Abstract

Background:

Despite the popularity of ice cream, its high content of sugar and fat is worrisome. Substituting sugar with natural and useful resources is one possible solution. Dates (Phoenix dactylifera) are rich in carbohydrates and are a good source of energy; they also have a large amount of phenolic compounds and anthocyanin.

Aims:

The aim of this study is to evaluate the effect of ice cream sugar replacement with date products.

Methods:

Accordingly, four ice cream samples with different sweeteners including 1) sucrose (as a control), 2) date pulp + sucrose, 3) date liquid sugar, and 4) sucrose + date liquid sugar, were produced. Total phenolics, anthocyanins, and antioxidant activities of dates and their effects on physicochemical and sensory properties of ice cream were investigated.

Results:

A large amount of phenolic compounds and anthocyanin was found in the ice cream contained date pulp and liquid sugar, which enhanced the reducing power and antioxidant effect of it. The overrun and density of an ice cream did not change with sugar replacement. Total substitution of sucrose by date liquid sugar, increased the titratable acidity, viscosity, and antioxidant properties of ice cream, but it was found to have some negative effects on the organoleptically score of color. However, the partial replacement of granular sugar with date pulp/liquid sugar, improved the antioxidant value of this dairy dessert without any change in its color.

Conclusion:

It seems that the addition of date pulp to an ice cream, not only maintain the quality and sensory properties of an ice cream, but also provides an antioxidant property.

Key Words: Antioxidants, Dates, Ice cream, Sugar

Introduction

Ice cream is the most nutritious and popular semi-solid dairy dessert in the world. It is an aerated suspension of water and fat in a concentrated sugar solution that contains proteins, stabilizers, emulsifiers, and flavoring agents, while is poor in some of the natural antioxidants (Erkaya et al., 2012 ▶). Consumer acceptance of ice cream depends largely on its textural quality and flavor. Sucrose is the main sugar in ice cream, which imparts flavor. Growing concern about health has encouraged people to decrease the consumption of food rich in sucrose.

Dates (Phoenix dactylifera) are one of the oldest and most well-known cultivated plants in the Middle East and North Africa (Al-Farsi et al., 2005 ▶). It is the second most important horticultural crop in Iran after pistachio (Hajian and Hamidi Esfahani, 2015 ▶), and its production was more than 1.15 million tons in 2014 (FAO, 2014). Dates contain a high percentage of carbohydrates with the predominance of glucose (G) and fructose (F), and also proteins, pectin, lipid, dietary fibers, and minerals (Al Farsi and Lee, 2008 ▶). Date varieties can be served as good natural antioxidants (Al-humaid et al., 2010 ▶). Antioxidants have received increased attention for their potential effects in the prevention of chronic diseases such as cardiovascular diseases and aging (Kaur and Kapoor, 2001 ▶). With the increasing consumer awareness of the relationship between diet and wellness, the production and consumption of functional foods have become of great interest today. The benefits of the dates make it a candidate for improvement of the nutritional value of food products (Habib and Ibrahim, 2009 ▶).

This study was aimed to examine the possibility of manufacturing a functional ice cream with date pulp or date liquid sugar instead of granular sugar and evaluate its sensory and physicochemical properties.

Materials and Methods

Analysis of raw materials

Date and date liquid sugar analysis

The sugar contents of date (pulp/liquid sugar) were determined using high-performance liquid chromatography (HPLC) (Shimadzu LC-10ATVP, Japan) with Supelcosil LC-NH2 (25 cm × 4.6 mm, 5 μm) column and a RID-10A refractive index detector. The mobile phase of acetonitrile: deionized water (8:2 v/v) by the rate of 1.3 ml/min and isocratic method was used. The volume of the sample injected was 20 μL.

The quantification of each sugar (fructose, glucose, and sucrose) was accomplished by comparing sample peak height to the standard peak height. The F/G ratio was then calculated (Bogdanov et al., 1997 ▶).

Milk analysis

The fat, protein, lactose, minerals, and moisture of milk were determined by Lacto Star (Gerber, Germany).

