Abstract

The objective of this work was to optimize the formulation of apple jellies enriched with 3 g/100 g of dietary fibre and to compare them with commercial apple jams in terms of structural and organoleptic properties. With that aim, a fibre mix with one part of psyllium and three parts of other fibre variety (apple, bamboo or wheat) was added to apple jelly, and the rheological, mechanical and sensory properties, as well as colour and syneresis (water loss) of the samples at different storage times were studied, and compared to two commercial apple jams. Those properties did not suffer significant changes during 30 days of cold storage, meaning that the product was stable. The reduction of psyllium proportion in the fibre mix (from 1:1 to 1:3) reduced the gumminess of the fibre enriched jellies, keeping the syneresis at 0 g/100 g. The jelly enriched with apple and psyllium fibre was the most similar to commercial apple jams in terms of rheological and mechanical properties. Consumers acceptability of fibre enriched jellies was higher than 72%, being the jelly enriched with bamboo and psyllium fibre the closest to a commercial apple jam, which was the consumer’s favourite.

Keywords: Dietary fibre, Fruit jelly, Sensory analysis, Rheology, Texture, Syneresis

Introduction

Jam and jellies are made by mixing either fruit pulp or juice, respectively, with sugars and concentrating by cook-evaporation until reaching soluble solids concentration (SSC) of about 60 to 70 g/100 g. The acidity might be adjusted by the addition of organic acids, to final pH values of approximately 2.8 to 3.5. These pH-SSC values give the proper conditions for the fruit native pectin to form a gel. For industrial production, the addition of pectin during processing may be required in order to guarantee a standard gel strength of the final product (Baker et al. 1996; Vibhakara and Bawa 2006). The amount of added pectin and the final SSC depends on the legislation of each country, being 0.5 g/100 g (maximum) and 65 g/100 g (minimum) respectively for the Argentine Food Code.

It is well known that the consumption of dietary fibre provides several health benefits (Chater et al. 2015; Dello Staffolo et al. 2012; Wu et al. 2015; Li and Komarek 2017; Dhingra et al. 2012; Guillon et al. 2012; Mackie et al. 2016). Jams (and marmalades) contain fruit pulp and/or small pieces of fruit, which contribute fibre. However, the exact amount of fibre in those products is a priori unknown. On the other hand, jelly is made from strained fruit juice (Garrido et al. 2015), and consequently does not contain fibre (other than pectin in small amounts). Therefore, the addition of known amounts of dietary fibre to fruit jellies opens the opportunity to obtain a product similar to a fruit jam, with the advantage that if 3 g of fibre per 100 g of product are added, the product can be declared “source of fibre”.

For a product like fruit jam, it is important to understand the relationships between the perception of food gel texture and structure (Renard et al. 2006). Sensory analysis in combination with mechanical measurements (textural and rheological) could represent the jam quality more precisely (Basu and Shivhare 2010). From the technological prospective, the addition of dietary fibre can impart some functional properties to food, like increase in water holding capacity and gel forming ability, which allow the development of fibre-enriched products with improved texture and reduced syneresis (Elleuch et al. 2011).

Previous results (Figueroa and Genovese 2019) showed that combination of pairs of fibre varieties (apple, bamboo, wheat and psyllium) in 1:1 proportion had a positive effect on the physical and organoleptic properties of fibre enriched fruit jellies. It was also observed that further improvement might be achieved by reducing the proportion of psyllium fibre on those combinations. Therefore, the objective of this work was to study the effect of fibre combinations in 3:1 proportion (where psyllium fibre is the one in the lowest proportion) on the physical properties (rheology, texture, syneresis and colour) and consumers acceptance of fibre enriched apple jellies, compared to commercial apple jams.

Materials and methods

Materials

Apples (cv. Granny Smith), high methoxyl pectin (CP Kelko), food-grade sucrose (Ledesma), anhydrous glucose (Anedra), anhydrous citric acid (Parafarm), distilled water, and dietary fibres were used for sample preparation. Apple fibre (Vitacel AF 400-30), wheat fibre (Vitacel WF 101), and bamboo fibre (Qualicel, CFF) were from JRS (Rosenberg, Germany). Psyllium fibre was from Konsyl Pharmaceuticals Inc. (Easton, MD, USA), and consisted of a mix of Plantago Ovata seed husks (72 g/100 g), maltodextrin (27 g/100 g) and amorphous silica (1 g/100 g). Commercial apple jams AJ1 (Alimentos Natali, Buenos Aires, Argentina) and AJ2 (Cabaña Micó, Río Negro, Argentina), were purchased in a local supermarket. Sample AJ1 presented large particles and small pieces of fruit and consequently it was not suitable for rheological measurements and sensory analysis. Instead, sample AJ2 was used in these analyses because it had a finely ground pulp (without fruit pieces) similar to the samples elaborated in this work.

pH and concentration of soluble solids (°Brix) of apple juice and jelly were measured with a digital pH-meter Altronix TPX II (Saen Srl, Buenos Aires, Argentina) and an Abbe refractometer WYA (ARCANO, Gea Srl, Santa Fe, Argentina), respectively.

