Abstract

Wastewater treatment is the means by which water that has been used and/or contaminated by humans or nature is restored to a desirable quality. Treatment may consist of chemical, biological, or physical processes or a combination thereof. Water may be treated to any level of quality desired; however, as its purity increases, so does the cost of attaining that purity. The required quality of water is dictated by its intended use, for example, aquatic life, drinking water, or irrigation. The purpose of this chapter is to describe wastewater treatment technologies predominantly in use today. Ultimately, the technology selected as appropriate for one application may not be the optimal for another. Selection will be based on site-specific factors, such as resources available, climate, land availability, economics, etc.

Keywords: Ecotoxicology, Environmental toxicology, Environmental and human health risk assessment, Soil and groundwater pollution, Transport and fate of chemicals in the environment, Waste reclamation, Resource management, Wastewater treatment, Water pollution control, Water resources management

Wastewater treatment is the means by which water that has been used and/or contaminated by humans or nature is restored to a desirable quality. Treatment may consist of chemical, biological, or physical processes or a combination thereof. Water may be treated to any level of quality desired; however, as its purity increases, so does the cost of attaining that purity. The required quality of water is dictated by its intended use, for example, aquatic life, drinking water, or irrigation. The purpose of this chapter is to describe wastewater treatment technologies predominantly in use today. Ultimately, the technology selected as appropriate for one application may not be the optimal for another. Selection will be based on site-specific factors, such as resources available, climate, land availability, economics, etc.

Wastewater Management Goals

The overall goal of wastewater management is the sustainable development of natural resources, including protection of public health and the environment. Sustainable development may be defined as the meeting of the needs of society today without compromise of those for future generations. In the context of water quality, sustainable development may be considered as the management of water resources such that current and future uses of this resource are not impaired. Consequently, objectives for water use, treatment, reclamation, and reuse should be consistent with this goal.

Water Quality Management

To understand the need for a particular degree of wastewater treatment, the concept of water quality management must be introduced. Water must be used and treated in such a way that deleterious effects are minimized, both for the environment and for the next user. From an engineering perspective, the intended use of a water should be determined, water quality requirements for that use delineated, and then treatment or other management techniques based on those requirements accomplished.

The dictionary defines pollution as something that makes the water physically impure, foul or filthy, dirty, stained, tainted, or defiled. Actually, the addition of anything to a water that adversely changes its existing quality constitutes pollution, including heat and sediment. Pollution may be caused by both humans and nature, and the effects may be similar.

The philosophy of water pollution control has changed considerably since the passage of the Public Health Service Act of 1912, which was primarily for the investigation of the spread of waterborne disease. Today, water quality standards are usually limited by aquatic life considerations. For example, the primary drinking water standard for zinc is 5 mg l− 1, while concentrations of zinc as low as 0.001 mg l− 1 may be toxic to aquatic life. The implications of this difference are obvious as the cost to protect aquatic life may be much greater than that for satisfying water quality standards for drinking water. It should be noted that the cost of removal of a contaminant increases considerably when the percentage of removal increases. From the technical standpoint, water can be made as pure as desired; however, from the practical perspective, the cost of achieving a given purity must be considered.

The 1987 Clean Water Act required that wastewater effluents potentially containing toxic contaminants undergo bioassay (whole effluent toxicity) testing to determine if such discharge may result in adverse effects on receiving water biota. Several aquatic species are employed and evaluated for acute and chronic affects. If it is determined that aquatic toxicity is a concern, then evaluation to reduce the toxicity must be conducted. This includes a Toxic Reduction Evaluation (TRE) and if necessary a Toxic Identification Evaluation (TIE) to identify and eliminate the toxicity causing agent (s).

Because of the increasingly stringent limits for selected pollutants due to potential toxicity and/or other deleterious effects on critical ecosystems and public health, the focus on wastewater treatment has shifted to one of wastewater management. This includes prevention instead of treatment/remediation and promotion of ‘clean technologies.’ Emphasis is now given by industry to waste minimization and product life cycle analysis to reduce raw materials, energy and environmental releases, thereby conserving natural resources, reducing risks/liability, and at the same time providing significant cost savings.

Receiving surface waters (lake, river, ocean, or estuary) have an innate ability to accept some contaminants without adverse environmental impact. This so-called self-purification capacity is denoted as the waste assimilative capacity. It is defined as the amount of contaminant that may be discharged into a receiving water, under defined low-flow (and in some cases high flow) conditions which will not result in deleterious effects. This concept often dictates the wastewater treatment requirements imposed on a wastewater discharger. However, where sufficient assimilative capacity does exist, regulations or standards may dictate at least a minimal degree of treatment obtainable by technology-based standards and are based on what can be achieved technologically rather than what is needed environmentally.

Where assimilative capacity is not sufficient to accommodate wastewater effluents and maintain stream standards, compliance to water-quality-based standards is required. Based on the designated use of the stream and results from ecotoxicological evaluations, total maximum daily loads (TMDLs) are determined by state environmental agencies. Considering contributions from non-point-source (diffuse) pollution, background conditions, and a factor of safety, a determination for each discharger is made as to acceptable point source effluent loadings. Accordingly, discharge permit restrictions are then imposed and enforced. These actions typically require a high degree of treatment, thereby shifting focus to resource management, waste reduction, and water reuse options.

Classification of Pollutants

It is convenient to classify pollutants into four categories as follows: chemical, physical, physiological, and biological. A brief discussion of these is in order as is their method of removal. It should be noted that, depending on the intended use of the water, every receiving water will have a limit as to how much of each of these kinds of wastes can be discharged into the water without adverse effects.

Chemical pollutants can be broadly categorized into inorganic and organic pollutants, where organic materials may be defined as those compounds containing organic carbon. The major problem with organic materials is their conversion to carbon dioxide and water as follows:

In as much as aquatic life requires a certain level of dissolved oxygen to live and propagate, it is obvious that if sufficient organic material is placed into the water, oxygen levels may be reduced to inimical concentrations. It is interesting to note that the process described is the same as that taking place in aerobic (presence of free oxygen) wastewater treatment processes. The common measure of oxygen depleting substances is the biochemical oxygen demand (BOD).

A prime consideration of inorganic chemicals is their toxicity. For example, changes in pH may occur from the discharge of soluble salts, and toxicity may occur directly from heavy metals. It should be noted, however, that organics may cause toxicity (e.g., pesticides), and inorganics may cause oxygen depletion (e.g., sulfurous acid). Also, not all materials containing carbon may cause an oxygen demand (e.g., bicarbonate). Some compounds containing organic carbon may be very difficult to biodegrade or non-biodegradable. Aquatic toxicity must be evaluated where appropriate and action taken to eliminate or reduce toxicity when necessary.

Other organic materials include compounds of a toxic nature, such as pesticides, and taste- and odor-producing compounds, including phenols and oils with their tendency to form surface films. The USEPA has defined a list of 126 toxic organic and inorganic chemicals that appear as specific limitations in discharge permits. These are identified as priority pollutants and can be found on the USEPA website www.epa.gov. Volatile organic chemicals (VOCs) such as benzene and toluene may result in public health problems and must be controlled under Clean Air Act legislation. The refractory organics are of particular concern because of the potential long-term cumulative effects of these materials in drinking water and the food chain. The Safe Drinking Water Act (SDWA) also requires the USEPA to list unregulated contaminants that are known or anticipated to occur in public water systems and may require regulation in the future. This list is called the Contaminant Candidate List (CCL) and is updated every five years and can be found on the USEPA website. The EPA uses the CCL to prioritize research efforts in order to make informed regulatory decisions about specific chemicals. The agency determines whether or not to regulate at least five chemicals on the CCL with each publication cycle. Newer organic pollutants, such as pharmaceuticals and personal care products (PPCPs) and endocrine disrupting chemicals (EDCs), have received increasing attention over the last decade. This is because of their wide distribution in surface waters, groundwater, and wastewater effluents, and their effects on the development of a variety of aquatic species, the development of antibiotic resistant pathogens, and possible effects on human health. Regulations for a number of these newer pollutants are currently being evaluated by the EPA. Some are currently banned in the United States and the European Union.

Physical pollutants include color, turbidity, temperature, suspended solids, foam, and radioactivity. Although color is not necessarily harmful, it may be aesthetically unacceptable for drinking water and some industrial uses. Color is often caused by organic colloids, thus making its removal expensive. Color may be the result of natural decay of vegetative organics such as fluvic and humic acids. These can react with free chlorine to form Trihalomethanes (THMs) which are of public health concern in drinking waters. Temperature is an important factor in biological activity and significantly affects chemical, biological, and physical reactions. It may also act synergistically with toxic materials, for example, heavy metal toxicity increases with increasing temperature. Turbidity is caused by colloidal material and/or suspended solids, and its removal requires coagulation and filtration. Suspended solids, which may cause turbidity, can result from wastewater discharges or from natural processes, such as erosion. This may inhibit photosynthesis by reducing light penetration, decrease benthic organism activity by covering the water bottom with sediment, and interfere with fish activity by clogging their gills. Solids may be organic or inorganic. Dissolved solids tend to increase in concentration with reuse. In most cases these are difficult and expensive to remove. Foam resulting from surface active agents may cause aesthetic problems, but developments by the detergent industry have minimized these effects. Surface active agents also may cause a reduction in the rate of oxygen gas transfer into the water. Radioactivity may be the result of fallout, natural sources, or waste discharges and can be incorporated into sludges or biological life or dissolved in the water. Because of the unique effects of radioactive substances, they must be controlled at the source.

