Abstract

A general framework of the emerging risks linked with advanced manufacturing processes and technologies is showed. For this, the systemic and occupational nature of said risks is considered. To achieve this general objective, the chapter is organized in two parts. In the first part, a theoretical basis is developed. This theoretical basis is configured by an explanation of the emerging risk concept, as well as by the development of an overview of advanced manufacturing processes and technologies. In the second part, contents and tools of practical application are exposed. To do this, the main emerging risks are shown first. Among the fields of application of these risks, some of the most important cross-cutting manufacturing technologies have been selected. One of the main risk governance frameworks is shown. Subsequently, this framework is deployed with two of its main applications on emerging risks: the management and characterization of the risk.

Keywords: Advanced manufacturing processes, Emerging risk, Emerging risk characterization, Emerging risk management, Manufacturing technologies, Occupational risk

1. Introduction

The first three industrial revolutions came about as a result of mechanization, electricity, and information technology (IT). Germany has proposed the concept of smart manufacturing to realize the fourth industrial revolution, that is, Industry 4.0 (Qian et al., 2017). Industry 4.0 is a “strategic initiative” of the German government that was adopted as part of the High-Tech Strategy 2020 Action Plan in November 2011 (Kagermann et al., 2013).

Despite great interest in the concept of Industry 4.0 worldwide, there is no formally respected definition for it (Mrugalska and Wyrwicka, 2017). The Technical Management Board of the International Standard Organization (ISO) in Geneva has now agreed to set up a Strategic Advisory Group (SAG) on Industry 4.0/Smart Manufacturing. One of the SAG's main tasks is to agree on a precise definition of Industry 4.0 (DIN, 2015).

Industry 4.0 in the simplest form concerns enabling manufacturing with the element of tactical intelligence using techniques and technologies such as the Internet of Things (IoT), cloud computing, and big data (Trappey et al., 2017). Decentralized intelligence helps create intelligent object networking and independent process management, with the interaction of the real and virtual worlds representing a crucial new aspect of the manufacturing and production process (GTAI – Germany Trade & Invest, 2014).

The terms “smart production,” “smart manufacturing,” and “smart factory” are used in Europe, China, and the United States to refer specifically to digital networking of production to create smart manufacturing systems, whereas the equally fashionable term “advanced manufacturing” embraces a broader spectrum of modernization trends in the manufacturing environment (Kagermann et al., 2013).

The scientific interest around these terms is clearly increasing during the last years. For example, this trend can be observed through a literature search using ScienceDirect databases. For this, using the previous keywords in the journal abstract, the results shown in Fig. 2.1 were obtained for the period between the years 2000 and 2017.

Figure 2.1.

Results from Science Direct databases (search keywords: Smart Production; Smart Manufacturing; Smart Factory; Advanced Manufacturing; Date: January 4, 2018).

European Commission (2012) identified six priority areas, with enormous potential for growth and jobs in Europe. Two of these areas are directly relevant to Industry 4.0 (Kagermann et al., 2013): the promotion of “advanced manufacturing technologies” and “key enable technologies.”

PCAST (2011) focuses in its report on advanced manufacturing, a family of activities that (1) depend on the use and coordination of information, automation, computation, software, sensing, and networking, and/or (2) make use of cutting-edge materials and emerging capabilities enabled by the physical and biological sciences, for example, nanotechnology, chemistry, and biology. According to that report, this involves new ways to manufacture existing products, and especially the manufacture of new products emerging from new advanced technologies

Technological change can reduce some risks while aggravating others or even creating new ones (OECD, 2003). ILO (2010) indicates that in the occupational safety health (OSH) field, recent decades have seen significant technological advances in the workplace, which, together with rapid globalization, have transformed work for many throughout the world. The effects of such changes on OSH have also been significant, so that in some cases, more traditional hazards and risks have been reduced or eliminated, for example, through plant automation, but new technologies have also created new risks (ILO, 2010).

Advanced manufacturing processes are characterized by innovative variables of a technological and organizational nature that tend to change with workplaces, processes and conventional work practices, and can generate, as well as traditional occupational risks, other so-called new and emerging risks (NERs) (Brocal and Sebastián, 2015a). This raises new challenges for workers and companies and, in turn, creates political demands, administrative and technical approaches that ensure high levels of safety and health at work (adapted from EU-OSHA, 2013).

The general objective of this chapter is to show a general framework of the emerging risks1 linked with advanced manufacturing processes and technologies. For this, the systemic and occupational nature of said risks is considered.

To achieve this general objective, the chapter is organized in two parts. In the first part, a theoretical basis is developed. This theoretical basis is configured by an explanation of the emerging risk concept, as well as by the development of an overview of advanced manufacturing processes and technologies. Among these manufacturing technologies, three of the most important have been selected in order to provide a broader overview. These three manufacturing technologies are: intelligent manufacturing, IoT-enabled manufacturing, and cloud manufacturing.

In the second part, contents and tools of practical application are exposed. To do this, the main emerging risks are shown first. Among the fields of application of these risks, some of the most important cross-cutting manufacturing technologies have been selected in order to develop them in greater detail. These manufacturing technologies are: automation; human machine interfaces (HMIs), and information and communication technologies (ICTs). Second, one of the main risk governance frameworks is shown. Subsequently, this framework is deployed with two of its main applications on emerging risks: the management and characterization of the risk. Finally, a brief summary of the chapter is presented, accompanied by the main conclusions.

2. Emerging Risk Concept

Risk is defined in many ways (Aven, 2010), and many perspectives on risk are developed and used for specific disciplines and areas (Aven, 2012). However, considering the most common definitions of risk found in scientific standards and literature, Aven (2010) states that the common feature of all these definitions is that the concept of risk comprises events (initiating events, scenarios), consequences (outcomes), and probabilities.

As Aven (2012) believes, though it is impossible to present and discuss all definitions of the risk concept suggested and used in scientific risk fields, the author proposes the categories of definitions/perspectives on risk as used in professional/scientific contexts (Table 2.1 ).

Table 2.1.

Categories of Definitions/Perspectives on Risk as Used in Professional/Scientific Contexts

| Cat. | Definitions/Perspectives |

|---|---|

| 1 | Risk = Expected value (loss) (R = E) |

| 2 | Risk = Probability of an (undesirable) event (R = P) |

| 3 | Risk=Objective Uncertainty (R = OU) |

| 4 | Risk = Uncertainty (R = U) |

| 5 | Risk = Potential/possibility of a loss (R = PO) |

| 6 | Risk = Probability and scenarios/Consequences/Severity of consequences (R = P&C) |

| 7 | Risk = Event or consequence (R = C) |

| 8 | Risk = Consequences/damage/severity of these + Uncertainty (R = C&U) |

| 9 | Risk is the effect of uncertainty on objectives (R = ISO) |

Adapted from Aven, T., 2012. The risk concept—historical and recent development trends, Reliability Engineering and System Safety 99, 33–44. https://doi.org/doi:10.1016/j.ress.2011.11.006.

The ISO 31000:2009 standard (ISO, 2009a) defines risk as the effect of uncertainty on objectives. Likewise (continuing with the definitions of this standard), objectives can have different aspects (such as financial, health and safety, and environmental goals) and can apply at different levels (such as strategic, organization-wide, project, product and process). Risk is often expressed in terms of a combination of the consequences of an event (including changes in circumstances) and the associated likelihood of occurrence(ISO, 2009a).

In the specific field of occupational risk, OHSAS 18001 standard defines risk as the combination of the likelihood of an occurrence of a hazardous event or the exposure and the severity of injury or ill health that can be caused by the event or exposure (Aenor, 2007). And the ISO 45001 standard (the current version is the ISO/DIS 45001.2: 2017) defines an occupational health and safety risk as the combination of the likelihood of an occurrence of a work-related hazardous event or exposure, and the severity of injury or ill health that can be caused by the event or exposure (ISO, 2017a). The standard is currently being developed by a committee of occupational health and safety experts, and will follow other generic management system approaches such as ISO 14001 (ISO, 2015a) and ISO 9001 (ISO, 2015b). It will take into account other International Standards in this area such as OHSAS 18001, the International Labor Organization's ILO-OSH Guidelines, various national standards, and the ILO's international labor standards and conventions (ISO, 2017b). The revision of this new standard, ISO 45001, is in its final stage (Aenor, 2017). The final publication of the standards is expected in March 2018 (ISO, 2017b).

