Abstract

The surface texture of dried jujube fruits is a significant quality grading criterion. This paper introduced a novel visual feature fusion based on connected region density, texture features, and color features. The single-scale Two-Dimensional Discrete Wavelet Transform was used to perform single-scale decomposition and reconstruction of dried Hami jujube image before visual features extraction. The connected region density was extracted by the two different algorithms, whereas the texture features were extracted by Gray Level Co-occurrence Matrix and the color features were extracted by image processing algorithms. Based on selected features which obtained by correlation analysis of visual features, the accuracy rate of the optimized Support Vector Machine classification model was 96.67%. In comparing with Extreme Learning Machine classification model and other fusion methods, the optimized Support Vector Machine based on selected visual features fusion was better.

Keywords: Features extraction, Correlation analysis, Dried Hami jujube, Optimized SVM, Visual features fusion

Introduction

Nowadays, Zizyphus jujube Mill (jujube fruit) has been much appreciated for its delicious taste and high nutritional value, an increasing number of people are planting jujube trees. Jujube fruit has been widely used as a crude drug and food for thousands of years (Li et al., 2005). Dried Hami jujubes are not only one of China’s geographical indication products, but also one of the most important agricultural products in Xinjiang.

Computer vision technology (CVT), which simulates human vision, has been used for outer quality detection and sorting of jujube fruits for many years. Manickavasagan et al. (2014) determined the efficiency of RGB color imaging technique to classify jujube fruits into three grades based on their hardness. Dai et al. (2017) studied on the image segmentation method of Lingwu Long Jujubes. A new extraction model of hue was proposed, which improved the accuracy of extracting Jujubes’ image. Wu et al. (2016) proposed a hyperspectral imaging technique for acquiring reflected images to identify common defects on surface of jujube fruit. Muhammad (2015) proposed an automatic system to sort different categories of jujubes based on various distinguished features (color, texture, and shape). However, most jujube fruits grading detection systems based on features such as size, color, defects, and internal qualities such as moisture content (Pu et al., 2018).

Wrinkles on jujube are a natural texture with irregular distribution features. In particular, the wrinkled area consists of sunken “valleys”, both sides being surrounded by raised “ridges”. The surface wrinkles of dried jujube fruits reflect their moisture content and defects, and are important sensory characteristics that affect consumers’ purchasing tendency. However, there are fewer researchers have studied them. Zhang et al. (2017) proposed an automatic watershed segmentation algorithm to extract jujube fruits’ wrinkle features. The results showed that the used method to describe the degree of wrinkles graded with the classification accuracy rate of 92%.

Nevertheless, there is little literature available related to surface texture based on selected fusion of connected regions density, texture, and color features. This article contributes to evaluating the surface texture of dried Hami jujube such as smooth, fold, huge pit, and other related contents by means of visual features fusion (connected regions density, texture, and color features) and optimized SVM method. The introduced methods were comprised in the subsequent flow; the single-scale Two-Dimensional Discrete Wavelet Transform (2D-DWT) (Beura et al., 2015) was used to perform single-scale decomposition and reconstruction of the dried Hami jujube image as preprocessing firstly; in the second step, visual features extraction, such as color features, texture features, and connected regions density. The connected regions density was extracted with two different algorithms. In the first algorithm, the centroid of dried Hami jujube was used as the coordinate system origin, and in the second algorithm, the average horizontal and vertical coordinates of each connected region center were used as the coordinate system origin, respectively. Finally, the classification models of Support Vector Machine (SVM) (Vapnik and Cortes, 1995) and Extreme Learning Machine (ELM) (Huang et al., 2006) were established to predict the surface texture level of dried Hami jujubes based on the selected features.

