Abstract

Background:

A new elastomeric impression material which is a combination of vinyl polysiloxane (VPS) and polyether (PE) elastomers called “polyvinyl ether silicone” (PVES) has been introduced with predictable accuracy and high-quality impressions. There is insufficient data on mechanical properties of this material.

Materials and Methods:

A comparative study of mechanical properties of VPS, PE, and PVES was carried out using light- and heavy-body consistencies of the three materials. Three standardized stainless steel molds were made to fabricate study specimens (n = 96). The specimens were tested for elastic recovery, strain under compression, tear energy, and tensile strength (TS) using the universal testing machine. Statistical analysis was done using two-way analysis of variance test.

Results:

Elastic recovery was higher in VPS as compared to other two materials. Strain under compression was higher for PE followed by PVES. Tensile energy was significantly higher in PVS while TS was higher in VPS, followed by PVES and PE.

Conclusion:

PVES tested was found to be more flexible with high tensile energy. This material can be preferred in cases with undercut areas favoring the removal of impressions without tear and distortion.

Keywords: Elastic recovery, strain under compression, tear strength, tensile strength

Introduction

The successful fabrication of restorations largely depends on an accurate impression from which a replica of the intraoral structures can be precisely created.[1,2] Elastomeric impression materials have always been the choice of material in fixed prosthodontics, due to inherent qualities such as reduced marginal voids and distortion resulting in improved quality of gypsum dies.[3] Among available elastomeric materials, the vinyl polysiloxanes (VPS) and polyethers (PEs) are used most frequently. Advances in elastomeric chemistries have led to the invention of a new generation of impression materials which is a combination of polyvinyl and PE called “polyvinyl ether silicone (PVES).”[4]

Few of the properties of this newly introduced material, that is, PVES have been reported by several authors.[5,6,7,8,9,10,11,12] Nassar et al.[5] investigated the dimensional stability of five PVES consistencies when stored for up to 2 weeks, with and without using a standard disinfection procedure. They found that the PVES was dimensionally stable for clinical use after disinfection for 30 min in glutaraldehyde and storage for up to 2 weeks. Shetaa et al.[6] compared the wettability, dimensional changes, flexibility, and tear resistance (TR) of PVES and VPS containing nanofillers with conventional VPS and PE impression materials. They found that all materials were hydrophilic, especially PVES and PE which recorded the highest wettability. VPS containing nanofillers showed the greatest dimensional stability. As related to flexibility, PE, VPES, and PVS recorded the higher flexibility than VPS containing nanofillers, while VPS containing nanofillers and PVES showed the highest TR. Pandey and Mehtra.[7] compared the dimensional stability and accuracy of PE, VPS, and PVES materials and observed that PVES yielded more accurate impressions than those of VPS and PE. Nassar et al.[8] compared the advancing contact angle of water on the surface of several set elastomeric impression materials such as VPS, PVES, and PE. They found that set VPS was more hydrophilic than PVES and PE. Lakshmi et al.[9] evaluated the compatibility of VPS, PVES, and PE impression materials to different tray materials. They reported that PE showed highest bond strength with acrylic resin tray than PVES, while light-activated resin tray produced the weakest bond strength with all the three impression materials. However, PVES showed higher bond strength than VPS. Tabesh et al.[10] compared the implant impression precision using PE, VPS, and PVES materials with direct and indirect techniques. They concluded that PE is recommended for direct technique while PE and PVES are recommended for indirect technique. Recommended technique for PVES is either direct or indirect and for PE and VPS is direct. Other studies[11,12] stated that PVES monophase impressions and PVES dual-viscosity impressions display the acceptable accuracy for clinical use with immersion disinfection since the results for PVES were comparable to the results for representative PE and VPS materials.

