Abstract

New trends in biomedical applications of the hybrid polymeric hydrogels, obtained by combining natural polymers with synthetic ones, have been reviewed. Homopolysaccharides, heteropolysaccharides, as well as polypeptides, proteins and nucleic acids, are presented from the point of view of their ability to form hydrogels with synthetic polymers, the preparation procedures for polymeric organic hybrid hydrogels, general physico-chemical properties and main biomedical applications (i.e., tissue engineering, wound dressing, drug delivery, etc.).

Keywords: organic hybrid polymeric hydrogels, natural polymers, medical applications, homopolysaccharides, heteropolysaccharides, polypeptides, proteins

1. Introduction

Hydrogels can be classified by taking into consideration many factors, such as source; preparation methods; network structure (as permanent (chemically crosslinked or irreversible), and non-permanent (physically crosslinked or reversible, hydrogen-bonded hydrogels); dimensions (macrogels, microgels, nanogels); sensitivity to stimuli (such as physical, chemical, and biochemical stimuli); charge of polymer network (nonionic, ionic, zwitterion, and amphoteric); physical aspect (micro-/nanoparticle, film, matrix, gel, etc.); configuration (amorphous and semicrystalline); composition (homopolymeric, multipolymeric or heteropolymeric, copolymeric, and interpenetrating polymer networks, hybrids, composites); degradability (biodegradable, bioabsorbable, bioerodible, and degradable in a controlled manner) (Scheme 1) [1,2].

Scheme 1.

Generally, hydrogels contain polar/charged functional groups which offer them hydrophilicity, water absorption capacity and, respectively, swelling in a certain medium, enhancement of their susceptibility to stimuli, etc. [3,4]. They can also differentiate in respect with their equilibrium swelling grade (SWD) as those low SWD hydrogels (20–50%), medium SWD hydrogels (50–90%), high SWD hydrogels (90–99.5%), and superabsorbent hydrogels (>99.5%) [5,6]. The hydrogels with high SWD show good permeability and biocompatibility [7] being preferred for use in the medical field.

Hybrid hydrogels definition is still debatable. They are defined either as a complex composed of hundreds of chemically or physically cross-linking nanogels [8], or it refers to systems combined with different polymers and/or with nanoparticles, such as plasmonic, magnetic, and carbonaceous nanoparticles, among others, or they are constituted by chemically, functionally, and morphologically distinct building blocks from at least two distinct classes of molecules, which can include biologically active polymers as polysaccharides and/or proteins, peptides, or nano/microstructures, interconnected via physical or chemical means [9]. Depending on the size and the nature of the building blocks, the hybridization can occur at molecular level or at microscopic scale [10,11].

For the purpose of this review, we refer only to the organic polymeric hybrid hydrogels containing natural polymers (Figure 1), defined according to the last definition and their medical applications (in medicine/nanomedicine).

Figure 1.

Schematic representation of organic hybrid hydrogels systems (adapted from [11]).

Each medical application involves the unique choice of a combination of the component materials, with the goal to match both desired structural and functional properties which must effectively produce an advanced polymeric system, with a new profile [12]. One of the most relevant examples is the combination protein/other polymers. Such combinations can be resulted by polymerization or conjugation (click chemistry) with synthetic polymers resulting compatible hybrid hydrogels both in vitro and in vivo as it was demonstrated by cell differentiation, proliferation, migration studies and drug delivery, tissue engineering, wound healing applications [13,14], respectively or sequestration of growth factors from the surrounding medium [15]. Commonly, the hybrid hydrogels are heterogeneous and this property is important to assure cell adhesion, organization, and cell–cell interactions required for medical applications [16,17,18,19].

1.1. Polymers Used in Hybrid Hydrogels

There are four main types of natural biodegradable polymers used in hybrid hydrogels described in this review—Table 1, including [20]: (1) homopolysaccharides, as: cellulose and derivatives, pullulan, dextran, starch, etc.; (2) heteropolysaccharides from which can be mentioned: chitosan/chitin and their derivatives [21], dextran, agarose, alginic acid and alginates, hyaluronic acid (HA), chondroitin and derivative sulphates, heparin, pectin, etc. (3) polypeptides/proteins, such as gelatin, collagen, albumin, fibrin and fibrinogen, soy and whey proteins, silk, Matrigel™, etc., and genetically engineered proteins [22,23,24] (calmodulin (a calcium-binding protein), elastin-like polypeptides, leucine zipper) [25]; (4) deoxyribonucleic acid (DNA) and ribonucleic acid (RNA) [26]. The protein/polysaccharide hybrid polymers like fibrin/cellulose, collagen/HA, gelatin/alginate and many others etc. were studied [27] and other many combination make now topics of undergoing researches. Lignin was also used [28,29]. Most of them are components of the extracellular matrix (ECM) in vivo. Their composition (bovine fibrinogen, rat tail collagen, etc.) may vary with source and processing method, being difficult to control their microstructures, properties and reproducibility between experiments.

Table 1.

Natural polymers used in organic hybrid hydrogels for medical applications.

| Polysaccharides | Polypeptides and Proteins | Polynucleotides and Others | |

|---|---|---|---|

| Homopolysaccharides | Heteropolysaccharides | ||

Cellulose and derivatives (carboxymethylcellulose, hydroxyethyl cellulose; hydroxypropylcellulose methylcellulose hydroxypropylmethylcellulose; cellulose acetophphalate)

|

|

|

|

Synthetic polymers commonly used in the hybrid hydrogels preparation can be classified into three main types: non-biodegradable [30,31], biodegradable [32], and bioactive polymers [33]. Most common synthetic polymers are: poly (lactic acid) (PLA), poly (ε-caprolactone) (PCL), poly(glycolic acid) (PGA) and copolymers [34], poly (ethylene glycol) (PEG) and poly(vinyl alcohol) (PVA) [35,36,37,38] to produce biodegradable hydrogels. Hydrogels may include vinyl monomers like 2-hydroxyethyl methacrylate (HEMA), N-isopropyl acrylamide (NIPAAm), 2-hydroxypropyl methacrylate (HPMA), acrylamide (AAm), acrylic acid (AAc) or macromers [37,38,39], methoxyl poly(ethylene glycol) (PEG), monoacrylates (mPEGMA or PEGMA), and diacrylates (PEGDA), ethylene glycol diacrylate (EGDA), Pluronic® polymers, etc. [39].

By combining the properties of synthetic and natural polymers to form hybrid hydrogels, a direct approach is created for bioactive hydrogel scaffolds for tissue engineering.

Comparatively with natural polymers, the synthetic polymers are easily synthesized even at large scale by polymerization, cross-linking, and functionalization (modification by block structures, by blending, copolymerization), their molecular structure, molecular weight, physical and chemical properties (mechanical strength, biodegradability [40,41]) are more reproducible, this aspect being critical for the medical applications mainly scaffolding. Unfortunately, applications of synthetic hydrogels as biomaterials are limited by their absence of bioactivity. The protein-polymer hybrid networks with complex abilities, including bioactivity, stimuli-responsiveness, catalytic activity, or ability to regulate cell behaviors have been/are created to overcome this limitation, maintaining good mechanical properties of materials [42,43,44,45,46].

1.1.1. Microgel

The term microgel describes a variety of particles that differ substantially in structure, physico-chemical properties, preparation and application and is interchangeably with terms such as nanogel, microsphere and macrogel depending on the numerous particle types falling within the broad sphere of nano-/microparticle shapes and sizes [47,48,49,50].

1.1.2. Hybrid Nanogels

Hybrid nanogels later developed are highly crosslinked nano-sized hydrogel systems [47,48] with diameter less than 100 nm [49,50] having a non-fluid colloidal/polymer network that combine the properties of both hydrogels and nanomaterials. The nanoscale provides a large surface area for bioconjugation, long time of circulation in blood, and the possibility of being actively or passively targeted to the desired site of action (e.g., tumor sites) [10]. Hybrid smart hydrogels/nanogels show the ability to respond to biomedically relevant changes like pH, temperature, ionic force/concentration, redox environment, light, glucose, magnetic field, electrical field, chemicals or specific biomarkers etc., by changing their volume, refractive index, and hydrophilicity/hydrophobicity etc. Micro- and nano-sized hydrogels are faster in responding to changes in their environment than their macroscopic or bulk counterparts and can be used more efficiently in medical and sensor applications [51].

1.1.3. Multifunctional Hybrid Nanogels

Multifunctional hybrid nanogels found applications in medical field/nanomedicine for continuous monitoring by optical sensing to mentioned stimuli in complex samples such as blood and bioreactor fluids as well as for intracellular imaging, contributing to the explanation of intricate biological processes, the development of novel diagnoses and therapy toward clinical applications. [52].

1.1.4. Hybrid Polymer Nanogel/Hydrogels

Hybrid polymer nanogel/hydrogels include interpenetrated networks (IPNs) and core-shell particles. The core-shell strategy is especially useful for targeting therapy, while the interpenetration allows the development of multiresponssive nanogels and the control of the drug release profile [53].

1.1.5. Physical Hydrogels

Physical hydrogels result by ionic and physical interactions, such as hydrogen bonds, coordination bonds, electrostatic and hydrophobic interactions in certain conditions and physico-chemical interactions (stereo-complexation, charge condensation, or supramolecular chemistry) [54]. By changing the temperature, pH, ionic strength or solvent composition, they form a homogeneous solution and re-gel when they return to their initial conditions, being reversible gels, generally unstable and mechanically weak [55]. The physical cross-links are also formed by crystallization, [56] between amphiphilic block and graft copolymers [57], and protein interactions [58]. Physically crosslinked hydrogels show stimuli-responsiveness and self-healing properties, but their mechanical strength is low and they often exhibit plastic flow [59].

