Abstract

In 2013, the “biofabrication window” was introduced to reflect the processing challenge for the fields of biofabrication and bioprinting. At that time, the lack of printable materials that could serve as cell-laden bioinks, as well as the limitations of printing and assembly methods, presented a major constraint. However, recent developments have now resulted in the availability of a plethora of bioinks, new printing approaches, and the technological advancement of established techniques. Nevertheless, it remains largely unknown which materials and technical parameters are essential for the fabrication of intrinsically hierarchical cell–material constructs that truly mimic biologically functional tissue. In order to achieve this, it is urged that the field now shift its focus from materials and technologies toward the biological development of the resulting constructs. Therefore, herein, the recent material and technological advances since the introduction of the biofabrication window are briefly summarized, i.e., approaches how to generate shape, to then focus the discussion on how to acquire the biological function within this context. In particular, a vision of how biological function can evolve from the possibility to determine shape is outlined.

Keywords: biofabrication, bioinks, biological function, regenerative medicine, tissue hierarchy

1. Introduction

The functionality of living tissues is intimately linked to their intricate and highly specialized architecture. Tissues and organs are composed of multiple types of cells and extracellular matrix (ECM) components and, with few exceptions, are infiltrated with vascular and neural networks. The hierarchical spatial arrangement of these elements is paramount to how they interact with each other and, thus, closely orchestrates several processes during embryonic development,[1] in healthy tissue homeostasis, as well as during tissue regeneration.[2] Strategies to generate cell–material constructs that ultimately yield a healthy and mature functional tissue remains a major challenge in the field of regenerative medicine.

With the introduction of additive manufacturing, technologies became available to design and fabricate 3D material scaffolds with unprecedented shape and precision. Although, many of these technologies are potentially harmful for active biological components, including living cells, biological matter can successfully be used as building blocks for the generation of living 3D objects. This constitutes the research field of biofabrication,[3] a revolutionizing toolkit for regenerative medicine that allows cells, biomaterials and bioactive moieties to be precisely combined and patterned into 3D constructs through automated, cell-friendly fabrication methods, such as bioprinting and bioassembly.[4] Indeed, modified extrusion,[5] (stereo)lithographic,[6] inkjet,[7] and laser printing methods[8] are now available for the processing of living cells and can be applied to recreate anatomical parts using medical images as blueprints.[9] Within the past decade there has been a particular focus on techniques and materials compatible with extrusion-based printing due to the high versatility in printing multiple materials, the relative low cost and easy access to the required hardware for this technology.[10] Taken together, biofabrication has gained significant momentum and provides a powerful approach to tackle major hurdles in the generation of engineered living tissues.

As building materials in biofabrication processes, two different types of printable “inks” can generally be distinguished.[11] Firstly, materials that are used to print acellular structures, on which cells are seeded or that can also be used as surgical tools or implants after fabrication, are termed biomaterial inks. Many different materials, including thermoplasts and metal powders, can be processed using a variety of technologies and the process parameters are only restricted by technology and the respective material. Secondly, the printable formulations that contain living cells are termed bioinks.[3] This simple but clear distinction severely limits the number of suitable fabrication technologies as the process must ensure viability of the embedded cells. Therefore, the printing process needs to be performed under physiological conditions and in an aseptic environment. Bioinks are generally aqueous formulations with adjusted rheology that can provide a highly hydrated environment for the encapsulated cells.[11] For this, often formulations of hydrogel precursors are applied that can be crosslinked postfabrication. An important challenge in this context is, however, the counterdirectional effect of polymer concentration on shape fidelity and cytocompatibility. In other words, low polymer content in the bioink results in soft, loosely crosslinked hydrogels after printing that are beneficial to support cell survival, migration and bioactivity, but such formulations do typically result in structures with poor shape fidelity. In contrast, bioinks with higher polymer content and thus higher viscosity can more rapidly be crosslinked into stiffer gels after printing and are in general preferred for the accurate 3D placement and postprinting shape retention,[12] resulting in a printed object that faithfully reproduces its original computer design. However, this comes with the cost of reduced ability of the cells to spread, migrate and colonize the hydrogel matrix with newly synthesized ECM. Additionally, high crosslinking density or polymer content can also hinder the ability of the embedded cells to remodel the hydrogel matrix over time, a process necessary for tissue maturation.

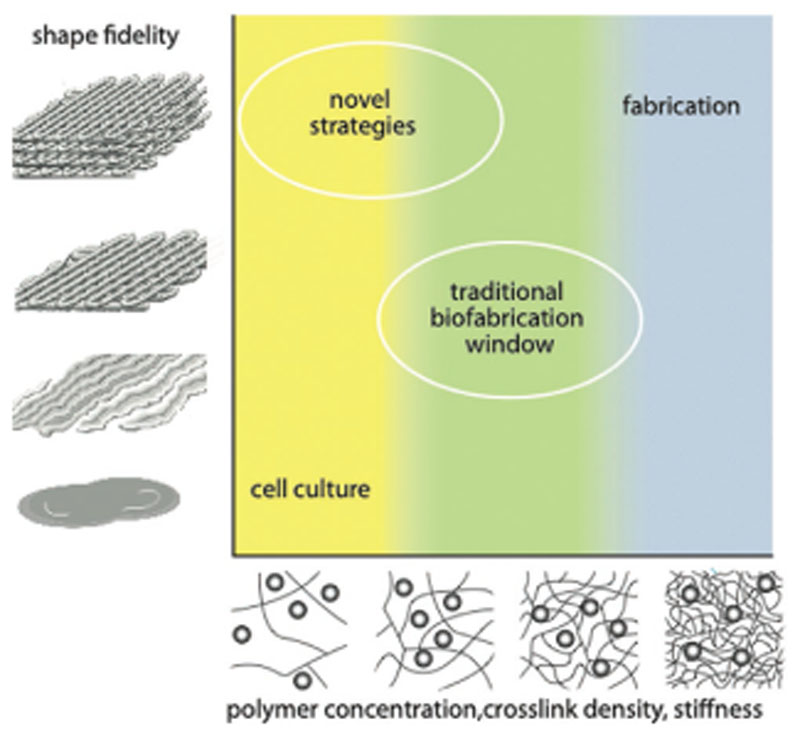

The simultaneous need for these opposing requirements led to the conceptualization of the biofabrication window, the range of material properties suitable both for printability with high shape fidelity and for the support of cell function (Figure 1).[12] This concept has since then widely been appreciated in the biofabrication community.[13–17] Strategies to extend this biofabrication window and allow for printing with good shape fidelity under cytocompatible conditions with as little material content as possible have been an important focus of recent research in the field.

Figure 1.

Schematic representation of the biofabrication window as introduced in 2013. Reproduced with permission.[12] Copyright 2013, Wiley-VCH.

Bioprinted structures are currently being studied as potential transplantable grafts for tissue restoration,[18] as advanced in vitro models to aid the testing of drugs and as potential alternatives to animal experimentation.[19–21] These are used to study tissue development and disease[22] and as components integrated within organ-on-chip devices.[23] While the development of new bioinks and adaptations of existing printing technologies is an important part of current biofabrication research, novel strategies have emerged, introducing alternative approaches to push the boundaries of the biofabrication window. This allows for the fabrication of larger, more sophisticated structures even when softer hydrogels are used and led to significant advances in the generation of 3D constructs displaying salient features of native tissues, such as those of bone,[24] skin,[25] cartilage,[26] cardiac muscle,[27] thyroid,[28] and liver tissue.[29] Despite these promising examples, studies that clearly demonstrate the advantage of bioprinting in achieving 3D cell–material constructs that exhibit, at least to a certain extent, functional characteristics of living tissues are not widespread.

In the present review, we summarize key strategies that have expanded the biofabrication window and that lead to improved control over shape. Building on such advances in material science, the main focus here is on the current and future steps toward mimicking salient functionalities of living tissues, through the creation of hierarchically structured constructs, in particular when using bioinks as building blocks for extrusionbased bioprinting. For this, the impact of bioprinted constructs with preformed spatial organization to facilitate tissue morphogenesis will be critically discussed. We highlight recent and upcoming developments in biofabrication that could influence the next generation of engineered tissues. Finally, we urge that future strategies embrace biological (developmental) processes and integrate them with bioprinting technologies to yield constructs with biological function toward the ambitious goal of printing functional tissues or even entire organs.

2. Recent Progress for Controlling Shape

Among the different subtypes of bioinks,[11] the most commonly used inks for extrusion bioprinting are based on hydrogels, either in the form of gel precursors or as preformed gels. These systems provide a highly hydrated environment that supports the encapsulated cells and generally offer shape retention to maintain the form of the as-printed constructs. During the last decade the biofabrication window has been extended by improving bioink performance and bioprinting techniques. Many excellent reviews discuss the current status of bioink development[16,30–34] and this is beyond the scope of the current review; however, several relevant components for bioinks and the respective crosslinking approaches are listed in Table 1.

Table 1.