Physiological effects of pollution are primarily the result of taste and odor. Although taste and odor problems may be minor in effect, public reaction many times results in magnification of problems and concomitant adverse publicity of the water purveyor. Taste and odor are particularly objectionable when present in drinking water or process water for food where palatability is important. It is significant to note that phenol is detectable at concentrations of 0.001 mg l− 1 and is pervasive in the wastewater discharges of the petrochemical industry. The ability of taste and odor-producing materials to taint fish is also important.

The biological category can also be divided into two subdivisions, public health considerations from waterborne diseases and eutrophication and/or biological growths resulting from nutrient additions.

The causative agents for waterborne disease include virus, protozoa, bacteria, and the helminths,. Contemporary epidemic problems include hepatitis (virally borne), giardiasis, and cryptosporidium (protozoan origin). Probably the most serious waterborne disease is cholera (bacterial origin), which caused major epidemics with high fatalities and morbidities in the 1800s in the United States and continues to be a problem in developing countries. Examples of some water borne diseases are presented in Table I .

Table I.

Examples of waterborne infectious diseases

| Bacteria | Campylobacter jejuni. |

| Enteropathogenic Escheria coli(gastroenteritis) | |

| Vibrio cholerae (cholera) | |

| Leptospira spp. (leptospirosis) | |

| Salmonella typhi, S. paratyphi (enteric fever) | |

| Shigella spp. (bacillary dysentery) | |

| Yersinia enterocolitica (gastroenteritis) Legionella pneumophillia (acute respiratory illness) | |

| Viruses | Rotavirus (gastroenteritis, upper respiratory infection) |

| Norovirus (gastroenteritis) | |

| Hepatitis A (infectious hepatitis) | |

| Hepatitis E (infectious hepatitis) | |

| Enteroviruses (including poliovirus) | |

| Protozoa | Entamoeba histolytica (amoebic dysentery) |

| Cryptosporidia spp. (cryptosporidiosis) | |

| Giardia lambia (giardiasis) | |

| Helminths | Dracunculiasis (guinea-worm disease) |

| Schistosoma spp. (schistosomiasis; Bilharzia) |

The second category, which may be called secondary biological pollution, is the deterioration of water quality resulting from the addition of phosphorus and/or nitrogen to receiving waters that may be from wastewater discharges or from pollution with no single point source (diffuse pollution). When excessive biological growths and associated water quality problems occur in lakes and estuaries, the phenomenon is known as eutrophication. Eutrophication is a natural geological process that may be accelerated by human cultural activities. Cyanobacteria (blue-green algae) can flourish in eutrophic waters. Some of these organisms are capable of producing toxins that have adverse human health effects, including liver, gastrointestinal, and nervous system effects. In many parts of the world including the U.S. water supply systems have been compromised due to these toxins. This impact is expected to worsen due to the effects of climate change.

It should be noted that nutrient removal (i.e., phosphorus and nitrogen removal) has been a major impetus for advanced wastewater treatment processes for discharges being made into affected water bodies.

Pollutants may also be classified as conventional, toxic, or nonconventional. Conventional contaminants are typical of domestic sewage and include BOD, suspended solids, pH, coliform, and oil and grease. Toxic pollutants include priority pollutants and other constituents resulting in aquatic toxicity and/or affecting public health. These may include behavioral or physiological abnormalities, cancer or genetic mutations upon exposure. Nonconventional pollutants are defined by USEPA as those that are neither conventional nor toxic. These include chemical oxygen demand (COD), total organic carbon (TOC), and nutrients (phosphorous and nitrogen) among others. The type and degree of treatment will depend on the classification of contaminants and that of the receiving waters.

Classification of Wastewater Treatment Methods

Wastewater treatment processes are categorized as source treatment, pretreatment, primary treatment, secondary treatment, and tertiary or advanced wastewater treatment.

Source treatment is used to remove toxics and/or other undesirable contaminants to prevent intermingling with other waste streams. This approach offers opportunities for reuse of these constituents such as metals, etc. Conventional treatment includes pre- and primary treatment followed by secondary-treatment processes. When necessary tertiary treatment processes are included in the treatment sequence to remove specific constituents to very low residue levels. Pretreatment is employed to render the raw wastewater compatible and/or amenable for subsequent treatment processes. Consideration is given to those constituents that pass through, interfere with, or accumulate in the sludge or are otherwise incompatible with following treatment processes. Equalization, spill retention, neutralization for pH adjustment, nutrient addition, toxics or inhibitory substance removal, oil and grease removal, and solids removal by flotation, sedimentation, or filtration are typical pretreatment processes. Primary treatment is a subset of pretreatment methods and involves physical separation by screening, grit removal, and sedimentation.

Depending on the amount of organics contained in the solid material, primary treatment may remove a significant portion of the oxygen-demanding substances (BOD). A well-designed and operated primary plant may remove as much as 35–40% of the BOD and as much as 60–65% of the settleable solids for municipal wastewaters.

Secondary treatment adds a biological process after primary treatment, which is commonly either activated sludge or trickling filtration for municipal wastewaters. Typically activated sludge or a modification of suspended growth treatment systems is used for industrial wastewater to achieve a high-quality effluent. These biochemical processes are typically aerobic and are the same as previously described as occurring in a river where organics are oxidized to carbon dioxide and water.

A well-operated and designed secondary treatment plant can be expected to remove 85–95% of both BOD and suspended solids. Under existing regulations in the United States, all discharges must be subjected to at least secondary treatment.

Conventional treatment is described by Best Conventional Treatment Technology (BCT) and is designed to remove conventional pollutants such as BOD, TSS, etc. common to municipal wastewaters. However, BCT does not effectively remove many constituents of present-day concern, especially those of industrial wastewater origin. These include many VOCs, toxics, non-biodegradable organics, persistent organic pollutants (POPs), nutrients and emerging contaminants such as EDCs and PPCPs. Hence, additional treatment technology is required.

Tertiary treatment may be defined as treatment in addition to primary and secondary processes. It may include precipitation, filtration, coagulation and flocculation, air stripping, ion exchange, adsorption, membrane processes, nitrification, and/or denitrification, and other processes. Those processes may be integrated into the secondary treatment plant or added onto the secondary effluent. Tertiary or advanced wastewater treatment can attain virtually any removal efficiency desired. However, as previously noted, as the percentage of contaminant removal increases, so does the cost of attaining it. These technologies are often referred to as Best Available Technology Economically Achievable (BTEA) and are applied to meet stream standards or to comply with TMDL requirements.

Tertiary treatment is employed to remove toxics, persistent organics, nonconventional pollutants, nutrients, etc. and is typically considered as BATEA. Tertiary treatment systems following secondary treatment, however, may not be efficient at industrial facilities because of the need for treatment of a large volume of flow with low contaminant concentrations. Many tertiary processes also may not be pollutant-specific. Generally, the most cost-effective approach is to address the problem at the source where flows are low and specific pollutants are present at high concentrations. Applicable technologies for source treatment will depend on the constituents in the process wastewater targeted for removal. For example, if VOCs and ammonia are to be removed, then air or steam stripping should be evaluated. If heavy metals are of concern, then oxidation/reduction, precipitation, filtration, ion exchange, and membrane processes may be investigated. Organic chemicals may require chemical oxidation, wet air oxidation, anaerobic treatment, granular activated carbon (GAC), polymeric resins, or reverse osmosis for effective removal.

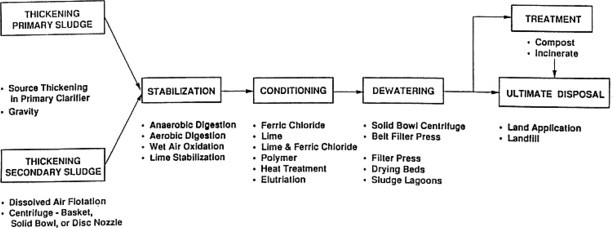

Special mention should be made of the solid material removed in any of these processes since residuals disposal is a major problem in wastewater treatment. Sludges are particularly troublesome because of their high water content, concomitant large volumes, and concentration of heavy metals, viruses, protozoa, and other constituents capable of causing environmental and public health harm. Costs of treatment may be one-half or more of that of the aqueous waste stream. Many of the processes mentioned in the preceding paragraphs produce solids. Solids from primary and secondary clarifiers must be effectively managed. Residual solids usually undergo a series of treatment steps involving thickening, dewatering, and final disposition or reuse. Organic sludge may also require stabilization prior to final disposal. Stabilization may be achieved by digestion [aerobic or anaerobic (no oxygen present)], lime stabilization, or by other means. Sludge thickening is typically accomplished by gravity, flotation, or centrifugation methods. Centrifuges, belt filters, and filter presses are dewatering options. The selection of unit processes and their sequence will depend primarily on the characteristics and volume of the sludge and on the final disposition or reuse option selected.

Ultimate disposal choices include incineration, landfill, land disposal (lagooning or application to land for reuse) or other reuse alternatives. Since this material is a resource, it is important that opportunities for reuse be fully considered. It is the ultimate disposal method selected that may significantly influence the unit operations selected for treatment.

