Abstract

Cloud instability and loss of fresh-like appearance are important quality defects of cloudy mixed juices determining consumer acceptability. Therefore, the aim of this study was to investigate the feasibility of high pressure homogenization (HPH) for improving cloud stability, flow behavior and physicochemical characteristics as well as reducing spoilage microorganisms in a cloudy mixed juice, consisting of carrot, apple and peaches. HPH treatments included pressure of 25 MPa, 100 MPa, 140 MPa and 180 MPa, pass of 1 and 2 and inlet temperature of 25 °C and 40 °C, respectively. Results indicated that increasing pressure and pass improved cloud stability, while increasing temperature had negative effect. Herschel Bulkey model could be well fitted to viscosity related data. Compared with control (non-homogenized, NH) sample, HPH at 140 MPa and 25 °C for 1 pass resulted in three times higher flow behavior index. Increasing inlet temperature also resulted in enhancing flow behavior. Besides, total soluble solids content was not affected by HPH, even though pH and color showed slight changes. Compared with NH sample, HPH at 140 MPa resulted in 4 log10 and 3 log10 reductions in total plate count and yeasts and molds count respectively. Thus, HPH at 140 MPa could effectively be used for enhancing cloud stability, improving flow behavior and reducing microorganisms in cloudy mixed juices.

Keywords: High pressure homogenization, Mixed juice, Cloud stability, Flow behavior, Microorganism reduction

Introduction

Cloudy mixed juices are widely consumed and provide alternatives to fresh fruits in a healthy diet. In recent years, mixed juices have become increasingly popular, ranking as the second most important type of fruit juice (19.4%) in the EU, following orange juice (36.7%) (AIJN 2016). Carrot, apple and peaches are preferable sources of mixed juice production due to presence of bioactive compounds including carotenoids, polyphenolics and dietary fiber, which are found to be positively associated with a reduction of the risk of developing degenerative diseases (Gao et al. 2017; Liang et al. 2013; Ma et al. 2015; Saini et al. 2015). Moreover, carrot and peaches are widely available in China. Since carrot contains less sugar, adjusting taste of mixed juice is possible with clear apple juice. However, cloud sedimentation is one main drawback in fresh cloudy mixed juice. Furthermore, thermal treatments that widely applied as means for microorganism reduction could further induce sedimentation. Thus, adopting innovative technologies in mixed juice processing could be effective in overcoming these drawbacks.

High pressure homogenization (HPH) has been considered one of the most encouraging alternatives as a partial or total substitute for the thermal processing for fruits and vegetables (Kubo et al. 2013). It involves mechanical impact on breaking plant tissue, and disrupting microbial cells suspended in the fluid (Hayes and Kelly 2003; Kubo et al. 2013). HPH also could modify both insoluble cell fragments (particle phase) and soluble cell contents (continuous liquid phase) of plant dispersions (Augusto et al. 2012; Lopez-Sanchez et al. 2011a). Furthermore, the modification of physical properties may depend on matrix characteristics of raw materials and applied processing parameters including pressure, number of passes and inlet temperature (Lopez-Sanchez et al. 2011b; Tan and Kerr 2015).

Although, many studies have been focused on HPH for individual fruit or vegetable based liquid systems to investigate impacts on particle size, physicochemical characteristics, rheological properties and microbiological status (Kubo et al. 2013; Leite et al. 2015, 2016; Silva et al. 2010; Tan and Kerr 2015; Van Buggenhout et al. 2015), lack of studies considered the effect of HPH on complex systems like mixed juices, in which several plant matrixes with different physical and chemical characteristics are involved. Therefore, this research investigated the effect of different HPH treatments on mixed juice (carrot, apple and peaches) attributes, with the objective of finding out the feasibility of HPH for improving stability, enhancing flow behavior, reducing juice spoiling microorganisms, while maintaining physicochemical characteristics.

Materials and methods

Materials

Fresh peaches, variety "Jiubao", were purchased, washed, deseeded and sliced. Peach slices were frozen with liquid nitrogen and stored at − 18 °C. Carrot, variety "Kuroda" purchased from local supermarket was cold stored at 4 °C until use. Clear apple concentrate with 68 °Brix friendly provided by one local juice factory.

Nutrient Agar and Rose Bengal Agar were purchased from Beijing Land Bridge Technology, Beijing, China. Other chemicals were analytical grade and purchased from Sinopharm Chemical, Shanghai, China.

Cloudy mixed juice preparation

Peach slices were thawed to room temperature. Peach juice was extracted by using a squeezer and filtered through four-layer gauze. The carrot was washed and blanched at 80 °C for 10 min with carrot and distilled water ratio of 1:1. The core temperature of the carrots during blanching at this condition is about 60 °C, where trans–cis-isomerization does not take place and total β-carotene remains as all-trans-β-carotene (Marx 2003). Blanched carrot was immediately cooled to room temperature using cold deionized water and mechanically disrupted in a blender (Joyong Electric Appliance, Shandong, China) for 2 min. Concentrated clear apple juice (68 °Brix) was diluted with addition of distilled water to 12 °Brix.

Carrot puree, apple juice and peach juice in a ratio of 30:50:20 was selected according to results of preliminary experiments and further used in this study. The prepared mixed juice was immediately subjected to high pressure homogenization treatments.

Cloudy mixed juice treated by high pressure homogenization

HPH was carried out in a bench scale high pressure homogenization (JN-02HC series, Guangzhou Juneng Biology and Technology, Guangdong, China) connected with a cooling circulating system. The cloudy mixed juice was subjected to pressure of 25 MPa, 100 MPa, 140 MPa and 180 MPa, pass of 1 and 2 and inlet temperature of 25 °C and 40 °C. The temperature of samples was set to the inlet temperature before feeding to the machine. Just after HPH, samples were cooled to 25 °C by using an ice bath. The treated samples were subjected to following analyses. Each sample was measured in triplicate.

