Abstract

Freezing process is one of the key steps in making frozen cooked noodles. Ice crystal formed in freezing process affects the quality of frozen cooked noodles. In this paper, we studied the effect of freezing treatment on frozen cooked noodles. Frozen cooked noodles were evaluated for microstructure and texture properties explored with a scanning electron microscope and texture analyzer at − 20 °C, − 30 °C and − 40 °C respectively. The results indicated that the microstructure and texture properties of frozen cooked noodles were significantly (P < 0.05) improved by a lower freezing temperature than a higher temperature. This present study also showed that the freezing rate is not the only parameter responsible for microstructure and texture properties that occur during freezing; the difference of flours also can be a factor. These findings, if generally applicable to frozen cooked noodle products, could have important economic implications for the convenience of the food industry.

Keywords: Frozen cooked noodles, Freezing rate, Ice crystals, Texture properties

Introduction

Noodles, which originated in China, are a traditional staple food in many Asian countries, and can be dated back more than four thousand years (Fu 2008). Noodles are popular among people because of their convenience and nutrients. They account for 30–45% of wheat product consumption in Southeast Asian countries (Hatcher 2007). There are many kinds of good properties of noodles, but their shortcomings are beyond doubt. Noodles are often sold as a fresh product, but because of their high content of water and nutrient substances, they must be consumed in a short time, before the quality declines (Xu et al. 2008). Another disadvantage of fresh noodles is that they darken in color soon after being made, while most consumers like noodles with a bright and clean appearance. The short shelf-life of fresh noodles has resulted in high levels of wastage in the industry, and it might also be a potential source of food poisoning (Ghaffar et al. 2009). To extend the shelf-life, noodles are dried in hot air during their processing, but it usually takes a long time to then cook dried noodles. To some extent, drying will also destroy the nutritional content and damage the quality of the noodles.

Now, with improvements in living standards, an accelerated pace of life, and food safety awareness, as well as the development of freezing technology, the quality of fresh cooked noodles can be extended to a reasonable period of time by using freezing technology, and it takes less than 1 min to thaw frozen cooked noodles, which can then be easily mixed with a sauce or soup and be ready to serve. Frozen noodles can retain the original color, aroma, taste, and nutrition of fresh noodles. Olivera and Salvadori investigated the influence of freezing on the quality of cooked organic pasta and found that the quality of fast frozen pasta was closer to that of fresh pasta than slow frozen pasta was (Danielaf and Vivianao 2009). Frozen cooked noodles allow people to serve tasty noodles conveniently and efficiently without the need to provide special training in noodle preparation. Frozen noodles are popular and have become a new fashion.

The processes of frozen cooked noodles include pre-cooking, cooling, freezing, and reheating. Freezing is one of the most popular and efficient methods among food preservation methods, and it consists of three stages. The phase transition part is the key step determining the efficiency of the process and the quality of the frozen product (Hatcher 2007; Alizadeh et al. 2007; Alvarez et al. 2010; Fennema et al. 1973; Lebail et al. 2010; Maity et al. 2012). On the one hand, large ice crystals, which are mostly extracellular, results in significant damage to structure of frozen product (Ahmad et al. 2012; Delgado and Rubiolo 2005; Ming et al. 2009; Streit et al. 2010; Yu et al. 2012). On the other hand, small crystals that are evenly distributed both inside and outside the gluten network leads to better preservation of the quality of the product due to less damage to the tissue. Many researchers have suggested that ice crystal formation when food is frozen results in negative effects. The freezing rate is a very significant factor affecting the quality of flour products, as referred to earlier (Ban et al. 2016). Ice crystal formation and growth can physically damage the gluten networks (Baier-Schenk et al. 2005). Therefore, the formation of ice crystals, which can be controlled by strict freezing conditions, should be properly controlled in order to obtain good quality in frozen foods (Yi and Kerr 2009). It is worth noting that the freezing rate is a parameter used to adjust the size of ice crystals in the process of freezing food (Petzold and Aguilera 2009), and there are many studies that explore the relationship between the freezing rate and product quality (Lebail et al. 2010).

Cooked noodles have higher water content than fresh noodles, thus suitable freezing temperature have an important impact on maintaining better quality of frozen cooked noodles. The aim of this work was to evaluate the effect of freezing treatment on the microstructure, the moisture loss, and the texture of frozen cooked noodles, in order to provide some theoretical basis for the industrialized production of quick-frozen cooked noodles.