Wastewater Characterization

It is mandatory that the composition and characteristics of a wastewater be known and understood in order to design and operate a wastewater treatment plant. For example, the BOD is a measure of the organic material present and its removal depends on its form. This may be suspended, colloidal, dissolved, molecular type, etc. Solids characteristics will determine the sludge handling and transport facilities. pH may indicate the metals speciation, toxicity, the and/or the need for neutralization. Oxygen content and oxidation reduction potential (ORP) may demonstrate the need for odor control if a lack of dissolved oxygen is present as well as chemical speciation. Grease and oil may cause operational problems and may require special removal facilities.

Wastes originating from industry may be toxic or inhibitory to biological processes, and thus their discharge to a municipal treatment plant must be regulated. Pollutants may include heavy metals, VOCs, priority pollutants, grease and oil, etc. Pretreatment ordinances are used by municipalities to control discharges into municipal sewerage systems.

A major consideration in characterizing wastewaters is the flow since it may vary considerably and contain different contaminants in different concentrations at different times. For example, one would expect to find low flows occurring at night and peaks occurring during periods of maximum water use for domestic wastewaters. Industrial waste flows are generally more random and must be analyzed statistically based on probability analysis. Sampling of wastewaters is often done in accordance with flow so that the mass of constituents can be determined on a weighted average basis (composite sampling).

Whereas the characteristics of municipal sewage are relatively constant, industrial waste characteristics and parameters of concern can change significantly. Important industrial waste parameters that are of significance to a given industry are defined by a Standard Industrial Classification (SIC) grouping. Wastewater characterization and effluent discharge requirements under the National Pollution Discharge Elimination System (NPDES) permit system are based on SIC classifications. The strength and volume of industrial wastewaters are usually defined in terms of units of production (i.e., gal bbl− 1 beer and lb BOD bbl− 1 beer for a brewery) and variation in characteristics and flow by statistical distribution. Industrial waste of organic nature can be correlated to municipal waste loadings by the use of population equivalents. Typically 0.17 lb BOD per capita per day is generated for domestic wastewaters. Assuming an industry generates 17 000 lb BOD per day, then this would be equivalent to a population of 100 000 people. Because of the inherent variability in industrial waste characteristics, treatability studies are often necessary to determine design parameters and potential pretreatment requirements.

Objectives of Wastewater Treatment

The processes introduced will be examined in the following for their role in treating the various components constituting a wastewater. The prime objectives are threefold: (1) separate the solid from the liquid fraction and concentrate the solids collected from the carrier water; (2) remove and/or render innocuous materials that will cause adverse effects when the effluent and resultant residuals are subjected to ultimate disposition; and (3) maximize reuse potential of treated wastewater and residuals. It is instructive to note that only 0.1% of domestic sewage is solids, the remainder being the carrier water.

In general, less than 50% of the waste material in domestic sewage remains in suspension, thus allowing separation by straining, skimming, or settling. These residuals must be destroyed or rendered removable. This is accomplished by biological, physical, or chemical means.

During chemical treatment the coagulating chemicals combine with the finely divided and colloidal (non-settleable) material to form settleable flocs. In aerobic biological treatment, living organisms metabolize finely divided colloidal and dissolved biodegradable substances and convert them into carbon dioxide and water and settleable films, slimes, or flocs, primarily consisting of cell material.

Physical treatment may involve adsorption processes; where, for example, contaminants containing a high affinity for activated carbon may be removed.

Wastewater Treatment Processes

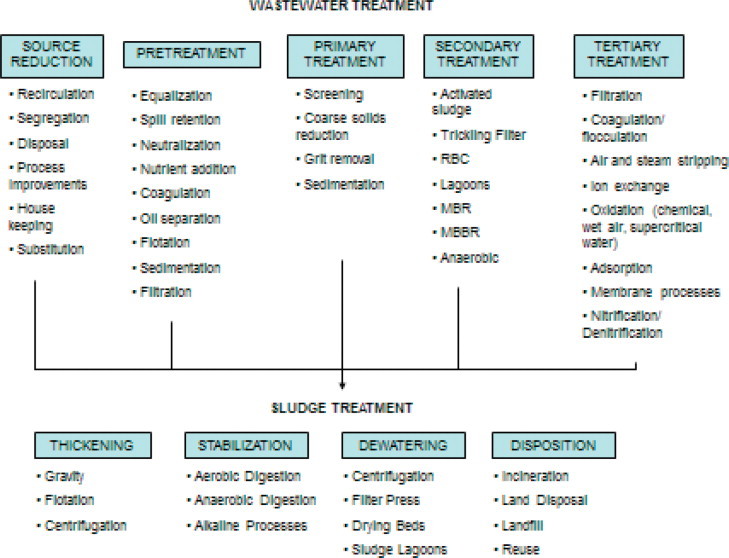

Wastewater treatment plant design is based on the selection and sequencing of various unit operations. A schematic illustrating integration of processes capable of treating a variety of wastewaters is shown in Figure 1 . Selection of a combination of processes depends on the characteristics of the wastewaters; the required effluent quality (including potential future restrictions); costs; and, availability of land. As previously indicated, treatment methods can be classified as pretreatment/primary treatment; secondary treatment; tertiary treatment; sludge treatment/stabilization; and, ultimate disposition or reuse treatment technologies for residuals.

Figure 1.

Typical wastewater treatment processes.

Pretreatment/Primary Treatment

Pretreatment methods are used to render the wastewater compatible with and/or amenable to subsequent treatment processes. Typical processes include equalization, neutralization, and oil and grease separation. Primary treatment involves physical separation for municipal wastewaters and usually consists of screening or comminution, followed by grit removal, and then sedimentation prior to secondary treatment.

Screening/Comminution

Screening is used to remove large, objectionable, solid matter that is removed periodically to prevent flow obstruction and head loss. The removed materials are putrescible and are usually buried or incinerated. A comminutor acting like a large ‘garbage grinder’ may be used to homogenize the solids as an alternative to screening. To protect the machinery the comminutor generally follows grit removal. The homogenized solids contribute to the organic load to the treatment facility, and hence screening is often the method of choice.

Grit Removal

Grit is composed of small coarse particles of sand, gravel, or other minute mineral material. Grit is removed to prevent damage to mechanical equipment and to maintain tank volume capacities. Grit may be removed in an aerated chamber where the amount of air is just sufficient to keep the organic matter in suspension and allow the heavier inorganic material to settle. Grit may also be removed by controlling the velocity of flow through a chamber such that the gritty material will settle and the organics remain suspended. Grit removed is typically washed and land disposed.

Oil and Grease Removal

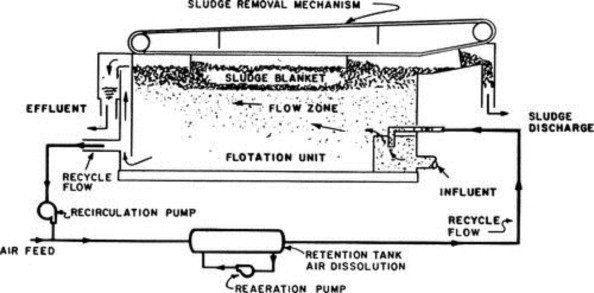

Excessive oil, grease, and finely divided suspended solids should be removed prior to discharge into the primary sedimentation tank or aeration basin. This can be accomplished by employing processes including gravity separation with skimming and/or flotation. An API separator or parallel plate/corrugated plate oil separator may be employed effectively to separate free oil by gravity allowing the lighter-than-water oil globules to rise to the tank surface to be skimmed off. The API gravity separator is designed to remove oil globules 0.015 cm or greater and can achieve an effluent oil of less than 50 mg l− 1. The corrugated plate separator (CPS) with a narrow separation space can remove oil globules 0.01 cm or greater to as low as 10 mg l− 1; however, it is more affected by hydraulic variation. Flotation can be accomplished by introducing air under pressure into recycled effluent water and then allowing the pressurized air–water mixture to escape at atmospheric pressure in the flotation unit as minute air bubbles. Oil globules, sludge flocs, and suspended solids are floated by these bubbles. The air–oil and/or air–solids mixture rises to the surface where it is skimmed off. Chemical coagulants are generally added to help break oil emulsions and promote flocculation and enhance bubble attachment and flotation. Flotation usually follows API separation. A schematic diagram of a dissolved air flotation unit is shown in Figure 2 . Where VOCs are of concern, API separators and flotation units are often covered and the space purged with methane or nitrogen to minimize explosion hazard.

Figure 2.

Dissolved air flotation unit.

(Courtesy of Komline–Sanderson Company)

Equalization and Neutralization

It is sometimes necessary, especially for industrial wastewaters, to install a basin to neutralize large fluctuations in pH and/or concentrations of contaminants in the incoming flow to the treatment plant. Control of fluctuations in flow with time may be required and necessitates a holding tank to equalize the flow variability. The use of equalization will assist in maintaining a relatively uniform flow and/or concentration through the plant and to the receiving water. Equalization is perhaps the most important unit operation in the treatment train for industrial wastewaters because of the desire to approach quasi steady-state conditions for design equation assumptions to hold true. Neutralization usually follows equalization so that acidic and alkaline streams can be partially neutralized in the equalization basin. Acidic wastewaters can be neutralized with lime, caustic, or limestone. Alkaline wastewaters can be neutralized with H2SO4 or HCl or by using flue gas (CO2). Usually a two-step process is required for pH control because of the logarithmic nature of pH. A pH of 6.5–8.5 is generally required prior to biological treatment.

