Abstract

Short-dough biscuits are popular snacks. Unfortunately, fat used in most of these products has low nutritional value due to the high content of saturated fatty acids. The most popular fat used in bakery products is palm oil. In this work high-oleic rapeseed oil was used in the form of oleogels structured by waxes (canelilla, rice bran, yellow and white beeswax), monoacyloglicerols and ethylcelullose. In this form oil keeps nutritional value and has solid consistency. Obtained oleogels were significantly different than palm oil in terms of texture and viscosity. However, using oleogel with 5% of monoacylglicerols, as a shortening let to obtain biscuits with similar properties to control sample (with palm oil). Addition of 2 and 3% of candelilla wax, 8% of ethylcelullose, 2% of rice bran wax and 5% of monoacylglicerols allowed to get products from which lipid fraction migration was similar or smaller then from control sample.

Keywords: Oleogels, Short-dough biscuits, Texture, Oil migration

Introduction

Short-dough products are becoming more popular thanks to their availability, long shelf-life and good sensorial properties (Onacik-Gür et al. 2015). Bakery and confectionery products have a particularly high content of saturated fatty acids (SFA) which results from the type of fat used for their production. Palm oil is used in majority of these products. It is widely used due to its technological suitability associated with a very good resistance to oxidation, solid consistency and plasticity (Dassanayake et al. 2011). Palm oil is increasingly being boycotted by consumers for low nutritional value and environmental issues. For cultivation of oil palm rain-forests are cut and plantation workers very often have poor working condition (Disdier et al. 2013). For this reason, it seems reasonable to replace palm oil with another raw material with a beneficial nutritional composition of fatty acids (Rangrej et al. 2015). According to the WHO recommendations, the daily SFA consumption should not exceed 10%E. A large majority of European population exceeds this recommended limit, for example in France this value is even 15.5%E (Eilander et al. 2015). Excessive intake of SFA negatively affects the human body, because it increases the risk of cardiovascular disease. Bakery products are a significant source of SFA and fat in the diet (Żbikowska et al. 2015). In countries such as England, Finland and Netherlands, these products cover 10–18% of the total fat consumed (Eilander et al. 2015).

The liquid consistency of vegetable oils rich in unsaturated fatty acids and the lack of solid phase makes it as a bad raw material in the production of short-dough biscuits. Baking fats should have appropriate technological properties, good plasticity, solid consistency and presence of solid phase (Dassanayake et al. 2011). Nowadays, there are more scientific reports about the possibility of structuring liquid oils to form so-called oleogels. Oil structuring is possible by the addition of substances such as: plant and animal waxes, ethylcelluslose, monoacylglycerols, sterols, lecithin and others. These substances form in the oleogel a 3-dimensional network that binds oil (Patel et al. 2013; Onacik-Gür et al. 2017). In line with expectations and growing consumer awareness, manufacturers of pastry products are focused on adding ingredients that could increase the nutritional value of their products. This usually applies to the use of flours with higher content of dietary fiber, addition of oatmeal, fat and sugar substitutes (Onacik-Gür et al. 2015; Struck et al. 2014; Żbikowska et al. 2018). However, for technological reasons, short-dough biscuits made with solid fat, rich in SFA, are only available on the market. That is why, it is reasonable to look for a possibility of introducing oil–raw material with high nutritional value to short-dough biscuits.

Oleic acid in one of the unsaturated fatty acids (UFA). It is significantly more oxidatively stable than other UFA (Roman et al. 2013). Consumption of oils rich in oleic acid has beneficial impact on human health: it lowers total cholesterol in the blood and increases HDL fraction (EFSA 2010).

The aim of this work was to determine the possibility of obtaining innovative short-dough biscuits with oleogels constituted by high-oleic rapeseed oil instead of palm oil and to investigate the influence of such fat material on the quality of a final product.

Materials and methods

Materials

Oleogels

Oleogels were obtained from high-oleic rapeseed oil (HORO) (Bunge, Poland) and structuring agents: ethylcellulose (EC) (EC20, The Dow Chemical Company, USA), candelilla wax (CLX), rice bran wax (RBX), white beeswax (WBX), yellow beeswax (YBX) (Strahl&Pitsch, Inc., USA) and monoacylglycerol (MAG) (Verol n-90, Lasenor, Spain). Seven types of oleogels were prepared. The percentage share of structure forming substances in oleogels was: 2 and 3% CLX, 2% RBX, 5% WBX, 5% YBX, 5% MAG and 8% EC. The structuring substances were mixed with HORO and heated until complete dissolution. The structuring substances were added into the oil, then mixed and heated until complete dissolution. The highest temperature was used for EC samples (150 °C). Oleogels were kept for solidification at room temperature.

Short-dough biscuits

Braun Multiquick mixer (type 4644, Poland) was used for the dough production. First, the palm oil (PF) (Bunge, Poland)/oil/oleogel (24% of dough weight) was used mixed with lecithin (1%) for 2 min at high speed. Water (9%) was added (emulsion was prepared), followed by powder sugar (17%) and it was all mixed further for 5 min. After obtaining a uniform consistency, flour (48%) with baking powder (1%) was added. After a minute of mixing (at the medium speed) the dough was kneaded until homogeneous consistency. Next, the dough was cooled at 4 °C for 30 min, then, sheeted to a thickness of 4 mm. The biscuits were cut into a circle shape with a diameter of 51 mm and baked in a pre-heated UNOX (type: BakerTop4 600 × 400, Italy) convection oven at 175 °C for 13 min.

Methods

Texture of oleogels and palm oil

The sample was analyzed using a texture analyzer TX.AT plus (MicroStable Systems, UK) using a penetration test. A cylindrical tip P/0.5R was used for the measurement, which was immersed in the sample to a depth of 5 mm, the cross-head speed was 1 mm/s. The test was carried out at room temperature (23 °C ± 2). The highest measured force value was defined as gel hardness and expressed in Newtons (N) (Yılmaz and Öğütcü 2014).