The required amounts of ingredients per 100 g of product were: 45 g of apple juice (above the minimum required by the CAA), 0.5 g of pectin, 3 g of fibre, 41 g of sucrose, 16.4 g of glucose y 3.6 g of water. The proportions of juice/sucrose/glucose were based on the jelly recipe proposed by the pectin manufacturer Herbstreith and Fox (Anonymous 2018). The 3 g of fibre were composed of two varieties in 3:1 ratio: apple-psyllium, bamboo-psyllium and wheat-psyllium, being psyllium fibre the one in the lower proportion. Accordingly, samples with apple, bamboo, wheat and psyllium fibre were identified as AP31, BP31 and WP31, respectively.

Methods

Juice extraction process

10 kg of apples were carefully washed and then milled in an industrial impact mill (FitzMill comminutor, Fitzpatrick Co., Chicago, IL, U.S.A.). The obtained pulp was split in several batches, each batch wrapped up in a canvas cloth and pressed in a hydraulic press (Delfabro, Delfabro SRL, Córdoba, Argentina). In total, approximately 8 L of juice were extracted. Next, the obtained juice was pasteurized in a stirred tank (Figmay, Córdoba Argentina), where it was heated for approximately 1 h until it reached 90 °C, and then immediately cooled to approximately 50 °C. Finally, the juice was bottled and frozen until use. The extracted juice had a pH = 3.92, and a concentration of soluble solids of 13.25 g/100 g.

Preparation of fibre enriched jellies

Pectin was dry-mixed with part of the sucrose in 1:15 ratio (Thakur et al. 1997). This mixture was hydrated in part of the apple juice, forming a pectin-sugar solution for later use. The remaining apple juice and sucrose were mixed with the fibre, and the dispersion was heated in a glycerine bath on a hotplate (Decalab SRL, Buenos Aires, Argentina) and stirred (at 100 rpm) with a vertical mechanical stirrer (DLAB OS40-Pro, Ontario, USA). In this way, the dietary fibre was hydrated, preventing lumps development. When the dispersion reached the boiling point, glucose and the pectin-sugar solution were added, and heating continued until the solution reached the desired concentration of soluble solids (67–69 g/100 g), refractometrically determined. At this point (but not before to avoid pre-gelation), a saturated solution of citric acid was added for pH adjustment, measured with a digital pH-meter equipped with a high temperature resistant electrode (Broadley F600, Irvine, USA). Finally, each sample was hot-filled at about 100 °C into three sanitized glass jars, sealed and stored in a fridge at 4.5 °C for later measurements. The refractometer and pHmeter used in this process were the same as those mentioned in “Juice extraction process” section.

Each sample was prepared three times, so that all the following measurements were made in triplicate (except otherwise stated).

Rheological properties

Rheological properties were measured in a Paar Physica MCR 301 rheometer (Anton Paar GmbH, Graz, Austria), using a plate-plate geometry (diameter d = 50 mm, gap = 2 mm), with Peltier controlled temperature. An aliquot of each sample was placed on the rheometer plate at 20.0 ± 0.1 °C. Next, the plate was lowered to the measuring position and excess sample was removed. Elastic (G′) and viscous (G″) moduli were determined from dynamic oscillatory measurements at angular frequencies (ω) from 0.1 to 100 rad/s, and at 0.5% strain corresponding to the linear viscoelastic range (LVR) of all the samples. Measurements were performed after different storage times: t0 = 0 d, t1 = 1 d, t2 = 3 d, t3 = 7 d, t4 = 14 d and t5 = 30 d.

In addition, loss tangent (tan δ), complex modulus (G*) and complex viscosity (η*) of each sample were calculated as:

| 1 |

| 2 |

| 3 |

Mechanical properties

Mechanical properties were determined in a TA Plus texture analyser (Lloyd Instruments-Ametek, Albany, USA), applying a penetration test designed for jams (Genovese et al. 2010) with some modifications, as detailed next.

For each sample, part of the hot jelly (with or without fibre) was poured in two glass jars that were filled to an approximate height of 3 cm. Each jar was sealed, and the sample was allowed to cool to room temperature. Next, the jars were placed in the refrigerator at 4.5 °C. The measurements were made at two different storage times (7 d and 30 d). Samples were tempered by taken them out of the refrigerator 2 h before measurement. Next, the test was performed, which consisted of two penetration cycles, where the samples were penetrated to a depth of 15 mm (~ 50% of their initial height) using a cylindrical probe (D = 25.5 mm) at a speed of 1 mm/s. A fixed 50 N load cell was used.

From the first peak of the force versus time curve four characteristic parameters were obtained, namely: (1) maximum force (Fmax): corresponds to the maximum of the peak, and is an indicator of the hardness or breaking point of the gel; (2) distance of rupture (d*): distance that the probe penetrates before the gel rupture occurs (in Fmax), is an indicator of the fragility of the gel; (3) force at 3 mm penetration (Fe), corresponding to the zone of low deformation of the gel, is an indicator of the strength of the gel; and (4) adhesiveness (Ad): calculated as the area under the negative region of the curve, is an indicator of the total work required to remove the probe from the sample. From both peaks of the force vs time curves another parameter was obtained, the gumminess (G): calculated as the product Fmax × Cohesiveness, where Cohesiveness is calculated as the ratio of the positive area under the first peak relative to the area of the second peak (Bourne 2002).

Syneresis

Syneresis was determined as the water loss of the samples during the first 24 h after the texture measurement (at room temperature). The purpose of this was to use samples with damaged structure, as fruit jams present in domestic use (after consumer’s extraction from the jar). Measurements were made at two different storage times (7 d and 30 d), as described by Figueroa and Genovese (2019).