2.1. Emerging Systemic Risk

IRGC (2010a) considers that there are emerging risks of a systemic nature, which typically span more than one country, more than one economic sector, and may have effects across natural, technological, and social systems. These risks may be relatively low in frequency, but they have broad ramifications of human health, safety and security, the environment, economic well-being, and fabric of societies. IRGC (2010b) aims to shed light on emerging risks with a perspective that has three elements: sources of risk, drivers of risk, and governance issues.

IRGC (2010a) defines as emerging a risk that is new, or a familiar risk that becomes apparent in new or unfamiliar conditions. The concept of familiarity assumes the existence of recognizable patterns and management regimes that are relatively stable and have proven to be effective if implemented according to certain rules. By contrast, emerging risks are characterized mainly by uncertainty regarding their potential consequences and/or probabilities of occurrence (IRGC, 2015a).

IRGC (2011) defines three categories of technology-related emerging risks. In Table 2.2 these categories are shown, with their descriptions, dominant features, and examples.

Table 2.2.

Categories of Technology-Related Emerging Risks

| Category | Description | Dominant Feature | Examples |

|---|---|---|---|

| A | Uncertain impacts: Uncertainty resulting from advancing science and technological innovation | Lack of knowledge and experience about consequences that could result from deploying new technology |

|

| B | Systemic impacts: Technological systems with multiple interactions and systemic dependencies | System complexity and interconnectedness: Loss of safety margins within evolving and interacting (complex) systems |

|

| C | Unexpected impacts: Established technologies in evolving environments or contexts | Surprises from knowable risk factors: Unforeseen or changed circumstances |

|

Adapted from International Risk Governance Council (IRGC), 2011. Improving the Management of Emerging Risks. IRGC, Geneva. Available at: www.irgc.org.

Twelve generic factors that may be seen as contributing to the creation of fertile ground from which new risks can emerge (or be amplified) (IRCG, 2010a): Scientific unknowns; Loss of safety margins; Positive feedback; Varying susceptibilities to risk; Conflicts about interests, values, and science; Social dynamics; Technological advances; Temporal complications; Communication; Information asymmetries; Perverse incentives; Malicious motives and acts. These factors are applicable across multiple domains, and before outlining them, it is useful situate them within the context of systems.

2.2. Emerging Occupational Risk

EU-OSHA defines NER through the reports cited as listed following by NER definition. In this definition, unlike the original sources cited (Flaspöler et al., 2005, Brun et al., 2007a, Brun et al., 2007b, Brun et al., 2009), it is the codification (Ci), which in this chapter is called “conditions,” that defines an NER (Brocal et al., 2017).

NER definition: any occupational risk that is both new and increasing:

-

•By “new,” we mean that:

- C1. the risk did not previously exist and is caused by new processes, new technologies, new types of workplace, or social, or organizational change; or,

- C2. a long-standing issue is considered as a new risk due to a change in social or public perceptions; or,

- C3. new scientific knowledge allows a long-standing issue to be identified as a risk.

-

•The risk is “increasing” if the:

- C4. number of hazards leading to the risk is growing; or

- C5. the exposure to the hazard leading to the risk is increasing (exposure level and/or the number of people exposed); or

- C6. the effect of the hazard on workers' health is getting worse (seriousness of health effects and/or the number of people affected).

The NER definition adopted by the EU-OSHA has been integrated into CWA 16649: 2013 (CEN, 2013). However, as Brocal et al. (2017) consider, such integration implies two modifications, a terminological modification and another of interpretation. So, instead of using the term “new and emerging risk,” the term “emerging risk” is employed, which has been defined as “any risk that is both new and/or increasing.”

In this regard, one can deduce that the term “new and emerging risk” has been simplified from “emerging risk” (Brocal et al., 2017). Such simplification can be seen, for example, in the work developed by EU-OSHA (2015). Similarly, Houtman et al. (2016) state that an “emerging OSH risk” is often defined as “any occupational risk that is both new and increasing.”

In any case, as Brocal (2016) indicates, these quotes reveal a clear problem with consensus about terminology and interpretation of the NER concept. Similarly, Flage and Aven (2015) feel that the term “emerging risk” has an intuitive appeal and meaning, although a consistent and consensual definition is lacking.

In addition, the NER definition has been developed without following any risk model reference, thus hindering its use in the NER identification and analysis (Brocal and Sebastián, 2015a, Brocal and Sebastián, 2015b). To solve this problem, Brocal and Sebastián (2015a) have developed a new risk model whose objective is to characterize the NER. Nevertheless, this model has two limitations (Brocal et al., 2017). First, the model does not contemplate the possibility of considering independently the new risks (NR) and increasing risks (IR). Second, this model does not allow monitoring the evolution of NER over time, therefore it is not currently possible to determine, in general, the temporary validity of such risks. In order to solve these problems, Brocal et al. (2017) have developed a theoretical framework for the modeling of the NER that allows its monitoring through the technology lifecycle (TLC), especially in industrial processes.

3. Overview of Advanced Manufacturing Processes and Technologies

Zhu et al. (2013) considered two major classifications of manufacturing processes: the first by Swift and Booker (2013) classifies processes into casting, cutting, forming, and fabrication. The second by Kalpakjian and Schmid (2010) is more comprehensive; they classify processes into casting, machining and finishing, joining, sheet metal, polymer processing, and bulk deformation processes.

As the traditional classifications have some difficulties in the identification of newly developed manufacturing technologies (Zhu et al., 2013), Nassehi et al. (2011) proposed a technology-based classification method consisting of five categories, namely joining, dividing, subtractive, transformative, and additive technologies. Zhu et al. (2013), briefly describe these five categories:

-

•

Joining technology: consists of processes by which two or more workpieces are joined to form a new workpiece;

-

•

Dividing technology: dividing processes are the opposite of joining processes;

-

•

Subtractive technology: subtractive/negative operations are material removal processes, by which material is removed from a single workpiece, resulting in a new workpiece;

-

•

Transformative technology: a single workpiece is used to create another workpiece and the mass does not change;

-

•

Additive technology: material is added to an existing workpiece to build a new workpiece, where the mass of the finished workpiece is greater than before.

Advanced manufacturing relies on new technologies that enable flexibility, agility, and the ability to reconfigure, as for example the following applicable areas: biomanufacturing, semiconductors, advanced materials, additive manufacturing, and nanomanufacturing (Esmaeilian et al., 2016). Emerging technologies can have game-changing impacts on manufacturing models, approaches, concepts, and even businesses (Zhong et al., 2017a).

As An and Ahn (2016) indicate, several organizations have forecasted emerging technologies and reported on their forecasts, so that some well-known forecasts are “Disruptive technologies” (McKinsey Global Institute), “10 Breakthrough Technologies” (MIT), “Next 5 in 5” (IBM), and “Top 10 Strategic Technologies” (Gartner Group). The main results of these forecasts are discussed next.

As McKinsey Global Institute indicates, economically disruptive technologies transform the way we live and work, enable new business models, and provide an opening for new players to upset the established order (Manyika et al., 2013). McKinsey Global Institute considers that the 12 potentially economically disruptive technologies are: Mobile Internet; Automation of knowledge work; IoT; Cloud technology; Advanced robotics; Autonomous and near-autonomous vehicles; Next-generation genomics; Energy storage; 3D printing; Advanced materials; Advanced oil and gas exploration and recovery; and Renewable energy (Manyika et al., 2013).

Every year MIT Technology Review publishes a list containing 10 breakthrough technologies. The list for the year 2017 is as follows (MIT, 2017): Reversing Paralysis; Self-Driving Trucks; Paying with Your Face; Practical Quantum Computers; the 360-Degree Selfie; Hot Solar Cells; Gene Therapy 2.0; the Cell Atlas; Botnets of Things; and Reinforcement Learning.

IBM (2017) considers five innovations that will change our lives in the next 5 years: With artificial intelligence (AI), our words will be a window into our mental health; hyperimaging and AI will give us superhero vision; macroscopes will help us understand Earth's complexity in infinite detail; medical labs “on a chip” will serve as health detectives for tracing disease at the nanoscale; and smart sensors will detect environmental pollution at the speed of light.

Every year Gartner publishes a list containing the Top 10 Strategic Technology Trends. The list for the year 2017 is as follows(Gartner Group, 2017): AI and advanced machine learning; Intelligent Apps; Intelligent Things; Virtual and Augmented Reality; Digital Twin; Blockchain and Distributed Ledgers; Conversational System; Mesh App and Service Architecture; Digital Technology Platforms; and Adaptive Security Architecture.