Particle size distributions

The particle size distribution (PSD) of juice samples was determined by using the Masterizer 2000 (Malvern Instruments, Malvern, U.K.). The volume mean particle diameter (D[4,3]), area mean diameter (D[3,2]), D50 and D90 were calculated by using the software (Microtrac-Bluewave) attached to the machine.

Microstructure analysis

The microstructure of juice samples were obtained by using an optical microscope (XSP-BM10A, Shanghai Optical Instruments Manufactory, Shanghai, China) with a 10 X lens, digital camera and software (ToupView 3). Each sample (20 µL) was carefully placed on a glass slide, covered with a cover slip and the microstructure was analyzed (Kubo et al. 2013).

Relative turbidity determination

The cloud stability of cloudy mixed juice was measured in terms of nephelometric turbidity units (NTU) using a portable Turbidimeter (Model 2100P) based on method of Mollov et al. (2006). Turbidity was expressed in NTU, and relative turbidity (Trel) was calculated as in Eq. (1).

| 1 |

where To and Tc were juice turbidities before and after centrifugation at 4200g for 15 min respectively.

Determination of viscosity curves and flow behavior properties

Viscosity measurements of mixed juice samples were carried out using a Physica MCR3001 rheometer (Anton Paar, Graz and Austria) equipped with 50 mm plate geometry (49.983 mm of diameter) with a gap of 1 mm. The shear rate was increased from 0.01 to 100 s−1 in a steady-state shear mode. Shear stress and viscosity were measured with the shear rate changes. Herschel-Bulkley model (Eq. 2) with better fitting coefficient was applied for describing all flow curves to calculate consistency index (k), flow behavior properties (n) and yield stress (η0).

| 2 |

Total soluble sugar and pH analysis

Total soluble solids (TSS) content of juice samples was determined as oBrix by using a digital refractometer (WZB 45, Shanghai Electronics and Analytical Instruments, Shanghai, China) at 25 ± 1 °C and pH was measured using a portable pH meter (Tesco 205, Tesco Industry Corporation, Germany) at 25 ± 1 °C.

Instrumental color analysis

Instrumental color of juice samples was measured using a Color Quest XT colorimeter (Hunter Associates Laboratory, Inc, USA). L* (lightness), a* (redness) and b* (yellowness) values were determined for treated samples. The total color difference was calculated using Eq. (3), where Lo*, ao* and bo* were the values for the control (NH) sample.

| 3 |

Microbiological analysis

To detect total plate count (TPC) and yeasts and molds (Y&M), the pour-plating method was used. The HPH treated and NH samples were serially diluted with sterile 0.8% NaCl solution and 1.0 mL of non-diluted and diluted samples were plated into duplicated plates of appropriate agar. The Nutrient Agar was used for detecting the viable cells of TPC and the plates were incubated at 37 °C for 48 ± 2 h. The Rose Bengal Agar was used for detecting the viable cells of Y&M, and the plates were incubated at 28 °C for 3–5 days. After incubation, plates of 30–300 CFU for the TPC and 10–150 CFU for the Y&M were chosen for enumeration. Number of microorganism colonies was converted to Log10 value.

Statistical analysis

All the experiments were conducted in triplicate and the results were expressed as mean ± standard deviation. Data were analyzed using one-way analysis of variance (ANOVA) following LSD multiple comparison using procedure of SAS 9.0 (SAS Institute). Significance was determined at 95% confidence level. The figures were plotted using Microsoft Office Excel software (2007).

Results and discussion

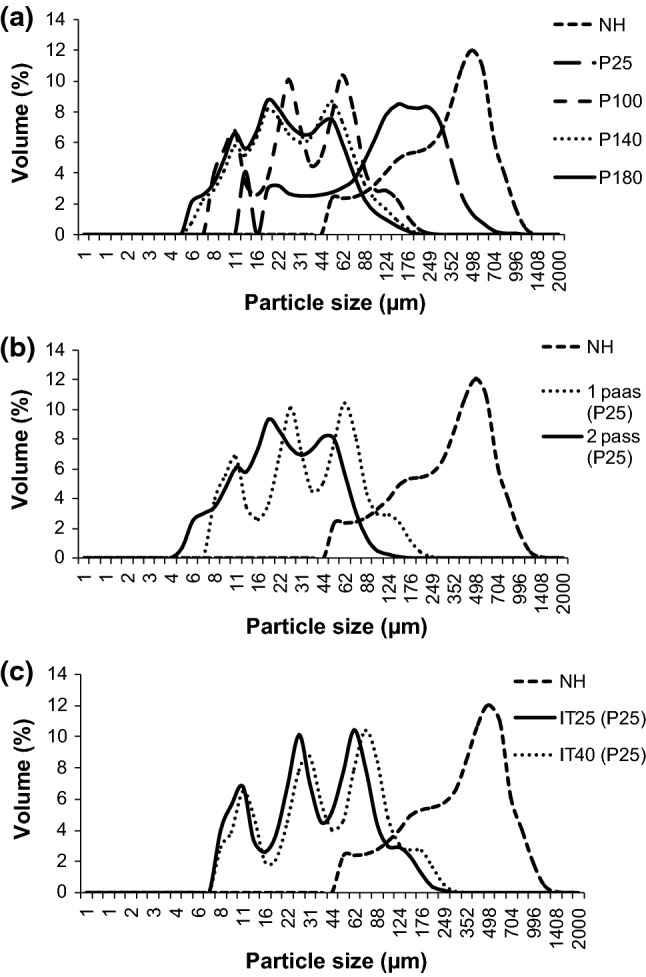

Particle size distribution

The PSD and mean particle diameters (D[4,3], D[3,2], D50 and D90) of non-homogenized (NH) and different HPH treated cloudy mixed juice samples are shown in Fig. 1 and Table 1, respectively. A prominent peak of large size particles was observed in the NH sample, while multimodal distributions of smaller size particles were observed for the homogenized samples. As reported previously, multiple peaks might be attributed to the complex composition of the cloudy mixed juice (Bayod and Tornberg 2011).