A sample was taken (in the area where the probe penetrated) using a plastic cylindrical mould (diameter = 33 mm, height = 48 mm); this portion of the sample was placed in a Büchner funnel with a filter paper at the base (previously weighed). The funnel with the sample was weighed and covered with a plastic film to avoid dehydration. Then the funnel was put in an Erlenmeyer (previously weighed) to collect the liquid lost from the sample by gravity. After 24 h, the funnel with the drained sample and the Erlenmeyer with the liquid were weighed. Syneresis was calculated as:

| 4 |

where mi and mf are the initial and final weights of the samples. Results were expressed as g water/100 g product.

Colour

Colour of the jellies with fibre was measured in a HunterLab UltraScan XE spectrophotometer colorimeter (Hunter Associates Laboratory Inc., Reston, USA). For each sample, part of the hot jelly was poured in two glass cells (10 mm thickness) and let cool down during 24 h. Reflected colour (specular component excluded, D65 illuminant, 10° observer angle) was measured. Results were expressed in terms of the CIELab scale parameters: L* [lightness, 0 = black, 100 = white], a* [greenness (−), redness (+)] and b* [blueness (−), yellowness (+)].

Sensory analysis

The sensory analysis of samples AP31, BP31, WP31 and AJ2 was carried out in order to determine the degree of acceptance of this product by the consumers. From the two commercial apple jams, only sample AJ2 was used in this analysis because it presented a finely ground pulp and it was more similar to our fibre enriched jellies. Unlike them, sample AJ1 presented larger particles and small pieces of fruit, and therefore it was discarded for the sensory analysis. A total of 100 untrained panellists (34 males and 66 females) participated in the study. Students and staff were selected from CCT CONICET- Bahía Blanca, identified as regular consumers of fruit jams, jellies and marmalades. Samples were prepared 3 days before degustation (in order to ensure that they reach their maximum stability according to the results obtained in this work) and stored in the fridge at 4.5 °C. One hour before the tests were performed, the samples were taken out of the fridge to be tempered. Each panellist evaluated in a single session the four samples mentioned, placed in respective plastic containers with approximately 15 g of sample each. The samples were presented to the panellists coded with a 3-digit number and sorted randomly. Each panellist was provided with a plastic spoon and knife and a pair of unsalted crackers to perform the test. In addition, they were provided with water to cleanse their palates between tasting samples. Panellists were instructed to consider the appearance, taste, consistency and spreadability of the samples, and based on these attributes they were asked to determine the overall acceptability of each sample on a 9-point hedonic scale (1 = I dislike it a lot, 5 = It’s indifferent to me, and 9 = I like it a lot).

Statistical analysis

Experimental data were statically analysed through single-factor Anova tests, and means were compared by Tukey’s tests at a significance level of 0.05, using the InfoStat v. 2014 software. In all cases, Box-Cox diagnosis tests were previously performed to check for Anova assumptions (normality and homoscedasticity), and data were transformed when necessary, using Design-Expert v 7.0.0 software.

It should be noted that in order to statistically compare rheological and mechanical properties, experimental data of commercial jams and fibre enriched jellies at 30 d were used, in order to have a balanced system in the number of replicas.

Results and discussion

Rheological properties

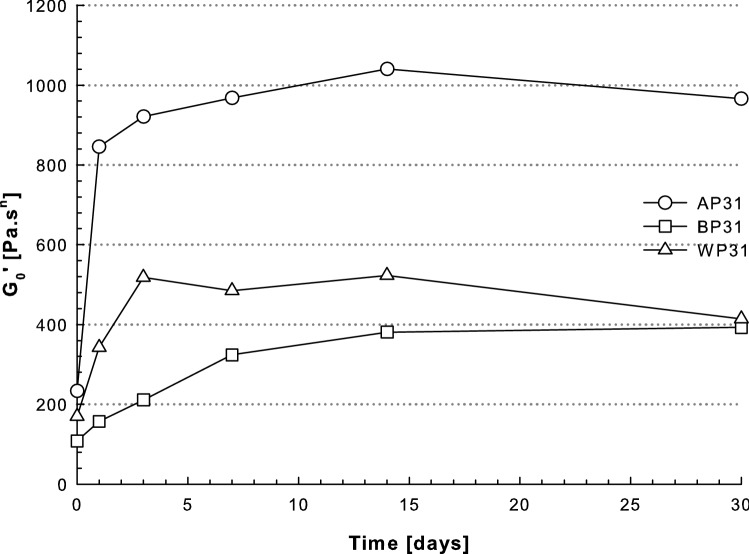

G′ versus ω data of samples AP31, BP31 and WP31 at the different storage times were adjusted with the potential function:

| 5 |

where G0′ is the predicted value of G′ at ω = 1 rad/s and n is the slope of the log G′ vs log ω curve. Calculated values of G0′ and n were represented in Fig. 1. After a significant initial increase of G0′ between 0 and 1 d, there were no significant changes of G0′ and n from 3 to 30 d, for samples AP31, BP31 and WP31. Therefore, it was considered that from day 3 the fibre enriched jellies reached their maximum equilibrium gel strength and then their rheological properties remained constant. Consequently, G′ and G″ data from 3 to 30 d were averaged, and used to calculate the rheological parameters shown in Table 1.

Fig. 1.