Apparent viscosity

The apparent viscosity was measured by Brookfield HA (USA) using DIN-87 spindle. The measurement was performed using a 25-step test in which the initial rotational speed was 10 rpm, and in each stage increased by 10 rpm. The measurement was carried out at 25 °C, placing the analyzed samples in a thermostat (Brookfield, type: TC-550, USA), the results were given in Pa·s. The obtained values of apparent viscosity (at each step of the test) were fitted to the Power Low equation (Onacik-Gür et al. 2017).

where τ—shear stress (Pa), k—flow consistency index (mPa s), D—shear rate (1/s), n—flow behavior index (–).

Oil binding capacity (OBC%) of oleogels and palm oil

Test tubes with 3 g of sample were centrifuged for 15 min on a centrifuge MPW340 (Poland) at 4000 rpm. Unstable oleogels separated into two phases where the upper phase was the separated oil. After centrifugation, the tubes were inverted and placed on a paper towel to remove the separated oil. After 5 min test probes with solid phase were weighted. Oil binding capacity (OBC%) was calculated from a formula (Yılmaz and Öğütcü 2014):

where Ms—weight of a centrifuged sample with test tube, Mp—weight of a test tube, Mo—weight of oleogel sample and test tube.

DSC analyzes of oleogels and palm oil-type

The assay was performed using a differential scanning calorimeter (DSC) TA Instruments (model Q200, USA). Weight of oleogels and PF samples was 10 mg. Probes were placed in aluminum hermetically closed vessels.

Oleogels structured with waxes and monoacyloglycerol were heated to 100 °C and maintained at this temperature for 15 min, then cooled to – 40 °C at a rate of 10 °C/min. Samples were kept at this temperature for 30 min and then reheated to 100 °C at a rate of 10 °C/min (Rocha et al. 2013).

Ethylcellulose oleogels were heated from 25 to 200 °C at a rate 5 °C/min, and then cooled at the same rate to 25%. The nitrogen flow was 30 ml/min (Davidovich-Pinhas et al. 2015).

From obtained thermograms the initial, final and peak temperature of melting were read.

Dough density

A dish of known volume was filled with dough and weighed with an accuracy of 0.01 g and the density (g/cm3) was calculated.

Texture analysis of dough

The study was carried out on a TA.TX plus texturometer (Stable Microsystems, Godalming, UK) equipped with a cylindrical mandrel with a diameter of 6 mm (P/6). 110 g of dough were flattened in the cylindrical vessel (A/DP). Sample was penetrated 20 mm with a speed of 3 mm/s. Hardness (N) was determined. The assay was carried out at room temperature (23 ± 2 °C) in triplicate.

Analysis of biscuits spread during baking

In the analysis of biscuits spread during baking, the time after which the product stopped increasing its size was determined (Jacob and Leelavathi 2007). In 1-min intervals diameter and height of biscuits were measured using an electronic caliper (TCM, type:234,990. Tschibo, Germany).

Geometry of biscuits

Dimensions of six biscuits were determined: diameter (D) and height (H) at the maximum point using an electronic caliper (TCM, type:234,990, Tchibo, Germany). The spreadability index (SI) was calculated from the formula:

Biscuits density

Based on the volume determined in rapeseed and weight of 6 biscuits the density was calculated (g/cm3).

Color of biscuits

The color of biscuits surface was determined by the instrumental method using the Konica Minolta trichromatic calorimeter (type:CR-200, Osaka, Japan). L*, a*, b* parameters were determined. Test was performed at three points on the product surface. 3 biscuits of each variant were analyzed.

Total color difference (ΔE) between biscuits with oleogels and control sample (palm oil based) was calculated from the formula:

where Lc*–L* of control sample (PF), Ls*–L* of a sample, ac*–a* of PF, as*–a* of a sample, bc*– b* of PF, bs*– b* of a sample.

Texture analysis of biscuits

Texture of biscuits was determined by 3-point breaking test on TA.TX plus texturometer at room temperature (23 ± 2 °C). The following test parameters were used: load 5 kg, knife speed 3 mm/s, depth at which knife moved was 5 mm. Parameters breaking strength (N) and fracturability (mm) were obtained. The assay was performed in 10 replications.

Determination of fat migration

Short-dough biscuits were placed in a thermostat preheated to 30 °C, on a Petri dish, on pre-weighted 5 layers of paper (120 g/m2). After 24 h, the weight of the paper with the dish was re-determined. The migration of fat from biscuits was calculated based on the difference in mass (g). The assay was performed in triplicate.

Statistics

In order to compare results, a one-way analysis of variance (ANOVA) was carried out using statistical program Statistica 12.0 (StatSoft Poland). The existence of differences between mean values was assessed by Tukey's test, the level of significance was α = 0.05. In order to check the occurrence of dependencies between variables and to illustrate the differences and similarities in biscuits, Principal Component Analysis (PCA) was performed. The number of factors taken into account was > 70%.

Results and discussion

Oleogels

The mechanical properties of plastic fats are important, in particular if they are used for the production of margarine, creams and shortenings. The texture of fats affects the ability to retain air in the batter and moisture in the structure of the bakery product and imparts an appropriate texture to bakery and confectionery products (Maache-Rezzoug et al. 1998).

The value of the penetration force varied depending on the type and amount of the oil structuring additive (Table 1). Palm oil (PF) had the highest value of hardness. This value differed significantly from penetration force all other products. In the oleogel group the highest value of penetration force was found in the CLX3% sample. Similarly, Yılmaz and Öğütcü (2014) also stated that oleogels with the addition of beeswax and monoacylglycerols did not differ statistically in terms of hardness.