1.1.6. Chemically or Covalently Crosslinked Hydrogels

Chemically or covalently crosslinked hydrogels with a permanently fixed shape at rest, exhibit a low fracture toughness and extensibility. Therefore, it is preferred to create both physically and covalently crosslinking hydrogels [60,61], resulting doubly-crosslinked hybrid gels that combine all mentioned properties [62]. Many double network (DN) hydrogels prepared by double chemically crosslinking or by hybrid physical/chemical crosslinking imply crosslinking agents, but they present toxicity which is an important disadvantage. Designing a new generation of DN gels comprising two non-covalent associated networks is a promising technique.

Kondo and coworkers [63] prepared a dually-crosslinked polymer gel with a very homogeneous network architecture, using a tetra-arm star-shaped poly(ethylene glycol) (PEG), PEG and poly(dimethylsiloxane) (PDMS) building blocks linked by orthogonal cross-coupling, The obtained network from hydrophilic and hydrophobic components regularly and uniformly distributed is non-covalent hydrophobic association whose strength is tuned by the molar ratio of the hydrophilic PEG and the hydrophobic PDMS segments [64].

1.1.7. Self-Assembling Hybrid Hydrogels

Self-assembling hybrid hydrogels containing peptides provide the desired biological functionality and biodegradability, are able to mimic biological structures and materials having direct biomedical applications, namely as carriers for drug and cell delivery (e.g., incorporation of bioactive sequences from natural proteins). To control mechanical, biocompatibility and degradation properties, the peptides are combined with polymeric networks [65,66] by chemical modification, covalently linking or non-covalent interactions between peptides and polymers [67].

Hybrid hydrogels self-assembled from graft copolymers via formation of coiled coil antiparallel heterodimers was also demonstrated [68], based on HPMA copolymers backbone and a pair of oppositely charged peptide grafts. The formation of these hybrid hydrogels was reversible [68]. A DNA/poly(lactic-co-glycolic acid) (PLGA) hybrid hydrogel (HDNA) was prepared for water-insoluble ophthalmic therapeutic delivery of dexamethasone and it may be applied in treatment of various eye diseases [69].

1.1.8. Interpenetrated and Semi-Interpenetrated Polymer Networks

To enhance the mechanical strength, the swelling/deswelling response, and to add new sensitivities to a nanogel, multicomponent networks as full IPNs and semi-IPNs (sIPNs) were prepared by simultaneous synthesis and sequential synthesis involving two or more polymers [70,71]. The reaction can take place in the presence of a crosslinking agent, in order to form a complete IPN or in the absence of the crosslinking initiator, to form a sIPN.

1.1.9. Core-Shell Polymer Networks

The most common techniques of synthesis of core-shell nanogels are the seed precipitation polymerization, crosslinking of amphiphilic micelles preformed by self-assembly or the reversible addition–fragmentation chain-transfer polymerization (RAFT) [72,73,74,75,76,77].

Several examples of hybrid polymeric hydrogel include:

1.1.10. Supramolecular Hydrogel

Supramolecular hydrogel are builded by blocks of peptides and polymers by the coupling/conjugation of specific peptide sequences (cell adhesive and/or enzymatically cleavable) to polymer chains. In such a way is obtained controlled cell responses (adhesion, migration, differentiation) because the components can self-assembly into hybrid hydrogels either, as peptide-polymer conjugates or combining individual components. These will determine the properties of the hydrogels (as stiffness, mesh structure, responsiveness, and biocompatibility) [84], cooperative folding/unfolding transitions control over the structure formation at the nanometer level. The new produced materials may possess unprecedented levels of structural organization and novel properties [85]. By optimizing the amino acid sequence, responsive hybrid hydrogels tailor-made for a specific application may be designed. Hybrid peptide/polymer molecular hydrogel design and synthesis showed significant research progress to mimic the natural proteins molecular architectures, dynamic responsiveness, and cellular functions, combined with tunability and processability provided by the synthetic polymer constituents.

2. Preparation Procedures for Polymeric Hybrid Hydrogels

2.1. Routes to Obtain Hybrid Hydrogels

Crosslinking techniques can be: (i) physical crosslinking (achieved by using repeated freezing/thawing cycles and led to cryogels) by ionic interaction, complex coacervation or H-bonding; (ii) chemical crosslinking or grafting by polymerization, co-polymerization, chemical conversion (using crosslinking agents such as borates, glyoxal, glutaraldehyde, etc.), and (iii) irradiation crosslinking or grafting (electron beam or gamma radiation, depending on irradiation dose). The properties of hydrogels can be controlled by different parameters, such as structures, by cross-linking type, end density, and synthesis of polymers, while in the case of physical hydrogels, by environment conditions (as pH, temperature, ionic strength etc.).

Chemically cross-linked gels are obtained by radical polymerization/crosslinking, emulsion, reverse microemulsion, inverse miniemulsion, heating, irradiation (ultraviolet, high-energy radiation, especially gamma and electron beams), photolithographic chemical reactions via crosslinker as di-sulfide crosslinking, ionic, click chemistry (such as azide-alkyne cyclo-addition reactions, thiol-ene couplings, Diels-Alder reactions and tetrazine-norbornene chemistry), Schiff base crosslinking with a huge ensemble of reactions, such as Michael type reaction, Michaelis-Arbuzov reaction, and nucleophile addition [86], and enzymatic cross-linking [87]. Both chemical and physical cross-linking approaches are employed for hydrogels preparation [2].

A breakthrough toward the synthesis of complex structures with a high degree of functionality and compositional variety is the utilization as synthesis ways the controlled/living radical polymerization technique such as the catalytic atom (group) transfer radical polymerization (ATRP), degenerative chain transfer polymerization represented by iodine-mediated polymerization (RITP), and reversible addition-fragmentation chain transfer polymerization (RAFT) [88]. A new strategy of hybrid hydrogels synthesis entails the non-covalent attachment of genetically engineered coiled-coil protein motifs to hydrophilic synthetic HPMA copolymer backbone. The physical crosslinking was established by self-assembly of the coiled-coil domains [89].

2.1.1. Chemical Modifications

Chemical modifications involve a plenty of ligands which can be used for targeted drug delivery, stimulus responsive drug release or preparation of complex materials. The cross-linking of the hybrid network and conjugating proteins to the gel backbone as a platform for immobilizing functional proteins was reported by Lim et al. [90].

2.1.2. Functionalization

Hybrid hydrogels/nanogels can also be surface functionalized with specific ligands to achieve targeted therapy and reduce toxicity [91]. Functionalization is also important in order to create different types of macro/micro/nanogels morphologies, as hairy microgels, core-and-shell, hallow, multilayer microgels, [92] etc.

2.1.3. Stealth Functionalization

Hybrid nanosystems/nanogels for drug delivery and biomedical purposes need a non-secondary requirement, as their biocompatibility necessary both to reduce the inflammatory or the immune response of the organism, and to improve blood circulation lifetime, biodistribution, and bioavailability of the carried drugs and also to overcome the self-defense mechanisms present in the bloodstream of the host organism. To achieve this requirement the hybrid nanogels must be specifically designed. A very wide variety of architectures result by their decoration, modification, and functionalization, [93], or they can be modified by conjugation with both organic [94] and inorganic [95] types of nanoparticles and nanostructures. The morphologies of hybrid nanogels vary both with the particle type and the assembly technique, each component being either core or shell, of different size and architecture [96]. These variable morphologies may be obtained by chemical reactions or through physical crosslinking based on hydrogen bonds, ionic interactions, and other intermolecular bonds. Therefore, a proper surface decoration and its biocompatibility, is a parameter capable of strongly influencing the biodistribution together with the dimensions, the surface charge and the ligands interaction. Many stealth functionalizations exploit hydrophilic polymeric chains, as polyethylene glycols or chitosan.

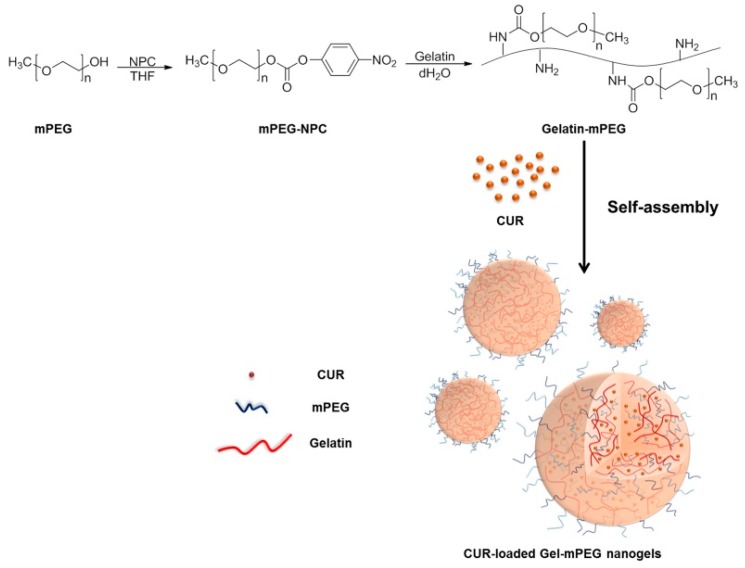

2.1.4. PEGylation

PEGylation is a solution to increase the bioavailability of the decorated nanostructures and to extend the circulating lifetime [97]. After this modification a protein corona is formed around the antifouling PEG functionalization [98]. It will create a hindered zone around the nanoparticles and reduces the wrapping by plasma proteins and the subsequent uptake by macrophages PEGylation depends on many factors such as hydrophilicity of the PEG chains, molecular weight (MW) which vary from 2000 to 13,000 Da.