Elastic modulus coefficient (G0′) vs cold-storage time (t) of the jellies enriched with fibre mixes with one part of psyllium and three parts of either apple (○), bamboo (□) or wheat (Δ)

Table 1.

Elastic modulus (G0′) and exponential (n) coefficients from Eq. (5), interaction force (a) and number of flow units (z) from Eq. (8), viscous modulus (G″(1 rad/s)), complex viscosity (η*(1 rad/s)) and complex modulus (G*(1 rad/s)) at an angular frequency of 1 rad/s, and upper and lower limits of the complex modulus (G*C1 and G*C2) predicted with Eqs. (6) and (7), respectively, of jellies enriched with 3 g/100 g of fibre mixes with one part of psyllium and three parts of either apple, bamboo or wheat (AP31, BP31 and WP31, respectively), and commercial apple jam (AJ2)

| Sample | G0′ (Pa.sn) | n (−) | a (Pa.s1/z) | z (−) | G″ (1 rad/s) (Pa) | η*(1 rad/s) (Pa.s) | G* (1 rad/s) (Pa) | G*C1 (Pa) | G*C2 (Pa) |

|---|---|---|---|---|---|---|---|---|---|

| AP31 | 966 ± 32b | 0.148 ± 0.005b | 981 ± 29b | 6.44 ± 0.12b | 191 ± 6b | 985 ± 32b | 993 ± 101 | 1003 | 957 |

| BP31 | 393 ± 42a | 0.164 ± 0.002a | 404 ± 45c | 5.45 ± 0.14c | 85 ± 6c | 402 ± 42c | 335 ± 80 | 486 | 466 |

| WP31 | 414 ± 27a | 0.163 ± 0.008a | 439 ± 87c | 5.30 ± 0.06c | 96 ± 21c | 425 ± 29c | 497 ± 78 | 453 | 426 |

| AJ2 | 1895 ± 71c | 0.129 ± 0.001c | 1937 ± 73a | 7.50 ± 0.03a | 395 ± 15a | 1935 ± 73a | – | – | – |

These parameters were obtained from G′ and G″ data averaged between 3 d and 30 d of storage of fibre enriched jellies

Means with a common letter (within the same column) are not significantly different (p > 0.05)

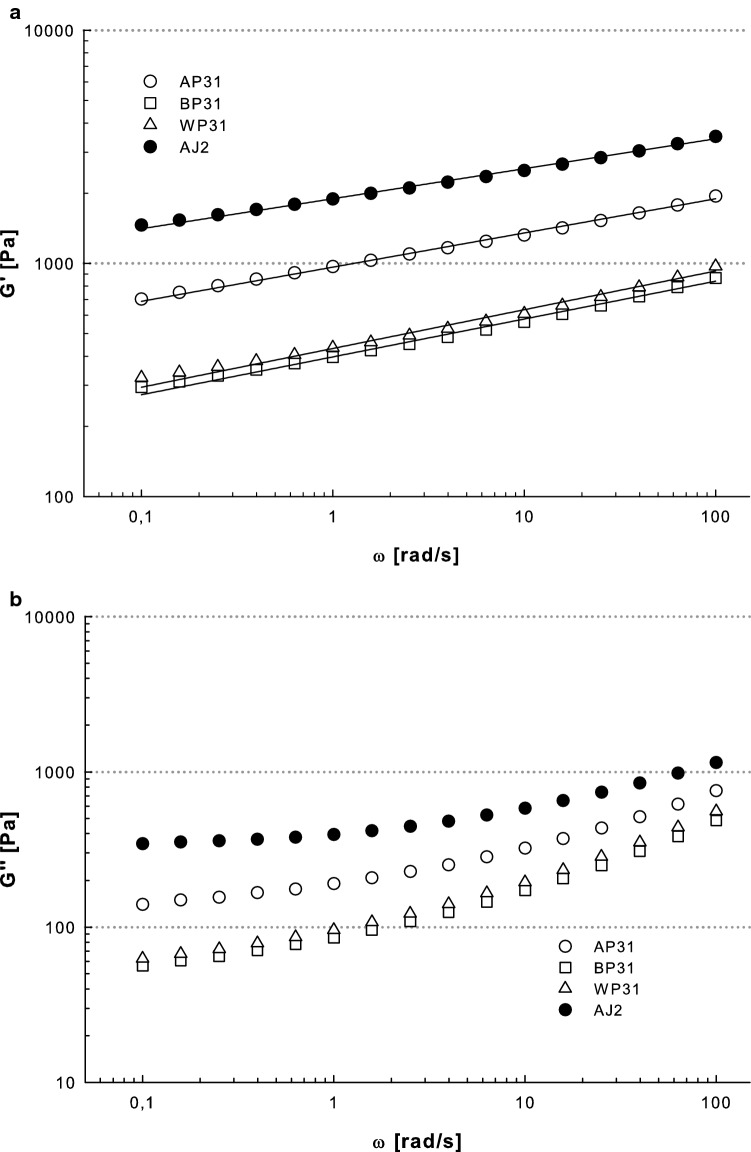

Figure 2a, b shows the elastic (G′) and viscous (G′’) moduli vs frequency sweep (ω) of the fibre enriched jellies (average data between 3 and 30 d) and the commercial apple jam (AJ2). Commercial jam AJ1 was not suitable for rheological measurement since it did not have a finely ground pulp but presented relatively large pieces of fruit. Firstly, it can be observed that all the samples behaved as weak gels, since G′ > G″ and both moduli varied with frequency (Rao 2007).