Table 1.

Textural and rheological properties of oleogels

| Sample | OBC (%) | Hardness (N) | Parameter | |||

|---|---|---|---|---|---|---|

| ηa | k | n | r2 | |||

| PF | 100 | 2.72d ± 0.21 | 495.5 ± 18.3 | 68,086.3ef ± 84.5 | 0.16 ± 0.03 | 0.92 |

| CLX 2% | 100 | 0.58ab ± 0.03 | 164.3 ± 1.2 | 11,282.0ab ± 1164.9 | 0.27 ± 0.02 | 0.97 |

| CLX 3% | 100 | 2.30c ± 0.21 | 219.3 ± 6.0 | 54,975.7de ± 548.6 | 0.04 ± 0.02 | 0.96 |

| RBX 2% | 99.8 | 0.69b ± 0.02 | 294.4 ± 15.3 | 74,715.0f ± 2615.3 | 0.01 ± 0.03 | 0.85 |

| WBX 5% | 100 | 0.74b ± 0.01 | 233.2 ± 5.3 | 27,284.0bc ± 1714.1 | 0.16 ± 0.01 | 0.94 |

| YBX 5% | 99.8 | 0.69b ± 0.00 | 197.6 ± 2.3 | 24,891.7bc ± 921.7 | 0.15 ± 0.01 | 0.94 |

| MAG 5% | 86.1 | 0.52a ± 0.02 | 219.3 ± 6.0 | 75,448.0f ± 233.0 | − 0.02 ± 0.00 | 0.93 |

| EC 8% | 99.3 | 0.75b ± 0.12 | 498.4 ± 28.1 | – | – | – |

a,b,c Homogenous groups in the same column

The measurement of viscosity is an important parameter for food products, because the swallowing activity is comparable to a shear rate of 5 to about 50 s−1 and higher values for mixing with machines (Martins et al. 2016).

The obtained values of apparent viscosity varied depending on the type of sample tested (amount and type of structuring substance). In all the oleogels, along with the increase of the shear rate, the apparent viscosity dropped (Table 1). This behavior is typical for oleogels and indicates that they are non-Newtonian, pseudoplastic fluids. Therefore, in order to confirm this theory, the results obtained were adjusted to the Power Low model (Sagiri et al. 2015). Sagiri et al. (2015) analyzed oleogels with stearic acid at 16, 22 and 25% and also characterized them as non-Newtonian pseudoplastic liquids, because the flow factor n was less than 1. In a study conducted by Martins et al. (2016), oleogels structured with beeswax showed properties of non-Newtonian liquids for the amount of agent addition of 4 and 8%. The consistency of ethylcellulose oleogels turned out to be heterogeneous, which caused very large deviations of the obtained results (changes in apparent viscosity versus speed) after substituting them for Power Law formula, therefore only the apparent viscosity results were included in the table. For the other oleogels and palm oil, the determination coefficient (r2) exceeded 0.85. High r2 indicates a very good match of the mathematical equation to the obtained results. A one-way analysis of variance for the consistency parameter k was carried out because it is a measure of apparent viscosity. The most similar to palm oil in terms of this parameter were oleogels: CLX3%, RBX2% and MAG5%.

Centrifuging the sample is an accelerated sedimentation test, compared to the gravitational sedimentation (Yılmaz and Öğütcü 2014). After centrifuging the samples, there was no separation of liquid fraction in oleogels of the following variants: CLX2%, CLX3%, WBX5%. The worst stability (86.1%) was characterized by the MAG5% (Table 1). Similar results were obtained by Yılmaz and Öğütcü (2014). They showed the lowest stability at 80.85% for oleogel with 3% of MAG addition in hazelnut oil. In turn, other oleogels with beeswax had the ability to maintain oil in more than 99%.

The highest melting point (158.1 °C) was characterized by the EC8% oleogel, while among the monomers—oleogel with rice bran wax (64.48 °C) (Table 2). The thermogram of MAG oleogel had an additional peak indicating the presence in the sample of a fraction with a lower melting point of 14.74 °C.

Table 2.

Thermal parameters and solid phase content (SF) at 20 °C oleogels and palm oil, determined by the DSC method

| Sample | Parameter | ||||

|---|---|---|---|---|---|

| Tpeak (°C) | ΔHm (J/g) | %SF | |||

| CLX 2% | 49.42 | 1.399 | 10.54 | ||

| CLX 3% | 53.15 | 1.921 | 10.75 | ||

| RBX 2% | 64.48 | 4.708 | 17.61 | ||

| WBX 5% | 48.50 | 4.954 | 16.04 | ||

| YBX 5% | 48.43 | 3.768 | 17.49 | ||

| MAG 5% |

pik 1 14.74 |

pik 2 49.45 |

pik 1 0.666 |

pik 2 2.082 |

11.42 |

| EC 8% | 158.10 | 28.15 | – | ||

| PF |

pik 1 2.58 |

pik 2 24.80 |

pik 1 52.86 |

pik 2 31.72 |

31.36 |

“–" none (calculation of SF content at 20 °C for 8% EC oleogel was not possible according to the DSC analysis temperature)

The highest enthalpy (ΔH) among all oleogels had EC8%. Among the other oleogels, the highest ΔH was characterized by WBX5%. For CLX2% and 3%, it was observed that with the increase in the size of the structuring additive, the energy needed to melt the sample increased. The total ΔH of palm oil for both melting peaks was 84.58 J/g, one of them corresponding to a temperature of 2.58 °C and the other of 24.80 °C (Table 2). In contrast, for oil in oleogels, ΔH had about 65.89 J/g and reached its peak at approximately − 11.58 °C. This indicates the need for more energy to melt PF than oleogel with the addition of structuring substances of fatty origin.