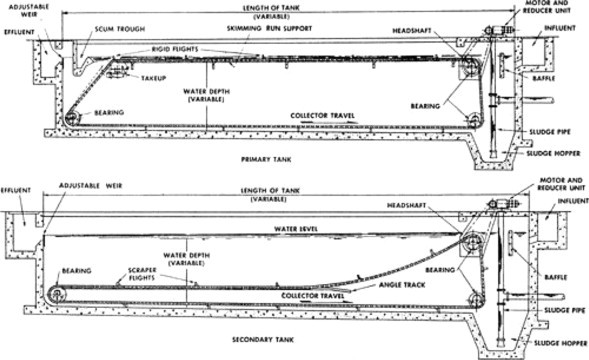

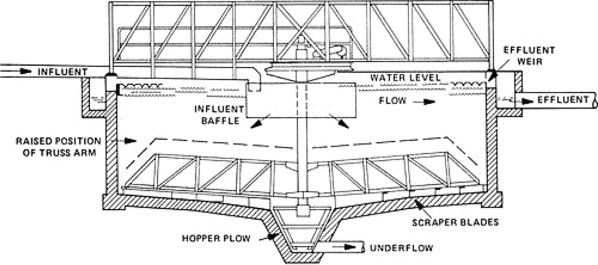

Primary Sedimentation

Settleable solids are removed by introducing the wastewater, after pretreatment, into a large rectangular or circular tank where solids settle by gravity. The supernatant overflows weirs and proceeds to secondary treatment for aerobic conversion to CO2 and water by biological oxidation. Primary clarification also acts as a barrier for oil and grease to prevent operational problems during subsequent treatment. Since solids will be collected at the bottom of the settling tank, provision must be made for their removal. This is usually accomplished by utilizing a continuous belt device as shown in Figure 3 . The solids (sludge) are then pumped from the sludge hopper to a sludge digester or other sludge treatment unit process. Note that the secondary sedimentation tank follows biological treatment. As shown in Figure 3, it differs from the primary tank because the provision for scum removal will generally not be required. Additionally, in place of a belt conveyor, a vacuum draw-off is often employed to remove solids quickly for activated sludge applications. It should be noted that chemicals are sometimes added prior to settling to enhance solids removal. The efficiency of solids removal for both primary and secondary clarification is a function of the overflow rate (gal ft− 2 day) which is essentially the velocity of the liquid exiting the tank. The settling velocity of the solids must be greater than the overflow rate if removal is to be effective. Liquid retention time must also be sufficient for efficient solids separation. It should be noted that for treatment of soluble industrial waste the primary settling tank is usually replaced with an equalization basin.

Figure 3.

Gravity settling tank

Secondary Treatment

Secondary treatment utilizes some form of biological treatment following pretreatment/primary treatment. Since much of the organic material in a wastewater may be colloidal or dissolved, the processes described thus far will be ineffective in its treatment. It has previously been shown that organic matter will be oxidized to carbon dioxide and water in the presence of microorganisms, oxygen, and nutrients. Thus, the conditions required for wastewater treatment are an adequate number of acclimated microorganisms that can metabolize the organic material, an oxygen supply, nutrients, a means of intimate contact between the microorganisms and the food (wastewater), and a method of containment. The process is identical to that occurring in an aerobic waterway, except that in the wastewater treatment plant, the process is optimized by reduced time requirements and a continuous supply of oxygen to maintain an aerobic state.

There are numerous ways to design a biological wastewater treatment process; however, the two most commonly used are the activated sludge process and the trickling filtration process. In the activated sludge process, the fine, suspended, and colloidal and soluble organic materials are brought into intimate contact with a biologically active sludge maintained in suspension in the tank by introducing air that not only serves to maintain turbulence and maximum contact, but supplies the microorganisms with the oxygen required for their metabolism. The activated sludge performs the work of adsorbing, assimilating, and flocculating the waste material.

The trickling filtration process is identical to the activated sludge process in principle. However, instead of the water flowing through the suspended sludge containing the microorganisms, the waste material flows over a suitable surface to which the microorganisms adhere. When wastewater flows over the fixed film surface, growth of bacteria and other microorganisms occurs. These microorganisms create a slimy, gelatinous film that transfers the matter held in suspension, both colloidal and in solution, to the microorganisms, which remove food (substrate) needed for their growth and transfer back to the liquid the end products of decomposition, including (in the aerobic process) nitrates, carbon dioxide, and sulfates. As is the case with the activated sludge process, the microorganisms working in the trickling filtration process need a continuous food supply, adequate oxygen, a suitable support, and appropriate nutrients.

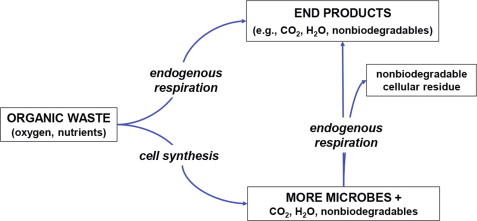

The processes taking place in any aerobic biological treatment plant can best be described schematically as shown in Figure 4 , where cell material is produced by synthesis (cell growth) and end products are generated by endogenous respiration (cell death), depending on the existing ratio of food to microorganisms (F M− 1 ratio) in the process. Thus, part of the energy may be utilized in reproducing new bacterial cells and the rest of the energy used in converting waste products to carbon dioxide and water. If the food supply becomes meager, the bacteria will eat themselves and bacterial cells will be converted into end products. This process, when the food-to-microorganism ratio is low is called endogenous respiration. It can also be seen from Figure. 4 that part of the waste material will be non-biodegradable. This is the residue of the waste material that will not be removed, either as cell material or as non-biodegradable residues produced during metabolism termed soluble microbial products (SMPs). The endogenous respiration process is analogous to a starving human who uses his own tissue to provide energy to sustain life processes. Note that SMPs are also generated during synthesis.

Figure 4.

Biological stabilization of organic waste materials.

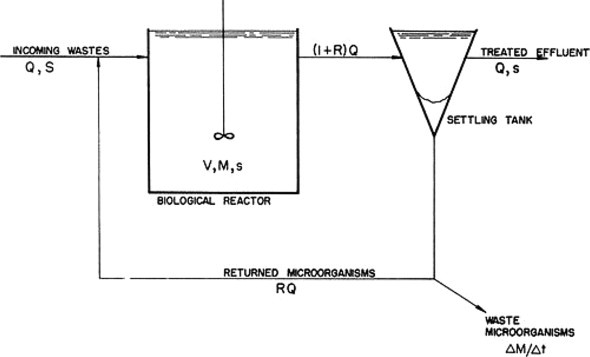

Figure 5 schematically demonstrates a complete-mix biological wastewater treatment process, where Q is the flow volume, S is the concentration of organics (substrate), V is the volume of the tank, M is the mass of microorganisms in the tank, s is the concentration of organics in the tank, and R is the fraction of return flow. The mass of microorganisms per day wasted divided into the inventory of microbes in the reactor is termed the sludge age or mean cell residence time (MCRT). This is used for system control to maintain a desired physiology of the biomass present. The required time for stabilization for industrial wastewaters, which are often soluble, is usually longer than that required for municipal wastewaters and will vary depending on the complexity of the waste. Retention time required may be hours to days and must be determined by treatability studies. Temperature effects are also significant depending on the nature of the wastewater, temperature extremes and temperature variation.

Figure 5.

Complete mix biological reactor.

Activated Sludge Process

The activated sludge process consists of maintaining an active biological floc in a tank supplied with oxygen so that maximum contact is made between the incoming wastewater and the microorganisms in the floc. In the conventional process, a rectangular tank is usually used and the wastewater is introduced into a concentration of microorganisms maintained in the tank. Typically, air is introduced, either in the form of bubbles through diffusers or by turbulent agitation of the liquid by an impeller. In some cases pure oxygen is used in place of air. The microbe concentration is maintained in the tank by returning a certain portion of the sludge that passes through the tank and is settled out in a secondary sedimentation basin. The activated sludge process produces new cell material by synthesis which will become part of the activated sludge mass. Part of the settled material therefore, must be disposed of, and a portion must be introduced into the incoming raw wastewater in order to have an active population of microorganisms that will feed on the organic compounds.

