Abstract

The chapter discusses the indoor environmental quality. A variety of factors have been found to contribute to poor indoor-air quality in buildings, the primary one being indoor pollution sources that release gases or particles into the air and the other major sources include outdoor pollutants . The chapter illustrates the factor affecting the indoor environmental quality which are inorganic contaminants, contaminants generated by combustion, organic contaminants, biological contaminants, and reducing exposure. People from different cultures have different comfort zones; even people belonging to the same family may feel comfortable under different conditions, and keeping everyone comfortable at the same time is an elusive goal at best. Thermal comfort involves temperature, humidity, and air movement. A comfort zone includes an optimal range and combinations of thermal factors, in which at least 80% of the building occupants feel satisfied. Ventilation is vital for the health and comfort of building occupants. It is needed to reduce and remove pollutants emitted from various internal and external sources. Good design combined with optimum air tightness is prerequisite to ensure healthy air quality, occupant comfort, and energy efficiency. There has been a lack of systematic experiments in which building materials are ranked according to their pollution strength and the impact on the indoor-air quality of using these materials in real rooms analyzed. These studies allow to quantify the extent to which using low-polluting building materials would reduce the energy needed for ventilation of buildings without compromising indoor-air quality.

7.1. General Overview

Poor indoor environmental quality has become a major concern in homes, schools, and workplaces; it can lead to poor health, learning difficulties, and productivity problems. Since the majority of us spend up to 90 percent of our time indoors (especially in the United States), it is not surprising that we should expect our indoor environment to be healthy and free from the plethora of hazardous pollutants. Yet studies by the American College of Allergies show that roughly 50 percent of all illness is aggravated or caused by polluted indoor air. Moreover, cases of building-related illness (BRI) and sick-building syndrome (SBS) continue to rise. The main reason is that the indoor environment we live in is often contaminated by various toxic or hazardous substances as well as pollutants of biological origin (Figure 7.1). In fact, recent studies point to the presence of more than 900 possible contaminants, from thousands of different sources, in a given indoor environment.

Figure 7.1.

Percentage of buildings with inappropriate concentrations of contaminants.

Source: HBI database of 2,500 buildings.

Indoor-air pollution is now generally recognized as having a greater potential impact on public health than most types of outdoor-air pollution, causing numerous health problems from respiratory distress to cancer. Furthermore, a building interior's air quality is one of the most pivotal factors in maintaining building occupants’ safety, productivity, and wellbeing.

This heightened public awareness has led to a sudden surge of demands from building occupants for compensation for their illnesses. Tenants are not only suing building owners but also architects, engineers, and others involved in the building's construction. To shift the blame, building owners have made claims against the consultant, the contractor, and others involved in the construction of the facility.

While architects and engineers to date have not been a major target of publicity or litigation arising out of IAQ issues, nevertheless the potential scope and cost of some of the incidents have resulted in everyone associated with a project being blamed when the inside air of a building appears to be the cause of occupants becoming sick. This is causing great concern among design professionals, because it can result in a loss of reputation as well as time and money.

Due to the intense competition to maintain high occupancy rates, forward-thinking owners and managers of offices and public buildings find themselves under increasing pressure to meet or exceed the demands of the marketplace in attracting and retaining tenants. Moreover, in today's increasingly litigious society, they add another factor to be addressed – protecting their investment from liability due to air-quality issues.

Technological breakthroughs are bringing down the cost of facility monitoring systems and making them more affordable for a wider range of building types. By reducing the cost of facility monitoring many financial and maintenance obstacles are removed, making permanent monitoring systems an appropriate consideration for a broader range of facility managers. Schools, healthcare facilities, and general office buildings can benefit from measuring many of the environmental conditions and using that information to respond to occupant complaints, optimize facility performance, and keep energy costs in check. In addition, feedback from the indoor environment can be used to establish baselines for building performance and document improvements to indoor-air quality.

Facility monitoring systems can be valuable instruments for improving indoor-air quality, identifying energy-savings opportunities, and validating facility performance. Automating the process of recording and analyzing relevant data and providing facility managers adequate access to this information can improve their ability to meet the challenge of maintaining healthy, productive environments.

Buildings are dynamic environments – but sometimes the original design calculations, which may have been sound, need modifying after they are operational. Experience tells us that a building's functions and occupancy rates may change. These changes can have a significant impact on the HVAC system's ability (as originally designed) to maintain a balance between occupant comfort, health, productivity, and operating costs.

Indoor pollution is found to exist under many diverse conditions from dust and bacterial buildup in ductwork to secondhand smoke and the offgassing of paint solvents, all of which are potential health hazards.

The primary causes of poor indoor-air quality are sources that release gases or particles into the air. Inadequate ventilation is considered the single most common cause of pollutant buildup (Figure 7.2a) because it can increase indoor pollution levels by not bringing enough outdoor air in to dilute emissions from indoor sources and by not removing indoor-air pollutants to the outside. High temperature and humidity levels can also increase concentrations of some pollutants. The second most common cause of pollutant buildup is inefficient filtration (Figure 7.2b). But despite fundamental improvements in air-filter technology, far too many buildings persist in relying on inefficient filters or continue to be negligent in the maintenance of filters.

Figure 7.2.

(a) Inadequate ventilation is the single most common cause of pollutant buildup. (b) Inefficient filtration is the second most important factor in indoor pollution.

Source: HBI Database.

An investigation into indoor-air contamination can be triggered by several factors including the presence of biological growth (mold), unusual odors, and adverse health concerns of occupants, including respiratory problems, headaches, nausea, irritation of eyes, nose, or throat, and fatigue.

Indoor environmental quality (IEQ) and energy efficiency may be classified into three basic categories: comfort and ventilation, air cleanliness, and building pollutants. Within these basic categories, facility-wide monitoring systems are available that can provide independent measurement of a range of parameters, such as temperature, humidity, total volatile organic compounds (TVOCs), carbon dioxide (CO2), carbon monoxide (CO), and airborne particulates. Any information that is extracted from continuous monitoring can help minimize the total investigative time and expense needed to respond to occupant complaints; the information can also be used proactively in the optimization of building performance.

Unfortunately, to this day there has been insufficient federal legislation governing indoor-air quality. This has led several engineering societies such as the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) to establish guidelines, which are now generally accepted by designers as minimum design requirements for commercial buildings. ASHRAE has established two procedures for determining minimum acceptable ventilation rates: the ventilation-rate procedure, which stipulates a minimum ventilation rate based on space functions within a specified building type and respiration rates resulting from occupants’ activities; and the indoor-air quality procedure, which requires the monitoring of certain indoor-air contaminants below specified values.

Air sampling techniques require the use of a device to impinge organisms from a specific volume of air and place it onto a sterile agar growth medium. The sample is then incubated for a specified period of time (say, seven days). The colonies are then counted and the results recorded. When testing the air of a potentially contaminated area, it is best practice to have comparative samples of air from both the contaminated area and the air outside the potentially contaminated building.

Sometimes building occupants complain of symptoms that do not appear to fit the pattern of any specific illness and are difficult to trace to any specific source. This has been labeled sick building syndrome (SBS) and is a fairly recent phenomenon. It is a term used to describe situations in which building occupants experience acute health and discomfort effects that appear to be attributed to time spent in a building, but often no specific illness or cause can be identified. Complaints may be localized in a particular room or zone or may be widespread throughout the building. Factors that may impact SBS include, noise, poor lighting, thermal discomfort, and psychological stress. The EPA's indoor-air-quality website contains pertinent information regarding strategies for identifying the causes of SBS as well as finding possible solutions to the problem. SBS indicators include:

-

•

Building occupants complaining of symptoms associated with acute discomfort, such as eye, nose, or throat irritation; headaches; respiratory infections and dry cough; dry or itchy skin; erythema (redness of the skin, inflammation); dizziness and nausea; irritability and forgetfulness; difficulty in concentrating; fatigue or lethargy; and sensitivity to odors.