In PF the solid phase content (SF) at 20 °C was the biggest (31.36%), for oleogels structured with monomers SF content was much lower than in PF (Table 2). The addition of structuring substances was small at the level of 2–5%, and liquid oils had a solid phase content at 20 °C at 0%. However, the SF value obtained by the DSC analysis for oleogels was higher, which may indicate that the crystals tightly bound liquid oil in the network.

Biscuits dough

The quality of a final product depends on the quality of dough. Biscuits dough should be smooth, uniform and plastic (Mamat and Hill 2014). During mixing of ingredients, differences in produced dough were observed. Formation of PF emulsions was more difficult than of oleogels and oil. The mass obtained from PF, water, lecithin and sugar was characterized by a stiff texture. After mixing with flour dough was uniform and plastic. HORO the cream (oil, water, lecithin, powdered sugar) was created very easily, it was smooth, uniform and liquid, but not aerated. Flour quickly merged with the mass and during mixing dough was becoming harder. During rolling of dough with oil, a problem with its adhesion to the roller was observed. Similar difficulties in the formation of short-dough with oil were observed by Jacob and Leelavathi (2007). The dough with oil and oleogels were less plastic than samples with palm oil. The most similar to palm oil consistency was dough with MAG.

The dough density depends on ingredients and their proportions. Fat plays an important role in its aeration during the kneading. Typical shortenings, with a solid consistency, have high content of SF, which keeps air in the structure. This results in better aeration of a final product and is related to the appropriate texture and sensory features (Devi and Khatkar 2016).

The differences of dough densities were statistically significant (Table 2). The lowest value of this parameter was characterized by PF, because of the highest solids content. Among dough made with oleogels, the smallest density had one with monoacylglycerols and the highest with ethylcellulose. The smallest density of MAG5% dough may be due to the emulsifying effect of monoacylglycerols and contribute to better aeration (Jacob and Leelavathi 2007). In studies carried out by Onacik-Gür et al. (2015), lecithin was also used with emulsifying properties. The authors observed that used additive resulted in reduction of density.

Fat affects the plasticity of the dough. It behaves like lubricant prevents water from entering the flour molecules and formation of gluten, thanks to which the dough is not elastic, which is desirable for short-dough (Maache-Rezzoug et al. 1998).

Dough with PF and CLX3%, WBX5% and YBX5% had the lowest value of hardness. These values did not differ significantly (p ≤ 0.05) (Table 2).

The dough with palm oil, which has a higher solid phase content, was softer than a dough with HORO. In studies carried out by Sciarini et al. (2013) authors found that dough with a fat of 10% of SF was harder than products with other blends with a higher SF content of 26.5–15.3%.

Emulsifiers significantly affect the properties of dough. The hardness of dough with MAG5% was smaller compared to dough with HORO (Table 2). There was also a decrease in the hardness of dough with the CLX2% and 3% oleogels, WBX5% and YBX5% compared to the HORO. This may indicate that these waxes have similar properties to emulsifiers and reduce the formation of gluten blocking access to water.

Also, in terms of strength of adhesion, dough with palm oil belonged to the group with the lowest value of this parameter (− 0.55 N), i.e. the highest adhesiveness of dough to the spindle (Table 3). Similar results were obtained by Manohar and Rao (1999), they showed that dough obtained with shortening and hydrogenated fat had greater adhesiveness compared to dough with sunflower oil.

Table 3.

Characteristics of dough and biscuits

| Parameter | Sample | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PF | HORO | EC 8% | CLX 2% | CLX 3% | MAG 5% | RBX 2% | WBX 5% | YBX 5% | ||

| Dough | Density (g/cm3) | 1,17a ± 0.01 | 1.23bc ± 0.02 | 1.24c ± 0.02 | 1.24c ± 0.02 | 1.23bc ± 0.01 | 1.21b ± 0.01 | 1.23bc ± 0.01 | 1.23bc ± 0.01 | 1.22bc ± 0.01 |

| Hardness (N) | 1.42a ± 0.18 | 2.11bc ± 0.22 | 2.45d ± 0.28 | 1.85b ± 0.22 | 1.50a ± 0.16 | 1.89b ± 0.14 | 2.33 cd ± 0.17 | 1.55a ± 0.16 | 1.47a ± 0.12 | |

| Adhesiveness (N) | − 0.55a ± 0.10 | − 0.34bc ± 0.16 | − 0.42abc ± 0.15 | − 0.30c ± 0.06 | − 0.39abc ± 0.09 | − 0.46abc ± 0.12 | − 0.35bc ± 0.09 | − 0.56a ± 0.14 | − 0.51ab ± 0.09 | |

| Biscuits | H (mm) | 7.20ab ± 0.38 | 6.93 a ± 0.34 | 6.96 a ± 0.10 | 7.18ab ± 0.31 | 7.32ab ± 0.07 | 7.46b ± 0.32 | 7.27ab ± 0.15 |

7.11ab ± 0.24 |

7.14ab ± 0.23 |

| W (mm) | 61.41a ± 1.70 | 61.41a ± 1.89 | 62.07ab ± 1.26 | 62.24ab ± 1.43 | 62.90b ± 1.47 | 61.54a ± 1.51 | 61.98ab ± 1.04 | 61.93ab ± 1.73 | 61.99ab ± 1.22 | |

| SI (W/H) | 8.53 | 8.86 | 8.92 | 8.67 | 8.59 | 8.27 | 8.53 | 8.71 | 8.68 | |

| D (g/cm3) | 0.60 a ± 0.04 | 0.68 c ± 0.01 | 0.64bc ± 0.03 | 0.66bc ± 0.01 | 0.65bc ± 0.01 | 0.62ab ± 0.02 | 0.67 c ± 0.02 | 0.66c ± 0.01 | 0.66 c ± 0.03 | |