2.2. Processing Methods

Processing methods include [1]: solution casting/drying, theta gelation, freezing or freezing/pressurizing, freeze drying, emulsion freeze drying, inverse microemulsion polymerization technique, solution blowing, electrospinning, coagulation treatment, CO2-in-water emulsion, sol-gel method/thermal annealing, CO2 bubbles template freeze drying, high hydrostatic pressure [HHP] method, supercritical gel-drying. Other new synthesis methods include the implementation of click chemistry reactions [99], photo-patterning, and rapid prototyping, 3D printing for the facile production of hybrid hydrogels, self-assembly [100,101], the use of biological molecules and motifs to promote a desired cellular outcome, and the tailoring of kinetics and transport behavior to obtain desired biomedical outcomes [102]. 3D bioprinting of hydrogels is performed in accordance with the native tissue architecture therefore it is expected to result in a new generation of engineered tissues. Bakarich et al. [103] fabricated by a new 3D-printing approach an interesting material with good mechanical performance based on κ-carrageenan and poly(oxyalkylene amine) (Jeffamine) based ionic-covalent entanglement hydrogels. The carrageenan induced a fast gelation, a structural integrity to the hydrogel system and thermoresponsiveness, while the epoxy-amine reaction to form covalent bonding takes place an ambient temperature for covalent bond formation.

Hydrogels and their products can be obtained in a wide range of shapes as temporary or permanent shape, shape memory, smart shape memory, quadruple-shape, sponges, soft or rigid, stretchable, films, sheets, bilayer, micro/nanoparticles with defined shapes, ultrathin microcapsules, matrix, scaffolds, hollow cube, hemisphere, pyramid, cylindrical, twisted bundle, patches for wound dressing, artificial ear, nose, and many others.

3. Properties

The specific physico-chemical key properties of the hybrid hydrogels are: remarkable thermodynamic stability, elevated capacity of solubilization, mildness, density, swelling/deswelling, high-water content and permeability, low surface tension and relative low viscosity, stiffness, mesh structure and size, responsiveness, biocompatibility and biodegradability (so avoiding its accumulation in the organs), non-immunologic response and capability of undergoing vigorous sterilization techniques [48], as well as their tunable viscoelasticity and structural similarity to the ECM. Their properties can be fine-tuned through selection of the hydrogel components (chemical composition), hydrophobicity/hydrophilicity ratio, and cross-linking strategy, crosslinking density etc. Hydrogels are commonly considered as highly biocompatible, owing to the high-water content and also to the physico-chemical similarity with the native ECM. Chemically cross-linked synthetic polymeric hydrogels have higher mechanical properties compared to self-assembling (physically crosslinked) systems, thanks to the high molecular weight of polymer materials, but they lack biological functionality, while self-assembling hydrogels, formed through physical cross-links, allow minimally invasive implantation in the body.

3.1. Swelling

The swelling of hydrogels is a process occurring in three steps, namely: (a) diffusion of water molecules into hydrogel network, (b) hydration of polymeric chains and their relaxation and (c) expansion of crosslinked polymeric network. The primary and secondary bound water is uptaken by the network by its interaction with the polar and hydrophobic sites, respectively and then the network is imbibed with additional water which is named free water. Finally at an infinite dilution to a maximum, level equilibrium water content is reached. The determination of swelling behavior is the main assay to establish the hydrogel quality, as it is also a means to evaluate other properties as: crosslinking degree, mechanical properties, degradation rate, etc. Swelling properties of the stimuli responsive hydrogels are significantly changed by the modification in parameters of the surrounding environment (i.e., temperature, pressure, pH, solvent composition, ionic strength, electrical potential, etc.). The polymeric hybrid hydrogels exhibit biodegradability and biocompatibility, high permeability, to oxygen, nutrients, and to water-soluble metabolites, being promising carriers and for cells encapsulation. They resemble with natural soft tissues [41,104] being very useful in regenerative medicine, for tissue scaffold or therapeutic transfer systems, promoting cell attachment and proliferation [2].

3.2. Mechanical Properties

The mechanical properties can be varied and tuned by changing the crosslinking degree, or lowered by heating. To seed osteoblast cells, it is necessary a more stiff material than in the case of adipocyte culture, as for this is also requirement for the development of a heterogeneous prosthetic device, as substitute for the intervertebral disc. The elastic nature of hydrated gels has been found to minimize irritation to the surrounding tissues after implantation.

3.3. Responsiveness

Generally, hydrogels have weak mechanical properties and a slow or delayed response to external stimuli. Novel hydrogel designs substantially enhanced mechanical properties and by creating the superporous and comb-type grafted hydrogels fast responses to external stimuli were obtained as also was done by development of self-assembling hydrogels from hybrid graft copolymers with property-controlling protein domains, and genetically engineered triblock copolymers containing hydrogels.

The low interfacial tension between the gel surface and body fluid minimizes protein adsorption and cell adhesion, reducing the chances of negative immune reactions [105].

3.4. Porosity and Permeation

The average pore size, the pore size distribution, and the pore interconnections included together in the parameter called « tortuosity » are important factors for a hydrogel matrix. They are influenced by the composition and the crosslink density of the hydrogel polymer network. Pores can show different morphologies: they can be closed, open as a blind end or interconnected, again divided in cavities and throats.

Net charge of the polyelectrolyte hydrogel is determined by the initial concentration of the cationic and/or anionic monomer.

Crosslinking influences all the other properties of the hydrogels. By controlling the crosslinking degree, the materials with tunable and optimized properties destined to different applications can be obtained [106].

The micro-/nanogels are valuable materials as drug-delivery carriers because they show high loading capacity, good stability, and reversible volume change in response to environmental stimuli (such as pH, temperature, and glucose level) [93].

4. Applications

Hydrogels remain the most appealing candidates for tissue engineering scaffolds. The development of hybrid hydrogels constituted from different polymers is based on numerous resources and they are applied for regenerative medicine, tissue engineering (including: bone regeneration [107,108,109,110], cartilage tissue, vascular tissue, cardiac tissue, cardiovascular tissue, meniscus tissue, human prostate tissue, skin tissue/wound, and other tissues), wound healing, artificial cornea, drug/gene delivery, cancer cells, nucleus pulposus bioelectronic interfaces due to their structural similarity to the natural ECM, inherent biocompatibility, tunable viscoelasticity, tunable physical and mechanical properties, and their ability to form scaffolds for different tissues, high-water content and high permeability for oxygen and essential nutrients [11]. Biomedical applications of hydrogels as the first materials developed for uses inside the patient started from the decade of 70 s [111].

It is considered that the development of the hydrogels for medical applications known three steps [100,112]. The first generation of hydrogels is characterized by various crosslinking procedures involving the chemical modifications of a monomer or polymer with an initiator to develop materials with high swelling and good mechanical properties. The second generation of materials is that capable to respond to specific stimuli (temperature, pH, ionic strength, different external fields or concentration of specific bioactive molecules etc.), known as smart hydrogels. Finally, the research for the third generation of hydrogels was focused on the investigation and development of hybrid, stereo complexed materials (e.g., PEG-PLA interaction) with a wide spectrum of tunable properties and trigger stimuli [113,114]. This last stage aimed to develop the so called “smart hydrogels” with a variety of possible applications. Hybrid hydrogels based on both natural and synthetic polymers offer infinite possibility to cells encapsulation, as matrices for repairing and regenerating a wide variety of tissues and organs [115], are capable of responding to biological signals in vivo or remote triggers and other many possible applications in biomaterials, biomedicine and nanomedicine [116].

Other important applications are [102] (Scheme 2): wound dressing/healing, treatment of severe burns, drug delivery/controlled release, injectable hydrogels, vaccines, cancer treatment, autoimmune disease, neurodegenerative disease, anti-inflammatory, ophthalmology, etc.

Scheme 2.

Biomedical applications of hydrid hydrogels based on natural and synthetic polymers.

Particularized examples of medical applications of hybrid hydrogels are described in the following sections.

5. Homopolysaccharides-Based Hybrid Hydrogels

5.1. Ability of Homopolysaccharides to Form Hybrid Hydrogels

Homopolysaccharides (HP) are subdivided into straight chain and branched chain ones, into plant polysaccharides, animal polysaccharides, microbial/bacterial polysaccharides, and seaweed polysaccharides.

Most homopolysaccharides can form hydrogels due to their intrinsic properties and the gel formation is generally driven by physical interactions. Amongst the plant-derived homopolysaccharides, cellulose and its derivatives possess plentiful hydrophilic functional groups (such as hydroxyl, carboxyl, and aldehyde groups) in the backbone that can be used to prepare hydrogels [117]. Starch is the most abundant storage polysaccharide in plants and includes two main structural components, namely amylose and amylopectin. The synthesis of starch hydrogels is determined by important features such as gelatinization and retrogradation, which are in turn affected by amylose and amylopectin ratio [118]. The hydrogels obtained from native starch, pure starch components and their derivatives are hydrophilic and of great significance in the biomedical domain because of their good swelling capacity in water, biocompatibility and biodegradability [119]. Carrageenan (CG) family of polysaccharides are soluble in hot water (>60 °C) and forms thermoreversible gels in a process that is dependent on temperature (when dropped down to 30 °C–40 °C gelation occurs) and the type of ions [120]. Due to the structural resemblance to glycosaminoglycans (GAGs) (that is a component of natural extracellular matrix—ECM) and its fine physical functional properties, CG is extensively used in biomedical applications. Formation of gellan gum (GG) (a linear anionic exopolysaccharide) –based hydrogels takes place in the presence of mono-, di- and trivalent cations and depends on the temperature [121].

5.2. Biomedical Applications of Homopolysaccharides-Based Hydrogels

Homopolysaccharides native or modified with the various conjugates have been extensively used to develop organic hybrid hydrogels, for combating last-ditch biomedical challenges. In Table 2 are listed the several examples of components in homopolyssaccharide-based organic hybrid hydrogels, their synthesis pathways and medical applications.

Table 2.

