 10.1021/bi990829u. [DOI] [PubMed] [Google Scholar]

- 17.Evans G.B., Furneaux R.H., Lewandowicz A., Schramm V.L., Tyler P.C. J Med Chem. 2003;46:5271–5276. doi: 10.1021/jm030305z. [DOI] [PubMed] [Google Scholar]

- 18.Evans G.B., Furneaux R.H., Lenz D.H. J Med Chem. 2005;48:4679–4689. doi: 10.1021/jm050269z. [DOI] [PubMed] [Google Scholar]

- 19.Thomas K., Haapalainen A.M., Burgos E.S. Biochemistry. 2012;51:7541–7550. doi: 10.1021/bi3009938. [DOI] [PubMed] [Google Scholar]

- 20.Hossain N., Hendrix C., Lescrinier E. Bioorg Med Chem Lett. 1996;6:1465–1468. [Google Scholar]

- 21.Wróblewski A.E., Głowacka I.E., Piotrowska D.G. Eur J Med Chem. 2016;118:121–142. doi: 10.1016/j.ejmech.2016.04.034. [DOI] [PubMed] [Google Scholar]

- 22.Jenkinson S.F., Best D., Saville A.W. J Org Chem. 2013;78:7380–7397. doi: 10.1021/jo4005487. [DOI] [PubMed] [Google Scholar]

- 23.Stocker B.L., Dangerfield E.M., Win-Mason A.L., Haslett G.W., Timmer M.S.M. Eur J Org Chem. 2010:1615–1637. doi: 10.1021/jo100004c. [DOI] [PubMed] [Google Scholar]

- 24.Lumbroso A., Coeffard V., Le Grognec E., Beaudet I., Quintard J.-P. Tetrahedron Lett. 2010;51:3226–3228. [Google Scholar]

- 25.Trost B.M., Bunt R.C., Lemoine R.C., Calkins T.L. J Am Chem Soc. 2000;122:5968–5976. [Google Scholar]

- 26.Barrow J.C., Ngo P.L., Pellicore J.M., Selnick H.G., Nantermet P.G. Tetrahedron Lett. 2001;42:2051–2054. [Google Scholar]

- 27.van den Nieuwendijk A.M.C.H., Ruben M., Engelsma S.E. Org Lett. 2010;12:3957–3959. doi: 10.1021/ol101556k. [DOI] [PubMed] [Google Scholar]

- 28.Swamy K.C.K., Kumar N.N.B., Balaraman E., Kumar K.V.P.P. Chem Rev. 2009;109:2551–2651. doi: 10.1021/cr800278z. [DOI] [PubMed] [Google Scholar]

- 29.Michel B.Y., Strazewski P. Tetrahedron. 2007;63:9836–9841. [Google Scholar]

- 30.Ludek O.R., Meier C. Eur J Org Chem. 2006;2006:941–946. [Google Scholar]

- 31.Johnson D.C., Widlanski T.S. Org Lett. 2004;6:4643–4646. doi: 10.1021/ol048426w. [DOI] [PubMed] [Google Scholar]

- 32.Ludek O.R., Meier C. Synthesis. 2003;2003:2101–2109. [Google Scholar]

- 33.Hernandez S., Ford H., Jr., Marquez V.E. Bioorg Med Chem. 2002;10:2723–2730. doi: 10.1016/s0968-0896(02)00099-8. [DOI] [PubMed] [Google Scholar]

- 34.Tan Y.X., Santhanakrishnan S., Yang H.Y., Chai C.L.L., Tam E.K.W. J Org Chem. 2014;79:8059–8066. doi: 10.1021/jo501248e. [DOI] [PubMed] [Google Scholar]

- 35.Howarth N.M., Wakelin L.P.G. J Org Chem. 1997;62:5441–5450. [Google Scholar]

- 36.Bessieres M., Roy V., Agrofoglio L.A. RSC Adv. 2014;4:59747–59749. [Google Scholar]

- 37.Vandenriessche F., Snoeck R., Janssen G. J Med Chem. 1992;35:1458–1465. doi: 10.1021/jm00086a015. [DOI] [PubMed] [Google Scholar]

- 38.Hohn C., Härtsch A., Ehrmann F.R. Chem Eur J. 2016;22:6750–6754. doi: 10.1002/chem.201600883. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.