Abstract

In Latin America, the energy potential from sugarcane straw, such as tops, secondary stalk, and leaves, has been debated, but the literature associated with organic crops and its implementation for energy purposes is limited. Sugarcane straw is either left in the field for soil recovery or used for animal feed. This paper presents an analysis of using organic sugarcane straw for energy generation. We have characterized the physicochemical properties of this organic sugarcane straw, including caloric value, moisture, carbon, and ash content, and have explored the environmental benefits of using biomass to replace coal as an energy source. The study showed that it is possible to achieve the replacement of coal using 16% of the residual biomass, with the benefit of generating lower CO2 emissions compared to coal combustion. Additionally, emissions derived from transporting the biomass from the field to the farm are 68% lower than those involved in transporting coal. The residual biomass from the organic crop showed similar properties relative to bagasse. The use of organic sugarcane straw biomass will result in the reduction of energy costs and will generate green energy with lower emission of CO2.

1. Introduction

A variety of products and by-products are obtained from sugarcane. Currently in South America, the most important by-product is bagasse, the pulpy residue left after the extraction of juice, which is used as a raw material for the pulp and paper industry, as feed for livestock, and as a starting material for bioenergy. In response to increased energy demands, the sugarcane industry is seeking alternatives to complement bagasse with another residual biomass that meets energy and environmental requirements. Above all, it is necessary to reduce the dependence on fossil fuels, like coal, and to move forward with the characterization of alternative biomass sources, which could be more environmentally friendly at a reduced cost.

In countries like Brazil, sugarcane straw, composed mainly of sugarcane tops, secondary stalk, and leaves, is broadly used to produce bioenergy.1−3 However, in Colombia, the same pathway has not been explored and more important is that the few studies available have focused only on sugarcane straw from traditional crops letting out of the scope residual biomass from organic crops. As the sugarcane industry is moving toward more sustainable practices, it is important to study the properties and advantages offered by organic products and by-products, like sugarcane straw. Currently, due to the high and stable local market demand for residual biomass, it is mainly used as a feed additive for livestock. The high nutritional content and energy stability make sugarcane straw easily digested by ruminants and other monogastric species.4 This paper reports a study of organic sugarcane straw from two perspectives: a comparative study of the physicochemical properties [caloric value, moisture, ash, and total organic carbon (TOC)] of this residual biomass relative to bagasse from traditional crops and the possibility of using this organic sugarcane straw for energy generation and replacement of coal in order to reduce negative environmental impacts.

2. Results and Discussion

This investigation was divided in two phases: the estimation of the amount of sugarcane straw required to replace coal for farm energy requirements, which was obtained by measuring the energy potential derived from organic residual biomass, and a theoretical analysis of CO2 emissions involved in the transport of coal versus transport of sugarcane straw to the farm for boiler fuel.

2.1. Physicochemical Properties of Organic Sugarcane Straw

The first phase was carried out by a physicochemical analysis of sugarcane straw samples and a statistical comparison of the data using a completely randomized block design (RBD). This design follows the model described in eq 1, where Yij is the corresponding measurement of sample i (tops, leaves, and secondary stalk) along blocks j (zones), μ is the average population of the experimental design, τ is the effect of the sample nature, γ is the effect of zones, and ε is the random error associated with the measurement Yij.

| 1 |

For the statistical analysis, the null hypothesis, H0, is μ1 = μ2 = μ3, and the alternative hypothesis, Ha, states that at least one of the μ values is different, where μ is the average of the evaluated parameter: moisture, TOC, ash content, and calorific value from tops, secondary stalks, and leaves. An ANOVA was performed to identify differences among the residual sugarcane biomass in terms of the physicochemical properties (see the Supporting Information, Figure S1). The p-values from the ANOVA were compared with the level of significance for each sample. When necessary, a Tukey’s test was also conducted to clarify differences among variables. The results of the physicochemical analyses are shown in Table 1.