-

•

Cause of symptoms not identified.

-

•

Most complainants find relief shortly after leaving building.

In contrast, building-related illness (BRI) is the general term used to describe symptoms of a medically diagnosable illness that is caused by or related to occupancy of a building and that can be attributed directly to airborne building contaminants. The causes of BRIs can be determined and are typically related to allergic reactions and infections. BRI indicators of include:

-

•

Building occupants complain of symptoms such as cough, fever, chills, chest tightness, and muscle aches.

-

•

Symptoms can be clinically defined and have clearly identifiable causes.

-

•

Complainants may require extended recovery times after leaving the building.

It should be noted that there is no particular manner in which these health problems appear. Sometimes, they begin to appear as workers enter their offices and diminish or disappear as workers leave; at other times symptoms persist until the illness is treated. On occasion there are outbreaks of illness among many workers in a single building; in other cases, they show up only in individual workers.

Complaints may also result from other causes. Since SBS symptoms are quite diverse and nonspecific, it can seem that they could arise from numerous other ailments completely unrelated to indoor air quality. In light of these types of complaints, technical and medical scholars have searched for a satisfactory definition of SBS, especially since it is the most common indoor-air-quality problem in commercial buildings today. To this end, some World Health Organization (WHO) experts estimated that 30 percent of all new and renovated commercial buildings in the U.S. suffer from SBS, and furthermore the expenses in terms of medical costs and lost production may be in the tens of billions of dollars per year in the U.S. alone.

According to industry IAQ standards, SBS is diagnosed if significantly more than 20 percent of a building's occupants complain of adverse health effects such as headaches, eye irritation, fatigue, and dizziness over a period of two weeks or more, but no clinically diagnosable disease is identified, and the SBS symptoms disappear or are diminished when the complainants leave the building.

We are surrounded by microorganisms both indoors and outdoors. Some microor-ganisms are good for our health, while others can harm us; most microorganisms are benign. It is important to prevent buildings from becoming breeding grounds for harmful microbes, and to do that one needs to deprive them of the essentials they need to live. Water is one of microbes’ main survival ingredients. It can come from leaky roofs, burst water pipes, or warm, moist air, as when water is absorbed by ceiling tiles, drywall, and carpet padding.

The greatest amount of our time is spent indoors, and more than half of today's work force spends much of it sitting in front of a computer screen. It is not surprising that we should witness a steady increase in chronic work-related illness, including repetitive stress injuries, asthma, and cardiovascular disease – all suggesting that much of our artificial environment is hazardous to workplace productivity.

It has been known for some time that indoor environments strongly affect human health. The EPA, for example, has estimated that pollutant concentration levels (such as volatile organic compounds) inside a building may be two to five times higher than outside levels. A 1997 study by W.J. Fisk and A.H. Rosenfeld (“Estimates of Improved Productivity and Health from Better Indoor Environments,” Indoor Air, vol. 7, pp. 158–172) estimates that the cost to the nation's workforce of upper-respiratory diseases in 1995 reached $35 billion in lost work, which doesn't include an estimated additional $29 billion in healthcare costs. The report suggests that these costs could be reduced by 10 to 30 percent by healthier and more efficient indoor environments.

Certain attributes of indoor environments can also have a strong impact on occupant wellbeing and functioning; these include personal control over environmental conditions, the amount and quality of light and color, the sense of privacy, access to window views, connection to nature, and sensory variety. Proper design that takes into consideration occupants’ psychological well-being will have a positive impact on worker productivity and effectiveness as well as on other high-value issues, such as stress reduction, job satisfaction, and organizational loyalty.

In order to fully profit from the fiscal, physical, and psychological benefits of healthy buildings, projects need to incorporate a comprehensive, integrated design and development process that seeks to:

-

•

Ensure adequate ventilation

-

•

Provide maximum access to natural daylight and views to the outdoors

-

•

Eliminate or control sources of indoor-air contamination

-

•

Prevent water leaks and unwanted moisture accumulation

-

•

Improve the psychological and social aspects of space

There are currently several environmental rating methods for buildings, but it is not always clear whether these methods assess the most relevant environmental aspects or whether other considerations lie behind the specific methods chosen. The Swedish rating method bases the selection on a number of factors such as the severity and extent of problems, mandatory rules, official objectives, and current practice. Upon identifying the presence of building-related health problems, possible indicators for monitoring these problems can be tested with respect to the theoretical and practical criteria applied in order to better understand the strengths and limitations of different indicators.

Concern for occupant health continues to increase with increased awareness, and this has translated into public demand for more exacting performance requirements for materials selection and installation, improved ventilation practices, and better commissioning and monitoring protocols.

Many of the building products used today contain chemicals that evaporate or off-gas for significant periods of time after installation. When substantial quantities of these products are utilized inside a building or products are used that have particularly strong emissions, they pollute the indoor air and can be hazardous. Some products readily trap dust and odors and release them over time. Building materials, particularly when damp, can also support growth of mold and bacteria, which can cause allergic reactions, respiratory problems, and persistent odors – i.e., SBS symptoms.

The Insurance Information Institute (III) reports a dramatic increase in IAQ-related lawsuits within the United States; there are currently more than 10,000 IAQ-related cases pending. Several lawsuits have resulted in large damage awards to building occupants suffering from health problems linked to chemicals off-gassed from building materials, setting legal precedents across the country.

The flood of IAQ-related lawsuits has prompted insurance companies to reexamine their policies and their clients’ design and building methods. An effective way to reduce health risks and thus minimize potential liability is to follow a rigorous selection procedure for construction materials aimed at minimizing harmful effects to occupants.

7.2. Indoor Environmental Quality and Factors Affecting the Indoor Environment

According to a report on indoor environmental quality released by the United States Access Board in July 2005, there is a growing number of people suffering a range of debilitating physical reactions from exposures to everyday materials and chemicals found in building products, floor coverings, cleaning products, and fragrances, among others. In addition, there are those who have developed an acute sensitivity to various types of chemicals, a condition known as multiple chemical sensitivity (MCS). The range and severity of these reactions vary as do the potential triggering agents.

7.2.1. Indoor-Air Quality

The health and productivity of employees and tenants are greatly influenced by the quality of the indoor environment, and studies consistently reinforce the correlation between improved indoor environmental quality and occupants’ health and wellbeing. The adverse effects to building occupants caused by poor air quality and lighting levels, the growth of molds and bacteria, and off-gassing of chemicals from building materials can be significant. One of the chief characteristics of sustainable design is to support the wellbeing of building occupants by reducing indoor-air pollution. This can best be achieved through the selection of materials with low off-gassing potential, appropriate ventilation strategies, adequate access to daylight and views, and optimum comfort through control of lighting, humidity, and temperature levels.

7.2.1.1. Inorganic Contaminants

Inorganic substances such as asbestos, radon, and lead are among the leading indoor contaminants whose exposure can create significant health risks.

7.2.1.1.1. Asbestos

Asbestos is a generic term given to a variety of naturally occurring, hydrated fibrous silicate minerals that posses unique physical and chemical properties that distinguish them from other silicate minerals. Such properties include thermal, electric, and acoustic insulation; chemical and thermal stability; and high tensile strength, all of which have contributed to their wide use by the construction industry (Figure 7.3).

Figure 7.3.

Partial list of materials that may contain asbestos.

High concentrations of airborne asbestos can occur during demolition and after asbestos-containing materials are disturbed by cutting, sanding, and other activities. Inadequate attempts to remove these materials could release asbestos fibers into the air, thereby increasing asbestos levels and endangering people living or working in these spaces.