| Breaking strength (N) | 4.25 cd ± 0.67 | 3.55ab ± 0.41 | 3.05a ± 0.44 | 3.24a ± 0.64 | 3.26ab ± 0.50 | 4.48d ± 0.80 | 3.79bc ± 0.70 | 3.35ab ± 0.76 | 3.41ab ± 0.47 | |

| Fracturability (mm) | 6.99c ± 0.44 | 6.67a ± 0.41 | 6.71ab ± 0.36 | 6.92bc ± 0.52 | 7.07 cd ± 0.32 | 7.27d ± 0.48 | 7.02c ± 0.37 | 7.00c ± 0.45 | 6.90abc ± 0.43 | |

| L* | 74.80c ± 1.00 | 71.32a ± 0.20 | 71.54a ± 1.74 | 71.85ab ± 0.89 | 71.77a ± 1.65 | 71.44a ± 0.89 | 72.14ab ± 0.64 | 72.78b ± 1.08 | 72.87b ± 0.16 | |

| a* | 3.29 cd ± 1.57 | 2.59abc ± 0.28 | 3.94d ± 1.40 | 2.46abc ± 0.43 | 3.01bcd ± 1.58 | 2.52abc ± 1.52 | 2.19ab ± 1.12 | 1.89a ± 1.17 | 1.68a ± 0.42 | |

| b* | 24.85a ± 1.64 | 24.95a ± 1.70 | 23.80a ± 0.68 | 24.62a ± 1.47 | 24.55a ± 1.06 | 24.74a ± 1.20 | 24.14a ± 0.76 | 24.05a ± 0.67 | 24.41a ± 0.99 | |

| ΔE | 0 | 3.55 | 3.49 | 3.06 | 3.05 | 3.45 | 2.96 | 2.59 | 2.55 | |

| Fat migration (g) | 0.16bc ± 0.1 | 0.66e ± 0.08 | 0.15b ± 0.01 | 0.06a ± 0.01 | 0.04a ± 0.01 | 0.20bcd ± 0.01 | 0,17bcd ± 0.03 | 0,23 cd ± 0.01 | 0,25d ± 0.07 | |

H height of cookies, W width, SI spreadability index, D density

a,b,c Homogenous groups in the same rows

During baking, short-dough in the initial phase increases its volume, as a result of the extraction of CO2 from its matrix, coming from the raising agents present in the baking powder and water vapor. Then, at the end of baking and after removing it from the oven, the cake begins to settle and its size decreases (HadiNezhad and Butler 2009).

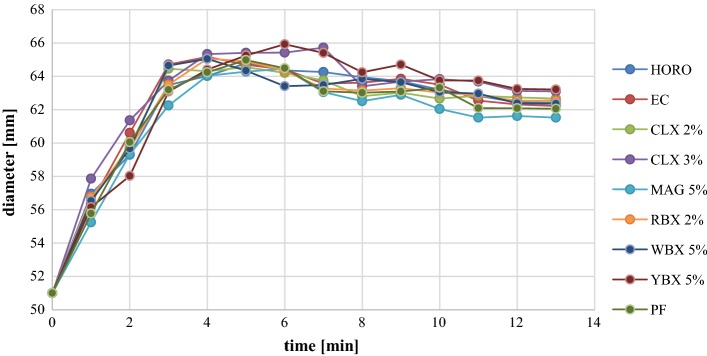

The diameter of biscuits with palm oil has stabilized after about 11 min of baking, while short-dough products with oil at the end of the thermal treatment. It was also observed that HORO biscuits diameter was larger at the end of baking, compared to the diameter of samples with palm oil (Fig. 1).

Fig. 1.

Values of diameter of short-dough cookies during baking

Similar observations were made by Jacob and Leelavathi (2007), they found that cookies with sunflower oil as last reached their final size, while the shape of cookies with shortening, margarine and hydrogenated fat stabilized much earlier.

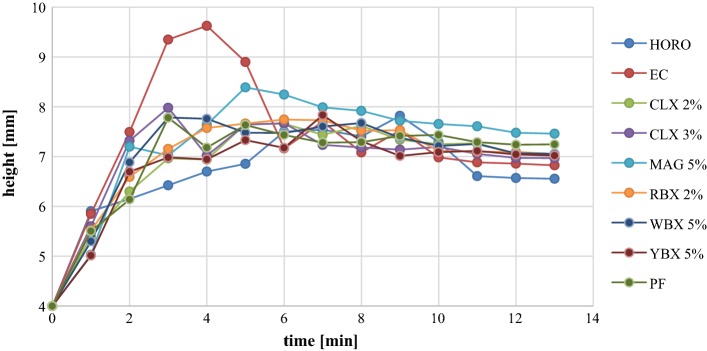

Additives used for oleogel preparation did not significantly affect the size of short-dough biscuits. Only the diameter of MAG5% products was smaller (at the end of baking) than diameter of control sample with PF (Fig. 1). The height of biscuits during baking varied in the same way as their diameter. Products with PF compared to biscuits with HORO have stabilized this dimension earlier. HORO biscuits, had a lower height, and the control sample was higher. Height of HORO biscuits grew the slowest, reaching a maximum value after 9 min of baking, while the remaining samples reached it between 3 and 5 min. The growth curve of short-dough biscuits with EC8% oleogel differed significantly from others. After about 4 min of baking, these biscuits reached a maximum height of 9.63 mm. Then a decrease in the height of these biscuits was observed (at 6 min). It can be assumed that this is related to reaching by a biscuit temperature at which ethylcellulose softens. Cookies with MAG5% at the end of baking were higher than other (Fig. 2).

Fig. 2.

Values of the height of short-dough cookies during baking

Short-dough biscuits

According to the geometry of biscuits measured 24 h after baking, the highest products with MAG 5%, the lowest with EC8% and HORO. Statistically the widest products were CLX3% (Table 3).