Materials and methods

Materials

Four kinds of winter wheat flours in Henan Province were collected as the experimental material. Regulating the wheat moisture content to 14–16%, and then letting the wheat stand for 24 h, wheat flour was made by using a Chopin CD1 grinding mechanism. The flour compositions were determined, such as the flour protein, wet gluten, starch, amylose, whiteness, pasting properties of farinograph properties, and tensile properties.

Preparation of cooked noodles

The basic formula for the noodles consisted of 100 g of flour and 34 ml distilled water. The flour and distilled water were put into a dough maker and stirred for 15 min. The dough pieces held together and become loose when we rubbed them gently. The prepared dough pieces were placed to rest in a plastic bag for 20 min. Then the dough pieces were sheeted through roll gaps of 2.0, 1.5, 1.2 and 1.0 mm two times after the dough was folded twice, respectively, and then it was cut into noodles with an electric noodle machine. The dimensions of the resultant noodle strands was 20 × 0.25 × 0.1 cm.

The 20 noodle samples were boiled in 500 ml of water for the optimal cooking time, which was determined according to the AACC 66-50 method (AACC 2000). When the noodles were cooked, they were removed from the boiling water with a colander, and rinsed for 30 s with 500 ml of distilled water to stop the cooking process.

Freezing process

Frozen curve

The cooked noodles were put on a plastic tray and frozen in a high and low temperature alternating refrigerator (Shanghai Dingheng instrument and equipment factory, HDGGJ-150). The temperature measurements had been calibrated previously. During the freezing process, a thermometer sensor probe was placed into the middle of the noodles, and the temperature change at the center of the dough was monitored using a data logger. The data logger recorded data every 10 s until the center temperature dropped to − 18 °C, going through different freezing temperatures (− 20 °C, − 30 °C, − 40 °C).The freezing curve was obtained by connecting the data.

Freezing rate

The freezing time was defined according to the International Institute of Refrigeration (1972) as the time required to reduce the central temperature from the initial freezing temperature to the target temperature.

where T1 and T2 are the initial temperature (0 °C) and final freezing temperatures (18 °C), and (t1 − t2) is the time elapsed between the beginning and the end of freezing, in min.

The moisture loss

In the formula, m1 is the quality before freezing; m2 is the quality after freezing. The unit of m is g.

Microstructure analysis

Scanning electron microscopy (SEM)

Frozen noodles were dried using a vacuum freeze drying machine at 0.1 mbar, − 40 °C for 24 h. The microstructure of the freeze-dried noodles was observed using a scanning electron microscope (SEM, S-3400 N, HITACHI Co., Japan) at a magnification of 1000×. The middle part of the cross-sectional area of the fractured frozen noodles was mounted on a stub using double-sided conductive adhesive tape, and subsequently coated with gold, prior to SEM observation at 30 kV.

Calculation of the size of ice crystal pores

The SEM images of the ice crystals were loaded into Matlab 2016a, and their sizes were measured. The contour of all pores on the images can be distinguished by the software by adjusting the sensitivity to the appropriate level. The software can automatically find the center points of the pores and calculate the average area means of samples (Hayta and Hendek Ertop 2018).

I = imread(‘1.jpg’);

imshow(I);title(‘original drawing’);

I1 = imcomplement(I);% invert Colors

figure;imshow(I1);title(‘grayscale image’);

I2 = im2bw(I1,180/255);% binarization

figure; imshow(I2);title(‘iteration thresholding segmented and binaried’);

se = strel(‘disk’,6);% The expansion determines the element structure

I3 = imclose(I2,se);% A closed form

I4 = imopen(I3,se);% A closed form

figure;imshow(I3);title(‘I3’)

figure; imshow(I4);title(‘Pore distribution map’);

I5 = I3&I4;

[r,num] = bwlabel(I5,4),

L = regionprops(r,’area’);

area = cat(1,L.Area);

totalarea = sum(area);

ratio = totalarea/(1792*2560);% The length and width of the array

averagearea = sum(area)/num;

Texture properties of frozen noodle samples

Twenty grams of frozen cooked noodles were cooked for 30 s. The noodles were removed from the boiling water with a colander, and the noodles were rinsed for 1 min with 500 ml of distilled water to stop the cooking process. The texture was measured using a TA-XT2i Texture Analyzer. Measurements were carried out at room temperature exactly 10 min after rinsing. For all of the texture analysis, the distance calibration was performed with a return trigger path at 20 mm and the trigger force was 5 g. For the texture profile analysis (TPA), hardness was measured using a P50 probe and calculated based on the texture profile analysis. The settings were: pretest speed was 2.0 mm/s, test and post-test speed was 0.8 mm/s; strain was 70%. For shear analysis, shear force was determined by an A/SFR probe. The settings were: pretest speed was 2.0 mm/s, test and post-test speed was 0.8 mm/s; strain is 90%. For tensile strength analysis, tensile force was determined with an A/SPR probe. The settings were: pre-test speed was 2.0 mm/s; test speed was 0.8 mm/s and post-test speed was 10 mm/s; distance was 100 mm (Dong et al. 2017).