Asbestos-containing material has become a high-profile public concern after federal legislation known as AHERA (Asbestos Hazard Emergency Response Act) was enacted in 1987. The Environmental Protection Agency and Consumer Product Safety Commission have also banned several asbestos products, and manufacturers have voluntarily limited uses of asbestos. Today, asbestos can still be found in older homes, in pipe and furnace insulation materials, shingles, millboard, textured paints and other coating materials, and floor tiles. Asbestos is considered the most widely recognized environmentally regulated material (ERM) during building evaluations.

Asbestos-containing materials are also found in concealed areas such as wall cavities, below ground level, and other hidden spaces. In many older establishments, asbestos-based insulation was used on heating pipes and on the boiler. An adequate asbestos survey requires the inspector to perform destructive testing (i.e., opening walls, etc.) to inspect areas likely to contain suspect materials.

7.2.1.1.2. Health Hazards

The most dangerous asbestos fibers are too small to be visible. The health danger of asbestos fibers depends mainly upon the quantity of fibers in the atmosphere and the length of exposure. Asbestos is made up of microscopic bundles of fibers that may become airborne when asbestos-containing materials are damaged or disturbed. Impaction and abrasion are typically the chief causes of increased airborne-fiber levels. The type, quantity, and physical condition of the asbestos-based material have a significant bearing on the degree of risk.

The risk of airborne asbestos fibers is generally low when the material is in good condition. However, when the material becomes damaged or if it is located in a high-activity area (family room, workshop, laundry, etc.) the risk increases. Increased levels of exposure to airborne asbestos fibers will cause disease. When these fibers get into the air, they may be inhaled and accumulate in the lung tissue, where they can cause substantial health problems including lung cancer, mesothelioma (a cancer of the chest and abdominal linings), and asbestosis (irreversible lung scarring that can be fatal). Symptoms of these diseases do not show up until many years after exposure began. Studies show that people with asbestos-related diseases were usually exposed to elevated concentrations on the job, although some developed disease from exposure to clothing and equipment brought home from job sites. While the process is slow and years may pass before health problems are evidenced, the results and thus the risks are well established.

7.2.1.1.3. Radon

Radon is a natural odorless, tasteless, radioactive gas that is emitted from the soil as a carcinogenic byproduct of the radioactive decay of radium-226, which is found in uranium ores (although radon itself does not react with other substances). The byproduct can cling to dust particles that, when inhaled, settle in bronchial airways. Generally, radon is drawn into a building environment by the presence of air-pressure differentials. The ground beneath a building is typically under higher pressure than the basement or foundation. Air and gas move from high-pressure areas to low-pressure areas. The gas can enter the building through cracks in walls and floors as well as penetrations associated with plumbing, electrical openings, and sump wells in building spaces coming in close contact with uranium-rich soil. Vent fans and exhaust fans also put a room under negative pressure and increase the draw of soil gas, which can increase the level of radon within a building. Radon exposure becomes a concern when it becomes trapped in buildings and indoor levels of concentrations build up.

Adequate ventilation is necessary to prevent radon from accumulating in buildings to dangerous levels, as this can pose a serious health hazard. Where radon is suspected, a survey should be conducted to measure the concentrations in the air and determine whether any actions will be required to reduce the contamination. Radon levels will vary from region to region, season to season, and building to building. Radon levels are typically at their highest during the coolest part of the day when pressure differentials are at their greatest.

According to the Environmental ProtectionAgency, radon is the cause of an estimated 14,000 lung-cancer deaths annually. The primary factors affecting radon concentrations in the air are ventilation and the radon source. The most common radon source is the presence of radium-226 in the soil and rock surrounding or adjoining basement walls and cellar floor slabs. Although you cannot see radon, it's not hard to find out if you have a radon problem in your home or office. There are many kinds of inexpensive, state-certified do-it-yourself radon test kits available through the mail or in hardware stores and other retail outlets. When radon decays and is inhaled into the lungs, it releases energy that can damage the DNA in sensitive lung tissue and cause cancer.

When high concentrations of radon in air are detected, it is often an indication of possible radon contamination of the water supply (if a private water supply is present). In this case, a water test for radon is the prudent first step. Should high concentrations of radon be found in the water, then an evaluation of ventilation rates in the structure as well as air-quality tests for radon are highly recommended. Generally speaking, high radon concentrations are more likely to exist where there are large rock masses, such as in mountainous regions. The Environmental Protection Agency (EPA) recommends that buildings should be tested every few years to assess the safety of radon levels.

7.2.1.1.4. Radon Mitigation

Everything being equal, elevated radon levels should not necessarily deter investors from purchasing a property, as the problem can usually be easily be resolved, even in existing buildings, without having to incur great expense. However, lowering high radon levels requires technical knowledge and special skills, which means a trained radon-reduction contractor who understands how to fix radon problems.

With new construction, some builders have starting to incorporate radon-prevention techniques in their designs. Some municipalities also have local building codes requiring prevention systems. The EPA has published several brochures and instructional aids regarding radon-resistant construction. This is perhaps the most cost-effective way to handle a radon problem, as it is easier to build the system into the building rather than to retrofit it later. If your building has a radon system built in, the EPA recommends periodic testing to ensure that the system is working properly and that the radon level in your building has not changed. The development of foundation cracks is one example of how the radon level could change.

EPA studies suggest that elevated radon levels are more likely to exist in energy-efficient buildings than otherwise. The reason is that radon can become hazardous indoors due to the limited outside air to dilute the indoor concentrations afforded by efficient construction. Although energy-efficient construction may save energy bills, it may also increase occupants’ exposure to radon and other indoor-air pollutants. It is also recommended that testing for radon should also be conducted when any major renovations are made to the building.

7.2.1.1.5. Health Risks

The principal health hazard associated with exposure to elevated levels of radon is lung cancer. Research suggests that, while swallowing water with high radon levels may also pose risks, these are believed to be much lower than those from breathing air containing radon.

During the decaying process, radon emits alpha, beta, and gamma radiation. However, the real threat is not so much from the gas itself but from the products that it produces when it decays, such as lead, bismuth, and polonium. These products are microscopic particles that readily attach themselves to dust, pollen, smoke, and other airborne particles in a building and are inhaled. Once in the lungs, the particles become trapped, and, as they begin to decay, they expose the sensitive lung tissue to the harmful radiation they emit during the decaying process. The effect is cumulative, and elevated levels of radon exposure cause lung cancer in both smokers and nonsmokers alike. The risk would be greatest for people with diminished lung capacity, asthma sufferers, and smokers.

7.2.1.1.6. Radon Testing Methods

For short-term testing, consultants typically use electret ionization chambers, which generally last about a week. The chamber method works by incorporating a small charged Teflon® plate screwed into the bottom section of a small plastic chamber. When the radon gas enters the chamber, it begins to decay and creates charged ions that deplete the charge on the Teflon® plate. By registering the voltage prior to deployment and then reading the voltage upon recovery, a mathematical formula is used to calculate the radon concentration levels within the building.

For long-term testing, consultants prefer to use either long-term electret chambers (like those used for the short-term measurements) or alpha tracks. The alpha track, when deployed in the building, records the number of alpha particles that scratch the plastic surface inside the detector. The laboratory counts these microscopic indentations and then mathematically calculates the radon levels within the building.

7.2.1.1.7. Lead

For many years now, lead has been recognized as a harmful environmental pollutant to the extent that in late 1991 the Secretary of the Department of Health and Human Services described it as the “number one environmental threat to the health of children in the United States.” There are many ways in which humans may be exposed to mineral particles of lead: in ambient air, drinking water, food, contaminated soil, deteriorating paint, and dust. Lead is a heavy metal; it does not break down in the environment and continues to be used in many materials and products to this day. Lead is a natural element; and most lead in use today is inorganic lead, which enters the body when an individual breathes (inhales) or swallows (ingests) lead particles or dust once it has settled. Lead dust or particles cannot penetrate the skin unless it is broken. (Organic lead, however, such as the type used in gasoline, can penetrate the skin.)