Table 1. Physicochemical Characteristics of Organic Sugarcane Straw Samples and Reported Data for Coal and Bagasse.

| feedstock | caloric content (103 kJ/kg) | ash (%) | moisture (%) | TOC (%) |

|---|---|---|---|---|

| Tops | 16.3 | 7.8 | 74 | 38 |

| secondary stalk | 15.0 | 6.9 | 87 | 38 |

| Leaves | 16.1 | 6.7 | 61 | 38 |

| Coal | 29.1 | 12.1 | 5 | 60 |

| Bagasse | 14.7 | 8.1 | 47 | 45 |

For the ash content, it was found that the p-value of 0.018 was smaller than the level of significance of 0.05, suggesting that the averages for ash content are statistically different among the tops, secondary stalk, and leaves at the 95% level of confidence. A comparison of data using the Tukey method was carried out to clarify where such differences were observed and to determine the component with greater ash content. Tops showed the highest average ash content at 7.8%, while leaves showed the lowest at 6.7%, suggesting that they are statistically different from each other. However, the average ash content of the secondary stalks of 6.9% is not statistically different from the content in the tops or leaves, because ash content shares a range of values with both. Results for the carbon content showed that there are no significant differences between the average carbon content in the tops, secondary stalk, and leaves, with an overall central trend of 38% in the residual biomass (p-value 0.474). However, the average moisture in the samples was statistically different with a p-value of 0.00 when the level of significance was 0.05. The Tukey method showed no similarities among the samples; consequently, the average moisture content of the secondary stalk (87%) is different from that of the tops (74%) and leaves (61%). Some studies have shown that the comparison of residual pulverized and crushed biomass exposed to different drying temperatures has a low impact on the final sample moisture. This is important since a high level of moisture has a direct impact on the boiler’s efficiency.5

As the ash content and moisture are different along the samples, it was expected that the caloric content would also be different for the three types of samples. The caloric content showed a p-value of 0.002, which is smaller than the level of significance of 0.01, suggesting that there are significant differences among the samples. Since the caloric content is a crucial variable for using the sugarcane straw in the boiler, a Tukey test was performed. The results showed that tops and leaves have statistically similar caloric content, with an average of 16,299 and 16,086 kJ/kg, respectively. Additionally, the caloric content of secondary stalk (15,063 kJ/kg) was statistically similar to the value for leaves. Consequently, due to the statistical similarities, it was possible to establish a range of caloric content along the samples of biomass from sugarcane straw from 15,574 to 16,192 kJ/kg.

Table 1 shows that the caloric content from organic sugarcane straw is similar to and even slightly higher than that from bagasse previously reported.6 Although the ash and carbon content from the sugarcane straw are comparable to, but lesser than, the data reported for bagasse, residues of biomass are promising materials for replacing bagasse in the boilers. Moisture constitutes the main difference, where tops, stalks, and leaves contained from 14 to 40% more water than bagasse. Thus, organic sugarcane straw should be carried through a drying process (e.g., sun-drying is recommended) before its integration into a combustion system. A similar process is included when sugarcane is pressed during the milling process and formation of bagasse. Consequently, the potential of using organic residual biomass instead of coal and bagasse as a source of bioenergy would provide the following advantages: higher caloric content than bagasse; lower ash content, which reduces slagging and fouling (indicating a cleaner combustion); and less sulfur than coal; according to Spliethoff and Hein,7,8 the co-combustion using biomass could reduce CO2 emissions up to 93%. Based on the analytical results, replacing 1 kg of coal would require a minimum of 1.9 kg of organic sugarcane straw to provide the same energy output. Table 2 shows the calculated mass of organic sugarcane straw necessary to replace 1 kg of coal or 1 kg of bagasse based on the calorific values. Thus, assuming the minimum calorific value, the replacement of 1 ton of coal would require 1.87 tons of residual biomass.

Table 2. Equivalent Amount of Organic Sugarcane Straw Required to Replace 1 kg of Coal or 1 kg of Bagasse.

| calorific

value (kJ/kg) × 103 |

equivalent

mass of sugarcane straw to replace 1 kg of fuel |

|||

|---|---|---|---|---|

| Feedstock | minimum | maximum | minimum | maximum |

| sugarcane straw (dry basis) | 15.0 | 16.3 | ||

| coal | 29.1 | 29.1 | 1.87 | 1.80 |

| bagasse | 14.7 | 14.7 | 0.95 | 0.90 |

Table 3 shows our experimental results for the physicochemical properties of biomass and the reported values found in the literature. Tops, green leaves, and dry leaves do not show appreciable differences, except for the ash content, where the reported values are 3.7–4.3%1 compared to 6.7–7.8% obtained in this study. In summary, our experimental results are in agreement with previously reported data for sugarcane residual biomass from another geographical source.