For a successful clinical outcome, an impression material should inherently have desirable physical as well as mechanical properties.[13] Adequate mechanical properties such as elastic recovery (K%), strain in compression (E%), TR, and tensile strength (TS) ensure that the impression material can withstand the various stresses upon removal of impression from the mouth while maintaining dimensional stability and integrity.[14] Elastic recovery is the ability of the impression material to recover after deformation.[15] This deformation is dependent on the depth of the undercut and is one of the most important properties in assessing the suitability of an impression material for clinical use. Strain in compression is a measure of the flexibility/stiffness of materials and indicates whether the polymerized impression can be removed from the mouth and have adequate stiffness in the more flexible portions of impressions so that the poured gypsum cast can be removed from the impression without fracture.[16] TR indicates the ability of a material to withstand tearing in thin interproximal and undercut areas and in the depth of the gingival sulcus, while retrieval of impression.[17,18]

TS reflects the maximum stress; a material can bear under tension before the breaking limit. Maximum tensile removal forces of impression materials have been shown to be greater than maximum compressive seating forces, especially when materials are stretched in tension as they are pulled from undercuts, sharp line angles, and interproximal spaces.[19,20,21] The purpose of this in vitro study was to comparatively evaluate the above-mentioned mechanical properties of VPS, PE, and new PVES elastomeric impression materials. Null hypothesis stated that there was no significant difference in the mechanical properties of the impression materials and consistencies.

Materials and Methods

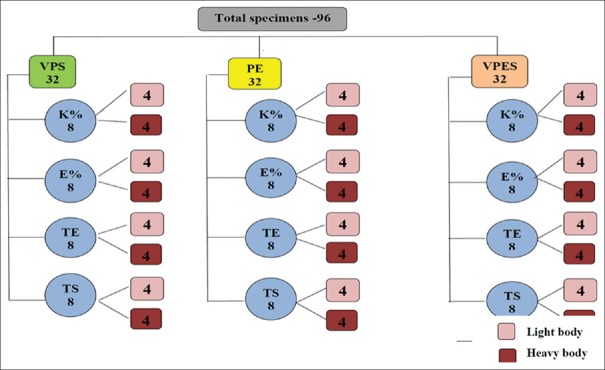

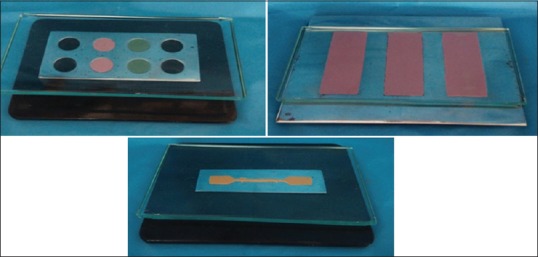

The materials tested in the study were VPS (Flexceed, GC Dental Products Corp., Japan), PE (Impregum™ Soft-3M ESP, 3M Deutschland GmbH, Germany), and VPS (EXA'lence™, GC Dental Products Corp., Japan). Light- and heavy-body consistencies were used for all three materials. For each type of material, 32 specimens were made and divided into four subgroups (n = 8) according to the properties to be tested, the three standardized stainless steel (SS) molds were made for three variable forms of specimens for different mechanical properties to be tested. To fabricate rectangular specimens for TE, a rectangular SS mold of 75 mm × 25 mm × 1 mm dimension was made. For studying TS and K%, a 2 mm wide and 1.5 mm thick dumbbell-shaped mold with an inner bar was made. A 25-mm long section of the inner bar was delineated by four semicircular notches in the mold. For analyzing E%, a hollow cylindrical mold with internal diameter of 15 mm and height 20 mm was made [Figure 1]. For each type of material, 32 specimens were made and divided into four subgroups (n = 8) according to the properties to be tested [Figure 2].

Figure 1.

Preparation of three different types of specimens

Figure 2.

Grouping of specimens

Elastic recovery was tested according to ISO4823. The specimens were deformed by 30% of its original length (L), then the load was released and after 2 min, the change in length (DL) was measured. For measuring strain in compression, load was added into the specimens gradually over a period of 10 s to produce a stress of 1000 g/cm2, the load was maintained for 30 s and the DL was measured. Tear energy (TE)/Tear strength was measured using specimens with dimensions (75 mm × 25 mm × 1 mm) as specified by Webber and Ryge. Using a sharp razor blade, a 50-mm slit was made, producing trouser leg-shaped specimens (12.5 mm wide). The legs of the specimens were placed vertically in opposite directions. The grip separation speed was 20 mm/min. When testing TE, the tear can deviate from the central axis of the test specimen, and then the calculation for the observed extension ratio would not be accurate, so such specimens were discarded. TS was measured following ASTMD412 (Test Method) on dumbbell-shaped specimens. Three measurements (for thickness and width, respectively) were made, 1 at the center and 1 at each reduced end. The rate of grip separation was 50 mm/min. TS was recorded and calculated by software (Series IX, Version 7.27.00, Instron Corp). All the tests were conducted using a screw-driven Universal Testing Machine (Model Mini4, Instron corp) and Digimatic Vernier Caliper. Statistical analysis was done using two-way analysis of variance (ANOVA).

