Abstract

In order to investigate the effects of celery powder (CP) on bread quality, wheat flour was replaced by CP which was produced from two celery varieties (‘Jinnan Shiqin’ and ‘Ventura’) at different levels (1, 2, 3 and 5/100 g flour). For both kinds of CPs, Mixolab analysis showed that the water absorption of dough increased with the increase of CP, while the protein network weakening (C2), peak viscosity (C3) and crystallinity of starch (C5–C4) decreased. The specific volume of bread decreased at higher CP level, whereas its crumb hardness and chewiness showed a reverse trend. The addition of CP significantly increased the total phenolics content of bread, and thus caused a significant improvement in antioxidant activities. The addition of CP significantly reduced the content of rapidly digestible starch in bread, while the contents of slowly digestible starch and resistant starch were increased. Additionally, bread prepared with a higher CP content showed a lower predicted glycaemic index. Based on the results of sensory analysis, bread incorporated with 2 g/100 g flour for ‘Jinnan Shiqin’ or 1 g/100 g flour for ‘Ventura’ didn’t show significant effect on its overall acceptability. The present study indicated that addition of CP could be an effective way to produce a bread with higher antioxidant activity and lower starch digestibility.

Keywords: Celery powder, Dough, Bread, Antioxidant activity, Starch digestibility

Introduction

Celery (Apium graveolens L.), a member of Umbelliferae family, is widely cultivated and used not only as everyday vegetable, but also as an ingredient in the food and cosmetic industries (Ross and Kasum 2002). Celery is rich in vitamins, carotene, protein, cellulose and other nutrients and is a good source of volatile oils and antioxidants (Li et al. 2018). All parts of the celery plant have been reported to possess medicinal properties such as anti-bacterial, anti-inflammatory, lowering blood glucose and serum lipid levels, strengthening heart, and preventing cardiovascular disease (Atta and Alkofahi 1998; Sowbhagya et al. 2010; Kooti and Daraei 2017).

Bread is one of the most widely consumed grain products in the world and traditionally produced from wheat flour. It is rich in carbohydrate and fat but low in functional components. With increasing living standards and health awareness, supplementing bread with nutritious additives in order to boost its physical and nutritional properties has become more common and desired (Reshmi et al. 2017). In recent years, many researches have been reported about bread supplemented plant ingredients in order to increase its functional properties, such as dried onion skin (Gawlik-Dziki et al. 2013), green tea powder (Ning et al. 2017), mallow powder (Fakhfakh et al. 2017) and plant essential oils (Gavahian et al. 2018).

Despite the scientific knowledge on the functional properties of celery, celery is widely used as daily vegetable consumption and there is a shortage of other celery food products in the market. Due to the high content of active ingredients in celery, the addition of celery into bread may significantly increase its functional properties. However, studies on celery have mainly focused on cultivation, breeding and chemical composition (Li et al. 2018). Therefore, the purpose of this study is to investigate the effects of the addition amounts and different varieties of celery powder (CP) on bread quality. Two commonly grown celery varieties (Ventura and Jinnan Shiqin) were used in this study. ‘Ventura’, a variety developed in the United States, is tall and compact with thick, glossy leaves. ‘Jinnan Shiqin’, a variety developed in China, is tall, and light green in color with hypertrophic leaves. The effects of CP on dough rheological properties and textural, antioxidant, starch digestibility, sensory properties of breads were investigated in the present study.

Materials and methods

Materials

Commercial bread wheat flour was supplied by Fengzheng Milling Company (Shandong, China), and instant dry yeast was purchased from Angle Company (Hubei, China). CPs from the varieties of ‘Ventura’ and ‘Jinnan Shiqin’ were provided by Hongsheng Food Co. Ltd. (Jiangsu, China). CPs were stored in plastic bags at − 18 °C until use.

Chemical analysis of wheat flour and celery powder

Dry matter, fat, ash, and protein were determined by AACC approved methods (AACC 2000). Total starch and dietary fiber were measured using AOAC Official Methods 996.11 (AOAC 1996b) and 991.43 (AOAC 1996a), respectively.

Mixolab testing of dough

According to AACC method 54–60.01 (2010b), the mixing and pasting properties of dough were determined using Mixolab (Chopin, Villeneuve-La-Garenne, France). Water absorption (%), development time (C1 time, min), stability time (min), protein network weakening (C2, Nm), starch gelatinization (C3, Nm), the crystallinity of starch (C5–C4, Nm) and final viscosity (C5, Nm) were measured.

Bread preparation

The formulation of control bread was: wheat flour (300 g, 14% mb), water (92% Mixolab water absorption), instant yeast (4.5 g), sugar (16 g) and salt (3 g). To prepare CP bread, wheat flour was replaced by CP at five levels (0, 1, 2, 3 and 5 g/100 g wheat flour). Before dough mixing, yeast, salt and sugar were dissolved in water, respectively. The dough was mixed in a spiral mixer (B20, Ye Chang Instruments Co., Ltd, Shanghai, China) for about 15 min until fully developed. Then the dough was divided into 170 g pieces and fermented at 30 °C, 80% RH in a dough fermentation cabinet (Shengheng Instruments Co., Ltd, Guangzhou, China). The fermented dough had its first and second punch at 105 min and 155 min of fermentation. After 180 min of fermentation, the dough was placed into a baking pan (13.9 × 8 × 5.8 cm) and proofed for 45 min. The proofed dough was baked in an oven (SJ943, Sinmag Equipment Co., Ltd, Wuxi, China) at 210 °C for 23 min and cooled for 60 min at room temperature for the further study.

Physical properties of bread

The volume of bread was determined by rapeseed replacement according to AACC approved method 10-05.01 (2010a). Specific volume (cm3/g) was determined using bread volume divided by weight. Bread slice (25 mm thickness) was used to determine the textural profile analysis (TPA), and compressed to 50% of its original height at a speed of 1 mm/s by the TA.XT Plus Texture Analyzer (Stable Micro Systems, Goldalming, UK) with a 36 mm-diameter cylinder probe. The software used for TPA was Exponent 6 (Stable Micro Systems, Goldalming, UK). Crumb hardness, springiness, chewiness and resilience were measured.