Statistical analysis

The data were expressed as the mean of at least three replicate determinations and analyzed by using the software SPSS20.0 for Windows (IBM SPSS Statistics, Chicago, IL, USA), Origin, and Matlab R2016a. The significance was defined at P < 0.05.

Results and discussion

Characterization of raw materials

Bainong-207, Zhongyu-10, Kaimai-18, and Zhoumai-32 contain weak gluten, medium gluten, weak strong gluten and strong gluten wheat respectively. The results of the flour quality analyses of these four wheat varieties are presented in Table 1. The protein, wet gluten, starch content and amylose content varied significantly. The rheological properties of the wheat flour were determined by the tensile indexes and the powder indexes, by which it can be concluded that the processing quality of different wheat flours could be different and the sample of the test is better (Liu et al. 2019).

Table 1.

The parameters of rheological parameters of wheat flour

| Item | Indicator | Bainong-207 | Kaimai-18 | Zhongyu-10 | Zhoumai-32 |

|---|---|---|---|---|---|

| Physical and chemical index | Protein/% | 14.07 ± 0.06c | 13.57 ± 0.06d | 14.43 ± 0.06b | 14.80 ± 0.10a |

| Wet gluten/% | 22.27 ± 0.55d | 31.70 ± 0.70a | 29.67 ± 0.06b | 27.43 ± 0.35c | |

| Starch/% | 74.50 ± 0.25c | 75.08 ± 0.00b | 74.44 ± 0.25c | 76.03 ± 0.26a | |

| Amylose/% | 19.25 ± 0.10a | 18.47 ± 0.00c | 17.58 ± 0.04d | 18.97 ± 0.06b | |

| RVA parameter | FV/cP | 2590 | 2691 | 2294 | 3007 |

| Trough 1/cP | 2004 | 2025 | 1521 | 2395 | |

| Breakdown value/cP | 586 | 666 | 773 | 612 | |

| Final Visc/cP | 3206 | 3171 | 2653 | 3590 | |

| Setback value/cP | 1202 | 1146 | 1132 | 1195 | |

| Peak Time/min | 6.47 | 6.4 | 6.2 | 6.67 | |

| Pasting Temp/°C | 86.35 | 87.95 | 86.45 | 86.60 | |

| Farino graph parameters | Water absorption/% | 64.2 | 59.2 | 62.2 | 60 |

| Stability time/min | 1.6 | 5.7 | 3.5 | 10.3 | |

| Development time/min | 2.4 | 4 | 2.7 | 5 | |

| Degree of softening/FU | 137 | 74 | 94 | 59 | |

| Farinograph quality number | 32 | 71 | 48 | 108 | |

| Extenco graph parameters | Energy/cm2 | 22 | 106 | 79 | 113 |

| R5min/BU | 106 | 354 | 300 | 358 | |

| Extensibility/mm | 132 | 155 | 145 | 157 | |

| Rmax/BU | 112 | 537 | 218 | 572 | |

| Draw ratio | 0.8 | 2.3 | 1.1 | 2.3 | |

| Maximum draw ratio | 0.9 | 2.5 | 1.3 | 3.7 |

The data in table are for M ± SD. The superscripts of lowercase English letters in the same line are different means there is a significant difference in means (P < 0.05)

Freezing of cooked noodles

The freezing curve

The freezing curve reflects the changes in the samples’ temperature, and the efficiency of heat transfer is directly related to the samples and their outside temperature. The temperature range of the noodles was measured in the frozen environment which is shown in Fig. 1.

Fig. 1.

The center temperature of cooked noodles during different freezing process (note the left picture above: Bainong-207; right picture above: Kaimai-18; left picture: Zhongyu-10; right picture below: Zhoumai-32)

The freezing curve can be divided into 3 stages by different freezing temperatures, as is shown in Fig. 1: The first stage is from the initial temperature of the noodles to the freezing point, in which the curve is steep; in the second stage, the curve is relatively flat during the maximum ice crystal formation. Due to the formation of ice crystals in noodles, more than 80% of the water is frozen, while the critical heat causes the temperature to drop slowly, and the curve is flat. In the third stage, the residual moisture in the noodles is frozen, and the frozen part continues to cool down to − 18 °C. This figure shows that there is a difference in the maximum ice formation and the freezing time, which may lead to a quality difference in the frozen cooked noodles.