As expected, the spreadability index (SI) of HORO products was higher compared to biscuits obtained with PF. Products with MAG5% had the smallest SI, while biscuits with EC8% the biggest (Table 3). In studies carried out by Sciarini et al. (2013), it was also observed that cookies with fat with the highest solid phase content had a lower SI and were higher than biscuits with other fats. Jang et al. (2015) reported that biscuits with oleogels (3 and 6% of candelilla wax) were characterized by a larger diameter and spreadability compared to sample with shortening, similarly to the presented work (Table 3).

In the general characteristics of short-dough, low density indicates the existence of pores in the product structure, which positively affects its quality. The smallest density had products with PF. These results confirm that the high solid phase content in fat promotes the retention of gases in the dough structure. In the group of products with oleogels, the smallest density had cookies with MAG5%.

Similarly, in the studies conducted by Manohar and Rao (1999) and Onacik-Gür et al. (2015), cookies with oil had lower density compared to the control sample with shortening. Calligaris et al. (2013) reported that monoacylglycerols addition increase in volume of sponge cakes. Additionally, the authors found that MAG increased number of pores and enlarged their diameters.

The brightest were biscuits with PF and significantly different (p ≤ 0.05) than the others (Table 3). Darker color is related to the non-enzymatic browning forming during baking: the Maillard reaction and sugar caramelization. A higher value of the L* parameter (brightness) indicates that fats with a higher SF content glue and block substrates of non-enzymatic browning, as a result reaction do not occur (Sciarini et al. 2013), which confirms the results obtained in this work (Table 1).

In the calculation of the total difference in color (ΔE) PF products were taken as standard. The largest ΔE was found for biscuits with HORO, while the lowest value for YBX5% (Table 3). If ΔE > 3 the difference in color is possible to be observed by the human eye (Francis and Clydesdale 1975). Therefore, for most products the difference was on the limit of detection.

Texture of pastry products is very important and may disqualify the product. Differences result from: a different response to the pressure force necessary to bite or break, geometric properties, water and fat content. Texture measurement can be done instrumentally (Paula and Conti-Silva 2014).

The greatest value of the strength needed to break biscuits was characterized by MAG5% biscuits. These products were the most similar, in terms of the value of this parameter, to biscuits with PF. In contrast, products with EC8% and CLX2% required the lowest breaking force. In the studies of Jang et al. (2015), biscuits made with oleogels with 3 and 6% of CLX were also characterized by lower breaking strength compared to samples with shortening. According to other authors, less strength is needed to break products with shortenings than with oil (Onacik-Gür et al. 2015; Jacob and Leelavathi 2007). The fat has a very significant impact on the hardness of pastry products. When solid fat melts, gluten proteins can interact and form the final structure of the product. Therefore, the lower content of SF in the fat, the more gluten can polymerize and then a product with a harder structure is formed (Pareyt et al. 2010). In the work of Sciarini et al. (2013) cookies in which fat had SF content of 10.2% and 15.3%, required less breaking force than fat products with a higher level of SF (47.1%). According to authors hardness was not only dependent on the solid phase content but also on fatty acids composition.

The fracturability was related to the force necessary to break biscuits. Values of both parameters were the highest for products prepared with oleogels with the addition of MAG5%. The closest to the control sample, in terms of this parameter, were RBX2% and YBX5% biscuits (Table 3).

The fat migration from product matrix is important for sensory and storage properties of a product. In the case of dry snacks, fat migration is associated with the formation of an oil layer on the surface of the product and inside the package. Such fat may undergo a degradation process faster, compared to inside the matrix. Its accelerated rancidity negatively affects the storage and sensory properties of food.

As expected, the largest fat migration was observed in biscuits with HORO, which was significantly higher than in other samples. It was observed that the addition of structuring substances caused a statistically significant reduction of oil migration. The most effective in stabilizing oil in the product was CLX. It caused less fat migration from the biscuits’ matrix than in the case of PF (Table 3), with the highest content of SF. Such good lipid binding properties may be due to a very good recovery of the crystalline structure of CLX network in oil and synergy of other ingredients. Smaller amount of migrated lipids, compared to the control sample, was also observed for products with ethylcellulose.

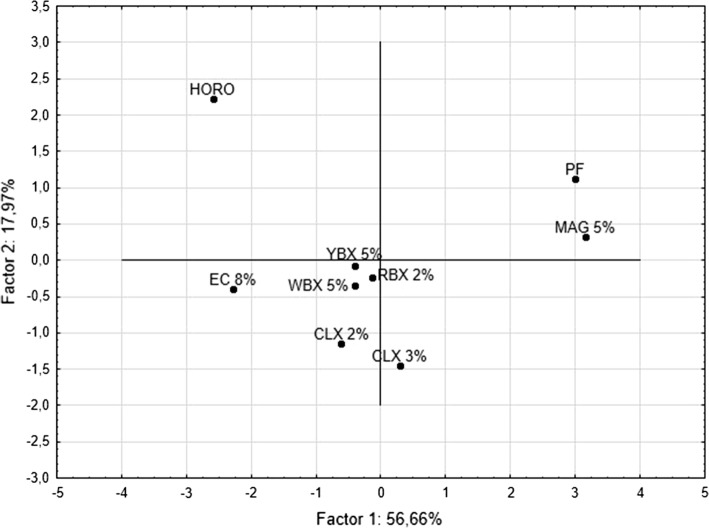

Principal Component Analysis (PCA) were conducted in order to check, which products were the most similar to control sample. Seven parameters determining product properties were selected for PCA: dough density, product density and hardness of dough, spreadability index, breaking strength, fracturability and fat migration. First factor explained 56.66% and was positively correlated with breaking strength and fracturability, while negatively with density of dough and biscuits and spreading index. The second factor explained 17.97% of variables and was positively correlated with fat migration.