Materials and methods

Image acquisition

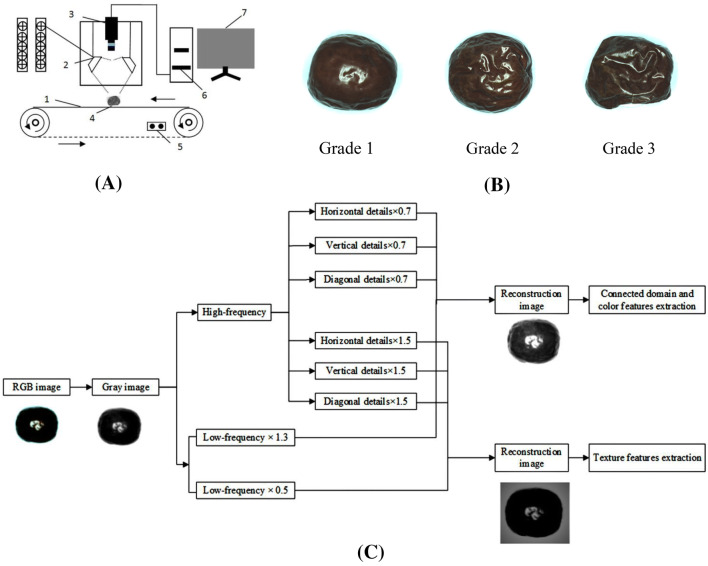

In this experiment, images of dried jujube fruits were acquired by a computer image acquisition system, which mainly consisted of an industrial camera, a collection box, an image acquisition card, image processing software, photoelectric sensors, and so on. The image acquisition system is shown in Fig. 1(A).

Fig. 1.

Materials and image preprocessing methods. (A) Schematic diagram for image acquisition system. 1. Conveyor belt; 2. LED light source board; 3. Industrial camera; 4. Dried jujube fruit; 5. Regulating valve; 6. Image acquisition card; 7. Industrial computer; (B) dried Hami jujube fruit sample; (C) flowchart of single scale two-dimensional discrete wavelet decomposition and reconstruction

The industrial camera (AI CV-M7 + CL CCD), a color CCD camera, combined with the image acquisition card (Matrox Solios XCL), was bought from Xi’an Weishi Company, Xi’an, China. The image acquisition card was purchased from Guangzhou Yahui Precision Company, Guangzhou, China. The RGB image was obtained with resolution 1380 × 1030 pixels and saved in a.bmp format on the computer. In order to reduce external light, LED light source board (AFT-BL250W) installed on the top of the camera obscure. The conveyor belt was installed at the bottom of the collection box for purpose of on-line measurement. These devices were controlled by a computer (Intel (R) i5 CPU, Windows7 × 86 system). To acquire an experiment image, a jujube fruit was placed on the conveyor belt, which has a white background. The strip light sources were firstly directly facing the lens. Finally, the camera was triggered to capture the images, and the captured images are shown in Fig. 1(B).

Sample preparation

A total of 270 dried Hami jujubes without obvious surface defects were collected from the town of Wubaoxiang which locates in north-central Hami area, Xinjiang, China in October, 2017. These jujube fruits grew to full red under natural conditions and air-dried in the farmyard until the experimental material requirements were met. According to requirements of surface texture in the local standard of dried Hami jujubes (China Standard., 2012; Zhang et al., 2017), the individual sample was divided by hand into three groups: grade 1, grade 2 and grade 3 (Fig. 1(B)). The first-grade dried Hami jujube has a smooth surface with slight pits. The surface wrinkles of the second grade were obvious but moderate, and the third-grade surface has more wrinkles and even sunken “valley”.

Single scale two-dimensional discrete wavelet decomposition and reconstruction

In this paper, single-scale 2D-DWT (Beura et al., 2015) was introduced to perform single-scale decomposition and reconstruction of dried Hami jujube images. The image was split into high- and low-frequency component by means of the decomposition of single-scale 2D-DWT. The low-frequency components reflect the outline of the image, and the high-frequency components reflect the details of the image. The specific process is shown in Fig. 1(C).

Connected regions extraction

The computer with Matlab 2017a was used to process dried Hami jujube images and extract characteristic parameters. Under illumination by a suitable light source, one or more highlight areas were formed on each image. Dried Hami jujube with better surface texture has more specular reflection, and the highlight areas of dried jujube image are brighter and smoother. However, the highlight areas of the edge can be easily distorted by the effect of the changing spatial location. The central area faces the camera without obvious distortion. Therefore, the connected region of the central region is stable and can be used to evaluate the surface texture of dried Hami jujubes.

