Abstract

Plastic pollution is a severe threat to our environment which necessitates implementation of bioplastics to realize sustainable development for a green world. Polyhydroxyalkanoates (PHA) represent one of the potential candidates for these bioplastics. However, a major challenge faced by PHA is the high production cost which limits its commercial application. Halophiles are considered to be a promising cell factory for PHA synthesis due to its several unique characteristics including high salinity requirement preventing microbial contamination, high intracellular osmotic pressure allowing easy cell lysis for PHA recovery, and capability to utilize wide spectrum of low-cost substrates. Optimization of fermentation parameters has made it plausible to achieve large-scale production at low cost by using halophiles. Further deeper insights into halophiles have revealed the existence of diversified and even novel PHA synthetic pathways within different halophilic species that greatly affects PHA type. Thus, precise metabolic engineering of halophiles with the help of advanced tools and strategies have led to more efficient microbial cell factory for PHA production. This review is an endeavour to summarize the various research achievements in these areas which will help the readers to understand the current developments as well as the future efforts in PHA research.

Keywords: Polyhydroxyalkanoates, Halophiles, Production improvement, Cost reduction, Novel PHA biosynthesis, Metabolic engineering

Background

The petrochemical-derived plastics feature one of the most important components in our daily lives. However, with skyrocketing plastic production and usage, plastic pollution has become one of the most alarming and obvious threat to all forms of life [1]. Despite of its enormous societal benefits, plastics account for significant waste accumulation which mostly remains undegraded and recalcitrant for decades in our ecosystem [2]. A possible panacea to these problems may be the use of biodegradable and biosynthetic plastics as an alternative. Polyhydroxyalkanoates (PHA) are linear polyesters synthesized by a variety of microorganisms, serving as an intracellular reservoir for energy and carbon supply [3, 4]. Owing to their combined properties of biodegradability, biocompatibility, and thermoplasticity, PHA has gained substantial importance as a promising candidate for bio-based plastics as well as biomaterials [5]. Interestingly, properties of PHA are highly tuneable and versatile as they vary depending on the type and amount of monomer constituents. Till now, over 150 different monomers have been incorporated into PHA chains under various fermentation conditions, yielding PHA with different characteristics [6]. PHA has tremendous market potential but the high production cost has limited its commercial applications [7]. Recently, halophiles are attracting considerable interest as a promising and cost-effective producer of PHA [8].

Halophiles represent a distinctive and diversified group of microorganisms that have the ability to survive in hypersaline habitats such as saline lakes, salt pans, and salt marshes. They are widely spread in all the three domains of life, Bacteria, Archaea, and Eukarya [9]. Based on their optimum salinity for growth, microorganisms requiring salts are classified as mild, moderate, and extreme halophiles. Mild halophiles grow at a salt concentration of 1–6% (w/v) whereas moderate and extreme halophiles can grow at salt concentrations of 7–15% (w/v) and higher than 15% (w/v), respectively [10]. As a survival strategy, halophiles maintain a high osmotic pressure to adapt to the surrounding hypersaline environment by accumulating either high concentrations of K+ salts or soluble organic solutes (known as compatible solutes) [11]. Some compatible solutes have captured the interest of researchers due to their high value-added property. For instance, ectoine has high commercial importance as an osmostress protectant in cosmetic industry [12]. Additionally, hydrolytic enzymes including amylase, cellulase, protease, and xylanase, secreted by halophiles are also very useful for industrial processes under hypersaline conditions [13]. Furthermore, halophiles are a potent source of biosurfactant, bioemulsifiers, and various other chemicals including aminophenoxazinones, carotenoids, and bacteriorhodopsin [8, 14]. Especially, most halophiles have the inherent ability to accumulate PHA intracellularly.

The adaptation of halophiles to extreme conditions has bestowed them with unique potentials and advantages for PHA production. The foremost advantage is that the high salinity requirement reduces the chances of microbial contamination to a great extent [15]. PHA recovery cost is further reduced as cells can be easily lysed in normal water due to the high intracellular osmotic pressure [16]. Moreover, compared to the non-halophilic microbes, halophiles have the ability to produce PHA by utilizing various inexpensive raw materials, thus reducing the fermentation cost [17]. Thus, they are considered as a promising candidate for PHA production. The company named Bluepha in China is producing polyhydroxybutyrate (PHB) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) using a Halomonas species as microbial cell factory. However, there are still some challenges when using halophiles for large-scale PHA production. For example, treatment of the saline fermentation effluent is difficult [18]. The high salt concentration of medium corrodes fermentation equipment. Additionally, lack of genetic engineering tools and less well-defined systems might be also great challenges for large-scale production of PHA using halophiles. With growing research, strategies have been developed to overcome these issues. Saline wastewater can be treated by marine bacteria [19]. Salt-resistant fermentation equipments made of plastics, ceramics or carbon steel have been used to culture halophiles [8]. Especially, development of genetically engineered halophilic strains is likely to enhance the efficiency of large-scale PHA production by halophiles.

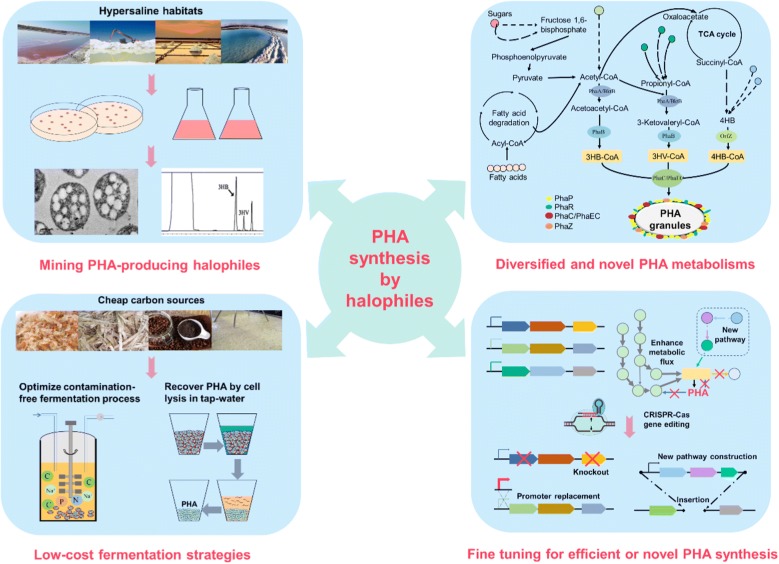

At present, there are many reviews already published on PHA synthesis, and its related challenges and future applications [15, 20–22]. However, most of these reviews focus on non-halophiles. An integrated review mainly presenting the current scenario of PHA synthesis by both the haloarchaea and halophilic bacteria is relatively less. Research on PHA synthesis by halophiles is accelerating and thus, it is urgent to present an updated and in-depth review on this field. In this review, the progresses on PHA synthesis by haloarchaea and halophilic bacteria have been outlined (Fig. 1). The first two parts of the review include significance of halophiles as PHA producer and the various fermentation strategies adopted to realize low cost halophile-mediated PHA production. The third part presents important insights on the PHA metabolism and its regulation in halophiles. Finally, the fourth part of the review deals with the application of metabolic engineering techniques for enhancement of PHA production and synthesis of novel PHA.

Fig. 1.

Summary of the PHA research achievements in Haloarchaea and Halophilic bacteria. Halophiles with strong PHA-accumulation ability are mined from various hypersaline habitats. PHA production cost is closely related with substrate usage, fermentation process, and PHA recovery. Halophiles are able to utilize a wide-range of low-cost substrates. PHA recovery from halophiles can be easily done by cell lysis using tap-water. The physicochemical parameters and fermentation modes have been optimized to enhance PHA production in halophiles. With the aim of genome sequencing technology and genetic manipulation tools, various PHA related genes, enzymes and pathways have been identified. With the help of advanced metabolic engineering tools and strategies, more efficient microbial cell factory has been developed for PHA production using halophiles

Halophiles as a promising platform for PHA production

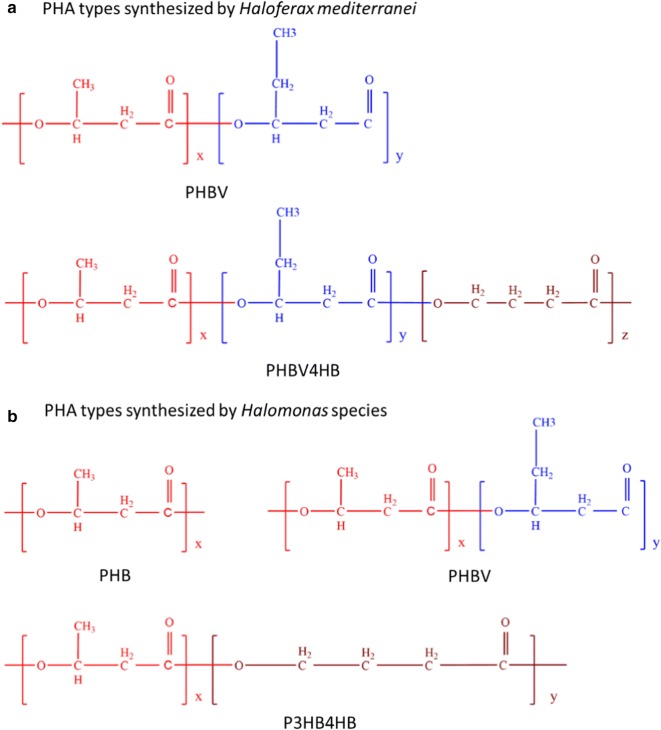

Among halophiles, the haloarchaeon Haloferax mediterranei and the Halomonas species from bacterial domain have been extensively studied for efficient PHA production. Up to now, Hfx. mediterranei has been reported to synthesize PHBV and poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4-hydroxybutyrate) (PHBV4HB) [23]; Halomonas species can accumulate PHB, PHBV, and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) (P3HB4HB) [24–26] (Fig. 2). More and more promising candidates from different genera have already marked their prominence in this field. Thus, the following section attempts to introduce the wide range of PHA-producing halophiles to the readers.