Fig. 2.

a Elastic modulus (G′) and b viscous modulus (G″) vs angular frequency (ω) of jellies enriched with fibre mixes with one part of psyllium and three parts of either apple (○), bamboo (□) or wheat (Δ) (average data between 3 and 30 d of storage) and commercial apple jam (●)

Secondly, comparing to previous results (Figueroa and Genovese 2019) and as expected, the jellies enriched with two fibre varieties had intermediate viscoelastic properties between the jellies with each one of those fibre varieties, and the fibre that was in higher proportion governed the rheological behaviour of the jelly. This suggests that the viscoelastic properties of the jellies enriched with two fibre varieties may be predicted from the rheological data of the jellies with each one of those fibre varieties, applying a mixing rule. The Takayanagi model (Rao 2007) provides expressions to predict the shear modulus of general two-component or polymer compounds. This model was adapted to calculate the upper and lower limits of the shear modulus of the jellies with two fibre varieties, namely G*C1 (also called iso-strain shear modulus, Eq. 6) and G*C2 (also called iso-stress shear modulus, Eq. 7), respectively:

| 6 |

| 7 |

where G*x y G*y correspond to the experimental values of the shear moduli of the jellies with one fibre variety (Figueroa and Genovese 2019), and x and y are the mass fractions of each fibre variety in the mix, in this case 0.25 for psyllium and 0.75 for the other fibre variety (apple, bamboo or wheat), respectively.

Calculated values of G*C1 and G*C2 were listed in Table 1, together with experimental values of G* at ω = 1 rad/s. Experimental value of the shear modulus of sample AP31 fall between the upper and lower limit values calculated with Eqs. (6) and (7). In the case of sample WP31, the experimental value was 9% higher than the upper limit, which is within the order of the experimental error. However, experimental value of sample BP31 was 39% lower than the lower limit. This negative deviation could be due to a change in the effective concentration of the fibre, i.e. when the fibres are mixed they could either agglomerate, break, or one of them could affect to a higher extent the surroundings of the other one, for example due to competition for available water.

It can also be observed that the commercial jam presented values of viscoelastic properties (G′ and G″) higher than those of the jellies with fibre, although the frequency dependency was similar. This means that although the commercial jam was also a weak gel, it was stronger than fibre enriched jellies. Since sample AJ2 has no added pectin (according to the manufacturer) and its soluble solids concentration (65 g/100 g) was lower than that of jellies with fibre (67–69 g/100 g), its higher gel strength could be attributed to a higher concentration of insoluble solids, or fruit pulp.

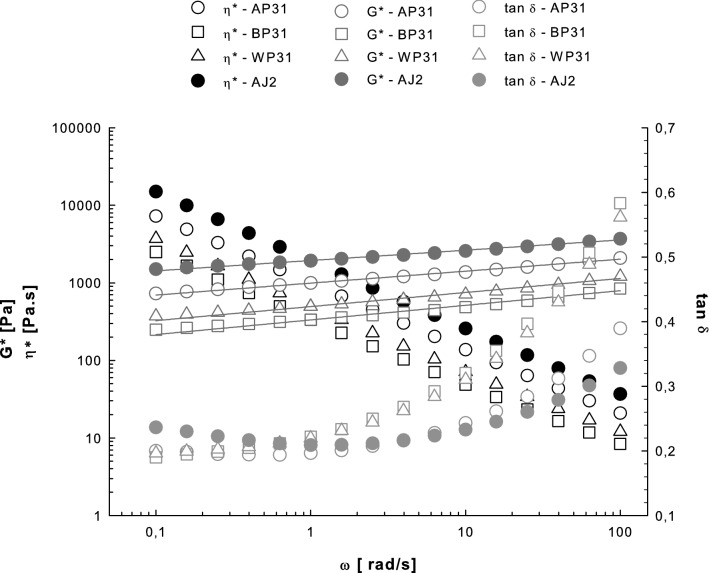

Figure 3 shows the evolution of tan δ, G* and η* calculated with Eqs. (1), (2) and (3), respectively, as a function of angular frequency. A general power law decreases of η* with ω was observed, meaning that all samples followed a pseudoplastic behaviour, while G* followed a power law increase with ω. Also, both complex modulus and complex viscosity of commercial jam (sample AJ2) were higher than those of the jellies with fibre (samples AP31, BP31 and WP31), although the slope of the curves are similar.

Fig. 3.

Loss tangent (tan δ), complex modulus (G*) and complex viscosity (η*) vs angular frequency (ω) of jellies enriched with fibre mixes with one part of psyllium and three parts of either apple (○), bamboo (□) or wheat (Δ) (average data between 3 d and 30 d of storage) and commercial apple jam (●)

The power law behaviour of G* versus ω is in agreement with the “weak gel” model proposed by Gabrielle et al. (2001) and previously used in fruit jams (Basu et al. 2011; Figueroa and Genovese 2019). In this model, the gel is seen as a network of strands, constituted by rheological or “flowing units” that do not break or disintegrate during flow, but the strands do. The complex modulus is represented as:

| 8 |

where a may be interpreted as the interaction force between the flow units (which is reflected in the gel strength) and z is called the “coordination number” and is equivalent to the number of flow units interacting whit one another and measures the extent of those interactions.