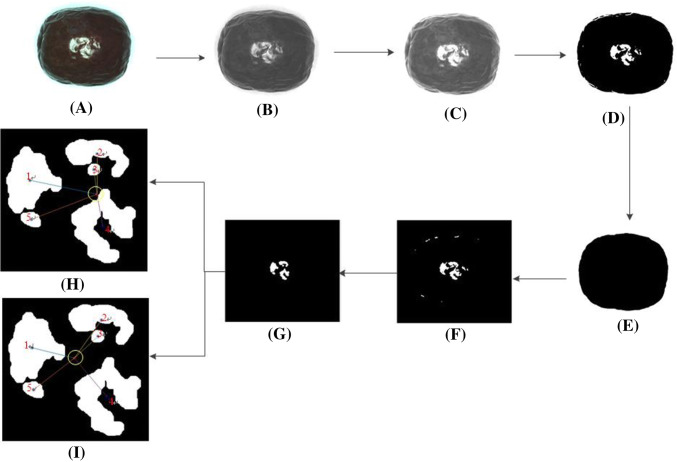

In order to obtain the central connected region, it was firstly necessary to segment the binary image (Fig. 2(D)) and contour image (Fig. 2(E)) of the dried Hami jujube. In addition, subtracting the contour image from the binary image, namely Fig. 2(F) = (D)–(E). Finally, the mathematical morphology was used to perform morphological operations on the central connected regions. The satisfied image of connected regions can be obtained (Fig. 2(G)).

Fig. 2.

The process of connected region density extraction of Dried Hami jujube fruits. (A) Original image; (B) gray image; (C) reconstruction; (D) binary image; (E) contour image; (F) the result image (D)–(E); (G) connected region; (H) the first algorithm; (I) the second algorithm

Connected region density algorithms

Two algorithms were proposed to quantitatively describe the density of connected regions. The centroid of each connected region is extracted by Eq. 1 (Lin et al., 2018).

| 1 |

where is the gray value of point in a connected region , and are the centroid coordinates of the target region. The dots with a number in Fig. 2(H, I) indicate the positions of centroids in connected region (the marked centroids are magnified to facilitate observation).

In the first algorithm (A1), the centroid of the image was taken as the origin of coordinate system and to calculate the average distance from the center of each connected region to the origin of the coordinate system (Fig. 2(H)). The equation is as follows:

| 2 |

where —the density of the connected regions, the smaller the value, the denser the connection region is; —the number of connected regions; —the centroid coordinate of dried Hami jujubes.

In the second algorithm (A2), the horizontal and vertical coordinates of the center of each connected region were averaged, respectively. They were taken as the origin of the coordinate system, and then the average distance from the center of each connected region was calculated to the origin of the coordinate system (Fig. 2(I)). The , , and can be expressed by following equations:

| 3 |

| 4 |

| 5 |

In which, —average of horizontal coordinates of each connected region center; —vertical coordinates of each connected region center; —connected regions density; —the number of the connected regions; —centroid coordinate of the connected region . The feature vectors of connected regions density were obtained by the two different algorithms, and the values of feature vectors are shown in Table 1.

Table 1.

The mean value of unnormalized feature vector of two different algorithms, GLCM and color