Examples of homopolysaccharide-based organic hybrid hydrogels, their obtaining methods and medical applications.

| Homopolysaccharide | Synthetic Component | Obtaining Method | Application | References |

|---|---|---|---|---|

| Cellulose | PVA and poly(acrylic acid-co-acrylamide-co22-acrylamido-2-methyl-1-propanesulfonic acid) | Graft copolymerization | In vitro gastrointestinal release of amoxicillin | [122] |

| PVA | Freezing/thawing (FT) cycles | 2D-layered skin model | [123] | |

| poly 2-(dimethylamino) ethyl methacrylate (PDMAEMA) | In situ radical polymerization | pH/temperature-responsive hydrogel | [124] | |

| Cellulose nanocrystal (CNC) | polyacrylamide (PAAm) | In situ polymerization (hydrophilic cross-linker PEGDA575) | Scaffolds for tissue engineering | [125] |

| Cellulose nanofibers | PAAm | Alkali treatment | Bio-medical load-bearing gel materials | [126] |

| CNC | PAAm and chitosan | Schiff base linkages and covalent crosslinking | Controlled drug release and dye adsorption | [127] |

| Bacterial cellulose (BC) | PAAm | Microwave irradiation | Oral drug delivery vehicles | [128] |

| poly(acrylic acid) (PAA) | Grafting by electron beam irradiation | Oral protein delivery | [129] | |

| poly(acrylic acid-co-acrylamide) | Microwave-assisted graft copolymerization | Controlled drug release | [130] | |

| poly(2-hydroxyethyl methacrylate) (PHEMA) | In situ UV radical polymerization | Cartilage, stent, and certain wound-dressing materials | [131] | |

| PGA | 60Co γ-irradiation crosslinking | Antibacterial contact materials | [132] | |

| poly(N-isopropylacrylamide) (PNIPAAm) | Atom transfer radical polymerization (ATRP) | Thermoresponsive hydrogels | [133] | |

| Hemicellulose grafting maleic anhydride (MA) | N-isopropylacrylamide (NIPAAm) | UV photocrosslinking | Smart biomaterials | [134] |

| Hydroxypropyl cellulose (HPC) | poly (l-glutamic acid-2-hydroxyethyl methacrylate) | Emulsion polymerization | Oral insulin controlled release | [135] |

| Hydroxyethyl cellulose (HEC) | PAA | Physical blending | pH-responsive material | [136] |

| Carboxymethyl cellulose (CMC) | PNIPAAm | Copolymerization | Protein delivery | [137] |

| carboxymethyl polyvinyl alcohol (CMPVA) | Grafting copolymerization (adipic dihydrazide as crosslinker) | Drug delivery and as scaffold in tissue engineering | [138] | |

| poly(dimethylamino ethyl methacrylate) (PDMAEMA) |

Chemical grafting | Protein-drug delivery | [139] | |

| PEG (norbornene immobilized tetra-arm PEG) | Chemical cross-linking (dithiothreitol as co-crosslinker) | pH-sensitive protein drug carrier | [140] | |

| CMC acrylate | PEO-hexa-thiols | Michael type addition reaction | Scaffolds for tissue engineering | [141] |

| Methacrylate carboxymethyl cellulose (MACMC) | NIPAAm | Polymerization of NIPAAm in presence of CMC and redox crosslinking | Protein delivery | [137] |

| Starch | AAc | Potassium persulfate (KPS)-initiated graft copolymerization; in the presence of N,N′-methylene bisacrylamide (MBA) as cross-linker | Colon-targeted oral drug delivery | [142] |

| NIPAAm | Polymerization of NIPAAm using ammonium persulfate (APS) and N,N,N′,N′-tetramethylethylenediamine (TEMED) as a pair of redox initiators and MBA as the cross-linker | temperature-sensitive hydrogel | [143] | |

| AAm and vinyl pyrrolidone (VP) | CAN-initiated free radical solution polymerization in the presence of MBA | Drug release | [144] | |

| polyvinylamine | In situ crosslinking using starch decorated with cholesterol group and aldehyde groups | Drug release | [145] | |

| AAc | 60Co-gamma-radiation-induced graft polymerization | Drug delivery | [146] | |

| PVA | Gamma and electron beam radiation | Not tested yet | [147] | |

| Maize starch modified with allyl chloride | methacrylic acid and acrylamide | Copolymerization using KPS as initiator | Not tested yet | [148] |

| Carboxymethyl starch (CMS) | poly methacrylic acid (MAA) | Free radical graft copolymerization using bisacrylamide as a crosslinking agent and persulfate as an initiator | Drug release | [149] |

| Pullulan | Poly(l-lactide) (PLLA) | Graft copolymerization | Triggered drug release | [150] |

| PVA/ Poly-l-Lysine/Gelatin |

FT method | Wound healing | [151] | |

| Oxidized pullulan (C6-OOH groups) | PVA | FT method | Wound dressing | [152] |

| Methacrylated pullulan (PULMA) | NIPAAm | Polymerization of NIPAAm using KPS as initiator and N,N,N′,N′-tetramethylethylenediamine as an accelerator | Proposed as temperature-responsive drug delivery system | [153] |

| Carboxymethyl pullulan (CMP) | PNIPAAm | Chemical cross-linking of NIPAAm in the presence of CMP followed by additional reticulation of CMP | Drug delivery | [154] |

| Cholesteryl-modified pullulan (CHP) | PNIPAAm | Graft free-radical copolymerization | Not tested yet | [155] |

| CHP | copolymer of NIPAAm and N-[4-(1-pyrenyl)butyl]-N-n-octadecylacrylamide] (PNIPAAm -C18Py) | Self-assembly | Not tested | [156] |

| Acrylate group-modified cholesterol-bearing pullulan (CHPANG) | Thiol group-modified poly (ethylene glycol) | Michael addition | Protein delivery | [157] |

| Acryloyl group modified-cholesterol-bearing pullulan (CHPOA) | Poly(methacrylic acid-g-ethylene glycol) (P(MAA-g-EG)) | Surface-initiated and bulk photopolymerization | Drug delivery | [158] |

| pentaerythritol tetra (mercaptoethyl) polyoxyethylene | Michael addition followed by freezing-induced phase separation | Advanced scaffold | [159] | |

| CG | poloxamer 407 copolymer (ethylene oxide and propylene oxide blocks) | Blending | Vaginal gel | [160] |

| ι-CG | PVA | FT technique | Cell adhesion | [161] |

| PEO | Blending with retinoic acid gel and Emulgen® 408 | Skin topical treatment | [162] | |

| κ-CG | PAAm and sodium alginate (SA) | Graft-copolymerization | Intestinal targeted drug delivery | [163] |

| PCL | Gel infusion within interpenetrating network (IPN) scaffolds of PCL incorporated with sucrose | Regenerative tissue engineering | [164] | |

| Poly(diethylacrylamide) (PDEA) | Crosslinking with methylene bisacrylamide | Not tested yet | [165] | |

| PNIPAAm | Electron beam radiation technique | Not evaluated yet | [166] | |

| PAAm | Dual physical-crosslinking strategy (hydrophobic associations and potassium ion (K+) cross-linking) | Cell culture | [167] | |

| PAA and super paramagnetic iron oxide nanoparticles (SPION) | Graft-copolymerization | Drug delivery | [168] | |

| poly(vinylpyrrolidone) (PVP) | Gamma irradiation | Wound healing | [169] | |

| PVP and PEG | 60Co gamma irradiation | Wound healing | [169] | |

| poly(oxyalkylene amine) | 3D-printing approach based on ionic-covalent entanglement | Not tested | [103] | |

| GG | PAAm | Cross-linking by Ca ions | Not evaluated | [170] |

| PEG | Ionic cross-linking with CaCl2 | Regenerative tissue engineering | [171] | |

| Polyethylene glycol diacrylate (PEGDA) | UV photo-crosslinking | Stem cells culture | [172] | |

| Poloxamer-Hep copolymer | Ionic cross-linking with CaCl2 | bone marrow stem cells delivery | [173] | |

| PVA | Emulsion cross-linking method | Drug delivery | [174] | |

| Gellan unsaturated esters | NIPAAm | Functionalization of GG with acrylic acid, acryloyl chloride or maleic anhydride and further co-polymerization | Not tested | [175] |

| Gellan maleate | NIPAAm | Free radical grafting/polymerization | Ocular inserts | [176] |

| Methacrylated gellan gum (MGG) | cationic polyurethane nanoparticles (CPUNs) | UV free radical polymerization | Tissue engineering | [177] |

5.2.1. Tissue Engineering

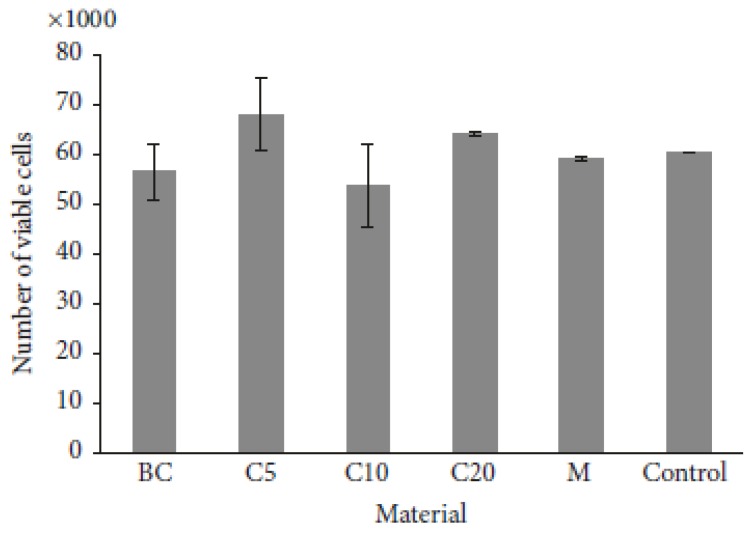

Multicomponent hydrogels based on PHEMA matrix and BC nanofibers were successfully prepared by in situ UV radical polymerization of HEMA monomer impregnated into wet BC nanofibrous structure. Biocompatibility tests demonstrated that BC-PHEMA hydrogels are non-toxic providing a favorable environment for proliferation of marrow stem cells isolated from rabbits (rMSCs)—Figure 2. Therefore, the obtained hydrogels can be seen as promising for application in the tissue engineering area, particularly in tissue replacement and wound healing [131].