The most notorious differences between the jellies with fibre and commercial apple jam were observed in tan δ curves, where at low frequencies sample AJ2 presented higher values than samples AP31, BP31 and WP31. As the frequency increased, tan δ of commercial jam remained almost constant, while it increased in the jellies with fibre until reaching higher values at high frequencies, indicating a higher viscous character of these samples.

G′ versus ω data (Fig. 2a) were fitted with Eq. (5), while G* vs ω data (Fig. 3) were fitted with Eq. (8). Values of G0′, n, a and z are shown in Table 1 (values of R2 greater than 0.991), together with values of G″ (obtained from Fig. 2b), G* and η* at ω = 1 rad/s (from Fig. 3).

Parameters G0′, G″ (1 rad/s), G*(1rad/s), η*(1rad/s), a and z decreased in the following order: AJ2 > AP31 > WP31 and BP31, with no significant differences between the last two samples. Values of n followed exactly the opposite trend. These results indicate that commercial jam had the strongest structure. The closer rheological behaviour was observed by the jelly enriched with apple fibre (probably because it was the sample more similar to an apple jam), although its gel strength was significantly lower. Jellies with wheat and bamboo were the weakest gels.

Mechanical properties

Mechanical properties were determined from the Force vs Time curves obtained from the penetration test carried out on the commercial jams and the fibre enriched jellies at different storage times (not shown). Jam AJ1 was measured assuming that the presence of large particles and eventual pieces of fruit would not affect the results obtained by a penetration test. Firstly, it was determined that there was no effect of the storage time on the mechanical properties between 7 and 30 d.

Table 2 shows the mean values of the texture parameters that were obtained for commercial apple jams and fibre enriched jellies at 30 d storage. Firstly, when comparing these values with those of jellies enriched with fibre varieties in equal proportions (Figueroa and Genovese 2019), it was observed that the reduction of psyllium proportion in the fibre mix reduced the gumminess of the jellies (which is a desired result), except for apple-psyllium combinations. Also, mechanical properties were dominated by the fibre that was present in higher proportion, as it happened with the rheological properties.

Table 2.

Maximum force (Fmax), distance of rupture (d*), force at 3 mm penetration (Fe), adhesiveness (Ad) and gumminess (G), of jellies enriched with 3 g/100 g of fibre mixes with one part of psyllium and three parts of either apple, bamboo or wheat (AP31, BP31 and WP31, respectively) and commercial apple jams (AJ1 and AJ2)

| Sample | Fmax (N) | Fe (N) | d* (mm) | Ad (N.s) | G (N) |

|---|---|---|---|---|---|

| AP31 | 5.49 ± 1.47a,b | 1.88 ± 0.73b,c | 14.57 ± 0.76a | − 4.31 ± 0.44b | 1.79 ± 0.48a |

| BP31 | 2.31 ± 0.37c | 0.51 ± 0.04d | 10.50 ± 1.07a | − 1.96 ± 0.17a | 0.82 ± 0.11b |

| WP31 | 3.45 ± 0.89b,c | 1.05 ± 0.30c,d | 13.12 ± 3.26a | − 4.28 ± 0.56b | 1.14 ± 0.28a,b |

| AJ1 | 4.05 ± 0.37a,b,c | 2.88 ± 0.53a,b | 8.65 ± 5.58a | − 2.88 ± 0.99a,b | 1.49 ± 0.13a,b |

| AJ2 | 5.74 ± 0.39a | 3.89 ± 0.26a | 6.68 ± 1.32a | − 2.56 ± 0.23a | 1.39 ± 0.10a,b |

Means with a common letter (within the same column) are not significantly different (p > 0.05)

Comparing to commercial jams, in the case of Fmax, only sample AJ2 was significantly higher than samples BP31 and WP31, while it did not present differences compared to AP31. The Fe value of sample AJ2 was significantly higher than all jellies with fibre, while the Fe value of sample AJ1 was only higher than samples BP31 and WP31. In both cases it could be due to a higher content of insoluble solids (pulp) in the commercial jams, which would give them a higher gel strength. Regarding d*, samples did not present significant differences in their fragility. With respect to adhesiveness, only values of the samples AP31 and WP31 were higher than AJ2, while AJ1 did not show differences compared to the jellies with fibre. Finally, gumminess of commercial samples was not significantly different from that of fibre enriched jellies.

In general, it could be concluded that jelly enriched with apple-psyllium fibres (sample AP31) was the most similar to samples AJ1 and AJ2, since it was the only sample that did not show significant differences in any of the mechanical properties, compared to the commercial apple jams. This is in agreement with the conclusion obtained from the rheological results.

Syneresis

Firstly, it was determined that there was no effect of the storage time in the syneresis (not shown). Table 3 shows the results of syneresis obtained for the jellies with fibre and commercial jams. Jam AJ1 presented a syneresis value above 10 g/100 g, proposed as the limit of acceptability (Figueroa and Genovese 2018). Jam AJ2 and jellies with fibre (samples AP31, BP31 and WP31) did not present any syneresis. Comparing to previous results (Figueroa and Genovese 2019), it is evident that the reduction of the proportion of psyllium in the fibre mix did not affect the syneresis, since it remained at 0 g/100 g. This was attributed to the hydration properties of the psyllium, in addition to the fact that this fibre is known as gel-forming mucilage with strong water-absorbing and gelling capacities (Dello Staffolo et al. 2017).