Fig. 2.

The PHA types synthesized by Haloferax mediterranei and Halomonas species. Hfx. mediterranei can synthesize PHBV and PHBV4HB. Halomonas species are able to accumulate PHB, PHBV, and P3HB4HB

Haloarchaea as PHA producers

Ever since Kirk and Ginzburg reported the presence of PHB in Halobacterium sp. isolated from Dead Sea, (presently known as Haloarcula marismortui), more and more haloarchaeal species with PHA-accumulating ability have been identified (Table 1) [27]. In 1986, Fernandez-Castillo et al. detected the presence of PHB in four more haloarchaeal species which are now known as Hfx. mediterranei, Haloferax volcanii, Haloferax gibbonsii, and Haloarcula hispanica [28]. In the period from 1990 to 2000, PHA accumulation was detected in two more Haloarcula species, namely, Haloarcula vallismortis [29, 30] and Haloarcula japonica [30]. Following this, Halopiger aswanensi was found to accumulate PHB accounting about 53% of its cell dry weight (CDW), when n-butyric acid and sodium acetate were used as carbon sources [31, 32]. The presence of PHA granules was further observed in two Haloquadratum walsbyi species [33]. By 2010, PHA accumulation was reported in several other haloarchaeal species including, Halostagnicola sp., Haloterrigena sp., Halobiforma sp., Haloarcula sp., Halobacterium sp., Halococcus sp., Halorubrum sp., Natrinema sp. and haloalkaliphiles including Natronobacterium sp. and Natronococcus sp. [34–37]. In 2017, it was reported that Halorubrum lacusprofundi, the third most abundant species in the Deep Lake community of Antarctica, produced PHA-like granules at low temperature [38]. To date, haloarchaeal species belonging to almost 17 genera have been reported to exhibit PHA-accumulating ability (Table 1).

Table 1.

Haloarchaeal genera with PHA-accumulating ability

| Genus | Species | References |

|---|---|---|

| Haloarcula | Haloarcula marismortui | [27] |

| Haloarcula hispanica | [28] | |

| Haloarcula vallismortis | [29, 30] | |

| Haloarcula japonica | [30] | |

| Haloarcula amylolytica | [35] | |

| Haloarcula argentinensis | [35] | |

| Haloferax | Haloferax mediterranei | [28] |

| Haloferax volcanii | [28] | |

| Haloferax gibbonsii | [28] | |

| Halopiger | Halopiger aswanensi | [31, 32] |

| Haloquadratum | Haloquadratum walsbyi | [33] |

| Halobacterium | Halobacterium noricense | [36] |

| Halobacterium cutirubrum | [35] | |

| Halobacterium halobium | [35] | |

| Halostagnicola | Halostagnicola larsenii | [35] |

| Haloterrigena | Haloterrigena hispanica | [37] |

| Haloterrigena turkmenica | [35] | |

| Halobiforma | Halobiforma nitratireducens | [35] |

| Halobiforma haloterrestris | [34] | |

| Halococcus | Halococcus morrhuae | [35, 36] |

| Halococcus saccharolyticus | [36] | |

| Halococcus salifodinae | [36] | |

| Halococcus dombrowskii | [36] | |

| Halococcus hamelinensis | [36] | |

| Halococcus qingdaonensis | [36] | |

| Halorubrum | Halorubrum coriense | [36] |

| Halorubrum chaoviator | [36] | |

| Halorubrum litoreum | [35] | |

| Halorubrum trapanicum | [35] | |

| Halorubrum lacusprofundi | [38] | |

| Halalkalicoccus | Halalkalicoccus tibetensis | [35] |

| Halogeometricum | Halogeometricum borinquense | [42] |

| Halogranum | Halogranum amylolyticum | [46] |

| Natrinema | Natrinema altunense | [35] |

| Natrinema pallidum | [35] | |

| Natrinema pellirubrum | [35] | |

| Natrinema ajinwuensis | [45] | |

| Natronobacterium | Natronobacterium gregoryi | [35, 36] |

| Natronorubrum | Natronorubrum tibetense | [35] |

| Natronococcus | Natronococcus occultus | [36] |

Among all the haloarchaeal strains, Hfx mediterranei is so far the most preferable PHA producer. It has several advantages such as high growth rate, metabolic versatility, genetic stability, and an efficient transformation system [14]. Many reports have also shown that Hfx. mediterranei has the ability to utilize various industrial and household waste products as carbon sources for synthesizing PHA with considerable amount of productivity. Moreover, detailed investigations have revealed that the PHA produced by the strain is a copolymer of 3-hydroxybutyrate (3HB) and 3-hydroxyvalerate (3HV) from unrelated carbon sources [39]. PHBV is a commercially more efficient and favourable polymer than PHB [4]. Most organisms require 3HV precursor for PHBV synthesis whereas Hfx. mediterranei can efficiently synthesize PHBV without any precursor, thus greatly reducing the production cost [40]. Moreover, it was clearly evident that the cost of PHA production using Hfx. mediterranei was much lower than other bacteria including Alcaligenes eutrophus, Pseudomonas hydrogenovora, and Hydrogenophaga pseudoflava [40]. Thus, Hfx. mediterranei is considered as one of the most promising microbial cell factories for large-scale PHBV production. Other strains including Har. hispanica, Halogeometricum borinquense, and Natrinema species were also found to accumulate PHBV only by utilizing unrelated carbon sources [41–44]. For example, Natrinema ajinwuensis accumulated PHBV containing 13.93 mol% 3HV by using glucose as the sole carbon source [45]. Halogranum amylolyticum could also efficiently accumulate PHBV with 20.1 mol% 3HV from glucose [46]. However, unlike Hfx. mediterranei, these haloarchaea have drawbacks as a platform to be further optimized for PHA production, such as low 3HV content in PHBV, slow growth rate, requirement for too high salinity, or absence of tractable genetic transformation system. Nevertheless, these reports indicate that with passing years more and more haloarchaea are being identified with PHBV synthesis capability.

Halophilic bacteria as PHA producers

Within the bacterial domain, most PHA producers requiring salts belong to the family Halomonadaceae. Of almost 12 genera (as of May 2017) of Halomonadaceae, the genus Halomonas is known to accumulate short-chain-length PHA (Table 2). Most Halomonas sp. have lower NaCl requirement (3–15%) for optimal growth compared to haloarchaea but the concentration is sufficient enough to prevent microbial contamination. Halomonas boliviensis, an alkali tolerant and moderately halophilic bacterium, has the ability to efficiently synthesize PHB at an average content of 50% (wt) by utilizing glucose, sucrose, maltose, xylose as well as wheat bran [47–49]. In 2010, an alkaliphilic halophile, Halomonas sp. KM-1 was reported to produce PHB using waste glycerol as sole carbon source [50]. Another halophilic strain Halomonas bluephagenesis TD01 was cultured in a two-stage unsterile, open and continuous fermentation process yielding PHB up to 65–70% (wt) using glucose [51]. More and more Halomonas species have been found to synthesize PHB by using glucose or other cheap carbon sources (Table 2).

Table 2.

Halophilic bacteria with PHA-accumulating ability

| Genus | Species | References |

|---|---|---|

| Halomonas | Halomonas boliviensis | [47–49] |

| Halomonas sp. KM-1 | [50, 144] | |

| Halomonas bluephagenesis TD01 | [51] | |

| Halomonas nitroreducens | [145] | |

| Halomonas sp. O-1 | [101] | |

| Halomonas elongata | [101] | |

| Halomonas halophila | [73] | |

| Halomonas marina | [53] | |

| Halomonas maura | [146] | |

| Halomonas ventosae | [147] | |

| Halomonas halodenitrificans | [148] | |

| Halomonas halodeneurihalina | [148] | |

| Halomonas salina | [148] | |

| Halomonas sp. SF2003 | [102] | |

| Halomonas profundus | [54] | |

| Halomonas campisalis | [56] | |

| Halomonas hydrothermalis | [77] | |

| Vibrio | Vibrio proteolyticus | [55] |

| Yangia | Yangia sp. ND199 | [57] |

| Yangia sp. CCB-MM3 | [107] | |

| Paracoccus | Paracoccus sp. LL1 | [75] |

However, unlike Hfx. mediterranei, most halophilic bacteria require 3HV precursor to produce PHBV. H. bluephagenesis TD01 produces PHBV when propionic acid or valeric acid is provided additionally with glucose [52]. Halomonas marina produces PHBV with 12.8 mol% 3HV in glucose medium supplemented with valeric acid [53]. Similarly, Halomonas profundus produces PHBV with different molar fractions of 3HV in the presence of valeric acid and propionic acid [54]. Very recently, a PHB-producing halophile named Vibrio proteolyticus was isolated from Korean seas and it was additionally found to produce PHBV containing 15.8 mol% 3HV when propionic acid was added as a co-substrate of fructose [55]. As an exception, Halomonas campisalis, a moderately haloalkalitolerant bacterium, was reported to produce PHBV with 3.6 mol% 3HV from maltose [56]. Although the 3HV content in this copolymer was quite low, this was a significant finding as it was the first report on PHBV synthesis by a halophilic bacterium using unrelated carbon source. In 2015, Yangia sp. ND199, belonging to the Rhodobacteraceae family, was reported to accumulate PHBV with a range of 1–7 mol% 3HV from unrelated carbon source including glucose, maltose, sucrose and glycerol [57]. Taken together, although H. bluephagenesis TD01 synthesize only PHB from unrelated carbon source, it has emerged as a strong candidate for industrial PHA production with the establishment of tractable genetic system, the completion of genome sequencing, and the wide application of metabolic engineering.