Overview of popular natural and synthetic components used in bioinks for extrusion-based bioprinting sorted by the main component. The table summarizes strategies for enabling the printability of common biomaterials using various functionalities and crosslinking approaches.

| Natural | Characteristics/chemical structure | Functionalities/derivates | Crosslinking/fabrication approaches | Remarks/biological activity |

|---|---|---|---|---|

| Polypeptides | ||||

| Gelatin | Denaturated collagen Mainly collagen I Gly-Pro-X (most abundant) Type A (derived from acidic-treated gelatin) → positive-charge at neutral pH Type B (derived from alkali-treated gelatin) → negative-charge at neutral pH Thermoreversible gelation |

Without functionalization[35–37] | Blending with stabilizing component (e.g., alginate, fibrin[37]) Enzymatic crosslinking: transglutaminase[38] tyrosinase[39] Radical (photo-) polymerization |

Biodegradable Cell adhesion motifs are present Moderate biological activity if used alone Common sources: Bovine skin Porcine skin Fish skin |

| Methacrylated[23,40-44]

Allylated[45] Norbornenet[46] Thiolatedt[47,48] Tyraminet[49] Furfury[50] |

Radical (photo-) polymerization | |||

| Collagen type I | Most abundant collagen in human body Gly-Pro-X pH-dependent fibrillogenesis and gelation |

Without functionalization | pH-dependent crosslinking[51–53] photo-crosslinking (e.g., with ribofavin[54]) crosslinked with genipin[55] | Biodegradable Cell adhesion motifs are present Common sources: Rat tail Bovine skin Rabbit skin Calf skin |

| Fibrinogen/fibrin | Fibrous and nonglobular glycoprotein Thrombin (factor IIa) and factor XIIIa can be used to covalently crosslink fibrinogen |

Without functionalization[18,35–37,43,51] | Enzymatic crosslinking (factor IIa, XIIIa and IV) Additionally blended with stabilizing component (e.g., gelatin, hyaluronic acid, and Pluronic F127[37]) | Biodegradable Cell adhesion motifs are present Limited long-term stability (can be prolonged by addition of aprotinin to culture medium) Common sources: Human plasma Bovine plasma Rat plasma |

| Silk/fibroin | Silkworm cocoons Gly-Ser-Gly-Ala-Gly-Ala units[56] Recombinant spider protein GSSAAAAAAAASGPGGYGPE NQGPSGPGGYGPGGP Physical crosslinking by β-sheet crystal formation | Without functionalization | Physical crosslinking[57]

Blended with stabilizing component (e.g., gelatin[57]) Enzymatic crosslinking by tyrosinase[39] |

Biodegradable Poor cell adhesion due to hydrophobic character[58]

Common sources: B. mori silkworm Recombinant silk protein eADF4(C16) mimicking Araneus diadematus silk protein sequences[59] |

| Poly-saccharides | ||||

| Agarose | d-Galactose and 3,6-anhydro-l-galactopyranose Thermoreversible gelation | Without functionalization[60,61] | Physical crosslinking | Biologically inert Biodegradable Often used as sacrifcial material[12] Can be used to modulate the viscosity[60] Common sources: Red algae |

| Alginate | Varying sequences and blocks of β-d-mannuronate (M) and α-l-guluronate (G) Ionic gelation by divalent cations (e.g., Ca[2+]) |

Without functionalization | Physical crosslinking via divalent ions Often blended with, e.g., GelMA, nanocellulose or agarose[40,44,60,62] to improve properties |

Biologically inert Sulfate can bind growth factors, such as FGF, TGF, and HFG Common sources: Brown algae |

| Sulfated[63]

Methacrylated[64] |

Radical (photo-) polymerization | |||

| Characteristics/chemical structure | Functionalities/derivates | Crosslinking/fabrication approaches | Remarks/biological activity | |

| Hyaluronic acid | Glycosaminoglycan (GAG) Units of d-glucuronic acid and N-acetyl-d-glucosamine Forms weak entangled molecular network[65] | Without functionalization[37,66] | Needs modifcation or blending with stabilizing component | Biodegradable Cell adhesion motifs are present Can be used to modulate the viscosity Common sources: Bacteria Bovine vitreous humor Rooster comb |

| Methacrylated[41,67–69]

Phenolic hydroxyl[49] Thiolated[47,48] |

Radical (photo-) polymerization | |||

| Poly(N-isopropylacrylamide)[67]

Adamantane (guest)[68] β-Cyclodextrin (host) Cucurbituril (host)[70] 1,6-diaminohexane (guest) |

Lower critical solution temperature behavior (LCST) Guest–host supramolecular assembly |

|||

| Gellan gum | Tetrasaccharide of repeating units of β-d-glucose, one β-d-glucuronic acid and one α-l-rhamnose[71]

Ionic gelation by mainly divalent cations Thermoreversible gelation |

Without functionalization | Physically crosslinked by cations Blended with stabilizing component (e.g., GelMA[42,72]) | Biodegradable Can be used to modulate the viscosity Common sources: Bacteria |

| Nano-cellulose | Linear linked d-glucose units Cellulose nanocrystals (CNC) Cellulose nanofibers (CNF) Bacterial nanocellulose (BNC) | Without functionalization | Blended with stabilizing and/or bioactive component (e.g., algi-nate[63,73,74]

or hyaluronic acid[62,75]) |

Biodegradable Can be used to modulate the viscosity Common sources: Plants Bacteria |

| Dextran | Branched or linear poly-α-d-glucose | Methacrylatedt[66] | Radical (photo-) polymerization | Biologically inert |

| Chitosan | Progressively deacetylated chitins Linear and random dispersed β-(1-4)-linked d-glucosamine and N-acetyl-d-glucosamine Long gelation time and low mechanical properties[76] | Without functionalization | Blended with stabilizing components (e.g., agarose and alginate[60]) | Biodegradable[77]

improves cell survival[60] cell adhesion properties controlled by N-acetylation groups[78] antibacterial ability[79] Common sources: Chitin shells of seafood (e.g., crabs, shrimps, and prawns) |

| Carboxymethylated[60]

(water soluble) |

||||

| Chondroitin sulfate | Sulfated glycosaminoglycan (GAG) units of N-acetylgalactosamine and glucuronic acid | Methacrylatedt[67] | Radical (photo-) polymerization | Biodegradable Common sources: bovine trachea Shark cartilage |

| Carrageenan | Kappa-carrageenan Ionic gelation mainly by potassium ions iota-carrageenan ionic gelation mainly by calcium ions Thermoreversible gelation |

Without functionalization[80] | Physically crosslinked by cations Blended with a secondary component for covalent polymer network[80]

or nanosilicates[81] |

Kappa-carrageenan mostly used due to its resemblance to natural glycosaminoglycans (GAGs)[82]

Common sources: Red algae |

| Methacrylatedt[83] | Radical (photo-) polymerization | |||

| Characteristics/chemical structure | Functionalities/derivates | Crosslinking/fabrication approaches | Remarks/biological activity | |

| ECM mixtures | ||||

| Matrigel | Solubilized basement membrane preparation Mainly laminin (L-111) and collagen IV, but in total over 1851 unique proteins and over 14 060 unique peptides[84] Temperature-dependent gelation at around RT-37 °C |

Without functionalization | Temperature-triggered gelation | Biodegradable Cell adhesion motifs are present Highly bioactive due to growth factors and vast amount of proteins and peptides No defned composition Batch-to-batch variations Common sources: Engelbreth–Holm–Swarm mouse sarcoma |

| dECM | Decellularized extracellular matrix of a specifc tissue like heart,[85–87]

cartilage,[85] adipose,[85,88,89] aorta,[90] skeletal muscle,[91] and liver[92] Temperature-dependent gelation |

Without functionalization | Temperature-triggered gelation Blended with stabilizing component (e.g., thiolated gelatin, hyaluronic acid, and PEGDA[29]) Vitamin B2-induced UV-A crosslinking[86] | Biodegradable Cell adhesion motifs are present Biodegradable Highly bioactive No defned composition Batch-to-batch variations Common sources: mammalian tissue |

| Synthetic | ||||

| PEG | Poly(ethylene glycol) H(OCH2CH2)nOH Linear or branched | Diacrylatedt[18]

Tetra-acrylatedt[44,48] |

Radical (photo-) polymerization | Biologically inert |

| Methacrylated[61]

Fibrinogen and diacrylate functionalization[18] |

||||

| Succinimidyl valeratet[43] | Amin-carboxylic acid coupling (NHS ester reaction) with, e.g., proteins | |||

| Pluronic | Triblock copolymer of poly(ethylene oxide) Nonionic tenside |

Without functionalization[37] | Temperature-triggered gelation | Biologically inert Often used as sacrifcial material[37] Not suitable for long-term cell culture |

| Diacrylated[93] | Radical (photo-) polymerization | |||

| Additives | ||||

| Nanosilicates | Laponite Na[+] 07[(Mg5.5Li0.3)Si8O20(OH)4]-0.7) |

Without functionalization[83,94] | Physically crosslinked Blended with other bioink components (e.g., kappa-carrageenan and GelMA[95] | Used to modulate the viscosity of an ink to improve printability Can improve cell adhesion and response[96–98] |

| Glycerol | C3H8O3

Viscous and hygroscopic liquid Backbone of many lipids |

Without functionalization | Blended with other bioink components | Can help to induce crosslinking of silk[57]

Can prevent nozzle clogging and used as rheology modifer[37] |

The first strategies to design bioinks involved the chemical modification, or blending of different hydrogels, to control the rheological properties that dictate the printability and shape fidelity of the ink. These efforts resulted in a multitude of applicable systems, including the use of synthetic and natural polymers,[41,67,99] and lay the foundation for improved reproducibility and higher resolutions in bioprinting. As a straightforward, but versatile approach, blending allows to create multimaterial inks, based on mixtures of two or more different materials. In these systems, each component can take on a different function, such as providing suitable biological or chemicophysical properties for bioprinting, including the ability to support a specific cell type or ensuring adequate viscosity for high shape fidelity fabrication. This concept is well exemplified by the inks based on the combination of materials, such as gelatin, fibrinogen, gellan gum, hyaluronic acid (HA), and glycerol[37] (see also Table 1).

Alongside the advances in bioink development, the design of the bioprinting hardware also evolved, offering additional possibilities to enable high shape fidelity prints. Most commercial and custom made bioprinters integrate multiple printheads, enabling the generation of heterocellular and multimaterial 3D constructs. Additionally, many printers incorporate extrusionbased printheads for higher viscosity bioinks, inkjet printheads for low viscosity cell suspensions, heating cores for extruding thermoplastics,[100,101] and recently even melt electrowriting (MEW) functionality within the same platform.[102–104] As such, the potential to converge different printing technologies into a single, hybrid printing process and, therefore, introduce features having spatial resolution spanning a wide range from the nano- to the microscale is becoming more accessible. Coprinting of cell-laden hydrogels and thermoplastic materials via extrusion-based techniques only, or in combination with MEW,[37,105] has been used as an effective approach to adapt the mechanical properties of hybrid constructs to the tissue of interest.[106] As an alternative to thermoplasts to reinforce soft bioinks, stiffer hydrogels,[107] and printable ceramics,[108] have also been used. Apart from the reinforcement and modulation of the construct’s mechanical properties, multimaterial printing can also introduce channels within constructs that can ultimately be perfused and thus would allow for the engineering of larger living structures.[24] Typically, sacrificial materials are being used that can be dissolved after the fabrication process and subsequently be seeded with endothelial cells.