The freezing rate

At the temperature of − 20 °C, the characteristic freezing time of maximum ice crystal formation ranged from 560 s to 570 s, and the freezing rates ranged from 1.89 to 1.93 °C/min. At the temperature of − 30 °C, the characteristic freezing time of maximum ice crystal formation ranged from 350 to 370 s, and the freezing rates ranged from 2.91 to 3.17 °C/min. At the temperature of − 40 °C, the characteristic freezing time of maximum ice crystal formation ranged from 260 to 280 s, and the freezing rates ranged from 3.83 to 4.16 °C/min, as shown in Fig. 1.

The moisture loss

Freezing temperature and freezing time will lead to dehydration of noodles during the freezing process. It can be seen from Table 2 that the moisture loss rate of the samples are significantly different in the refrigerator with different temperatures (− 20, − 30 and − 40 °C). Lower freezing temperature could shrink freezing time, while the rate of moisture loss of frozen cooked noodles is reduced.

Table 2.

The rate of weight loss of frozen cooked noodles during different freezing process

| Sample | Freezing temperature | ||

|---|---|---|---|

| − 20 °C | − 30 °C | − 40 °C | |

| Bainong-207 | 3.31 ± 0.13a | 2.74 ± 0.14b | 2.21 ± 0.15c |

| Kaimai-18 | 3.56 ± 0.12a | 3.14 ± 0.15b | 2.41 ± 0.15c |

| Zhongyu-10 | 3.44 ± 0.15a | 3.17 ± 0.15a | 2.49 ± 0.16b |

| Zhoumai-32 | 3.57 ± 0.22a | 3.14 ± 0.17b | 2.34 ± 0.08c |

The data in table are for M ± SD. The superscripts of lowercase English letters in the same line are different means there is a significant difference in means (P < 0.05)

The moisture loss rate during the freezing process is due to the destruction of hydrogen bonds, hydrophobic bonds and ionic bonds caused by protein denaturation. The changes of protein conformation can result in nondirective movement of water in the gluten network structure gap, and these changes decrease the binding capacity of the gluten network structure, causing water loss during the freezing process. In addition, the surface temperature, the freezing surroundings, and the air temperature of the product can form vapor pressure between the inside and the outside of the noodles; also, ice sublimation can cause moisture loss in noodles. Within a certain range, with a decrease of the freezing rate of noodles, the moisture loss rate increases gradually.

Microstructure analysis

Microstructure of frozen cooked noodles

SEM has been a very attractive technology for food scientists because both surface and internal features can be studied, and a wide range of magnification is possible (Luo et al. 2015; Seetapan et al. 2015).

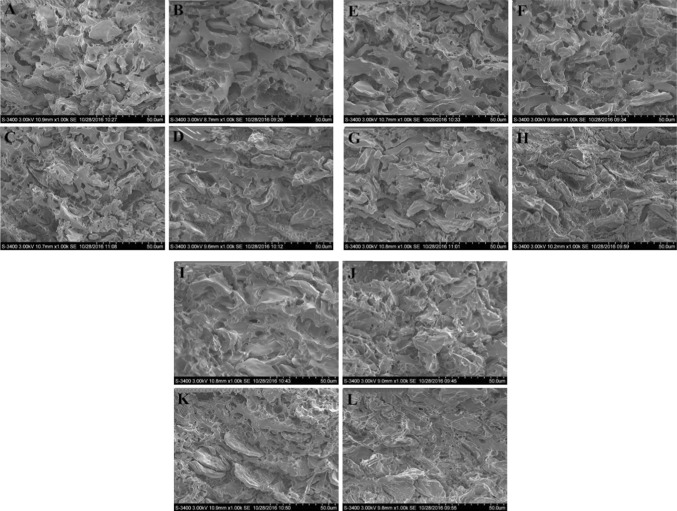

The cross-sections of freeze-dried frozen cooked noodles were examined using scanning electron microscopy (SEM), as is shown in Fig. 2. There are clear differences among the samples. The SEM images of ice crystals in the frozen cooked noodles under different freezing temperatures (− 20, − 30, and − 40 °C) (Fig. 2) show that the freezing temperature has a great influence on the formation of ice crystals. There are some irregular spaces in the noodles, which may have been formed due to vacuum sublimation of ice crystals.

Fig. 2.