Figure 2.

Number of viable rMSCs afer 72 h of growth onto BC-PHEMA hydrogels determined by cell viability AlamarBlue Assay (Reprinted from [131], open access Hindawi).

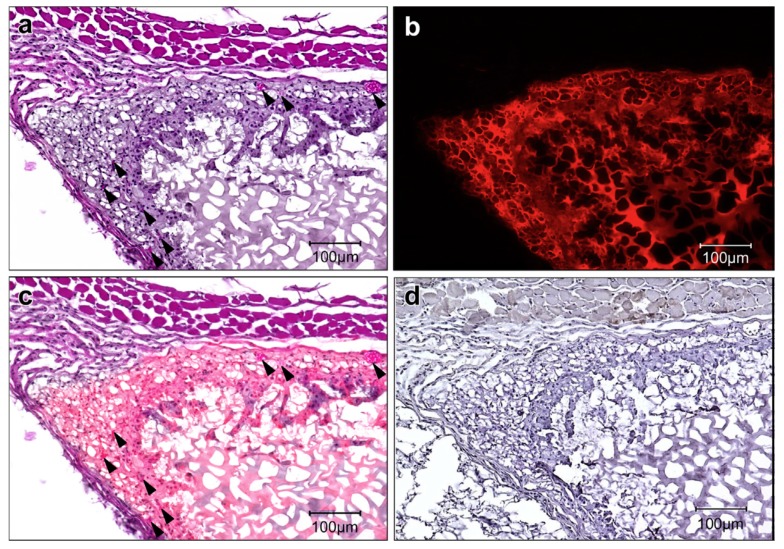

PAAm/cellulose nanofibers (CNF) DN gels were synthesized by simply using an alkali treatment (15 wt % NaOH) at room temperature. Investigating the morphology of this DN gel it was noticed that the CNF network was embedded in the PAAm matrix, in this manner improving the strength of these hybrid gels. The obtained PAAm/CNF DN gels present notably improved mechanical properties that are proper for application as biomedical load-bearing gel materials [126]. Hydrogels based on PVA blended with cellulose (PVA-Cel) were obtained through FT cycles and were evaluated in terms of appropriateness as a part of a structure simulating the length scale dependence of human skin [123]. CMC-PEO hydrogels and porous gel films, with excellent biocompatibility, were prepared by mixing CMC-acrylate and PEO-hexa-thiols, as precursor solutions. The porous gel films were obtained by using ammonium bicarbonate particles as porogens, prior added in the precursor solutions. The obtained hydrogels and gel films show significant potential for tissue engineering applications [141]. Hashimoto et al. [159] has fabricated an amphiphilic crosslinked porous nanogel (NanoCliP), which self assembles, and presents the ability to embedded proteins, liposomes, and cells. This NanoCliP gel was synthetized using Michael reaction, by addition of a self-assembled nanogel of acryloyl group-modified cholesterol-bearing pullulan to pentaerythritol tetra (mercaptoethyl) polyoxyethylene, followed by freezing-induced phase separation. The in vivo tests show that the NanoCliP gel brings suitable features as a scaffold for tissue engineering, demonstrating improved cell infiltration, tissue ingrowth and neovascularization as observed from Figure 3.

Figure 3.

Histology of subcutaneously implanted NanoCliP gel in mice. (a) H&E staining of the NanoCliP gel 4 weeks after transplantation. Arrows indicate the newly formed vessels in the NanoCliP gel. (b) The confocal LSM image of the rhodamine-labeled NanoCliP gel confirms that the NanoCliP gel has remained in situ. (c) Superimposed image of a and b shows the region containing the remaining NanoCliP gel. (d) F4/80 staining shows no monocytes and macrophages in or around the transplanted NanoCliP gel. Scale bar ¼ 100 mm: with permission from [159]. Copyright 2020 Elsevier.

Zhang et al. [161] fabricated PVA-i-CG based organic hybrid hydrogels, via a facile FT technique, as tissue engineering scaffolds. The hydrogels demonstrated increased pore structure stability, enhanced attachment and proliferation of ATDC5 cells, good hemocompatibility, and low adverse effects. Li et al. [172] has prepared a DN hydrogel GG/PEGDA by combining GG with PEGDA. The effects of viscoelasticity of GG/PEGDA DN hydrogel on the biological behavior of bone mesenchymal stem cells (BMSCs) were explored in vitro and in vivo. GG/PEGDA DN hydrogel shows excellent mechanical and relaxation properties which provide a favorable physical environment for cell proliferation and spreading, and induce chondrogenic differentiation. In another study was developed a DN hydrogel based on a GG gel and a poloxamer-Hep (PoH) network (PoH/GG DNH) to overcome the drawbacks of each gel network and to enhance the microenvironment for cell delivery. The DNH system was tested on bone marrow stem cells isolated from rabbits (rBMSCs) revealing that supported cell survival, maintained cell’s morphology and phenotype. The in vivo results have demonstrated that PoH/GG DNH endorse the cell distribution, adherence, and ECM production [173].

5.2.2. Wound Dressing

Gamma irradiated PVP/κ-CG based hydrogel obtained by gamma irradiation was intensively studied and applied as a biomaterial for wound dressing. This system presents several advantages such as a single step simultaneous sterilization and hydrogel formation, without the need of using initiator or crosslinker [169]. To enhance the poor mechanical strength of γ-irradiated PVA/PVP/κ-CG hydrogel, silk was added as a reinforcement agent [178]. PVP/κ-CG/PEG hydrogel dressing presents a long shelf life, have a high tensile strength, thus assuring an easy removal because it maintain its physical integrity. The advantages mentioned above make these systems to present increased patient compliance and are more effective than the commercially available ones [169]. PEG/GG hydrogel showed superior biocompatibility (N 90%), cell adhesion and improved cell growth compared to simple gellan gum hydrogel. In addition, reverse transcription polymerase chain reaction (RT-PCR) was used to confirm RPE-specific gene expression, and the result showed that it was positively influenced. As a result, it was observed that PEG/GG hydrogel promotes retinal regeneration compared to that of pure GG [171].

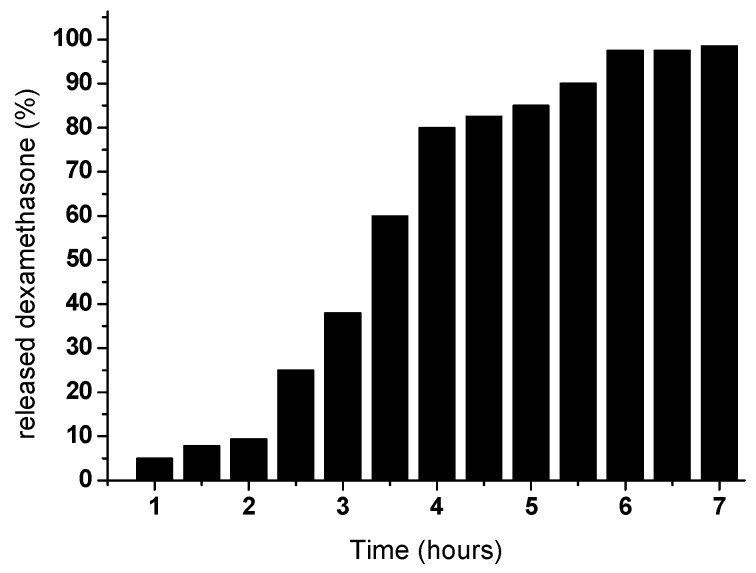

5.2.3. Drug Delivery

Superabsorbent polymer compositions (SAPCs) based on poly(acrylic acid-co-acrylamide-co-22-acrylamido-2-methyl-1-propanesulfonic acid)-grafted nanocellulose /poly(vinyl alcohol)-P(AA-co-AAm-co-AMPS)-g-NC/PVA, were obtained using graft copolymerization reaction, to create a system for amoxicillin drug delivery. The SAPCs drug delivery vehicle obtained was intended to apply for the treatment of peptic and duodenal ulcers induced by Helicobacter pylori [122]. Smart (thermo- and pH-responsive) microgel particles based on HPC-AAc and poly(l-glutamic acid-2-hydroxyethyl methacrylate) were synthetized by emulsion polymerization. The microgel was tested for controlled delivery of insulin, being noted that the system is resistant to gastric pH (1.2) and release insulin in a controlled manner at intestinal pH (6.8) [135]. By NIPAAm/CMC copolymerization were obtained copolymeric (CP) sIPN hydrogels, which were redox crosslinked using N,N′-methylenebisacrylamide (BIS) and N,N′-bis(acryloyl)cystamine (CBA). The hydrogels were tested for egg white protein lysozyme delivery at pH 1.2 while the system cross-linked with BIS showed higher swelling and maximum release [137]. A hydrogel system based on CMC and CMPVA grafted copolymer was developed by crosslinking with adipic dihydrazide. This copolymeric hybrid hydrogel was proposed as a carrier for drug delivery and as a scaffold for tissue engineering, based on its biocompatibility with the living cells and the fact that ensures outstanding survival rate at lower polymer concentration [138]. Hydrogels based on bacterial cellulose-g-poly(acrylic acid) that are stimuli-responsive were fabricated using electron beam irradiation and evaluated as oral delivery system for proteins (e.g., bovine serum albumin (BSA)). This method offers the advantage that no cross-linking agents are involved, thus overcoming the eventual toxic effects related to cross-linkers use [129]. Pandey et al. [128] using microwaves irradiation has developed hydrogels based on solubilized BC/AAm as a drug delivery system for theophylline. Different sets of BC-g-poly(acrylic acid-coacrylamide) hydrogels were obtained through microwave-assisted graft copolymerization using NaOH/urea as solvent system. These series of hydrogels have demonstrated a pH-sensitivity, which had influence on in vitro drug release profile, namely lower level of release in simulated gastric fluid (SGF) than in simulated intestinal fluid (SIF). This behavior indicates that the hydrogels may be efficient as a potential oral, controlled-release drug delivery system for the lower gastrointestinal (GI) tract [130]. Another hydrogel based on BC-g-PAA was prepared by electron beam irradiation technique. BSA was loaded into the BC-g-PAA hydrogel and showed low release in acidic SGF and higher penetration across the intestinal mucosa. The in vivo tests revealed that the hydrogel is biocompatible and non-toxic [129]. Ceresh et al. [146] obtained copolymeric hydrogels by graft-copolymerization of acrylic acid on three types of starch (potato, corn and rice starches) via 60Co-gamma irradiation. The starch-based hydrogels presented potential as prolonged drug (e.g., sodium salicylate and theophylline) delivery vehicles; in Figure 4 being illustrated the rate of release of theophylline from copolymeric hydrogels.