7.2.1.1.8. Indoor Lead Levels

Because of its widespread use, lead has for some time been known to be a common contaminant of interior environments. For centuries lead compounds such as white lead and lead chromate have been used as white pigments in commercial paints. In addition to their pigment properties, these lead compounds were valued because of their durability and weather resistance, which made them viable particularly in exterior paints. In addition to lead's durability properties, it was also added to paint to improve its drying characteristics.

Old lead-based paint is considered the most significant source of lead exposure in the U.S. today. In fact, the majority of homes and buildings built before 1960 contained heavily leaded paint. Even as recently as 1978 there were homes and buildings that used lead paint. This paint may have been used on window frames, walls, the building's exterior, or other surfaces. The improper removal of lead-based paint from surfaces by dry scraping, sanding, or open-flame burning can create harmful exposures to lead. High concentrations of airborne lead particles in a space can also result from lead dust from outdoor sources, including contaminated soil tracked inside; Harmful effects can also result from the use of lead in certain indoor activities such as soldering and stained-glassmaking.

Because of potentially serious health hazards and negative publicity, lead content was gradually reduced until it was eliminated altogether in 1978 (in the U.S.). In commercial buildings, lead was used primarily as a paint preservative.

Lead piping has sometimes been used in older buildings, and, while not legally required to be replaced, it can create a health hazard because frequently the piping deteriorates and leaches into the building's drinking water. In some buildings lead solder has also been used in copper-pipe installation, but in most jurisdictions this procedure has now been banned due to water contamination resulting from the deterioration of the solder. In any case, any evaluation for lead contamination requires that the water content be analyzed by a laboratory and action then taken to mitigate the hazards if lead content is found to be in excess of regulated limits. The potential for water contamination can often be removed by chemical treatment of the water. Where this cannot be accomplished, the piping may have to be replaced.

Unfortunately, lead is still allowed in paint for bridge construction and machinery and thus remains a significant source of exposure. Its continued use is mainly due to its ability to resist corrosion and its ability to expand and contract with the metal surface of a structure without cracking. But even if its use were banned today, there would still be potential exposure to workers and surrounding communities for many years to come because of the many metal structures such as bridges that have been coated with it.

7.2.1.1.9. Health Risks

Lead is a highly toxic substance that affects a variety of target organs and systems within the body, including the brain and the central nervous, renal, reproductive, and cardiovascular systems. High levels of lead exposure can cause convulsions, coma, and even death. However, the nervous system appears to be the main target organ system for lead exposure.

One of the best methods to assess human exposure to lead is to measure the blood lead level, because it is a sensitive indicator of exposure that has been correlated with a number of health endpoints. It also gives an immediate estimate of the level of a person's recent exposure to lead. The negative aspect of measuring blood lead level is that, while it will tell you how much lead is in the bloodstream, it will not tell you what is stored in soft tissues or bones. Additionally, the test will not spell out your body burden of lead or any damage if any that has occurred.

Effects of lead poisoning depend largely on dose exposure. Contact with lead-contaminated dust is the primary method by which most children are exposed to harmful levels of lead. It enters a child's body mainly through ingestion. Lead-contaminated dust is often hard to see but can get into the body and create substantial health risks. Pregnant women, infants, and children are more vulnerable to lead exposure because lead is more easily absorbed into growing bodies, and the tissues of small children are more sensitive to the damaging effects of lead. Ingestion of lead has been proven to cause delays in children's physical and mental development as well as negatively impacting their developing nervous systems, causing lower IQ levels, increased behavioral problems, and learning disabilities.

In adults, high lead levels have many adverse effects, including kidney damage, digestive problems, high blood pressure, headaches, diminishing memory and concentration, mood changes, nerve disorders, sleep disturbances, and muscle or joint pain. A single very high exposure to lead can also result in lead poisoning. Adults’ bones and teeth contain about 95 percent of the body burden (total amount of lead stored in the body). Likewise, lead can seriously impact the ability of both men and women to bear healthy children.

7.2.1.1.10. Testing for Lead Paint

Inspectors employ various methods and procedures to assist them in identifying the presence of lead paint. In the field, the most widely applied method is the use of an x-ray fluorescent lead-in-paint analyzer (XRF). The XRF analyzer is normally held up to the surface being tested for several seconds. The analyzer then emits radiation, which is absorbed and then fluoresces (is emitted) back to the analyzer. The XRF unit breaks down the signals to determine if lead is present and if so in what concentration. An XRF analyzer can normally read through up to 20 layers of paint, but these analyzers are expensive and should only be used by trained professionals.

7.2.1.2. Contaminants Generated by Combustion

Some examples of combustion byproducts include fine particulate matter, carbon monoxide (CO), and nitrogen oxides. Tobacco smoke is another source.

Combustion (burning) byproducts are essentially gases and tiny particles that are created by the incomplete burning of fuels. These fuels (such as natural gas, propane, kerosene, fuel oil, coal, coke, charcoal, wood, gasoline, and materials such as tobacco, candles, and incense), when burned, produce a wide variety of air contaminants. If fuels and materials used in the combustion process were free of contaminants and combustion were complete, emissions would be limited to carbon dioxide (CO2), water vapor (H2O), and high-temperature reaction products formed from atmospheric nitrogen (NOx) and oxygen (O2). Sources of combustion-generated pollutants in indoor environments are many and include wood heaters and wood stoves, furnaces, gas ranges, fireplaces, and car exhaust (in an attached garage).

There are several combustion-generated contaminants including CO2, H2O, carbon monoxide (CO), nitrogen oxides (NOx) such as nitric oxide (NO) and nitrogen dioxide (NO2), respirable particles (RSP), aldehydes such as formaldehyde (HCHO) and acetaldehyde, as well as a number of volatile organic compounds (VOCs); fuels and materials containing sulfur will produce sulfur dioxide (SO2). Particulate-phase emissions may include tar and nicotine from tobacco, creosote from wood, inorganic carbon, and polycyclic aromatic hydrocarbons (PAHs).

Carbon dioxide (CO2) is a colorless, odorless, heavy, incombustible gas that is found in the atmosphere and formed during respiration. It is typically obtained from the burning of, gasoline, oil, kerosene, natural gas, wood, coal, and coke. It is also obtained from carbohydrates by fermentation, by the reaction of acid with limestone or other carbonates, and naturally from springs. CO2 is absorbed from the air by plants in a process called photosynthesis. Although carbon dioxide is not normally a safety problem, a high CO2 level can indicate poor ventilation, which in turn can lead to a buildup of particles and more harmful gases such as carbon monoxide that can negatively impact people's health and safety. CO2 is used extensively in industry as dry ice or carbon dioxide snow, in carbonated beverages, fire extinguishers, etc.

Carbon Monoxide (CO) is an odorless, colorless, lighter than air, nonirritating gas that interferes with the delivery of oxygen throughout the body. CO is the leading cause of poisoning deaths in the United States; it occurs when there is incomplete combustion of carbon-containing material such as coal, wood, natural gas, kerosene, gasoline, charcoal, fuel oil, fabrics, and plastics.

At low concentrations levels, healthy people may experience fatigue and shortness of breath during exertion. Flushed skin, tightness across the forehead, and slightly impaired motor skills may also occur. People with heart disease may encounter chest pain. The first and most obvious symptom is usually a headache with throbbing temples. Infants, children, pregnant women, the elderly, and people with heart or respiratory problems are most susceptible to carbon-monoxide poisoning. The fact that CO cannot be seen, smelled, or tasted makes it especially dangerous, because you are not aware when you are being poisoned. Moreover, CO poisoning is frequently misdiagnosed by both victims and doctors.