| Method | Grade 1 | Grade 2 | Grade 3 |

|---|---|---|---|

| Connected region density | |||

| A1 | 1.3577 ± 0.4949 | 1.7139 ± 0.341 | 2.5639 ± 0.379 |

| A2 | 0.7816 ± 0.1873 | 1.3625 ± 0.2454 | 2.3201 ± 0.3827 |

| GLCM | |||

| MaxP | 0.0799 ± 0.012 | 0.0874 ± 0.0152 | 0.0997 ± 0.0208 |

| Corr | 0.9988 ± 0.0003 | 0.9981 ± 0.0004 | 0.9977 ± 0.0006 |

| Con | 13.4683 ± 3.1642 | 20.5448 ± 4.5846 | 26.7192 ± 5.8177 |

| Asm | 0.013 ± 0.0023 | 0.0125 ± 0.0028 | 0.0146 ± 0.0047 |

| Hom | 0.6341 ± 0.016 | 0.6052 ± 0.0233 | 0.5946 ± 0.0256 |

| Ent | 8.6283 ± 0.2061 | 8.9482 ± 0.2677 | 8.948 ± 0.2917 |

| Color features | |||

| mR | 91.4526 ± 4.8931 | 96.1883 ± 4.1448 | 97.6403 ± 4.3123 |

| mG | 90.0636 ± 4.5307 | 93.723 ± 4.3307 | 95.0487 ± 3.5378 |

| mB | 85.0286 ± 4.0819 | 87.9638 ± 4.5015 | 89.58327 ± 4.0523 |

| sR | 0.1849 ± 0.0119 | 0.1927 ± 0.0513 | 0.1929 ± 0.0578 |

| sG | 0.123 ± 0.0147 | 0.1295 ± 0.0166 | 0.1271 ± 0.0168 |

| sB | 0.3484 ± 0.0172 | 0.3632 ± 0.0159 | 0.369 ± 0.0146 |

| sH | 0.1824 ± 0.0136 | 0.1918 ± 0.0671 | 0.1914 ± 0.0771 |

| sS | 0.2398 ± 0.023 | 0.2505 ± 0.0252 | 0.2498 ± 0.0229 |

| sI | 0.3799 ± 0.019 | 0.3974 ± 0.0159 | 0.4024 ± 0.0155 |

Values are mean of texture feature ± standard deviation

Texture features and color features extraction

Gray Level Co-occurrence Matrix (GLCM) was used to extract dried Hami jujubes’ texture (Lloyd et al., 2017). GLCM stands for Grayscale Co-occurrence Matrix (GCM), which is a statistical method for the detection of texture that takes into account pixel spatial relationships. GLCM functions characterize the image texture by determining the frequency of occurrence pairs of the pair with specific value occur in an image. The Co-occurrence probability is calculated by following mathematical formulation:

| 6 |

| 7 |

In which, —the probability; —the co-occurrence probability between grey levels i and j within the given a distance and an orientation ; —the number of the occurrence of the gray levels (Clausi, 2002).

After calculation, six texture features (max-probability, correlation, contrast, energy, homogeneity, entropy) were extracted. Mathematical formulations of these features are provided by Eqs. 8, 9, 10, 11, 12 and 13. The value of feature vectors is shown in Table 1.

| 8 |

| 9 |

| 10 |

| 11 |

| 12 |

| 13 |

The color parameters of a dried Hami jujube, including red, green, and blue components’ mean value (mR, mG, and mB), the standard deviation of hue, saturation, and intensity (sH, sS, and sI), red, green, and blue (sR, sG, and sB). These 9 color features were selected as characteristic parameters for detection of surface texture value.

Feature fusion

Correlation analysis on visual features

In order to obtain the optimal combination features to predict the surface texture of dried Hami jujubes, a correlation analysis on the sample GLCM and image feature variables (A1, A2, and color features) was conducted. The results of the correlation are shown in Table 2, except for sH, sS, sR, and sG, all the feature variables were significantly correlated with max-probability, correlation, contrast, energy, and homogeneity (uniformity homogeneity and correlation were significantly negatively correlated). Therefore, A1, A2, Maxp, Corr, Con, Asm, Hom, mRGB, sB, and sI were selected as visual features. In addition, the feature variables of the image were also correlated with each other to a certain extent. For instance, the correlation between mG and sI was as much as 0.94. The correlation between these variables would cause large information overlap and over-fitting of the established model. Therefore, in further modeling, dimensionality reduction of principal components of image feature variables should be performed, which could eliminate collinearity and reduce machine learning time while image information correlated with the surface texture of dried Hami jujubes was retained.

Table 2.

Correlation between connected region density value, color feature value and GLCM value

| Parameter | A1 | A2 | mR | mG | mB | sR | sG | sB | sH | sS | sI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 1.000 | 0.799** | 0.309 | 0.290 | 0.282 | − 0.067 | 0.065 | 0.311 | − 0.098 | 0.104 | 0.300 |

| A2 | 0.799** | 1.000 | 0.414* | 0.374 | 0.358 | − 0.093 | 0.070 | 0.402* | − 0.130 | 0.126 | 0.397 |

| mR | 0.309 | 0.414* | 1.000 | 0.896** | 0.788** | 0.000 | 0.298 | 0.940** | − 0.094 | 0.406 | 0.987** |

| mG | 0.290 | 0.374 | 0.896** | 1.000 | 0.918** | 0.252 | 0.062 | 0.979** | 0.155 | 0.103 | 0.940** |

| mB | 0.282 | 0.358 | 0.788** | 0.918** | 1.000 | 0.473* | − 0.251 | 0.938** | 0.388 | − 0.153 | 0.847** |

| sR | − 0.067 | − 0.093 | 0.000 | 0.252 | 0.473* | 1.000 | − 0.757** | 0.249 | 0.991** | − 0.747** | 0.102 |

| sG | 0.065 | 0.070 | 0.298 | 0.062 | − 0.251 | − 0.757** | 1.000 | 0.044 | − 0.787** | 0.955** | 0.229 |

| sB | 0.311 | 0.402 | 0.940** | 0.979** | 0.938** | 0.249 | 0.044 | 1.000 | 0.154 | 0.134 | 0.972** |

| sH | − 0.098 | − 0.130 | − 0.094 | 0.155 | 0.388 | 0.991** | − 0.787** | 0.154 | 1.000 | − 0.780** | 0.008 |