Fermentation strategies for reducing the cost of halophile-mediated PHA production

The large-scale production of PHA has high benefits in fermentation industry. A major drawback of PHA production is its economical uncompetitiveness with petroleum-based plastics. However, it has been possible to employ non-halophiles including Alcaligenes latus, Bhurkolderia sp., Ralstonia eutropha, and recombinant Escherichia coli for industrial PHA production after numerous attempts of cost reduction [58]. It is obvious that commercialization of halophiles will have added benefits of cost-effective and contamination-free fermentation compared to these non-halophiles. Three important factors contribute to the cost of PHA production-substrate usage, fermentation process, and PHA recovery. As PHA recovery from halophiles can be easily done by cell lysis using tap-water, rigorous efforts have been devoted to the first two factors. PHA synthesized by various halophiles using cheap carbon sources are summarized in Tables 3 and 4.

Table 3.

PHA production by haloarchaea using various substrates

| Microorganism | Carbon source | PHA type | PHA production | Fermentation operation mode | References |

|---|---|---|---|---|---|

| Har. hispanica | Glucose | P(3HB-co-3.18 mol% 3HV) | Content of 12.26% (wt) | Shake flasks | [105] |

| Har. marismortui | 100% pre-treated vinasse | PHB | Content of 30% (wt); yield of 0.77 g/g; productivity of 0.02 g/L/h | Shake flasks | [69] |

| Hfx. mediterranei | Glucose | P(3HB-co-12.4 mol% 3HV) | Content of 16.4% (wt) | Shake flasks | [35] |

| Hfx. mediterranei | Extruded starch | P(3HB-co-10.4 mol% 3HV) | Content of 50.8% (wt) | Fed-batch | [85] |

| Hfx. mediterranei | 25% pre-treated vinasse | P(3HB-co-12.36 mol% 3HV) | Content of 70% (wt); yield of 0.87 g/g; productivity of 0.21 g/L/h | Shake flasks | [61] |

| Hfx. mediterranei | 50% pre-treated vinasse | P(3HB-co-14.09 mol% 3HV) | Content of 66% (wt); yield of 0.52 g/g; productivity of 0.18 g/L/h | Shake flasks | [61] |

| Hfx. mediterranei | Olive mill wastewater | P(3HB-co-6.5 mol% 3HV) | Content of 43% (wt) | Shake flasks | [62] |

| Hfx. mediterranei | Enzymatic hydrolysate of cheese whey | P(3HB-co-6 mol% 3HV) | Content of 72.8% (wt), yield of 0.29 g/g; productivity of 0.09 g/L/h | 42-L bioreactor | [23] |

| Hfx. mediterranei | Chemical hydrolysate of cheese whey | P(3HB-co-1.5 mol% 3HV) | Content of 53% (wt); yield of 0.78 g/g; productivity of 4.04 g/L/day | 2-L bioreactor | [64] |

| Hfx. mediterranei | Waste stillage | P(3HB-co-15.4 mol% 3HV) | Content of 71% (wt); yield of 0.35 g/g; productivity of 0.17 g/L/h | Shake flasks | [65] |

| Hfx. mediterranei | Waste stillage | P(3HB-co-17.9 mol% 3HV) | Content of 63% (wt); yield of 0.27 g/g; productivity of 0.14 g/L/h | Plug-flow reactor | [66] |

| Hfx. mediterranei | Crude glycerol | P(3HB-co-10 mol% 3HV) | Content of 76% (wt); yield of 0.19 g/g; productivity of 0.12 g/L/h | 10-L bioreactor | [68] |

| Hfx. mediterranei | Ulva sp. hydrolysate | P(3HB-co-8 mol% 3HV) | Content of 55% (wt); productivity of 0.035 g/L/h | Duran bottle | [71] |

| Hfx. mediterranei | Whey sugars, sodium valerate and γ-butyrolactone | P(3HB-co-21.8 mol% 3HV-co-5.1 mo% 4HB) | Content of 87.5% (wt); yield of 0.20 g/g; productivity of 0.14 g/L/h | 10-L bioreactor | [23] |

| Hfx. mediterranei | Crude glycerol phase and γ-butyrolactone | P(3HB-co-10.0 mol% 3HV-co-5.0 mol% 4HB) | Content of 68.5% (wt); yield of 0.16 g/g; productivity of 0.10 g/L/h | 10-L bioreactor | [68] |

| Hgn. amylolyticum | Glucose | P(3HB-co-20.1 mol% 3HV) | Content of 26.1% (wt) | Shake flasks | [46] |

| Hgn. amylolyticum | Starch | P(3HB-co-18.7 mol% 3HV) | Content of 16.2% (wt) | Shake flasks | [46] |

| Hgn. amylolyticum | Glycerol | P(3HB-co-19.6 mol% 3HV) | Content of 7.2% (wt) | Shake flasks | [46] |

| Hgm. borinquense | Sugarcane bagasse hydrolysate | P(3HB-co-13.29 mol% 3HV) | Content of 45.7% (wt); yield of 0.253 g/g; productivity of 0.0113 g/L/h | Shake flasks | [43] |

| Nnm. ajinwuensis | Glucose | P(3HB-co-13.93 mol% 3HV) | Content of 61.02% (wt); productivity of 0.21 g/L/h | Repeated shake flasks | [45] |

Table 4.

PHA production by halophilic bacteria using various substrates

| Microorganism | Carbon source | PHA type | PHA content (% CDW) | Fermentation operation mode | References |

|---|---|---|---|---|---|

| H. halphila | Glucose | PHB | 81.5 | Shake flasks | [73] |

| H. halphila | Cellobiose | PHB | 90.8 | Shake flasks | [73] |

| H. halphila | Spent coffee grounds | PHB | 61.95 | Shake flasks | [73] |

| H. halphila | Molasses | PHB | 64.06 | Shake flasks | [73] |

| H. halphila | Cheese whey hydrolysate | PHB | 38.32 | Shake flasks | [73] |

| H. halphila | Sawdust hydrolysates | PHB | 46.85 | Shake flasks | [73] |

| H. halphila | Diluted corn stover hydrolysate | PHB | 38.67 | Shake flasks | [73] |

| H. boliviensis | Maltose | PHB | 58.8 | Shake flasks | [48] |

| H. boliviensis | Starch hydrolysate | PHB | 35–49 | 2-L fermentor | [48] |

| H. boliviensis | Butyric acid and sodium acetate | PHB | 54 | Shake flasks | [47] |

| H. boliviensis | Butyric acid and sodium acetate | PHB | 88 | 2-L fermentor | [47] |

| H. boliviensis | Glucose or sucrose | PHB | ~ 55 | 2-L fermentor | [47] |

| H. boliviensis | Wheat bran and digested potato waste | PHB | 43 | 2-L fermentor | [49] |

| H. boliviensis | Volatile fatty acid (VFA) | P(3HB-co-8.5 mol% 3HV) | 70 | 2-L bioreactor | [74] |

| Halomonas sp. KM-1 | 3% Waste glycerol | PHB | 39 | Shake flasks | [50] |

| H. marina | Glucose | PHB | > 59 | Shake-flasks | [53] |

| H. marina | Glucose and 0.1% (w/v) valerate | P(3HB-co-12.8 mol% 3HV) | 80 | Shake-flasks | [53] |

| V. proteolyticus | Fructose | PHB | 54.7 | Shake flasks | [55] |

| V. proteolyticus | Fructose and 0.3% propionic acid | P(3HB-co-15.8 mol% 3HV) | ≈ 30 | Shake flasks | [55] |

| H. hydrothermalis | Jatropha biodiesel byproduct | PHB | 75 | Shake flasks | [77] |

| H. hydrothermalis | Jatropha biodiesel byproduct and 0.35% SDCLA | P(3HB-co-81 mol% 3HV) | 73.3 | Shake flasks | [78] |

| H. campisalis | Maltose | P(3HB-co-3.6 mol% 3HV) | 45–81 | Shake flasks | [56] |

| Paracoccus sp. LL1 | Glucose | PHB | 62 | Shake flasks | [75] |

| Paracoccus sp. LL1 | Xylose | PHB | 59 | Shake flasks | [75] |

| Paracoccus sp. LL1 | Cellobiose | PHB | 59 | Shake flasks | [75] |

| Paracoccus sp. LL1 | Corn stover hydrolysate | PHB | 72.4 | 5-L fermentor | [75] |

| Yangia sp. ND199 | Glycerol | P(3HB-co-2.9 mol% 3HV) | 52.8 | Shake flasks | [57] |

| H. bluephagenesis TD01 | Glucose | PHB | 65–70 | Open fed-batch and continuous | [51] |

| H. campaniensis | Mixed substrate similar to kitchen waste | PHB | 70 | Open fed-continuous | [95] |

Low-cost substrate usage by haloarchaea

Besides the common challenges faced by halophiles, the major bottleneck faced by haloarchaea species, such as Hfx. mediterranei, is the low PHA productivity resulted from slow growth rate, and failing to achieve high cell-density cultivation and continuous fermentation. Due to this problem, Hfx. mediterranei has not been used to produce PHA in a large scale despite the fact that it does not require additional 3HV precursor. A possible strategy to overcome these challenges is usage of low-cost substrate which can compensate the high production cost resulting from low productivity. The raw materials account for almost 40–48% of the PHA production cost [59]. Replacement of the pure and expensive raw materials for PHA production is a big challenge for the researchers.