Mild to moderate CO poisoning may cause flulike symptoms or gastroenteritis, particularly in children, including nausea, lethargy, and malaise. As the CO level or exposure time increases, symptoms become more severe and additional ones appear: irritability, chest pain, fatigue, confusion, dizziness, and impaired vision and coordination. Higher levels cause fainting upon exertion, marked confusion, and collapse. At very high concentrations, we may witness coma and convulsion as well as permanent damage to the brain, central nervous system, or heart and finally death.

The four primary sources of CO in the environment are:

-

•

Automobile exhaust from attached garages combined with inadequate ventilation is responsible for two-thirds of all accidental CO deaths. Lethal levels of the gas can accumulate in as little as 10 minutes in a closed garage. Certain occupations are exposed regularly to elevated levels of CO. These include toll-booth attendants, professional drivers, highway workers, traffic officers, and tunnel workers. Likewise, certain indoor events, such as tractor pulls and car and truck exhibitions, if not adequately ventilated, can expose spectators and participants to elevated CO levels.

-

•

Faulty heating equipment accounts for almost one-third of accidental CO fatalities. These fatalities can be caused by home or office heating systems (e.g., leaking chimneys and furnaces or back-drafting from furnaces, gas water heaters, wood stoves, fireplaces; and gas stoves) and also by improperly vented or unvented kerosene and gas appliances, propane space heaters, charcoal grills or hibachis, and Sterno-type fuels. Dangerous amounts of carbon monoxide can be released when there is inadequate fresh air or a flame is not sufficiently hot to completely burn a fuel.

-

•

Fires have been found to raise CO levels in the blood of unprotected persons to 150 times normal in a single minute; CO poisoning is the most frequent cause of immediate death associated with fire. Environmental tobacco smoke can also cause elevated CO levels in both smokers and nonsmokers who are exposed to the smoke.

-

•

Methylene chloride is a solvent used in some paints and varnish strippers that is readily absorbed by the body and changes to CO. Using products that contain methylene chloride for more than a few hours can raise CO levels in the blood 7 to 25 times normal. It is particularly dangerous for persons with preexisting cardiac conditions who use these products in unventilated spaces, as they risk heart attack and death.

An electronic device known as a carbon-monoxide alarm is the only reliable method currently used to test for the presence of carbon monoxide. Most fire departments, gas companies, and some specialized contractors have sophisticated equipment that can measure and record carbon-monoxide levels. In the home, detectors should be placed in areas where the family spends most of its time, such as the family room, bedroom, or kitchen. Detectors should be placed far enough away from obvious and predictable sources of CO, such as a gas stove, to avoid false alarms.

CO poisoning can be prevented by following a number of simple steps:

-

•

Keep gas appliances properly adjusted and have them checked periodically for proper operation and venting.

-

•

Open flues when fireplaces are being used and ensure that flues, chimneys, and vents are clear of debris and working properly.

-

•

Have CO monitors installed at home and in the workplace and ensure that they are properly maintained.

-

•

Refrain from using unvented space heaters, gas stoves, charcoal grills, or Sterno-type fuels as sources of heat. Wood stoves when used should be properly sized and certified to meet EPA emission standards.

-

•

When working around CO sources such as propane-powered forklifts and space heaters, ensure that adequate ventilation is in place. Whenever exposure is unavoidable, CO monitoring badges should be worn.

-

•

The car's exhaust system should be checked regularly and properly maintained at all times. Cars or other gasoline-powered engines should not be run inside a garage, even with the doors open.

-

•

Do not use paint strippers that contain methylene chloride. If the use of solvents containing this substance is unavoidable, make sure the area is properly ventilated.

-

•

A trained professional should be brought in at least once a year to inspect, clean, and tune up the central-heating system (furnaces, flues, and chimneys) and repair any leaks promptly.

Nitrogen dioxide (NO2) is a colorless, odorless gas that irritates the mucous membranes in the eye, nose, and throat and causes shortness of breath when exposed to high concentrations. Nitrogen dioxide is also a major concern as an air pollutant because it contributes to the formation of photochemical smog, which can have significant impacts on human health. Documented evidence indicates that high concentrations or continued exposure to low levels of nitrogen dioxide increases the likelihood of respiratory problems. Because nitrogen dioxide is relatively nonsoluble in tissue fluids, it enters the lungs, where it may expose lower airways and alveolar tissue. Nitrogen dioxide inflames the lining of the lungs and can reduce immunity to lung infections. There is also documented evidence from animal studies that repeated exposures to elevated nitrogen-dioxide levels may lead or contribute to the development of lung diseases such as emphysema. People at particular risk from exposure to nitrogen dioxide include children with asthma and older people with heart disease or other respiratory diseases.

Exposure can cause problems such as wheezing, coughing, colds, flu, and bronchitis. Increased levels of nitrogen dioxide can also have significant impacts on people with asthma because it can cause more frequent and more intense attacks.

There are numerous combustion-generated contaminants including several mucous-membrane and upper-respiratory-system irritants. Aldehydes such as HCHO are the most common, although in some cases acrolein, RSP, and SO2 may also be included. Aldehydes cause irritation to the eyes, nose, throat, and sinuses and are discussed in greater detail in the following section. Respirable particles vary in composition, and their primary effect is irritation of the upper-respiratory passages and bronchi. Because of its solubility in tissue fluids, SO2 can cause bronchial irritation.

7.2.1.3. Organic Contaminants

In today's environment, natural and synthetic organic chemicals comprise many different types and can be found virtually everywhere, including soil, ground water, surface water, plants, and our bodies. Modern industrialized societies have developed such a massive array of organic pollutants that it is becoming increasingly difficult to generalize in a meaningful way as to sources, uses, or impacts. These contaminants find their way into the natural environment through accidental leakage or spills, such as leaking underground storage tanks, or through planned spraying of pesticides to agricultural land and urban areas.

The main organic compounds include volatile organic compounds (VOCs), very volatile organic compounds (VVOCs), semivolatile organic compounds (SVOCs), and solid organic compounds (POMs). Solid organic compounds may comprise components of airborne or surface dusts. Organic compounds often pose serious indoor contamination problems; they include the aldehydes, VOCs, and SVOCs (which include a large number of volatile as well as less volatile compounds, and pesticides and biocides, which are largely SVOCs).

Organic compounds that are known to be contaminants of indoor environments include a large variety of aliphatic hydrocarbons, aromatic hydrocarbons, oxygenated hydrocarbons (such as aldehydes, ketones, alcohols, ethers, esters, and acids), and halogenated hydrocarbons (primarily those containing chlorine and fluorine).

Volatile-organic-compound concentrations levels are generally higher in indoor environments than in outdoor air. Studies suggest that indoor air may contain several hundred different VOCs. Moreover, VOCs can be released from products while being used and to a lesser degree while in storage. Fortunately, the amounts of VOCs emitted tend to decrease as the product ages and dries out.

There has been a steady increase in the number of identified VOCs in recent years. They are characterized by a wide range of physical and chemical attributes – the most important of which are their water solubility and whether they are neutral, basic, or acidic. VOCs are released into the indoor environment by many sources, including building materials, furnishings, paints, solvents, air fresheners, aerosol sprays, adhesives, fabrics, consumer products, building cleaning and maintenance materials, pest-control and disinfection products, humans themselves, office equipment, tobacco smoking, plastics, lubricants, refrigerants, fuels, solvents, pesticides, and many others.

Among the health hazards many VOCs pose is that they are potent narcotics that cause depression in the central nervous system; others can cause eye, nose, and throat irritation; headaches; loss of coordination; nausea; and damage to the liver, kidneys, and central nervous system (Figure 7.4). A number of these chemicals are suspected or known to cause cancer in humans.

Figure 7.4.

Diagram showing inhalation of volatile organic compounds.

Source: Air Advice Inc.