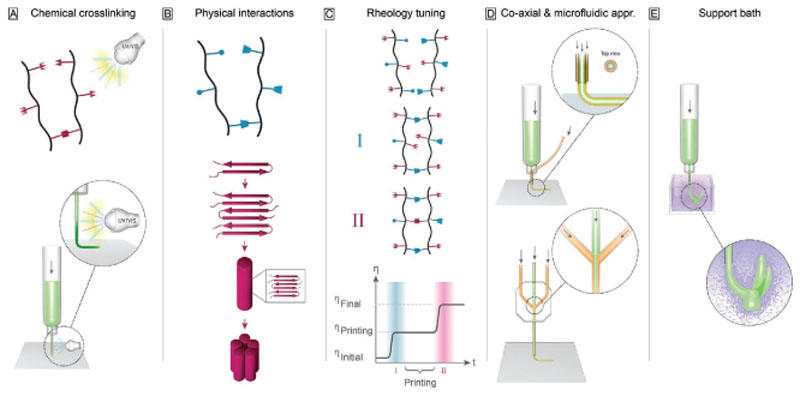

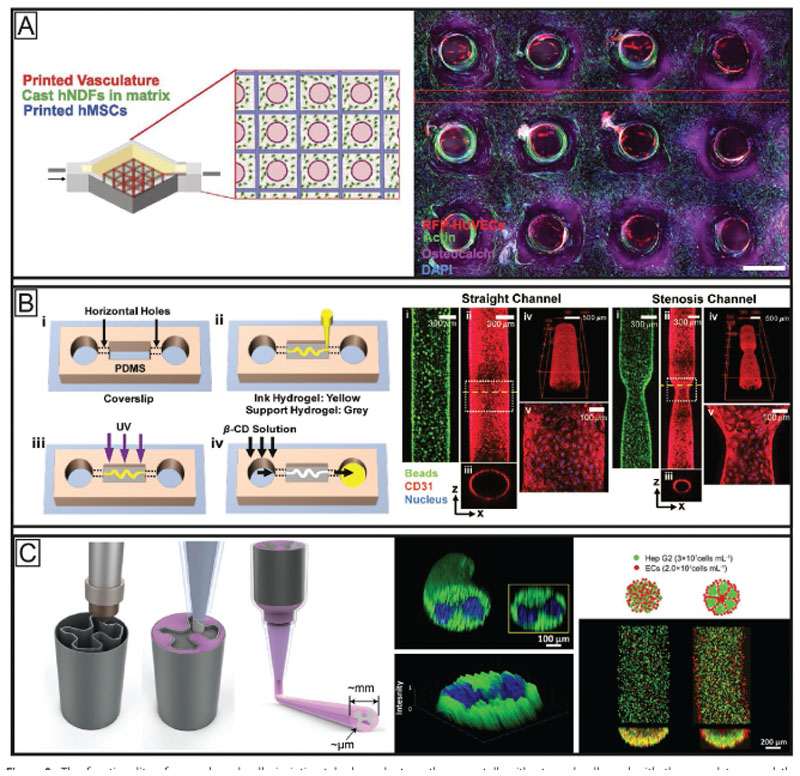

While these hybrid printing methods allow the introduction of structural elements, alternative strategies and further technological developments are necessary to improve shape fidelity of printed structures. In view of this, we here highlight a number of recent important developments that specifically can enhance our ability to create high shape fidelity constructs. These developments can be categorized as methods focusing on bioink design, mainly involving: i) new concepts for chemical crosslinking, ii) hydrogels based on physical interactions beyond ionotropic gelation, and iii) rheological tuning of the ink; as well as methods focusing on the redesign of the printing environment, via the introduction of iv) coaxial and microfluidic printheads, and v) printing into buoyant media as support baths for low-viscosity inks. An overview of the different strategies is depicted in Figure 2 and Table 2 summarizes the advantages and limitations of the fabrication strategies. The evolving strategies will be discussed in more detail in the following chapters. A focus of this chapter is to demonstrate how the recent advantages in the field have helped to extend the biofabrication window and have laid a foundation for tackling new challenges in the field.

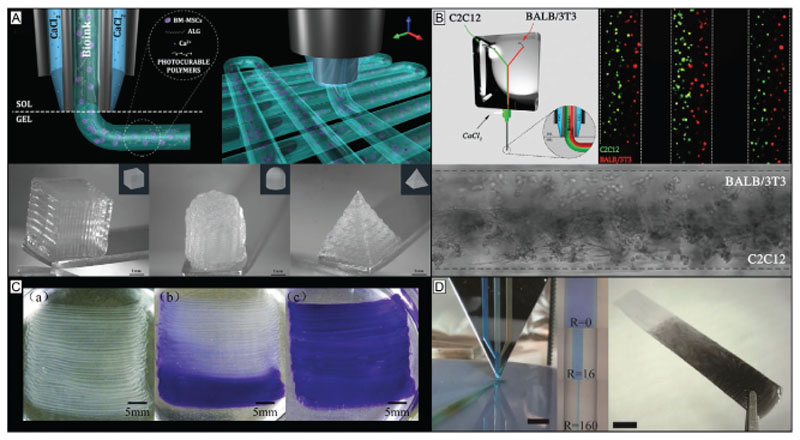

Figure 2.

Overview—evolving strategies for controlling shape in bioprinting. A) To enhance chemical crosslinking strategies mainly step growth reactions and the transition from ultraviolet to visible light crosslinking have been applied more frequently. Also, technological advances like in situ photo-crosslinking can improve shape fidelity and broaden the spectrum of applicable materials based on chemical crosslinking strategies. B) In terms of physical interactions, weak bonds, like host–guest interactions and β-sheets, are applied to adjust the rheological properties of the materials. C) Rheological tuning is leading toward a two-step crosslinking utilizing a first step of crosslinking to enable printing with high shape fidelity and a second step to ensure long-term stability enabling to adjust the viscosity of the material to a level that is needed for the different fabrication steps. D) Further technological advances, like coaxial bioprinting and the application of microfluidic approaches in bioprinting, help broadening the spectrum of materials that can be applied for bioprinting. E) Also, printing into support baths is a promising strategy to enable fabrication of more sophisticated structures with less stringent demands on viscoelastic properties of bioinks.

Table 2.

Overview of advantages and limitations of the discussed technological enhancements for extrusion bioprinting.

| Technological advances | Advantages | Limitations |

|---|---|---|

| In situ photo-crosslinking |

|

|

| Coaxial printing |

|

|

| Microfuidic-enhanced printing |

|

|

| Support bath printing |

|

|

2.1. New Concepts for Chemical Crosslinking

2.1.1. Step Growth Reactions

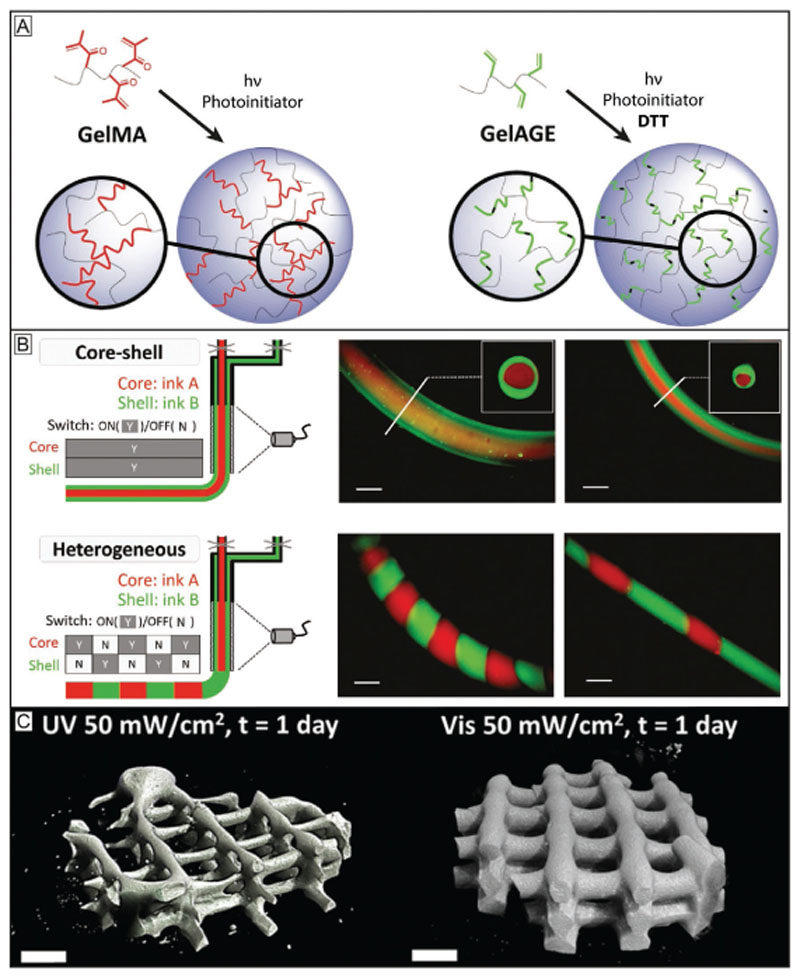

Accurate control over the crosslinking reaction of a bioink is essential to modulate its ultimate mechanical and physical properties, as well as to lead to well defined products that can be obtained under mild, cell-friendly crosslinking conditions. While within the field chain growth-based crosslinking, i.e., the formation of hydrogels by the rapid propagation of active centers through monomers containing multiple carbon–carbon double bonds, has widely been used, step growth systems offer some important advantages. Prominent examples of chain-growth-based system are inks based on acryloyl and vinyl chemistries, such as gelatin methacryloyl (GelMA). Benefits include its stability and straightforward use as no additional crosslinkers are required (Figure 3A). However, the chain growth reaction is prone to oxygen inhibition and leads to a limited control over the number of reacted functionalities resulting in oligo(methacrylamides) and thus also reduced control over mechanical properties and degradation products.[33,109,110] In contrast, thiol–ene step growth reactions, like those based on the modification of gelatin with applied, e.g., to other biopolymers like alginate,[111] or modified hyaluronic acid,[17,100] as well as to synthetic materials, like polyglycidols,[100] and poly(ethylene glycol).[112] This variability and the accompanied improved control over crosslinking render step-growth reactions a suitable tool to expand the biofabrication window toward higher shape fidelity as faster and more homogeneous network formation with more controlled spatiotemporal degradation properties. The difference between the reaction products in chain growth which are less controlled compared to step-growth reactions is schematically depicted in Figure 3A.

