Abstract

Representing 3D geometry for different tasks, e.g. rendering and reconstruction, is an important goal in different fields, such as computer graphics, computer vision and robotics. Robotic applications often require perception of object shape information extracted from sensory data that can be noisy and incomplete. This is a challenging task and in order to facilitate analysis of new methods and comparison of different approaches for shape modeling (e.g. surface estimation), completion and exploration, we provide real sensory data acquired from exploring various objects of different complexities. The dataset includes visual and tactile readings in the form of 3D point clouds obtained using two different robot setups that are equipped with visual and tactile sensors. During data collection, the robots touch the experiment objects in a predefined manner at various exploration configurations and gather visual and tactile points in the same coordinate frame based on calibration between the robots and the used cameras. The goal of this exhaustive exploration procedure is to sense unseen parts of the objects which are not visible to the cameras, but can be sensed via tactile sensors activated at touched areas. The data was used for shape completion and modeling via Implicit Surface representation and Gaussian-Process-based regression, in the work “Object shape estimation and modeling, based on sparse Gaussian process implicit surfaces, combining visual data and tactile exploration” [3], and also used partially in “Enhancing visual perception of shape through tactile glances” [4], both studying efficient exploration of objects to reduce number of touches.

Keywords: Point cloud, Tactile sensing, Visual depth sensing, Shape modeling, Shape completion, Implicit surface, Gaussian process, Regression

Specifications Table

| Subject | Artificial Intelligence |

| Specific Subject Area | 3D Shape Modeling and Completion |

| Type of Data | Matrices including 3D point coordinates as .mat files and object scans as .obj files |

| How data were acquired | The data was acquired using two robot setups. The first robot is composed of a 6-degree-of-freedom KUKA arm, a three-finger Schunk Dextrous Hand (7 degrees of freedom) equipped with tactile sensing arrays and a Kinect stereo vision camera. The second robot is a PR2 robot. ROS was used in programming robot motions, communication and data recording. The data was acquired by letting the robot hands touch the experiment objects at predefined locations and recording tactile and visual measurements from tactile sensors on fingers and Kinect cameras, in the form of 3D point clouds, which later on were mapped to the same reference frame based on camera calibrations and registration to initial frame. We also provide 3D scans of objects for comparing shape approximations from real sensory data to ground truth. |

| Data format | Raw |

| Parameters for data collection | The explorative touch locations were discretized, given a fixed object pose, i.e. we used a fixed number of approach directions and heights to touch objects. |

| Description of data collection | The robots touch the experiment objects in a predefined manner at various exploration configurations and gather visual and tactile points in the same coordinate frame, based on calibration between the robots and the used cameras and registration to initial frame. |

| Data source location | KTH Royal Institute of Technology, Stockholm, Sweden |

| Repository name: Visual and Tactile 3D Point Cloud Data from Real Robots for Shape Modeling and Completion | |

| Data accessibility | Data identification number: DOI: https://doi.org/10.17632/ztkctgvgw6.1 |

| Direct URL to data: https://data.mendeley.com/datasets/ztkctgvgw6 | |

| Related Research Article | G. Zarzar Gandler, C. H. Ek, M. Björkman, R. Stolkin, Y. Bekiroglu, Object shape estimation and modeling, based on sparse Gaussian process implicit surfaces, combining visual data and tactile exploration, Robotics and Autonomous Systems, 2020, doi: https://doi.org/10.1016/j.robot.2020.103433. |

Value of the Data

|

1. Data description

The dataset includes visual and tactile readings in the form of 3D point clouds obtained using two different robot setups that are equipped with visual and tactile sensors. It contains three different files for every object, which include a point cloud from the vision sensor, a point cloud from the tactile sensors and the ground-truth object scan. The data files containing point clouds use the .mat format, i.e. they are MATLAB formatted files, while the ground-truth object scans are .obj files, representing the 3D geometry of objects. The data files are available at a Mendeley data repository [11] , which includes these three files for every object:

-

•

<object_name>_v.mat, containing the visual data (n x 3 double, where n is the number of visual points for this object),

-

•

<object_name>_t.mat, containing the tactile data (m x 1 cell, with each element being ki x 3 double, where m is the number of touches for this object and ki, the number of tactile points for touch i).