Fig. 1.

Particle size distribution of non-homogenized and high pressure homogenized mixed juice a homogenization pressure, b homogenization pass, c inlet temperature. NH non-homogenized, P pressure, IT inlet temperature

Table 1.

The mean particle diameters and Herschel Bulkey model parameters of non-homogenized and high pressure homogenized mixed juices

| Mean particle diameters (µm) | Herschel Bulkey model parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| D[4,3] | D[3,2] | D50 | D90 | Consistency index (k) (Pa.sn) | Flow behavior index (n) (-) | Yield stress (η0) (Pa) | R2 | |

| NH | 480.2 ± 1.9a | 342.2 ± 2.0a | 324.4 ± 9.0a | 623.4 ± 8.7a | 0.448 ± 0.011a | 0.29 ± 0.04f | 0.23 ± 0.04a | 0.99 |

| 25/1(25) | 242.7 ± 2.9b | 149.2 ± 1.4b | 126.5 ± 5.7a | 297.8 ± 9.7b | 0.223 ± 0.119b | 0.58 ± 0.12e | 0.10 ± 0.01c | 0.99 |

| 100/1(25) | 70.8 ± 1.8d | 42.9 ± 0.4d | 31.4 ± 4.1 cd | 87.0 ± 5.7d | 0.029 ± 0.003bc | 0.81 ± 0.10c | 0.05 ± 0.01d | 0.99 |

| 140/1(25) | 57.4 ± 0.6e | 35.2 ± 0.7de | 26.1 ± 1.0de | 70.5 ± 0.8de | 0.002 ± 0.001c | 1.11 ± 0.12b | 0.22 ± 0.09a | 0.95 |

| 180/1(25) | 50.2 ± 0.1e | 30.6 ± 0.1e | 22.4 ± 0.0e | 61.4 ± 0.2e | 0.003 ± 0.001c | 1.05 ± 0.06b | 0.18 ± 0.03b | 0.96 |

| 100/2(25) | 40.1 ± 0.2f | 27.2 ± 0.5e | 21.3 ± 0.6e | 53.3 ± 0.5f | 0.038 ± 0.003bc | 0.69 ± 0.07d | 0.05 ± 0.02d | 0.99 |

| 100/1(40) | 87.9 ± 0.1c | 52.3 ± 0.5c | 38.1 ± 1.3c | 107.7 ± 0.6c | 0.010 ± 0.002c | 1.35 ± 0.10a | 0.21 ± 0.06a | 0.97 |

Values are the means of three replicates ± SD. Different letters in each column indicate significant differences among treatments at 0.05 level according to ANOVA analysis

The D[4,3] and D[3,2] were reduced in simultaneous proportions with the increase of homogenization pressure. As reported by Lopez-Sanchez et al. (2011b), the D[4,3] and D[3,2] were influenced by large and small size particles respectively, hence these results indicated that both size particles have similar impact during the HPH process. Moreover, the most reduction occurred when the pressure increased up to 100 MPa and size was reduced less decreasing rate at pressure of 140 MPa and 180 MPa. Leite et al. (2014) reported that this asymptotic behavior could be related to gap dimensions and the shear stress, since the stress required for disrupting smaller size particles becomes greater. Subsequent two passes also resulted in significant reduction (p < 0.05) in both D[4,3] and D[3,2] compared with single pass at 100 MPa. However, increasing the temperature from 25 to 40 °C resulted in a significant (p < 0.05) increase of D[4,3] and D[3,2]. Santiago et al. (2016) also observed a slight increase of particle size in carrot puree treated by high temperature followed by HPH. Moreover, it has been reported that the particle size of thermally treated carrot juice could be significantly increased, attributed to heat induced protein coagulation (Zhou et al. 2009). No significant (p < 0.05) difference was found in D50 and D90 values among samples treated at 100 MPa, 140 MPa and 180 MPa (Table 1), indicating that further decrease in cumulative particle sizes could not be obtained by increasing the pressure beyond 100 MPa. Furthermore, the D90 at 100 MPa and 25 °C for 1 pass was 87 µm, which found to be quite smaller to carrot cells (125 µm) (Lemmens et al. 2010) and peach cells (200–300 µm × 100–300 µm) (Rojas et al. 2016). These pointed out that more than 90% of cell disruption of carrot and peaches could be taken place at 100 MPa or more.

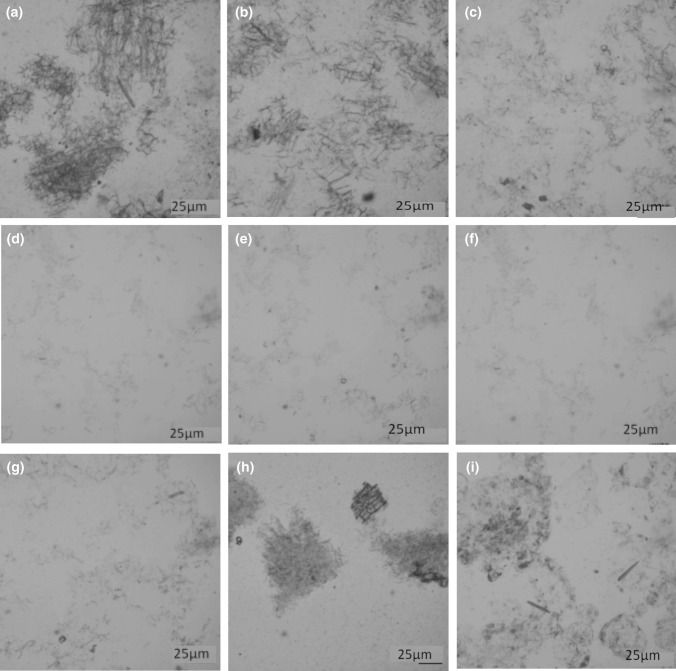

Microstructure

Figure 2 shows optical micrografts of NH and HPH treated mixed juice samples as well as carrot puree and peach juice. Moreover, particles could not be observed in clear apple juice under magnification of 10. Whole cells and cell clusters were visible in carrot puree, peach juice and NH mixed juice samples. Upon HPH at 25 MPa and 25 °C for 1 pass, it was difficult to see distinct outlines of the cellular material. Small cell fragments were resulted at 100 MPa, indicating further disruption of cell material. More uniformly distributed smaller size particles were visible at 140 MPa and 180 MPa. Furthermore, increasing pass and inlet temperature also resulted in uniform distribution of smaller size particles.