Results

Table 1 lists the mean and standard deviations of tested properties. For all the tested materials, K% was ≥98%. E% was significantly higher in PE material. Overall, the light-body material had significantly lower TE and TS than heavy-body materials. TE was highest with PVES and TS was highest with VPS material. ANOVA shown in Table 2 describes that interaction between the material and consistencies had statistically significant influence on the properties tested. Pearson's correlation coefficient was strongly positive between K% and TS [Table 3].

Table 1.

Elastic recovery, strain in compression, tear energy, and tensile strength of tested impression materials

| Properties | ||||||

|---|---|---|---|---|---|---|

| VPS | PE | VPES | ||||

| LB | HB | LB | HB | LB | HB | |

| K% | 98.49±0.34 | 99.81±0.15 | 98.07±0.63 | 98.59±0.07 | 98.32±0.67 | 98.75±0.63 |

| E% | 5.66±0.25 | 3.38±0.24 | 9.22±0.13 | 8.41±0.86 | 8.16±0.95 | 7.41±0.48 |

| TE (J/m2) | 596.25±51.65 | 669.00±19.10 | 685.75±26.11 | 749.75±29.40 | 746.50±49.65 | 987.50±5.80 |

| TS (MPa) | 3.49±0.13 | 5.60±0.54 | 1.80±0.36 | 2.40±0.42 | 2.55±0.45 | 3.52±0.34 |

K%: Elastic recovery; E%: Strain in compression; TE: Tear energy; TS: Tensile strength; VPS: Vinyl polysiloxane; PE: Polyether; VPES: Vinyl polyether silicone; HB: Heavy body; LB: Light body

Table 2.

Summary of two-way analysis of variance

| K% | E% | TE | TS | |||||

|---|---|---|---|---|---|---|---|---|

| F | P | F | P | F | P | F | P | |

| Material | 6.373 | 0.008* | 120.099 | 0.000* (<0.001) | 95.462 | 0.000* (<0.001) | 79.301 | 0.000* (<0.001) |

| Consistency | 14.847 | 0.001* | 29.232 | 0.000* (<0.001) | 80.648 | 0.000* (<0.001) | 58.794 | 0.000* (<0.001) |

| Interaction | 3.120 | 0.044* | 4.514 | 0.026* (<0.05) | 16.874 | 0.000* (<0.001) | 8.066 | 0.003* (<0.001) |

*Effect is significant at 0.05 levels. K%: Elastic recovery; E%: Strain in compression; TE: Tear energy; TS: Tensile strength

Table 3.

Correlation between the mechanical properties tested

| Correlation between | Pearson’s correlation coefficient | P |

|---|---|---|

| K% and E% | −0.666 (strong negative relationship) | 0.000* |

| K% and TE | −0.016 (no or negligible relationship) | 0.939 |

| K% and TS | 0.746 (very strong positive relationship) | 0.000* |

| E% and TE | 0.319 (moderate positive relationship) | 0.128 |

| E% and TS | −0.898 (very strong negative relationship) | 0.000* |

| TE and TS | −0.056 (no or negligible relationship) | 0.794 |

*Correlation is significant at 0.05 levels. K%: Elastic recovery; E%: Strain in compression; TE: Tear energy; TS: Tensile strength

Discussion

The viscoelastic properties of the elastomeric impression materials play a major role in their successful applications as high accuracy impression materials.[13] The amount of permanent deformation attributed to the dashpot is dictated by the duration of tension or compression exerted on the material.[22] An arbitrary 0.4% deformation has been estimated to be the clinically significant deformation limit.[23]

In the present study, the viscoelastic/mechanical properties of VPS, PE, and PVES were compared and correlated. The null hypothesis that there is no difference in the mechanical properties of the impression materials and consistencies tested was rejected. Elastic recovery is important in determining the accuracy of an impression material.[24] Jorgensen demonstrated that a 60% deformation was induced in an elastomeric impression material when removing it from structures with undercuts 1 mm high and deep.[25] de Araujo et al.[26] recorded the relationship between the induced and permanent deformation of elastomeric dental impression materials during and after setting. They reported the mean recovery time ranges from 2.8–6.8 min. In the present study, all of the materials tested met the requirement of ISO4823, which requires ≥96.5% recovery.[27] The PE and PVES had lower elastic recovery than VPS and showed statistically significant difference. The greater elastic recovery of PVS is attributed to the excellent cross-linking with the hydride group between the polymeric chains.[13] However, among consistencies, heavy body had higher K% than light body, due to the presence of fillers in the heavy body. These findings were in agreement with a study by Lu et al.[14] in which silicone materials showed greater recovery than PE. Inoue et al.[28] have demonstrated that there was increase in permanent deformation in thinner sections of set material than the thick sections when subjected to shear.