Table 3. Comparison of Physicochemical Properties of Sugarcane Straw from an Organic Crop Relative to Reported Data for Traditional Crops.

2.2. Potential of Using Organic Sugarcane Straw in the Boiler

In the sugarcane sector, two types of coal are used as fuel for boilers: sub-bituminous coal, with caloric content ranging from 18.2 to 24.5 MJ/kg, and lignite and peat coal, with caloric content ranging from 9.83 to 18.2 MJ/kg.11 The biggest problem during coal combustion is the formation of products that are highly polluting, such as carbon dioxide. There is an opportunity for the sugarcane industry to explore and utilize other types of biomass as cleaner energy sources. Developing countries have traditionally ignored the creation of value from residual biomass for generating energy, and large-scale exploitation is still meager.12 However, with rising fossil fuel prices and reduced fuelwood supplies, this material is emerging as a valuable source of renewable energy. Sugarcane mills use bagasse to generate steam and electricity as fuel for their operation plants, while other by-products, such as leaves, tops, and secondary stalk, from an organic crop, like the studied case, have been undervalued. In Brazil, each ton of sugarcane can generate around 14% of biomass residue that is left on the field,1,9 while in Australia, 23% of tops and leaves and 7% of secondary stalk are left on the field.13

The energy requirements of the Lucerna farm, which are typical for the local industry, are composed of 65% coal and 35% bagasse. Currently, the amount of coal used ranges from 20 to 25 ton/month, which indicates that the combustion process requires approximately 742–927 GJ/month. Table 4 shows the minimum and maximum amount of coal and bagasse used historically and the calculated total energy produced per month from the mixture of bagasse and coal. Considering the biomass/coal ratio of 1.87 tons of biomass/ton of coal and assuming the lowest calorific value of the organic sugarcane straw of 15 MJ/kg, the equivalent amount of biomass required to fulfill the company’s energy needs ranges from 38 to 47 ton/month.

Table 4. Energy Currently Generated at Lucerna Farm as a Mix of Coal and Bagasse.

| mass of coal (ton/month) | mass of bagasse (ton/month) | caloric content LHV coal Cundinamarca (103 kJ/kg) | caloric content LHV bagasse (103 kJ/kg) | energy from coal (103 MJ/month) | energy from Bagasse (103 MJ/month) | total energy (103 MJ/month) |

|---|---|---|---|---|---|---|

| 20 (min) | 10.77 | 29.17 | 14.74 | 583.4 | 158.8 | 742.17 |

| 25 (max) | 13.46 | 29.17 | 14.74 | 729.2 | 198.46 | 927.71 |

Since the goal is to replace coal (i.e., 25 ton/month), the amount of energy that can be supplied by the organic sugarcane straw in the boiler was determined in terms of the amount of biomass per hectare that is generated and the biomass content collected from the field. Currently, Lucerna farm produces 35–40 tons of organic sugarcane straw (wet mass, 61–87% moisture) per hectare and harvests 8.33 ha per month, which means that 291–333 tons of residual biomass are recovered per month. Consequently, it was possible to estimate the amount of biomass from the total hectares harvested per month necessary to replace the total coal currently used. As shown in eq 2, it is possible to replace all of the coal with only 16.2% of the total organic sugarcane straw collected per month.

| 2 |

2.3. Theoretical Emissions Analysis

Environmental pollution studies previously performed in Colombian sugarcane mills showed that replacing coal with bagasse results in a considerable reduction in CO2 emissions (5–10%).14,15 For calculating the total benefits on emissions in this study, two scenarios were considered: the combustion of coal versus organic sugarcane straw in the existing Lucerna’s mill and the impact on the current logistics of transporting coal from another state versus transporting the organic residual biomass from the field to the plant.