Fig. 2.

Microstructure of non-homogenized and high pressure homogenized mixed juice compared with carrot puree and peach juice a NH mixed juice, b pressure of 25 MPa, c pressure of 100 MPa, d pressure of 140 MPa, e pressure of 180 MPa, f pass 2 at 100 MPa, g inlet temperature 40 °C at pressure of 100 MPa, h carrot puree and i peach juice

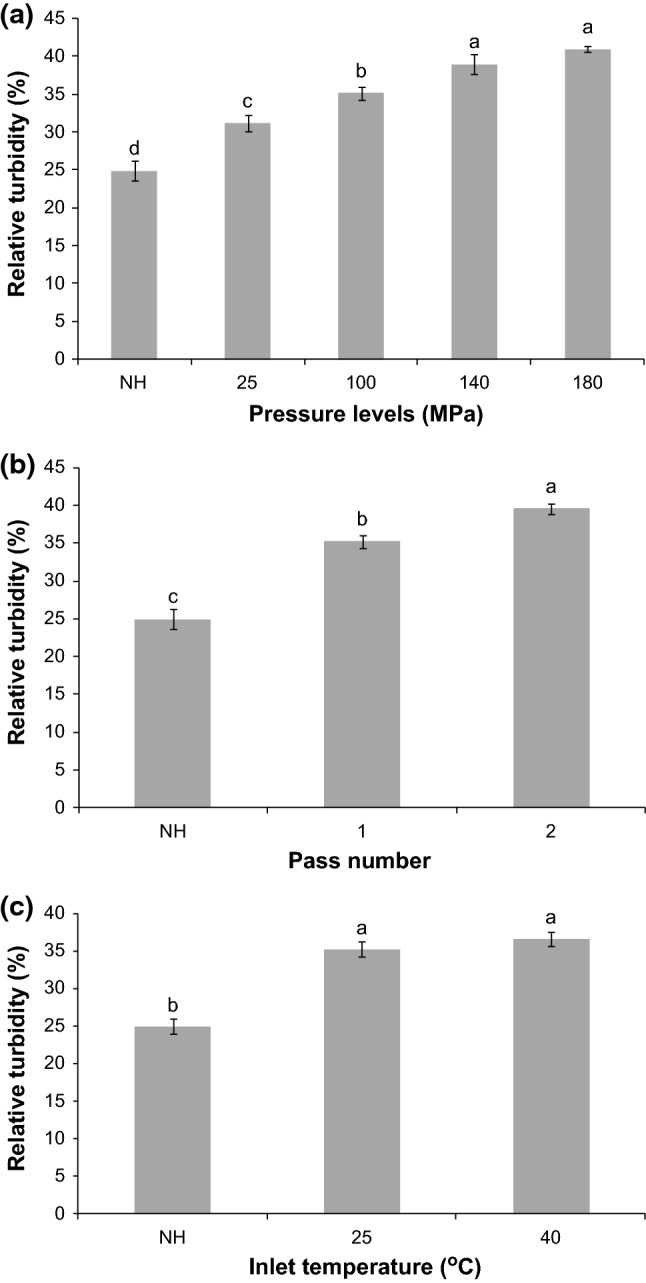

Relative turbidity (Trel)

The relative turbidity (Trel) of cloudy mixed juices was enhanced from 25 to 140 MPa, which might be attributed to stronger shear rate induced by increasing pressure (Fig. 3). However, the Trel showed no significant increase from 140 to 180 MPa. Besides, the NH mixed juice resulted in Trel value around 25%, which might be attributed to tissue disintegration during simple blending or crushing. Moreover, pass from 1 to 2 at 100 MPa also resulted in significant increase in Trel, which might be attributed to further disruption of particles with subsequent passes. However, Trel showed non-significant increase from 25 to 40 °C. The Trel is an indicative of cloud stability, which is one of the visual quality attributes decisive for consumer acceptance of cloudy juices (Beveridge 2002). It has been shown that interactions among small size particles and serum possibly made sedimentation more difficult. Therefore, it is explained that not only the particle disruption, but also structural changes in serum pectin induced by HPH might play important roles by binding with particles and making the homogenized mixture more stable (Augusto et al. 2012; Santiago et al. 2017).

Fig. 3.

Effects of high pressure homogenization parameters on relative turbidity (Trel) of mixed juice a homogenization pressure b homogenization pass, c inlet temperature. NH non-homogenized; P pressure; IT inlet temperature. Different letters indicate statistical difference (p < 0.05)