The evolution of integrated and intelligent manufacturing (i2M) technology is driven not only by the market demand but also by technological advances. There are 10 major technologies (Fig. 2.2 ) that can be identified as the key elements of the new manufacturing paradigm (Chen, 2017).

Figure 2.2.

Ten major technologies for i2M (Chen, 2017).

Zhong et al. (2017a) consider that the three major advanced manufacturing technologies are the following: intelligent manufacturing, IoT-enabled manufacturing, and cloud manufacturing. These manufacturing technologies are briefly described in the following sections.

3.1. Intelligent Manufacturing

Intelligent manufacturing systems represent one of the latest developments in both manufacturing technologies and organization (Dumitrache and Caramihai, 2010). The basic idea involves flexibility in systems, monitoring, and adaptation to changing needs (Kumar, 2017). The targeted objective is to gain the most benefit for product quality, cost reduction, and increase of efficiency in general (Zillner et al., 2016). Qian et al. (2017) consider four objectives in relation to the layer of engineering technology: digitization, intellectualization, cyberization (to develop cyber-physical systems), and automation. At the same time, these authors consider four objectives in relation to enterprise production and operation: agility, high efficiency, environmental sustainability, and safety.

Intelligent manufacturing makes use of advanced computational technologies and the advancements in digital systems and machine learning processes to support decision-making, run self-sufficiently via networks of distributed control, and to self-adjust and self-correct should problems arise (Oliff and Liu, 2017). Systems' theory, communications, and nanotechnologies, all characterized by solid formal supports, have contributed decisively to a transition from the C2 paradigm (Computer-Control) to the C4 paradigm (Computer, Communication, Cognition for Control) (Dumitrache, 2008). Intelligent manufacturing systems represent a reality in the framework of C4 paradigm and should be analyzed and designed as cyber-physical systems (CPSs) (Dumitrache and Caramihai, 2010). Currently, there is an ongoing transformation of classical products and machinery toward CPSs (Becker and Stern, 2016). CPSs link the physical world seamlessly with the virtual world of information technology and software (Sztipanovits and Ying, 2013). Main features of these systems are the real-time data exchange between various technical and computational elements enabled by communication technologies and data processing ability provided by embedded systems (Becker and Stern, 2016).

The introduction of both CPS and the IoT, where things are supposed to initiate both a process of preparation, design, planning, optimization, tasks for tools, and humans if necessary, is leading in a fourth industrial revolution referring to the future (Mrugalska and Wyrwicka, 2017). This idea is represented schematically through Table 2.3 .

Table 2.3.

Production Evolution (Mrugalska and Wyrwicka, 2017)

| Past | Present | Future | |

|---|---|---|---|

| Communication System | Analog | Internet and Intranet | Cyber Physics System and Internet of Things |

| Concept | Neo-Taylorism | Lean Production | Smart Factory |

| Solution | Mechanization and Automation | Automation and Computerization | Virtualization and Integration |

Qian et al. (2017) consider that the intrinsic safety of the manufacturing process as well as enterprise information security must be ensured, and to realize the safe running of manufacturing processes by means of fault diagnoses and self-healing control techniques. For example, with advancements in networking and Internet technologies, cyberattacks on physical systems are becoming a growing phenomenon (DeSmit et al., 2017).

3.2. IoT-Enabled Manufacturing

Tarkoma and Ailisto (2013) indicate that recent advances in radio, network, mobile, and cloud technologies have supported the development of the first-generation IoT services and products. These authors consider that IoT as a concept is not new as it was proposed over 10 years ago in the MIT Auto-ID Center, so that the concept has since gained momentum and importance, and now it is considered in Europe, the United States, and Asia, not only on the implementation and deployment level but also on the societal level.

Early IoT applications are based on radio frequency identification (RFID) and wireless sensor network (WSN) technologies, and deliver tangible benefits in several areas, including manufacturing, logistics, trade, retail, and green/sustainable applications, as well as in other sectors (Kefalakis et al., 2016). The adoption of IoT in manufacturing enables the transition of traditional manufacturing systems into modern digitalized ones, generating significant economic opportunities through industries' reshaping (Mourtzis et al., 2016). For example, IoT technologies such as RFID and wireless communications are used for capturing real-time machine status (Zhong et al., 2017b). Industrial IoT devices for manufacturing include sensors/actuators, computers with wireless networks, etc., which have contributed significantly to different aspects of manufacturing such as automation and tracking (He et al., 2017). Trappey el al. (2017) divides the IoT architecture into four layers, as briefly described in Table 2.4 .

Table 2.4.

Brief Description of the Four Layers of the IoT Architecture

| Layer | Description |

|---|---|

| Perception | Perception deals with the types of sensors (e.g., sensors are used to detect temperature, weight, motion, vibration, etc.) and actuators that help the physical object to perceive. Perception is used in upper layers to achieve the final goal of micro intelligence at the application layer. |

| Transmission | Transmission is the second layer in the IoT ecosystem. The next step after perception (collection of sensor information) is to transmit the information to the upper layers. |

| Computation | The computation layer describes means of receiving data, processing data, making decisions, and delivering the decisions to the application layer. The computation layer consists of hardware, software, algorithms, cloud computing, big data analysis, and security. |

| Application | The application layer provides tactical understanding by using information collected and transmitted from lower layers. |

Adapted from Trappey, A.J.C., Trappey, C.V., Govindarajan, U.H., Chuang, A.C., Sun, J.J., 2017. A review of essential standards and patent landscapes for the Internet of Things: a key enabler for Industry 4.0. Advanced Engineering Informatics 33, 208–229. https://doi.org/10.1016/j.aei.2016.11.007.

IoT-enabled manufacturing is an advanced principle where typical production resources are converted into smart objects that are able to sense, interconnect, and interact with each other to automatically carry out the manufacturing activities (Zhong, 2017). Considering the work developed by Tao et al. (2014), it can achieve the complete connection between terminal devices and the enterprise information management system for the automatic control of the IoT-enabled manufacturing execution in workshops. Therefore, three functions should be addressed: the access, identification, and control of the physical manufacturing execution process from materials and semifinished products to the final products (Tao et al., 2014).

3.3. Cloud Manufacturing

Computers play an essential role in increasing efficiency, capability, and adaptability of manufacturing systems, as for example: computer integrated manufacturing, distributed manufacturing, agile manufacturing, CPS, and cloud manufacturing (Yu et al., 2015).

Cloud computing is emerging as one of the major enablers for the manufacturing industry; it can transform the traditional manufacturing business model, help it to align product innovation with business strategy, and create intelligent factory networks that encourage effective collaboration (Xu, 2012). In general, cloud-related manufacturing research can be categorized into two types: cloud computing in manufacturing industry, and cloud manufacturing systems (Wang et al., 2017).

In 2010, Bohu et al. (2010) put forward the concept of cloud manufacturing (Xin-yu and Wei-jia, 2011). Cloud manufacturing is a new, networked, and intelligent manufacturing model that is service oriented, knowledge based, high performance, and energy efficient. In this model, state-of-the-art technologies such as informatized manufacturing, cloud computing, IoT, semantic Web, and high-performance computing are integrated in order to provide secure, reliable, and high-quality on-demand services at low prices for those involved in the whole manufacturing lifecycle (Bohu et al., 2010).

Ooi et al. (2018) note that cloud technology enables on-demand service and resource access, which revolutionized the computing service market. These authors consider that the flexibility and borderless resources provided by cloud technology motivated manufacturers to take advantage of the cloud application service in an effort to improve and innovate their manufacturing process. The cloud application service provided manufacturers with cloud-based software application, Web-based management dashboard, and cloud-based collaboration, which bring the manufacturing process, management, and monitoring to the cloud, hence the birth of cloud manufacturing (Ooi et al., 2018). Compared with cloud computing systems, one of the biggest challenges cloud manufacturing faces involves numerous types of physical resources, e.g., machine tools and robots (Wang et al., 2017).

According to Yu et al. (2015), cloud manufacturing may either apply or not apply the CPS′s cyber architecture. In other words, cyber systems in cloud manufacturing may choose to be networked or not, and more significantly, cloud manufacturing tries to imitate the paradigm of cloud computing in which design, manufacturing, and other resources are encapsulated as services (Yu et al., 2015).