Formaldehyde (HCHO) is a colorless, pungent-smelling gas, and one of the more common VOCs found indoors. It is an important chemical used widely by industry to manufacture building materials and household products. It is also a byproduct of combustion and certain other natural processes and thus may be present in substantial concentrations both indoors and outdoors.

Formaldehyde is the most common of the aldehydes and is considered by many as possibly the single most critical indoor pollutant because of its common occurrence and its strong toxicity. Formaldehyde is a colorless, gaseous substance with an unpleasant smell. On condensing it forms a liquid with a high vapor pressure. Due to its high reactivity, it rapidly polymerizes with itself to form paraformaldehyde. Because of this reaction, liquid HCHO needs to be kept at a low temperature or mixed with a stabilizer (such as methanol) to prevent or minimize polymerization.

Formaldehyde, by itself or in combination with other chemicals, serves a number of purposes in manufactured products. For example, it is used to add permanent-press qualities to clothing and draperies, as a component of glues and adhesives, and as a preservative in some paints and coating products. It is also used in a variety of deodorizing commercial products, such as lavatory and carpet preparations.

Formaldehyde is commercially available as both paraformaldehyde and as formalin, an aqueous solution that typically contains 37 to 38 percent HCHO by weight and 6 to 15 percent methanol. HCHO is also used in many different chemical processes, such as the production of urea and phenol-formaldehyde resin.

Urea-formaldehyde (UF) copolymeric resins are present in many building materials such as wood adhesives, which are used in the manufacture of pressed-wood products including particle board, medium-density fiber board (MDF), and plywood and in finish coatings (acid-cured), textile treatments, and urea-formaldehyde foam insulation (UFFI).

People are often unaware that formaldehyde is given off by materials other than UFFI. Certain types of pressed-wood products (composition board, MDF, paneling, etc.), carpeting, and other materials can be formaldehyde sources. Many of these products use a urea-formaldehyde-based resin as an adhesive. Some of these materials will continue to give off formaldehyde much longer than UFFI. Like the majority of VOCs, formaldehyde levels will decrease substantially with time and/or with increased ventilation rates.

For some people formaldehyde can be a respiratory irritant, and continuous exposure to it can be dangerous. More specifically, chronic, low-level, continuous, and even intermittent exposure can cause chemical hypersensitivity and provide an accelerating factor in the development of chronic bronchitis and pulmonary emphysema. HCHO also has the ability to cause irritation, inflammatory-type symptoms, and symptoms of the central nervous system such as headache, sleeplessness, and fatigue. Elevated HCHO exposures (above 0.1 parts per million) can trigger asthma attacks, nausea, diarrhea, unnatural thirst, and menstrual irregularities.

Acetaldehyde is a two-carbon aliphatic aldehyde with a pungent, fruity odor. It is used in a number of industrial processes and is a major constituent of automobile exhaust fumes. It is also a predominant aldehyde found in tobacco smoke. Compared to HCHO, it is a relatively mild irritant of the eye and upper respiratory system.

Acrolein is a three-carbon aldehyde with one double bond. It is highly volatile gas with an unpleasant choking odor. It is primarily used in the production of a variety of compounds and products and is released into the environment as a combustion oxidation product from oils and fats containing glycerol, wood, tobacco, and automobile/diesel fuels. At relatively low exposure concentrations it is a potent eye irritant.

Glutaraldehyde is a five-carbon dialdehyde. It is found in liquid form and has a sharp, fruity odor. Its main application is as an active ingredient in disinfectant formulations widely used by the medical and dental professions. The main health effects associated with glutaraldehyde exposures include irritation of the nose and throat, nausea and headache, and pulmonary symptoms such as chest tightening and asthma.

Polychlorinated biphenyls (PCBs) are oils used primarily as coolants in electrical transformers. Although the production and sale of PCBs were banned by the Environmental Protection Agency (EPA) in 1979, a large number of PCB-filled transformers remain in use. It has also been estimated that some 2,000,000 mineral-oil transformers still contain some percentage of PCBs. PCBs may also be found in light ballasts and elevator hydraulic fluids. PCBs are a suspected carcinogen, but properly sealed or contained PCBs do not pose a hazard. However, PCBs do become a hazard when they catch fire, creating carcinogenic byproducts that can contaminate air, water, and the finishes and contents of a building. Leaking PCBs can also contaminate building materials and soil. PCB evaluations typically focus on identifying the presence of or potential for PCB leakage, measuring of PCB concentration levels, and determining the presence of combustible materials adjacent to PCB-containing equipment.

Hydrocarbons are a class of organic chemical compound consisting only of the elements hydrogen (H) and carbon (C). They are cardinal to our modern way of life and being one of the Earth's most important energy resources. Hydrocarbons are the principal constituents of petroleum and natural gas and are also derived from coal. The bulk of the world's hydrocarbons are used for fuels and lubricants, as well as for electrical-power generation and heating. The chemical, petrochemical, plastic, and rubber industries are also dependent upon hydrocarbons as raw materials. Hydrocarbons are colourless, flammable, toxic liquids.

Symptoms associated with exposure to aliphatic hydrocarbons may include watery eyes, nausea, vomiting, dizziness, weakness, and central-nervous-system effects such as depression, convulsions, and, in extreme cases, coma. Other symptoms may include pulmonary and gastrointestinal irritation, pulmonary edema, bronchial pneumonia, anorexia, anemia, nervousness, pain in the limbs, and numbness. Noticeable odors similar to gasoline and oil all suggest that some hydrocarbon contamination may be present. Likewise, leaking subsurface tanks at fuel stations and other facilities have created significant health and safety problems by contaminating the soil around the buildings. Benzene is found in most hydrocarbons and is considered to be one of the more serious contaminants, known to cause leuaemia. Air-quality tests may be necessary as well as tests for contaminants in the soil around the foundation.

Pesticides are chemical poisons, designed to control, destroy, or repel plants and animals such as insects (insecticides), weeds (herbicides), rodents (rodenticides), and mold or fungus (fungicides). They include active ingredients (those intended to kill the target) and inert ingredients, which are often not “inert” at all. Pesticides are generally toxic and can be absorbed through the skin, swallowed, or inhaled; as such are unique contaminants of indoor environments.

Studies show that approximately 16 million Americans are sensitive to pesticides; their immune systems have been damaged as a result of prior pesticide exposure. In addition, pesticides have been linked to a wide range of serious and often fatal conditions: cancer, leukemia, miscarriage, genetic damage, decreased fertility, liver damage, thyroid disorders, diabetes, neuropathy, still-births, decreased sperm counts, asthma, and other autoimmune disorders (lupus, etc.).

Federal and state governments carefully regulate pesticides to ensure that they do not pose unreasonable risks to human health or the environment. There are currently more than 1055 active ingredients registered as pesticides, which are formulated into thousands of different products that are available in the marketplace, including some of the most widely used over the past 60 years. These include aldrin, chlordane, DDT, dieldrin, endrin, heptachlor, mirex, toxaphene, and lindane (hexachlorocyclohexane, HCH). Many pesticides (most notably chlordane, used for termite treatment) are serious hazards. It is hoped that ecological methods of pest control will in the future replace the overdependence on chemicals that now threatens our ecosystem.

7.2.1.4. Biological Contaminants

Biological pollutants arise from various sources such as microbiological contamination – e.g., fungi, bacteria, viruses, mites, pollens – and the remains and dropping of pests such as cockroaches. Such pollutants of biological origin can significantly impact indoor-air quality and cause infectious disease through airborne transmission. Of particular concern are those biological contaminants that cause immunological sensitization manifested as chronic allergic rhinitis, asthma, and hypersensitivity pneumonitis.

Moisture in buildings is one of the major contributors to poor indoor-air quality, unhealthy buildings, and mold growth; by controlling the relative humidity level, the growth of some sources of biologicals can be minimized. Standing water, water-damaged materials, rainwater leaks, or wet surfaces also serve as a breeding ground for molds, mildews, bacteria, and insects. Likewise, damp or wet areas such as cooling coils, humidifiers, condensate pans, or unvented bathrooms can serve as suitable breeding grounds. Contaminated central HVAC systems can then distribute these contaminants through the building.