Hfx. mediterranei have the ability to utilize cheap carbon source and even agro-industrial wastes to synthesize PHA (Table 3). Utilization of waste by-products not only helps in waste management but also contributes to reducing PHA production cost. For instance, ethanol production from sugarcane or sugar beet generates considerable amounts of vinasse, which if indiscriminately disposed can be a potential risk to the eco-system [60]. Interestingly, Hfx. mediterranei can utilize pre-treated vinasse and accumulate 70% (wt) PHBV [61]. Olive mill wastewater, a highly problematic waste generated from olive oil industry, serves as the sole carbon source for Hfx. mediterranei, yielding 43% (wt) of PHBV [62]. Chitin is one of the most abundant natural polysaccharides. Seafood industries generate enormous amounts of chitin waste which are mostly recalcitrant in nature. Hfx. mediterranei encodes the enzymes of chitin catabolism and can effectively utilize chitin as a sole carbon source to produce PHBV at a concentration of 1 g/L [63]. Cheese whey, the major by-product of dairy industry is an enriched source of milk nutrients. Since, Hfx. mediterranei was unable to utilize lactose, enzymatically hydrolysed cheese whey was used as the sole carbon source, and 72.8% (wt) of PHBV was produced [23]. Because enzymatic hydrolysis can incur additional cost, chemical hydrolysis using hydrochloric acid was further employed to hydrolyse whey into glucose and galactose [64]. Micronutrients were additionally supplemented to favour galactose utilization for PHBV synthesis after glucose was consumed, which led to production of 53% (wt) PHBV in Hfx. mediterranei. Stillage emanating from rice-based ethanol manufacturing unit is an attractive low-cost substrate for PHA production. Hfx. mediterranei utilized raw stillage and produced 71% (wt) PHBV [65]. When stillage was used to produce PHBV in a plug-flow reactor configuration of the activated sludge process, Hfx. mediterranei was able to accumulate 63% (wt) PHBV while 99.3% of the medium salt was recovered for re-use [66]. Additionally, the cost for 1890 tons of PHBV was estimated to be as low as US$ 2.05/kg. This was almost comparable with the production cost of 2000 tons PHB by Cupriavidus necator (US$2.58/kg) [67]. Thus, this study holds high significance for constructing pilot-scale plant for PHBV production using Hfx. mediterranei and also forms a basis for integration of PHA production with ethanol manufacturing unit to minimize the overall cost. Crude glycerol is the waste by-product of biodiesel production. Interestingly, Hfx. mediterranei could utilize crude glycerol to give a PHBV concentration (16.2 g/L) similar to that produced from pure glycerol (13.4 g/L) [68]. Thus, utilization of crude glycerol opens up a possibility to integrate PHA production with the existing biodiesel production. This will significantly save the operational and transportation cost.

Other haloarchaeon including Har. marismortui and Hgm. borinquense strain E3 also have the ability to use low-cost substrates. Har. marismortui can utilize pre-treated vinasse to accumulate 30% (wt) PHB [69]. Sugarcane bagasse is a major lignocellulosic fibrous residue of sugarcane industry. Hgm. borinquense strain E3 showed 45.7% (wt) accumulation of PHBV when hydrolysates of sugarcane bagasse were utilized as a feedstock for PHA synthesis [43].

Other than the agro-industrial wastes, macroalgal biomass is a non-conventional yet promising feedstock for PHA production. Macroalgae has several advantages such as renewable, independent of land cultivation, and requirement of very less nutrition for growth [70]. Ulva sp., a green macroalgae, is a potential candidate for wastewater remediation. Interestingly, Hfx. mediterranei was capable to produce 55% (wt) PHBV by utilizing supercritical hydrolysate of Ulva sp. [71]. Thus, this is a double benefitted approach towards value-added polymer synthesis as well as waste remediation. Additionally, recycling of the waste streams emanating from PHA production unit is also a sustainable approach. Koller et al. investigated the possibility to recycle the spent fermentation broth during PHA synthesis by Hfx. mediterranei using the surplus whey from dairy industry [72]. Interestingly, a considerable part of the fresh PHA fermentation medium could be replaced with the spent fermentation broth. Furthermore, cell debris left after PHA production could replace almost 29% of the yeast extract in the fresh fermentation process. However, the salty spent fermentation broth might contain inhibitory metabolites which can adversely affect the growth of Hfx. mediterranei, although, further experimentation and fine-tuning of the process can help to overcome the drawback.

Low-cost substrate usage by halophilic bacteria

There are several halophilic bacteria which can efficiently utilize low-cost substrates for PHA production. Spent coffee grounds, the primary waste by-product of coffee processing industry, are still an unusual substrate for valorization. Halomonas halophila was capable of utilizing hydrolysates of spent coffee grounds to produce 61.95% (wt) of PHB [73]. Furthermore, H. halphila showed the ability to utilize molasses, cheese whey hydrolysates, sawdust hydrolysates, and twice diluted corn stover hydrolysate to produce up to 64% (wt) PHB. This indicated the robustness of H. halphila for PHA production by using inexpensive raw materials. Volatile fatty acids (VFA) are organic compounds that are produced in huge quantity during acidogenic fermentation of food waste or municipal solid waste. H. boliviensis inherently produces PHB, however, in presence of VFA mixture containing acetic acid, propionic acid, butyric acid, and valeric acid, it could generate PHBV with 17.5 mol% and 8.5 mol% 3HV fraction in shake flask experiments and 2-L bioreactor, respectively [74]. Wheat bran is a cheap and readily available agricultural residue that gives high potentials to commercial production of PHB. Additionally, anaerobic digest of potato waste is a potent source of acetic and butyric acid. Using wheat bran hydrolysate and digested potato waste, H. boliviensis accumulated 43% (wt) PHB [49]. In a study conducted by Sawant et al., pre-treated corn stover was enzymatically hydrolysed by crude cellulase obtained from co-culture of Trichoderma reesei and Aspergillus niger [75]. The obtained hydrolysate mainly contained glucose, xylose, and cellobiose. This hydrolysate was further used as a feedstock for Paracoccus sp. LL1 (a moderate halophile) and 72.4% (wt) of PHB was achieved. Interestingly, the PHA yield was higher than that obtained from the sugar mixture containing pure glucose, xylose, and cellobiose. Jatropha curcas is a potential biofuel plant due to the high amounts of oil in its seeds [76]. Halomonas hydrothermalis SM-P-3 M has the ability to utilize the crude glycerol generated during the biofuel production process, without any pre-treatment or pH adjustment, to produce PHB up to 75% (wt) [77]. Thus, Jatropha biodiesel by-product, which is otherwise difficult to handle for its impurity and huge quantity, emerged as a possible substrate for PHB production. This is an innovative strategy which can make both the biodiesel and PHA production process economically more feasible. In the subsequent study, the PHA production process was modified to produce PHBV [78]. κ-carrageenan, extracted from granular biomass of Kappaphycus alvarezii, was subjected to hydrolysis to obtain SDCLA (seaweed derived crude levulinic acid). 3HV molar fraction ranging from 50 to 80 mol% was incorporated into polymer chains when different concentrations of SDCLA were co-fed with the Jatropha biodiesel by-product. PHA production was inhibited to half when pure levulinic acid was co-fed which indicated that the composition of SDCLA has a vital effect on the PHA accumulation by H. hydrothermalis. Thus, application of SDCLA with biodiesel residue is an economical and practical approach towards production of PHA with high 3HV molar fraction.

Effect of fermentation conditions on PHA synthesis in haloarchaea

Optimizing the fermentation conditions is another key to improve PHA production. Process parameters and substrate feeding strategies are important influencing factors for product synthesis. For instance, Cui et al. cultivated Hfx. mediterranei in synthetic molasses wastewater at different temperatures (15, 20, 25, and 35 °C), and found that large quantities of PHA were accumulated at 35 °C [79]. At high culture temperatures, Hfx. mediterranei undergoes temperature-driven fast metabolism which causes nitrogen deficiency and triggers PHA overproduction. Thus, the following sections are an overview showing how the physico-chemical parameters and fermentation modes can affect the PHA production in haloarchaea, both quantitatively and qualitatively.

C/N ratio

Hfx. mediterranei is a well-researched haloarchaeon for PHA synthesis since 1980’s. Early investigations on Hfx. mediterranei have shown that phosphate limitation, nitrogen source, and abundant carbon supply are important factors for accumulating large amounts of PHB (later reconfirmed as PHBV) [28, 80]. These fermentation conditions were also found to be an influencing factor for 3HV content in PHBV. Hfx. mediterranei produces PHBV containing almost 10 mol% of 3HV inherently from glucose. Ferre-Guell et al. showed that it is possible to obtain PHBV with varying 3HV content by changing nitrogen source [81]. Ammonium salt enhanced the 3HV content in the polymer compared to nitrate salt. Moreover, the carbon/nitrogen (C/N) molar ratio also affected the 3HV molar fraction in a narrow range. For example, in the presence of ammonium salt, increasing the C/N molar ratio from 8 to 34 decreased the 3HV fraction from 16.9 to 11.7 mol%. With further increasing the C/N ratio to 42, no 3HV fraction was observed in PHA. Contrarily, for the nitrate salt, increasing the C/N ratio from 8 to 42, only slightly changed the 3HV fraction from 12.5 to 11.6 mol%. Thus, altering the nitrogen source and C/N ratio can be a helpful strategy to obtain PHBV polymer with different 3HV contents from Hfx. mediterranei. A major drawback that lowers the efficiency of Hfx. mediterranei as a PHA producer is secretion of an extracellular polymeric substance (EPS) during PHA production. Simultaneous synthesis of EPS not only increases substrate demand but also adds to production cost. The C/N ratio greatly affects the EPS and PHA accumulation [82]. It was observed that increased nitrogen concentration led to enhanced EPS production whereas, nitrogen deficiency promoted PHA accumulation. The percentage of PHA yield coefficient in the sum of EPS and PHA yield coefficients at C/N ratio 5 and 35 was 51.32 and 92.8%, respectively. This indicated that most of the carbon source was converted to PHA synthesis during nitrogen limitation.

Salinity effect

At very high salt concentration, PHA was found to be degraded faster compared to its synthesis in response to high osmotic stress when using activated sludge as inoculum (Paracoccus and Thauera as the dominant genera) [83]. In the early study of Fernandez-Castillo et al., PHA accumulation was higher at 15% salt concentration than 30% [28]. Several salt concentrations of 15, 20, 25 and 30%, were further tested on PHA accumulation in Hfx. mediterranei. It was clarified that the total salt (containing NaCl, MgCl2, MgSO4, CaCl2, KCl, NaHCO3 and NaBr) at a concentration of 25% was optimal for PHA accumulation [80]. Similarly, Alsafadi et al. found salt concentration of 22% to be better than 30% for PHA accumulation in Hfx. mediterranei [62]. Recently, salinity was found to be a parameter influencing EPS and PHA accumulation in Hfx. mediterranei [84]. Increasing NaCl concentration from 7.5 to 25% slightly decreased EPS production from 371.36 to 319.74 mg/g CDW, whereas PHA content increased from 46.7 to 71.1% of CDW in this strain. High salinity tends to divert carbon towards polymer storage by disrupting EPS synthesis in Hfx. mediterranei.