Ice cream manufacturing

The ice cream was prepared according to the four formulations presented in Table 1. The granular sugar was used for the control group. Date pulp (3rd grade Kabkab) and date liquid sugar (Brix=70) for sugar replacement, were purchased from Shahd Babe Pars Company, Tabriz, Iran.

Table 1.

The different ice cream mix ingredients and proportions

| Treatment groups | Ice cream mix ingredients (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Raw milk | Vegetable oil | Granular sugar | Date liquid sugar | Date pulp | Skim milk powder | Whey powder | Vanillin | Emulsifier/Stabilizer | |

| C | 70 | 8 | 18 | - | - | 2 | 1.4 | 0.1 | 0.5 |

| PDS | 70 | 8 | 9 | 9 | - | 2 | 1.4 | 0.1 | 0.5 |

| TDS | 70 | 8 | - | 18 | - | 2 | 1.4 | 0.1 | 0.5 |

| PDP | 70 | 8 | 9 | 9 | 2 | 1.4 | 0.1 | 0.5 | |

C: Control, PDS: Partial substitution of granular sugar with date liquid sugar (50%), TDS: Total substitution of granular sugar with date liquid sugar, and PDP: Partial substitution of granular sugar by date pulp (50%)

Dry ingredients including: Skim milk powder (Pegah, Iran), whey powder (Pegah, Iran), granular sugar, and emulsifier/stabilizer (Palsgaard® Extrulce 379, Denmark) were added to the previously heated milk (45°C) and mixed. The mixtures were homogenized (at 70°C) and pasteurized at 80°C for 1 min. Then they were cooled to 15°C and stored for 16 h at 4°C for aging. All ice cream mixes were flavored with vanilla extract prior to freezing at 0.4% (V/V). The soft ice cream was made from the mixtures by ice cream maker (Moulinex, Italy 03051 410). Then, they were divided into weights of 120 g and packed in plastic containers and transferred to a -30°C hardening freezer, and held for 48 h. Ice cream samples were stored at -18°C until further analysis. The manufacturing process was similar for all treatments. The production process was done in triplicate.

Determination of pH and acidity

The pH of ice cream samples was measured using a glass electrode pH meter (Methrohm AG, Herisau, Switzerland). Titratable acidity of samples was determined by titration with NaOH 0.1N, and reported as the percentage of lactic acid/100 g of ice cream (AOAC, 2000 ▶).

Determination of density, apparent viscosity, and overrun

The density of ice cream samples was determined at 20°C using Pycnometer (Brand, England). The apparent viscosity of the melted ice cream was determined at 4°C using a rotational Brookfield Viscometer DV-II (Brookfield, USA) at the speed of 20 rpm at 30 s using a spindle #5 (LV model, Brookfield, USA), and was expressed in centipoises (cp) (Özer et al., 1997 ▶).

The overrun of the product was determined according to the following equation (Dervisoglu and Yazici, 2006 ▶):

Determination of total anthocyanin content

Total anthocyanins were determined according to Hwang et al. (2009). Exactly 2 ml of samples (2 g of dates) was mixed with 2 ml acidified methanol (containing 100 g/kg HCl) and centrifuged at 3000 × g for 10 min. The supernatant (1 ml) was added to 9 ml HCl (Merck, Germany) 1 mol equiv/L. The optical density was measured at 520 nm. Total anthocyanin content was calculated as below:

Anthocyanin content (mmol/ml) = Absorbance520 × 101 × 18.89

Determination of total phenolic content

The total concentration of phenols in the samples was measured according to Hwang et al. (2009) ▶ using Folin-Ciocalteu (F-C) colorimetric method. About 5 g of an ice cream, date, and date liquid sugar were extracted in 25 ml of methyl alcohol (Merck, Germany). After 12 h refrigeration, the extracts were filtered (Whatman No. 4) and used for the determination of phenolics and DPPH )2,2-diphenyl-1-picrylhydrazyl (scavenging activity.