2.3.1. Emissions from Combustion

The coal combustion emission from the process used to supply energy to the mill was theoretically calculated as shown in eq 3. Currently, the Lucerna farm uses 20–25 ton/month of coal purchased and transported from Cundinamarca (i.e., a farther location) with a carbon content of 60%.6Table 5 shows the CO2 emissions per month of coal relative to the emissions of the organic sugarcane straw with an estimated 38% of carbon content. It is noteworthy that, while the CO2 emissions range from 26 to 32 tons/month when biomass is used to produce energy, higher emissions are produced when using coal (44–55 tons/month). These theoretical findings suggest that the combustion of residual biomass will reduce the CO2 emissions by about 40% relative to coal combustion.

| 3 |

Table 5. Coal and Biomass Emission of CO2 by Combustion.

| feedstock | amount required (ton) | coal (%) | emissions (tons CO2/month) |

|---|---|---|---|

| Coal | 20 (min) | 60 | 44.3 |

| 25 (max) | 60 | 55.4 | |

| organic sugarcane straw | 38 (min) | 38 | 26.3 |

| 47 (max) | 38 | 32.8 |

2.3.2. Emissions from Transportation

A diesel-fueled dump truck is currently used to transport coal from the supplier to the farm. The shortest route is 471 km, with a dump truck efficiency of 2.5 and 6 mpg (i.e., 1 and 2.5 km/L), full and empty load, respectively.16 For transporting sugarcane straw to the mills, currently a tractor truck class 7 is used with an efficiency of 4 and 8 mpg (i.e., 1.7 and 3.4 km/L), full and empty load, respectively. The CO2 emissions per trip range from 4.5 to 9.3 kg of CO2/trip, with a round trip of 5.8 km.

As expected, transporting biomass from the field to the mill is directly influenced by the way the straw matter is gathered and packed, and the pre-treatment processes may affect the number of trips required. The methods of collection for the organic sugarcane straw are similar to the ones used for sugarcane. Table 6 shows a comparison of transport emissions among baling, chopping, and absence of any gathering or packing process. It is important to clarify that since baling procedures and techniques might vary, only the transportation of each collection method was considered. While transporting the biomass without any packing process produces 152–387 kg of CO2/month, baling and chopping are more environmental friendly since they reduce the number of trips and hence the CO2 emissions. Based on transportation, baling is the collection method with the lowest CO2 emissions from 76 to 155 kg of CO2/month. Baled biomass is much more compact, leaving less dead volume in the tractor truck cargo and fewer trips for a given mass. Consequently, baling the organic sugarcane straw will reduce emissions by approximately 75–82%. In terms of energy efficiency and CO2 emissions, using the residual biomass currently left in the plantation fields shows clear advantages. Thus, replacing coal with organic sugarcane straw makes sense and will lead to positive economic and environmental impacts.

Table 6. Comparison of Monthly CO2 Emissions due to the Transportation of Coal from the Supplier and Organic Sugarcane Straw from the Field to the Mill.

| no.

of trips |

distance

(km) |

emission

kg CO2/month |

|||||

|---|---|---|---|---|---|---|---|

| feedstock | method of collection | min | max | min | max | min | max |

| coal | N/A | 1 | 1 | 471 | 505 | 428 | 621 |

| sugarcane straw | baled biomass | 2 | 2 | 11.6 | 11.6 | 76 | 155 |

| chopped biomass | 2 | 3 | 11.6 | 17.4 | 76 | 232 | |

| nonea | 4 | 5 | 23.2 | 29 | 152 | 387 | |

No operation was done. The biomass was collected as it was in the field.