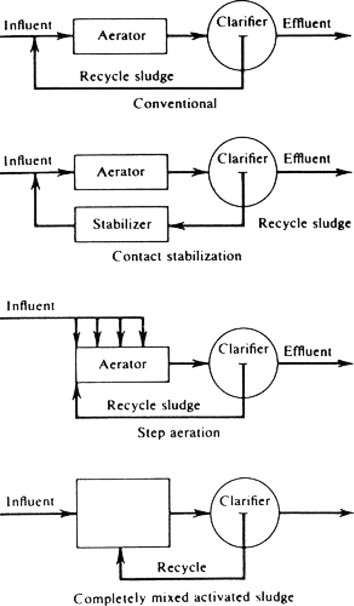

As might be expected, the design of an activated sludge process will depend on the ratio of the food, or waste, to the microorganisms, or activated sludge. For domestic sewage characterized by a high suspended solids and colloidal content, most organic materials are adsorbed by the sludge floc in 15–45 min, although most conventional plants are designed with at least 30–90 min of contact time for adequate adsorption by the sludge floc. Retention times may be 24 h or longer for extended aeration package plants. With the activated sludge process, it is possible to obtain removals of BOD on the order of 95% or greater with a higher quality effluent than with most other biological oxidation processes. Many modifications of the activated sludge process exist, including a high-rate process where the food to-microorganism ratio is high, thus producing more sludge, typically used for pretreatment; a step-aeration process, where the influent is added at intervals along the aeration tank; tapered aeration, where the introduction of air is varied along the length of the tank, the higher concentration being at the influent point of the tank; and the contact stabilization process, where a portion of the sludge is aerated separately, thus adding flexibility to the process. Most conventional activated sludge basins treating municipal wastewaters are designed for plug flow to minimize hydraulic retention time and optimize settling properties of the floc. In a true plug flow unit all particles entering the reactor stay for an equal amount of time. This of course is not possible in practice. However, plug flow can be approached by dividing the aeration tank into a series of reactors. With complete-mix reactors the incoming wastewater is completely mixed with the reactor contents upon entry. Because of its ability to absorb shock loadings and reduce toxic/inhibitory constituents by dilution to below threshold levels it is often used for treating industrial wastewaters. With the increasing need for nutrient removal staged reactors are often used with combinations of anaerobic, anoxic and aerobic cells incorporating internal recycle for both phosphorus and nitrogen biological removal.

A modification of the activated sludge process is called extended aeration, where long detention times are given to the aeration operation. It is usually designed for complete-mix conditions. This means that a high solids content or a low food-to-microorganism ratio and long sludge age will exist. Thus, endogenous respiration of the sludge will occur and the sludge will ‘burn itself up.’ The process is sometimes called complete oxidation, although there will always be some biological residue, inorganics, and solids that will necessarily emanate from the system. Because of the long sludge age, nitrogen is converted to nitrate within the reactor, thereby reducing the oxygen demand of the effluent on the receiving water. The process of extended aeration is frequently used in small installations such as schools, subdivisions, and motels. Many industrial plants employ extended aeration to enhance priority pollutant removal, reduce toxicity, and PPCPs and EDCs due to the longer mean cell residence time, MCRT (sludge age). Priority pollutants can be reduced to μg l− 1 levels and BOD soluble to<10 mg l− 1. Figure 6 shows some of the modifications of the activated sludge process commonly employed.

Figure 6.

Activated sludge process modifications

The complete mix activated sludge system is generally employed for industrial waste treatment since it maximizes dampening of fluctuations of influent wastewater quality, including toxicity. However, the process for readily degradable wastes may tend to promote the growth of filamentous microbes, which do not settle well in the secondary clarifier. For these cases a selector may be employed preceding the aeration basin. In a selector, degradable organics are removed by the floc due to biosorption and therefore are not available as a food source for the filaments. A contact time of approximately 15 min is generally used.

Another modification of the activated sludge process popular for both municipal and industrial wastewaters is the sequencing batch reactor (SBR). This is a combination of complete mix and plug flow operated on an intermittent basis,that is, aeration, sedimentation, and decanting of effluent all in the same basin. This system has been shown to provide a good settling floc and an effluent of high quality low in nutrients without the need for an external clarifier. The system offers low cost and high flexibility. The SBR utilizes two or more basins operating in parallel such that when one is filling the other is emptying.

Lagoons and Oxidation Ponds

Stabilization ponds are probably one of the oldest wastewater treatment processes in existence and are still used in many locations in the United States today. They can be used alone or in combination with other wastewater treatment processes. Design and utilization depend on many factors, including weather, land availability, purpose, and location. Detention time varies from 7 to 180 days, depending on the type of pond and climate conditions.

Ponds can be classified into four categories: facultative, aerated, aerobic, and anaerobic, the most common being the facultative pond.

Facultative ponds are usually 6–8 ft in depth and operate aerobically in the upper layers and anaerobically in the lower depths. Oxygen in the upper portion is supplied by photosynthesis and surface reaeration. The organic loading is based on climate and on surface area which must be sufficiently low to maintain dissolved oxygen produced by algae. The algae present in the effluent may create problems however. The detention time of a facultative pond will vary from 30 to 180 days or more depending on climate conditions and nature of the wastewater. Effluent BOD values range from 20 to 60 mg l− 1 and effluent suspended solids from 30 to 150 mg l− 1 in warmer climates due to algae content. Multiple ponds in series are recommended for greater operational flexibility and to prevent short-circuiting.

Aerated lagoons are supplied with oxygen by mechanical or diffused aeration and are usually 6–20 ft deep with detention times varying from 3 to 12 days. Hence, large land areas are required, although less than for facultative ponds. The aerated lagoon can be used for pretreatment or may be designed in series to achieve a higher quality effluent. In a two or three basin system, the first basin is fully mixed, thereby maintaining all solids in suspension. This maximizes the organic removal rate. A second basin operates at a lower power level, thereby permitting solids to deposit on the bottom. The solids undergo anaerobic degradation and stabilization. A third basin is frequently employed for further removal of suspended solids and enhanced clarification. Aerated lagoons are employed for the treatment of nontoxic or nonhazardous wastewaters such as food processing and pulp and paper.

Aerobic or maturation ponds are about 18–36 in. deep and maintain oxygen throughout their depth. The oxygen is supplied by photosynthesis and surface reaeration, which is sometimes aided by mixing. These high-rate ponds are limited to warm, sunny climates and have a detention time of 3–5 days. In addition, unless algae removal is practiced, the effluent will contain a high percentage of suspended solids. These ponds will usually produce an effluent of high microbial quality.

Anaerobic ponds have such heavy loading that no aerobic zone exists. They are usually used for strong industrial or agricultural wastes as pretreatment. They are 8–15 ft deep and have detention times of 20–50 days. A major problem is with odor produced from the anaerobic process. Addition of sodium nitrate may be used to reduce or eliminate this problem.

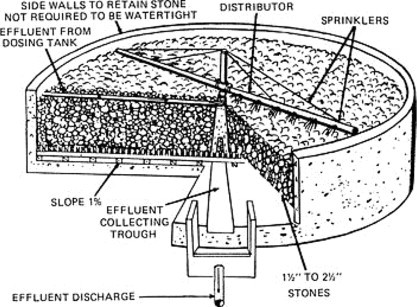

Trickling Filtration

As previously mentioned, the trickling filtration process is similar to the activated sludge process, except that the microorganisms working to stabilize the organic waste material are attached to a fixed bed rather than being suspended. Following pretreatment and sedimentation the wastewater is distributed from rotary nozzles over the bed, which usually consists of coarse, rough, hard material that gives support to the biological film. The organics in the wastewater are oxidized after assimilation by the bacteria. Periodically, the film will become so thick that it can no longer be supported on the medium and will slough off and be discharged into the effluent from the filter. This sludge will then go to the secondary settling tank and be removed with that from the primary settling tank. The trickling filtration process is said to be advantageous because it can provide good performance with a minimum of skilled operator attention and use less energy. However, the process is highly temperature dependent and will not always perform in accord with the requirements of present-day regulatory agencies. Other variables affecting performance include the organic and hydraulic loading rates and the biodegradability of the wastewater. While effluent quality is less than that from the activated sludge process, quality can be enhanced by following the trickling filter with a biological contactor. The contactor is usually designed for a retention time of 15 min and a solids content similar to that maintained in the activated sludge process. For the treatment of industrial wastewaters, a trickling filter is considered a pretreatment process usually designed to remove approximately 50% of the BOD. Note that recirculation of the effluent into the influent is commonly practiced to reduce influent organic concentration and maintain a ‘wetted’ filter growth. Both carbonaceous and nitrogenous oxygen demand can be reduced using trickling filters.

Figure 7 is a schematic diagram of a typical ‘old style’ rock filled trickling filter installation. Oxygen is supplied because of the ‘open-air’ nature of the filter, and the wastewater is applied to the filter medium via the distributor, which rotates because of the momentum induced by the carrier water. The medium shown is stone, although today filters utilize synthetic media such as PVC, which allows greater depths of filtration and a larger specific surface for microbial growth. Multi-stage filters can be used if needed to comply with more stringent effluent standards. Filters may also be covered and off gases treated to reduce or eliminate odor problems.

Figure 7.

Schematic diagram of a rock filled trickling filter.

Membrane Bioreactors (MBRs) and Moving Bed Bioreactors (MBBRs)

Membrane Bioreactors (MBRs) consist of a biological reactor with suspended biomass and solids removal by ultra- and microfiltration membranes. These can be used for municipal or industrial wastewaters. The MBRs allow for a much higher biomass concentration to be maintained, thereby allowing smaller bioreactors to be used and saving space. Separation of solids by membrane filtration eliminates the need for secondary sedimentation, and small pore size prevents the discharge of most pathogens. The MBRs can be operated with a longer solids retention time, allowing for more complete oxidation of organics and the maintenance of a population of slow-growing bacteria capable of nutrient, EDC and PPCPs removals and reduced biosolids generation. The disadvantage of MBRs is their high capital costs, periodic membrane replacement, high energy costs and need to control membrane fouling. They offer a competitive alternative when nutrient removal is required. Energy costs have recently been significantly reduced and comparable with advanced wastewater treatment systems.