Extracts (0.2 ml) were mixed with 1.8 ml of distilled water, 1 ml of F-C reagent (Sigma-Aldrich, USA), and 2 ml of 20% sodium carbonate (Merck, Germany). The mixture was kept at 25°C for 20 min and the absorbance was measured at 735 nm. Different concentrations of gallic acid (GA) (0, 0.1, 0.25, 0.5, 0.75, and 1 mg/ml) were used for calibration curve and the results were expressed as mg GA equivalent/100 g of sample. All measures were obtained in triplicate.

Evaluation of antioxidant activity using the DPPH method

The extract (0.3 ml) obtained in the previous step was mixed with 1.2 ml methanol and 1.5 ml DPPH solution in methanol (0.5 mmol/L). After 90 min of reaction at room temperature, the sample absorbance was measured at 515 nm (Singh et al., 2002 ▶). Methanol was applied as a blank. The DPPH scavenging activity was calculated as shown below:

Determination of the reducing power of ice cream, dates, and date liquid sugar

An aliquot of 0.1 ml of each extract was mixed with 0.5 ml of phosphate buffer (0.2 M, pH = 6.6) and 0.5 ml of 0.01% potassium ferricyanide (Merck, Germany). The mixture was incubated at 50°C for 20 min. After cooling, 0.5 ml trichloroacetic acid (1%) was added and the mixture was centrifuged (30 min at 7000 × g). The supernatant was diluted with distilled water (1+1) and then mixed with 0.2 ml ferric chloride solution (0.001%), and the absorbance was read at 700 nm. Butylated Hydroxytoluene (BHT) was used as a standard and the reducing power was reported as BHT equivalent/100 g of sample (Ferreira et al., 2007 ▶).

Sensory analysis

The sensory analysis of ice cream samples was carried out after 2 weeks of storage by twenty trained panelists (10 men and 10 women, age 30-45 years), using a 5 point scale as follows:

5 = Really like

4 = Like moderately

3 = Neither like nor dislike

2 = Dislike moderately

1 = Dislike really

Panelists were asked to evaluate the color, flavor, and texture. Samples were offered in plastic cups, coded with 3-digit numbers. Assessors were nonsmokers and regular consumers of dairy products. All panelists were asked to rinse their mouths with distilled water between samples.

Statistical analysis

All experiments were done in triplicate. Data were subject to analysis of variance (ANOVA) and Duncan’s multiple range tests using an SPSS package (SPSS 16 for Windows, SPSS Inc., Chicago, IL, USA). The Kruskal-Wallis test was used for sensory data analysis. P-values less than 0.05 were considered statistically significant.

Results

Analysis of raw materials

Some physical and chemical properties of raw milk, date, and date liquid sugar are summarized in Table 2.

Table 2.

The chemical properties of milk, date pulp, and date liquid sugar

| Parameters | Milk | Date pulp | Date liquid sugar |

|---|---|---|---|

| Fat (%) | 3.36 ± 0.63 | - | - |

| Protein (%) | 3.71 ± 0.38 | - | - |

| Solid non-fat (SNF) (%) | 10.46 ± 1.15 | - | - |

| Lactose (g/100 g) | 5.59 ± 0.62 | - | - |

| Glucose (g/100 g) | - | 32.92 ± 0.64 | 34.42 ± 1.28 |

| Fructose (g/100 g) | - | 30.53 ± 0.20 | 31.10 ± 1.51 |

| Sucrose (g/100 g) | - | 8.96 ± 0.98 | 8.38 ± 2.46 |

| Glucose/Fructose (G/F) | - | 1.08 ± 0.01 | 1.11 ± 0.33 |

| Minerals (%) | 0.66 ± 0.18 | - | - |

| Moisture (%) | 86.18 ± 1.78 | - | - |

| Freezing point (°C) | -0.59 ± 0.07 | - | - |

The data are presented as mean±SD

The glucose (G) was a predominant carbohydrate in date, followed by fructose (F) and sucrose.

Physicochemical properties of ice creams

The results obtained from the physicochemical properties of all ice cream formulations are shown in Table 3. The partial replacement of sugar with date liquid sugar or date pulp did not have a significant effect on pH and acidity (P>0.05) while complete replacement of granular sugar by date liquid sugar, significantly decreased the pH and increased the acidity (P<0.05), which may be due to the different acids in the date.