Total phenolics content and antioxidant activity of bread

Preparation of extraction samples

To obtain bread powder, bread slices without crust were freeze-dried, ground and sieved through 80-mesh screen. Then bread powder or CP (1 g dm) was extracted with 25 mL of methanol: water (80:20) at 50 °C for 3 h in a rotary shaker (Yiheng Technology Co., Ltd, Shanghai, China). After the extract was centrifuged (3200 g, 20 min), the supernatant was collected as extraction sample and stored at − 18 °C in darkness until the total phenolics content (TPC) and antioxidant activity were determined, within 1 week.

Determination of total phenolics content

The TPC of CP or bread was determined using Folin-ciocalteu method as reported by Sumczynski et al. (2015), and the result was expressed as Gallic acid equivalent (μg GAE/g dm).

Determination of antioxidant activity

DPPH radical-scavenging activity of bread samples was determined according to the method of Das et al. (2012) with some modifications. The DPPH radical solution was made by dissolving 10 mg of DPPH in 250 mL of methanol: water (80:20). The above extract sample (2 mL) was mixed with DPPH radical solution (2 mL), shaken vigorously and reacted in darkness for 30 min at room temperature. The absorbance of the solution was measured at 515 nm using a spectrophotometer (α-1900S, Shanghai Lab-Spectrum Instruments Co., Ltd, China) against a blank of methanol: water (80:20) without DPPH solution. The control was made from dissolving 2 mL of DPPH radical solution in 2 mL of methanol: water (80:20). The percent inhibition was calculated as follows: Inhibition (%) = (Abscontrol − Abssample) × 100/Abscontrol.

The Ferric reducing power (FRAP) of bread samples was determined according to the method of Seczyk et al. (2017). Extract (1 mL), phosphate buffer (2.5 mL, 200 mmol/L, pH 6.6) and potassium ferricyanide aqueous solution (2.5 mL, 1 g/100 mL) were mixed. After the mixture was incubated (50 °C, 20 min), trichloroacetic acid (0.5 mL, 10 g/100 mL) was added and centrifuged (3000 g, 10 min) to obtain the upper layer of solution. The upper layer (2.5 mL), distilled water (2.5 mL) and FeCl3 (0.5 mL, 0.1 g/100 mL) were mixed. The absorbance of the solution was measured at 700 nm using a spectrophotometer (α-1900S, Shanghai Lab-Spectrum Instruments Co., Ltd, China) and FRAP was calculated as trolox equivalents (mg TE/g dm).

In vitro starch digestibility of bread

In vitro starch digestibility of bread was determined according to the method of Chen et al. (2017), with some modifications. Bread powder (200 mg) prepared as above was mixed with sodium acetate buffer (15 mL, 0.2 mol/L, pH 5.2) to obtain a suspension. After the suspension was equilibrated in a shaking-water bath at 37 °C for 10 min, five glass balls (diameter: 5 mm) and 15 mL of an enzyme solution (α-amylase and amyloglucosidase mixed in a proportion of 120 U/80 U/mL) were added to start hydrolysis in a shaking water bath (160 rpm). Samples (1 mL) of the digestive solutions were taken out at 0, 10, 20, 60, 90, 120, and 180 min from when the enzyme solution was added. To inactivate the enzymes, 4 mL of ethanol was added. The solutions were centrifuged (4000 g, 10 min) and the supernatants were used for the determination of glucose content using the DNS method (Miller 1959).

The percentages of rapidly digested starch (RDS), slowly digested starch (SDS) and resistant starch (RS) were calculated as follows: RDS = 0.9 × (G20 − FG), SDS = 0.9 × (G120 − G20), RS = 0.9 × (TG − G120). Where FG, G20, G120 and TG are the glucose contents (%) released after 0, 20, 120 and 180 min, respectively.

According to the method used by Bae et al. (2016), the kinetics of starch hydrolysis was calculated using the equation: C = C∞(1 − e−kt), where C, C∞ and k denote the hydrolysis degree at each time, the maximum hydrolysis extent and the kinetic constant, respectively. The hydrolysis index (HI) was obtained as the ratio of the area of samples to the area of a standard material (glucose) under the hydrolysis curve (0–180 min). The pGI was calculated by the following equation: pGI = 39.71 + 0.549 HI.

Sensory evaluation

The sensory evaluation of the freshly baked bread was measured according to the method used by Seczyk et al. (2017). The crumb color, aroma, taste, texture and overall acceptability were evaluated by a panel of 40 untrained consumers (18–50 years old) consisting of 20 males and 20 females. A nine-point hedonic scale (where 1: dislike extremely, 5: neither like nor dislike, and 9: like extremely) was used. Bread samples were sliced (slices about 1.5 cm), coded and served. All participants were informed about the purpose of this study and signed the informed consent forms prior to sensory tests. Before and after each test, they were asked to drink plain water to rinse the mouth.

Statistical analysis

All measurements were repeated at least 3 times. Statistical analyses were carried out in SPSS 20.0 (SPSS Inc., Chicago, USA) using one-way analysis of variance (ANOVA). P < 0.05 was considered to be significant using Duncan’s test.

Results and discussion

Chemical composition

The major components of the two types of CPs and wheat flour are shown in Table 1. In comparison to wheat flour, the CPs had higher contents of fat, ash and protein. Furthermore, high levels of dietary fiber and TPC were also found in CPs. Therefore, CP could be considered as a natural ingredient with bioactive components that could be incorporated in wheat products. In addition, there were significant differences between the two kinds of CPs. ‘Ventura’ had higher protein, fat and dietary fiber contents but lower ash content than ‘Jinnan Shiqin’. These differences between the CPs could be due to varietal differences, indicating they might have different effects on dough properties and bread qualities when added to wheat flour.

Table 1.