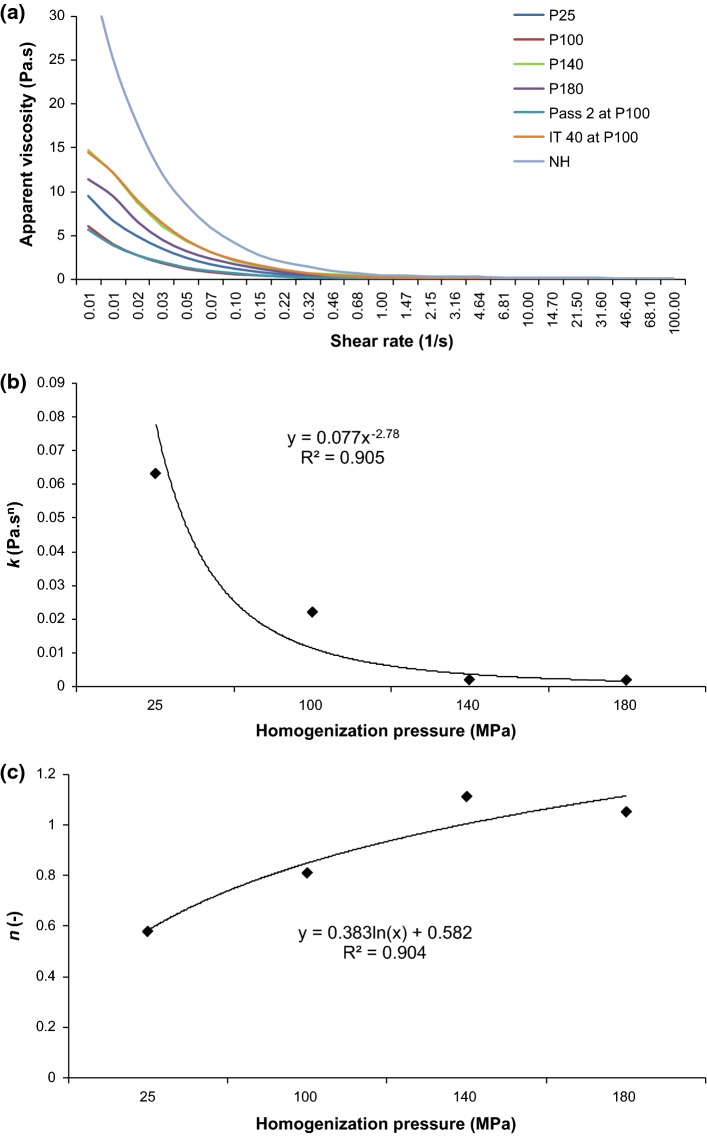

Viscosity curves and flow behavior properties

Figure 4a shows the apparent viscosity vs. shear rate of NH and HPH treated mixed juices. The apparent viscosity showed a decreasing trend with increasing shear rates, independent of treatments (Muthukumarappan et al. 2016). Similarly, a decrease in viscosity for samples after HPH has been reported in orange juice (Leite et al. 2016) and tomato puree (Tan and Kerr 2015). The NH mixed juice samples showed higher apparent viscosity as shown in Fig. 4a. Among the HPH treated samples, the highest apparent viscosity was observed at pressure of 140 MPa. Santiago et al. (2018) showed that the higher extent of branching or presence of branched rhamnogalacturonan I could result in high molecular weight pectic polymers. Increasing pressure beyond an optimum value (140 MPa) might result in removal of side branches, thus lower molecular weight and reduced viscosity. Two subsequent passes at 100 MPa also resulted in a little increase in apparent viscosity compared to 1 pass, which might be attributed to the increased interactions of pectin polymers. Moreover, Santiago et al. (2017) hypothesized that the intense shear promoted the interactions between WSP polymers, which in turn, changed structure. Furthermore, a significant increase in viscosity was observed when increasing temperature from 25 to 40 °C. This might be due to thermosolubilization of pectin at higher temperature (Sila et al. 2009), which enhanced polymer concentration in the juice.

Fig. 4.

Effect of high pressure homogenization parameters on viscosity and rheological attributes of mixed juices a apparent viscosity versus shear rate, b high pressure homogenization pressure on k described by power law equation and c high pressure homogenization pressure on n by logarithmic equation. k consistency index; n flow behavior index

The Herschel–Bulkley model could well fit all flow curves with higher coefficient (95—99%) and the representative parameters of the model influenced by HPH treatments are shown in Table 1. The highest consistency index (k) was present in the NH control. However, increasing homogenization pressure resulted in gradual decrease in k value. It was in accordance with the previous reported results in tomato puree and concentrated orange pulp treated by HPH (Leite et al. 2014; Tan and Kerr 2015).

Although the k decreased with increasing homogenization pressure, flow behavior index (n) showed an opposite behavior. The n provides valuable information about the flow characteristics of fluids, and could be useful in optimizing energy consumption during juice processing. The NH mixed juice sample had the lowest η (0.29), indicating greater shear thinning behavior, which could be due to lack of interactions among particles in the initial mixture. With the increase of the HPH pressure, the η increased significantly (Table 1). Similarly, by using the Herschel-Bulkley model, Leite et al. (2015) reported that cashew apple juice homogenized at 150 MPa and 25 °C showed decreased k value of 0.023 Pa sn and increased n value of 0.815 compared to NH sample with the values of 0.426 Pa.sn and 0.426, respectively. Moreover, similar tendencies were also obtained by different models for pineapple pulp and concentrated orange juice (Leite et al. 2014; Silva et al. 2010).

In this research, the highest n was observed for samples treated at 140 MPa (3.8 times of the NH sample) followed by 180 MPa. Furthermore, Schmelter et al. (2002) found that low-molecular weight pectin could result in increasing flow behavior. Furthermore, Leite et al. (2015) explained that the decrease in k and increase in n for the HPH treated samples could be attributed to lubricant effect of smaller size particles and smooth surface morphology that could cause reduction in resistance to flow.

The response of k to the homogenization pressure was regressed into power law equation with R2 value of 0.91, while n was regressed into a logarithmic equation, with R2 value of 0.90 (Fig. 4b and c). The similar trends and values of k and n vs. homogenization pressure were also found in flaxseed gum (Wang et al. 2011). Besides, predicting of k and n in response to the homogenization pressure might be useful in the point of industrial view.

The NH mixed juice sample showed the highest yield stress (η0) followed by the HPH treated mixed juice sample at pressure of 140 MPa. However, significant difference was not found between two values (Table 1). Moreover, η0 values were decreased in an order of 180 MPa, 25 MPa and 100 MPa. Moreover, Lopez-Sanchez et al. (2011b) demonstrated that the inter-particle forces could contribute for increasing η0. A significant increase in η0 could not be observed between single pass and 2 subsequent passes. However, increasing inlet temperature from 25 to 40 °C resulted in higher η0, which might be attributed to forces created by heat induced aggregates of particles.