Feeding strategy

When Hfx. mediterranei was cultivated in a fed-batch fermentation by feeding extruded cornstarch and yeast extract at a ratio of 1/1.7 (g/g), a CDW of 39.4 g/L containing 50.8% (wt) PHBV was obtained [85]. During this fermentation process, a pH-stat controlled feeding system was applied to maintain the pH value at 6.9–7.1. The same feeding strategy was further followed when extruded rice and extruded cornstarch at an optimized ratio of 1:8 (g/g) was fed to Hfx. mediterranei in repeated fed-batch fermentation [86]. A CDW of 140 g/L containing 55.6% (wt) of PHBV was obtained, indicating that the developed process was potentially more economical for semi-continuous fermentation at large-scale. Hgn. amylolyticum efficiently produces PHBV containing 20.1 mol% 3HV from glucose, which is the highest 3HV fraction reported among haloarchaeal species [46]. However, CDW and PHBV concentration was only 5.9 g/L and 1.5 g/L, respectively in batch mode. In order to improve PHBV productivity, fed-batch fermentation was employed where glucose was supplemented up to 10 g/L once residual glucose concentration dropped below 0.5 g/L. This fed-batch technique enhanced CDW to 29 g/L and PHBV concentration to 14 g/L [46].

Effect of process parameters on PHA synthesis in halophilic bacteria

Stanley et al. optimized the nutritional requirements and process parameters for PHA production using Halomonas venusta KT832796 in 2-L bioreactor [87]. This strain produced CDW of 3.86 g/L containing 70.56% (wt) PHB at a volumetric productivity of 0.160 g/L/h by using glucose (20 g/L) and ammonium citrate (2 g/L). A further fed-batch cultivation using four different feeding strategies was employed [87]. During carbon limitation, the pH value of medium increases due to build-up of ammonium ions [88]. Thus, the first strategy was based on pH signal where feed pump was manually switched on as pH increased above 7.0 [87]. The PHB volumetric productivity significantly increased to 0.257 g/L/h but the PHB content decreased to 39.15% (wt) as the carbon flux got diverted towards biomass synthesis yielding CDW of 87.3 g/L. In the second strategy, residual glucose concentration in the feed was controlled at 10–20 g/L. CDW of 25.7 g/L containing 58.36% (wt) of PHB was obtained with the volumetric productivity maintained at 0.156 g/L/h. In the third strategy, the residual glucose concentration was controlled at 20–50 g/L. Under this condition, PHA content of 76.67% from a CDW of 29.45 g/L was obtained. However, the PHB volumetric productivity further decreased to 0.138 g/L/h. In the fourth strategy, a high concentration of glucose close to 100 g/L was fed as a single pulse and, once utilized, feed was supplied so that the residual glucose concentration was maintained at 1–2 g/L. This strategy helped to maintain the pH value at 7.0. A net PHB content of 88.12% from a CDW of 37.9 g/L was achieved. Furthermore, PHB volumetric productivity of 0.248 g/L/h was attained, which was almost comparable to pH-signal based strategy. This work is an explicit example showing how feeding methods can enhance PHB productivity.

Halomonas boliviensis, can accumulate PHB when cultivated on different sugar sources. However, one of its drawbacks is the low cell density which results in low PHA productivity. Optimization of the process parameters showed that oxygen depletion in the presence of excess carbon source led to seven-fold increase in cell mass. Using this strategy, an improved CDW of 14 g/L containing 54% (wt) PHB was obtained, which was comparable with the PHA production reported by other non-halophilic producers in batch systems [89]. Additionally, in a fed-batch cultivation mode, effects of nitrogen and phosphorous sources were studied to optimize the PHB production in H. boliviensis [90]. NH4Cl and K2HPO4 were added to the medium during the initial hours of cultivation to favour cell growth. Monosodium glutamate, a cheap replacement of yeast extract, was further added for faster consumption of NH4Cl. After attaining cell growth, feeding of these salts were suppressed to promote PHB accumulation. This strategy led to a 44 g/L of CDW containing 81% (wt) PHB, illustrating it to be an efficient approach for obtaining high PHA production. Using the similar strategy, co-production of 42.47 g/L of PHB and 4.3 g/L of ectoine was further realized in a process comprising of two fed-batch cultures [91]. The culture condition of the first fed-batch system was conducive for high cell mass. Cells from the first fed-batch culture were harvested during the exponential phase and transferred into the second fed-batch culture. Nitrogen and phosphate supply were limited in the second fed-batch culture which favoured product formation. Ectoine was synthesized during the exponential phase whereas PHB was synthesized during the late exponential phase and stationary phase. Co-production of the two metabolites from a single fermentation unit is a promising strategy which would lower the production cost of the respective molecules. Simultaneous Saccharification and Fermentation (SSF) methodology is an energy efficient technique commonly used in the first generation biorefinery. To integrate PHA production into the biorefinery scheme, SSF technique was employed to produce PHB by H. boliviensis using corn mash as carbon source [92]. Interestingly, PHB production was 60% higher using SSF mode than Separate Hydrolysis and Fermentation (SHF) mode wherein corn mash was saccharified separately before fermentation. Additionally, SSF mode required less inoculum volume, single reaction vessel and moreover, saved 47% of the overall processing time. In 2015, Air-Lift Reactors (ALR) was successfully employed to produce 41% (wt) PHB from H. boliviensis by using starch hydrolysate and monosodium glutamate as the respective carbon and nitrogen source [93]. Although the obtained PHB content was lower compared to fed-batch reactors, ALR has the advantages of reduced construction and operational costs.

PHBV production by H. campisalis MCMB-1027 at different aeration and agitation in 14-L fermentor revealed that controlling dissolved oxygen is important for enhancing PHA production [94]. When dissolved oxygen was controlled within a range of 1–5% after attainment of growth phase, PHBV accumulation increased to 56.23% (wt) compared to 42.06% (wt) under uncontrolled condition. However, too low CDW of 1.33 g/L containing 49.17% (wt) PHBV was obtained when fermentation was scaled up to 120-L fermentor by keeping dissolved oxygen maintained at 1–5%.

Effect of fermentation apparatus on PHA synthesis

One of the exclusive advancements in PHA research is employment of open, unsterile, and continuous fermentation process for PHA production by halophiles. Application of open fermentors is an effective strategy for low-cost PHA production mainly due to reduced sterility requirement. Tan et al. carried out a 14-day unsterile fermentation of H. bluephagenesis TD01 using fed-batch and continuous feeding methods [51]. The process involved two fermentors. Cells collected from the first fermentor were pumped into the second fermentor for promoting PHA accumulation by maintaining nitrogen limitation in medium. 40 g/L of CDW containing 60% (wt) PHB was obtained from the first fermentor whereas 20 g/L of CDW containing 65% (wt) PHB was obtained in the second. This process aims at lowering cost and saving energy as the overall process does not involve any sterilization step and tap-water is used instead of distilled water. Moreover, use of two or more fermentors together brings up a possibility to obtain different types of PHA if different substrates are provided. Furthermore, when Halomonas campaniensis strain LS21 was cultured in an open and continuous sea-water based fermentation process, it could grow in a mixed substrate, whose constituent was similar to kitchen wastes, such as soluble and insoluble cellulose, proteins, fats, fatty acids, and starch [95]. During a 65-day fermentation process, a maximal CDW of 73 g/L and PHB content up to 70% (wt) were obtained without any contamination. Thus, H. campaniensis strain LS21 is another potential halophile for long-lasting, low-cost, and bulk production of PHB.

Other than low cost and enhanced production, efficient commercial scale fermentation also requires easy detection and determination of product formation. The methods available for PHA detection and determination are tedious and time-consuming [96]. Flow cytometry (FC) is a fully-automated and multiparametric technique for PHA determination. It rapidly and precisely studied PHB accumulation in a clear correlation with PHB concentration measured by GC-analysis in H. boliviensis [97]. FC also distinguished between two bacterial populations on the basis of presence or absence of PHB. Thus, implementations of FC in PHA production will not only allow monitoring the time for maximal productivity in a short time but will also save time for sample preparation.

PHA metabolism and its regulation in halophiles

PHA metabolism involves its biosynthesis and degradation processes. PHA biosynthesis in halophiles has been extensively studied to reveal the synthetic pathways leading to production of different kinds of PHA [98, 99]. Three classical enzymes directly involved in PHB or PHBV synthesis include β-ketothiolase (PhaA), β-ketoacyl-CoA reductase (PhaB), and PHA synthase (PhaC). In contrast, PHA depolymerase (PhaZ) is mainly responsible for PHA mobilization. Rigorous researches have shown the immense diversity of PHA metabolic enzymes and pathways, based on the kind of halophile as well as the substrate utilized [16]. The regulation of PHA metabolism is a complex phenomenon with only a few studies reported in halophiles. Among haloarchaea, several novel proteins including PhaEC, PhaA/BktB, PhaP, PhaR, PhaZ, BdhA (3HB dehydrogenase) and PhaJ ((R)-specific enoyl-CoA hydratase) (Table 5), and four novel propionyl-CoA supplying pathways have been identified and characterized. In this section, we will attempt to summarize the important genes, proteins, and pathways involved in PHA metabolism and its regulation in halophiles to provide a bird’s eye view of the PHA research to the readers.

Table 5.