Compositional characteristics of wheat flour and celery powder

| Parameters | Wheat flour | Celery powder | |

|---|---|---|---|

| ‘Jinnan Shiqin’ | ‘Ventura’ | ||

| Fat (g/100 g dm) | 0.99 ± 0.21a | 1.33 ± 0.09b | 1.62 ± 0.02c |

| Ash (g/100 g dm) | 0.66 ± 0.13a | 12.46 ± 0.16c | 11.45 ± 0.02b |

| Crude protein (g/100 g dm) | 12.75 ± 0.05a | 12.97 ± 0.65a | 16.72 ± 0.04b |

| Total starch (g/100 g dm) | 73.40 ± 0.12c | 8.68 ± 0.03a | 10.23 ± 0.01b |

| TDF (g/100 g dm) | 3.60 ± 0.32a | 32.09 ± 0.49b | 36.82 ± 0.46c |

| SDF (g/100 g dm) | nd | 20.58 ± 0.04a | 25.30 ± 0.43b |

| IDF (g/100 g dm) | nd | 11.51 ± 0.71a | 9.70 ± 1.36a |

| TPC (μg GAE/g dm) | 787.1 ± 37.5a | 3678.0 ± 72.3c | 2908.4 ± 20.7b |

Results are reported as mean ± SD. Values with different letters in the same line are significantly different (P < 0.05)

TDF total dietary fiber, SDF soluble dietary fiber, IDF insoluble dietary fiber, TPC total phenolics content expressed as gallic acid equivalent (μg GAE/g dm), nd not detected

The mixing and pasting properties of doughs

A typical Mixolab curve can be divided into two phases. The first phase determines the protein properties during dough mixing at 30 °C and the water absorption, development time, stability time and C2 value of dough are shown in Table 2. For both CPs, a slight increase was observed in the water absorption of dough with increase of CP. This might attribute to the high fiber content in the CPs (as shown in Table 1). The large number of hydroxyl groups in the structure of fiber would result in greater interactions with water through hydrogen bonds, and thus would increase the water absorption of dough (Rosell et al. 2010). For ‘Jinnan Shiqin’, the development time (C1 time) increased with increasing CP content. However, addition of CP produced from ‘Ventura’ did not result in a significant effect (P > 0.05) on the C1 time at levels of 1.0–5.0 g/100 g flour. The stability time represents the mixing resistance of dough, with longer time associated to stronger dough to some extent. The addition of CPs from the two celery varieties differentially affected the stability time. Addition of CP from ‘Jinnan Shiqin’ increased the stability time, while addition of ‘Ventura’ CP decreased the stability time with increasing CP content. In a study of nonstarch polysaccharides, increasing or decreasing trends in development and stability times when added to dough depended upon their chemical nature and water absorption capacity (Saeed et al. 2016). The content and chemical structure of the fiber, protein and starch in the two types of CPs (as shown in Table 1) are different, which might result in the different effect on the development and stability time of dough between them. C2 is the minimum torque recorded during mixing and increasing system temperature, which represents the weakening of the protein on the basis of mechanical action and elevated temperature. As it can be seen in Table 2, addition of the two kinds of CPs decreased C2 values of dough. When the same amount of CP was added, dough supplemented ‘Ventura’ showed a lower C2 value than ‘Jinnan Shiqin’, indicating addition of ‘Ventura’ had more detrimental effect on the formation of gluten network in dough.

Table 2.

Mixolab thermo-mechanical parameters of wheat flour or wheat flour with celery powder

| Samplesa | WAb (%) | C1 time (min) | Stability (min) | C2 (Nm) | C3 (Nm) | C5–C4 (Nm) | C5 (Nm) |

|---|---|---|---|---|---|---|---|

| ControlJ1 | 61.9 ± 0.1a | 2.89 ± 0.35ab | 5.13 ± 0.21d | 0.42 ± 0.03d | 1.66 ± 0.01c | 0.90 ± 0.02f | 2.48 ± 0.05c |

| J1 | 62.3 ± 0.1b | 2.93 ± 0.21ab | 5.17 ± 0.19d | 0.40 ± 0.01d | 1.64 ± 0.02bc | 0.76 ± 0.01d | 2.31 ± 0.03b |

| J2 | 62.2 ± 0.0b | 3.04 ± 0.06b | 5.10 ± 0.31d | 0.39 ± 0.03 cd | 1.62 ± 0.00b | 0.75 ± 0.01 cd | 2.29 ± 0.05b |

| J3 | 62.3 ± 0.1b | 3.19 ± 0.13c | 5.90 ± 0.06e | 0.36 ± 0.03bc | 1.62 ± 0.04b | 0.67 ± 0.02b | 2.29 ± 0.15b |

| J5 | 62.5 ± 0.1c | 3.30 ± 0.26c | 6.02 ± 0.27e | 0.32 ± 0.02b | 1.56 ± 0.03a | 0.66 ± 0.02b | 2.28 ± 0.09b |

| V1 | 62.4 ± 0.1bc | 2.87 ± 0.25ab | 4.51 ± 0.27c | 0.41 ± 0.00d | 1.64 ± 0.04bc | 0.78 ± 0.01e | 2.31 ± 0.16b |

| V2 | 62.5 ± 0.1c | 2.75 ± 0.07a | 4.18 ± 0.13b | 0.36 ± 0.02bc | 1.60 ± 0.05b | 0.73 ± 0.01c | 2.23 ± 0.16ab |

| V3 | 62.5 ± 0.0c | 2.81 ± 0.34a | 3.88 ± 0.06a | 0.34 ± 0.02b | 1.56 ± 0.07a | 0.64 ± 0.01a | 2.19 ± 0.11a |

| V5 | 62.6 ± 0.1c | 2.80 ± 0.19a | 3.46 ± 0.35a | 0.28 ± 0.03a | 1.53 ± 0.11a | 0.62 ± 0.01a | 2.16 ± 0.09a |

Results are reported as mean ± SD. Values with different letters in the same column are significantly different (P < 0.05)

aControl: 0.0 g celery powder/100 g flour; J1, J2, J3, J5:1.0, 2.0, 3.0, 5.0 g ‘Jinnan Shiqin’ celery powder/100 g flour; V1, V2, V3, V5:1.0, 2.0, 3.0, 5.0 g ‘Ventura’ celery powder/100 g flour

bWA water absorption (14% moisture basis)

In the second phase of the Mixolab analysis, the starch pasting properties of dough were determined under mixing and heating constraints. Addition of either ‘Jinnan Shiqin’ or ‘Ventura’ CP decreased the C3 value. With increasing CP content, the C3 value further decreased, which possibly due to the lower starch content in CP when compared to wheat flour. In addition, the higher fiber content in CP could compete with starch for water absorption, and thus limit the swelling of starch granule (Chareonthaikij et al. 2016). The C5–C4 value represents the degree of starch retrogradation. With increasing of CP levels, the C5–C4 value decreased, indicating a decreased degree of starch retrogradation. This trend is consistent with those reported in Ktenioudaki et al. (2013) and Khan et al. (2013), in which apple pomace and spinach powder, respectively, decreased starch retrogradation when added to wheat dough.