The results of the present study showed that all the tested values for E% were within the range required by ISO4823 (0.8%–20% for light-body material and 2%–20% for heavy-body material).[27] The VPS was more rigid than the PE and PVES. However, the newer generation of PE has been incorporated with more amount of plasticizes, rendering it more flexible.[29] According to Jamani et al.[30], rigidity of material is always greater when tested 30 min after the start of mix than when tested at the setting time. This is because the polymerization continues after the setting time.[30] This was supported by Harcourt who found that leaving the impression in the mouth beyond setting time led to an in increase in rigidity.[31] Furthermore, E% was correlated with K%, TE, and TS. The flexible materials would be expected to have less cross-linking, less fillers, or more plasticizer, so they would be expected to be weaker than the stiffer materials and more easily torn. Elastic recovery and strain in compression were inversely correlated. When developing materials, a balance should be chosen that maximizes the elastic recovery, while maintaining flexibility in an acceptable range.[32]

TE indicates the ability of a material to withstand tearing in thin interproximal areas and in the depth of the gingival sulcus. Tear strength is influenced by the chemical composition, consistency, and manner of removal of material. A rapid rate of force application during removal usually increases the tear strength.[14] There are no standard methods proposed by the American National Standard Institution/American Dental Association specification No. 19 or ISO4823 to determine the tear strength.[33] Rivlin and Thomas[34] developed a simple extension tear test, currently used to study the tear strength. The method was later adapted by Webber and Ryge as “Trouser tear test.” In the present study, TE was measured by the “Trouser tear test” developed for thin sections of elastomeric materials.[24] Results showed that there was statistically significant difference in TE among all three materials. The TE of PVES and PE was higher than the VPS. Braden and Elliot. concluded that PE had shear modulus four times high as that of addition PVS, and there is direct relationship between the shear modulus and difficulty encountered in removing an impression from the mouth.[35] Statistical analysis showed TS of VPS was higher than PE and PVES (mean, TS = 3.49). However, PVES was better than PE in this regard. This result was in accordance with a similar study by Lu,[22] in which TS of addition silicones was greater than the PE. Lawson et al.[36] compared the elastic recovery from tensile strain for 5-VPS materials. This study demonstrated that elastomeric impression materials permanently deform following 50% and 100% tensile strains. The variation in tensile elastic recovery among VPS materials is related to components of their composition, including the proportions of base silica, copolymer, filler, and chain extenders.[35,36] Thus, the selection of an impression material for a particular application should be based on property data, rather than on the type and class of the elastomeric impression material.[37,38]

The present study was conducted in an in vitro environment. Although the impressions were made of standardized SS dies, the intraoral conditions could not be simulated to determine the acceptable range of viscoelastic parameters, a clinical investigation should be undertaken, in which several materials of known modulus should be used for impression taking.

Conclusion

Within the limitations of this study, it could be concluded that the newer material PVES tested was found to be more flexible with high-tensile energy. This material can be preferred in cases with undercut areas, favoring the removal of impressions without tear and distortion.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

References

- 1.Chee WW, Donovan TE. Polyvinyl siloxane impression materials: A review of properties and techniques. J Prosthet Dent. 1992;68:728–32. doi: 10.1016/0022-3913(92)90192-d. [DOI] [PubMed] [Google Scholar]

- 2.Chai J, Takahashi Y, Lautenschlager EP. Clinically relevant mechanical properties of elastomeric impression materials. Int J Prosthodont. 1998;11:219–23. [PubMed] [Google Scholar]

- 3.Rubel BS. Impression materials: A comparative review of impression materials most commonly used in restorative dentistry. Dent Clin North Am. 2007;51:629–42, vi. doi: 10.1016/j.cden.2007.03.006. [DOI] [PubMed] [Google Scholar]