The SEM photo of frozen cooked noodles during different freezing process (the pictures from A to D are Bainong-207, Kaimai-18, Zhongyu-10 and Zhoumai-32 respectively under − 20 °C; The pictures from E to H are Bainong-207, Kaimai-18, Zhongyu-10 and Zhoumai-32 respectively under − 30 °C; The pictures from I to L are Bainong-207, Kaimai-18, Zhongyu-10 and Zhoumai-32 respectively under − 40 °C)

At a high freezing temperature (− 20 °C), the growth rate of ice crystals is greater than the nucleation rate, so small ice particles can grow into large ice crystals. At a low freezing temperature (− 30 °C), because of the larger cooling rate, the ice nucleation rate increases, and the growth rate of ice crystals is smaller than the nucleation rate, and the water in the noodles can quickly form a large number of ice crystals. When the freezing temperature is down to − 40 °C, the rapid heat transfer results in a pyknotic structure of ice crystals (Thiebaud et al. 2002; Schoof et al. 2001). In addition, the shape of the ice crystals in the noodles may also be affected by the speed and direction of the heat transfer during the freezing process.

The microstructure of the different samples is different in the same freezing conditions; this may be caused by the interactions of the wheat flour groups, thus forming different gluten network structures, and hindering the effect on moisture migration, which is also different (Marti et al. 2016).

The size of the ice crystals

To further demonstrate the impact of freezing temperature on the size of the ice crystals and noodle pores, pictures of the ice crystal pores were disposed by Matlab, as is shown in Fig. 3, where it is easier to observe the differences among the samples than in the SEM images. The average area and numbers of ice crystals are listed in Table 3. The number of holes, the average area, and the percentage of the total area occupied by the image are shown in Fig. 3 and Table 3.

Fig. 3.

The pore-distribution photo of frozen cooked noodles in different freezing process (the pictures from a to d are Bainong-207, Kaimai-18, Zhongyu-10 and Zhoumai-32 respectively under − 20 °C; The pictures from e to h are Bainong-207, Kaimai-18, Zhongyu-10 and Zhoumai-32 respectively under − 30 °C; The pictures from i to l are Bainong-207, Kaimai-18, Zhongyu-10 and houmai-32 respectively under − 40 °C)

Table 3.

The parameters of pore-distribution photos of frozen cooked noodles

| Sample | Temperature/°C | Pore number | Mean pore area | Total pore area | Pore percent/% |

|---|---|---|---|---|---|

| Bainong-207 | − 20 | 61 | 373.2459 | 22,768 | 4.20 |

| − 30 | 75 | 426.7067 | 32,003 | 5.90 | |

| − 40 | 36 | 297.8056 | 10,721 | 1.98 | |

| Kaimai-18 | − 20 | 73 | 482.6849 | 35,236 | 6.50 |

| − 30 | 67 | 440.8955 | 29,540 | 5.45 | |

| − 40 | 47 | 262.0000 | 12,314 | 2.27 | |

| Zhongyu-10 | − 20 | 79 | 509.7595 | 40,271 | 7.43 |

| − 30 | 70 | 454.3143 | 31,802 | 5.86 | |

| − 40 | 28 | 377.5714 | 10,572 | 1.95 | |

| Zhoumai-32 | − 20 | 47 | 312.0426 | 14,666 | 2.70 |

| − 30 | 45 | 430.5778 | 19,376 | 3.57 | |

| − 40 | 48 | 271.6250 | 13,038 | 2.40 |

As is shown in Fig. 3, at the freezing temperature of − 20 °C, the ice crystals of the noodles are the fewest and have a larger average area, and their pore area also occupies a large percentage. Under the condition of freezing at − 40 °C, the number of pores in the image is the largest, and the average area is the smallest. With decreased freezing temperature, the pores got smaller, but finally exhibited a pyknotic structure.

With a decrease of the freezing temperature and an increase of the freezing rate, the pore area is reduced, the volume of ice crystals becomes smaller, and the mechanical damage to the structure of the gluten network is small, which is consistent with the analysis of the SEM diagram.

Effects of freezing rates on the texture of cooked noodles

The texture of cooked noodles is an important quality which determines the acceptance of the product by consumers. Thus, a texture retention similar to that of fresh noodles is an important standard for consumers to accept frozen cooked noodles. In this study, aspects of noodle texture were detected using three methods, including texture profile analysis (TPA), shear, and tensile strength to evaluate the noodle quality. The textural properties of cooked noodles at different freezing temperatures were measured and summarized in Table 4.

Table 4.