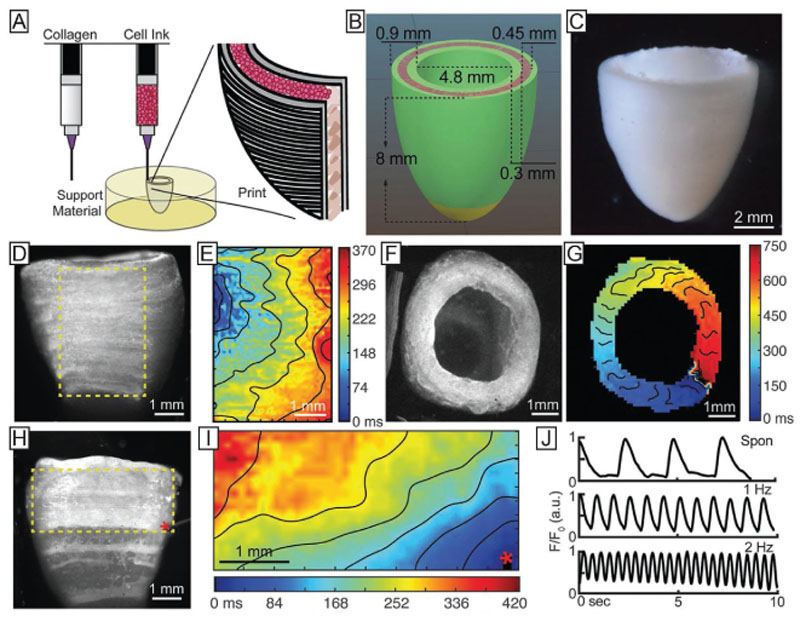

Figure 3.

Chemical crosslinking strategies broaden the biofabrication window of inks and improve control over their resulting physicochemical properties. A) The chain growth-based crosslinking, represented here by gelatin methacryloyl (GelMA), is susceptible to oxygen inhibition and lacks precise control over the reaction products and results in undefined oligo(methacrylates) and thus uncontrolled degradation products. In contrast, the step growth reaction, represented here by the thiol–ene reaction between allyl functionalized gelatin (GelAGE) and the crosslinker dithiothreitol (DTT), provides faster reactions and conversation rates, forms more homogeneous networks and is not prone to oxygen inhibition. Reproduced with permission.[45] Copyright 2017, Wiley-VCH. B) In situ photo-crosslinking utilizes photo-crosslinking of materials through a light permeable printing nozzle. This enables printing of low viscosity precursors and the generation of core–shell as well as filaments from different materials. Reproduced with permission.[17] Copyright 2017, Wiley-VCH. C) Visible light crosslinking is a promising strategy to improve photoreactions used in bioprinting. Shown are °CT images of GelMA/collagen constructs crosslinked with UV and Irgacure 2959 (left) or visible light and Ru/SPS (right) at the same conditions. The visible light approach resulted in more homogeneous constructs, while the UV-crosslinked construct exhibited weakly defined lattice structures with gaps and varying filament diameters. Reproduced with permission.[116] Copyright 2016, American Chemical Society.

Rheological tuning is leading toward a two-step crosslinking utilizing a first step of crosslinking to enable printing with high shape fidelity and a second step to ensure long-term stability enabling to adjust the viscosity of the material to a level that is needed for the different fabrication steps.

Further technological advances, like coaxial bioprinting and the application of microfluidic approaches in bioprinting, help broadening the spectrum of materials that can be applied for bioprinting. E) Also, printing into support baths is a promising strategy to enable fabrication of more sophisticated structures with less stringent demands on viscoelastic properties of bioinks.

2.1.2. In Situ Photo-Crosslinking

Besides controlling the chemistry of the crosslinking reaction, shape fidelity can also be tuned through the timing of the crosslinking processes. Therefore, strategies termed in situ photocrosslinking have been introduced as promising approaches to broaden the biofabrication window. In extrusion-based bioprinting, bioinks that crosslink via photoinduced reactions are typically crosslinked after the deposition of the material.[114] This can be performed either by a single crosslinking after the completion of the print,[115] by continuous crosslinking following deposition,[113,114] or by a layer-by-layer crosslinking.[116] All these crosslinking approaches demand initial retention of shape after deposition of the material and thus still need to overcome the challenges described by the biofabrication window concept.

A solution to this is the photo-crosslinking immediately before the extrusion instead of afterward. A first step into this direction was based on aspirating a cell-laden hydrogel precursor (GelMA) into a light-permeable glass capillary, followed by a photocrosslinking. Afterward the strands of crosslinked hydrogel were deposited to produce lattices and stacked-fiber constructs.[117] This approach was refined and continuous printing of different cell-laden inks (GelMA, poly(ethylene glycol) (PEG) diacrylate (PEGDA), methacrylated hyaluronic acid, and norbornene-modified hyaluronic acid) through a photopermeable capillary, which was used as a nozzle, was demonstrated.[17] The length of the capillary that is exposed to the light source and the feed rate of the ink determine the crosslinking density of the ink. This approach permits to print the bioinks applying low extrusion forces and enabling higher cell viability compared to dispensing of pre-photocrosslinked bioinks (>90%).[17] Moreover, it enabled the fabrication of both heterogeneous and hollow filaments when core–shell capillary tubes and multiple inks were used (see Figure 3B). Importantly, it was demonstrated that this strategy can be used for bioinks with viscoelastic properties that cannot be printed with classical extrusion-based approaches.[17]

2.1.3. Visible-Light Photoinitiating Systems

Photo-crosslinking systems are widely used in biofabrication, as they offer rapid and on demand triggering of the polymerization reaction. Early biofabrication approaches have utilized photoinitiators, like Irgacure 2959, that rely on ultraviolet (UV) light to generate radicals, which induce the crosslinking reaction.[72,118,119] As UV light can potentially be harmful for cells,[116,120] the irradiation dose should be limited and several studies have indeed identified irradiation times that permit preservation of cell viability and functionality.[121,122] However, using low intensity UV energies is particularly challenging when using systems characterized by high oxygen inhibition. One possible solution to this is to use materials that rely on step growth reaction with higher conversion rates of functional groups, which generally results in limited oxygen inhibition,[33] leading to shorter exposure times and thus to lower irradiation doses. Another option to reduce the potential risks caused by UV exposure is to use lower energy (visible) light. The different wavelengths generally also require different photoinitiators. For biofabrication purposes a number of UV-A or visible light sensitive photoinitiators have successfully been evaluated, including lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP),[123] eosin Y,[124] and ruthenium (Ru)/ sodium persulfate (SPS) (Ru/SPS).[116] Interestingly, crosslinking of GelMA with visible light in the presence of Ru/SPS yielded higher viability of human articular chondrocytes (HACs) and bone marrow-derived mesenchymal stromal cells (BMSCs) than crosslinking with UV in the presence of Irgacure 2959 (see Figure 3C).[116] In a follow up study comparing GelMA hydrogels photo-crosslinkable at wavelengths between 400 and 450 nm, higher metabolic activity of HACs and higher penetration depths enabling crosslinking of thicker constructs were shown in comparison to initiator systems at 405 nm or in the near-UV range.[125] Due to these advantages, we expect visible-light crosslinking to become a more prominent strategy in the field of bioprinting and help expanding the biofabrication window by preventing the use of potentially harmful irradiation methods and thus making the bioprinting process more cytocompatible.[45] In addition, higher penetration depths can lead to more homogeneous crosslinking especially when bigger construct dimensions are of interest.

2.1.4. Dynamic Covalent Interactions

Given the nature of the extrusion bioprinting process, in which hydrogel-based inks transition from a flowing state in the nozzle to a nonflowing state postprinting, chemistries involving dynamic covalent bonds are offering a promising tool to improve shape fidelity. For example, combination of partially oxidized alginate and gelatin was used to establish a bioink system based on dynamic covalent bonds for extrusion-based bioprinting.[126] The aldehydes resulting from oxidation of the alginate saccharides subunits, in combination with the amino groups of hydroxylysine of gelatin, led to imine formation based on Schiff’s base reactions.[127] These dynamic covalent bonds enabled a cytocompatible gel formation and altered the viscoelastic properties of the material resulting in printable bioinks. Noncovalent crosslinking based on CaCl2 was used to stabilize the constructs after printing for cell culture.[126] Due to the dynamic nature of the bonds, the cell–material interactions can be designed in a way that enables controlling bioink properties like cell migration. This property can be used to design environments which enable cells to reorganize during the maturation process, a useful tool, for example, for researching developments of neuronal network formation. More recently, imine-type dynamic covalent chemistry was also applied for bioink development.[128] Partially oxidized alginate and linear, low molecular weight imine type crosslinkers (alkoxy, semicarbazide, and hydrazide) were used to adjust the viscoelastic properties of the bioinks through dynamic covalent crosslinks (oxime, semicarbazone, and hydrazone). Secondary crosslinking was not necessary to ensure stability over seven days in vitro.[128] Double network formation from dynamic covalent interactions and thiol–ene click photochemistry is another promising approach demonstrating the potential of dynamic covalent interactions for bioink development.[129]

2.2. Physical Interactions beyond Ionotropic gelation

Physical interactions have a dynamic and reversible nature, yielding comparable behavior to dynamic covalent bonds and can be tuned to exhibit shear thinning and recovery behavior. While classic examples among the first bioinks to be developed were based, for instance, on the ionotropic gelation of alginate, more refined and complex chemistries can be used to provide improved control over a wide range of mechanical properties and stability of the crosslinked network. Exploring these chemistries for bioink development resulted in the introduction of weak but highly directed and specific supramolecular interactions like hydrogen bonds or π–π interactions enabling the formation of polymer networks to bioprinting. Such networks can either be based on interactions between noncovalently associated monomers, like polypeptides or via supramolecular interactions, that link covalently bound polymer chains via noncovalent chain interconnections.[130]