- 4.Shetty RM, Bhandari RG, Mehta D. Vinyl poly siloxane ether: A breakthrough elastomeric impression materials. World J Dent. 2014;5:134–7. [Google Scholar]

- 5.Nassar U, Flores-Mir C, Heo G, Torrealba Y. The effect of prolonged storage and disinfection on the dimensional stability of 5 vinyl polyether silicone impression materials. J Adv Prosthodont. 2017;9:182–7. doi: 10.4047/jap.2017.9.3.182. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Shetaa MS, El-Shorbagyb ZA, Abdel Karima UM, Abd-Allab S. Laboratory comparative study of wettability, dimensional changes, flexibility and tear resistance of two recent elastomeric impression materials. Tanta Dent J. 2017;14:89–95. [Google Scholar]

- 7.Pandey A, Mehtra A. Comparative study of dimensional stability and accuracy of various elastomaric materials. J Dent Med Sci. 2014;13:40–5. [Google Scholar]

- 8.Nassar U, Tavoossi F, Pan YW, Milavong-Viravongsa N, Heo G, Nychka JA. Comparison of the contact angle of water on set elastomeric impression materials. J Can Dent Assoc. 2018;84:i6. [PubMed] [Google Scholar]

- 9.Lakshmi CB, Umamaheswari B, Devarhubli AR, Pai S, Wadambe TN. An evaluation of compatibility of three different impression materials to three different tray acrylic materials using tray adhesives: An in vitro study. Indian J Dent Sci. 2018;10:37–41. [Google Scholar]

- 10.Tabesh M, Alikhasi M, Siadat H. A comparison of implant impression precision: Different materials and techniques. J Clin Exp Dent. 2018;10:e151–7. doi: 10.4317/jced.54457. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Wadhwani CP, Johnson GH, Lepe X, Raigrodski AJ. Accuracy of newly formulated fast-setting elastomeric impression materials. J Prosthet Dent. 2005;93:530–9. doi: 10.1016/j.prosdent.2005.03.007. [DOI] [PubMed] [Google Scholar]

- 12.Kang AH, Johnson GH, Lepe X, Wataha JC. Accuracy of a reformulated fast-set vinyl polysiloxane impression material using dual-arch trays. J Prosthet Dent. 2009;101:332–41. doi: 10.1016/S0022-3913(09)60066-4. [DOI] [PubMed] [Google Scholar]

- 13.Shen C. Impression materials. In: Anusavice KJ, editor. Philips' Science of Dental Materials. 11th ed. St. Louis: Elsevier; 2003. pp. 224–31. [Google Scholar]

- 14.Lu H, Nguyen B, Powers JM. Mechanical properties of 3 hydrophilic addition silicone and polyether elastomeric impression materials. J Prosthet Dent. 2004;92:151–4. doi: 10.1016/j.prosdent.2004.05.016. [DOI] [PubMed] [Google Scholar]

- 15.Anusavice KJ, editor . Philips' Science of Dental Materials. 11th ed. Philadelphia, PA: Saunders; 2003. Mechanical properties of dental materials; pp. 73–102. [Google Scholar]

- 16.Donovan TE, Chee WW. A review of contemporary impression materials and techniques. Dent Clin North Am. 2004;48:vi. doi: 10.1016/j.cden.2003.12.014. [DOI] [PubMed] [Google Scholar]

- 17.Cohen BI, Pagnillo MK, Musikant BL, Deutsch AS. Tear strength of four irreversible hydrocolloid impression materials. J Prosthodont. 1998;7:111–3. doi: 10.1111/j.1532-849x.1998.tb00189.x. [DOI] [PubMed] [Google Scholar]

- 18.Keck SC, Douglas WH. Tear strength of non-aqueous impression materials. J Dent Res. 1984;63:155–7. doi: 10.1177/00220345840630021201. [DOI] [PubMed] [Google Scholar]

- 19.Chai J, Takahashi Y, Lautenschlager EP. Clinically relevant mechanical properties of elastomeric impression materials. Int J Prosthodont. 1998;11:219–23. [PubMed] [Google Scholar]

- 20.Sandrik JL, Vacco JL. Tensile and bond strength of putty-wash elastomeric impression materials. J Prosthet Dent. 1983;50:358–61. doi: 10.1016/s0022-3913(83)80092-4. [DOI] [PubMed] [Google Scholar]