Summary of key enzymes and proteins involved in PHA metabolism and regulation identified from halophiles

| Process | Proteins | Organism | Features | Refs. | |

|---|---|---|---|---|---|

| PHA synthesis | PhaEC | Haloarchaea | Haloarcula marismortui | Class III type; constitutes the active PHA synthase; co-transcription; constitutive expression; conserved lipase box-like sequence, amino acid triad (Cys-Asp-His), conserved motif of class III PHA and longer C-terminal sequence | [104] |

| Haloarcula hispanica | [104] | ||||

| Haloferax mediterranei | [41] | ||||

| Halogranum amylolyticum TNN58 | Conserved lipase box-like sequence and catalytic triad residues; 64% and 62% identity with PhaE and PhaC from Hfx. mediterranei | [46] | |||

| PhaC1 | Haloferax mediterranei | Lipase box-like sequence, conserved motif of class III PHA synthase and longer C-terminal sequence | [105] | ||

| PhaC2 | Ala instead of the last Gly in lipase box-like sequence; conserved motif not strongly conserved; longer C-terminal sequence missing, without PhaC function | [105] | |||

| PhaC3 | Lipase box-like sequence, conserved motif of class III PHA synthase and longer C-terminal sequence | [105] | |||

| PhaC | Halorubrum lacusprofundi | High abundance at low temperature; C-terminal has 47% identity with the C-terminal of Haloferax mediterranei PhaC | [38] | ||

| PhaC | Halophilic bacteria | Halomonas elongata DSM2581 | Two candidate genes; phaC1 is functional; unique serine instead of the first glycine in lipase box-like sequence; PhaC1 has affinity towards both 3HB and 3HV monomers | [101] | |

| Halomonas sp. O-1 | |||||

| Halomonas sp. R5-57 | Three candidate encoding genes; the third PhaC is truncated | [106] | |||

| Yangia sp. CCB-MM3 | Class I type; two candidate encoding genes | [107] | |||

| PhaC1 | Halomonas bluephagenesis TD01 | Conserved catalytic triad (Cys-Asp-His) and the conserved lipase box-like; Ser instead of first Gly in lipase box-like sequence | [52] | ||

| PhaC2 | Conserved catalytic triad (Cys-Asp-His) and the conserved lipase box-like; longer C-terminus; shorter N-terminus; Ala instead of the last Gly in lipase box-like sequence | ||||

| BktB | Haloarchaea | Haloferax mediterranei | Two subunits, α and β; α is the catalytic subunit and the catalytic residues are Ser-His-His; β subunit comprises of oligo-sachharide binding domain | [109] | |

| PhaA | |||||

| PhaA | Halophilic bacteria | Halomonas elongata BK-AG18 | One subunit, catalytic residues are Cys-His-Cys | [112] | |

| PhaB | Haloarchaea | Haloferax mediterranei | NADPH-dependent; two candidate encoding genes, phaB1 and phaB2; PhaB1 and PhaB2 responsible for 3HB-CoA and 3HV-CoA formation | [113] | |

| Haloarcula hispanica | NADPH-dependent; only FabG1 responsible for PHA synthesis | [114] | |||

| Halophilic bacteria | Halomonas bluephagenesis TD01 | NADH-dependent | [115] | ||

| PHA regulation | PhaP | Haloarchaea | Haloferax mediterranei | Consists of conserved amino acids and aspartate/glutamate rich regions in C-terminal; lysine acetylated | [117, 119] |

| Halophilic bacteria | Halomonas bluephagenesis TD01 | Three candidate encoding genes; only PhaP1 responsible for the amount and size of PHA granules | [116] | ||

| PhaR | Haloarchaea | Haloferax mediterranei | Consists of AbrB (antibiotic resistance protein B)—like domain; regulates function of PhaP | [118] | |

| Halophilic bacteria | Halomonas bluephagenesis TD01 | Regulates PHA synthesis; amphiphilic property; strong and robust emulsifier | [98, 116] | ||

| PHA degradation | PhaZh1 | Haloarchaea | Haloferax mediterranei | Palatin-like protein; Contains classical lipase box-like | [121] |

| BdhA | Encoding gene located upstream of phaZh1; hydrolyses 3HB monomers generated by PhaZ1 from natural PHA granules | [121] | |||

| PhaJ | Dehydrates 3-hydroxyacyl-CoA to enoyl-CoA | [100] | |||

| PhaZ1 | Halophilic bacteria | Halomonas bluephagenesis TD01 | Lacks signal peptide, intracellular depolymerase | [52] | |

| PhaZ2 | |||||

| PhaZ3 | Signal peptide present, extracellular depolymerase | ||||

Diversity of PHA gene clusters in halophiles

The PHA-related genes are generally organized into clusters but their arrangements are highly diversified. Mostly, the PHA gene cluster is conserved within haloarchaea and organised as maoC-phaR-phaP-phaE-phaC [100]. Compared to this, halophilic bacteria display significant differences. H. elongata DSM2581 and Halomonas sp. O-1 demonstrated a genetic organization of phaP1phaP2phaC1 where the two phasin proteins encoded by phaP1 and phaP2 constituted the structural proteins of the PHA granules [101]. Halomonas sp. SF2003 is another PHA-producing species belonging to the Halomonadaceae family [102]. It was noteworthy that the PHA related genes including phaA, phaB, phaC1/phaC2, and phaR were not clustered in one operon rather were located distantly apart from each other [103]. In the genome of H. bluephagenesis TD01, only phaP and phaC1 were connected by a space of 92 bp whereas all other genes were scattered in the genome [52]. However, phaC1 had an independent promoter which suggested that phaP and phaC1 were separately transcribed driven by their own promoters. These cluster organizations might provide useful evidences about the evolution of the PHA-related genes among different groups of halophiles.

PHA synthase

PHA synthase is the key enzyme involved in PHA biosynthesis that functions by polymerizing the hydroxyalkanoate monomers into PHA chains. In haloarchaea, PHA synthase is composed of two subunits, PhaC and PhaE, and belongs to Class III type. In contrast, PHA synthase in halophilic bacteria consists of only PhaC subunit and belongs to Class I type, which is similar to most of the PHA-accumulating bacteria. Haloarchaeal PHA synthase possesses several novel features that have been discussed in the following paragraphs.

In 2002, archaeal PHA synthase activity was detected for the first time in extremely halophilic archaeon named as strain 56 [34]. PHA synthase was covalently associated with PHB granules and its expression was found to be induced only in the condition of PHB accumulation. However, due to the lack of sequence similarity, molecular characterization of the enzymes was not possible. With the help of complete genome sequence of Har. marismortui, Han et al. investigated the molecular characterization of its PHA synthase genes for the first time within Archaea domain [104]. The annotated PhaC protein contained the highly conserved lipase box-like sequence (Gly-X-Cys-X-Gly-Gly), the amino acid triad (Cys162-Asp317-His346), and the conserved motif of class III PHA synthase (Arg-Met-Glu-X-Trp-Ile-X-Asp-X-X-Asp). These features showed its high similarity with bacterial class III PHA synthases, indicating that the annotated PhaC might be a subunit of class III PHA synthase in Har. marismortui. Interestingly, the protein encoded by the open reading frame immediately upstream of the phaC gene contained the conserved “PhaE box” and the encoded protein showed 21 to 25% identity with the PhaE subunits of bacterial class III PHA synthases. Thus, this open reading frame was designated as phaE gene. Har. hispanica, a phylogenically close archaeon to Har. marismortui, consisted of highly homologous phaEC genes and produced 9.9% (wt) of PHB [104]. Only coexpression of phaC and phaE in ΔphaEC mutant strain restored the PHA accumulation in Har. hispanica. Interestingly, unlike the haloarcheon strain 56, the PHA synthase was expressed even when Haloarcula cells were not cultured in PHA-accumulating medium. However, only the PhaC protein was found to be stably attached to the PHA granules whereas PhaE was not. This phenomenon indicated that PhaC and PhaE subunits constituted a novel form of class III PHA synthase in Haloarcula species.

Similarly, the PHA synthase of Hfx. mediterranei is also composed of PhaE and PhaC subunits and both the proteins constitutively expressed in nutrient-limited as well as nutrient-rich media [41]. In 2015, the PHA synthase from Hgn. amylolyticum TNN58 was characterized and it was reported that the phaE and phaC genes constituted an operon [46]. The amino acid sequence of PhaE and PhaC from TNN58 showed 64% and 62% identity with the counterparts from Hfx. mediterranei. Moreover, the PhaC subunit from TNN58 contained the conserved lipase box-like sequence (Gly-X-Cys-X-Gly-Gly) and the catalytic triad residues (Cys150-Asp305-His333). In 2017, a multi-domain protein showing 47% sequence identity in its C-terminal region with the C-terminal of Hfx. mediterranei PhaC was identified in Hrr. lacusprofundi [38]. Interestingly, this haloarchaeon is known to produce PHA at low temperatures as higher abundances of PhaC proteins were observed at low temperatures.

The molecular weight of haloarchaeal PhaE and PhaC was found to be 20 kDa and 50.1 to 58.5 kDa, respectively, which greatly differed from bacterial class III PHA synthase (40 kDa) [35]. Compared to bacterial PhaC, haloarchaeal PhaC consists of a longer C-terminal [35, 41]. This longer C-terminus is indispensable for a fully active PHA synthase as its truncation led to less accumulation of PHA. The longer C-terminal was found when PHA synthase in 18 other strains belonging to 12 haloarchaeal genera was investigated [35]. In addition to the catalytic triad (C162-D317-H346), haloarchaeal PhaC subunit also possesses two additional residues (C143 and C190), important for its enzymatic activity [35]. Moreover, unlike bacterial PhaE subunit, PhaE box was only present in Haloarcula and Halorhabdus utahensis DSM 12940, indicating that this box is not so conserved in haloarchaeal PhaEs. The alignment and phylogenetic analysis of the conserved sequences of haloarchaeal and bacterial PHA synthase distinctly clustered them into two separate domains [35]. These findings clearly suggest that haloarchaeal PHA synthase constitutes a novel subtype of class III PHA synthase.