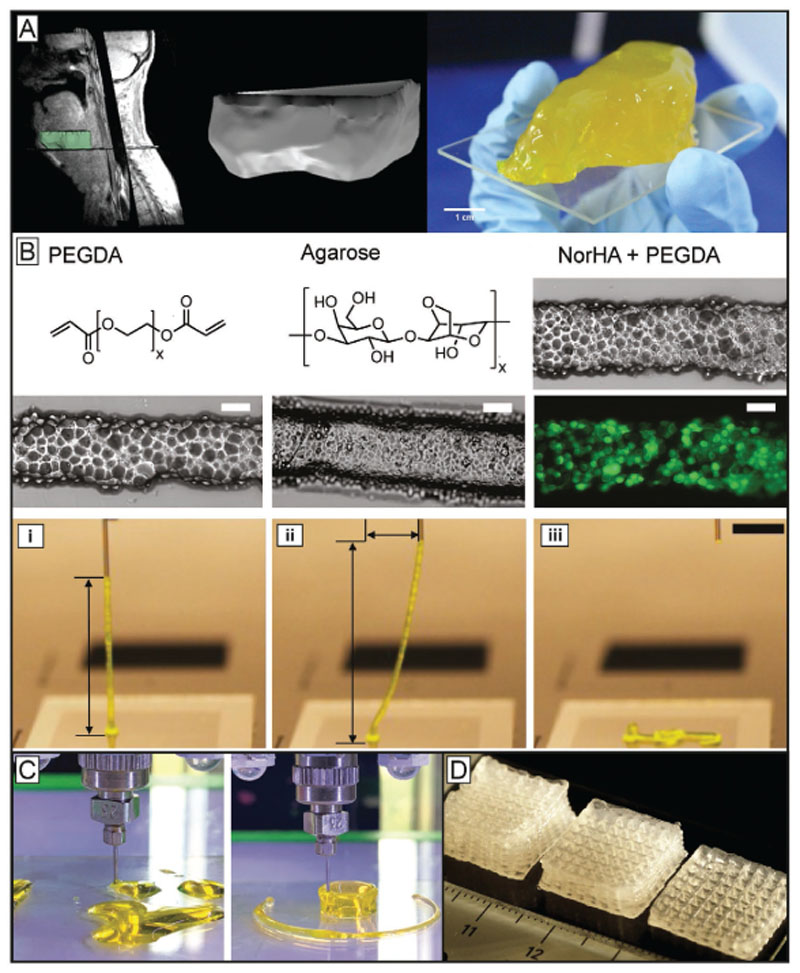

2.2.1. Low Molecular Weight Gelators—Polypeptides and Proteins

The concept of gels formed by noncovalently bound smaller subunits known from biopolymers like collagen,[131] or elastin,[132] is now also being transferred to synthetic bioinks via polypeptide chemistry.[133] Due to their structure, these materials are biocompatible and biodegradable. Hydrogels can be formed from polypeptide-based materials through different functionalization methods.[134] When stress is applied to these gels, the interaction between the subunits can be destroyed leading to a decrease of material viscosity. After deposition, the materials can recover and thus retain the shape after extrusion. Examples include polyisocyanate hydrogels used as biomaterial inks[135] or oligo-peptide bioinks.[136] Besides polypeptides also proteins are used as physical gels for bioink development. Many native proteins are also able to undergo structural transition that results in the formation of hydrogels. Harnessing the occurrence of such interactions can potentially permit to create shape stable architectures post printing. Silk and silk-like proteins exhibit promising properties as bioink components, since they are nontoxic, low immunogenic, have slow degradation and display shear thinning properties and recovery potential, mainly due to the formation of β-sheet structures during gelation.[137] Recombinant spider silk proteins, for example, can self-assemble into nanofibrillar networks and can, at the right concentration and conditions, form hydrogels based on β-sheet formation. These hydrogels proved to be printable and cytocompatible.[138] They even could be printed without the addition of thickeners and without postprocess crosslinking steps. As silk proteins lack cell binding domains, these needed to be modified with arginine– glycine–aspartic acid (RGD) sequences to improve cell–material interactions. Another option to improve the cell–bioink interaction and to prevent clotting of the nozzle was demonstrated by combining silk fibroin from silk cocoons (Bombyx mori) with gelatin.[39] In situ enzymatic crosslinking by addition of tyrosinase or physical gelation induced by sonication both proved to be suitable crosslinking mechanisms for bioink development. More recently another bioink based on silk fibroin (B. mori) and gelatin was developed (Figure 4A).[57] In contrast to the previous work, glycerol was used to induce physical crosslinking via β-sheet formation. To ensure stability under physiological conditions, the printed constructs were dried for a short period of time and dipped into a glycerol bath to enhance crosslinking of the silk gelatin ink. In general, the physically crosslinking polypeptides and proteins show potential to facilitate the development of new bioinks by already bringing many crucial biomaterial properties with them, such as biocompatibility, degradability and often also bioactivity. Furthermore, they potentially allow chemical or sequential modification of their amino acids to engineer specific mechanical and biochemical properties on demand. Taken together, the approach can help designing bioinks that can expand the biofabrication window toward higher shape fidelity at printing conditions that are more cytocompatible as they can help reducing the shear rates cells are exposed to during extrusion. In addition, properties that are important during maturation like biophysical and biochemical stimuli can be controlled more precisely and thus the materials can be more cell-supportive without sacrificing shape fidelity.

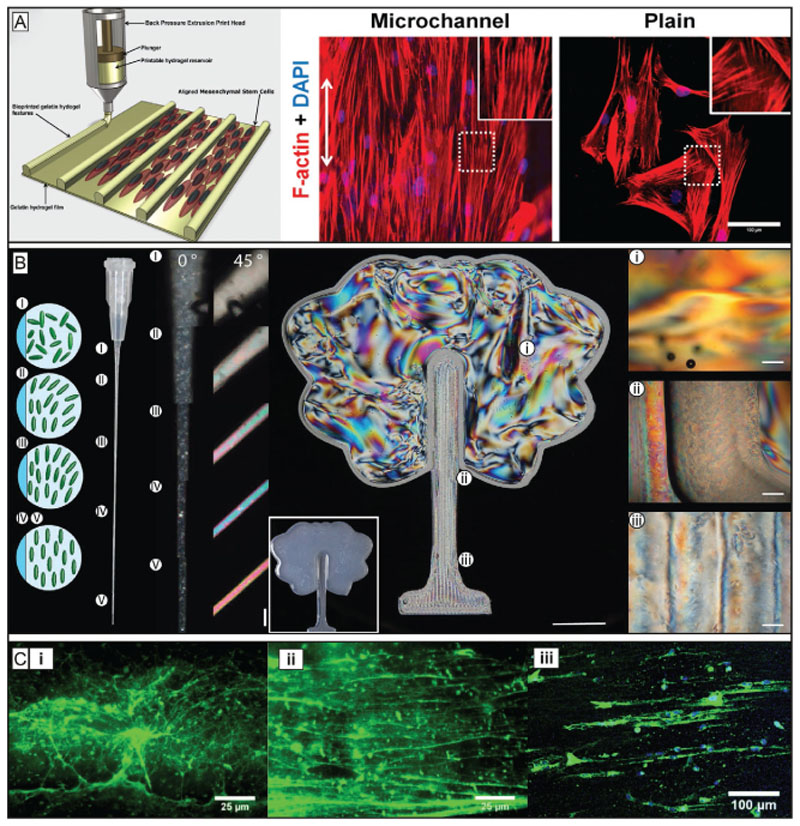

Figure 4.

Physical crosslinking strategies take advantage of reversible interactions to provide bioprinted filaments with structural stability, allowing to broaden the biofabrication window of low viscosity and low polymer density inks, as well as that of colloidal inks. A) From CT data to a printed cheek geometry of cm-scale using silk gelatin inks. To make the physically crosslinked, B. mori derived silk printable, it was mixed with gelatin and glycerol. The additives and the preparation enables the formation of β-sheets, increased the biological activity and helped preventing nozzle clogging. Reproduced with permission.[57] Copyright 2017, Elsevier. B) Colloidal inks from different precursors as deposited strands (scale bar 200 μm) demonstrating viscoelastic properties as proven by the intact filament spanning from the collector to the nozzle tip (i–iii). The approach shows potential to make a broader range of hydrogel systems printable due to its independency from the used crosslinking mechanism. The scale bar represents 5 mm. Reproduced under the terms of the Creative Commons CC-BY 4.0 License (https://creativecommons.org/licenses/by/4.0/).[139] Copyright 2019, The Authors, Published by Wiley-VCH. C) Extruded PEGDA without (left) and with Laponite (right). Reproduced with permission.[98b] Copyright 2019, Wiley-VCH. D) Alginate methylcellulose with Laponite as viscosity enhancer, pointing out the principle of viscosity modulators and their benefits for bioprinting by significantly improving shape fidelity of the constructs. Reproduced with permission.[98a] Copyright 2015, American Chemical Society.

2.2.2. Macromolecular Physical Gels

Noncovalent, supramolecular interactions between covalently bound polymer chains have also been used to develop bioinks based on physical gels. In particular, host–guest interactions have been applied to design bioinks with defined properties.[17,139,140] Blends of HA functionalized with either adamantane or β-cyclodextrin form shear thinning and selfhealing hydrogels based on reversible host–guest complexes between the two functional groups.[141] Given the reversible nature of this bond, irreversible stabilization has also been achieved introducing methacryloyl groups, to enable conventional free radical polymerization. This approach made printing of stable constructs with filament diameters between 100 and 500 μm possible.[17] Besides host–guest interactions, molecular recognition has also been used to improve the printability of bioinks. Alginate was, for example, modified with a peptide (P1; proline-rich peptide domain) and a recombinant, engineered protein (C7) containing cell adhesive domains (RGD).[142] These two components resulted in a weak, physically crosslinked and dispensable gel. It was shown that the damage during the printing process to the cell membrane of 3T3 and hASC encapsulated in the modified alginate compared to nonmodified alginate could be reduced significantly. After extrusion a second crosslinking step via calcium ions stabilized the constructs.

2.2.3. Colloidal Inks

Another approach that enables the decoupling of material printability from its rheological properties, relies on the use of densely packed microgels rather than homogenous hydrogel-forming solutions, also referred as jammed microgels (Figure 4B).[112,139] Here, hydrogel precursors are first processed into stable, crosslinked microgels. This step is followed by the removal of excess water until the increasing physical interactions between the gel particles cause a transition in overall rheological properties from viscosity-dominated to elasticity-dominated viscoelastic behavior. This particle interaction is similar to tightly packed colloidal suspensions known from ceramic processing. The dominance of the interparticle interactions generates so called rest structures that can be disintegrated by external shear stress during printing.[143,144] This is the basis for shear thinning and recovery properties accompanied with a yield stress seen in the jammed microgels. When printed under optimal conditions, it results in intact long filaments (Figure 4Bi–iii) making this approach a promising strategy to generate biomaterial inks and bioinks.