Specific volume and textural properties of breads

Loaf volume is one of the most important visual characteristics, that strongly influences consumer choice. Hence, it is a key parameter in evaluating bread quality. The specific volume of bread added with CP was found significant (P < 0.05) lower than control bread. Increasing levels of CP caused further decreases in this parameter (Table 3). Similar results were reported in breads after addition of quinoa leaves (Swieca et al. 2014) and green tea powder (Ning et al. 2017). The reduction of specific volume is primarily due to the dilution of gluten in the flour blends. In addition, replacing wheat flour with CP could disrupt the homogeneity and continuity of the gluten network (Lauková et al. 2017). Between the two kinds of CPs, bread supplemented with ‘Jinnan Shiqin’ showed higher specific volume than ‘Ventura’ at the same addition level. This result agrees with the higher stability and C2 value observed in dough with ‘Jinnan Shiqin’ when compared with ‘Ventura’ (Table 2).

Table 3.

Effect of celery powder on the specific volume and textural properties of bread

| Samplesa | Specific volume (cm3/g) | Hardness (N) | Springiness | Chewiness (N) | Resilience |

|---|---|---|---|---|---|

| Control | 3.54 ± 0.04e | 10.46 ± 0.44a | 0.92 ± 0.01c | 7.12 ± 0.51a | 0.42 ± 0.01c |

| J1 | 3.36 ± 0.04d | 12.43 ± 0.51b | 0.91 ± 0.01c | 8.59 ± 0.70b | 0.38 ± 0.02b |

| J2 | 3.32 ± 0.08d | 14.60 ± 0.20c | 0.89 ± 0.02b | 8.78 ± 0.58b | 0.37 ± 0.02b |

| J3 | 3.19 ± 0.04c | 15.42 ± 0.69d | 0.87 ± 0.01ab | 10.32 ± 0.92 cd | 0.37 ± 0.02b |

| J5 | 2.78 ± 0.05b | 17.63 ± 0.14e | 0.86 ± 0.01a | 11.53 ± 0.55d | 0.35 ± 0.02a |

| V1 | 3.30 ± 0.01d | 11.64 ± 0.27b | 0.91 ± 0.01c | 7.50 ± 0.48a | 0.43 ± 0.03c |

| V2 | 3.15 ± 0.06c | 14.68 ± 1.63 cd | 0.89 ± 0.02b | 9.92 ± 1.31c | 0.39 ± 0.03b |

| V3 | 3.10 ± 0.03c | 16.82 ± 0.56d | 0.88 ± 0.01b | 8.79 ± 0.94bc | 0.35 ± 0.02a |

| V5 | 2.65 ± 0.05a | 22.99 ± 1.77f | 0.85 ± 0.02a | 13.30 ± 1.73e | 0.33 ± 0.03a |

Results are reported as mean ± SD. Values with different letters in the same column are significantly different (P < 0.05)

aAbbreviations (Control, J1, J2, J3, J5, V1, V2, V3, V5) are the same as in Table 2

The textural parameters of breads are shown in Table 3. Hardness is strongly correlated with consumer perception of bread freshness (Gül and Şen 2017). For both celery varieties, CP addition significantly (P < 0.05) increased crumb hardness, which might be due to its lower specific volume. According to De la Hera et al. (2014), bread with a lower specific volume has more compact gas cells and thus increase the crumb hardness. Chewiness signifies the energy that food is chewed into a state which can be swallowed, and a lower chewiness is associated with a better tasting property. Hardness of bread has been found to have positive correlation with chewiness (Patil et al. 2016). As shown in Table 3, changes in the chewiness of bread exhibited the same pattern as hardness. Similarly, Ning et al. (2017) observed that hardness and chewiness of whole wheat bread increased after addition of green tea powder. Low springiness and resilience values are associated with a loss of elasticity, and high values are associated with freshness in bread (Özkaya et al. 2017). Opposite to hardness and chewiness, addition of CP significantly (P < 0.05) decreased springiness and resilience of bread, revealing a disadvantageous effect of CP on bread texture. In the study of Luyts et al. (2013), they found pound cake baked by ohmic heating method showed a softer texture than that baked in an oven during 12 days of storage. Therefore, further studies are needed to develop new baking methods in order to reduce the disadvantageous effect of CP on bread texture.