Based on the projection of variables (Fig. 3), three groups were observed. In the upper left corner, there is a single case, corresponding to biscuits with HORO, to the right cases corresponding to PF and MAG5%. The last group consisted of other products with oleogels. This shows that biscuits with MAG were the most similar to the control sample in terms of selected variables. Other biscuits did not resemble HORO (without structuring additives). Analyzing the third (last) group, it can also be observed that the biscuits with ethylcellulose differed from the other products in terms of the first factor. The shift of this case (EC8%) to the left indicates differences in density and spreadability in relation to the other cases.

Fig. 3.

PCA of cookies: a projection of cases (variants)

Conclusion

Despite the fact that properties of oleogels were significantly different than of a typical bakery shortening, palm oil, they could be used successfully as its substitute. Although over 90% of oleogels weight was constituted by high-oleic rapeseed oil when used as a bakery fat, they behaved differently than pure high-oleic rapeseed oil (not structurized). Type of structuring agent had a significant influence on properties of dough and final product such as: texture, density, geometry, and oil migration. Oleogel with 3% of candelilla wax was the most similar to palm oil. Nevertheless, oleogel with 5% of monoacyloglicerol used as a bakery fat helped to obtain biscuits with the most similar properties to the control sample. It was also found that even oleogels with a very small amount of solid phase (at 20 °C) were able to hold liquid oil phase in the biscuit matrix significantly better than (CLX3% and 2%) or at a similar level as (EC8%, MAG5%, RBX2%) palm oil.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Calligaris S, Manzocco L, Valoppi F, Nicoli MC. Effect of palm oil replacement with monoglyceride organogel and hydrogel on sweet bread properties. Food Res Int. 2013;51:596–602. doi: 10.1016/j.foodres.2013.01.007. [DOI] [Google Scholar]

- Dassanayake LSK, Kodali DR, Ueno S. Formation of oleogels based on edible lipid materials. Curr Opin Colloid Interface Sci. 2011;16:432–439. doi: 10.1016/j.cocis.2011.05.005. [DOI] [Google Scholar]

- Davidovich-Pinhas M, Barbut S, Marangoni AG. The gelation of oil using ethyl cellulose. Carbohydr Polym. 2015;117:869–878. doi: 10.1016/j.carbpol.2014.10.035. [DOI] [PubMed] [Google Scholar]

- Devi A, Khatkar BS. Physicochemical, rheological and functional properties of fats and oils in relation to cookie quality: a review. J Food Sci Technol. 2016;53(10):3633–3641. doi: 10.1007/s13197-016-2355-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Disdier AC, Marette S, Millet G. Are consumers concerned about palm oil? Evidence from a lab experiment. Food Policy. 2013;43:180–189. doi: 10.1016/j.foodpol.2013.09.003. [DOI] [Google Scholar]

- EFSA (2010) Scientific opinion on dietary reference values for fats, including saturated fatty acids, polyunsaturated fatty acids, monounsaturated fatty acids, trans fatty acids, and cholesterol. EFSA J 8(3):1461, 1–107. 10.2903/j.efsa.2010.1461

- Eilander A, Harika RK, Zock PL. Intake and sources of dietary fatty acids in Europe: are current population intakes of fats aligned with dietary recommendations? Eur J Lipid Sci Technol. 2015;117(9):1370–1377. doi: 10.1002/ejlt.201400513. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Francis FJ, Clydesdale FM (1975) Food colorimetry: theory and applications. The AVI Publishing Co. Inc. Westport.

- HadiNezhad M, Butler F. Effect of flour type and dough rheological properties on cookie spread measured dynamically during baking. J Cereal Sci. 2009;49:178–183. doi: 10.1016/j.jcs.2008.09.004. [DOI] [Google Scholar]

- Hughes NE, Marangoni AG, Wright A, Rogers MA, Rush JW. Potential food application of edible oil organogels. Trends Food Sci Technol. 2009;20(10):470–480. doi: 10.1016/j.tifs.2009.06.002. [DOI] [Google Scholar]

- Jacob J, Leelavathi K. Effect of fat-type on cookie dough and cookie quality. J Food Eng. 2007;79:299–305. doi: 10.1016/j.jfoodeng.2006.01.058. [DOI] [Google Scholar]

- Jang A, Bae W, Hwang H-S, Lee HG, Lee S. Evaluation of canola oil oleogels with candelilla wax as an alternative to shortening in bakery goods. Food Chem. 2015;187:525–529. doi: 10.1016/j.foodchem.2015.04.110. [DOI] [PubMed] [Google Scholar]

- Maache-Rezzoug Z, Bouvier JM, Allaf K, Patras C. Effects of principal ingredients on rheological behavior of biscuit dough and on quality of biscuits. J Food Eng. 1998;35:23–42. doi: 10.1016/S0260-8774(98)00017-X. [DOI] [Google Scholar]

- Mamat H, Hill SE. Effect of fat types on the structural and textural properties of dough and semi-sweet biscuits. J Food Sci Technol. 2014;51(9):1998–2005. doi: 10.1007/s13197-012-0708-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Manohar RS, Rao PH. Interrelationship between rheological characteristics of dough and quality of biscuits; use of elastic recovery of dough to predict biscuit quality. Food Res Int. 2002;35:807–813. doi: 10.1016/S0963-9969(02)00083-2. [DOI] [Google Scholar]

- Manohar RS, Rao PH. Effect of emulsifiers, fat level and type on the rheological characteristics of biscuit dough and quality of biscuits. J Sci Food Agric. 1999;79:1223–1231. doi: 10.1002/(SICI)1097-0010(19990715)79:10<1223::AID-JSFA346>3.0.CO;2-W. [DOI] [Google Scholar]