Although only a small number of studies was published on that topic to date, it was shown that this approach is independent of the used hydrogel material, as long as it can be processed into microgels. So far, for the production of microgels thiol–ene crosslinked norbornene-modified hyaluronic acid, photo-crosslinked poly(ethylene glycol) diacrylate, thermosensitive agarose,[139] and photo-crosslinked norbornenemodified poly(ethylene glycol)[112] have been used. However, due to the weak physical interactions between the particles, the printed construct needed to be stabilized in a secondary crosslinking step for long term stability in aqueous solutions. Here, photoinitiated polymerization has been successfully used to crosslink remaining unreacted photoactive groups.[112,139] To prepare bioinks and enable cell-loaded printing, two options to incorporate cells into the biomaterials exist. These are direct encapsulation into the particles or mixing the cells with the microgels. Encapsulation has the advantage of shielding the cells from the shear stress usually experienced during the extrusion. However, to not impede cellular migration and proliferation, the hydrogel needs to be biodegradable,[139] except a spatial cellular confinement is desired, for instance, in drug delivery applications. In contrast, mixing the cells with microgels does not require a biodegradable material to allow spreading and proliferation, since the microporosity of the platform provides sufficient space for the cells.[112] Given the common basis of particle interaction, this approach should be potentially compatible with mixing or separately printing of microgels of different nature or cargo to create multimaterial and hetero-cellular[139] constructs. Taken together, jammed microgels are a promising method to broaden the window of bioprinting, the generalized character still needs to be proved and especially the second crosslinking to stabilize the inks within physiological conditions and reproducible jamming methods still need to be further developed.

2.3. Rheology Tuning

Since the early stage of bioink development, tuning the ink’s rheological properties was and still is a key challenge. It is a highly relevant tool for designing materials that enable high shape fidelity in combination with improved process cytocompatibility and thus help expanding the window of biofabrication. Early approaches were based on increasing polymer concentration or the addition of rheological modifiers like high molecular weight hyaluronic acid or gellan gum to the modified gelatin compromising cytocompatibility.[63,72,145,146] Alternative approaches, like methods to control the crosslinking degree or through addition of nanoscale elements, have been developed to improve shape fidelity while maintaining high cytocompatibility of the bioink and the printing process.

2.3.1. Nanocomposites

Nanosilicates are very prominent additives that, even at very low concentrations, increase shear thinning properties of the precursors they are added to. They can induce self-healing properties and improve shape fidelity. Numerous nanocomposites are used to tune rheological properties of inks and a conclusive discussion is outside the scope of this paper. The interested reader is referred to a list of excellent papers and reviews covering this topic.[16,31,81,147] However, in view of the recent developments for bioprinting a small number of examples is highlighted. The addition of a synthetic nanosilicate clay, called Laponite (Laponite is a trademark of the company BYK Additives Ltd.), to GelMA resulted in improved printability.[94] In addition, the modifications impacted on stiffness and degradation properties of the materials. Laponite was recently also used to adjust the rheological properties of bioinks based on PEGDA, as well as alginate methylcellulose. Besides the exceptional printability of the materials (Figure 4C,D), the alginate methylcellulose-based ink also enabled printing viable human mesenchymal stem cells (hMSC), while the additives showed positive effects on the biological function.[98a,b] Another nanostructure that can be used to tailor printability of inks is nanocellulose. It was, for example, shown that the addition of nanocellulose improved the shape fidelity of alginate-based inks and enabled printing of human nasoseptal chondrocytes although it did impact on their viability.[73]

2.3.2. Pre-Crosslinking Strategies

Pre-crosslinking typically encompasses a stepwise crosslinking procedure that includes two or more different crosslinking methods. For example, inks have been developed that contain linear and branched amine-presenting polyethylene glycol (PEGX; X: succinimidyl valerate),[43] which can act as a crosslinker for macromolecules, like gelatin and fibrinogen via amine-carboxylic acid coupling. A first crosslinking step is performed to adjust the rheological properties of the ink and a second crosslinking step is then introduced to ensure construct stability over extended periods of time and during exposure to physiological conditions. This second step was either chain growth polymerization of GelMA with UV-based initiators, thrombin-based crosslinking of the fibrinogen or EDC (N-(3-dimethylaminopropyl)-N-ethylcarbodiimide)/ NHS (N-hydroxysuccinimide) in terms of gelatin.[43] An additional example of a pre-crosslinking strategy was based on a tyramine-modified hyaluronic acid (HA-Tyr) bioink. Enzymatic crosslinking, mediated by horseradish peroxidase (HRP) and hydrogen peroxide (H2O2), was performed as a first precrosslinking step to adjust the viscoelastic properties of the bioink. This was followed by a second step based on visible light crosslinking in the presence of Eosin Y to crosslink the remaining HA-Tyr components. Furthermore, other approaches involving physical and chemical crosslinking were also demonstrated to be suitable pre-crosslinking strategies,[17,29] emphasizing the potential as a general strategy for rheological tuning of bioinks.

2.4. Coaxial Printing and Microfluidics

2.4.1. Coaxial Printing

The coaxial extrusion allows the concurrent and concentric deposition of different materials through the use of distinct nozzles assembled in a coaxial fashion resulting in double- or multilayered filaments (Figure 5A,B). It enables printing various materials in a core–shell arrangement to fabricate homogenous or heterogeneous solid or tubular filaments.[17,44,148] In addition, the spatial separation of crosslinker and ink solutions until the very end of the nozzle tip allows the use of lower viscous hydrogel precursors compared to conventional extrusion-based approaches while still maintaining shape fidelity crucial for expanding the biofabrication window. The crosslinker can either be incorporated in the outer compartment and the cell-laden material in the inner one to form solid filaments or vice versa to fabricate hollow filaments. To process medium- or low-viscous inks through a coaxial nozzle, a fast crosslinking mechanism is mandatory to provide the required shape fidelity. The coaxial system has proven to be very suitable for the processing of alginate and its blends, where calcium chloride is used as a crosslinking agent.[18,27,40,149] To enhance its biological activity, alginate is typically blended with more active components. In terms of coaxial printing it can also be coprinted with such components (e.g., collagen, GelMA, and bioactive glass).[27,40,150,151] In addition, coaxially printed, noncrosslinked alginate can also be used as a cytocompatible temporary mechanical support, for example when combined with photocurable bioactive polymers, including GelMA, PEGDAfibrinogen, methacrylated hyaluronic acid and chondroitin sulfate amino ethyl methacrylate.[18,27,40,149,152] Coaxial extrusion can also be used to process materials that exhibit low mechanical stability or long gelation times, such as collagen, Matrigel, fibrin or laminin.[150,153,154] In particular, the coextrusion with mechanically stronger materials can improve their processability while simultaneously increasing the functionality of the resulting constructs.[155,156]

Figure 5.

Coaxial and microfluidic methods are versatile tools to induce rapid crosslinking of extruded filaments. Additionally, using such extrusion devices permit to print multiple materials in a single process, as well as to control the composition and physicochemical properties of the forming hydrogel strands. A) Coaxial bioprinting of an alginate-based bioink (inner compartment) and its crosslinking agent CaCl2 (outer compartment). The rapid crosslinking via calcium ions enabled in situ crosslinking ensuring high shape fidelity printing. Reproduced with permission.[149] Copyright 2016, IOPScience. B) Microfluidic approaches like the utilization of y-junctions in combination with a coaxial nozzle allowed the deposition of strands with parallel aligned multiple cell types, but has also been used to extrude different types of materials. Reproduced with permission.[18] Copyright 2017, Elsevier. C) By coaxially extruding an alginate-based ink through the outer and the crosslinking agent through the inner nozzle, perfusable inks could be produced. Reproduced with permission.[148] Copyright 2015, Elsevier. D) Microfluidic approaches can be used to generate gradients which play crucial roles in biology. Methods like flow focusing (images in the middle) can be also applied to 3D printing and help reducing filament diameters. Reproduced under the terms of the Creative Commons CC-BY 4.0 License (https://creativecommons.org/licenses/by/4.0/).[163] Copyright 2018, The Authors, Published by MDPI.

As the supply of sufficient nutrients in larger bioprinted tissue constructs is still a significant challenge,[157–160] coaxial extrusion offers a promising solution as perfusable vascularlike structures can be generated by, for instance, coprinting alginate with a calcium solution for crosslinking (Figure 5C). Here, in one of the first attempts a concentrated paste of alginate (16.7% (w/w)) and aqueous poly(vinyl alcohol) (6% (w/v)) was used to fabricate meter-long hollow fibers.[161] Further, coaxial printing enabled the fabrication of fully perfusable scaffolds with single- or double-walled hollow filaments using other material combinations.[17,44,148] To improve the quality of the extruded tubes, active perfusion of the interior channel with a temporary and mechanically supporting ink, such as Pluronic F127 or gelatin,[44,90,148,162] can prevent the hollow filament from collapsing.

2.4.2. Microfluidic-Enhanced Bioprinting

The microfluidic bioprinting systems can precisely manipulate the behavior of liquids at microscale level and offer a promising solution to accurately control the deposition of, so far, up to seven materials.[18,40,163,164] Each material has its own inlet to a microchannel in a microfluidic chip or nozzle. By merging the different channels, different materials can be mixed together or separately extruded by optimizing the actuation of the syringe pumps. Rapid switching (500 ms) between different inks is possible and the technique also allows for a seamless transition between multiple materials. This renders the approach an interesting tool for creating gradients by varying the spatiotemporal deposition of different materials (Figure 5D). In addition, hydrodynamic focusing of the center flow stream, containing the bioink, can be realized by microfluidic approaches (Figure 5D). By pinching the core bioink flow with at least two side flows, the width of the filament can be reduced.[165] Further, microfluidic-based printheads bear the potential to expand the range of printable materials toward low viscosity bioink by allowing the deposition of multiple materials through a single extruder. A good example are approaches combining coaxial nozzles with microfluidic chips that enable switching between different inks or combining them during printing. Utilizing this approach heterogeneous filaments could be fabricated with a distinct longitudinal interface by using a Y-junction setup.[18,40] Here, the coaxial nozzle concept was used to provide CaCl2 solution for in situ crosslinking through the exterior nozzle and the microfluidic concept to provide up to two different alginate-based bioinks through the interior nozzle (Figure 5B). Furthermore, concentrically layered filaments have been also generated using a microfluidic approach by inserting three needles into a wavy microfluidic channel at different locations. For each needle used, the horizontal microfluidic channel made a vertical turn to allow a vertical and concentric penetration of the respective needle. This setup enabled multiaxial extrusion of up to four different solutions and the fabrication of bi-and tri-layered hollow channels.[166] The cytocompatibility of this approach has been demonstrated by bioprinting alginate-based bioinks containing either fibroblasts or endothelial cells.