Mobile CPS has emerged with advances in cloud computing and wireless sensing technologies (Chen, 2017). Liu et al. (2017) consider that a CPS for manufacturing is not a manufacturing cloud if it does not use virtualization technique in cloud computing and service-oriented architecture in service computing. On the other hand, these authors note that a manufacturing cloud is not a CPS if it does not have components for direct interactions with machine tools and other physical devices.

Liu et al. (2017) point out that it is necessary to integrate cloud manufacturing and CPS for providing manufacturing services, which can directly operate and monitor machine tools in a manufacturing cloud. As a result, said authors indicate that a new paradigm of a cyber physical manufacturing cloud (CPMC) is created, so that a CPMC is a type of manufacturing cloud where machining tools can be directly monitored and operated over the Internet from clouds (Liu et al., 2017).

4. Emerging Risks Linked With Advanced Manufacturing Processes and Technologies

This section discusses the main emerging risks linked with advanced manufacturing processes and technologies. First, a general framework on emerging systemic risks related to new technologies is shown. Next, this framework is expanded specifically to the OSH field. Third, some of the most important cross-cutting manufacturing technologies have been selected in order to develop them in greater detail. These manufacturing technologies are: automation, HMIs, and ICTs. These manufacturing technologies are related to both occupational accidents and major accidents. Therefore, the related emerging risks have a broad nature.

4.1. Emerging Systemic Risks

In the report on emerging systemic risks developed by the OECD (2003), five categories of such risks are addressed: natural disasters, industrial accidents, infectious diseases, terrorism, and food safety. According to this report, three aspects of emerging technologies will influence risk: connectedness, the speed and pervasiveness of technological change, and the fundamental changes in the landscape they might induce. The analysis and main conclusions from OECD (2003) hold true today, which underlines the need for policy makers to pay added attention to risks that are ever more present and ominous (OECD, 2011).

CEN workshop agreement (CWA) on managing emerging technology-related risks (CWA 16,649:2013) is one of the main results of the European research project iNTeg-Risk (“Early Recognition, Monitoring and Integrated Management of Emerging, New Technology related Risks”). CWA 16649:2013 gives guidance on steps for applying/implementing the proposed emerging risk management framework (ERMF) in industrial organizations. This CWA has a number of additional (informative) parts dealing with emerging risks related to (A) new technologies, (B) new materials, (C) new production processes and new production networks, (D) new policies, (E) uncertainties in measurements and characterization, (F) factors of emergence, (G) used tools, and (H) sample list of emerging risk. Fig. 2.3 shows a diagram with the relationships between annexes A, B, C, and D.

Figure 2.3.

Relations among the informative Annexes A, B, C and D.

Adapted from CWA 16649:2013.

iNTeg-Risk 17 of such technologies are proposed as so-called emerging risk representative applications (ERRAs). These ERRAs are considered as sources of “multiple risk” in iNTeg-Risk Project (Jovanović and Baloš, 2013). Among these 17 ERRAs, Table 2.5 includes four application examples in the field of advanced manufacturing processes and technologies. Each of these four examples is linked to one of the annexes shown in Fig. 2.3 (ERRA group name).

Table 2.5.

Application Examples in the Field of Advanced Manufacturing Processes and Technologies

| ERRA Group Name | ERRA |

|---|---|

| New Technologies | Emerging risks related to the industrial use of automated and unmanned surveillance of industrial infrastructure. |

| New Materials and Products | Emerging risks related to development and use of advanced engineering materials, composite materials. |

| New Technologies and Production Networks | Remote operation in environmentally sensitive areas. |

| Related Policies | Emerging risks related to interaction between natural hazards and technologies at the community level. |

Adapted from CWA 16649:2013.

4.2. Emerging Occupational Risks

EU-OSHA took the first steps in the field of NERs with the publication of four specific reports on emerging physical risks (Flaspöler et al., 2005), emerging biological risks (Brun et al., 2007a), emerging psychosocial risks (Brun et al., 2007b), and emerging chemical risks (Brun et al., 2009). The methodology used in these reports to identify NERs was based on the Delphi method, using the Likert 5-point scale to classify such risks. For each risk identified, the mean values (MVs) and the standard deviations were calculated. In this way, each risk was classified as “risk strongly agreed as emerging,” “risk agreed as emerging,” “undecided,” “there is agreement that the risk is not emerging,” or “there is strong agreement that the risk is not emerging.”

The top 10 NERs of each of these reports are shown in Table 2.6, Table 2.7, Table 2.8, Table 2.9 . For this, the MVs have been taken into account. These NERs are classified as “risks strongly agreed as emerging” and “risks agreed as emerging.”

Table 2.6.

The Top 10 Emerging Physical Risks (MV > 4: Risk Strongly Agreed as Emerging; 3.15 < MV ≤ 4: Risk Agreed as Emerging) (Flaspöler et al., 2005)

| The Top 10 Emerging Physical Risks | ||

|---|---|---|

| No | Description | MV |

| 1 | Lack of physical activity (e.g., prolonged sitting at the workplace, during business trips, or due to the use of automated systems, etc.). | 4.57 |

| 2 | Combined exposure to vibration and awkward postures. | 4.56 |

| 3 | Poor awareness of thermal risks among low-status worker groups exposed to unfavorable thermal conditions (e.g., migrant workers in agriculture and construction areas working overtime in hot/cold areas such as greenhouses/cold stores). | 4.50 |

| 4 | Multifactorial risks (e.g., call centers: combined effects of poor ergonomic design, poor work organization, and mental and emotional demands. | 4.42 |

| 5 | Combined exposure to musculoskeletal disorders (MSD) risk factors and psychosocial risk factors (e.g., fear of future, insecurity). | 4.43 |

| 6 | Thermal discomfort (there are prescriptions against thermal stress but not against thermal discomfort at industrial workplaces). | 4.40 |

| 7 | Combined exposure to vibration and muscular work. | 4.38 |

| 8 | Complexity of new technologies, new work processes, and human machine- interfaces leading to increased mental and emotional strain. | 4.35 |

| 9 | Insufficient protection of high-risk groups (older workers, low-status workers, foreign workforce, etc.) against long-standing ergonomic risks. | 4.21 |

| 10 | General increase of exposure to UV radiation (during leisure time; occupational outdoor activities; new UV technologies at the workplace) increasing the sensitivity to UV radiation at the workplace. | 4.17 |

Table 2.7.

he Top 10 Emerging Psychosocial Risks (MV > 4: Risk Strongly Agreed as Emerging; 3.25 < MV ≤ 4: Risk Agreed as Emerging) (Brun et al., 2007b)

| The Top 10 Emerging Psychosocial Risks | ||

|---|---|---|

| No | Description | MV |

| 1 | Precarious contracts in the context of unstable labor market. | 4.56 |

| 2 | Increased worker vulnerability in the context of globalization. | 4.38 |

| 3 | New forms of employment contracts. | 4.25 |

| 4 | Feeling of job insecurity. | 4.25 |

| 5 | Aging workforce. | 4.19 |

| 6 | Long working hours. | 4.13 |

| 7 | Work intensification. | 4.07 |

| 8 | Lean production and outsourcing. | 4.06 |

| 9 | High emotional demands at work. | 4.00 |

| 10 | Poor work−life balance. | 4.00 |

Table 2.8.