| sS | 0.104 | 0.126 | 0.406 | 0.103 | − 0.153 | − 0.747** | 0.955** | 0.134 | − 0.780** | 1.000 | 0.325 |

| sI | 0.300 | 0.397 | 0.987** | 0.940** | 0.847** | 0.102 | 0.229 | 0.972** | 0.008 | 0.325 | 1.000 |

| MaxP | 0.349 | 0.419* | 0.698** | 0.716** | 0.808** | 0.216 | − 0.212 | 0.772** | 0.130 | − 0.056 | 0.694** |

| Corr | − 0.501** | − 0.680** | − 0.326 | − 0.310 | − 0.250 | − 0.005 | − 0.164 | − 0.311 | 0.011 | − 0.172 | − 0.334 |

| Con | 0.570** | 0.740** | 0.409 | 0.444* | 0.426* | 0.101 | 0.031 | 0.446* | 0.073 | 0.061 | 0.430* |

| Asm | 0.126 | 0.114 | 0.249 | 0.321 | 0.536** | 0.301 | − 0.411 | 0.378 | 0.261 | − 0.356 | 0.258 |

| Hom | − 0.419* | − 0.556** | − 0.468* | − 0.399 | − 0.251 | 0.019 | − 0.337 | − 0.397 | 0.055 | − 0.320 | − 0.460* |

| Ent | 0.277 | 0.408 | 0.378 | 0.377 | 0.213 | 0.040 | 0.329 | 0.342 | 0.016 | 0.258 | 0.400 |

**Correlation is significant at the 0.01 level (two-tailed)

*Correlation is significant at the 0.05 level (two-tailed)

Data processing

In order to eliminate the limitation of dimension and order of magnitude, this paper proposed a standardized conversion (Zscore) method (Booth et al., 2004) to preprocess the original data. The principal component analysis (PCA) (Ajay and Adrian, 2018) was used to extract characteristic variables from the original data. The extracted data was then used as input variables for the model. In this study, nine groups of principal components were used as input.

Classification phase

As mentioned above, 270 samples were processed and their image features were extracted. The samples were divided into three groups, each group contained 90 samples. The proportion of training set and prediction set was 2:1. 60 samples were selected randomly from each group as a training group, and the remaining dried jujube fruits were used as testing sets. No sample was used as training sample or prediction sample at the same time. For selecting the best classification model, SVM and ELM were developed and compared to find the best model for predicting the surface texture of dried Hami jujubes.

Classification model based on SVM

SVM, a supervised learning method, has been proven to widely conduct classification tasks in pattern recognition and computer vision. Although SVM was designed for two types of tasks originally, the fundamental SVM approach can be extended to solve the multi-class classification problems (Hastie and Tibshirani, 1998). SVM accomplishes classification by mapping input vectors into higher-dimensional space and building a hyper-plane, which optimizes the data separation in high-dimensional space. To classify surface texture of dried Hami jujubes into three different groups, “one-against-the-one” (Guttormsen et al., 2016) approach was used to convert binary classification into multi-classification problems. The training process involves the following optimization problem with training samples () of instance-label pairs () considered.

| 14 |

| 15 |

In which, —constant; —penalty coefficient; —the vector of coefficient; —a parameter to deal with non-separable data (input); —an implicit mapping based on the kernel .

When is a positive value, SVM will classify the sample as positive class (label + 1) and classify the negative values in a similar method. For nonlinear SVM, the radial basis function (RBF) was selected as the kernel function (Jia et al., 2016). Its kernel can be expressed as The recommended classification model selection technique was a grid search for the RBF kernel hyper-parameters (gamma, g) and penalty coefficient () using K-fold cross-validation. In order to increase the accuracy of SVM model of this study, each feature of this paper can be linearly scaled to the range [0, 1]. Training process of SVM classification model was performed on the training set with fivefold cross validation (Jang et al., 2012).

Classification model based on ELM

In order to evaluate the suggested model, an ELM model was created. ELM, a simple and liable single hidden layer feed forward neural networks learning algorithm, was proposed by Huang (2015). Its simplified neural network structure increases the learning speed and has been successfully applied to the classification of EEG signals (Yuan et al., 2011). ELM model includes input layer, hidden nodes and output layer. When the model is built, the number of neurons and activation function directly affect the accuracy of the model. These experimental results showed that the model had the best classification accuracy rate when selecting the sigmoid function with 50 hidden nodes.