2.5. Support Bath and in Gel Printing

The support bath approach (Figure 6) relies on support materials that are placed into a container. Extrusion-based bioprinting is then applied to deposit the desired bioink into this supporting material. The benefit of this key strategy is that the bath provides neutral buoyancy and spatial confinement of the extruded material and allows to print materials that would otherwise not keep their shape. One of the first attempts used a hydrophobic high-density fluid called perfluorotributylamine to support printing a stem cell-laden agarose construct.[167] This first development was then followed by the introduction of hydrogel-based support baths.[51,168,169] Printing into support baths significantly expands the biofabrication window by negating gravity and surface tension,[168] enabling to even process low viscosity inks with a loss modulus (G″) below < 1 Pa (G″ > G′ at a frequency of 1 Hz).[51] The spatial support and confinement of the deposited ink facilitates the fabrication of more delicate and sophisticated structures, which would be difficult or even impossible to fabricate using other extrusionbased bioprinting strategies.[168,169] Besides enhancing the resolution, a support bath can also provide long-term stability in a humid environment, limiting the risk of cell damage during the manufacturing process. This paves the way for long or slow prints and the generation of larger, more clinically relevant constructs and helps expanding the window of biofabrication as it enables more cytocompatible processes without sacrificing shape fidelity (Figure 6A,B).[168,170] But the use of support bath also comes with new challenges. Although the ink does not need to meet the typical requirements for printability, a potential support bath system needs to behave like a non-Newtonian liquid and obey rheological confinements. When shear stress is exerted on the support bath by the movement of a printer nozzle, it has to liquefy locally. After the shear stress caused by the needle movement vanishes, its viscosity needs to increase to trap the deposited ink and support the shape of the printed constructs. Taken together, the benefits of less stringent rheological properties for the dispensed material are associated with the need to accurately tune the properties of the support bath material. In addition to the rheological requirements, a support bath material should also be cytocompatible, easy to remove without leaving significant amounts of residues and not interfere with the crosslinking of the printed materials. To be able to remove the construct safely from the support bath, the ink must undergo a crosslinking step in situ after its deposition and the bath material must allow easy removal of the printed construct without affecting it negatively. Hereby, the crosslinking mechanism of the ink should not interfere with the support bath material itself (or vice versa), to avoid a change in viscoelastic behavior of the bath during printing and the formation of crosslinking artifacts. Furthermore, it is beneficial to have a bath material that allows a controlled transition from solid to liquid state, as offered, for example, by thermoreversible systems, to facilitate the extraction of printed constructs with filigree structures. Collagen I, for instance, can be used as an ink, as it is soluble under acidic conditions and by printing it into a buffered bath the pH-dependent fibrillogenesis and gelation is triggered, resulting in a stable construct that can be harvested as shown in Figure 6A.[53] Another example of a biomaterial class are materials that crosslink with the help of a secondary component, such as alginate with calcium ions or fibrinogen with thrombin. By the addition of the respective crosslinking component into the support bath, the corresponding materials can be printed in liquid-state followed by subsequent in situ crosslinking.[51] Although the development of appropriate support baths is challenging, promising results have been demonstrated. Based on their nature and crosslinking mechanisms, these bath materials can be classified as: i) microparticle-based systems and ii) macromolecule- and nanosilicate-based systems.

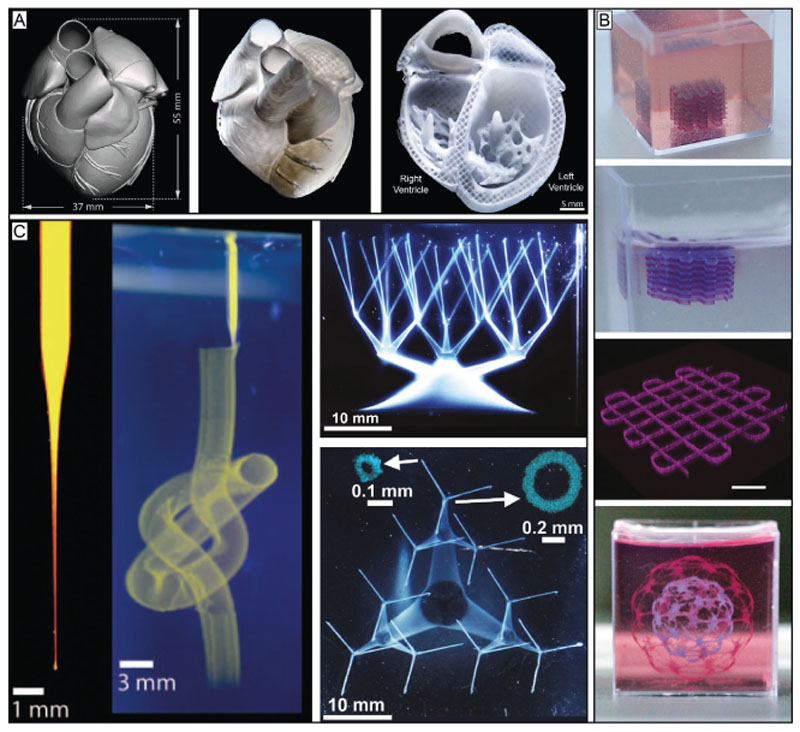

Figure 6.

Support bath printing allows to print suspended structures and overhangs, and provides structural stability when using low viscosity bioinks, enhancing control over shape and resolution. A) Based on a CAD-model a construct from collagen I, a material that is usually not printable by itself, was printed using the support bath approach. The support bath, based on gelatin, allowed the deposition of a low viscous collagen ink, utilizing an in situ crosslinking approach, and fabrication of complex structures with high shape fidelity that closely resemble the CAD file templates. Reproduced with permission.[53] Copyright 2019, AAAS. B) The method can also be used to generate filigree multimaterial constructs which could not be printed with classical extrusion-based bioprinting. The alginate-based support bath was enzymatically degraded to gently harvest the fragile objects. Reproduced under the terms of the Creative Commons CC-BY 4.0 License (https://creativecommons.org/licenses/by/4.0/).[88] Copyright 2019, The Authors, Published by Wiley-VCH. C) Carbopol as bath material in combination with a very thin nozzle (50 μm tip) enabled printing of structures with high resolution and challenging shapes. Reproduced with permission.[168] Copyright 2015, The Authors, published by AAAS. Reproduced/modified from ref. [16]. © 2016, The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC).

2.5.1. Microparticle-Based Systems

Carbopol, a synthetic poly(acrylic acid) with high molecular weight that can be used to make gels consisting of swollen, hydrophilic and spherical-shaped elastic domains with a diameter of ≈7 μm, is one of the first materials that have been successfully utilized as support baths.[171–173] At the right concentration, Carbopol exhibits a yield point and shows excellent self-healing properties. This enables a rapid stabilization of the microparticles after a sudden change in applied shear stress exceeding or undershooting the yield point.[174] Carbopol concentrations between 0.2 and 0.9 wt% did not impede cell migration and proliferation.[175] Although demonstrated in a cell-free approach, Carbopol-based support bath printing (Figure 6C) showed the potential to generate constructs composed of strands with diameters as small as 35–50 μm. This revealed the possibilities offered by the support bath approach and enabled printing of highly complicated structures (Figure 6C).[168,169] Printing cell containing materials into Carbopol allowed the fabrication of objects with a resolution between 100 and 200 μm.[175] A layer thickness of 100 μm could be achieved and even a single-cell ejection along the printing direction by increasing translation speed was possible. A broad range of cells has been printed into Carbopol, including endothelial, epithelial and mesenchymal stem cells with a viability of in average about 94% after 24 h in the gel.[175]

Another common example of granular support baths are those based on so-called fluid or sheared gels,[176] such as agarose or gelatin.[51,177] These microgel-based materials also exhibit rapid self-healing properties postshearing, allowing the quick trapping of extruded inks. Sheared gels from 0.5 wt% agarose particles have been successfully used as support.[170,177] The particle size ranged from 2 to 11 μm and formed a weak, reversible network. It has been demonstrated that an increase of viscosity of the sheared gel correlates with an improved resolution in XY dimensions, but with a decrease in Z dimension. Support baths based on gelatin, which have also been termed freeform reversible embedding of suspended hydrogels (FRESH), included a particle size of ≈25 μm.[53] This enables cell-free print resolution of filaments with diameters of 25 μm. The thermoreversibility of gelatin-based support baths at about 30–40 °C has the advantage of easy removal of the support from the printed construct. However, in the case of using a bioink based on extracted ECM such as Matrigel, a temperature-dependent curing process at 37 °C is required for long-term stabilization of the print. Here, a gelatin-based system would lead to the destruction of delicate structures before they can stabilize. One solution to this issue was demonstrated by supplementing the ink with temperature-independent crosslinking materials, such as fibrinogen or collagen type I.[51] Another option would be to address the problem from the support bath side. Recently another suitable system has been developed, consisting of alginate microparticles and xanthan gum, to support the print and curing of an omental ECM-based bioink.[88] This support setup tolerated a broader range of temperatures and can be enzymatically or chemically degraded to gently harvest the printed object. The used alginate microparticles had a size below 25 μm and enabled printing cellloaded single strands with 100 μm of diameter. Filigree structures, such as a miniaturized hand, heart and spherical network with up to two different materials have been printed (Figure 6B). This setup supported the print of induced pluripotent stem cell (iPSC)-derived cardiac and endothelial cells, as well as human umbilical vein endothelial cells (HUVECs), neonatal cardiomyocytes and fibroblasts with an overall cellular viability of >90%.