The Top 10 Emerging Biological Risks (MV > 4: Risk Strongly Agreed as Emerging; 3.25 < MV ≤ 4: Risk Agreed as Emerging) (Brun et al., 2007a)

| The Top 10 Emerging Biological Risks | ||

|---|---|---|

| No | Description | MV |

| 1 | Globalization leading to epidemics of old and new pathogens (e.g., severe acute respiratory syndrome (SARS), avian flu, viral hemorrhagic fever, tuberculosis, human immunodeficiency virus (HIV), hepatitis C, hepatitis B):

The risk is often underestimated, which leads to a lack of preventive measures. |

4.51 |

| 2 | Poor or difficult assessment of biological risks. | 4.06 |

| 3 | General increased use of antibiotics for human health care and for animal breeding in the food industry leading to the appearance of drug-resistant pathogens (e.g., methicillin-resistant Staphylococcus aureus (MRSA), tubercule bacillius). Health effects observed: increase in staff infected with MRSA in Western hospitals; increasing antibiotic resistance of livestock farmers and in the population in general. | 3.97 |

| 4 | Lack of information on biological risks in different workplaces (e.g., office workplaces, agriculture). | 3.97 |

| 5 | Poor maintenance of air-conditioning (whose use is increasing) and water systems (e.g., legionella, aspergillosis in hospitals). New knowledge about the presence of legionella will help the correct diagnosis of symptoms so far wrongly attributed to other diseases like flu. | 3.92 |

| 6 | Inadequate training, poor knowledge of OSH, or even poor basic awareness of risks of local authorities' staff (e.g., sewage, excavations, waste collection, etc.). | 3.92 |

| 7 | Biohazards in waste treatment plants (e.g., selective sorting, manufacture of compost) leading to allergies, infectious diseases (bacteria, viruses), toxinic diseases (endotoxins, mycotoxins), and cancers (oncogenes). Especially in composting facilities where there is a wide variety of microorganisms present at the different stages of the composting process, the risks are not completely identified yet. | 3.89 |

| 8 | Bioaerosols and chemicals, the combined effects of which have been very little studied but lead to allergies. More knowledge will help identify the real multifactorial causes of symptoms for which monocausal explanations have been given so far. | 3.81 |

| 9 | Endotoxins: High concentrations in various industrial settings (e.g., in workplaces exposed to organic materials (straw, wood, cotton dust), waste treatment, poultry houses, swine confinement buildings) leading to asthma, loss of lung function, etc. | 3.81 |

| 10 | Molds in indoor workplaces due to new construction methods and materials, due to the aim of saving energy and due to the lack of maintenance: Exposure to fungal spores for office workers and especially workers involved in building restoration, leading to sensitization and allergies. | 3.78 |

Table 2.9.

The Top 10 Emerging Chemical Risks (MV > 4: Risk Strongly Agreed as Emerging; 3.25 < MV ≤ 4: Risk Agreed as Emerging) (Brun et al., 2009)

| The Top 10 Emerging Chemical Risks | ||

|---|---|---|

| No | Description | MV |

| 1 | Nanoparticles and ultrafine particles: emerging risks due to increasing (new) industrial applications creating ultrafine particles (e.g., laser treatment of material) and nanoparticles, to lack of knowledge on toxicity of ultrafine particles leading to inappropriate or insufficient protective measures, to poor risk assessment, and to unfavorable workplace design and environment. Health effects of ultrafine particles in general may have been underestimated so far. Potential health effects: inflammatory lung diseases, secondary effects on cardiovascular system (e.g., heart attack, stroke), tumors. | 4.60 |

| 2 | Poor control of chemical risks in SMEs. | 4.39 |

| 3 | Outsourcing (e.g., for cleaning and maintenance activities) performed by subcontracted workers with poor knowledge of chemical risks. | 4.34 |

| 4 | Increasing use of epoxy resins (e.g., in the construction of wings for wind turbines as power generators or in the cabins of large aircraft, or on construction sites). | 4.14 |

| 5 | Exposure to dangerous substances in the treatment of domestic, clinical, and industrial waste. | 4.11 |

| 6 | Dermal exposure leading to skin diseases. | 4.11 |

| 7 | Diesel exhaust. | 4.02 |

| 8 | Isocyanates leading to allergic reactions: exposure occurs not only at the production stage but also during further processing (e.g., thermal or chemical degradation of polyurethane, grinding and welding of products containing polyurethane, for example, in car repair shops). | 4.02 |

| 9 | Man-made mineral fibers (e.g., refractory ceramic fibers, carbon/graphite fibers, or composites): lack of knowledge on health effects of (new) fiber substitutes for asbestos, the use of which is increasing and for which exposure levels seem high enough for concern in certain areas. Potential health effects: respiratory diseases, cancer. |

3.96 |

| 10 | Construction industry (civil and industrial sector, including demolition, rebuilding, and renovation activities): exposure to dangerous substances (crystalline silica dust, asbestos, wood dust, diesel engine exhaust, welding fumes) leading to occupational cancers. | 3.96 |

Brocal and Sebastián (2015b) analyzed the NERs included in the four specific reports on emerging physical risks (Flaspöler et al., 2005), emerging biological risks (Brun et al., 2007a), emerging psychosocial risks (Brun et al., 2007b), and emerging chemical risks (Brun et al., 2009). These authors considered only the NERs classified as “risk strongly agreed as emerging” and “risk agreed as emerging.” Each risk classified as “undecided,” “there is agreement that the risk is not emerging,” and “there is strong agreement that the risk is not emerging,” cannot be considered as NER. Among the results obtained, Brocal and Sebastián (2015b) identified a set of technological aspects (Table 2.10 ) and organizational aspects (Table 2.11 ) linked to advanced manufacturing processes.

Table 2.10.

Identification of Technological Aspects Linked to Advanced Manufacturing Processes (Brocal and Sebastián, 2015b)

| Classification | Technological Aspects |

|---|---|

| Technical | Automation; Damping properties of antivibration devices; Electromagnetic compatibility; Electronic article surveillance and similar devices; Human-machine interfaces; Latest generation of safety systems; New LED technology; New processes; New technologies; Personal protective equipment; Poor ergonomic design; Sources of ionizing radiation; Special protective clothing; Visual display units. |

| Material | Acrylate monomers (drying inks); Additives (foods and textiles); Biocides; Bituminous materials; Combination of carcinogenic substances; Crystalline silica; Disinfection and cleaning agents; Endocrine disruptors; Enzymes; Epoxy resins; Hardeners (polymer production); Hydrocarbons mixtures; Isocyanates; Magnesium alloys; Man-made fibers; Metals (ions of nickel, cobalt, chromium); New products and new applications; Nitrogen monoxide; Organic acid anhydrides; Organic solvents; Persistent organic pollutants; Polymers; Powder paints; Replacements for trichloroethylene (degreasing); Reprotoxicants; Water-based paints and solvents. |

| Biological | Aspergillus; Bioaerosols and chemical risks; Endotoxins; Environmental allergens; Fungal spores; Legionella; Molds; Mycotoxins. |

Table 2.11.

Identification of Organizational Aspects Linked to Advanced Manufacturing Processes (Brocal and Sebastián, 2015b)

| Classification | Organizational Aspects |

|---|---|

| NERs Physical | Increased work space; Insufficient protection of high-risk groups; Lack of physical activity; More hours (longer working hours); Older workers and physical demands; Poor awareness of thermal risks among low-status worker groups exposed to unfavorable thermal conditions. |

| NERs Biological | Improper methods of measurement or measurement equipment/analysis to biological agents; Inadequate or lack of emergency preparedness and/or response plan concerning biological risks; Lack of information on biological hazards; Lack or poor maintenance of the workplace; Misunderstanding of hygiene; Poor risk assessment. |

| NERs Chemical | Importance given to psychosocial factors; Increasing importation of chemicals not complying with EU regulations; Migrant workers; Outsourcing (e.g., for cleaning and maintenance activities) performed by subcontracted workers with poor knowledge of chemical risks; Poor control of chemical risk (on SMEs); Workplaces poorly supervised. |

| NERs Psychosocial | Aging workforce/workers elderly population; Changing contexts, new roles, skills, etc.; Disability; Emotional demands; Ethical conflicts at work; General deterioration of psychosocial working conditions, deteriorating industrial relations and social dialogue, interpersonal conflicts and problems, more individuality in the workplace; Imbalance/problems reconciling family and working life; Intensification of work, high workload/work pressure; Job insecurity; Lack of effectiveness of the OSH management; Long working days; Mobility in the labor market; Unemployment, downsizing, difficulty reentering the labor market/employability, job market unstable, precarious contracts, etc.; Violence and bullying; Vulnerability of the worker; Workers from other cultures; integration of people from other cultural backgrounds. |

In the prospective study on NER associated with new technologies in 2020 (Ellwood et al., 2014), the key technologies that may be introduced in green jobs by 2020, which may lead to NERs in the workplace, are the following: wind energy (industrial scale); green construction technologies (buildings); bioenergy and the energy applications of biotechnology; waste processing; green transport; green manufacturing technologies and processes, including robotics and automation; electricity transmission, distribution, and storage, and domestic and small-scale renewable energy; and nanotechnologies and nanomaterials. It is expected that by 2020 approximately 20% of all goods manufactured around the world will be based to some extent on the use of nanotechnology (ILO, 2010).