Total phenolics content and antioxidant activity of breads

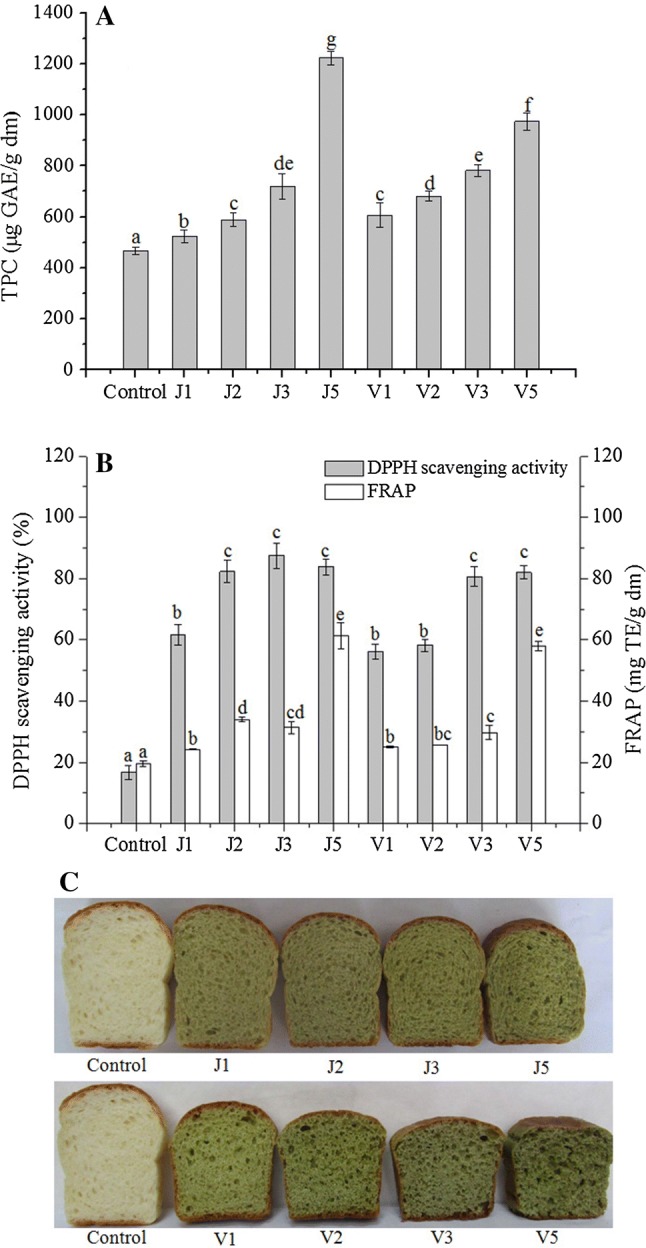

The TPC and antioxidant activity of bread are presented in Fig. 1. As the level of CP in the bread increased from 1.0 to 5.0 g/100 g flour, the TPC increased from 524.4 to 1222.4 μg GAE/g dm for ‘Jinnan Shiqin’ and 606.0 to 973.8 μg GAE/g dm for ‘Ventura’. The most abundant phenolic compounds in wheat kernel are insoluble fractions (Zhu et al. 2016). In a study of whole wheat bread, Borczak et al. (2016) found fruits could be a complementary material in other phenolics, and thus created the possibility to enhance the TPC and antioxidant properties of wheat bread. However, Zhu et al. (2016) found the increase of TPC in steamed bread was lower than expected after addition of black tea. The processes (mixing, fermentation and baking) applied during bread production could significantly affect TPC and antioxidant activity (Seczyk et al. 2017). In this study, there were strong correlations between the addition levels of CP and the TPC (R2 = 0.989, P < 0.01 for ‘Jinnan Shiqin’; R2 = 0.954, P < 0.05 for ‘Ventura’), indicating addition of CP into bread is an effective method to enhance its TPC.

Fig. 1.

Total phenolics content (A), antioxidant activities (B) and slices (C) of breads supplemented with different amounts of celery powder Results are reported as mean ± SD. Means with different small letter superscripts are significantly different at P < 0.05. TPC: total phenolics content and expressed as gallic acid equivalent (μg GAE/g dm). FRAP: Ferric reducing power and expressed as trolox equivalents (mg TE/g dm). Abbreviations (Control, J1, J2, J3, J5, V1, V2, V3, V5) are the same as in Table 2

Antioxidant activity of bread samples determined by two different methods (DPPH radical-scavenging activity and FRAP) is presented in Fig. 1. Similar to TPC, addition of CP significantly (P < 0.05) increased the antioxidant activity in breads depending on the addition level. The bread at the level of 1.0–5.0 g/100 g flour of CP increased DPPH radical-scavenging activity by about 44.9–67.2% for ‘Jinnan Shiqin’ and 39.8–65.3% for ‘Ventura’, respectively. An increase of FRAP by about 23.5–213.3% for ‘Jinnan Shiqin’ and 27.6–196.0% for ‘Ventura’ was also observed. These results indicated addition of CP could be a practical way to increase the antioxidant activity of bread.

Starch digestibility and predicted glycaemic index of breads

The contents of RDS, SDS, and RS in bread samples are shown in Table 4. Compared to control bread, a decrease of RDS by about 17–25% for ‘Jinnan Shiqin’ or 12–27% for ‘Ventura’ was observed. Previous study has found a high relationship between RDS levels and the glycaemic response in humans (Englyst et al. 2003). Therefore, a decrease in RDS indicates that bread enriched with CP might be favorable for the controlling of acute increase in postprandial blood glucose level after ingestion. SDS is slowly digested in the small intestine, causing a gradual increase in postprandial blood glucose and insulin levels. RS comprises the sum of intact starch and retrograded starch that passes into the large intestine (Liu et al. 2016). Addition of both kinds of CPs significantly increased the contents of SDS and RS in bread. Similar trends in the changes of RDS, SDS and RS were also reported by Borczak et al. (2016) in whole wheat bread after addition of wild grown fruits. In addition to its own structural characteristics and physical state, the presence of other constituents in a food matrix can also affect the digestion rate of starch (Seczyk et al. 2017). Many studies reported that bread enriched with phenolic or fiber samples, such as onion skin (Gawlik-Dziki et al. 2013), quinoa leaves (Swieca et al. 2014), apple dietary fiber (Bae et al. 2016), and flax fiber (Kurek et al. 2018) all decreased the starch digestibility. Therefore, the high contents of phenolics and fiber in CPs might be the main ingredients which resulted in the decrease of starch digestibility in bread.

Table 4.