Results and discussion

Model comparison and discussion

In this section, the performance of classification model based on SVM and ELM were compared (Table 3). The results showed that SVM classifier was obviously better than ELM classifier. From the Table 3, the connected region density (A1 or A2), one color, and one texture features as well as their combination including connected region density (A1 or A2) + texture features, connected region density (A1 or A2) + color features, and connected region density(A1 or A2) + texture features + color features were proposed. It can be observed that the performance of features fusion was far better than the performance of connected region density (A1 or A2), texture features, and color features individually. In addition, the classification accuracy rate was improved further by selected features combination. The reason for these performances was that correlation analysis on visual features eliminated the features (sH, sS, sR, sG, Ent) that were less relevant with surface texture of dried Hami jujubes.

Table 3.

Accuracy of classification models for surface texture of dried Hami jujube fruit samples and comparison of our systems with other previously systems

| Features | Methods | SVM | ELM | ||

|---|---|---|---|---|---|

| Training group (%) | Testing group (%) | Training group (%) | Testing group (%) | ||

| Connected region density | A1 | 78.89 | 80 | 78.89 | 73.33 |

| A2 | 93.89 | 86.67 | 92.78 | 86.67 | |

| Texture feature | GLCM | 85 | 78.89 | 86.67 | 72.22 |

| Color features | mR, mG, mB; | 98.33 | 61.11 | 72.22 | 61.11 |

| sR, sG, sB; | 90.56 | 56.67 | 71.11 | 54.44 | |

| sH, sS, sI; | 79.44 | 61.11 | 75.56 | 65.56 | |

| 9 color features | 92.22 | 67.78 | 62.22 | 55.56 | |

| Features fusion | |||||

| Without selecting fusion | A1 + GLCM; | 93.89 | 87.78 | 70.56 | 66.67 |

| A2 + GLCM; | 96.11 | 93.33 | 95 | 90 | |

| A1 + 9 color features | 81.67 | 77.78 | 75 | 72.22 | |

| A2 + 9 color features | 92.22 | 87.78 | 85.56 | 86.67 | |

| A1 + GLCM + 9 color features | 95 | 84.44 | 95 | 83.33 | |

| A2 + GLCM + 9 color features | 97.77 | 93.33 | 93.89 | 92.22 | |

| Selected fusion | A1 + MaxP, corr, con, Asm, Hom | 93.89 | 91.11 | 93.89 | 87.78 |

| A2 + MaxP, corr, con, Asm, Hom | 97.78 | 94.44 | 95.56 | 91.11 | |

| A1 + mRGB, sB, sI | 87.22 | 75.56 | 85.56 | 73.33 | |

| A2 + mRGB, sB, sI | 95.56 | 92.22 | 94.44 | 91.11 | |

| A1 + sB, sI, mRGB, + MaxP, corr, con, Asm, Hom | 94.44 | 92.22 | 92.78 | 88.89 | |

| A2 + sB, sI, mRGB + MaxP, corr, con, Asm, Hom | 98.89 | 96.67 | 97.22 | 94.44 | |

| Author(s) | Method(s) | Recognition rate (%) |

|---|---|---|

| The comparison of our systems with other previously systems | ||

| Ma et al. (2012) | Jujubes’ defects + BP | 91.43 |

| Manickavasagan et al. (2014) | Wrinkles of jujube fruit + K-means | 92.11 |

| Zhang et al. (2017) | Color of dates + LDA | 86.10 |

| Our new proposed system 1 | A2 + sB, sI, mRGB + maxP, corr, con, Asm, Hom + ELM | 94.44 |

| Our new proposed system 2 | A2 + sB, sI, mRGB + maxP, corr, con, Asm, Hom + SVM | 96.67 |