Table 3.

Physicochemical properties of all ice cream formulations

| Formulas | Dry matter (%) | Fat (%) | pH | Acidity (g/L) | Density (g/L) | Viscosity (cp) | Overrun (%) |

|---|---|---|---|---|---|---|---|

| C | 38.74 ± 4.22a | 10.53 ± 1.76a | 6.48 ± 0.08a | 1.53 ± 0.68a | 868 ± 32a | 926.00 ± 11.00a | 100 ± 0.00a |

| PDS | 36.52 ± 5.03a | 10.84 ± 2.11a | 6.39 ± 0.21a | 1.57 ± 0.31a | 820 ± 43a | 932.67 ± 13.01a | 100 ± 0.00a |

| TDS | 37.66 ± 6.16a | 10.58 ± 1.36a | 5.90 ± 0.01b | 2.47 ± 0.95b | 838 ± 69a | 1616.00 ± 16.10b | 100 ± 0.00a |

| PDP | 37.91 ± 3.95a | 10.29 ± 1.85a | 6.32 ± 0.02a | 2.11 ± 0.19a | 835 ± 85a | 2164.33 ± 15.04c | 100 ± 0.00a |

C: Control, PDS: Partial replacement (50%) of granular sugar with date liquid sugar, TDS: Total replacement of granular sugar with date liquid sugar, and PDP: Partial replacement (50%) of granular sugar with date pulp. The data are presented as mean±SD. Means in the same column with different superscript letters indicate significant differences (P<0.05) between treatments

According to the results, no significant difference (P>0.05) in the overrun and density of ice creams was

Viscosity is one of the most important properties of an ice cream, which is necessary for good texture and resistance to melting. Replacing sucrose with dates (pulp or liquid sugar) increased the ice cream viscosity. The lowest value of viscosity was seen in the control sample while by total replacement of sugar with date liquid sugar, the highest viscosity value was obtained (P<0.05).

Phenolics, anthocyanin and antioxidant content

Total phenolics and anthocyanin content of ice creams, DPPH scavenging activity, and the reducing power of samples are summarized in Table 4. Sugar replacement with date (pulp/liquid sugar) significantly increased the total phenols and anthocyanin content of ice creams (P<0.05). Thus, the control group had the lowest phenolic and anthocyanin content (P<0.05).

Table 4.

Total phenolic and anthocyanin content, DPPH scavenging activity, and the reducing power of ice cream samples

| Formulas | Total phenols (mg GA/100 g) | Anthocyanin (mmol/ml) | DPPH scavenging (%) | Reducing power |

|---|---|---|---|---|

| C | 1.95 ± 0.16a | 190.65 ± 0.64a | 18. 14 ± 0.29a | 0.23 ± 0.60a |

| PDS | 4.24 ± 0.06b | 267.23 ± 10.32b | 18. 14 ± 0.29a | 0.23 ± 0.60a |

| TDS | 6.71 ± 0.60c | 312.22 ± 7.27c | 34.80 ± 0.23c | 1.53 ± 0.03c |

| PDP | 6.58 ± 0.95c | 390.24 ± 6.26d | 41.45 ± 1.17d | 1.63 ± 0.01d |

DPPH: 2,2-diphenyl-1-picrylhydrazyl, C: Control, PDS: Partial replacement of granular sugar with date liquid sugar (50%), TDS: Total replacement of granular sugar with date liquid sugar, and PDP: Partial replacement (50%) of granular sugar with date pulp. The data are presented as mean±SD. Different letters in the same column are significantly different (P<0.05)

seen.