Moving Bed Bioreactor (MBBR) technology is an advanced secondary wastewater treatment process that incorporates attached growth media within a suspended growth reactor in order to increase the amount of biomass in the treatment basin. It has a smaller footprint compared to conventional suspended growth systems. Existing aerated treatment process can be easily retrofitted to an MBBR process by adding the plastic media and effluent screens. Because of longer sludge retention times, enhanced nitrification and priority pollutant removal is achieved.

Anaerobic Treatment

Anaerobic treatment processes involve the biological breakdown of organic waste to methane and carbon dioxide gases in the absence of oxygen. Because of lower cost compared to aerobic processes, the beneficial use of methane production, low sludge production, and low energy and nutrient requirements, anaerobic processes have become more attractive alternatives for the stabilization of certain wastes, in particular high-strength industrial wastes (e.g., food industries) and biological sludge. Now over 850 anaerobic treatment systems are in operation globally with about 75% of these treating wastewaters from the food or related industries. Today, more than 60 anaerobic treatment systems are being employed in the chemical and petro-chemical industries. Examples of anaerobic processes are anaerobic filter reactor, anaerobic contact process, fluidized-bed reactor, upflow anaerobic sludge blanket, ADI-BVF process, and expanded granular sludge bed process. These processes are discussed in detail in other texts including Eckenfelder et al., Metcalf & Eddy, etc.

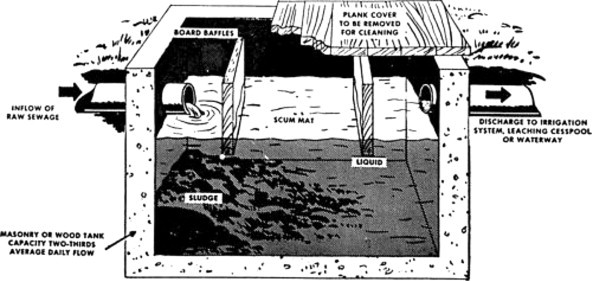

Septic Tanks

A discussion of biological treatment would not be complete without mentioning the septic tank, inasmuch as a large segment of the population is still served by this primitive device, as shown in Figure 8 . From previous discussion, it can be seen that the process is anaerobic, will accumulate solids, and unless periodically pumped out (every 2 to 3 years) will discharge objectionable material. The discharge from such a tank usually flows into a designed drain field and ultimately into the groundwater and/or surface water. A well-designed drainage system into a suitable soil is mandatory since the septic tank itself acts only as a settler and its discharge remains high in soluble organic and microbial contaminants. Proper hydrogeologic conditions are therefore critical in effective drainage field treatment.

Figure 8.

Septic tank.

Residuals (Sludge) Treatment

One of the most pervasive problems in water pollution control is the disposal of the solids produced in the various separation processes. If chemicals are added, the sludge produced may be different from a biological sludge and will increase the sludge volume produced. Thus, the nature of the solids produced may vary considerably and therefore necessitate different treatment scenarios prior to ultimate disposition.

The choices for the ultimate disposition of sludge are few and consist of some type of land application, incineration, or reuse. Incineration leaves a residue that must be disposed of, and concern exists regarding air-quality impacts. Thus, the ultimate residing place of the solids produced in wastewater treatment is into/onto the land or some other reuse alternative.

The objectives of the processes used to treat sludge prior to its final disposition are to reduce the volume, destroy pathogens, remove water, improve efficiency of subsequent processes, control putrescibility, and stabilize organics. Because the final product must be transported to its ultimate disposal or reuse site, attainment of these objectives will reduce transportation costs and minimize adverse environmental/public health effects. As indicated by Figure 9 , the sequence of unit processes for residuals management typically includes thickening, stabilization, dewatering, and ultimate disposal or reuse.

Figure 9.

Sequence of unit processes for residuals management.

Thickening

The primary objective of sludge thickening is to concentrate the solids, thus reducing the volume of sludge. Thickeners may increase the solids concentration by a factor of 2–5 and produce a clarified liquid effluent. Thickening is accomplished by either gravity or dissolved-air flotation. A gravity thickener is shown in Figure 10 . The operation of a dissolved-air flotation unit is similar to that described for pretreatment. Decanted liquid is recirculated to the treatment plant influent.

Figure 10.

Gravity thickener.

(Courtesy of Link-Belt, FMC Co.)

Sludge Stabilization

Organic sludge must be stabilized before reuse or ultimate disposal except in the case of incineration. The most common method to stabilize residual solids is by aerobic or anaerobic digestion. Aerobic digestion stabilizes excess biological solids by the oxidation of cellular organic matter through endogenous metabolism. Conventional aerobic digestion employs aeration of primary and secondary clarifier underflow in one or more completely mixed aeration basins. Diffused air or surface mechanical aerators are used to provide mixing and oxygen requirements. An aeration time of 10–20 days is usually provided based on temperature. Volatile solids reduction are in the range of 30–50%, with greater than 44% being most desirable. The digested sludge can be disposed of without causing odor or other nuisance conditions. The oxygen required for aerobic digestion can be estimated as 1.4 lb of oxygen consumed for each pound of volatile suspended solids destroyed. Nitrogen and phosphorus will be released by the oxidation process and nitrification will usually occur. As the sludge age is increased in the bioreactor, more of the degradable biomass is oxidized and less will be oxidized in the aerobic digester. The digester can be used as a source of biological seed if toxicity or inhibition is observed in the secondary treatment unit.

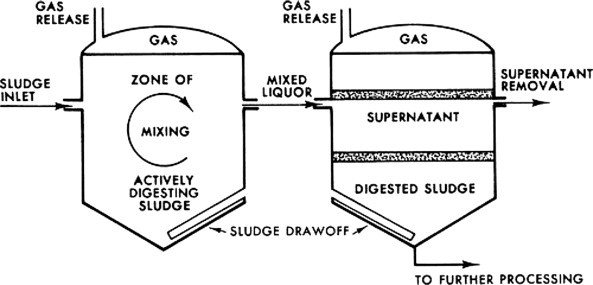

Anaerobic fermentation or sludge digestion decomposes organic matter in the absence of molecular oxygen. In contrast to the aerobic stabilization process, anaerobic digestion produces methane and carbon dioxide from the organic material as follows:

The process actually has two reactions occurring: one where complex organics are hydrolyzed and fermented into simple organic acids, and a second in which the organic acids are converted to methane and carbon dioxide. Anaerobic digesters are usually operated at a temperature near 95 F, which means that heat must be supplied. Depending on the process used, detention times may vary from 10 to 60 days, and the gas composition of a well-operated digester is about 70% methane and 30% carbon dioxide. The methane gas may be used to heat the digester or to run machinery in the plant; however, any hydrogen sulfide present must be removed because of its corrosive nature. Thermophilic digestion may be employed. It occurs at temperatures between 120 and 135 F. At the higher temperatures reaction rates are greater and thus the required retention time is reduced compared to mesophilic digestion. Other reported advantages include: improved dewaterability and increased pathogen destruction. Disadvantages are high energy requirements, poorer quality supernatant, odors and less process stability.

A two-stage anaerobic digestion operation is shown schematically in Figure 11 . Note that if the gas is not utilized, it must be flared. In addition, the supernatant shown is high in BOD and solids and must be directed into the plant influent for treatment.

Figure 11.

Two-stage anaerobic digester

Advantages of the process include no oxygen required, a reduction in sludge volume, methane production, inactivation of pathogens, and the production of a good soil conditioner. The major disadvantages are a high capital cost and the need for careful operation.

Sludge Dewatering

Several methods of sludge dewatering are available, depending on the size of the plant, the kind of sludge, and site-specific considerations.

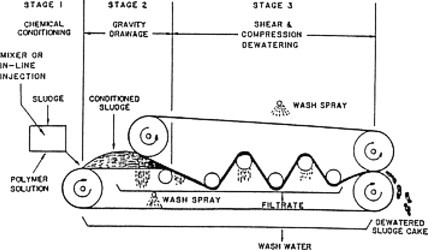

A commonly employed unit process for dewatering thickened municipal and industrial sludge is the belt filter press. As shown in Figure 12 , chemically conditioned sludge is fed through two filter belts and is squeezed by force to drive water through these belts. Chemical polymers are required to promote flocculation and enhance dewatering. A final solids concentration range of from 20 to 35% can be expected depending on the characteristics of the sludge and the method of operation.

Figure 12.