Effect of celery powder on the in vitro starch digestibility and predicted glycemic index of bread

| Samplesa | RDSb (%) | SDSc (%) | RSc (%) | HIc (%) | pGIc |

|---|---|---|---|---|---|

| Control | 42.75 ± 0.22d | 44.76 ± 0.85a | 12.49 ± 0.04a | 66.03 ± 0.88e. | 75.96 ± 0.48d |

| J1 | 35.48 ± 0.88b | 51.00 ± 1.26c | 13.52 ± 0.32b | 60.67 ± 1.02c | 73.02 ± 0.56c |

| J2 | 35.20 ± 1.22b | 49.62 ± 0.88bc | 15.18 ± 0.12c | 57.62 ± 0.66b | 71.34 ± 0.36b |

| J3 | 34.58 ± 0.36b | 49.37 ± 0.54bc | 16.05 ± 0.08d | 56.78 ± 0.54ab | 70.88 ± 0.30a |

| J5 | 32.22 ± 1.64a | 47.78 ± 0.66b | 20.00 ± 0.12f | 54.65 ± 0.86a | 69.71 ± 0.47a |

| V1 | 37.49 ± 0.12c | 49.58 ± 1.26bc | 12.93 ± 0.54ab | 63.27 ± 1.32d | 74.44 ± 0.72c |

| V2 | 34.58 ± 0.46b | 51.37 ± 0.66c | 14.05 ± 0.58b | 61.89 ± 0.76c | 73.69 ± 0.42c |

| V3 | 32.53 ± 0.75a | 51.61 ± 0.30c | 15.86 ± 0.44d | 60.72 ± 0.56c | 73.04 ± 0.31c |

| V5 | 31.38 ± 1.02a | 51.12 ± 0.22c | 17.50 ± 0.76e | 55.39 ± 2.52a | 70.12 ± 1.38ab |

Results are reported as mean ± SD. Values with different letters in the same column are significantly different (P < 0.05)

aAbbreviations (Control, J1, J2, J3, J5, V1, V2, V3, V5) are the same as in Table 2

bRDS rapidly digested starch, SDS slowly digested starch, RS resistant starch, HI hydrolysis index, pGI predicted glycemic index

The HI and the corresponding pGI are also presented in Table 4. The control bread showed the highest HI (66.03%) and pGI values (75.96), which decreased with increasing levels of CP. Reshmi et al. (2017) sorted foods by their GI values, labeling them low (≤ 55), medium (56–69) and high GI (≥ 70). In this study, even for the CP breads with highest addition level (5.0 g/100 g flour), their pGI values were 69.71 for ‘Jinnan Shiqin’ and 70.12 for ‘Ventura’, which still belong to high GI foods. Further study should be done to optimize the processing method of CP bread in order to reduce its pGI value.

Sensory evaluation

Figure 1 shows the slices of breads with or without CP and their consumers’ sensory assessments are shown in Table 5. Color is one of the most important visual characteristics of bread to determine its acceptability. The control bread, without any CP, has the highest crumb color score. This score decreased as the level of added CP increased. However, there was no significant influence (P > 0.05) on bread acceptability except for bread supplemented with ‘Ventura’ at 3, 5 g/100 g flour. Because of chlorophyll and other pigments in CP, CP gave greenish color characteristic to bread. The altered color of cereal food products may be an attractive character for consumers. The aroma scores (ranging from 6.6 to 7.8) showed a decreasing trend with the increase of CP. The inherent aroma of celery was similar to herbs, which was somewhat unacceptable to the panelists. Higher levels of CP also imparted a stronger taste and coarser texture to the bread. At the same addition level, bread supplemented with ‘Ventura’ showed a coarser crumb grain than that containing ‘Jinnan Shiqin’. This result is consistent with the Mixolab analysis of dough (Table 2). The dough supplemented with ‘Ventura’ during processing formed a higher degree of gas cell coalescence, which could be explained by their weak dough characteristics (low stability time and C2 value) that exhibited poor gas cell stability (Peressini and Sensidoni 2009). In terms of overall acceptability, bread supplemented with 1, 2 g/100 g flour for ‘Jinnan Shiqin’ and 1 g/100 g flour for ‘Ventura’ did not cause significant difference (P > 0.05) to the control bread. It is therefore concluded that highly acceptable quality breads can be prepared using up to 2 g/100 g flour for ‘Jinnan Shiqin’ and 1 g/100 g flour for ‘Ventura’.

Table 5.

Effect of celery powder on the sensory quality of bread

| Samplesa | Crumb color | Aroma | Taste | Texture | Overall acceptability |

|---|---|---|---|---|---|

| Control | 8.1 ± 0.6c | 7.8 ± 0.8b | 8.1 ± 1.0c | 7.8 ± 1.6c | 8.0 ± 1.6c |

| J1 | 7.7 ± 1.1c | 7.6 ± 1.1b | 7.8 ± 1.1c | 7.5 ± 1.0c | 7.4 ± 0.7c |

| J2 | 7.6 ± 1.0c | 7.3 ± 1.0b | 7.1 ± 1.0bc | 7.2 ± 0.9c | 7.2 ± 1.2c |

| J3 | 7.3 ± 1.2c | 6.9 ± 0.8ab | 6.5 ± 1.0b | 7.0 ± 1.2bc | 6.3 ± 0.8b |

| J5 | 7.3 ± 1.4c | 6.7 ± 0.8a | 6.5 ± 1.4b | 6.8 ± 1.0b | 6.2 ± 0.8b |

| V1 | 7.5 ± 1.2c | 7.7 ± 1.4b | 7.0 ± 1.0bc | 6.7 ± 1.6b | 6.9 ± 1.0bc |

| V2 | 7.2 ± 1.0c | 7.6 ± 1.2b | 6.4 ± 1.4b | 6.2 ± 1.5b | 6.6 ± 1.1b |

| V3 | 6.1 ± 1.1b | 6.7 ± 1.0a | 6.0 ± 0.9b | 6.0 ± 0.8ab | 6.1 ± 0.7b |

| V5 | 5.3 ± 0.6a | 6.6 ± 1.0a | 4.9 ± 1.0a | 5.5 ± 1.0a | 4.7 ± 1.0a |

Results are reported as mean ± SD. Values with different letters in the same column are significantly different (P < 0.05). Nine-point hedonic scale with 1, 5 and 9 representing extremely dislike, neither like nor dislike, and extremely like, respectively

aAbbreviations (Control, J1, J2, J3, J5, V1, V2, V3, V5) are the same as in Table 2

Similar to our results, many studies have reported that breads enriched with plant materials showed lower sensory scores than the control bread. A survey of the literatures showed that bread supplemented with up to 3–5% of functional ingredients (e.g. onion skin, black tea, spinach powder, mallow powder, coriander leaf powder) gave satisfactory consumer acceptability (Das et al. 2012; Gawlik-Dziki et al. 2013; Khan et al. 2013; Zhu et al. 2016; Fakhfakh et al. 2017), which were little higher than the CP in our results.