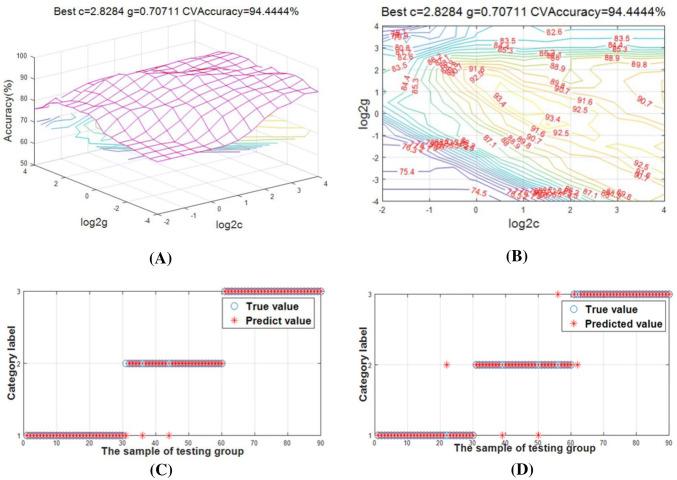

In SVM classification model: the best results for all the performances metrics validation was obtained by the fusion of the second algorithm of connected region density (A2) + color features (mRGB, sB, sI) + texture features (Maxp, Corr, Con, Asm, Hom). The optimization process is shown in Fig. 3(A, B). When c = 2.8284 g = 0.70711, the best performance with a prediction accuracy rate of 98.89% for the training group, 96.67% for the testing group, and 94.44% for the cross-validation accuracy.

Fig. 3.

Accuracy of different classification models. SVM model parameters optimization (AB); (A) c&g optimization (3D map) and (B) c&g optimization results (contour map); accuracy of per category based on SVM (C) and ELM classification model (D)

Accuracy of per category is one of the indispensable characteristics when working with classification problems of surface texture of dried Hami jujube. This fact emphasizes the more confusing categories that require more attention. The average accuracy rate of each class based on A2 + mRGB, sB, sI + Maxp, Corr, Con, Asm, Hom are show in Fig. 3(C, D). The analysis showed that both classification models (SVM and ELM) had relatively low prediction ability on the second grade compared to the other grades (grade 1 and grade 3). The main reason is that there are irregular wrinkles and some slender pits on the surface of the secondary dried Hami jujube. Therefore, the probability of being misjudged as another category is greater.

Through the above discussion, the following conclusions can be drawn. (1) The results showed that SVM model has better performance than the ELM model, with the prediction accuracy rate of 80% (the first algorithm), 86.67% (the second algorithm), 78.89% (GLCM), and 65.56% (Color features). It can also be noticed that the prediction accuracy of feature vectors extracted by connected region density was better than texture features (GLCM) and color features. In addition, the second algorithm of connected region density had better prediction accuracy than the first algorithm. (2) The selective fusion method of correlation analysis was superior to other combination methods (without correlation analysis on visual features). The best feature combination (Our new proposed system 2) was obviously better than the other previously systems. (3) This study has provided a theoretical basis to develop online evaluation system and quality detection of jujubes.

Acknowledgements

This work was supported by the Natural Science Foundation of China (Grant Number 61763043) and the National Key Technologies R&D Program of China (Grant Numbers 2015BAD19B03).

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Xiuzhi Luo, Email: lxz_shz@163.com.

Benxue Ma, Email: mbx_shz@163.com.

Wenxia Wang, Email: 695551716@qq.com.

Shengyuan Lei, Email: 1755793541@qq.com.

Yangyang Hu, Email: 860656338@qq.com.

Guowei Yu, Email: 986119533@qq.com.

Xiaozhan Li, Email: 320389750@qq.com.

References

- Ajay G, Adrian B. Parameterized principal component analysis. Pattern Recogn. 2018;78:215–227. doi: 10.1016/j.patcog.2018.01.018. [DOI] [Google Scholar]

- Beura S, Majhi B, Dash R. Mammogram classification using two dimensional discrete wavelet transform and gray-level co-occurrence matrix for detection of breast cancer. Neurocomputing. 2015;154:1–14. doi: 10.1016/j.neucom.2014.12.032. [DOI] [Google Scholar]

- Booth HS, Maindonald JH, Wilson SR, Gready JE. An efficient Z-score algorithm for assessing sequence alignments. J. Comput Biol. 2004;11:616–625. doi: 10.1089/cmb.2004.11.616. [DOI] [PubMed] [Google Scholar]

- China Standard. Product of geographical indications Hami big jujubes (DB65/T 3460-2012). Available from: http://www.zbgb.org/50/standardDetail2306572.htm. Accessed Dec. 21, 2017.