-

•

<object_name>_scan.obj, containing the scanned object,

Where <object_name> can be box1, box2, box3, cyl1, cyl2, cyl3, cyl4, spray1, spray2 or spray3, for the experiments with the first robot, and box1, box2, box3, cyl1, cyl2, cyl3, cyl4, bottle1, bottle2 or bottle3, for the experiments with the second robot. Visual and tactile points are defined in the same frame.

2. Experimental design, materials, and methods

The data was acquired by using two different robot setups. The first robot is composed of a 6-degree-of-freedom KUKA arm, a three-finger Schunk Dextrous Hand (7 degrees of freedom) equipped with tactile sensing arrays and a Kinect stereo vision camera. The robot can acquire tactile imprints via pressure sensitive tactile pads mounted on the Schunk hand's fingers. Each finger of the hand has 2 tactile sensor arrays composed of 6 × 13 and 6 × 14 cells, which yields at most 486 tactile points after one touch. For each touch, the hand is set to a fixed initial joint configuration, where the thumb opposes the other two fingers, then fingers are closed until contact is sensed. The ten objects were placed on a table-top with the Kinect camera overlooking objects from one side.

An observed object is segmented from its background using a segmentation and tracking system. The system uses stereo vision, the Kinect camera, in a heterogeneous Markov-Random-Field-based framework [12], which uses color and depth information to divide the scene into either planar surfaces, bounded objects or uniform clutter models. From the resulting object segments we get point clouds that serve as starting points for object modeling. To fully cover an object with tactile measurements, up to 54 touches (27 for cyl3 and 18 for box2 due to their lower heights) were performed from the side parallel to the table in a grid of 9 approaching angles (22.5° apart) and 6 heights (spaced at a vertical distance of 2 cm) with respect to the table. The tactile measurements are illustrated as red points in Fig. 2 in Ref. [3]. In order to minimize the potential displacements that can be caused by object movements after touching, before and after a touch, point clouds were registered using the Iterative Closest Point algorithm [13] and measurements were transformed to the initial object frame. Example readings from 3 objects in the dataset can be seen in Fig. 1.

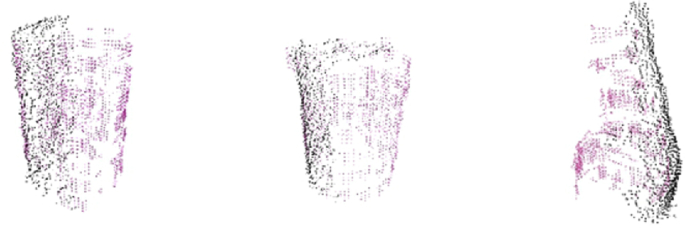

Fig. 1.

Example readings from objects in the dataset, for the first robot setup. Tactile and visual readings are plotted in red and black, respectively, for box1, cyl1 and spray1. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

The second robot is a PR2 equipped with two fingers and tactile pads as shown in Fig. 3 in Ref. [3]. The robot hand was guided to touch the objects at different locations to gather tactile observations. The action space was defined by 9 different heights (with a spacing of 2 cm) and 7 different approaching angles (approaching objects from angles between −60° and +60° with a spacing of 20°). Thus at most 63 tactile readings were recorded, complementing the original visual data. For many objects fewer touches were applied due to their size, e.g. box1 with the fewest touches (21 in total). Details about the objects used in the experiments are given in Table 1. Note that objects belong to three different shape categories, namely boxes, cylinders and spray bottles or bottles. We also provide scans of the objects using a Makerbot Digitizer [14].

Table 1.

Details about objects used in experiments with the first (left) and second (right) robot setups, including i.a. Object names and the number of visual and tactile points.