Interestingly, besides the phaC gene clustered with phaE, the whole genome sequence analysis presented three additional phaC paralogs (designated as phaC1, phaC2 and phaC3) in Hfx. mediterranei [105]. All the PhaC proteins exhibited 43–58% identity and contained the amino acid triad (Cys-Asp-His). Similar to PhaC, PhaC1 and PhaC3 contained the lipase box-like sequence, the conserved motif for class III PHA synthase as well as the longer C-terminal sequence. However, in the case of PhaC2, lipase box-like sequence contained an “Ala” residue instead of the last “Gly” residue. Furthermore, the conserved motif was not strongly conserved and the longer C-terminal sequence was missing in PhaC2. Although the three additional genes were not transcribed during PHBV accumulation, the heterologous expression of Hfx. mediterranei PhaE with each of the PhaC genes in a PHA synthase gene deleted strain, Har. hispanica PHB-1, led to accumulation of PHBV with varied 3HV content, except PhaC2. Phylogenetic tree analysis based on the four PhaCs from Hfx. mediterranei and PhaCs from other haloarchaea revealed that only PhaC was closely related to other haloarchaeal PhaCs whereas the three additional PhaC might have evolved by horizontal transfer from other source and not directly from PhaC of Hfx. mediterranei.

In the case of halophilic bacteria, PHA synthase shows some significant differences with the haloarcheal PHA synthase. Most importantly, PHA synthase of halophilic bacteria belongs to class I type and is composed of only one subunit, PhaC. H. elongata DSM2581 and Halomonas sp. O-1 have two phaC candidate genes, phaC1 and phaC2 [101]. Expression of only PhaC1 in E. coli JM109 led to the accumulation of PHB proving phaC1 to be the primary functional gene. Notably, the lipase box-like sequence in the Halomonas PhaC1 is comprised of unique serine instead of the first glycine (Ser-X-Cys-X-Gly), which is another significant difference with haloarchaeal PhaCs. Substitution of this serine with glycine did not affect PHB content. However, substitution of the central cysteine by alanine completely abolished PHB accumulation, indicating it to be the catalytic cysteine of PhaC1. Interestingly, expression of PhaC1 in a non PHA-accumulating mutant of R. eutropha in the presence of sodium valerate led to PHBV synthesis, suggesting the affinity of PhaC1 towards both 3HB and 3HV monomers. The genome of Halomonas sp. R5-57, a marine member of the Halomonadaceae family, has three genes annotated as phaC [106]. PhaC (HALO1802) showed 91% and 86% homology with PhaC1 of H. boliviensis and H. campaniensis, respectively. The second PhaC, HALO2716, differed from PhaC1 but showed 75% homology with another PhaC from H. boliviensis. The third PhaC encoded by loci HALO3139 and HALO3140 was truncated, generating stop codon after 67 amino acids. Recently, Yangia sp. CCB-MM3, isolated from soil sediment in the estuarine possessed two PHA synthase genes, phaC1Ys and phaC2Ys, located on chromosome 1 and 2, respectively [107]. Both of them encoded 598-amino acid proteins. Similar to Halomonas sp., Yangia PHA synthase consisted of only one subunit and belonged to class I PHA synthase.

Interestingly, new PHA synthase even exists among the halophilic bacteria. The genome of H. bluephagenesis TD01 consisted of two putative genes encoding PhaC [52]. PhaC1 showed almost 44% and 34% sequence similarity with the PHA synthase from R. eutropha H16. Furthermore, its molecular mass was found to be about 70 kDa, which was within the range of classical Class I PHA synthase (61–73 kDa). However, PhaC2 from the H. bluephagenesis TD01 showed some differences from the classical PHA synthase. First, the molecular mass of PhaC2 and its homologues from H. elongata DSM 2581, Chromohalobacter salexigens DSM 3043, and Aromatoleum aromaticum EbN1 were between 81 and 92 kDa, which was higher than the classical class I PHA synthase. Second, in the phylogenetic analysis, the common ancestor for PhaC2 from strain TD01 and its homologues were distantly clustered from the well characterized PHA synthases. Third, compared to classical class I PHA synthase, PhaC2 displayed a longer C-terminus and a shorter N-terminus. Nevertheless, the conserved catalytic triad (Cys-Asp-His) and the conserved lipase box-like were recognized in both PhaC1 and PhaC2. Interestingly, instead of the traditional lipase box-like amino acids, Gly-X-Cys-X-Gly, PhaC1 contained Ser-X-Cys-X-Gly and PhaC2 contained Gly-X-Cys-X-Ala. These differences indicate the presence of new PHA synthases in the halophilic bacteria.

Understanding the biochemical properties and the underlying catalytic mechanisms of the PhaCs will definitely enhance the biotechnological applications of these halophilic strains. Microbial mats are highly diversified microbial community which commonly accumulate high quantities of PHA. Interestingly, in a recent study, Martínez-Gutiérrez et al. identified six PHA-producing strains from hypersaline microbial mats, of which three belonged to Halomonas species [108]. Their PCR amplicons using primers specific to phaC gene showed high identity values (94–97%) with class I PHA synthase of Halomonas aestuarii. Microbial mats are a potential source for identifying new PHA-producing strains. Thus, the genomic reports already available will be useful for comparative genome analysis of new PHA-producing halophiles.

β-ketothiolase

During PHA synthesis, two acety-CoA molecules are condensed to one acetoacetyl-CoA molecule by the β-ketothiolase enzyme. In halophilic bacteria, β-ketothiolase is composed of a single subunit, PhaA, whereas haloarcheal β-ketothiolase is composed of two subunits. Moreover, the amino acid residues in their catalytic subunits are distinct.

Bioinformatic and genetic analysis revealed that the β-ketothiolase enzyme responsible for PHBV accumulation in Hfx. mediterranei was encoded by two sets of cotranscribed genes, designated as bktBαβ and phaAαβ [109]. PhaA could only produce acetoacetyl-CoA through condensation of two acetyl-CoA molecules. Interestingly, BktB catalyzed the production of 3-ketovaleryl-CoA through condensation of acetyl-coA and propionyl-coA, along with acetoacetyl CoA formation. BktBα and PhaAα were the catalytic subunits due to the presence of the thiolase domain. The catalytic residues of these subunits comprised of “Ser-His-His” in contrary to the bacterial “Cys-His-Cys”. The other subunit, i.e., BktBβ and PhaAβ, contained oligo-sachharide binding domain which are indispensable for the β-ketothiolase activity as deletion of this domain in both BktBβ and PhaAβ completely abolished PHA synthesis. However, the N- and C-terminal regions of the BktBβ and PhaAβ had differential effects on the enzymatic activity. Deletion of the C-terminal of BktBβ reduced PHA synthesis by 70% but effect was not so significant for its N-terminal deletion. Contrarily, N-terminal deletion in PhaAβ reduced PHA synthesis by 93% and C-terminal deletion led to a complete loss of PHA synthesis. Thus, C-terminal is indispensable for both the β-subunits but N-terminal is essential for only PhaAβ activity. Furthermore, construction of hybrid enzyme, i.e, BktBα-PhaAβ and PhaAα-BktBβ demonstrated that α-subunits determined the substrate specificity and β-subunits were functionally interchangeable. This can be explained by the fact that BktBα-PhaAβ could accumulate PHBV whereas PhaAα-BktBβ accumulated PHB. Thus, BktBα-PhaAβ and PhaAα-BktBβ have similar substrate specificity like BktB and PhaA, respectively. However, knockout strain of bktBβ could accumulate only PHB. Only by increasing the expression level of PhaAβ restored the PHBV accumulation ability. This implied that PhaAβ inherently prefers interacting with PhaAα over BktBα to form an active β-ketothiolase.

In halophilic bacteria, PhaA is a classical β-ketothiolase similar to that of bacteria. This enzyme is composed of a single subunit. A few halomonas species and engineered H. bluephagenesis TD01 have the ability to accumulate PHBV from unrelated carbon source and thus their PhaA enzyme could condense acetyl CoA or acetyl-CoA and propionyl-CoA to generate acetoacetyl-CoA or 3-ketovaleryl-CoA [56, 98, 110, 111]. The protein structure of the putative PhaA of H. elongata BK-AG18 showed 68.72% identity to the β-ketothiolase structure of Ralstonia eutropha H16. Furthermore, the residues Cys88, His348, and Cys378 were identified to be the catalytic residues of PhaA, which is similar to the bacterial β-ketothiolase but different from the haloarcheal β-ketothiolase [112].

β-ketoacyl-CoA reductase

The generated 3-ketoacyl-CoA is further reduced to (R)-3-HB-CoA and/or (R)-3-HV-CoA by a PHA specific 3-ketoacyl-CoA reductase (PhaB). PhaB uses NAD(P)(H) as a cofactor during this process. Most of the identified PhaB enzymes use NADPH as the cofactor. The PhaB enzyme from H. bluephagenesis TD01 utilizes NADH instead of NADPH as its cofactor.

Hfx. mediterranei genome encodes two PhaB proteins namely, PhaB1 and PhaB2 [113]. Knocking out of phaB1 did not affect PHBV synthesis. However, phaB2 knockout significantly decreased PHA synthesis and the 3HV monomer fraction in the polymer. Strikingly, knockout of phaB1 and phaB2 in combination completely abolished PHBV synthesis. Thus, PhaB1 has no obvious function in the presence of PhaB2; whereas PhaB1 is responsible for precursor supplying when phaB2 was knocked out. Like PhaB, FabG belongs to the short-chain dehydrogenase/reductase (SDR) superfamily. The genomes of Har. marismortui ATCC 43049 and Har. hispanica encode multiple FabG paralogs but their amino acid identity with the bacterial counterpart is quite low, ranging from 25 to 38% [114]. Under both nutrient-rich and nutrient-limiting conditions, all the fabG paralogs were transcribed, however, disruption of only fabG1 abolished PHA synthesis in Har. hispanica. Further complementation of the fabG1 gene restored PHA synthesis. Intriguingly, coexpression of fabG1 and phaEC in Hfx. volcanii DS70, a non PHA-accumulating haloarchaeon, resulted in PHA accumulation. However, coexpression of other fabG paralogs with phaEC could not lead to PHA synthesis in Hfx. volcanii DS70. Additionally, biochemical analysis revealed that disruption of fabG1 decreased the NADPH-dependent acetoacetyl-CoA reductase activity. Whereas, disruption of other fabG genes neither affected NADPH- nor NADP-dependent acetoacetyl-CoA reductase activity. Thus, this investigation unquestionably demonstrated that fabG1 encoded the PhaB protein in Haloarcula genus.