The textural quality of frozen cooked noodles during different freezing process

| Samples | Freezing temperature (°C) | Hardness/N cm2 | Adhesiveness | Springiness | Cohesiveness | Gumminess | Chewiness | Break strength/10−3 N | Firmness/10−3 N |

|---|---|---|---|---|---|---|---|---|---|

| Bainong-207 | − 20 | 11.97 ± 0.28Bb | − 1.98 ± 0.89 | 0.91 ± 0.03 | 0.80 ± 0.02A | 3672.20 ± 145.30Bb | 3339.75 ± 230.27Bb | 1638.07 ± 4.92Cc | 156.87 ± 5.82Bb |

| − 30 | 12.28 ± 0.14Bb | − 1.73 ± 0.52 | 0.92 ± 0.01 | 0.81 ± 0.01A | 3797.92 ± 31.41Cb | 3473.23 ± 58.33Bb | 1744.99 ± 8.63Db | 168.43 ± 0.57Ba | |

| − 40 | 13.23 ± 0.21Ca | − 1.44 ± 0.16 | 0.93 ± 0.00 | 0.80 ± 0.01A | 4064.35 ± 86.26Ca | 3788.44 ± 77.52Ca | 1788.56 ± 4.26 Da | 172.68 ± 1.61Ca | |

| Kaimai-18 | − 20 | 13.36 ± 0.31Ac | − 1.87 ± 0.28 | 0.92 ± 0.01b | 0.77 ± 0.01B | 3910.23 ± 77.61ABc | 3577.51 ± 97.37ABb | 1929.03 ± 9.21Bb | 168.10 ± 2.43Bc |

| − 30 | 14.20 ± 0.27Ab | − 1.52 ± 0.26 | 0.87 ± 0.09ab | 0.77 ± 0.01B | 4170.98 ± 56.65Bb | 3627.87 ± 370.94ABab | 1931.52 ± 21.55Bb | 186.00 ± 6.35Ab | |

| − 40 | 14.93 ± 0.39Ba | − 1.86 ± 0.23 | 0.94 ± 0.01a | 0.76 ± 0.01B | 4339.52 ± 80.61Ba | 4095.02 ± 69.90Ba | 2007.46 ± 4.58Ba | 196.56 ± 1.64Aa | |

| Zhongyu-10 | − 20 | 13.68 ± 0.05Ac | − 1.67 ± 0.10 | 0.89 ± 0.02 | 0.76 ± 0.01B | 3982.86 ± 55.14Ac | 3546.10 ± 55.50AB | 1556.50 ± 13.50Dc | 169.51 ± 1.21Bb |

| − 30 | 14.53 ± 0.08Ab | − 1.35 ± 0.50 | 0.89 ± 0.07 | 0.76 ± 0.01B | 4241.87 ± 65.50Bb | 3772.84 ± 297.74AB | 1871.57 ± 5.49Cb | 192.36 ± 4.39Aa | |

| − 40 | 15.65 ± 0.18Aa | − 1.59 ± 0.09 | 0.94 ± 0.00 | 0.77 ± 0.01B | 4629.06 ± 39.99Aa | 4352.33 ± 20.67A | 2020.37 ± 4.22Ca | 196.23 ± 1.05Aa | |

| Zhoumai-32 | − 20 | 14.01 ± 054ABb | − 1.50 ± 0.30 | 0.90 ± 0.02b | 0.78 ± 0.01B | 4168.84 ± 213.92Aab | 3736.35 ± 115.23Ac | 2092.07 ± 10.41Ac | 188.49 ± 1.65A |

| − 30 | 14.82 ± 0.06Aab | − 1.50 ± 0.18 | 0.94 ± 0.01a | 0.77 ± 0.01B | 4371.68 ± 39.72Ab | 3741.17 ± 313.49Bb | 2213.79 ± 15.36Ab | 188.85 ± 0.00A | |

| − 40 | 15.76 ± 0.31Aa | − 1.64 ± 0.18 | 0.94 ± 0.01a | 0.77 ± 0.01B | 4646.34 ± 67.54Aa | 4360.34 ± 67.54Aa | 2362.52 ± 3.25Aa | 187.77 ± 1.86B |

The data in table are for M ± SD. The superscripts of lowercase English letters in the same line are different means there is a significant difference in means (P < 0.05);The superscripts of uppercase English letters in the same list are different means there is a significant difference in means (P < 0.05)