Conclusion

In the present study, the dough properties and bread qualities were significantly influenced by the addition of CP. Generally, supplementation of wheat bread with CP was a successful approach to increase its phenolics content and antioxidant activity. Furthermore, the addition of CP significantly decreased the in vitro digestibility of starch and predicted glycemic index. The addition of CPs, especially at higher concentrations, affected bread quality parameters—causing a decrease in bread volume and an increase in crumb hardness. Based on sensory evaluation, we recommend that CP can be incorporated into breads at levels up to 2 g/100 g flour for ‘Jinnan Shiqin’ and 1 g/100 g flour for ‘Ventura’ without decreasing the sensory quality of bread.

Acknowledgements

This study was financially supported by Anhui Natural Science Foundation (11008761) and the Anhui Science and Technology Plan Project (1704a07020098) and (NIlj20170144).

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Naifu Wang, Email: naifuwang@126.com.

Yan Xu, Email: 958424082@qq.com.

Huimei Chao, Email: 654464500@qq.com.

Min Zhang, Email: 1780431156@qq.com.

Yibin Zhou, Email: zhouyibin@ahau.edu.cn.

Mingchun Wang, Email: 52956869@qq.com.

References

- AACC . AOAC Official Method 991.43. Washington DC: American Association of Cereal Chemists; 1996. [Google Scholar]

- AACC . AOAC Official method 996.11. Washington DC: American Association of Cereal Chemists; 1996. [Google Scholar]

- AACC . Approved methods of the AACC. 10. St. Paul: American Association of Cereal Chemists; 2000. [Google Scholar]

- AACC . Approved methods of the AACC 10–05.01. St. Paul: American Association of Cereal Chemists; 2010. [Google Scholar]

- AACC . Approved methods of the AACC 54–60.01. St. Paul: American Association of Cereal Chemists; 2010. [Google Scholar]

- Atta A, Alkofahi A. Anti-nociceptive and anti-inflammatory effects of some Jordanian medicinal plant extracts. J Ethnopharmacol. 1998;60:117–124. doi: 10.1016/S0378-8741(97)00137-2. [DOI] [PubMed] [Google Scholar]

- Bae IY, Jun Y, Lee S, Lee HG. Characterization of apple dietary fibers influencing the in vitro starch digestibility of wheat flour gel. LWT Food Sci Technol. 2016;6:158–163. doi: 10.1016/j.lwt.2015.07.071. [DOI] [Google Scholar]

- Borczak B, Sikora E, Sikora M, Kapusta-Duch J, Kutyła-Kupidura EM, Fołta M. Nutritional properties of wholemeal wheat-flour bread with an addition of selected wild grown fruits. Starch-Stärke. 2016;68:675–682. doi: 10.1002/star.201500298. [DOI] [Google Scholar]

- Chareonthaikij P, Uan-On T, Prinyawiwatkul W. Effects of pineapple pomace fibre on physicochemical properties of composite flour and dough, and consumer acceptance of fibre-enriched wheat bread. Int J Food Sci Tech. 2016;51:1120–1129. doi: 10.1111/ijfs.13072. [DOI] [Google Scholar]

- Chen L, Tian Y, Zhang Z, Tong Q, Sun B, Rashed MMA, Jin Z. Effect of pullulan on the digestible, crystalline and morphological characteristics of rice starch. Food Hydrocolloid. 2017;63:83–390. [Google Scholar]

- Das L, Raychaudhuri U, Chakraborty R. Supplementation of common white bread by coriander leaf powder. Food Sci Biotechnol. 2012;21:425–433. doi: 10.1007/s10068-012-0054-9. [DOI] [Google Scholar]

- De la Hera E, Rosell CM, Gomez M. Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem. 2014;151:526–531. doi: 10.1016/j.foodchem.2013.11.115. [DOI] [PubMed] [Google Scholar]

- Englyst KN, Vinoy S, Englyst HN, Lang V. Glycaemic index of cereal products explained by their content of rapidly and slowly available glucose. Brit J Nutr. 2003;89:329–334. doi: 10.1079/BJN2002786. [DOI] [PubMed] [Google Scholar]

- Fakhfakh N, Jdir H, Jridi M, Rateb M, Belbahri L, Ayadi MA, Nasri M, Zouari N. The mallow, Malva aegyptiaca L. (Malvaceae): phytochemistry analysis and effects on wheat dough performance and bread quality. LWT Food Sci Technol. 2017;75:656–662. doi: 10.1016/j.lwt.2016.10.015. [DOI] [Google Scholar]

- Gavahian M, Chu YH, Lorenzo JM, Khaneghah AM, Barba FJ. Essential oils as natural preservatives for bakery products: understanding the mechanisms of action, recent findings, and applications. Crit Rev Food Sci. 2018 doi: 10.1080/10408398.2018.1525601. [DOI] [PubMed] [Google Scholar]

- Gawlik-Dziki U, Swieca M, Dziki D, Baraniak B, Tomilo J, Czyz J. Quality and antioxidant properties of breads enriched with dry onion (Allium cepa L.) skin. Food Chem. 2013;138:1621–1628. doi: 10.1016/j.foodchem.2012.09.151. [DOI] [PubMed] [Google Scholar]

- Gül H, Şen H. Effects of pomegranate seed flour on dough rheology and bread quality. CyTA-J Food. 2017;15:622–628. doi: 10.1080/19476337.2017.1327461. [DOI] [Google Scholar]