Figure 4.

Rate of release of theophylline from graft copolymers obtained from grafting starch with acrylic acid in weight ratios of 1:12.5; 1:25, and 1:37.5: used permission from [146]. Copyright 2020 John Wiley and Sons.

CMC functionalized with thiol groups (obtained by reaction with cysteamine in presence of 1-(3-dimethyl aminopropyl)-3-ethylcarbodiimide hydrochloride (EDC)) was cross-linked, using dithiothreitol, with norbornene immobilized tetra-arm PEG (PEG-Nor) forming CMC-PEG hydrogels. The presence of thiol-bearing CMC into hydrogel structure determined pH sensitivity of the gels, demonstrating improved swelling and faster release of loaded BSA protein at basic pH [140]. Moreover, thermo-responsive CMC-Nor hydrogels was developed by its crosslinking with a dithiol end functionalized PNIPAAm, determining temperature-induced shrinkage of the gel, at temperatures above the lower critical phase transition temperature (LCST) (around 32 °C) [179].

Bajpai and Saxena [142] performed potassium persulfate (KPS)-initiated graft copolymerization of AAc onto soluble starch in the presence of N,N′-methylene bisacrylamide (MBA) as the cross-linker. The hydrogels obtained were pH-sensitive and enzymatically degradable, exhibiting minimum swelling in an acidic pH and extensive swelling at pH 7.4 (i.e., simulating intestinal fluid). The behavior at acidic pH is determined by the formation of a complex hydrogen-bonded structure and at intestinal pH enzymatic degradation occurred along with the swelling controlled by chain-relaxation, being suitable for colon targeted drug delivery. Saboktakin et al. [149] have obtained pH-sensitive starch hydrogels by free radical graft copolymerization of PMAA onto CMS, using bisacrylamide as a crosslinking agent (CA) and persulfate as an initiator. The pH-responsive behavior of CMS-g-PMAA hydrogels is characterized by a transition between the swollen and the collapsed states that occurs at high and low pH. The CMS-based hydrogels were tested for drug delivery. Double hydrophilic thermo-responsive pullulan-g-PNIPAAm copolymers with two different molecular weights of thermosensitive grafts were synthesized and used for preparation of indomethacin-loaded nanoparticles by dialysis and nanoprecipitation method [180]. The sustained-release properties of poloxamer 407-based in situ gel were enhanced by the combination with CG, and present high potential to be used in vaginal in situ gel drug delivery systems with prolonged local residence and therefore for better clinical outcome [160]. Hamcerencu et al. [176] performed free radical grafting/polymerization of unsaturated esters (gellan maleate) with NIPAAm, using N,N′-methylenebisacrylamide as cross-linker, to design thermosensitive hydrogels. These hybrid hydrogels were tested for their swellability, in vitro loading and release of different drugs (e.g., adrenaline and chloramphenicol) and in vivo biocompatibility. By in vivo evaluation was not observed necrosis, calcification and acute inflammation, only the formation of a thin fibrous capsule around the implanted hydrogels, thus they being preliminary proposed for ophthalmic applications.

5.2.4. Other Biomedical Applications

The BC/PGA hydrogels were prepared by 60Co γ-irradiation crosslinking method. The BC nanofibers and PGA can form the multicomponent hydrogels with double crosslinking structure via γ-irradiation. The addition of BC increases compressive strength, storage modulus (G’) and the gel fraction but decreases the equilibrium swelling ratio of the BC/PGA composite hydrogels. The compressive strength and storage modulus of hydrogels increase 5 times and 10 times respectively at the irradiation dose of 50 kGy. Moreover, the BC/PGA hydrogels are non-toxic, indicating their safety for biomedical application [132]. By UV photo-crosslinking were obtained temperature sensitive hydrogels based on hemicellulose (Hce) obtained from acetic acid pulping of Eucalyptus and NIPAAm. The protocol involved two steps; firstly, a Hce derivative was synthetized by grafting MA to Hce that contains vinyl bonds within the side chains followed by UV photocrosslinking of Hce-MA with NIPAAm in LiCl/DMF solvent. The equilibrium swelling ratio and morphology of the hydrogels were dependent on environment temperature, implying their potential as smart materials for medical application [134]. All-trans retinoic acid aqueous gels composed of ι-CG and polyethylene oxide were proposed to be applied as a topical treatment of skin. In these gels, the PEO was selected for its high mucoadhesion property and spinnability, while ι-CG was chosed for its texture modification property and gelling feature. Combination of these components maximizes the optima properties of each entity by reducing the drawbacks of each individual polymer [162].

Deng et al. developed a novel κ-CG/PAAm (KC/PAAm) DN hydrogel through a dual physical-crosslinking strategy, with the ductile, hydrophobically associated PAAm being the first network, and the rigid potassium ion (K+) cross-linked KC being the second network. The DN (DPC-DN) hydrogels with optimized KC concentration exhibit excellent fracture tensile stress and toughness, comparable to those fully chemically linked DN hydrogels and physically-chemically cross-linked hybrid DN hydrogels. Additionally, DPC-DN demonstrated rapid self-recovery, remarkable notch-insensitivity, self-healing capability, as well as excellent cytocompatibility towards stem cells [167]. In a similar manner were obtained hybrid hydrogels based on Iota-Carrageenan and polyacrylamide to be used as matrix for silver nanoparticles designed for bacterial inactivation applications [181].

6. Heteropolysaccharides-Based Hybrid Hydrogels

6.1. Ability of Heteropolysaccharides to Form Hybrid Hydrogels

A biocompatible and biodegradable heteropolysaccharide that forms hydrogels by mixing with multivalent cations is the alginic acid [182,183]. Spherical core–shell gel-bead structures (or worms) were obtained by combining alginic acid with 1,3,2,4-di-(4-acylhydrazide)-benzylidenesorbitol (DBS-CONHNH2) [184]. The gels based on alginic acid proved to have important applications in domains like drug delivery and tissue engineering [185].

Microspheres (MS) of hybrid hydrogels that can adjust their mechanical properties and durability in function of the biological environment were obtained using SA with heterotelechelic PEG derivatives [186]. These hydrogels are appropriate for cell transplantation applications.

For enhancing the ability of liquid uptake and the mechanical properties of the hydrogels based on chitosan (CS), this natural polymer was associated with synthetic polymers or grafted with vinyl monomers, such as acrylic acid and acrylamide [187,188].

Chen et al. [189] prepared macroporous PVA/CS hydrogel sponges that showed higher antimicrobial and haemostatic activity than pure CS sponges.

Hyaluronic acid (HA) is abundant in connective, epithelial, and neural tissues [190]. HA macromolecules showed anti-inflammatory, immunosuppressive properties and block angiogenesis, while cleaved small fragments induce opposite behavior, enabling endothelial cells migration and angiogenesis [191]. Kim et al. [192] obtained PVA/HA hydrogel nanofibers by chemical crosslinking, using HCl and glutaraldehyde. They observed that the swelling ratio of these hydrogels is higher in respect with that corresponding to pure PVA hydrogel. A good biocompatibility of PVA/HA hydrogel nanofibers was evidenced by a higher cell adhesion at their surfaces, independent on the HA presence.

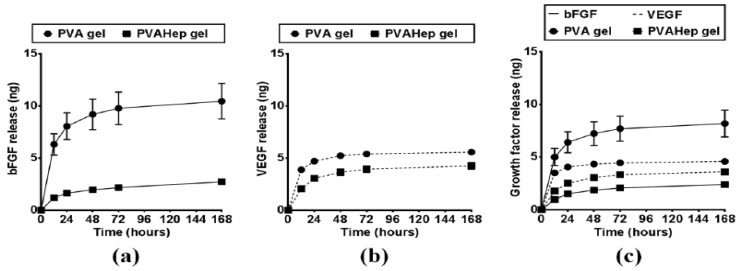

Heparin (Hep) has a high negative charge, the 3-D hydrogels based on it being used in tissue engineering, implantation, biosensor domain, drug delivery. Because Hep poses some safety problems (because it is often obtained from animal sources), analogous Hep-mimicking polymers and hydrogels obtained from synthetic sources were proposed.

The use of Hep in hydrogels by delivery growth-factors generates proliferation signals to cells because of its protein polysaccharide interactions closely mimicking the native structure and functioning of ECM [193].

Supramolecular hybrid hydrogels self-assembled were obtained from low-molecular-weight gelator (LMWG, which are small organic molecules which self-assemble in water or organic solvents, forming a 3D network that entraps the liquid phase resulting in gel formation) building blocks with the polymer gelator (PG) (e.g., calcium alginate) [184]. This type of hydrogel can be used in regenerative medicine [194], in controlled drug delivery [195], or in electronics devices as patterned conducting gels where they contact interface with living media. The components usually used for obtaining self-assembled multi-component hybrid hydrogels are: a pH activated LMWG, a temperature activated PG, an anionic biopolymer (such as Hep) and a cationic system capable of binding Hep.

6.2. Biomedical Applications of Heteropolysaccharides-Based Hybrid Hydrogels

Some examples of heteropolysaccharide-based hybrid hydrogels used in different biomedical domains are listed in the Table 3 where are also mentioned preparation methods and general properties.