As is shown in Table 4, freezing temperature has a significant effect on the texture of frozen cooked noodles. At a low freezing temperature (− 40 °C), the texture indicators of cooked noodles, such as the hardness, gumminess, chewiness, shear stress, and tensile strength of the cooked noodles showed the highest value than the noodles frozen at − 20 °C and − 30 °C. The hardness, gumminess, and chewiness of the − 40 °C group had significant differences from those properties of the − 30 °C and − 20 °C groups (P < 0.05), but the hardness, gumminess, chewiness of the − 30 °C group had no significant difference from the properties of the − 20 °C group (P < 0.05). The tensile strength was different among the groups of − 40 °C, − 30 °C and − 20 °C. The shear of the − 20 °C group had no significant difference from the properties of the − 30 °C group and the − 40 °C group (P < 0.05). The adhesiveness, springiness, and cohesiveness of the frozen cooked noodles had no significant difference among the freezing temperatures of − 40 °C, − 30 °C and − 20 °C (P < 0.05). The frozen cooked noodles made of Kaimai-18, Zhongyu-10, and Zhoumai-32 had similar analysis to that of Bainong-207, and we will not repeat them here.

From the analysis, it is easy to find that lower freezing temperatures would speed up freezing rate, so that the frozen cooked noodles have a better texture. The water content decreases and ice crystals form during freezing. The formation of ice crystals has a destructive effect on the internal structure of the frozen cooked noodles; thus, the TPA index of noodles can be negatively influenced. The hardness, springiness, cohesiveness, and gumminess are closely related to the structure and water content of noodles. Chewiness is equal to the product of hardness, cohesiveness and springiness in value, and it is influenced by many factors. The tensile strength mainly reflects the binding capacity within the gluten network. To sum up, water rapidly freezes into ice at a lower freezing temperature, the higher freezing rate at a lower freezing temperature results in smaller ice crystals, and thus, the ice crystals do little damage to the noodle structure.

Conclusion

Microstructure and texture structure methods can be used to evaluate the influence of freezing rate on the quality of frozen cooked noodles. The overall results confirmed that the freezing rate had a significant effect on the microstructure and structure parameters of frozen cooked noodles (P < 0.05).

In general, the changes in the microstructure of frozen cooked noodles may be due to the formation of ice crystals and the mechanical action of ice crystals, which results in the dehydration of the noodles. Noodles processed with higher freezing rates were observed to have higher texture properties. However, the four materials have different microstructures, water moisture, and texture decreases. An explanation is that the differences may be caused by the components and the rheological properties of the wheat flours, thus resulting in differences such as the microstructure, the water moisture and textures.

These findings, if generally applicable to cooked noodle products, could have important quality and economic implications for the convenience of the food industry.

Acknowledgements

This research was supported by National Key R&D Program of China (2018YFD0400605). Henan Science and Technology Research Project (18102110064).

Compliance with ethical standards

Conflicts of interest

The authors declare no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Zhili Pan, Email: zp44@cornell.edu.

Zhilu Ai, Email: zhila@163.com.

References

- Ahmad S, Yaghmaee P, Durance T. Optimization of dehydration of lactobacillus salivarius, using radiant energy vacuum. Food Bioprocess Technol. 2012;5(3):1019–1027. [Google Scholar]

- Alizadeh E, Chapleau N, Mde L, Le-Bail A. Effect of different freezing processes on the microstructure of atlantic salmon (salmo salar) fillets. Innov Food Sci Emerg Technol. 2007;8(4):493–499. [Google Scholar]

- Alvarez MD, Fernández C, Canet W. Oscillatory rheological properties of fresh and frozen/thawed mashed potatoes as modified by different cryoprotectants. Food Bioprocess Technol. 2010;3(1):55–70. [Google Scholar]

- Baier-Schenk A, Handschin S, Schönau MV, Bittermann AG, Bächi T, Conde-Petit B. In situ observation of the freezing process in wheat dough by confocal laser scanning microscopy (clsm): formation of ice and changes in the gluten network. J Cereal Sci. 2005;42(2):255–260. [Google Scholar]

- Ban C, Yoon S, Han J, Sang OK, Han JS, Lim S, et al. Effects of freezing rate and terminal freezing temperature on frozen croissant dough quality. LWT Food Sci Technol. 2016;73:219–225. [Google Scholar]

- Danielaf O, Vivianao S. Effect of freezing rate in textural and rheological characteristics of frozen cooked organic pasta. J Food Eng. 2009;90(2):271–276. [Google Scholar]

- Delgado AE, Rubiolo AC. Microstructural changes in strawberry after freezing and thawing processes. Lebensmittel-Wissenschaft und-Technologie. 2005;38(2):135–142. [Google Scholar]

- Dong Jiaxu, Fang Xiaoyan, Wang Huihui, et al. Abalone muscle texture evaluation and prediction based on TPA experiment. J Food Qual. 2017;2:1–9. [Google Scholar]