3. Conclusions

In a local farm, four physicochemical properties of residual biomass from an organic sugarcane crop were analyzed to compare relative to coal and bagasse as a source of energy in the boilers. The organic sugarcane straw showed properties similar to those of bagasse, suggesting that the replacement of coal and bagasse would be beneficial for the company. The only significant difference found in this organic feedstock is its moisture content, which may be adjusted by a drying step before its use in the boilers. Since the case studied is an organic farm in Colombia, a sun-drying process is recommended to avoid the energy consumption or emission from mechanical systems. Since the farm uses 15% of biomass to feed cattle, 31% of the total biomass would be collected for use as feedstock and energy requirements. It is recommended to leave the remaining 69% in the field for soil recovery. According to Rasche,2 a balanced straw recovery rate (i.e., 40–60%) led to lower fertilizer consumption and lower soil erosion when using green cane harvesting instead of the traditional slash-and-burn method. In the case of Hacienda Lucerna, it would be possible to achieve a complete replacement of coal using 16% of the organic sugarcane straw obtained from the total hectares harvested (8.33 ha/month) while preserving the farm conditions for soil recovery. This scenario will potentiate the value created by the organic sugarcane straw allowing to supplement animalsʼ diet and not investing in other food sources, serving as a source of energy while reducing the expenses associated to the coal supply, and finally, providing nutrients to the soil by reducing the amount of artificial fertilizers. Since Lucerna consumes 20–25 tons of coal per month (i.e., US$62/ton), a replacement using sugarcane straw (i.e., US$11/ton) could save the company almost US$62,000 (66% approximately) in five years, a considerable amount for a small organic farm, which was calculated from the cost of collecting the material from the field, transporting, and then using the material. Additionally, the emissions from transporting coal will be reduced up to 82% just by gathering and baling 31% of the total biomass. Although saving money is significant, more importantly and according to findings and the literature, the organic sugarcane straw generates lower carbon dioxide emissions and sulfur across the lifecycle relative to coal.7 We are currently investigating optimal conditions for best results at the boilers, including the consideration of the mineral content that could form incrustations inside the boiler pipes as well as combustion experiments of the organic sugarcane straw to determine the ignition energy and the combustion efficiency accurately.

4. Experimental Section

4.1. Area of Study and Sugarcane Description

The Colombian sugarcane industry is located mainly along the valley of the Cauca River. In the region, 225,000 hectares are planted with sugarcane, of which 25% correspond to lands owned by sugarcane mills and the remaining 75% owned by more than 3000 farmers.17 About 70% of the Colombian territory grows the same variety of sugarcane, which on average in Colombia produces 120 tons of sugarcane per hectare, giving 13.3 tons of sugar per hectare. Sampling was carried out in the farm named Hacienda Lucerna S.A. between 9:00 am and 1:00 pm following the structure presented in Figure 1. The Lucerna farm is a certified organic farm dedicated to the production of organic sugarcane and organic panela (raw-sugar cakes), which produces 35–40 tons of biomass per hectare. The organic certification (CERES—Certification of Environmental Standards Colombia) ensures that products are developed under processes according to environmental and ecological standards from the field to the market.18 Thus, Lucerna organic practices include plant sugarcane in small plots to test different varieties and choose the ones with a better performance; use sheep for weeding instead of burning cane; and harvest in green to avoid the loss of organic matter, to reduce microorganisms in the soil, and to generate carbon dioxide.

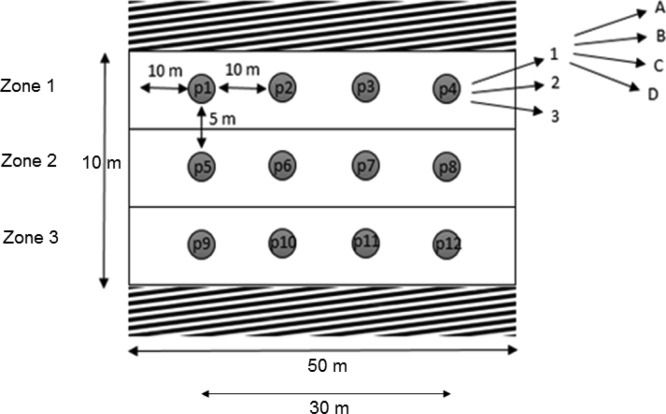

Figure 1.

Sampling design for the sugarcane straw physicochemical analysis.

The solid stem of the sugarcane has spongy, sweet tissue in the central area that is characterized by a high content of sucrose. The peripheral area, which is rich in fiber, is useful for extracting the bagasse. The remaining components are tops, secondary stalk, and leaves, which are not used to produce either sugar or energy; instead, those residues or straw is left on the field as a natural fertilizer or used as a source of complementary food for livestock.19 It is important to highlight that this does not compete with another food source, and there is an excess of biomass that complements the current livestock diet.