Sensory analysis

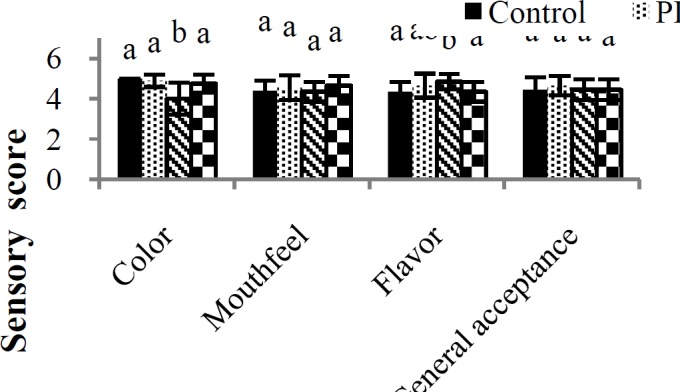

The findings obtained from the sensory evaluation are shown in Fig. 1. The effect of adding dates on the colour of the ice cream depended on their concentration since the partial replacement of sugar with date pulp or liquid sugar had no significant effect on colour (P>0.05) while the complete replacement with date liquid sugar significantly decreased the color score (P<0.05), that could be due to the brownish color of the date liquid sugar. Similar results were observed by adding date fiber to ice cream (Yangilar, 2015 ▶).

Fig. 1.

Effect of sugar replacement with date (pulp/liquid sugar) on the sensory profile (mean±SD) of ice creams. PDS: Partial replacement (50%) of granular sugar with date liquid sugar, TDS: Total replacement of granular sugar with date liquid sugar, and PDP: Partial replacement (50%) of granular sugar with date Pulp. Different superscript letters in each sensory attribute indicates significant differences (P<0.05) among treatments

All ice creams had a similar mouth feeling (P>0.05). Adding date liquid sugar significantly improved the flavor of ice creams (P<0.05). The scores for flavor significantly increased with the increase in the date liquid sugar concentration. But, the addition of date pulp had no effect on the scores of flavor (P>0.05). Panelists preferred the flavor of ice cream samples made with 18% date liquid sugar.

Discussion

The G and F were the main sugars in the date. Sahari et al. (2007) also reported that the G (16.41-54.23 g/100 g) and F (12.62-43.31 g/100 g) were predominant sugars in thirty-four date varieties. Al-humaid et al. (2010) ▶ also reported the same results and added that sucrose was not detected in most varieties of palm in Saudi Arabia. The sugar content of date, might considerably change with variety, soil, and climatic conditions (Hulme, 1970), but generally, it is an excellent source of readily available sugars (Ahmed et al., 1995 ▶) which are easy to digest in human cells and useful for getting the energy for metabolic processes. The G/F ratio in the present study was 1.08. Due to higher concentrations of G, the G/F ratio in this product is usually higher than one. Ahmed et al. (1995) ▶ reported a G/F ratio of 1-1.2 in various species of date.

The results indicated a concentration dependent effect of the sugar substitution percent on the acidity of ice cream. Similar results were expressed by Abdollahzadeh et al. (2018) ▶, in which the acidity of yogurt increased by increasing the concentration of date extract to 12%. In the present study, it was found that replacing sugar with date did not have a significant effect on the ice cream density and overrun, but increased the viscosity. Ozdemir et al. (2008) ▶ showed that sucrose substitution with honey, high F corn liquid sugar, and G liquid sugar could decrease the overrun of the ice cream. Gohari Ardebili et al. (2005) ▶ reported that 50% replacement of sugar with date palm increased the overrun percentage of an ice cream; however, with the increasing replacing rate, the overrun percent decreased. They also expressed that the ice cream viscosity increased with increasing the date concentration. Similar findings were observed by adding cape gooseberry to ice cream (Erkaya et al., 2012 ▶). The increase of viscosity in samples can be explained by the high content of dietary fiber in date.

Replacing dates with sugar increased the amount of phenolic compounds in ice cream. The use of date pulp had a greater effect on the phenolic and anthocyanin content of an ice cream than the date liquid sugar (P<0.05). The thermal process used to make the liquid sugar seems to decompose some phenolic compounds (Shahidi and Naczk, 2003). Many studies have reported different amounts of phenolic compounds in dates (Al-Farsi et al., 2005 ▶; Biglari et al., 2008 ▶). The amount of phenolic compounds varies depending on the variety and the growth stage (Singh et al., 2012 ▶).