| Name | Object | # of sensory points |

# of vertices |

Name | Object | # of sensory points |

# of vertices |

||

|---|---|---|---|---|---|---|---|---|---|

| Visual | Tactile | in scans | Visual | Tactile | in scans | ||||

| box1 |  |

6979 | 1714 | 102011 | box1 |  |

1919 | 190 | 35681 |

| box2 |  |

5450 | 445 | 71097 | box2 |  |

3113 | 207 | 48960 |

| box3 |  |

12620 | 1952 | 167970 | box3 |  |

3911 | 524 | 79532 |

| cyl1 |  |

5029 | 1580 | 82930 | cyl1 |  |

3290 | 323 | 64150 |

| cyl2 |  |

4528 | 1460 | 84755 | cyl2 |  |

5465 | 676 | 95832 |

| cyl3 |  |

2765 | 829 | 48739 | cyl3 |  |

3948 | 620 | 71019 |

| cyl4 |  |

5071 | 1975 | 95008 | cyl4 |  |

4431 | 737 | 96935 |

| spray1 |  |

4252 | 1214 | 94658 | bottle1 |  |

3759 | 478 | 82667 |

| spray2 |  |

4084 | 1508 | 92439 | bottle2 |  |

3044 | 327 | 83357 |

| spray3 |  |

2937 | 1166 | 63231 | bottle3 |  |

2915 | 321 | 63770 |

Acknowledgements

Swedish Foundation for Strategic Research and Swedish Research Council.

Contributor Information

Yasemin Bekiroglu, Email: yaseminb@kth.se.

Mårten Björkman, Email: celle@kth.se.

Gabriela Zarzar Gandler, Email: gabriela@peltarion.com.

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Bohg J., Morales A., Asfour T., Kragic D. Data-driven grasp synthesis—A survey. IEEE Trans. Robot. April 2014;30(2):289–309. [Google Scholar]

- 2.Billard A., Kragic D. Trends and challenges in robot manipulation. Science. June 2019;364(6446):eaat8414. doi: 10.1126/science.aat8414. [DOI] [PubMed] [Google Scholar]

- 3.Zarzar Gandler G., Ek C.H., Björkman M., Stolkin R., Bekiroglu Y. Object shape estimation and modeling, based on sparse Gaussian process implicit surfaces, combining visual data and tactile exploration. Robot. Autonom. Syst. 2020;126 [Google Scholar]

- 4.Björkman M., Bekiroglu Y., Högman V., Kragic D. IEEE/RSJ International Conference on Intelligent Robots and Systems. Nov 2013. Enhancing visual perception of shape through tactile glances; pp. 3180–3186. [Google Scholar]

- 5.Yuan W., Khot T., Held D., Mertz C., Hebert M. 2018 International Conference on 3D Vision (3DV) 2018. Pcn: point completion network; pp. 728–737. [Google Scholar]

- 6.Berger M., Tagliasacchi A., Seversky L.M., Alliez P., Guennebaud G., Levine J.A., Sharf A., Silva C.T. A survey of surface reconstruction from point clouds. Comput. Graph. Forum. 2017;36(1):301–329. https://onlinelibrary.wiley.com/doi/abs/10.1111/cgf.12802 [Online]. Available. [Google Scholar]

- 7.Ottenhaus S., Renninghoff D., Grimm R., Ferreira F., Asfour T. IEEE/RAS Int. Conf. Humanoid Robots (Humanoids) 2019. Visuo-haptic grasping of unknown objects based on Gaussian process implicit surfaces and deep learning. [Google Scholar]

- 8.Dragiev S., Toussaint M., Gienger M. IEEE International Conference on Robotics and Automation. May 2013. Uncertainty aware grasping and tactile exploration; pp. 113–119. [Google Scholar]

- 9.Dragiev S., Toussaint M., Gienger M. 2011 IEEE International Conference on Robotics and Automation. May 2011. Gaussian process implicit surfaces for shape estimation and grasping; pp. 2845–2850. [Google Scholar]

- 10.Park J.J., Florence P., Straub J., Newcombe R.A., Lovegrove S. IEEE Conference on Computer Vision and Pattern Recognition, CVPR 2019, Long Beach, CA, USA, June 16-20, 2019. 2019. Deepsdf: learning continuous signed distance functions for shape representation; pp. 165–174. [Google Scholar]

- 11.Bekiroglu Y., Björkman M., Zarzar Gandler G., Exner J., Ek C.H., Kragic D. vol. 1. Mendeley Data; 2020. Visual and Tactile 3D Point Cloud Data from Real Robots for Shape Modeling and Completion. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Björkman M., Kragic D. Proc. BMVC. Vol. 119. 2010. Active 3d segmentation through fixation of previously unseen objects; pp. 1–11. [Google Scholar]

- 13.Besl P.J., McKay N.D. A method for registration of 3-d shapes. IEEE Trans. Pattern Anal. Mach. Intell. Feb. 1992;14(2):239–256. [Google Scholar]

- 14.Makerbot Digitizer 2019. www.makerbot.com/digitizer Online.