- Khan MA, Mahesh C, Semwal AD, Sharma GK. Effect of spinach powder on physico-chemical, rheological, nutritional and sensory characteristics of chapati premixes. J Food Sci Technol. 2013;52:2359–2365. doi: 10.1007/s13197-013-1198-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kooti W, Daraei N. A review of the antioxidant activity of celery (Apium graveolens L) J Evid-Based Compl Alt. 2017;22:1029–1034. doi: 10.1177/2156587217717415. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ktenioudaki A, O’Shea N, Gallagher E. Rheological properties of wheat dough supplemented with functional by-products of food processing: brewer’s spent grain and apple pomace. J Food Eng. 2013;116:362–368. doi: 10.1016/j.jfoodeng.2012.12.005. [DOI] [Google Scholar]

- Kurek MA, Wyrwisz J, Karp S, Wierzbicka A. Effect of fiber sources on fatty acids profile, glycemic index, and phenolic compound content of in vitro digested fortified wheat bread. J Food Sci Technol. 2018;55:1632–1640. doi: 10.1007/s13197-018-3061-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lauková M, Kohajdová Z, Karovičová J, Kuchtová V, Minarovičová L, Tomášiková L. Effects of cellulose fiber with different fiber length on rheological properties of wheat dough and quality of baked rolls. Food Sci Technol Int. 2017;23:490–499. doi: 10.1177/1082013217704122. [DOI] [PubMed] [Google Scholar]

- Li MY, Hou XL, Wang F, Tan GF, Xu ZS, Xiong AS. Advances in the research of celery, an important Apiaceae vegetable crop. Crit Rev Biotechnol. 2018;38:172–183. doi: 10.1080/07388551.2017.1312275. [DOI] [PubMed] [Google Scholar]

- Liu X, Mu T, Sun H, Zhang M, Chen J, Fauconnier ML. Comparative study of the nutritional quality of potato–wheat steamed and baked breads made with four potato flour cultivars. Int J Food Sci Nutr. 2016;68:167–178. doi: 10.1080/09637486.2016.1226272. [DOI] [PubMed] [Google Scholar]

- Luyts A, Wilderjans E, Van Haesendonck I, Brijs K, Courtin CM, Delcour JA. Relative importance of moisture migration and amylopectin retrogradation for pound cake crumb firming. Food Chem. 2013;141:3960–3966. doi: 10.1016/j.foodchem.2013.06.110. [DOI] [PubMed] [Google Scholar]

- Miller GL. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem. 1959;31:426–428. doi: 10.1021/ac60147a030. [DOI] [Google Scholar]

- Ning J, Hou GG, Sun J, Wan X, Dubat A. Effect of green tea powder on the quality attributes and antioxidant activity of whole-wheat flour pan bread. LWT Food Sci Technol. 2017;79:342–348. doi: 10.1016/j.lwt.2017.01.052. [DOI] [Google Scholar]

- Özkaya B, Baumgartner B, Özkaya H. Effects of concentrated and dephytinized wheat bran and rice bran addition on bread properties. J Texture Stud. 2017;49:84–93. doi: 10.1111/jtxs.12286. [DOI] [PubMed] [Google Scholar]

- Patil SS, Rudra SG, Varghese E, Kaur C. Effect of extruded finger millet (Eleusine coracan L.) on textural properties and sensory acceptability of composite bread. Food Biosci. 2016;14:62–69. doi: 10.1016/j.fbio.2016.04.001. [DOI] [Google Scholar]

- Peressini D, Sensidoni A. Effect of soluble dietary fibre addition on rheological and breadmaking properties of wheat doughs. J Cereal Sci. 2009;49:190–201. doi: 10.1016/j.jcs.2008.09.007. [DOI] [Google Scholar]

- Reshmi SK, Sudha ML, Shashirekha MN. Starch digestibility and predicted glycemic index in the bread fortified with pomelo (Citrus maxima) fruit segments. Food Chem. 2017;237:957–965. doi: 10.1016/j.foodchem.2017.05.138. [DOI] [PubMed] [Google Scholar]

- Rosell CM, Santos E, Collar C. Physical characterization of fiber-enriched bread doughs by dual mixing and temperature constraint using the Mixolab. Eur Food Res Technol. 2010;231:535–544. doi: 10.1007/s00217-010-1310-y. [DOI] [Google Scholar]

- Ross JA, Kasum CM. Dietary flavonoids: bioavailability, metabolic effects, and safety. Annu Rev Nutr. 2002;22:19–34. doi: 10.1146/annurev.nutr.22.111401.144957. [DOI] [PubMed] [Google Scholar]

- Saeed F, Ahmad N, Nadeem MT, Qamar A, Khan AU, Tufail T. Effect of arabinoxylan on rheological attributes and bread quality of spring wheats. J Food Process Preserv. 2016;40:1164–1170. doi: 10.1111/jfpp.12697. [DOI] [Google Scholar]

- Seczyk L, Swieca M, Dziki D, Anders A, Gawlik-Dziki U. Antioxidant, nutritional and functional characteristics of wheat bread enriched with ground flaxseed hulls. Food Chem. 2017;214:32–38. doi: 10.1016/j.foodchem.2016.07.068. [DOI] [PubMed] [Google Scholar]

- Sowbhagya HB, Srinivas P, Krishnamurthy N. Effect of enzymes on extraction of volatiles from celery seeds. Food Chem. 2010;120:230–234. doi: 10.1016/j.foodchem.2009.10.013. [DOI] [Google Scholar]

- Sumczynski D, Bubelova Z, Sneyd J, Erb-Weber S, Mlcek J. Total phenolics, flavonoids, antioxidant activity, crude fibre and digestibility in non-traditional wheat flakes and muesli. Food Chem. 2015;174:319–325. doi: 10.1016/j.foodchem.2014.11.065. [DOI] [PubMed] [Google Scholar]

- Swieca M, Seczyk L, Gawlik-Dziki U, Dziki D. Bread enriched with quinoa leaves-the influence of protein-phenolics interactions on the nutritional and antioxidant quality. Food Chem. 2014;162:54–62. doi: 10.1016/j.foodchem.2014.04.044. [DOI] [PubMed] [Google Scholar]

- Zhu F, Sakulnak R, Wang S. Effect of black tea on antioxidant, textural, and sensory properties of Chinese steamed bread. Food Chem. 2016;194:1217–1223. doi: 10.1016/j.foodchem.2015.08.110. [DOI] [PubMed] [Google Scholar]