Anthocyanin, phenolic, and flavonoid contents of dates is responsible for their antioxidant activity (Matsumoto et al., 2002 ▶; Mansouri et al., 2005 ▶; Al-Turki et al., 2010 ▶). Accordingly, total phenol (28.9 ± 0.8), reducing power (1.72 ± 0.002), anthocyanin content (586.68 ± 20.23) and DPPH scavenging activity (82.08 ± 1.31) of date pulp were significantly higher than the liquid sugar (4.10 ± 0.06, 1.65 ± 0.04, 180.27 ± 8.1, and 1.65 ± 0.04, respectively) (P<0.05). As date liquid sugar concentration increased, the reducing power and DPPH scavenging activity of ice cream also increased (P<0.05). The antioxidant activity of phenolics is a result of their redox activity, which can absorb and neutralize free radicals, quench singlet and triplet oxygen, or decompose peroxides (Osawa, 1994; Brewer, 2011 ▶). Al-humaid et al. (2010) ▶ also reported the antioxidant activity of date in camel milk.

All samples received high scores for general acceptability in terms of flavor, mouthfeel, and colour and no marked off-flavor was reported. Ozdemir et al. (2008) ▶ revealed that the partial substitution of sucrose with G syrup, honey, and high F corn syrup had a better effect on sensory properties of an ice cream than the complete substitution. Milani and Koocheki (2011) ▶ showed that as date syrup concentration increased (0-50%), the sensory (flavor, texture, and total acceptability) scores of the frozen yogurt decreased.

Dates are one of the most important agricultural products in Iran, and every year large quantities of this valuable product are wasted due to the lack of proper treatment. Dates are a good source of natural antioxidants and their use in different foods may help them to become a functional food. Adding dates (pulp/liquid sugar) to ice cream increases the amount of phenolic compounds, antioxidant properties, and flavor of ice cream. Partial replacement (50%) of sugar by date pulp was revealed to have a greater antioxidant effect than a complete replacement by date liquid sugar. However, no adverse effect of dates on the sensory attributes was observed; thus, partial replacement (50%) of sugar with date pulp in ice cream production is recommended.

Aknowledgements

The authors acknowledge the Research Affairs Office of Shiraz University and the assistance of Miss. M. Aghazi.

References

- Abdollahzadeh SM, Zahedani MR, Rahmdel S, Hemmati F, Mazloomi SM. Development of Lactobacillus acidophilus-fermented milk fortified with date extract. LWT-Food Sci. Technol. 2018;98:577–582. [Google Scholar]

- Ahmed IA, Ahmed AWK, Robinson RK. Chemical composition of date varieties as influenced by the stage of ripening. Food Chem. 1995;54:305–309. [Google Scholar]

- Al-Farsi M, Alasalvar C, Morris A, Baron M, Shahidi F. Comparison of antioxidant activity, anthocyanins, carotenoids, and phenolics of three native fresh and sun-dried date (Phoenix dactylifera L) varieties grown in Oman. J. Agric. Food Chem. 2005;53:7592–7599. doi: 10.1021/jf050579q. [DOI] [PubMed] [Google Scholar]

- Al-Farsi MA, Lee CY. Nutritional and functional properties of dates: a review. Crit. Rev. Food Sci. Nutr. 2008;48:877–887. doi: 10.1080/10408390701724264. [DOI] [PubMed] [Google Scholar]

- Al-humaid AI, Mousa HM, El-mergawi RA, Abdel-Salam AM. Chemical composition and antioxidant of dates and dates-camel milk mixtures as a protective meal against lipid peroxidation in rats. Am. J. Food Technol. 2010;5:22–30. [Google Scholar]

- Al-Turki S, Shahba MA, Stushnoff C. Diversity of antioxidant properties and phenolic content of date (Phoenix dactylifera L) fruits as affected by cultivar and location. JFAE. 2010;8:253–260. [Google Scholar]

- AOAC. Official methods of analysis. 16th Edn. 2000. Methods No. 942.05, Washington, D.C., USA, Gaithersburg, Md. [Google Scholar]

- Biglary F, Alkarkhi AFM, Easa AM. Antioxidant activity and phenolic content of various date palm (Phoenix dactylifera) fruits from Iran. Food Chem. 2008;107:1636–1641. [Google Scholar]