4.2. Biomass Characterization and Replacement of Coal

Four different physicochemical properties of the sugarcane straw biomass were determined: caloric content, moisture, TOC, and ash content. Tops, secondary stalk, and leaves were analyzed separately in a ripe, organic crop containing the three components. An RBD experiment was developed, in which the component types (tops, secondary stalk, and leaves) were designated as the factors, and the three zones shown in Figure 1 were the experimental blocks. The RBD consisted of four response variables: calorific value (A), moisture (B), TOC (C), and ash content (D).

The size of the experimental area was 30 × 10 m (300 m2), and the average temperature was 31 °C. A total of 144 samples were collected from the field. Each sampling point (e.g., p4 in Figure 1) included samples of the three components (tops, secondary stalk, and leaves), and for each component, four samples were analyzed for a total of 12 samples per point, 48 samples per geographical zone, and 144 samples total.

The moisture content of the samples was determined as the difference in mass before and after drying at 110 ± 5 °C for 24 h. The moisture was reported in g/kg for comparison with data reported in the literature. Additionally, the drying process gave an insight into the behavior of the straw matter as a source of energy, because additional straw was burned to fuel the boilers.

The carbon content was determined as TOC for each of the biomass components. Although the TOC is not the total carbon content, our discussion is based on TOC since the inorganic carbon is usually very low for vegetable tissues, which makes this a very low-cost approximation. The analysis was carried out in 3 phases: an acidification process, which eliminated the total inorganic carbon and the removable organic carbon; followed by the oxidation of the carbon; and finally, a process of detection and quantification of the carbon content present in the sample. Results were reported in g/kg in order to estimate the mass of CO2 emitted to the environment during the combustion process in the boilers.

The caloric content was determined using a bomb calorimeter according to ASTM D5865-04.20 Small amounts of pulverized solid samples were deposited in the bomb (1–1.5 g), which was loaded with oxygen to initiate the combustion process. The results were reported in kcal/kg.

The ash content was determined according to the NTC 435 standard as the residue of noncombustible inorganic substances, such as mineral salts, in the sample. A small amount (about 2 g) of the biomass was weighed into an empty crucible. The sample was then pre-calcined on a heating plate to prevent it from catching fire, followed by incineration in a muffle furnace at 550° C for 8 h. The sample was then cooled in a desiccator and weighed to determine the ash content. Results were reported in % (m/m).

Subsequently, an ANOVA was performed to determine any significant differences among the three components of the residual biomass and the relative differences for each test performed. Results were compared to data reported in the literature. Thus, the characterization of the organic sugarcane straw (i.e., tops, secondary stalk, and leaves) with its physicochemical properties, including moisture, calorific value, and carbon and ash content, were determined. These properties were used to determine the recovery potential for energy generation.

A theoretical analysis of the CO2 emissions produced by the Lucerna farm was carried out considering two scenarios: (1) the theoretical emissions of CO2 derived from the combustion of sugarcane straw relative to the use of coal as an energy source in the boiler and (2) the theoretical emissions of CO2 generated during the transport of coal from the state of Cundinamarca to the studied farm (the current scenario), relative to the emissions generated during the transport of the sugarcane straw from the field to the farm. Thus, the environmental impact analysis considered both the use of residual biomass as an energy source and the benefits obtained by reducing carbon dioxide emissions during the transport of the fuel (coal vs sugarcane straw) to the farm.

Acknowledgments

The authors thank Hacienda Lucerna S.A. for supporting this research, providing data and samples. Authors would also like to thank the Department of Industrial Engineering and the Department of Chemistry at Universidad Icesi for providing equipment and analysis.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acsomega.9b04340.

Data from the ANOVA of the ash content, carbon content, moisture, and calorific value. (PDF)

The authors declare no competing financial interest.