Table 3.

Syneresis (g of water/100 g of product), colour parameters (L* a* b*, after 1 d of storage), ang global acceptability of jellies enriched with 3 g/100 g of fibre mixes with one part of psyllium and three parts of either apple, bamboo or wheat (AP31, BP31 and WP31, respectively), and commercial apple jams (AJ1 and A2)

| Sample | Syneresis | Colour | Global acceptability | ||

|---|---|---|---|---|---|

| (g/100 g) | L* | a* | b* | (−) | |

| AP31 | 0.00 ± 0.00b | 13.12 ± 0.55d | 14.00 ± 0.69b | 14.47 ± 0.85c | 5.63 ± 2.19b |

| BP31 | 0.00 ± 0.00b | 29.53 ± 0.15c | 8.37 ± 0.68c | 26.11 ± 0.69b | 6.49 ± 1.75 ª |

| WP31 | 0.00 ± 0.00b | 29.80 ± 1.18c | 9.36 ± 0.57c | 27.20 ± 0.69b | 5.78 ± 1.88b |

| AJ1 | 20.4 ± 1.1a | 40.35 ± 1.03a | 17.67 ± 0.35a | 43.35 ± 1.01a | NE |

| AJ2 | 0.00 ± 0.00b | 35.91 ± 0.34b | 14.04 ± 0.27b | 40.61 ± 0.98a | 6.76 ± 1.78 a |

Means with a common letter (within the same column) are not significantly different (p > 0.05)

NE not evaluated

Colour

Table 3 shows the results of colour parameters of the jellies with fibre (measured after 1 d of storage) and commercial jams. The luminosity values (L*) of the commercial jams were significantly higher than jellies with fibre. The value of a* of AJ1 was significantly higher (more reddish) than samples AP31, BP31 and WP31, while jam AJ2 was significantly more reddish than samples BP31 and WP31. Finally, both commercial jams resulted significantly more yellowish (higher b* value) than jellies with fibre.

In general, it can be concluded that there were significant differences between the colour of the fibre enriched jellies and the commercial jams. One possible reason for the differences in the luminosity could be related to the intensity of the cooking-concentration process. Longer times and/or higher temperatures are expected to give darker products, due to Maillard reactions and sugars caramelization. In this work, fibre enriched jellies were concentrated until 67–69 g/100 g of soluble solids, while commercial jams AJ1 and AJ2 presented 62 and 65 g/100 g of soluble solids, respectively. This suggests that commercial jams were cooked during shorter times, suffering less darkening (higher L* values). Also, the manufacturer of sample AJ2 claimed that the jam was concentrated under vacuum, meaning lower cooking temperatures, and lower darkening.

Comparing to previous results (Figueroa and Genovese 2019), the reduction of psyllium proportion in the fibre mix did not produce significant changes in the colour of the fibre enriched jellies, except in the case of jellies enriched with psyllium and apple fibres, which became darker and less yellowish.

Sensory analysis

Within the 100 individuals who participated in the sensory analysis, 66 were women and 34 were men, and 61 were between 26 and 35 years old. Although the percentage of women was higher, it is known that the sexual category does not interfere in the acuity of the sensory analysis (Lago-Vanzela et al. 2011). More than 70% of the panellist declared to consume fruit jams daily or at least 2 to 3 times a week, fulfilling the requirement of being frequent consumers of this type of products.

Table 3 shows the means obtained for the global acceptability of the jellies enriched with fibre and a commercial jam. The average values of global acceptability were between 5.63 and 6.76 in the hedonic scale of 9 points. Considering the score 5 of the hedonic scale as “acceptable”, the resulting preference order was calculated: AJ2 (88%) > BP31 (87%) > WP31 (73%) > AP31 (72%), where the number in parentheses indicates the acceptance percentage of each sample. From this result it can be said that more than 70% of the panellist considered that jellies with fibre were acceptable. On the other hand, no significant differences were found between the commercial jam and sample BP31 (Table 3).

Conclusion

The first important conclusion of this work is that there was no effect of storage time on any of the properties analysed, i.e. the product obtained was stable. Second, the reduction of psyllium proportion in the fibre mix reduced the gumminess of the jellies enriched with two fibre varieties in equal proportions (except apple-psyllium), without affecting the syneresis (which remained at 0 g/100 g), which is a highly desirable result. Third, rheological and mechanical properties were dominated by the fibre that was in greater proportion. The mixing rule model applied predicted reasonably well the complex modulus of the jellies enriched with the mix of fibre, based on the rheological data of the jellies enriched with one fibre variety.

In terms of viscoelastic and mechanical properties, sample AP31 was the closest to commercial jams, probably because it was the most similar to an apple jam. Only one of the commercial jams did not present syneresis, and as for the color both were more luminous than the jellies with fibre. Perhaps the most important conclusion of this work was that fibre enriched jellies were acceptable to consumers, and there was no difference in acceptability between commercial jam and jelly with bamboo and psyllium fibre (ratio 3:1). Given that sample BP31 was the most different compared to commercial jams in terms of rheological and mechanical properties, this suggests that consumers preference was not based on the consistency or texture of the samples, but probably on their flavour.