- Fennema OR, Powrie WD, Marth EH. Low temperature preservation of foods and living matter. New York: M. Dekker; 1973. pp. 467–472. [Google Scholar]

- Fu BX. Asian noodles: history, classification, raw materials, and processing. Food Res Int. 2008;41(9):888–902. [Google Scholar]

- Ghaffar S, Abdulamir AS, Bakar FA, Karim R, Saari N. Microbial growth, sensory characteristic and ph as potential spoilage indicators of chinese yellow wet noodles from commercial processing plants. Am J Appl Sci. 2009;6(6):1059–1066. [Google Scholar]

- Hatcher DW. Influence of frozen noodle processing on cooked noodle texture. J Texture Stud. 2007;35(4):429–444. [Google Scholar]

- Hayta M, Hendek Ertop M. Evaluation of microtextural properties of sourdough wheat bread obtained from optimized formulation using scanning electron microscopy and image analysis during shelf life. J Food Sci Technol. 2018;55(1):1–9. doi: 10.1007/s13197-017-2823-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lebail A, Nicolitch C, Vuillod C. Fermented frozen dough: impact of pre-fermentation time and of freezing rate for a pre-fermented frozen dough on final volume of the bread. Food Bioprocess Technol. 2010;3(2):197–203. [Google Scholar]

- Liu Qian, Guo Xiao-Na, Zhu Ke-Xue, et al. Effects of frozen storage on the quality characteristics of frozen cooked noodles. Food Chem. 2019;6(283):522–529. doi: 10.1016/j.foodchem.2019.01.068. [DOI] [PubMed] [Google Scholar]

- Luo LJ, Guo XN, Zhu KX. Effect of steaming on the quality characteristics of frozen cooked noodles. Lebensmittel-Wissenschaft und-Technologie. 2015;62(2):1134–1140. [Google Scholar]

- Maity T, Raju PS, Bawa AS. Effect of freezing on textural kinetics in snacks during frying. Food Bioprocess Technol. 2012;5(1):155–165. [Google Scholar]

- Marti A, Bock JE, et al. Structural characterization of proteins in wheat flour doughs enriched with intermediate wheatgrass (Thinopyrum intermedium) flour. Food Chem. 2016;194:994–1002. doi: 10.1016/j.foodchem.2015.08.082. [DOI] [PubMed] [Google Scholar]

- Ming LC, Rahim RA, Wan HY, Ariff AB. Formulation of protective agents for improvement of lactobacillus salivarius, I 24 survival rate subjected to freeze drying for production of live cells in powderized form. Food Bioprocess Technol. 2009;2(4):431–436. [Google Scholar]

- Petzold G, Aguilera JM. Ice morphology: fundamentals and technological applications in foods. Food Biophys. 2009;4(4):378–396. [Google Scholar]

- Schoof H, Apel J, Heschel I, Rau G. Control of pore structure and size in freeze-dried collagen sponges. J Biomed Mater Res. 2001;58(4):352–357. doi: 10.1002/jbm.1028. [DOI] [PubMed] [Google Scholar]

- Seetapan N, Limparyoon N, Gamonpilas C, Methacanon P, Fuongfuchat A. Effect of cryogenic freezing on textural properties and microstructure of rice flour/tapioca starch blend gel. J Food Eng. 2015;151:51–59. [Google Scholar]

- Streit F, Corrieu G, Béal C. Effect of centrifugation conditions on the cryotolerance of lactobacillus bulgaricus, cfl1. Food Bioprocess Technol. 2010;3(1):36–42. [Google Scholar]

- Thiebaud M, Dumay EM, Cheftel JC. Pressure-shift freezing of o/w emulsions: influence of fructose and sodium alginate on undercooling, nucleation, freezing kinetics and ice crystal size distribution. Food Hydrocoll. 2002;16(6):527–545. [Google Scholar]

- Xu Y, Wolf-Hall C, Manthey F. Fungistatic activity of flaxseed in potato dextrose agar and a fresh noodle system. Int J Food Microbiol. 2008;121(3):262–267. doi: 10.1016/j.ijfoodmicro.2007.11.005. [DOI] [PubMed] [Google Scholar]

- Yi J, Kerr WL. Combined effects of dough freezing and storage conditions on bread quality factors. J Food Eng. 2009;93(4):495–501. [Google Scholar]

- Yu S, Ma Y, Zheng X, Liu X, Sun DW. Impacts of low and ultra-low temperature freezing on retrogradation properties of rice amylopectin during storage. Food Bioprocess Technol. 2012;5(1):391–400. [Google Scholar]