Supplementary Material

References

- Hassuani S. J.; Lea M. R. L. V.; Macedo I. C.. Biomass Power Generation: Sugar Cane Bagasse and Trash, 1st ed.; PNUD—Programa das Nações Unidas para o Desenvolvimento: Piracicaba, Brazil, 2005; p 217. [Google Scholar]

- Rasche L.; Diego R. S.D. Pros and Cons of Sugarcane Straw Recovery in São Paulo. BioEnergy Res. 2019, 1–10. 10.1007/s12155-019-10078-7. [DOI] [Google Scholar]

- Okuno F. M.; Cardoso T. d. F.; Duft D. G.; Luciano A. C.; Dos S.; Neves J. L. M.; Soares C. C.; Dos S. P.; Leal M. R. L. V. Technical and Economic Parameters of Sugarcane Straw Recovery: Baling and Integral Harvesting. BioEnergy Res. 2019, 12, 930–943. 10.1007/s12155-019-10039-0. [DOI] [Google Scholar]

- Chaves Solera M. Uso de La Caña de Azúcar Como Forraje. Vent. Leche. 2008, 10, 45–51. [Google Scholar]

- Woytiuk K.Sugar Cane Trash Processing for Heat and Power Production. Master Thesis, 2006, Lulea university of Technology, p 79. [Google Scholar]

- UPME . Calculadora de emisiones. http://www.upme.gov.co/Calculadora_Emisiones/aplicacion/calculadora.html (accessed Feb 4, 2020).

- Spliethoff H.; Hein K. R. G. Effect of Co-Combustion of Biomass on Emissions in Pulverized Fuel Furnaces. Fuel Process. Technol. 1998, 54, 189–205. 10.1016/s0378-3820(97)00069-6. [DOI] [Google Scholar]

- Sahu S. G.; Chakraborty N.; Sarkar P. Coal-Biomass Co-Combustion: An Overview. Renewable Sustainable Energy Rev. 2014, 39, 575–586. 10.1016/j.rser.2014.07.106. [DOI] [Google Scholar]

- Rípoli T. C. C.; Molina W. F. Jr.; Rípoli M. L. C. Energy Potential of Sugar Cane Biomass in Brazil. Sci. Agric. 2000, 57, 677–681. 10.1590/s0103-90162000000400013. [DOI] [Google Scholar]

- Alonso Pippo W.; Luengo C. A.; Alonsoamador Morales Alberteris L.; Garzone P.; Cornacchia G. Energy Recovery from Sugarcane-Trash in the Light of 2nd Generation Biofuel. Part 2: Socio-Economic Aspects and Techno-Economic Analysis. Waste Biomass Valorization 2011, 2, 257–266. 10.1007/s12649-011-9069-3. [DOI] [Google Scholar]

- Candil N. A. N.; Moreno J. R.; Castañeda J. F. F.; Villazón R. A.; Galvis J. J. M.. Cadena Del Carbón, 1ra ed.; Imprenta Naional de Colombia: Bogota, 2012. [Google Scholar]

- Smithers J. Review of Sugarcane Trash Recovery Systems for Energy Cogeneration in South Africa. Renewable Sustainable Energy Rev. 2014, 32, 915–925. 10.1016/j.rser.2014.01.042. [DOI] [Google Scholar]

- Cerqueira L.; Edye L. A.; Wegener M. K.; Scarpare F.; Renouf M. A.. Optimising Sugarcane Trash Management for Advanced Biofuels Production. In International Society of Sugar Cane Technologists: Proceedings of the XXVIIIth Congress, June 24 to June 27, 2013, São Paulo, Brazil; Sociedade dos Técnicos Açucareiros e Alcooleiros do Brasil; STAB, 2013; pp 155–166.

- Incauca S. A. Informe de Sostenibilidad. Rev. Incauca 2011, 1, 95. [Google Scholar]

- Ingenio Providencia S. A. Informe de Sostenibilidad. Rev. Ingenio Provid. 2013, 1, 70. [Google Scholar]

- Vehichal Technologies . Heavy Trucks. 2014 Vehichal Technologies Mark Reports 2012, 100.

- ASOCAÑA . El sector azucarero colombiano en la actualidad. https://www.asocana.org/publico/info.aspx?Cid=215 (accessed Feb 4, 2020).

- Lucerna . CERES—Certification of Environmental Standards Colombia. https://cerescolombiacert.wordpress.com/tag/lucerna/ (accessed Feb 4, 2020).

- Procaña . Subproductos y derivados de la caña de azúcar https://www.procana.org/new/quienes-somos/subproductos-y-derivados-de-la-caña.html (accessed Feb 4, 2020).

- ASTM International . D5865-13 Standard Test Method for Gross Calorific Value of Coal and Coke. West Conshohocken, PA, 2013. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.