Total soluble solids content and pH

The TSS (oBrix) and pH of the NH and HPH treated mixed juice samples are shown in Table 2. The TSS did not change significantly (p < 0.05) among the NH and HPH treated mixed juices. This implied that the desired TSS of juice could be regulated during HPH processing. The HPH had an impact on pH of the mixed juice. The initial pH of NH mixed juice was 4.25. Mixed juice subjected to 25 MPa significantly decreased the pH value to 4.15, followed by significant increase at 100 MPa (pH value of 4.20), and remained unchanged at 140 MPa and 180 MPa. The pH was not changed between 1 and 2 passes. However, the pH significantly increased from 25 to 40 °C. Dissolving cellular materials such as pectins and proteins during the HPH process might be the reason for the pH increment as reported previously (Gul et al. 2017).

Table 2.

The basic physicochemical and microorganism (total plate count, TPC and yeast and moulds, Y&M) attributes of non-homogenized and high pressure homogenized mixed juices

| TSS (°Brix) | pH | L* | a* | b* | ΔE with NH | Counts (log10 CFU/mL) | ||

|---|---|---|---|---|---|---|---|---|

| TPC | Y&M | |||||||

| NH | 8.07 ± 0.03a | 4.23 ± 0.01b | 21.47 ± .82a | 22.46 ± 0.37a | 13.79 ± 0.61a | – | 6.41 ± 0.01a | 4.21 ± 0.01a |

| 25/1(25) | 8.03 ± 0.08a | 4.15 ± 0.02e | 19.89 ± 0.46ab | 20.41 ± 0.32bc | 12.59 ± 0.14bc | 2.86 | 5.28 ± 0.02b | 3.36 ± 0.04b |

| 100/1(25) | 8.04 ± 0.03a | 4.20 ± 0.01d | 18.57 ± 0.51b | 20.47 ± 0.18bc | 12.31 ± 0.21bcd | 3.81 | 3.82 ± 0.06c | 2.91 ± 0.01c |

| 140/1(25) | 8.03 ± 0.11a | 4.20 ± 0.01 cd | 18.66 ± 0.50b | 20.41 ± 0.73bc | 12.24 ± 0.40bcd | 3.81 | 2.85 ± 0.09e | 1.82 ± 0.05d |

| 180/1(25) | 7.97 ± 0.07ab | 4.20 ± 0.01 cd | 18.15 ± 2.00b | 19.38 ± 1.34bc | 11.87 ± 0.37d | 4.92 | 2.73 ± 0.06e | 1.67 ± 0.02e |

| 100/2(25) | 7.87 ± 0.09b | 4.22 ± 0.01c | 18.18 ± 1.11b | 19.78 ± 1.11bc | 11.84 ± 0.74d | 4.67 | 3.41 ± 0.01d | 1.57 ± 0.08e |

| 100/1(40) | 7.97 ± 0.12ab | 4.27 ± 0.01a | 18.77 ± 1.54b | 20.71 ± 0.63b | 12.63 ± 0.51b | 3.42 | 3.43 ± 0.01d | 0.18 ± 0.01f |

Values are the means of three replicates ± SD. Different letters in each raw indicate significant differences among treatments at 0.05 level according to ANOVA analysis

Instrumental color

The instrumental color in terms of L* (lightness), a* (redness) and b* (yellowness) are shown in Table 2. The color of the mixed juice was bright orange resembling the color of carrot. However, the HPH treated mixed juice samples resulted in lower L* compared with the NH mixed juice, which might be attributed to disrupted particles. A trend of decreasing L* with increasing pressure might be resulted by uniform distribution of disrupted particles. The a* and b* were significantly lower in the HPH treated mixed juice samples than that in the NH sample. However, HPH variables were not found to impact on a* and b* values. Furthermore, the HPH treated mixed juice samples resulted in observable color change (ΔE > 2) compared with the NH mixed juice. Moreover, Zhou et al. (2017) observed a reduction in L*, an increase in a*and b* as well as higher values for ΔE in HPH treated mango puree.

Reduction of natural microorganisms

Table 2 shows the effect of HPH treatments on total plate count (TPC) and yeast and molds (Y&M) count. The mesophilic bacteria count (determined by TPC) was reduced by 1 log10 CFU/mL with homogenization pressure of 25 MPa. Further reduction was observed with the increasing of homogenization pressure, where 4 log10 and 3 log10 reductions were resulted in the TPC at 140 MPa and 180 MPa respectively, compared with the NH sample. However, total inactivation was not possible with the pressure levels used in the present study. Compared with the NH sample (6.41 log10 CFU/mL), the TPC value decreased to 3.82 log10 CFU/mL and 3.41 log10 CFU/mL under the HPH pass of 1 to 2, while 3.82 log10 CFU/mL and 3.43 log10 CFU/mL at the HPH inlet temperature of 25 °C and 40 °C, respectively. Similar to our results, Welti-Chanes et al. (2009) reported a 3 log10 reduction in mesophiles in orange juice homogenized 5 times both at 100 MPa and 250 MPa. They further showed that the mesophiles treated at 45 °C was significantly lower in comparison to that of 22 °C and 35 °C.

The Y&M counts were reduced by 3 log10 at 140 MPa and 180 MPa compared with NH samples (Table 2). Furthermore, compared with the NH sample (4.21 log10 CFU/mL), the Y&M counts reduced to 2.91 log10 CFU/mL and 1.57 log10 CFU/mL under pass of 1–2. Furthermore, HPH inlet temperature of 25 °C and 40 °C resulted in the value decrease to 2.91 log10 CFU/mL and 0.18 log10 CFU/mL respectively. Similarly, Corbo et al. (2010) used HPH as a means to control molds in tomato juice and found that the level of Fusarium oxysporum decreased to some extend with pressure between 30 and 150 MPa, and could be eliminated after 3 passes in the homogenizer.