Belt filter press

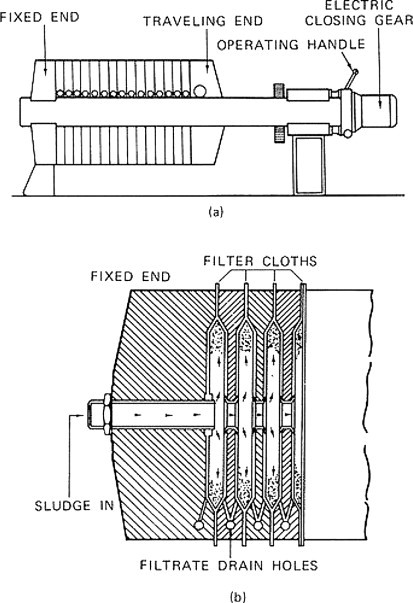

The pressure filter, as shown in Figure 13 (a) and Figure 13 (b), is another alternative. The sludge is fed into the press and pressure is applied so that the filtrate passes through the cloth with the solids being retained and forming a cake on the cloth. The medium is usually precoated. The filtrate is collected in the drainage ports provided at the bottom of each press chamber. The pressure operation ceases when the filtrate flow is near zero, at which time the press is opened and the cakes released. Most municipal sludge can be dewatered to produce a cake solids of 40–50% with 225-lb in− 2 filters. Conditioning chemicals such as lime, ferric chloride, or polymers are often used to enhance dewatering and minimize cloth plugging. Fly ash and coal fines have also been employed to reduce cake compressibility, thereby enhancing dewatering but adding to the sludge volume.

Figure 13.

(a) Side view of a filter press; (b) filter press cutaway view.

Several types of centrifugal dewatering are also used, where the centrifuge uses centrifugal force to enhance the sludge particle sedimentation rate and concentrate the solids. Flocculants are added with the sludge to increase removal of fines. Solid-bowl centrifuges are typically employed for dewatering to 20–35% solids. Both centrate and cake solids are continuously discharged from the machine. The centrate must be returned to the plant influent for treatment.

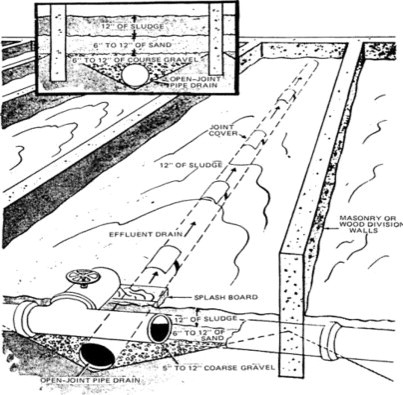

Sludge drying beds are often used for small sludge volumes, which drain and dry rapidly. Application is usually restricted to the more arid climates. A schematic is presented in Figure 14 . The filtrate is returned to the treatment plant. About 10–30% solids can be expected depending on specific application. With good weather, well-digested sludge may achieve as high as 45% solids concentration in 6 weeks. Covered beds have also been employed in wetter climates.

Figure 14.

Sand drying beds

Other methods of sludge treatment include composting, thermal treatment, incineration, advanced alkaline stabilization, and wet oxidation. Of course, combustion methods may lead to air pollution problems and have residual ash to be disposed. It should be noted that other less utilized methods exist, and treatment may be used prior to the methods described for stabilization and/or conditioning.

Ultimate Disposition of Solids

The quality/ultimate disposition of sludge (termed biosolids for municipal wastewater residuals) is currently governed by the USEPA through 40 CFR Part 503 of the 1987 Clean Water Act Amendments. The EPA promotes practices that provide for the beneficial use of municipal sewage sludge biosolids, while maintaining or improving environmental quality and protecting public health. These practices typically include land application of biosolids as a soil amendment or fertilizer supplement and various procedures that derive energy from biosolids or convert them to useful products.

Part 503 standards provide for a wide range of end-use possibilities for biosolids that depend on sludge characteristics and treatment methods. Processes defined as Processes to Significantly Reduce Pathogens (PSRP) generate a ‘Class B’ sludge that may be used under restricted conditions. Those biosolids processed by Processes to Further Reduce Pathogens (PFRP) are termed a ‘Class A’ sludge and can be used unrestrictedly. The term ‘Exceptional Quality’ is often used to describe a biosolids product which meets Class A requirements. The end product must be stable (i.e., no odors, no vector attraction), noninfectious, and of sufficiently low metals content so as not to translocate and bioaccumulate to undesirable levels. Some treatment technologies capable of producing a Class A sludge include composting, heat drying, auto-thermal thermophilic aerobic digestion, pasteurization and gamma radiation.

The constraints on the use of sludge for growing edible crops are primarily associated with the presence of heavy metals, the nitrogen content, and the possibility of the presence of phytotoxic materials in the sludge. Particular care must be given if the solids contain contributions from industry.

Some metals of concern include arsenic, mercury, lead, zinc, copper, and nickel, although the limiting metal is usually cadmium. Cadmium is of particular concern because of its potential translocation from the soil to the fruit and the ability of certain crops, such as chard, to accumulate significant quantities in the edible portion of the plant. Other metals such as arsenic may also be accumulated in fruit and grain to levels exceeding FDA and other regulatory limits.

Nitrogenous material is also of concern and may be a limiting factor in sludge application rates. Because soil biochemical reactions are mostly aerobic, nitrification will occur, and if the nitrogen is not used by the crops, it will be converted to nitrate. Nitrate in groundwater can cause methemoglobinemia in infants.

The helminths may pose a pathogen threat because they concentrate in the sludge and possess the ability to survive extremely adverse environments. For example, Ascaris ova have been found to survive for as long as 7 years. Other pathogens may cause restrictions on crops grown in sludge application sites.

Groundwater is of primary concern in areas where sludge is applied and potential adverse effects must be considered. The travel of various contaminants through soil depends on many factors, including the soil composition, the contaminant, its concentration and speciation, and the groundwater hydrology.

As previously indicated, when biosolids are effectively treated and recycled they can be used as a significant resource. Reduced disposal volume conserves land disposal facility capacity. Other benefits include improved soil fertility and tilth, reduced need for fertilizers, better growth and quality of crops, and decreased energy consumption. According to the USEPA Biosolids Fact Sheet for Land Application of Biosolids in 2000, nationally about 60% of biosolids were land applied. In California it was 70% and in Oregon 95%. Stabilized biosolids have also been employed as intermediate and final landfill cover; to recover lands devastated by mining; and, smelting activities, and for wetlands reclamation.

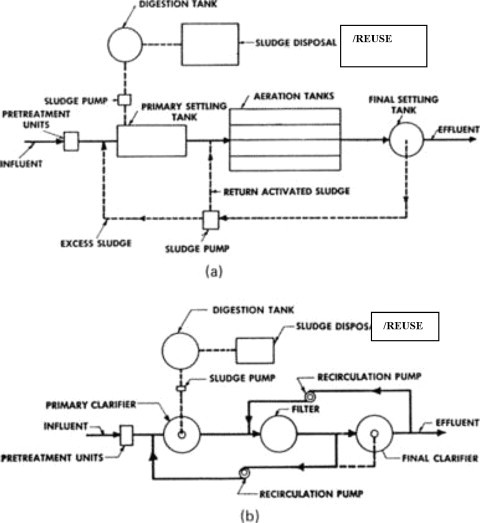

Advanced Wastewater (Tertiary) Treatment

Thus far, the conventional treatment of wastewaters has been described (BCT), and one may conclude that organic waste materials (BOD), suspended solids, and bacteria can be reduced with relatively high efficiency, as shown in Table II . The treatment plant flow scheme may be arranged as shown in Figure. 15(a) (activated sludge) or Figure 15(b) (trickling filtration). Considering the concepts previously discussed, one can trace the flow and removal of the three parameters of primary concern (BOD, suspended solids, and the bacterium Escherichia coli) by conventional treatment.

Table II.

Efficiencies of treatment processes for domestic sewage

| Treatment | BOD (%) | Suspended solids (%) | Escherichia coli (%) |

|---|---|---|---|

| Plain sedimentation | 25–40 | 40–70 | 25–75 |

| Chemical precipitation | 50–85 | 70–90 | 40–80 |

| High-rate trickling filtration preceded and followed by plain sedimentation | 65–95 | 65–92 | 80–95 |

| Low-rate trickling filtration preceded and followed by plain sedimentation | 80–95 | 70–92 | 90–95 |

| High-rate activated sludge preceded and followed by plain sedimentation | 65–95 | 65–95 | 80–95 |

| Conventional activated sludge preceded and followed by plain sedimentation | 75–95 | 85–95 | 90–98 |

| Chlorination of biologically treated sewage | – | – | 98–99 |

Figure 15.

Flow schemes for conventional municipal wastewater treatment

Other contaminants may not be significantly reduced using secondary treatment and therefore must be subjected to other removal techniques or tertiary treatment (BATEA). These contaminants include toxic organics, VOCs, phosphorus, nitrogen, heavy metals, refractory organics, and difficult-to-remove pathogens such as Giardia lamblia. Some processes investigated and applied with success for removals include coagulation and flocculation, filtration, ion exchange, nitrification, denitrification, membrane processes, air stripping, adsorption, and chemical oxidation. These will be discussed briefly in the following sections.

Suspended Solids Removal

Total Suspended solids (TSS) removal by tertiary treatment implies the removal of those materials that have been carried over from a secondary clarification process. Pretreatment is required prior to physical chemical treatment processes. Influent suspended solids concentration must be less than about 100 mg l− 1 or backwashing requirements become excessive for sand filtration. Finely dispensed suspended solids may require the addition of coagulant prior to filtration. Several means for removal of suspended solids have been proposed and tested. These include the use of diatomaceous earth filtration, pressure filtration, chemical clarification, sand filtration with conventional and multimedia units, ultrafiltration, and the moving-bed filter. With the exception of the chemical clarification processes, these methods all involve removal by physical straining of the finely divided solids.