Bioinformatics analysis predicted one phaB gene in halophilic bacterium, H. bluephagenesis TD01 [115, 116]. Interestingly, the NAD(P)(H) binding domain of PhaB had a glutamate which was crucial for hydrogen bond formation with hydroxyl groups on the adenine ribose of NAD(H). The specific activity of PhaB towards NADH (30.67 mU/mg) was significantly higher than NADPH (1.71 mU/mg), indicating that PhaB from H. bluephagenesis TD01 is NADH-dependent.

Propionyl-CoA synthetic pathway

Among haloarchaea, Hfx. mediterranei is one of the most promising and versatile PHBV-producing haloarchaeon because of its ability to incorporate 3HV monomer up to 10 mol% from unrelated and cheap carbon sources. This high 3HV molar fraction is mainly due to the presence of multiple 3HV monomer supplying pathways in Hfx. mediterranei. Yangia sp. CCB-MM3 is one of the very few halophilc bacteria which can naturally produce PHBV. One 3HV monomer supplying pathway has been predicted in Yangia sp. CCB-MM3. Discovery of these pathways provides a novel opportunity to engineer the PHBV synthetic pathway for obtaining PHBV polymers with controlled 3HV molar fraction.

Propionyl-CoA is an important precursor for 3HV monomer generation. Hfx. mediterranei simultaneously utilizes four pathways for supplying propionyl-CoA during PHBV synthesis when glucose is the main carbon source: citramalate/2-oxobutyrate pathway, aspartate/2-oxobutyrate pathway, methylmalonyl-CoA pathway, and 3-hydroxypropionate pathway [99]. Both citramalate/2-oxobutyrate pathway and aspartate/2-oxobutyrate pathway transforms 2-oxobutyrate to propionyl-CoA. Citramalate/2-oxobutyrate pathway generates 2-oxobutyrate from acetyl-CoA and pyruvate while aspartate/2-oxobutyrate pathway proceeds by converting oxaloacetate-derived threonine and methionine into 2-oxobutyrate. Finally, 2-oxobutyrate generated from these two pathways is decarboxylated to propionyl-CoA. Methylmalonyl-CoA pathway converts succinyl-CoA via (S)-methylmalonyl-CoA to propionyl-CoA. The fourth pathway, 3-hydroxypropionate pathway, was a novel finding, proposed in haloarchaea for the first time. It converts acetyl-CoA and CO2via formation of 3-hydroxypropionate to propionyl-CoA. Interestingly, almost 83.6% of the 3-HV monomer composition is provided by the citramalate/2-oxobutyrate and 3-hydroxypropionate pathway. Unlike the other two pathways which begin with TCA intermediates, these pathways begin with pyruvate and acetyl-CoA and directly store their excess carbon in PHBV granules. Recently, Williams et al. reported that higher abundance of ABC transporter proteins and enzymes involved in branched chain amino acids (BCAA) synthesis were observed in Hrr. lacusprofundi at low temperatures. Since, degradation of BCAA or its intermediate oxoacid precursor can generate propionyl-CoA, it was hypothesized that PHA accumulation was linked to the demand for BCAA in Hrr. lacusprofundi [38].

Yangia sp. CCB-MM3 accumulates PHBV with 7 mol% 3HV from unrelated carbon source [107]. The complete set of genes encoding the enzymes of methylmalonyl-CoA pathway including methylmalonyl-CoA mutase, methylmalonyl-CoA epimerase, and methylmalonyl-CoA decarboxylase have been predicted in this strain [107]. It can be hypothesized that succinyl-CoA is isomerized to (R)-methylmalonyl-CoA by methylmalonyl-CoA mutase. (R)-methylmalonyl-CoA is converted to its S-form by methylmalonyl-CoA epimerase. Finally, (S)-methylmalonyl-CoA is decarboxylated to propionyl-CoA by methylmalonyl-CoA decarboxylase. Thus, methylmalony-CoA pathway might supply propionyl-CoA for PHBV synthesis in Yangia sp. CCB-MM3.

Regulation of PHA synthesis

Formation of uniform sized PHA granules and their distribution is a well-regulated process. Two novel PHA granule associated proteins phasin (PhaP) and GAP12 (PhaR) have been identied involved in the regulation of PHA synthesis in haloarchaea [117, 118]. The two proteins are located on the PHA granules. Their encoding genes form a cluster of maoC-phaR-phaP-phaE-phaC in several haloarchaeal species, including Hfx. mediterranei, Har. hispanica, Halomicrobium mukohataei, Har. marismortui, Halorhabdus tiamatea, Htg. turkmenica, Hpg. xanaduensis, and Hqr. Walsbyi [117].

PhaP consists of several conserved amino acids and aspartate/glutamate rich regions in its C-terminal that might be important for their function [117]. PhaR protein consists of an AbrB (antibiotic resistance protein B)—like domain and plays an important role in regulating PHA accumulation and granule formation [118]. The phaP gene was cotranscribed with phaR but had higher abundance probably due to its higher translational efficiency or stability. Interestingly, the expression level of phaRP was enhanced in the presence of PHA as the activity of the phaRP promoter decreased by twofolds in the ΔphaEC and ΔphaPEC mutants of Hfx. mediterranei [121]. However, knocking out of the phaR gene increased the activity of the phaRP promoter by fourfolds in the ΔphaRPEC mutant, indicating that PhaR is a negative regulator of the phaRP operon [118]. In the case of PHA accumulation, knockout of phaP gene led to 30–40% decrease in PHA yield whereas knockout of both phaR and phaP genes resulted in 75–85% decrease. Surprisingly, complementation of phaR gene in the ΔphaRP mutant fully restored PHA synthesis, unlike phaP which could only partly restore the PHA yield. However, knockout of either phaP or phaR led to irregular formation of PHA granules. ΔphaP mutant strain consisted of only one large round PHA granule with diameter of approximately 1 µm compared to the multiple granules of wild strain. Whereas, ΔphaR produced irregular shaped small or medium sized granules. Thus, a proper amount of PhaP protein, which is regulated by PhaR, is critical for the uniform sized PHA granule formation and separation.

Additionally, lysine acetylation is another probable factor regulating PHA synthesis [119]. Lysine acetylation is an important post-translational modification of proteins that plays a crucial regulatory role in different cellular activities. Almost 17.3% of the total proteins are lysine acetylated in Hfx. mediterranei [119]. Lysine acetylome of Hfx. mediterranei revealed that some of the key enzymes of PHA biosynthesis were acetylated including PhaAα, BktBα, and PhaE subunits [119]. Deacetylation of PhaE significantly reduced PHA synthesis probably due to inefficient interaction between deacetylated PhaE and PhaC subunit on the PHA granules [120]. Additionally, the PhaP protein was also lysine acetylated [119]. Thus, lysine acetylation plays an important role in PHA biosynthesis and its regulation in Hfx. mediterranei.

H. bluephagenesis TD01 genome consists of one gene encoding PhaR and three putative phaP genes [52, 116]. Among the three phaPs, only phaP1 was directly related to the amount and size of PHA granules [116]. However, all the three phaPs were involved in PHB synthesis as their deletion led to low PHB accumulation.

PHA mobilization and degradation

Under conditions of carbon limitation, the intracellularly accumulated PHA is hydrolyzed by PHA depolymerase and other related enzyems so that it can be utilized by the host for growth and survival. The intracellular PHBV gradually degrades when the PHA-rich cells of Hfx. mediterranei are transferred into a fresh medium without carbon source [121]. Strikingly, in addition to the five PHA granule associated proteins, two new proteins were observed on the PHA granules in this strain. One protein, identified as the novel intracellular PHA depolymerase PhaZh1, was a palatin-like protein and contained a classical lipase box-like sequence (Gly-Thr-Ser-Gly-Gly), critical for hydrolytic activity. Although PhaZh1 hydrolyzed PHA granules in vitro, knockout of its encoding gene had no effect on intracellular PHA mobilization. This indicated the presence of alternative PHA degradation pathway in Hfx. mediterranei. The other protein BdhA (3HB dehydrogenase) was encoded by the gene located upstream of phaZh1 [121]. BdhA converted 3HB monomers generated by PhaZ1 from natural PHA granules into acetoacetate. H. bluephagenesis TD01 has three PhaZs among which only PhaZ3 probably is an extracellular depolymerase due to the presence of a signal peptide, while PhaZ1 and PhaZ2 are intracellular depolymerases because they lacked signal peptides [52].

The fifth gene (maoC) of the cluster maoC-phaR-phaP-phaE-phaC in Hfx. mediterranei, redesignated as phaJ, encodes (R)-specific enoyl-CoA hydratase [100]. Despite of its organization with other pha genes, this gene has no function in PHA synthesis as PHBV yield was unaffected by its deletion. Instead, when the PHA-rich cells were transferred into fresh medium without carbon source, this protein catalyzed the dehydration of 3-hydroxyacyl-CoA to enoyl-CoA [100]. Enoyl-CoA is an intermediate of β-oxidation pathway, implying that PHA accumulated in Hfx. mediterranei is degraded and mobilized through β-oxidation pathway. As a confirmation, the expressions of genes encoding 3-hydroxyacyl-CoA dehydrogenase, the key enzyme of β-oxidation pathway, were clearly up-regulated after PHA-rich cells were transferred to fresh medium. Probably, this linkage of PHA degradation to β-oxidation pathway is a common route in haloarchaea as 96% of the species possessing PhaJ also contains the full set of genes involved in β-oxidation pathway.

The series of studies involving bioinformatics analysis and molecular characterization have provided valuable insights into the divisity of PHA metabolism and regulation in haloarchaea and halophilic bacteria [100–121]. Futhermore, the above-mentioned achievements in this secion have also refined the differences between the domains of Bacteria and Archaea.

Strategies for novel PHA synthesis and production improvement