In the manufacturing sector, the following OSH issues in particular need to be considered (this list is not comprehensive) (Ellwood et al., 2014):

-

•

New processes and materials leading to potential exposure to new (green) substances, including nanomaterials, or substances used or emitted (including dust) from new (green) manufacturing processes;

-

•

The extent of chemical use and the potential for exposure as manufacturing is distributed to smaller units as a result of rapid manufacturing techniques (3D printing);

-

•

The difficulty in monitoring OSH in distributed manufacturing taking place in smaller businesses;

-

•

The increasing use of lasers in techniques such as rapid manufacturing; the potential physical risks from human-robot interaction as robots gain increasing autonomy and become free-roaming;

-

•

Potential psychosocial risks: (a) the high cognitive load of the HMI, “lean” production and just-in-time principles all have the potential to contribute to job intensity and pressure and to result in psychosocial problems; (b) the potential effect of renewable energy, with its intermittent nature currently, on shift work in those companies that take interruptible supplies, resulting in more unpredictable working hours;

-

•

Workers possibly resorting to human performance-enhancing technologies as they feel the need to keep up with coworkers, and maybe even with robots (this could also be a feature of other sectors); and

-

•

A focus on safety as opposed to health in competitive scenarios owing to the greater impact of accidents on productivity (this could also be a feature of other sectors).

Cross-cutting issues are inevitably more general than those concerning specific technologies, but they are important, often more so. In the field of manufacturing processes, the following cross-cutting technologies can be specially considered (based on the study by Ellwood et al., (2014)):

-

•

Rapid innovation: it may lead to a variety of OSH risks, with new materials and new processes, and little time to learn how to use them safely;

-

•

New materials: they have the potential for major unexpected impacts on health and environment: nanomaterials, new insulating materials, new composites, smart materials, new organisms, biofuels, and by-products;

-

•

Automation: it is most likely to be very positive for safety in the long term, but absolute reliability is essential;

-

•

Human-machine and human-ICT interfaces: they can give rise to complex risks (e.g., ergonomics and high cognitive load) and overreliance on ICT.

4.3. Specific Manufacturing Technologies

The automation of manufacturing processes can produce emerging risks, linked both to the process and a whole (system), and to specific components, such as robots, HMIs, and ICTs (Brocal et al., 2018).

In this way, among the different manufacturing technologies that have been studied throughout this chapter, automation, HMIs, and ICTs can be selected in order to expand them as possible sources of emerging risks.

Ellwood et al., (2014) indicate that in the field of manufacturing processes, such technologies can be considered as cross-cutting technologies. Therefore, studying them can expand the overview of emerging risks.

4.4. Automation

Automation is the growing phenomenon of human labor being replaced by machinery and robotics (Euromonitor International, 2013). Industrial automation is a vast and diverse discipline that encompasses processes, machinery, electronics, software, and information systems working together toward a common set of goals: increased production, improved quality, lower costs, and maximum flexibility (Mehta and Jaganmohan, 2014).

The reasons to automate manufacturing processes include increased quality and efficiency demands, as well as the presence of hazardous working conditions and the high cost of specialized manual laborers (Botti et al., 2017). Granell et al. (2006) conducted a survey with the aim of discovering the perception of production managers and manufacturing engineers working in industry about concepts such as levels of automation and automation strategy, and to determine the current status of manufacturing and automation issues. The sample was derived from the Association of Swedish Engineering Industries. The factors and results when making decisions about automation are shown in Table 2.12 .

Table 2.12.

Questions About Automation Decisions (Granell et al., 2006)

| Parameter | Percentage “Very Low and Low Degree” (%) | Percentage “High Degree and Very High Degree” (%) | Don't Know |

|---|---|---|---|

| Quality | 4.8 | 95.2 | – |

| Work environment | 11.3 | 88.7 | – |

| Rationalization | 14.5 | 85.5 | – |

| Financial | 16.1 | 83.8 | – |

| Production capacity | 21.0 | 79.1 | – |

| Risk analysis | 24.2 | 74.2 | – |

| Volume | 30.6 | 69.3 | – |

| Time perspective | 30.7 | 66.1 | 3.2% |

| Available workforce | 58.1 | 42.0 | – |

In the expert forecast on emerging physical risks related to OSH published by EU-OSHA (Flaspöler et al., 2005), these emerging risks related to automation were identified: “automation leading to an increase in occupational accidents in maintenance and production tasks” and “automation leading to poor job content (repetitive and monotonous work) and consequently to Musculoskeletal Disorders (MSDs) and stress.” Thus, the two NERs above can be classified into two groups, in light of their consequences (Brocal et al., 2018):

-

a.

Accident risks: Flaspöler et al. (2010) state that increased automation involves an increased risk of accidents from human errors, and they usually affect users, but—especially in the case of high-risk industries—have the potential for serious consequences beyond the operator to include fellow workers, the community at large, and the environment. With this increased automation, operator tasks have been reduced from directly controlling the process to monitoring the control systems and controlling them (Chidambaram, 2016). This drop in hands-on knowledge and responsibility can lead to a lack of sufficient understanding of the underlying process, which can in turn lead to an accident due to someone doing something inappropriate or not knowing what to do when something goes wrong (Stacey et al., 2017). New technologies, when introduced poorly, entail the risk of increasing operators' mental workload and also of reducing their degree of control over the task, so that if the measures taken are not appropriate increases the risk of negative health effects such as stress and is likely to result in overreliance on automated safety systems (Flaspöler et al., 2010).

-

b.

Psychosocial and musculoskeletal risks: these risks are intimately related, and can be studied together or independently, depending on prevention targets. From the joint perspective on new and emerging risks, Flaspöler et al. (2010) states that in automated processes, psychosocial and musculoskeletal problems are caused by reduced physical activity, more static postures, and higher mental workload (e.g., when monitoring and controlling); less privacy at work (as technology allows closer and more intrusive supervision); and more decision-making problems.

From the latest EU-OSHA European Survey of Enterprises on New and Emerging Risks (ESENER 2)2 conducted in 2014 (EU-OSHA, 2014), and from the analysis of the survey performed by Irastorza et al. (2016), one can see that the risk of accidents with machines or hand tools is the most frequently reported risk factor in mining and quarrying (86% of establishments in the sector in the EU-28); water supply, sewerage, waste management and remediation activities (83%); construction (82%); electricity, gas, steam, and air conditioning supply (81%); agriculture, forestry and fishing (78%); and manufacturing (77%).

In the ESENER 2 analysis conducted by Irastorza et al. (2016), the measures to prevent psychosocial risks are generally less likely to be implemented in construction and manufacturing, as well as in agriculture, forestry, and fishing. The two most frequently reported psychosocial risk factors across all sectors are: “Having to deal with difficult customers, patients, pupils, etc.” and “Time pressure.” Regarding musculoskeletal problems, Irastorza et al. (2016) synthesize that in the manufacturing sector, after risk of “accidents with machines or hand tools 77%,” the most frequent risk factor was “repetitive hand or arm movements (58%).” Stacey et al. (2017) indicate that use of computers and automated systems at work leads to immobile body postures and physical inactivity at work. Physical inactivity is associated with increased health risks such as coronary heart disease, being overweight and obesity, certain types of cancers, and psychological disorders such as depression and anxiety (Stacey et al., 2017).

4.5. HMIs and ICTs

The basic requirements for system control, including networks and HMIs, are introduced together with basic principles of safety and guarding for automation systems (Wilson, 2015). The HMI governs the flow of information from the machine to the user (in terms of displays, warning sounds, etc.) and from the user to the machine (in terms of input or control devices such as keyboards, switches, levers, etc.) (Flaspöler et al., 2010).

The use of ICT is radically changing the collective experience of work, from a group of people who interact physically to a dispersed community of contacts, whose interaction may be more ad hoc (Eurofound, 2016). As Messenger and Lutz (2015) note, forms of ICT, like smartphones and tablets, promise historic changes in the way we work, as they provide new possibilities for working anytime and anywhere. This new spatial independence changes the role of technology in the work environment, bringing both new opportunities and new challenges (Messenger and Lutz, 2015).

Increasing complexity and increasing use of ICTs in automated manufacturing has led to HMI issues (Ellwood et al., 2014). ICT, including ICT-enabled technologies (ICT-ETs) such as robotics and AI, are likely to have major impacts on the nature and location of work over the next 10 years (Stacey et al., 2017). How humans will react to the continuous high cognitive load of increasingly complex HMIs is still unknown (Ellwood et al., 2014). Workers are more likely to make mistakes due to a poorly designed HMI (Stacey et al., 2017).