- 21.Klooster J, Logan GI, Tjan AH. Effects of strain rate on the behavior of elastomeric impression. J Prosthet Dent. 1991;66:292–8. doi: 10.1016/0022-3913(91)90252-r. [DOI] [PubMed] [Google Scholar]

- 22.Inoue K, Wilson HJ. Viscoelastic properties of elastomeric impression materials. II: Variation of rheological properties with time, temperature and mixing proportions. J Oral Rehabil. 1978;5:261–7. doi: 10.1111/j.1365-2842.1978.tb01243.x. [DOI] [PubMed] [Google Scholar]

- 23.Craig RG. Review of dental impression materials. Adv Dent Res. 1988;2:51–64. doi: 10.1177/08959374880020012001. [DOI] [PubMed] [Google Scholar]

- 24.Salem NS, Combe EC, Watts DC. Mechanical properties of elastomeric impression materials. J Oral Rehabil. 1988;15:125–32. doi: 10.1111/j.1365-2842.1988.tb00761.x. [DOI] [PubMed] [Google Scholar]

- 25.Jörgensen KD. A new method of recording the elastic recovery of dental impression materials. Scand J Dent Res. 1976;84:175–82. doi: 10.1111/j.1600-0722.1976.tb00476.x. [DOI] [PubMed] [Google Scholar]

- 26.de Araujo PA, Jorgensen KD, Finger W. Viscoelastic properties of setting elastomeric impression materials. J Prosthet Dent. 1985;54:633–6. doi: 10.1016/0022-3913(85)90237-9. [DOI] [PubMed] [Google Scholar]

- 27.International Organization for Standardization 4823 for Elastomeric Impression Materials. International Organization for Standardization Technical Committee. 2000 [Google Scholar]

- 28.Inoue K, Wilson HJ. Viscoelastic properties of elastomeric impression materials I. A method of measuring shear modulus and rigidity during setting. J Oral Rehabil. 1978;5:89–94. doi: 10.1111/j.1365-2842.1978.tb00395.x. [DOI] [PubMed] [Google Scholar]

- 29.Chee WW, Donovan TE. Polyvinyl siloxane impression materials: A review of properties and techniques. J Prosthet Dent. 1992;68:728–32. doi: 10.1016/0022-3913(92)90192-d. [DOI] [PubMed] [Google Scholar]

- 30.Jamani KD, Harrington E, Wilson HJ. Rigidity of elastomeric impression materials. J Oral Rehabil. 1989;16:241–8. doi: 10.1111/j.1365-2842.1989.tb01338.x. [DOI] [PubMed] [Google Scholar]

- 31.Harcourt JK. A review of modern impression materials. Aust Dent J. 1978;23:178–86. doi: 10.1111/j.1834-7819.1978.tb02908.x. [DOI] [PubMed] [Google Scholar]

- 32.Webber RL, Ryge G. The determination of tear energy of extensible materials of dental interest. J Biomed Mater Res. 1968;2:281–96. doi: 10.1002/jbm.820020302. [DOI] [PubMed] [Google Scholar]

- 33.American Society for the Testing of Materials. Standard test Methods for Vulcanized Rubber and Thermoplastic Elastomers Tension [ASTM D412-98a] West Conshohocken, PA: American National Standards Institute, Annual Book of ASTM Standards; 2002. pp. 43–55. [Google Scholar]

- 34.Rivlin RS, Thomas AG. Rupture of rubber. Characteristic energy for tearing. J Polym Sci. 1953;10:291. [Google Scholar]

- 35.Braden M, Elliott JC. Characterization of the setting process of silicone dental rubbers. J Dent Res. 1966;45:1016–23. doi: 10.1177/00220345660450040101. [DOI] [PubMed] [Google Scholar]

- 36.Lawson NC, Burgess JO, Litaker MS. Tensile elastic recovery of elastomeric impression materials. J Prosthet Dent. 2008;100:29–33. doi: 10.1016/S0022-3913(08)60131-6. [DOI] [PubMed] [Google Scholar]

- 37.Sneed WD, Miller R, Olson J. Tear strength of ten elastomeric impression materials. J Prosthet Dent. 1983;49:511–3. doi: 10.1016/0022-3913(83)90313-x. [DOI] [PubMed] [Google Scholar]

- 38.Braden M. Characterization of the rupture properties of impression materials. Dent Pract. 1963;14:67–9. [Google Scholar]