Table 3.

Heteropolysaccharide-based hybrid hydrogel systems with biomedical applications.

| Hybrid Hydrogel Composite | Obtainment Method | Properties | Application | Reference |

|---|---|---|---|---|

| Alginate-based hybrid hydrogels | ||||

| PVA/alginate (Alg) | Physical crosslinking of PVA, followed by chemical crosslinking with alginate | * highly porous, open-cellular pore structures * pore size very 290–190 μm, depending on PVA concentration * scaffolds softer and more elastic than the control alginate, without affecting the mechanical strength * better cell adhesion and faster growth than the control alginate |

Scaffolds for cartilage tissue engineering | [196] |

| PVA/SA hydrogel, containing nitrofurazone | FT method | * increase of SA concentration in PVA hydrogel films increased the swelling ability, elasticity, and thermal stability of PVA/SA hydrogel system * increase of SA content led to significant decreases in gel fraction %, and mechanical properties of PVA/SA hydrogel * low SA content resulted in a decreased protein adsorption, indicating a better blood compatibility |

Wound dressing | [197] |

| Biodegradable PVA/SA-clindamycin-loaded hydrogel film | Physical crosslinking conducted by the FT method |

* increasing SA concentration decreased the gelation (%), maximum strength and break elongation, but it resulted in an increase in the swelling ability, elasticity and thermal stability of the hydrogel film * SA content had an insignificant effect on the release profile of clindamycin from the PVA/SA film, whereas PVA/SA-clindamycin improved the healing rate of artificial wound in rats |

Wound dressing |

[198] |

| PVA/Alg (1/1 weight ratio) nanofiber hydrogels | In situ crosslinking using citric acid (5 wt%) + curing at 140 °C, for 2 h + conditioning at room temperature | * enhanced thermal stability and insolubility in both water and simulated body fluid (SBF) for 2 days | Tissue engineering | [199] |

| PVA/calcium alginate nanofiber web | Electrospinning technique | * a maximum calcium alginate content showed the maximum water vapor transmission rate that help in maintaining the local moist environment for accelerating wound healing * apparently new epithelium formation without any harmful reactions, when the wound is covered with the PVA based nanofiber |

Wound healing | [200] |

| PVA/Alg reinforced with cellulose nanocrystals (CNCs) | Acidic hydrolysis | * fibrous porous structure (95.2% porosity) and improved mechanical stability * good properties for in vitro cell attachment |

Scaffolds with good proliferation for fibroblast cells | [201,202] |

| Chondroitin sulfate-based hybrid hydrogels | ||||

| Chondroitin sulfate (CTS)/PEG | FXIIIa-mediated crosslinking of chondroitin sulfate grafted with PEG | * tuned growth factor binding and release * promoting of stem cell proliferation and osteogenic differentiation |

Treatment of osteogenesis | [203] |

| PVA/HA/CTS hydrogels | Gamma irradiation (5–25 kGy) | * hydrogels with a higher content of HA/CTS exhibited higher enzymatic degradation rates * PVA/HA/CTS hydrogels cultures with human keratinocytes (HaCaT) showed higher cell viability (more than 90%), when compared to the control sample |

Potential application in skin tissue engineering | [204] |

| Glucan-based hybrid hydrogels | ||||

| PVA/glucan films | Physical blending, followed by drying at 110 °C, without using chemically crosslinking | * no covalent bond between PVA and glucan was found in the formed film; glucan can be released to facilitate wound healing * an increase in glucan content led to a decrease in the tensile strength and an increase of the breaking elongation * a high glucan content with PVA film can hinder the cell mobility and prolong the time of healing * healing time of wound can be shortened by 48%, when glucan content is optimized |

Wound dressing | [205] |

| Chitosan (CS) and chitosan derivatives-based hydrogels | ||||

| PVA/CS hydrogels | Crosslinking induced by exposure to different doses of γ-radiation | * gel fraction and mechanical properties of the hydrogels increased with increasing PVA concentration and irradiation dose * swelling ability of the hydrogels increased with increasing the CS content |

Prevention of microbiological growth, such as bacteria, fungi and microorganisms, with possible use as wound dressing material | [206] |

| PVA/CS hydrogel membranes | FTcycle, followed by γ-irradiation process | * larger swelling capacity, high mechanical strength, lower water evaporation, and high thermal stability were obtained * good antibacterial activity against Escherichia coli with increasing CS content |

Wound dressing | [207] |

| Addition of glycerol into PVA/CS hydrogels | Irradiation followed by FT | * acceleration of the healing process of wounds in a rat model * nontoxicity toward L929 mouse fibroblast cells * mature epidermal architecture was formed after the 11th day postoperatively |

Wound dressing | [208] |

| Temperature-sensitive CS/PVA hydrogel | Chemical crosslinking, using glutaraldehyde | * the release of paclitaxel (PTX) in PBS (pH 7.4) is sustainable for 13 days * the antitumor activity of the drug-loaded composite hydrogel is 3.7 fold higher than that of Taxol |

Intratumoral delivery of PTX | [209] |

| PVA/CS hydrogel loaded with vitamin B12 | Physical blending between different portions of PVA and water soluble CS, followed by treatment with formaldehyde to convert –NH2 group of CS into -N=C group in PVA/CS membranes |

* increasing of CS content increases water content, water vapor transmission, and permeability of loaded vitamin B12 through PVA/CS membranes | Potential biomedical applications | [210] |

| Minocycline loaded PVA/CS hydrogel films | FT method | * high CS concentrations decreased gel fraction, mechanical properties, and thermal stability, and it increased the swelling ability, water vapor transmission, elasticity, and porosity of PVA/CS hydrogel films * faster healing of the wound when compared to the conventional sterile gauze control |

Wound dressing | [211] |

| Nano-insulin loaded CS/PVA hydrogel | Chemical crosslinking, using glutaraldehyde as the cross-linking agent | * miscibility of nano-insulin and hydrogel * porous structure, with good deformability and flexibility * constant release of the insulin * high permeation rate of nano-insulin |

Transdermal insulin delivery | [212] |

| CS / PVA nanofiber mats | Electrospinning, using different CS salts (CS-hydroxybenzotriazole (HOBt), CS-ethylenediaminetetraacetic acid (EDTA), and CS-thiamin pyrophosphate (TPP)) | * increase of the swelling degree with increasing CS; concentration, whatever the CS salt * no toxic compounds that reduce the cellular growth of fibroblasts * highest antibacterial activity and better healing activity were obtained for CS-EDTA/PVA fiber |

Wound healing system | [213] |

| PVA/CS/gelatin hydrogel, incorporating polycaprolactone microspheres |

Physically incorporation | * improvement of the mechanical properties by PVA * improvement of cell adhesion by gelatin |

Delivery of basic fibroblast growth factor (bFGF) |

[214] |

| CS/gelatin/PVA hydrogels | Gamma-irradiation | * increase of the swelling capacity with increasing the CS/gelatin ratio * 3D network structure with a good evaporation rate * about 10–20% water retained in 24 h; * good coagulation effect |

Wound dressing | [215] |

| Gelatin/CS/PVA/ Arabic gum nanofibers |

Electrospinning | * steady permeability of large molecules (e.g., BSA) * excellent cell attachment and proliferation |

Wound healing | [216] |

| Gelatin/CS/PVA hydrogels | FT process | * non-toxic for the HT29-MTX-E12 cell line | Potential for tissue engineering applications | [217] |

| CS/polyethylenimine (PEI) 3D hydrogels | Physical mixture | * stable under cell culture conditions * could support the growth of primary human fetal skeletal cells |

Gene transfection agent | [218] |

| CS-PEG co-polymer (CS-g-PEG) | Chemically grafting of monohydroxy PEG onto the CS backbone, using Schiff base and sodium cyanoborohydride chemistry | * obtainment of an injectable, thermoreversible gel * by optimizing PEG content (45–55 wt.%) and PEG molecular weight, the resultant system underwent a thermoreversible transition from an injectable solution at room temperature to a gel at body temperature |

Potential carrier matrices for a wide range of biomedical and pharmaceutical applications |

[219] |

| Thermo-responsive PEG-grafted CS hydrogel | Physical crosslinking | * steady protein release pattern for a period of 70 h after an initial burst release in the first 5 h * by crosslinking with genipin, it was obtained a prolonged quasi-linear release of the protein for up to 40 days; the initial burst release was reduced |

Sustained BSA release | [220] |

| Injectable composite scaffold obtained from collagen-coated polylactide micro carriers/CS hydrogel | Physical crosslinking | * collagen-coated polylactide micro carriers enhanced the mechanical properties * cell metabolic activity increased before 9 days of in vitro chondrocytes growth within the scaffold * after 9–12 days, confluent cell layers were formed |

Tissue engineering applications, particularly in orthopedics |

[221] |

| CS/Poly(ε-caprolactone) (PCL)/polypyrrole | Electrospun | enhanced attachment and proliferation of PC12 cells | Neural tissue substrate | [222] |

| Maleiated CS/thiol-terminated PVA | Solvent casting | fetal porcine hepatocytes survived at least 14 days | Hepatocyte attachment | [223] |

| PVA/carboxymethyl chitosan (CM)-chitosan hydrogels | Electron beam rosslinking at room temperature | * mechanical properties and swelling degree improved after adding CM-chitosan * considerable antibacterial activity against E. coli for a low CM-chitosan content |

Antibacterial activity | [224] |

| PVA/CM/honey | FT method | * inhibition of the growth of Escherichia coli bacteria * presence of honey leads to faster wound healing |

Wound dressing | [225] |

| Carboxyethyl chitosan (CE)/PVA nanofiber mats | Electrospinning of aqueous CE-chitosan/PVA solution |

* CE-chitosan/PVA nanofiber mat was nontoxic to the L929 cells * good in promoting the L929 cell attachment and proliferation |