- Martins AJ, Cerqueira MA, Fasolin LH, Cuha RL, Vicente AA. Beeswax organogels: Influence of gelator concentration and oil type in gelation process. Food Res Int. 2016;84:170–179. doi: 10.1016/j.foodres.2016.03.035. [DOI] [Google Scholar]

- Olewnik MC, Kulp K. The effect of mixing time and ingredient variation on farinograms of cookie dough. Cereal Chem. 1984;61:532–537. [Google Scholar]

- Onacik-Gür S, Żbikowska A, Jaroszewska A. Effect of high-oleic sunflower oil and other pro-health ingredients on physical and sensory properties of biscuits. CyTA J Food. 2015;13(4):621–628. doi: 10.1080/19476337.2015.1032358. [DOI] [Google Scholar]

- Onacik-Gür S, Żbikowska A, Kapler E, Kowalska H. Effect of barley b-glucan addition as a fat replacer on muffin quality. Acta Sci Polon Technol Aliment. 2016;15(3):247–256. doi: 10.17306/J.AFS.2016.3.24. [DOI] [PubMed] [Google Scholar]

- Onacik-Gür S, Żbikowska A, Przybysz M, Kowalska M. Assessment of physical properties of structured oils and palm fat. Mater Plast. 2017;54(4):800–805. doi: 10.13140/RG.2.1.5121.1287. [DOI] [Google Scholar]

- Palla C, Giacomozzi A, Genovese DB, Carrin ME. Multi-objective optimization of high oleic sunflower oil and monoglycerides oleogels: searching for rheological and textural properties similar to margarine. Food Struct. 2017;12:1–14. doi: 10.1016/j.foostr.2017.02.005. [DOI] [Google Scholar]

- Pareyt B, Talhaoui F, Kerckhofs G, Brijs K, Goesaert H, Wevers M, Delcour JA. The role of sugar and fat in sugar-snap cookies: structural and textural properties. J Food Eng. 2009;90:400–408. doi: 10.1016/j.jfoodeng.2008.07.010. [DOI] [Google Scholar]

- Patel AR, Schatteman D, De Vos WH, Lesaffer A, Dewettinck K. Preparation and rheological characterization of shellac oleogels and oleogel-based emulsion. J Colloid Interface Sci. 2013;411:114–121. doi: 10.1016/j.jcis.2013.08.039. [DOI] [PubMed] [Google Scholar]

- Paula AM, Conti-Silva AC. Texture profile and correlation between sensory and instrumental analyses on extruded snacks. J Food Eng. 2014;121:9–14. doi: 10.1016/j.jfoodeng.2013.08.007. [DOI] [Google Scholar]

- Rangrej V, Shah V, Patel J, Ganorkar PM. Effect of shortening replacment with flaxseed oil on physical, sensory, fatty acid and storage characteristics of cookies. J Food Sci Technol. 2015;52(5):3694–3700. doi: 10.1007/s13197-014-1430-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rocha JCB, Lopes JD, Mascarenhas MCN, Arellano DB, Guerreiro LMR, da Cunha RL. Thermal and rheological properties of organogels formed by sugarcane or candelilla wax in soybean oil. Food Res Int. 2013;50(1):318–323. doi: 10.1016/j.foodres.2012.10.043. [DOI] [Google Scholar]

- Roman O, Heyd B, Broyart B, Castillo R. Maillard M (2013) Oxidative reactivity of unsaturated fatty acids from sunflower, high oleic sunflower and rapeseed oils subjected to heat treatment, under controlled conditions. LWT Food Sci Technol. 2013;30:1–11. doi: 10.1016/j.lwt.2012.12.011. [DOI] [Google Scholar]

- Sagiri SS, Singh VK, Pal K, Banerjee I, Basak P. Stearic acid based oleogels: A study on the molecular, thermal and mechanical properties. Mater Sci Eng C. 2015;48:688–699. doi: 10.1016/j.msec.2014.12.018. [DOI] [PubMed] [Google Scholar]

- Sciarini LS, Van Bockstaele F, Nusantoro B, Perez GT, Dewettinck K. Properties of sugar-snap cookies as influenced by lauric-based shortenings. J Cereal Sci. 2013;58:234–240. doi: 10.1016/j.jcs.2013.07.005. [DOI] [Google Scholar]

- Struck S, Jaros D, Brennan CS, Rohm H. Sugar replacement in sweetened bakery goods. Int J Food Sci Technol. 2014;49(9):1963–1976. doi: 10.1111/ijfs.12617. [DOI] [Google Scholar]

- Toro-Vazquez JF, Morales-Rueda JA, Dibildox-Alvarado E, Charo-Alonso M, Alonzo-Macias M, Gonzalez-Chavez MM. Thermal and textural properties of organogels developed by candelilla wax in safflower oil. J Am Oil Chem Soc. 2007;84:989–1000. doi: 10.1007/s11746-007-1139-0. [DOI] [Google Scholar]

- Yılmaz E, Öğütcü M. Properties and stability of hazelnut oil organogels with beeswax and monoglyceride. J Am Oil Chem Soc. 2014;91:1007–1017. doi: 10.1007/s11746-014-2434-1. [DOI] [Google Scholar]

- Żbikowska A, Rutkowska J, Kowalska M. Consumption safety of pastries, confectionery and potato products as related to fat content. J Am Collage Nutr. 2015;34(6):507–514. doi: 10.1080/07315724.2014.942472. [DOI] [PubMed] [Google Scholar]

- Żbikowska A, Kowalska M, Pieniowska J (2018) Assessment of shotcrust biscuits with reduced fat content of microcrystalline cellulose and psyllium as a fat replacements. J Food Process Preserv. 10.1111/jfpp.13675