Proactive preventive and remedial measures include rainwater-tight detail design, preventing uncontrolled air movement, reducing indoor-air moisture content, reducing water-vapor diffusion into walls and roofs, selecting building materials that have appropriate water-transmission characteristics, and maintaining proper workmanship quality control.

A proven method for deterring rainwater intrusion into walls is the rain-screen approach, which incorporates cladding, air cavities, drainage planes, and airtight support walls to offer multiple moisture-shedding pathways. The concept of the rain screen is simple; it separates the plane in a wall where rainwater is shed and where air infiltra-tion is halted. In terms of construction, this means that there is an outer plane that sheds rainwater but allows air to freely circulate and an inner plane that is relatively airtight.

7.2.1.4.1. Mold and Mildew

Mold and mildew are types of musty-smelling fungi that thrive in moist environments. Their function in nature is primarily to break down and decompose organic materials such as leaves, wood, and plants. They grow, penetrate, and infect the air we breathe. There is no normal way to eliminate all mold and mold spores in the indoor environment, and thus the key to controlling indoor mold growth is to control moisture content. Exposure to fungi in indoor-air settings has emerged as a significant health problem of great concern in both residential environments as well as in workplace settings. There are three major health hazards associated with fungi: infection, allergies, and toxins.

Fungi are primitive plants that lack chlorophyll and therefore feed on organic matter that they digest externally and absorb. True fungi include yeast, mold, mildew, rust, smut, and mushrooms. Given sufficient moisture they can grow on almost any material, even inorganic. When mold spores land on a damp spot indoors, they can grow and digest whatever they are growing on. There are molds that can grow on wood, paper, carpet, fabric, and foods, but they usually grow best in dark, moist habitats, especially if organic matter is available.

There are thousands of species of molds, including pathogens, saprotrophs, aquatic species, and thermophiles. Molds are part of the natural environment and are present everywhere in nature; their presence is only visible to the unaided eye when mold colonies grow (Figure 7.5).

Figure 7.5.

Table showing partial list of typical types of molds found in damp buildings.

Molds produce small spores to reproduce; they float through indoor and outdoor air continually. These spores may contain a single nucleus or be multinucleate. Mold spores can be asexual or sexual; many species can produce both types. Some species can remain airborne indefinitely, and many are able to survive extremes of temperature (some molds can begin growing at temperatures as low as 2 degrees C) as well as extremes of pressure. When conditions do not foster or enable growth, most molds have the ability to remain alive in a dormant state within a wide range of temperatures before they die. Different mold species vary enormously in their tolerance to temperature and humidity extremes.

For mold to grow or establish itself, it needs four vital elements: viable spores, a nutrient source (organic matter such as wood products, carpet, and drywall), moisture, and warmth. The mere presence of humid air, however, is not necessarily conducive to fostering mold growth except where it has a relative humidity (RH) level at or above 80 percent and is in contact with a surface. Mold spores are carried by air currents and can reach all surfaces and cavities of buildings. When the surfaces and/or cavities are warm and contain the right nutrients and amounts of moisture, the mold spores will grow into colonies and gradually destroy what they grow on.

The key to controlling mold growth is to control indoor moisture and the temperatures of all surfaces, including interstitial surfaces within walls. Mold generally needs a temperature range between 40 and 100 degrees F to grow, and maintaining relative-humidity levels between 30 and 60 percent will help control many of these known biological contaminants. Humidity control prevents the indoor growth of mold, mildew, viruses, and dust mites. Winter humidification and summer dehumidifica-tion controls/modules can supplement central HVAC systems when climate excesses require additional conditioning measures. Likewise, by removing any of the four essential growth elements the growth process will be inhibited or nonexistent.

The first step in a mold-remediation project includes determining the root cause of the mold growth. The next step is to evaluate the order of magnitude of the growth; this is usually done through visual examination. Since old mold growth may not always be visible, investigators may need to use instruments such as moisture meters, thermal-imaging equipment, or borescope cameras to identify moisture in building materials or “hidden” mold growth within wall cavities, HVAC ducts, etc. Mold assessments and inspections should always include HVAC systems and their air-handler units, drain pans, coils, and ductwork in their surveys. In addition, depending on the age of the building, the inspector should take samples of the building materials, such as ceiling tiles, drywall joint compounds, and sheet flooring for the presence of asbestos. All these organisms may contribute to poor indoor-air quality and can cause serious health problems.

Fungi in indoor environments include microscopic yeasts and molds, called micro-fungi, whereas plaster and wood-rotting fungi are referred to as macrofungi because they produce spores that are visible to the naked eye. Some molds produce toxic liquid or gaseous compounds, known as mycotoxins, in addition to infectious airborne mold spores, which often cause serious health problems to residents and workers. Toxicity can arise from inhalation or skin contact with toxigenic molds. Some of these toxic molds can only produce the dangerous mycotoxins under specific growing conditions. Mycotoxins are harmful or lethal to humans and animals when exposed to high concentrations. Toxic molds and fungi are a significant source of airborne VOCs that create IAQ problems (Figure 7.6).

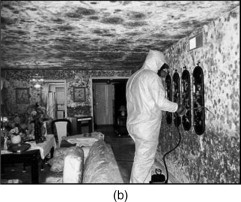

Figure 7.6.

(a) Example of mold on a ceiling, often found in damp buildings. (b) Example of an extreme case of toxic mold growth in the process of being treated.

(a).

Source: mold-kill.com

(b).

Source: Applied Forensic Engineering, LLC

7.2.1.4.2. Bacteria and Viruses

Tens of millions of people around the world suffer daily from viral infections of varying degrees of severity at immense cost to the economy, including the costs for medical treatment, lost income due to inability to work, and decreased productivity. In fact, viruses have been identified as the most common cause of infectious diseases acquired within indoor environments, particularly those causing respiratory and gastrointestinal infection. The most common viruses causing respiratory infections include influenza viruses, rhinoviruses, corona viruses, respiratory syncytial viruses (RSVs), and parainfluenza viruses (PIVs); viruses responsible for gastrointestinal infections include rotavirus, astrovirus, and Norwalk-like viruses (NLVs). Some of these infections, like the common cold, are very widely spread but are not severe, while influenza-like infections are relatively more severe.

Bacteria and viruses are minute in size and readily become airborne, remaining suspended in air for hours. Airborne bacteria and viruses in interior spaces are a cause of considerable concern due to their ability to transmit infectious diseases. Bacteria, viruses, and other bioaerosols that are common in both the home and the workplace may increasingly contribute to sick-building syndrome (SBS) if humidity levels are either too low or too high, depending on how their growth and our respiratory system are affected.

There are many pathways to infection spread, and among the most significant, from an epidemiological point of view is airborne transport. Microorganisms can become airborne when droplets are given off during speech, coughing, sneezing, vomiting, or atomization of feces during sewage removal. Q fever is another emerging infectious disease among U.S. soldiers serving in Iraq. Fever, pneumonia, and/or hepatitis are the most common signs of acute infection with Q fever.

Liquid and solid airborne particles (aerosols) in indoor air originate from many indoor and outdoor sources. These particles may differ in size, shape, chemical composition, and biological composition. Particle size signifies the most important characteristic affecting particle fate during transport, and it is also significant in affecting biological properties. Bacterial aerosols have also been found to be a means to transmit several major diseases, as shown in Figure 7.7.

Figure 7.7.

Major infectious diseases associated with bacterial aerosols.