Skin regeneration and healing | [226] |

| PVA/quaternary chitosan (Q-chitosan mats | Photo-crosslinking electrospinning technique |

* efficient inhibition toward growth of Gram-positive and Gram-negative bacteria | Wound dressing applications | [227] |

| Q-chitosan/polyaniline/ oxidized dextran (DEX) |

Lyophilization | High antibacterial activity and enhanced proliferation of C2C12 myoblasts | In situ forming antibacterial and electroactive hydrogels | [228] |

| Quaternary ammonium chitosan/PVA hydrogels | Gamma irradiation, at different radiation doses and for different polymer ratios | * very good swelling ability (1000–4000%), water evaporation rate and mechanical properties * for doses <40 kGy, the tensile strength increases with increasing the radiation dose * higher crosslinking degree of the hydrogel with increasing the radiation dose * for doses >40 kGy, the hydrogel degraded * inhibition of the growth of Staphylococcus aureus and Escherichia coli |

Antimicrobial system | [229] |

| Poly-4-styrenesulfonic acid/methacrylated glycol CS (MeGC) hydrogel or poly-vinylsulfonic acid/MeGC | Photo-crosslinking | * the initial burst was decreased after adding PSS or PVSA * higher human bone morphogenetic protein-2 (BMP-2)-induced osteogenesis differentiation |

Efficient protein delivery | [230] |

| pH and temperature dual-sensitive hydrogel between glycol chitosan and benzaldehyde-modified Pluronic |

Schiff base reaction | in physiological conditions, it was obtained the release of doxorubicin (DOX) and prednisolone from the hydrogels, without any initial burst release | Drug delivery system | [231] |

| Thermo-responsive Pluronic grafted CS hydrogel | Grafting of Pluronic onto chitosan using EDC/NHS chemistry | * higher mechanical properties than Pluronic hydrogels * in vitro culture of bovine chondrocytes in the hydrogel showed that the cell number and synthesized glycosaminoglycan (GAG) increased spontaneously over a period of 28 days |

Cartilage regeneration | [232] |

| CS-Pluronic nano-hydrogel with targeting peptides | Photo-crosslinking | * high accumulation efficiency in brain tissues |

Delivery of β-galactosidase to brain | [233] |

| CS-Pluronic hydrogels with encapsulated recombinant human epidermal growth factor (rhEGF) |

Photo-croslinking | * the release of rhEGF is highly related to the degradation rate of the hydrogels * difference in rhEGF release patterns within 1 day, for different photoirradiation time (2 min–5 min) * epidermal differentiation is highly enhanced * good muco-adhesive property with animal skins |

Wound curing | [234] |

| Semi-interpenetrating polymer network CS/ PEG/acrylamide (AAm) hydrogels | Chemical crosslinking | * increase of the protein half-life * improvement of the CS biocompatibility * increasing PEG content increased the swelling ratio, protein loading capacity, and entrapment efficiency |

Closed-loop insulin delivery | [235] |

| Methacrylate derivative of CS/poly(ethylene oxide diacrylate) (PEODA) | Photo-crosslinking (intensity of UV light ≈ 10 mW/cm2, at a wavelength of 365 nm) | * good mechanical strength * degradation of the gels in the presence of chondroitinase enzyme in a dose-response manner * no degradation in the absence of the enzyme * compatibility with chondrocytes |

Cartilage tissue engineering | [236] |

| Hyaluronic acid-based hybrid hydrogels | ||||

| Maleiated HA/thiol-terminated PEG | Mould-casting | quick gelation, porous structures, tunable degradation, and cytocompatibility with L929 cells | In situ formed scaffolds for tissue engineering | [237] |

| HA/PEG-diacrylate coencapsulated with TGF-β-3 | Photo-crosslinking | Cartilage differentiation | Cartilage tissue engineering | [238] |

| Injectable hydrogels of thiolated HA and 4-arm PEG-vinyl sulfone | Michael-type addition reaction | * gelation time decreased with the increase in the molecular weight (45–185 kDa) of HA * degradation time increased (15 days) with the molecular weight of HA and its degree of substitution * degradation in the presence of chondrocytes increased after 14 and 21 days, maybe due to the production of hyaluronidase enzyme by the incorporated chondrocytes |

Cartilage tissue engineering | [79] |

| Methacrylated HA/N-vinyl pyrrolidone, using Alg as a temporal spherical mold | Photo-polymerization (long wavelength UV, 7W/cm2—intensity) | * degradable in the presence of hyaluronidase enzyme | Cartilage tissue engineering | [239] |

| Hybrid injectable hydrogel, consisting of deferoxamine-loaded poly(lactic-co-glycolic acid) nanoparticles (NPs) incorporated into a HA/CS hydrogel |

Physical crosslinking | * angiogenesis was induced by deferoxamine drug release, but also by the presence of HA/CS hydrogel * cytocompatibility and cell proliferation * maximal blood vessels formation * beneficial effect of deferoxamine for neovascularization after 28 days when compared to HA/CS hydrogel |

Suitable support for microvascular extension |

[240] |

| Hydrogels of HA with thermosensitive poly(N-isopropyl acrylamide-co-acrylic acid), incorporated with dexamethasone and growth factor TGF β-3 |

Temperature-induced crosslinking | * enhancement of chondrogenic differentiation and expression of aggregan, collagen type I and type II | Injectable tissue engineering construct for cartilage repair | [241] |

| Xanthan gum-based hybrid hydrogels | ||||

| PVA and xanthan gum (XG), in different molar ratios | Crosslinking, using trisodium trimetaphosphate | * for a molar ratio of 4:1 between PVA and XG, mechanical, swelling, and thermal properties superimposed with those of human nucleus pulposus (HNP) tissue * the hydrogels did not show any signs of cytotoxicity towards mouse fibroblasts (NIH3T3) |

Good candidate as a potential HNP substitute | [242] |

| Hybrid (chitosan-g-glycidyl methacrylate) (CS–g–GMA)/xanthan hydrogel | Dissolved CS-g-GMA was mixed with the xanthan solution, under nitrogen gas flow, while keeping the temperature at 50 ± 1 °C under constant magnetic agitation |

viability of fibroblasts when cultured onto the synthesized hydrogels | Potential for use in biomedical engineering applications | [243] |

| Heparin based hybrid hydrogels | ||||

| Hep/PEG hybrid gels | UV-initiated thiolene reaction between thiolated Hep and diacrylated poly(ethylene) glycol (PEG-DA) | * hepatocyte growth factor (HGF) was retained after 5 days in the hybrid Hep/PEG hydrogel microstructures, but was rapidly released from pure PEG gel microstructures * hepatocytes residing next to Hep/PEG hydrogels were producing ∼4 times more albumin at day 7, compared to cells cultured next to inert PEG hydrogels |

* Designing cellular microenvironment in vitro * Vehicles for cell transplantation in vivo |

[244] |

| Hep-based hydrogel system, formed by thiolated heparin and diacrylated PEG | Michael-type addition reaction | * encapsulation by the Hep -based hydrogel did not affect the chondrocyte viability (better than calcium-induced alginate gel) * hydrogel promoted chondrocyte proliferation, while maintaining chondrogenic nature |

Promising material for chondrocyte culture, potentially applicable for cartilage regeneration | [245] |

| Hep/acrylated PEG hydrogel, with rat hepatocytes entrapped | Michael-type addition reaction | * the hydrogel was non-cytotoxic to cells, and promoted the hepatic function * hepatocytes entrapped in the Hep-based hydrogel maintained high levels of albumin and urea synthesis after three weeks in culture * hepatocyte growth factor (HGF) incorporated in the hydrogel was released in a controlled manner (only 40% of GF molecules released after 30 days in culture) |

Good characteristics for matrices for in vitro differentiation of hepatocytes or stem cells and as vehicles for transplantation of these cells |

[246] |

| Hep-based hydrogel sheet containing thiolated Hep and diacrylated PEG | Photo polymerization |

* in vitro sustained release profile of human epidermal growth factor (hEGF) loaded in the hydrogel * acceleration of the wound healing after application of the hydrogels * advanced granulation tissue formation, capillary formation, and epithelialization in wounds treated by hEGF loaded Hep-based hydrogel |

Wound healing | [247] |

| Hep-poloxamer/decellular spinal cord extracellular matrix (dscECM), used for fibroblast growth factor-2 (FGF2) attachment | EDC/NHS method | * treatment with FGF2-dscECM-HP hydrogel induced the recovery of the neuron functions and tissue morphology in rats that suffered from spinal cord injury (SCI) | Delivery of macromolecular proteins | [248] |

6.2.1. Tissue Engineering

Generally, the scaffolds used in tissue engineering should have several properties, such as biocompatibility, cell proliferation, controlled swelling, ease of administration, antimicrobial, stability, porosity, adhesion, low immunogenicity, colonization of host cells without inducing any histological changes, integration with host tissues [249,250,251,252], biodegradability, bio mineralization, non-toxic degradation products, and also degradation of scaffolds should be inversely proportional to the rate of synthesis of the newly regenerated tissue [253].

Pok et al. [254] obtained 3D scaffolds of self-assembled PCL in a gelatin-CS hydrogel, for possible application in congenital heart defects. They observed similarities between the mechanical properties of the hydrogel with those of the native tissue, as well as migration of neonatal rat ventricular myocytes (NRVMs) [254]. Zhao et al. [228] synthesized hydrogel scaffolds by chemical crosslinking between quaternized CS and polyaniline, using oxidized dextran as cross-linker. The obtained hydrogels presented decreased cytotoxicity, higher antibacterial activity, and enhanced proliferation of C2C12 myoblast cells when compared with quaternized CS hydrogel. These hydrogels could be used for muscle, nerve, and cardiovascular repair [228]. PVA hydrogel was loaded on one side only with Hep for possible application in vascular tissue engineering [255], because release of Hep from PVA/Hep hydrogel can prevent clot formation.