Moreover, Y&M counts reduced from 2.91 log10 CFU/mL to 0.18 log10 CFU/mL when the temperature was increased from 25 to 45 °C at 100 MPa, however, TPC could only be reduced from 3.82 to 3.43 log10 CFU/mL under similar condition. It indicated that yeasts and molds were more sensitive to increment of inlet temperature compared to mesophilic bacteria found in the mixed juice.

Conclusion

The results indicated that HPH at pressure of 140 MPa could be effective in improving stability and flow behavior properties, while reducing mesophilic bacterial and yeasts and molds counts of cloudy mixed juice of carrot, apple and peaches. Increasing HPH pressure and pass number could enhance the stability. Pressure of 140 MPa and inlet temperature of 40 °C could improve flow behavior index. The total soluble solids content could not be changed by the HPH treatments, even though the pH and color could slightly be changed. HPH at 140 MPa resulted in 4 log10 and 3 log10 reductions in total plate count and yeasts and molds count respectively. Moreover, yeasts and molds were more sensitive to increment of inlet temperature than mesophilic bacteria. However, the underlying mechanisms of enzyme activities of PME and PE on stability and consistency of mixed juice during storage as well as bioaccessibility of bioactive components, including carotenoids, polyphenolics and pectin need to be further investigated.

Acknowledgements

This work was supported by the National Key Research and Developement Program of China (No. 2018YFD0400905), the National Natural Science Foundation of China (Grant No. 31671868), the National Key Research and Development Program of China No. 2016YFD0400302-3) and the Central Public-interest Scientific Institution Basal Research Fund (No. S2019RCJC02).

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Jinfeng Bi, Email: bjfcaas@126.com.

Xuan Liu, Email: liuxuancaas@126.com.

References

- AIJN (2006) AIJN European Fruit Juice Association. 2016 Liquid Fruit Market Report. Brussels, Belgium: European Fruit Juice Association

- Augusto PED, Ibarz A, Cristianini M. Effect of high pressure homogenization (HPH) on the rheological properties of tomato juice: time-dependent and steady-state shear. J Food Eng. 2012;111(4):570–579. doi: 10.1016/j.jfoodeng.2012.03.015. [DOI] [Google Scholar]

- Bayod E, Tornberg E. Microstructure of highly concentrated tomato suspensions on homogenisation and subsequent shearing. Food Res Int. 2011;44(3):755–764. doi: 10.1016/j.foodres.2011.01.005. [DOI] [Google Scholar]

- Beveridge T. Opalescent and cloudy fruit juices: formation and particle stability. Crit Rev Food Sci Nutr. 2002;42(4):317–337. doi: 10.1080/10408690290825556. [DOI] [PubMed] [Google Scholar]

- Corbo MR, Bevilacqua A, Campaniello D, Ciccarone C, Sinigaglia M. Use of high pressure homogenization as a mean to control the growth of food borne molds in tomato juice. Food Cont. 2010;21(11):1507–1511. doi: 10.1016/j.foodcont.2010.04.023. [DOI] [Google Scholar]

- Gao YF, Zhou YB, Zhang Q, Zhang K, Peng P, Chen LC, Xiao B. Hydrothermal extraction, structural characterization, and inhibition HeLa cells proliferation of functional polysaccharides from Chinese tea Zhongcha 108. J Funct Foods. 2017;39:1–8. doi: 10.1016/j.jff.2017.09.057. [DOI] [Google Scholar]

- Gul O, Saricaoglu FT, Mortas M, Atalar I, Yazici F. Effect of high pressure homogenization (HPH) on microstructure and rheological properties of hazelnut milk. Inno Food Sci Emer Technol. 2017;41:411–420. doi: 10.1016/j.ifset.2017.05.002. [DOI] [Google Scholar]

- Hayes MG, Kelly AL. High pressure homogenisation of milk (b) effects on indigenous enzymatic activity. J Dairy Res. 2003;70(3):307. doi: 10.1017/S0022029903006319. [DOI] [PubMed] [Google Scholar]

- Kubo MTK, Augusto PED, Cristianini M. Effect of high pressure homogenization (HPH) on the physical stability of tomato juice. Food Res Int. 2013;51(1):170–179. doi: 10.1016/j.foodres.2012.12.004. [DOI] [Google Scholar]

- Leite TS, Augusto PED, Cristianini M. The use of high pressure homogenization (HPH) to reduce consistency of concentrated orange juice (COJ) Inno Food Sci Emer Tech. 2014;26:124–133. doi: 10.1016/j.ifset.2014.08.005. [DOI] [Google Scholar]

- Leite TS, Augusto PED, Cristianini M. Using high pressure homogenization (HPH) to change the physical properties of cashew apple juice. Food Biophys. 2015;10:169–180. doi: 10.1007/s11483-014-9385-9. [DOI] [Google Scholar]

- Leite TS, Augusto PED, Cristianini M. Frozen concentrated orange juice (FCOJ) processed by the high pressure homogenization (HPH) technology: effect on the ready-to-drink juice. Food Bioproces Tech. 2016;9(6):1–9. doi: 10.1007/s11947-016-1688-z. [DOI] [Google Scholar]

- Lemmens L, Buggenhout SV, Loey AMV, Hendrickx ME. Particle size reduction leading to cell wall rupture is more important for the β-carotene bioaccessibility of raw compared to thermally processed carrots. J Agric Food Chem. 2010;58(24):2769. doi: 10.1021/jf102554h. [DOI] [PubMed] [Google Scholar]

- Liang R, Shoemaker CF, Yang X, Zhong F, Huang Q. Stability and bioaccessibility of Î2-carotene in nanoemulsions stabilized by modified starches. J Agric Food Chem. 2013;61(6):1249–1257. doi: 10.1021/jf303967f. [DOI] [PubMed] [Google Scholar]

- Lopez-Sanchez P, Nijsse J, Blonk HC, Bialek L, Schumm S, Langton M. Effect of mechanical and thermal treatments on the microstructure and rheological properties of carrot, broccoli and tomato dispersions. J Sci Food Agric. 2011;91(2):207–217. doi: 10.1002/jsfa.4168. [DOI] [PubMed] [Google Scholar]