There is also evidence that over the next decade there are likely to be significant and accelerating changes in relation to ICT-ETs, which will considerably change the nature of work across Europe and affect most people in some way (Stacey et al., 2017). The expert forecast on emerging physical risks related to OSH published by the EU-OSHA (Flaspöler et al., 2005) states that a poor design of the interface may result in increased mental and emotional demands on the operator. Hence a potential increase in the incidence of stress, human errors, and accidents.

Flaspöler et al. (2010) published a report that aimed to follow up the results obtained in this expert forecast. This report further researched HMI as an emerging risk, exploring whether complexity of HMIs leads to safety and health risks such as increased mental and emotional strain for users. Thus, the conclusions drawn in the report that merit mention include:

-

•

The design of HMI has important consequences for health and safety at work because of the growing potential for accidents and ill poor health for machine operators;

-

•

Deficiencies in the HMI present two different risks: (a) psychosocial risk (stress can result from cognitive overload or underload); and (b) accident risk (occupational accidents and major accidents can result from operating errors);

-

•

The majority of machine users work in SMEs, mostly in manufacturing.

According to Koshti and Joshi (2007), many will recognize the most typical HMI “issues,” as shown in Table 2.13 .

Table 2.13.

The Most Typical HMI “Issues”

| HMI - Issues | Description |

|---|---|

| Display Fragmentation | The user must constantly switch between screens to perform the steps required by a single procedure. |

| Display Confusion | This is the reverse problem, when too much information is presented on the same screen, with no obvious purpose or structure. |

| Inconsistent Controls | Similar controllable objects that react differently depending on which display they are located, or conversely, many dissimilar controls all related to the same task. |

| Irrelevant Operational Steps | Additional procedural steps unrelated to the equipment being controlled, but required by internal functions of the control system. This happens frequently when users are forced through several levels of submenus in order to reach the desired action. |

| Slow Response | Although computer performance keeps improving, software complexity increases at the same rate. The problem of slow response to user actions will usually be inferior during a plant upset, precisely when fast response is the most important. |

| Alarm Overload | This happens when operators are deluged with system messages and alarms. The determination of the cause of equipment “trip” becomes a painstaking investigation through interminable alarm logs. |

| Maintain and Modify | This is perhaps the area where recent systems have improved the most. However, application programmers still require significant time investment to modify or expand existing systems. |

Adapted from Koshti, V.M., Joshi, S.M., 2007. Design of human machine interface for plc based automation system, IFAC Proceedings Volumes 40 (18), 343–346. https://doi.org/10.3182/20070927-4-RO-3905.00057.

5. Risk Governance

IRGC (2005) puts forward an integrated analytic framework for risk governance that provides guidance for the development of comprehensive assessment and management strategies to cope with risks, in particular at the global level.

The Council of the Society for Risk Analysis (SRA) has developed a glossary about key generic concepts within the field of risk analysis (SRA, 2015). The glossary terms are divided into three categories: (1) Terminology on basic concepts; (2) Terminology on related concepts, methods, procedures; and (3) Terminology on risk management actions. The definition of risk governance is one of these key terms. Its definition is the following: risk governance as the application of governance principles to the identification, assessment, management, and communication of risk. Governance refers to the actions, processes, traditions, and institutions by which authority is exercised and decisions are taken and implemented. Risk governance includes the totality of actors, rules, conventions, processes, and mechanisms concerned with how relevant risk information is collected, analyzed, and communicated and management decisions are taken.

IRGC Risk Governance Framework (IRGC, 2005) is illustrated in Fig. 2.4 . This framework is divided into three main phases: preevaluation, appraisal, and management.

Figure 2.4.

IRGC Risk Governance framework (IRGC, 2005).

A fourth phase that includes the characterization and evaluation of risk is added. IRGC (2005) places this phase between the appraisal and management phases and, depending on whether those charged with the assessment or those responsible for management are better equipped to perform the associated tasks, it can be assigned to either of them—thus concluding the appraisal phase or marking the start of the management phase. The risk process has communication as a companion to all phases of addressing and handling risk and is itself of a cyclical nature (IRGC, 2005).

The risk science and safety literature and leaders in the study of human behavior agree that in many organizations, there is not enough effective communication (IRGC, 2011). However, the clear sequence of phases and steps offered by this process is primarily a logical and functional one and will not always correspond to reality (IRGC, 2005).

IRGC Risk Governance Framework (IRGC, 2005) is a worthwhile basis for diagnosing governance deficits, and is broad and flexible enough to be adapted to diverse governance issues and contexts. Thereby, various organizations use this framework to structure their thinking and inspire guidelines, roadmaps, or models, for example (IRGC, 2017): US Joint Chiefs of Staff; United States Nuclear Regulatory Commission; US Department of Homeland Security; European Commission/Institutions of the European Union; CEN Workshop Agreement CWA 16649: 2013 on managing emerging technology-related risks; SAFE FOODS; and Health Council of the Netherlands.

5.1. Risk Management

Since the publication of the IRGC Framework, other guidance documents or frameworks have been published, such as ISO 31000:2009, Risk management – Principles and Guidelines (IRGC, 2017).

ISO 31000:2009 standard provides principles and generic guidelines on risk management, and it can be used by any public, private, or community enterprise, association, group, or individual. Therefore, ISO 31000:2009 is not specific to any industry or sector. It can be applied throughout the life of an organization, and to a wide range of activities, including strategies and decisions, operations, processes, functions, projects, products, services, and assets. Likewise, ISO 31000:2009 can be applied to any type of risk, whatever its nature, whether having positive or negative consequences (ISO, 2009a).

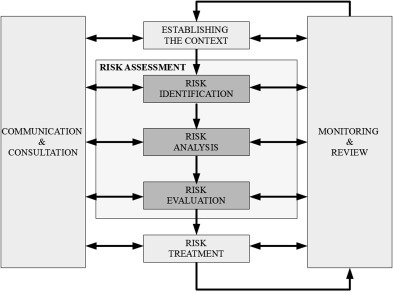

ISO 31000:2009 standard defines risk management as coordinated activities to direct and control an organization with regard to risk. This process includes the activities shown in Fig. 2.5 . SRA (2015) defines risk management as those activities to handle risk such as prevention, mitigation, adaptation, or sharing. It often includes trade-offs between costs and benefits of risk reduction and choice of a level of tolerable risk.

Figure 2.5.

Risk management process (ISO 31000:2009).

Among these activities (Fig. 2.5), the risk assessment process can be considered key to successful risk management. ISO 31000:2009 standard defines risk assessment as the overall process of risk identification, risk analysis, and risk evaluation. SRA (2015) defines risk assessment as systematic process to comprehend the nature of risk, express and evaluate risk, with the available knowledge.

The perspectives of the glossaries included in ISO 31000: 2009 and SRA (2015) should be considered different. In this regard, SRA (2015) indicates that its glossary is unique in its approach compared to existing risk analysis–related glossaries (including the ISO 31000 on risk management terminology), with its incorporation of different perspectives and its between overall qualitative concepts and their measurements.

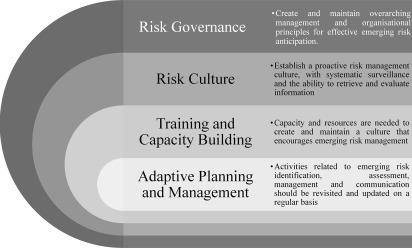

5.2. Emerging Risk Management

In the case of emerging risks, IRGC (2011) focuses on these risks in technology and industry. Such focus is on how to overcome the major obstacles that commonly prevent organizations from improving their emerging risk management. For this, IRGC (2011) presents 11 themes for the three categories of risk A, B, and C described in Table 2.2. Each theme derives from one obstacle and is described in such a way as to provide clarity and operational significance for managers who have the task of identifying, assessing, evaluating, prioritizing, and managing the early phases of development of an emerging issue. These 11 themes interact considerably, but for conceptual clarity, IRGC (2011) has grouped them according to the relevant dimensions of risk governance within which they fit best. These four dimensions of risk governance (from the broad, foundational level to the more specific) and the 11 themes are shown in Fig. 2.6 and are summarized in Table 2.14 .

Figure 2.6.

Overview: the four risk governance dimensions and the 11 themes.

Adapted from International Risk Governance Council (IRGC), 2011. Improving the Management of Emerging Risks. IRGC, Geneva. Available at: www.irgc.org.