2.5.2. Macromolecule- and Nanosilicate-Based Systems

Besides the use of granular materials, there are also support bath concepts that are based on intermolecular guest–host interaction,[169] or Laponite nanoclay.[178–180] In this case the subunits of the support bath are in the molecular scale. For support baths based on guest–host interactions, HA was modified with either adamantane or β-cyclodextrin and then mixed. The reversible supramolecular assembly of the two functional groups through guest–host complexes provided a yield point and thus self-healing properties. This enabled the fabrication of up to 35 μm thick filaments with cell-free printing and structures with ≈600 μm of width with cell-loaded printing.[174] Here, mesenchymal stem cells were printed into support gels containing 3T3 fibroblasts, exhibiting a viability of <90%. Furthermore, the host–guest-modified HA can also include methacrylate groups resulting in a support bath that can be stabilized by a secondary crosslinking step.[174] This allowed the fabrication of perfusable channels, by first extruding an ink as placeholder, followed by a secondary crosslinking step of the support bath and subsequent removal of the ink.[169] In the case of Laponite, the structural components are disk-shaped particles, which release sodium and hydroxide ions in aqueous solutions. This results in areas of positive and negative charge, enabling electrostatic interactions and their arrangement into a colloidal suspension with a yield stress and rapid recovery after exposure to shear stress.[178,181] Depending on the travel speed of the nozzle and Laponite concentration, filaments from gelatin-alginate with a diameter of ≈600 μm could be produced. Taken together, the support bath approach expands the biofabrication window by allowing for the deposition of bioinks in the liquid-phase and thereby the use of low-pressure extrusion-based bioprinting. The humid environment of the bath facilitates long prints by protecting the printed construct from drying out. The buoyancy effect of the support material makes it possible to print delicate and usually mechanically fragile constructs. Moreover, the low initial viscosity of the deposited inks provides more freedom regarding tailoring of local mechanical properties of the biomaterial postprinting. This may be an important step toward improving the imitation of the natural ECM environment.

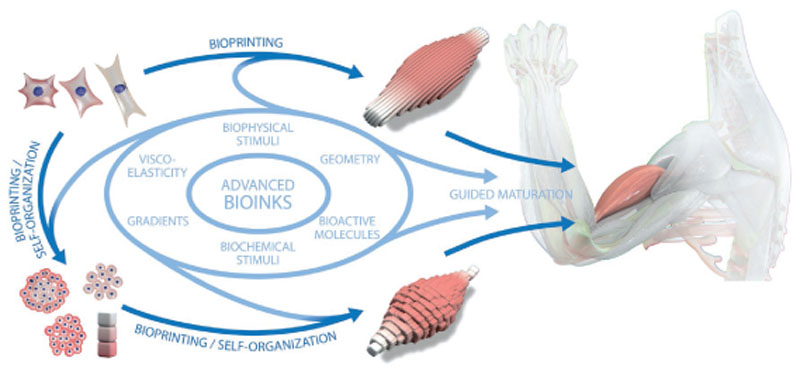

3. Strategies to Evolve from Shape to Function

3.1. Biological Function in the Context of Biofabrication

A growing number of bioprinting strategies allows for the creation of shapes with intricate architectures and continuously improving resolutions. However, faithfully reproducing the anatomy of a tissue, as permitted by high-shape fidelity bioprinting approaches, does not ensure per se the acquisition of the functionality of the native tissue. Once good control over the spatial deposition of cells and materials is achieved, biological constructs will need to undergo maturation and morphogenesis, which has been defined as an integral part of the bioprinting process.[4] Nonetheless, the achieved widening of the biofabrication window now enables to challenge the core hypothesis of bioprinting that a hierarchical 3D arrangement of cells and (bio-)material/matrix facilitates, accelerates or improves the formation of functional tissue analogues.

However, until now, examples of studies are still limited in which such direct advantage of bioprinting for the evolution of biological function on a tissue level has been demonstrated. One reason for this is that studies focusing on (bio)material development frequently have overlooked this aspect and printing is often shown in proof-of-concept tests, even in cases when conventional fabrication technologies may be sufficient. In other words, an exponential number of contributions to scientific literature and international meetings have included the printing of the materials (with or without cells) without a clear demonstration of an advantage of printing in terms of improvement of the functionality for the ultimate application. This observation is underscored by the fact that there is only a handful of reports that successfully showed the replication or restoration of key functions of specific tissues or organs. One successful example relates to biofabricated ovaries, obtained by including ovary follicle cells in printed gelatin-based scaffolds with cell-instructive architectures that were shown to rescue reproductive capacity, enabling sterilized mice to obtain healthy offspring from natural mating.[182] An additional example of a functional bioprinted structure are the printed spheroids of vascular and thyroid gland cells that were capable of replacing the bioactivity of native thyroid, including its thermoregulatory ability and thyroxine hormone secretion into the systemic circulation, when implanted in mice with a surgically induced hypothyroidism.[28] Also, bioprinted muscle cell-laden hydrogel fibers were demonstrated to mature into homogenously shaped bundles of myofibers, which exhibited contractile function, and could be matured upon ectopic implantation in vivo, showing a more pronounced organization and alignment compared to nonprinted controls.[18]

These few examples show that bioprinting can yield biologically functional constructs. It is however still unclear what the required resolution of the architecture—dictated by the printing process—needs to be and to what extent the fabricated construct can rely on self-organization during the maturation phase. Importantly, based on its ultimate application, the required functionality of the bioprinted structure can be significantly different. Bioprinted tissues for transplantation should ideally recapitulate all functions of the native tissue, either at the time of implantation (i.e., after in vitro culture), or after a maturation period in vivo. The same accounts for in vitro tissue models for diseases, or that are intended to replace animal experiments.

On the other hand, 3D in vitro models that are intended to be used for drug screening, may only need to display a certain salient feature of the replicated biological structure. This concept is well exemplified by the current state-of-the-art of organ-and body-on-a-chip technology, involving soft lithography and replica molding as production processes.[183–185] Such models are often composed by horizontally or vertically aligned microfluidic channels, each representing a tissue compartment, which are interfaced to allow intercompartment cell communication. This geometrical simplification, often displaying planar symmetry, is an elegant and effective way to replicate specific tissue functions, i.e., the barrier function of lung and intestine[183,186] or the invasiveness of tumor cells,[187] and has recently been successfully used to show metabolic interaction between microtissues that are connected via microfluidic channels for drug testing.[188] Nevertheless, they cannot fully recapitulate the hierarchical organization of native tissues. While the exact degree of similarity required for a fully functional engineered tissue is still unclear, there is increasing evidence that controlling shape and architecture of printed constructs in terms of cell and material composition and interaction between the multiple components is essential in order to bridge the gap between engineered and native tissues. The following sections will highlight how cell and tissue functionality can be guided through the biofabrication process, specifically via stimuli derived from: i) the architecture and geometry of the printed structures, ii) the building blocks (bioink) used for printing, and iii) the coordination and cross-talk of multiple cell populations patterned in 3D constructs.

3.2. Design Specifications in Bioprinting to Drive Functional Tissue Maturation

Many studies at the crossroads of regenerative medicine, biomaterials and cell biology have highlighted how different cell types drive tissue morphogenesis and maturation through a combination of cues presented by their extracellular environment.[189] In fact, cells sense and respond to mechanical (e.g., stiffness and viscoelasticity), biochemical (e.g., adhesion molecules and peptides, soluble factors, metabolites) and geometrical cues, including porosity and surface topography. The presentation of such signals to bioprinted cells can be tuned, either during the printing process or through the modification of the hydrogel–bioink composition, effectively enabling a wide array of opportunities to guide cell response and promote the acquisition of the desired tissue functions.

3.2.1. Geometrical Considerations

Porosity

The macroscale architecture of a construct can influence its biological performance and guide functionality of biofabricated tissues. Geometrical cues from scaffolding materials, including surface and 3D topography, shape, size and tortuosity of porous elements, are known to provoke a wide array of responses in cells both in vitro and in vivo, and such reactions greatly differ based on the dimensional scale of these cues. For example, cells can preferentially home or align along topographical features at the micrometer and submicrometer scales, such as nanofibrous elements[190] or periodic grooves and channels,[191] a phenomenon described as contact guidance.[192] At a larger scale, micrometer to submillimeter features play a pivotal role in cell survival and tissue regeneration. For instance, pore sizes in the range of 200–400 μm are fundamental for nutrient diffusion throughout large constructs and for bone infiltration in vivo.[193] Vigorous blood vessel ingrowth and little fibrosis have been observed accompanied with polarization of macrophages toward an M2 phenotype (generally regarded as stimulatory for tissue regeneration) in structures with pores in the 30–40 μm range. In contrast, smaller and larger pores resulted in the formation of fibrotic scar tissue.[194]

Using biofabrication strategies that ensure high shape fidelity and resolution, virtually any convoluted 3D patterns of materials and cells could be created, while providing control over the presentation of topographical and geometrical cues.

In 3D extrusion-based biofabrication processes, strut sizes are typically in the order of 100 μm, and the associated porosity can be accurately tuned from the millimeter scale down to 10 μm, as it can be accurately tuned via the design of the strut-to-strut distance and the laydown angles between each printed layers. Laydown angles and pore geometries have, e.g., shown to greatly influence hepatic cell maturation,[195] stem cell differentiation,[196] macrophage polarization and inflammatory response,[197] and muscle tissue regeneration.[198] Moreover, porosity profiles can be varied across each printed layer. This can, for example, lead to controlled oxygen gradients, mimicking the metabolite concentration across an osteochondral plug.[199]

The phenomena underlying the observed responses are diverse. In some cases cells are directly affected by the physical cues, i.e., via contact guidance, cytoskeletal reorganization or mechanotransduction.[200] This is the case in the responses to strut size and roughness or to attachment to fibers forming different angles at their intersections. However, in many cases the characteristic dimensions of the features of extrusion printed hydrogel structures are too large for cells to sense preferential orientations directly. The selection of a specific geometry only indirectly influences cell behavior, i.e., through favoring cell–cell clustering and via proximity and confinement effects. For example, enhanced maturation of a hepatocytic cell line and improved expression of cytochromes was observed when the cells were seeded onto 0°–60° laydown gelatin constructs, instead of the more common 0–90°. This effect was due to the fact that the narrower angles facilitated cell aggregation at the corners of the pores improving cell aggregation and cell–cell contact, effectively inducing the formation of hepatic spheroids throughout the printed scaffold.[195] Likewise, high densities of chondrocytes bioprinted into porous polycaprolactone (PCL) microchambers were shown to lead to aggregation into spheroids, which grew over time from the depth of the microchamber to its surface, depositing a vertically aligned network of collagen fibers, mimicking the orientation observed in native cartilage.[201]