Professor Lidia Morawska of Queensland University of Technology, Australia, says that the degree of hazard created by biological contaminants including viruses in indoor environments is controlled by a number of factors:

-

•

The type of virus and its potential health effects

-

•

Mode of exit from the body

-

•

Concentration levels

-

•

Size distribution of aerosol containing the virus

-

•

Physical characteristics of the environment (temperature, humidity, oxygenation, UV light, suspension medium etc.)

-

•

Air-circulation pattern

-

•

Operation of heating, ventilation, and air-conditioning system

The physical characteristics of the indoor environment as well as the design and operation of building ventilation systems are of paramount importance. Ducts, coils, and recesses of ventilation systems often provide fertile breeding grounds for viruses and bacteria that have been proven to cause a wide range of ailments from influenza to tuberculosis. Likewise, a number of viral diseases may be transmitted in aerosols derived from infected individuals. A number of infectious viral diseases and associated causal viruses transmitted through air are shown below in Figure 7.8.

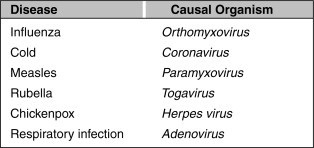

Figure 7.8.

Some of the major infectious diseases associated with viral aerosols.

7.2.1.4.3. Mites

Mites are microscopic bugs that thrive on the constant supply of shed human skin cells (commonly called dander) that accumulate on carpeting, drapes, furniture coverings, and bedding (Figure 7.9). The proteins in the combination of feces and skin shedding are what cause allergic reactions in humans. Dust mites are perhaps the most common cause of perennial allergic rhinitis. Dust mites are the source of one of the most powerful biological allergens and flourish in damp, warm environments. Depending on the person and level of exposure, estimates given suggest that dust mites may be a factor in 50 to 80 percent of asthmatics, as well as in numerous cases of eczema, hay fever, and other allergic ailments.

Figure 7.9.

Drawing of a dust mite.

Source: EHSO.

It is estimated that up to 15 percent of people are allergic to dust mites, which due to their very small size (250 to 300 microns in length) and translucent bodies are not visible to the naked eye. To be able to give an accurate identification, one needs at least a 10x magnification. Dust mites have eight hairy legs, no eyes or antennae, a mouth group in front of the body (resembling a head), and a tough, translucent shell. Dust mites, like their insect cousins, have multiple developmental stages. They commence with an egg and develop into larva, several nymph stages, and finally the adult.

Biological contaminants such as dust mites prefer warm, moist surroundings like the inside of a mattress particularly when someone is lying on it, but they may also accumulate in draperies, carpet, and other areas where dust collects. The favorite food of mites appears to be dander (both human and animal skin). Humans generally shed about 0.2 ounce of dander (dead skin) a week.

Dust-mite populations are usually highest in humid regions and lowest in areas of high altitude and/or dry climates. Control measures are needed to reduce concentrations of dust-borne allergens in the living/working environment by controlling both allergen production and the dust that serves to transport it.

7.2.1.4.4. Rodent, Insect, and Animal Allergens

According to the Illinois Department of Public Health, a typical large city in the United States annually receives more than 10,000 complaints about rodent problems and performs tens of thousands of rodent-control inspections and baiting services. Effective measures should therefore be taken to prevent rodents, insects, and pests from entering the home or office. Cockroaches, rats, termites, and other pests have plagued commercial facilities for far longer than computer viruses. Increasingly, research has confirmed and pinpointed pest infestation as the trigger or cause of a host of diseases, and according to the National Pest Management Association pests can cause serious threats to human health, including such diseases as rabies, salmonellosis, dysentery, and staph. But in addition to these serious health concerns they also detract from a facility's appearance and value.

Today, communities of rats exist within and beneath cities, traveling unnoticed from building to building along sewers and utility lines. Each rat colony has its own territory, which can span an entire city block and harbor more than 100 rats. As they explore their territories, rats and mice discover new food sources and escape routes. A rat's territory or “home range” is generally within a 50- to 150-foot radius of the nest, while mice usually have a much smaller range, living within a 10- to 30-foot radius of the nest. In places where all their needs (food, water, shelter) are met, rodents have smaller territories (Figure 7.10).

Figure 7.10.

Drawing showing typical home range of rodents.

Source: Illinois Department of Public Health.

Rodents are known to carry disease and fleas and to leave waste. Wild and domestic rodents reportedly harbor and spread as many as 200 human pathogens. Diseases include the deadly hantavirus and arena virus. Hantavirus is usually contracted by inhaling airborne particles from rodent droppings, urine, or saliva left by infected rodents or through direct contact with infected rodents.

Today, more than 900,000 species of insects have been identified, and additional species are being identified every day. Some of these insects are known sources of inhalant allergens that may cause chronic allergic rhinitis and/or asthma. They include cockroaches, crickets, beetles, moths, locusts, midges, termites, and flies. Insect body parts are especially potent allergens for some people. Cockroach allergens are also potent and are commonly implicated as contributors to sick-building syndrome in urban housing and facilities with poor sanitation. Most of the allergens from cockroaches come from the insect's discarded skins.As the skins disintegrate over time, they become airborne and are inhaled. This type of allergen can be resolved by eliminating the cockroach population.

Cockroaches are known carriers of serious diseases, such as salmonella, dysentery, gastroenteritis, and other stomach organisms. They adulterate food and spread pathogenic organisms with their feces and defensive secretions. Cockroaches have been reported to spread at least 33 kinds of bacteria, six kinds of parasitic worms, and at least seven other kinds of human pathogens. They can pick up germs on their bodies as they crawl through decaying matter and then carry these onto food surfaces (Figure 7.11). Cockroaches molt regularly throughout their life cycle. The discarded skin becomes airborne and can cause severe asthmatic reactions, particularly to children, the elderly, and people with bronchial ailments.

Figure 7.11.

Drawing of an American cockroach.

There are in excess of 20 varieties of ants invading homes and offices throughout the United States, particularly during the warm months of the year (Figure 7.12). Worldwide, there are more than 12,000 species, but of these only a limited number actually cause problems. The one trait all ants share is that they are unsightly and contaminate food. Ants range in color from red to black.

Figure 7.12.

Illustration identifying primary features of an ant.

Destructive ant species include fire and carpenter ants. Others types include the pharaoh, honey, house, Argentine, and thief ant. Fire ants are vicious, unrelenting predators and have a powerful, painful sting. More than 32 deaths in the U.S. have been attributed to severe allergic reactions to fire-ant stings.

Termites can pose a major threat to structures, which is why it is important to address any termite infestation as soon as possible. A qualified termite-control company or inspector should look for the many tell-tale signs termites usually provide, such as small holes in wood, straw-shaped mud tubes, crumbling drywall, termite insect wings, and sagging doors or floors (Figure 7.13).

Figure 7.13.

Illustration of a termite.

Allergens are produced by many mammalian and avian species; they can be inhaled by humans and cause immunological sensitization as well as symptoms of chronic allergic rhinitis and asthma. These allergens are normally associated with dander, hair, saliva, and urine of dogs, cats, rodents, and birds. Likewise, pollens, ragweed, and a variety of other allergens find their way indoors from the outside. Ragweed is known to cause what is commonly referred to as “hay fever,” or what allergist/immunologists refer to as allergic rhinitis. In the United States seasonal allergic rhinitis (hay fever), which is caused by breathing in allergens such as pollen, affects more than 35 million people. Sufferers of allergic rhinitis exposure often experience sneezing, runny noses, and swollen, itchy, watery eyes. These allergy symptoms can have a major impact on a person's quality of life, including his or her ability to function well at school or work.

7.2.1.5. Reducing Exposure

Resolving air-quality problems in buildings requires first the consideration of all the various contaminants, causes, and concentrations to better be able to address the problems and find appropriate solutions. The location where a person is exposed may also play a pivotal role. While the average worker is exposed approximately 40 hours per week, many individuals are in their home 24/7. Exposure times, therefore, as well as concentration levels become part of the equation.