- Lopez-Sanchez P, Svelander C, Bialek L, Schumm S, Langton M. Rheological and microstructure of carrot and tomato emulsions as a result of high-pressure homogenization conditions. J Food Sci. 2011;76(1):E130–E140. doi: 10.1111/j.1750-3841.2010.01894.x. [DOI] [PubMed] [Google Scholar]

- Ma T, Tian C, Luo J, Sun X, Quan M, Zheng C, Zhan J. Influence of technical processing units on the α-carotene, β-carotene and lutein contents of carrot (Daucus carrot L.) juice. J Funct Foods. 2015;16:104–113. doi: 10.1016/j.jff.2015.04.020. [DOI] [Google Scholar]

- Marx M. Effects of thermal processing on trans–cis-isomerization of β-carotene in carrot juices and carotene-containing preparations. Food Chem. 2003;83(4):609–617. doi: 10.1016/S0308-8146(03)00255-3. [DOI] [Google Scholar]

- Mollov P, Mihalev K, Buleva M, Petkanchin I. Cloudy stability of apple juices in relation to their particle charge properties studied by electro-optics. Food Res Int. 2006;39:519–524. doi: 10.1016/j.foodres.2005.10.008. [DOI] [Google Scholar]

- Muthukumarappan K, Tiwari B, Oonnel P, Cullen P. Ultrasound processing: rheological and functional properties of food. In: Ramaswamy H, Kasapis S, Boye J, editors. Ahmed J. Novel food processing: Effects on rheological and functional properties. CRE press; 2016. pp. 85–102. [Google Scholar]

- Rojas ML, Leite TS, Cristianini M, Alvim ID, Augusto PED. Peach juice processed by the ultrasound technology: changes in its microstructure improve its physical properties and stability. Food Res Int. 2016;82:22–33. doi: 10.1016/j.foodres.2016.01.011. [DOI] [Google Scholar]

- Saini RK, Nile SH, Park SW. Carotenoids from fruits and vegetables: chemistry, analysis, occurrence, bioavailability and biological activities. Food Res Int. 2015;76:735–750. doi: 10.1016/j.foodres.2015.07.047. [DOI] [PubMed] [Google Scholar]

- Santiago JSJ, Christiaens S, Loey AMV, Hendrickx ME. Deliberate processing of carrot purées entails tailored serum pectin structures. Inn Food Sci Emer Tech. 2016;33:515–523. doi: 10.1016/j.ifset.2015.10.020. [DOI] [Google Scholar]

- Santiago JSJ, Kermani ZJ, Xu F, Loey AMV, Hendrickx ME. The effect of high pressure homogenization and endogenous pectin-related enzymes on tomato purée consistency and serum pectin structure. Inn Food Sci Emer Tech. 2017;43:35–44. doi: 10.1016/j.ifset.2017.07.028. [DOI] [Google Scholar]

- Santiago JSJ, Salvia-Trujillo L, Zucca R, Loey AMV, Grauwet T, Hendrickx ME. In vitro digestibility kinetics of oil-in-water emulsions structured by water-soluble pectin-protein mixtures from vegetable purées. Food Hydrocol. 2018;80:231–244. doi: 10.1016/j.foodhyd.2018.02.007. [DOI] [Google Scholar]

- Schmelter T, Wientjes R, Vreeker R, Klaffke W. Enzymatic modifications of pectins and the impact on their rheological properties. Carbohydr Polym. 2002;47(2):99–108. doi: 10.1016/S0144-8617(01)00170-9. [DOI] [Google Scholar]

- Sila DN, Buggenhout SV, Duvetter T, Fraeye I, Roeck AD, Loey AMV, Hendrickx M. Pectins in processed fruits and vegetables: part II—structure–function relationships. Compre Rev Food Sci Food Safe. 2009;8(2):86–104. doi: 10.1111/j.1541-4337.2009.00071.x. [DOI] [Google Scholar]

- Silva VM, Sato ACK, Barbosa G, Dacanal G, Ciro-Veláquez HJ, Cunha RL. The effect of homogenization on the stability of pineapple pulp. Int J Food Sci Technol. 2010;45(10):2127–2133. doi: 10.1111/j.1365-2621.2010.02386.x. [DOI] [Google Scholar]

- Tan J, Kerr WL. Rheological properties and microstructure of tomato puree subject to continuous high pressure homogenization. J Food Eng. 2015;166:45–54. doi: 10.1016/j.jfoodeng.2015.05.025. [DOI] [Google Scholar]

- Van Buggenhout S, Wallecan J, Christiaens S, et al. Influence of high pressure homogenization on functional properties of orange pulp. Inn Food Sci Emer Technol. 2015;30:51–60. doi: 10.1016/j.ifset.2015.05.004. [DOI] [Google Scholar]

- Wang Y, Li D, Wang LJ, Xue J. Effects of high pressure homogenization on rheological properties of flaxseed gum. Carbohyd Polym. 2011;83(2):489–494. doi: 10.1016/j.carbpol.2010.08.015. [DOI] [Google Scholar]

- Welti-Chanes J, Ochoa-Velasco CE, Guerrero-Beltrán JÁ. High-pressure homogenization of orange juice to inactivate pectinmethylesterase. Inno Food Sci Emer Technol. 2009;10(4):457–462. doi: 10.1016/j.ifset.2009.05.012. [DOI] [Google Scholar]

- Zhou L, Wang Y, Hu X, Wu J, Liao X. Effect of high pressure carbon dioxide on the quality of carrot juice. Inno Food Sci Emer Technol. 2009;10(3):321–327. doi: 10.1016/j.ifset.2009.01.002. [DOI] [Google Scholar]

- Zhou L, Guan Y, Bi J, et al. Change of the rheological properties of mango juice by high pressure homogenization. LWT Food Sci Technol. 2017;82:121–130. doi: 10.1016/j.lwt.2017.04.038. [DOI] [Google Scholar]