Table 2.14.

Overview: The Four Risk Governance Dimensions and the Eleven Themes

| Dimensions | Theme |

|---|---|

| Risk governance |

|

| Risk Culture |

|

| Training and capacity building | Build capacity for:

|

| Adaptive planning and management |

|

Adapted from International Risk Governance Council (IRGC), 2011. Improving the Management of Emerging Risks. IRGC, Geneva. Available at: www.irgc.org.

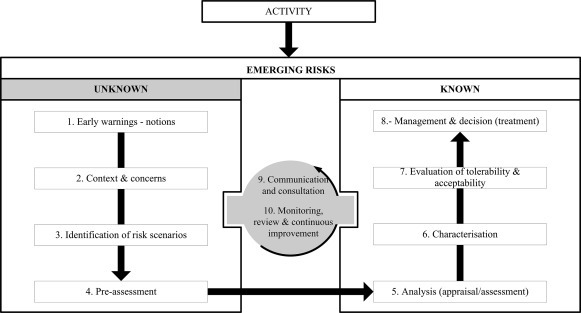

The IRGC Guidelines for Emerging Risk Governance (IRGC, 2015a) describe key steps and associated methodologies for early identification and management of emerging risks. The process is described schematically in Fig. 2.7 , and covers an overarching, flexible, and adaptable set of guidelines designed to deal with complex, evolving, and uncertain environments (IRGC, 2015b).

Figure 2.7.

IRGC guidelines for emerging risk governance.

Adapted from International Risk Governance Council (IRGC), 2015b. Guidelines for Emerging Risk Governance. Appendix. Lausanne: International Risk Governance Council (IRGC). Available at: www.irgc.org.

IRGC (2015b) reviews other existing emerging risk governance frameworks. These emerging risk governance frameworks are the following: European Union Agency for Network and Information Security, the European Food Safety Authority, the Swiss Reinsurance Company (SONAR system), the CWA 16649:2013, and the Dutch framework for identifying and managing emerging risks involved in the use of chemicals.

The CWA 16649:2013 is one of the main results of iNTeg-Risk. This project has summarized its results in a set of major deliverables, labeled, at the end of the project by the developers, as the “Big 7” of iNTeg-Risk. They are (Jovanović and Baloš, 2013): (1) iNTeg-Risk Catalogue of Emerging Risks – RiskEars system; (2) iNTeg-Risk Framework for Emerging Risk Management; (3) the library of iNTeg-Risk Methods, Handbooks and Guidelines for emerging risk analysis; (4) iNTeg-Risk dynamic library of emerging Risks Key Indicators; (5) iNTeg-Risk CEN Workshop Agreement (CWA) 16649:2013 document – the European prestandardization document for emerging risk management; (6) European Master and Certification in the area of Risk Engineering and Management – education and training for improved emerging risks management in the EU; and, (7) iNTeg-Risk Risk Radar and 1StopShop.

CWA 16649:2013 gives guidance on steps for applying/implementing the proposed ERMF in industrial organizations. This ERMF is heavily influenced by the IRGC (2005) risk governance framework and the ISO 31000:2009 risk management process. The main difference is that some issues that are included in other steps in IRGC (2005) and/or ISO 31000:2009 have been explicitly addressed as a separate step in the ERMF, and a particular focus on capturing the earliest signs of an emerging risk (CWA 16649:2013). The 10 steps of the ERMF are illustrated in Fig. 2.8 .

Figure 2.8.

The 10 steps of the ERMF.

Adapted from CWA 16649:2013.

5.3. Emerging Risk Characterization

Risk characterization allows decision makers to distinguish scientific facts from policy orientations when analyzing risk assessment results (CWA 16649:2013). The most controversial phase of handling risk, risk characterization and evaluation, aims at judging a risk's acceptability and/or tolerability (IRGC, 2005). In the report on emerging systemic risks developed by the IRGC (2010b), it is indicated that some emerging risks do not prove to be as significant as originally feared, but others may prove to be worse than expected, with a high potential for major losses. In this report it is added that typically, the future consequences of emerging risks cannot be defined in monetary terms, at least not to any satisfactory degree of precision, so the conventional approaches to projecting loss size, relative frequencies, or probability distributions over time or severity of consequences are ineffective. Indeed, it is often difficult to establish causality between the source of the emerging risk and its consequences using conventional technical or scientific data (IRGC, 2010b).

Brocal and Sebastián (2015a) have developed a new risk model whose objective is to characterize the NER. This characterization is based on the so-called risk model. This model describes a risk as a structure consisting of five components, being: the source of risk, causes, events, consequences, and the likelihood.

This risk model is compatible with the risk characterization defined by SRA (2005). This definition is the following: risk characterization as a qualitative and/or quantitative picture of the risk; i.e., a structured statement of risk usually containing the elements: risk sources, causes, events, consequences, uncertainty representations/measurements (for example, probability distributions for different categories of consequences—casualties, environmental damage, economic loss, etc.) and the knowledge that the judgments are based on.

IRGC (2011) concludes that managers need to be open to the possibility of adverse future events and to plan for them, using the best information they can obtain. Investments in increased vigilance, and the skills needed to identify and characterize emerging risks, could be highly beneficial in avoiding disasters (IRGC, 2011).

From the work done by Brocal and Sebastián, 2015a, Brocal et al., 2017 have developed a theoretical framework for the modeling of the NER that allows its monitoring through the TLC, especially in industrial processes. This new framework allows characterizing and differentiating the new qualities from the increasing qualities associated to risk. With this theoretical framework, Brocal et al. (2018) have designed a technique that is compatible with standards ISO 31000:2009 (ISO, 2009a) and ISO/IEC 31010:2009 (ISO, 2009b) and permits the NERs generated by a system and its components to be identified and characterized. This technique is called the technique to identify and characterize NERs (TICHNER) and is one of the main results of the Spanish research project A2NERSYS (“Analysis and Assessment of technological requirements for the design of a New and Emerging Risks standardized management SYStem”). TICHNER can be applied at any stage of the lifecycle of a manufacturing process and it may also be used in combination with other risk identification techniques (Brocal et al., 2018) .

As scientific understanding of emerging risks may be changing—sometimes quite rapidly—the challenge for risk managers in government and industry can be serious, and it is easy to criticize managers after a risk has emerged, regardless of how competent their ex ante decisions may have been, given the information available (IRGC, 2010b).

6. Conclusions

With this chapter, a general framework of the emerging risks linked with advanced manufacturing processes and technologies has been shown. These processes and technologies are part of the fourth industrial revolution, called Industry 4.0, whose scientific interest is clearly increasing during the last years.

The main aspects of this general framework are summarized herein along with their most relevant conclusions.

From a global perspective, several organizations have forecasted emerging technologies and reported on their forecasts, such as “Disruptive technologies” (McKinsey Global Institute), “10 Breakthrough Technologies” (MIT), “Next 5 in 5” (IBM), and “Top 10 Strategic Technologies” (Gartner Group).

From a specific perspective, the advanced manufacturing processes can be classified into five categories, namely (Nassehi et al., 2011): joining, dividing, subtractive, transformative, and additive technologies. Zhong et al. (2017a) consider that the three major advanced manufacturing technologies are the following: intelligent manufacturing, IoT-enabled manufacturing, and cloud manufacturing.

The general framework of the emerging risks linked with advanced manufacturing processes and technologies has been shown using the CWA 16649:2013 as main reference. Next, this framework is expanded specifically to occupational field. In this field, the main results of reports by EU-OSHA have been shown. Among these results, three emerging manufacturing technologies linked to emerging risks have been developed: automation, HMIs, and ICTs.

IRGC (2005) puts forward an integrated analytic framework for risk governance, in particular at the global level. Complementarily, the IRGC (2011) focuses on these risks in technology and industry. Since the publication of the IRGC Framework, other guidance documents or frameworks have been published, such as ISO 31000:2009 standard. This standard provides principles and generic guidelines on risk management.

CWA 16649:2013 gives guidance on steps for applying/implementing the proposed Emerging Risk Management Framework (ERMF) in industrial organizations. This ERMF is heavily influenced by the IRGC (2005) and ISO 31000:2009 frameworks.

The IRGC Framework is divided into four main phases: preevaluation, appraisal, management and characterization, and evaluation of risk. Risk characterization allows decision makers to distinguish scientific facts from policy orientations when analyzing risk assessment results (CWA 16649:2013).