- Clausi DA. An analysis of co-occurrence texture statistics as a function of grey level quantization. Can. J. Remote Sens. 2002;28:45–62. doi: 10.5589/m02-004. [DOI] [Google Scholar]

- Dai YP, Wang YT, Xue JR, Liu XN, Liu BH, Guo XY. Research of Segmentation Method on Image of Lingwu Long Jujubes Based on a New Extraction Model of Hue. IEEE Sens. J. 2017;17:6029–6036. doi: 10.1109/JSEN.2017.2731376. [DOI] [Google Scholar]

- Guttormsen E, Toldnes B, Bondø M, Eilertsen A, Gravdahl J, Mathiassen J. A Machine Vision System for Robust Sorting of Herring Fractions. Food Bioprocess. Tech. 2016;9:1893–1900. doi: 10.1007/s11947-016-1774-2. [DOI] [Google Scholar]

- Hastie T, Tibshirani R. Classification by pair wise coupling. Ann. Appl Stat. 1998;26:451–471. doi: 10.1214/aos/1028144844. [DOI] [Google Scholar]

- Huang GB. What are extreme learning machines? Filling the gap between Frank Rosenblatt’s dream and John von Neumann’s puzzle. Cogn Comput. 2015;7:263–278. doi: 10.1007/s12559-015-9333-0. [DOI] [Google Scholar]

- Huang GB, Zhu QY, Siew CK. Extreme learning machine: theory and applications. Neurocomputing. 2006;70:489–501. doi: 10.1016/j.neucom.2005.12.126. [DOI] [Google Scholar]

- Jang KH, Choi JL, Yoo TK, Kwon MK, Kim DW. Survival prediction of rats with hemorrhagic shocks using support vector machine. J. Biomed. Eng. Res. 2012;33:1–7. doi: 10.9718/JBER.2012.33.1.001. [DOI] [PubMed] [Google Scholar]

- Jia WK, Zhao Dean, Ding L. An optimized RBF neural network algorithm based on partial least squares and genetic algorithm for classification of small sample. Appl. Soft Comput. 48: 373-384 (2016)

- Lloyd K, Rosin PL, Marshall D, Moore SC. Detecting violent and abnormal crowd activity using temporal analysis of grey level co-occurrence matrix (GLCM)-based texture measures. MACH VISION APPL. 2017;28:361–371. doi: 10.1007/s00138-017-0830-x. [DOI] [Google Scholar]

- Li JW, Ding SD, Ding, XL. Comparison of antioxidant capacities of extractes from five cultivars of Chinese jujubes. Process. Biochem. 40: 3607-3613 (2005)

- Lin D, Zhang A, Gu J, Chen X, Wang Q, Yang L, Chou Y, Liu G, Wang J. Detection of multipoint pulse waves and dynamic 3D pulse shape of the radial artery based on binocular vision theory. Comput. Meth. Prog. Bio. 2018;2018:61–73. doi: 10.1016/j.cmpb.2017.11.025. [DOI] [PubMed] [Google Scholar]

- Manickavasagan A, Al-Mezeini NK, Al-Shekaili HN. RGB color imaging technique for grading of dates. Sci. Hortic-Amsterdam. 2014;175:87–94. doi: 10.1016/j.scienta.2014.06.003. [DOI] [Google Scholar]

- Muhammad G. Date fruits classification using texture descriptors and shape-size features. Eng. Appl. Artif. Intel. 2015;37:361–367. doi: 10.1016/j.engappai.2014.10.001. [DOI] [Google Scholar]

- Ma BX, Qi XX, Wang LL, Zhu RG, Chen QG, Li FX, Wang WX. Size and defect detection of Hami Big Jujubes based on computer vision. pp. 750-754. In: Advanced Materials Research. August 30, Jinan Hotel, Shandong, China. Translation Technology Publications, Changsha, China (2012)

- Pu YF, Ding T, W WJ, Xiang YJ, Ye XQ, Li M, Liu DH. Effect of harvest, drying and storage on the bitterness, moisture, sugars, free amino acids and phenolic compounds of jujube fruit (Zizyphus jujuba cv. Junzao). J. Sci. Food Agric. 98: 628-634 (2018) [DOI] [PubMed]

- Vapnik V, Cortes C. Support vector networks. Mach Learn. 1995;20:273–297. [Google Scholar]

- Wu LG, He JG, Liu GS, Wang SL, He XG. Detection of common defects on jujube using Vis-NIR and NIR hyperspectral imaging. Postharvest. Biol Tec. 2016;112:134–142. doi: 10.1016/j.postharvbio.2015.09.003. [DOI] [Google Scholar]

- Yuan Q, Zhou W, Li S, Cai D. Epileptic EEG classification based on extreme learning machine and nonlinear features. Epilepsy. Res. 2011;96:29–38. doi: 10.1016/j.eplepsyres.2011.04.013. [DOI] [PubMed] [Google Scholar]

- Zhang JX, Ma QQ, Li W, Xiao TT. Feature extraction of jujube fruit wrinkle based on the watershed segmentation. Int. J. Agr Biol Eng. 2017;10:165–172. [Google Scholar]