Acknowledgements

We express our gratitude to Consejo Nacional de Investigaciones Científicas y Técnicas (PIP 2015-2017 N° 0156), and Universidad Nacional del Sur (PGI 24/M152), Argentina, for supporting this work.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Anonymous (2018) Jam, jellies and marmalades. Publishing Herbstreith and Fox Web: https://www.herbstreith-fox.de/en/service/#1563871338042-6b25bab2-8a72

- Baker RA, Berry N, Hui YH. Fruit Preserves and Jams. In: Somogyi LP, Ramaswamy HS, Hui YH, editors. Biology, principles, and applications. Basel: Technomic Publishing Co., Inc.; 1996. pp. 117–128. [Google Scholar]

- Basu S, Shivhare US. Rheological, textural, micro-structural and sensory properties of mango jam. J Food Eng. 2010;100(2):357–365. [Google Scholar]

- Basu S, Shivhare US, Singh TV, Beniwal VS. Rheological, textural and spectral characteristics of sorbitol substituted mango jam. J Food Eng. 2011;105(3):503–512. [Google Scholar]

- Bourne MC. Principles of objective texture measurement. In: Taylor SL, editor. Food texture and viscosity: concept and measurement. San Diego: Academic Press; 2002. pp. 182–186. [Google Scholar]

- Chater PI, Wilcox MD, Pearson JP, Brownlee IA. The impact of dietary fibres on the physiological processes governing small intestinal digestive processes. Bioact Carbohydr Diet Fibre. 2015;6(2):117–132. [Google Scholar]

- Dello Staffolo M, Bevilacqua A, Rodríguez MS, Albertengo L. Dietary fiber and availability of nutrients: a case study on yoghurt as a food model. In: Karunaratn DN, editor. The complex world of polysaccharides. Rijeka: Intech; 2012. pp. 455–490. [Google Scholar]

- Dello Staffolo M, Sato ACK, Cunha RL. Utilization of plant dietary fibers to reinforce low-calorie dairy dessert structure. Food Bioprocess Technol. 2017;10(5):914–925. [Google Scholar]

- Dhingra D, Michael M, Rajput H, Patil RT. Dietary fibre in foods: a review. J Food Sci Technol. 2012;49(3):255–266. doi: 10.1007/s13197-011-0365-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H. Dietary fibre and fibre-rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem. 2011;124(2):411–421. [Google Scholar]

- Figueroa LE, Genovese DB. Pectin gels enriched with dietary fibre for the development of healthy confectionery jams. Food Technol Biotechnol. 2018;56(3):441–453. doi: 10.17113/ftb.56.03.18.5641. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Figueroa LE, Genovese DB. Fruit jellies enriched with dietary fibre: development and characterization of a novel functional food product. LWT Food Sci Technol. 2019;111:423–428. [Google Scholar]

- Gabriele D, de Cindio B, D’Antona P. A weak gel model for foods. Rheol Acta. 2001;40:120–127. [Google Scholar]

- Garrido JI, Lozano JE, Genovese DB. Effect of formulation variables on rheology, texture, colour, and acceptability of apple jelly: modelling and optimization. LWT Food Sci Technol. 2015;62(1):325–332. [Google Scholar]

- Genovese DB, Ye A, Singh H. High methoxyl pectin/apple particles composite gels: effect of particle size and particle concentration on mechanical properties and gel structure. J Texture Stud. 2010;42(2):171–189. [Google Scholar]

- Guillon F, Champ M, Thibault JF, Saulnier L. Dietary fibre functional products. In: Saarela M, editor. Functional foods: concept to product. 2da. Cambridge: Woodhead Publishing; 2012. pp. 582–622. [Google Scholar]

- Lago-Vanzela ES, dos Santos GV, de Lima FA, Gomes E, da Silva R. Physical-chemical, caloric and sensory characterization of light jambolan (Syzygium cumini Lamarck) jelly. Ciênc Tecnol Aliment. 2011;31(3):666–673. [Google Scholar]

- Li YO, Komarek AR. Dietary fibre basics: health, nutrition, analysis, and applications. Food Qual Saf. 2017;1(1):47–59. [Google Scholar]

- Mackie A, Bajka B, Rigby N. Roles for dietary fibre in the upper GI tract: the importance of viscosity. Food Res Int. 2016;88:234–238. [Google Scholar]

- Rao MA. Rheological behavior of food gels systems. In: Barbosa-Cánovas GV, editor. Rheology of fluid and semisolids foods. Boston: Springer; 2007. pp. 319–356. [Google Scholar]

- Renard D, van de Velde F, Visschers RW. The gap between food gel structure, texture and perception. Food Hydrocoll. 2006;20(4):423–431. [Google Scholar]

- Thakur BR, Singh RK, Handa AK. Chemistry and uses of pectin. A review. Crit Rev Food Sci Nutr. 1997;37(1):47–73. doi: 10.1080/10408399709527767. [DOI] [PubMed] [Google Scholar]

- Vibhakara HS, Bawa AS. Manufacturing jams and jellies. In: Hui YH, editor. Handbook of fruits and fruit processing. USA: Blackwell Publishing; 2006. pp. 189–204. [Google Scholar]

- Wu Y, Qian Y, Pan Y, Li P, Yang J, Ye X, Xu G. Association between dietary fiber intake and risk of coronary heart disease: a meta-analysis. Clin Nutr. 2015;34(4):603–611. doi: 10.1016/j.clnu.2014.05.009. [DOI] [PubMed] [Google Scholar]