Diatomaceous earth filtration is a form of mechanical separation that uses diatomaceous earth, a powdered filter aid, that is built up on a supporting medium. As filtration proceeds, the solid material that will not pass through the diatomaceous earth is retained and eventually builds up a pressure that will no longer allow filtration. At that point, the unit is backwashed and made ready for another cycle. It should be noted that the diatomaceous earth filtration process was developed during World War II to remove the cysts that cause amoebic dysentery and is presently quite common in swimming pool filtration.

Chemical clarification consists of four phases: coagulation, flocculation, sedimentation, and filtration. Coagulation, essentially the addition of chemicals that are rapidly mixed with the water, usually involves the use of polymers and/or the oxides of aluminum, iron, or calcium. Once the coagulation step (charge neutralization) is accomplished, the flocculation process then allows aggregation, neutralization, and adsorption of the floc particles. This process is followed by the sedimentation process, where the flocs that have been previously formed are allowed to settle. Although most of the flocculated material will be removed in the sedimentation tank, it is usually required to further remove the floc particles that do not settle by the use of a filtration process that is conducted in beds of porous media such as sand.

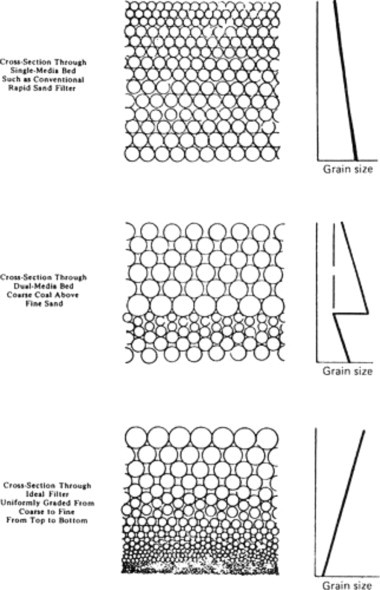

The usual means of filtration has been through sand beds containing graded sand placed on a supporting medium containing an underdrain to collect the filtered effluent. As wastewater containing solids is passed through this type of filter, the solids will accumulate and eventually clog up the openings causing high head loss and/or poor effluent quality. Thus, some provision must be made to remove the collected material. The procedure usually followed is to backwash the sand, that is, to reverse the flow, usually with air scour, so that the sand is suspended and the lighter material is washed away. It should be noted that subsequent to a backwashing operation, the sand will settle according to size and thus become stratified, with the smaller particles at the top. Since these particles will filter out most of the solid material, it may be concluded that the entire depth of a sand bed is not utilized in a filtration process. To alleviate this problem, a multimedia filter is employed, involving different filtration materials, each having a different specific gravity. Materials commonly used are sand, coal, and garnet, as shown in Figure. 16 . This type of filter extends the length of the filtration runs and demonstrates high efficiency. Filter loadings are usually designed from 2 to 6 gpm/ft2 with 4 gpm/ft2 being the most typical.

Figure 16.

Stratification of different types of filters. (a) The activated sludge process; (b) the trickling filtration process.

The moving-bed filter is a technique that is essentially a form of countercurrent extraction, that is, feeding the sand countercurrent to the filtering water. As the filter surface becomes clogged, the filter medium is moved forward and a new surface is exposed. It is said that, theoretically, 1% of the filter is being backwashed 100% of the time as compared to a conventional backwashing operation where 100% of the filter is backwashed 1% of the time.

Ultrafiltration or nanofiltration uses pressure to drive a liquid through a membrane permeable to some consituents including fine particles, viruses, bacteria and protozoans. This process is similar to reverse osmosis, but differs with respect to the size of the particles that are separated. Ultrafiltration will generally not retain a particle whose weight is 500–1000 times the molecular weight, and thus it fails to separate inorganic salts. The pressures used in ultrafiltration are on the order of 50 lb/in2 as contrasted to pressures exceeding 500 lb/in2 in reverse osmosis. The process is essentially one of pressure filtration, using semipermeable membranes that act as molecular screens and separate colloidal and molecular materials that are dissolved or suspended in the liquid phase.

Organic Removal

As previously indicated, wastewaters may contain measurable amounts of refractory soluble organics, toxics, VOCs and other contaminants not removed by conventional processes. These problem organics may be removed at the source (usually recommended), within the biological treatment step, and/or in the tertiary treatment stage following conventional treatment. The composition of refractory organics is not always precisely known. Although they are not easily biologically oxidizable, they may exercise a BOD in a receiving water over time. In addition, these materials may cause taste and odor problems in a water supply, and more important, the potential toxicological effects on the aquatic environment and on humans have not been precisely delineated. Toxics are of concern and must be removed or reduced to below threshold concentrations prior to biological treatment. VOCs may result in noncompliance with air regulations and result in worker and public health concerns.

Volatile organics (benzene, toluene, etc.) should be removed by pretreatment prior to biological treatment. Air stripping or steam stripping can be used depending on the characteristics of the volatile organics. Air stripping is accomplished in packed or tray towers with countercurrent air–liquid flow. The off gas must be treated through vapor-phase carbon, biofilters, combustion or other methods. Steam stripping introduces steam in a packed tower, causing volatiles to be removed in the vapor phase. Biofilters can also be employed to treat off-gases from the stripper and/or aeration basin. This low-cost method employs a porous medium that promotes sorption into a liquid film on the medium surface followed by microbial stabilization. Powdered activated carbon (PAC) has been used in the aeration basin to adsorb VOCs and toxic compounds.

Chemical oxidation is typically employed to treat contaminants that may be non-biodegradable (refractory), toxic or inhibitory to microbial growth, and odor causing. Oxidizing agents used include ozone, O3; hydrogen peroxide, H2 O 2; permanganate, MnO− 4; various chlorine compounds; or even oxygen. These reactions frequently require catalysts to be cost effective. Such catalysts include UV light for ozone and hydrogen peroxide. Ferrous iron (FeSO4 or Fenton's reagent) at pH of about 3.5 is frequently employed for use with H2O2. Metal oxides such as titanium dioxide have also been employed for O3 catalysis. Ozone and UV plus various catalysts may be combined for specific waste in advanced oxidation processes. It is often not cost effective to carry the chemical oxidation to completion. Partial oxidation to compounds may be sufficient to render specific compounds such as many priority pollutants less toxic and more amenable to subsequent and less expensive biological treatment.

Adsorption may also be used to remove toxics, refractory organics, some heavy metals, and VOCs. Activated carbon possesses the property of attracting many contaminants to adhere to its surface via adsorption. Activated carbon is very porous with a very high surface-area-to-unit-weight ratio and thus possesses a high adsorption capacity for the hydrophobic soluble organics in wastewater. It can be contacted with wastewater either as a very fine powder or as granules. Since the powdered form is not conducive to column operation, granular activated carbon is used most frequently in advanced wastewater treatment plants. As the wastewater passes through the bed and the constituents from the wastewater are adsorbed onto the carbon, the sites available for adsorption will be exhausted and the bed must be replaced. The replacement can either be by new activated carbon material or by thermal regeneration of the exhausted bed. The sorption capacity of regenerated carbon however may be reduced as compared to the virgin material. In large plants, regeneration by high temperatures is usually practiced. Powdered activated carbon (PAC) can be added to the activated sludge process for enhanced performance (the PACT process). This has been shown effective for removing many priority pollutants and refractory organics. It can also remove color and enhance nitrification.

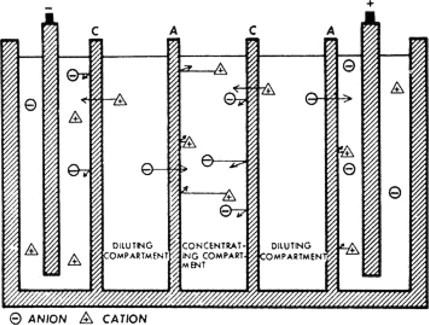

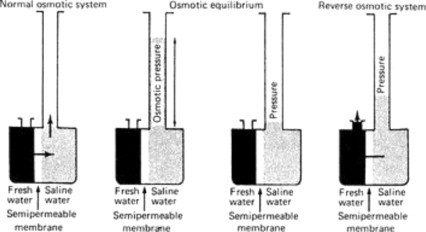

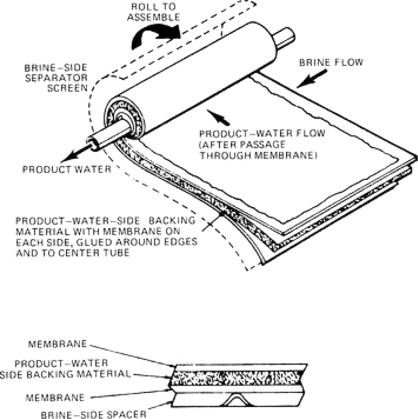

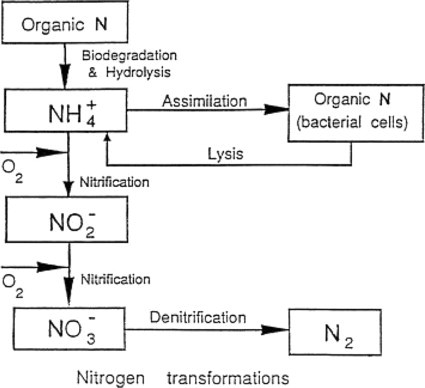

Inorganic Removal