- Bogdanov S, Martin P, Lullmann C. Harmonized methods of the European Honey Commission. 1997;Apidologie. Extra Issue:1–59. [Google Scholar]

- Brewer MS. Natural antioxidants: sources, compounds, mechanisms of action, and potential applications. Compr. Rev. Food Sci. F. 2011;10:221–247. [Google Scholar]

- Dervisoglu M, Yazici F. The effect of citrus fibre on the physical, chemical and sensory properties of ice cream. Food Sci. Technol. Int. 2006;12:59–164. [Google Scholar]

- Erkaya T, Dağdemir E, Şengül M. Influence of Cape gooseberry (Physalis peruviana L) addition on the chemical and sensory characteristics and mineral concentrations of ice cream. Food Res. Int. 2012;45:331–335. [Google Scholar]

- Ferreira ICFR, Baptista M, Vilas-Boas L, Barros L. Free radical scavenging capacity and reducing power of wild edible mushrooms from northeast Portugal: individual cap and stipe activity. Food Chem. 2007;100:1511–1516. [Google Scholar]

- Gohari Ardebili A, Habibi Najafi MB, Haddad Khodaparast MH. Effect of date syrup as a substitute for sugar on the physicochemical and sensory properties of soft ice-cream. Iran. Food Sci. Tech. Res. J. 2005;1:23–31. [Google Scholar]

- Habib HM, Ibrahim WH. Nutritional quality evaluation of eighteen date pit varieties. Int. J. Food Sci. Nutr. 2009;60:99–111. doi: 10.1080/09637480802314639. [DOI] [PubMed] [Google Scholar]

- Hajian S, Hamidi Esfahani Z. Date palm status and perspective in Iran. In: Al-Khayri JM, SM and J , Johnson DV, editors. Date palm genetic resources and utilization. Illustrated Edn. Vol. 2. Asia and Europe, CRC Press; 2015. p. 16. [Google Scholar]

- Hwang JY, Shyu YS, Hsu CK. Grape wine less improves the theological adds antioxidant properties to ice-cream. LWT-Food Sci. Technol. 2009;42:312–318. [Google Scholar]

- Kaur C, Kapoor HC. Antioxidants a fruits and vegetables-the millenniums health. Int. Food Sci. Technol. 2001;36:703–725. [Google Scholar]

- Mansouri A, Embarek G, Kokkalou E, Kefalas P. Phenolic profile and antioxidant activity of the Algerian ripe date fruit (Phoenix dactylifera) Food Chem. 2005;89:411–420. [Google Scholar]

- Matsumoto H, Nakamura Y, Hirayama M, Yoshiki Y, Okubo K. Antioxidant activity of black currant anthocyanin aglycons and their glycosides measured by chemiluminescence in a neutral pH region and in human plasma. J. Agric. Food Chem. 2002;50:5034–5037. doi: 10.1021/jf020292i. [DOI] [PubMed] [Google Scholar]

- Milani E, Koocheki A. The effects of date syrup and guar gum on physical, rheological and sensory properties of low-fat frozen yoghurt dessert. Int. J. Dairy Technol. 2011;64:121–129. [Google Scholar]

- Ozdemir C, Dagdemir E, Ozdemir S, Sagdic O. The effect of using alternative sweeteners to sucrose on ice cream quality. J. Food Qual. 2008;31:415–428. [Google Scholar]

- Özer BH, Robinson RK, Grandison AS, Bell AE. Comparison of techniques for measuring the rheological properties of labneh (concentrated yogurt) Int. J. Dairy Technol. 1997;50:129–133. [Google Scholar]

- Sahari MA, Barzegar M, Radfar R. Effect of varieties on the composition of dates (Phoenix dactylifera L) J. Food Sci. Technol. 2007;13:269–275. [Google Scholar]

- Singh V, Guizani N, Essa MM, Hakkim FL, Rahman MS. Comparative analysis of total phenolics, flavonoid content and antioxidant profile of different date varieties (Phoenix dactylifera L) from Sultanate of Oman. Int. Food Res. J. 2012;19:1063–1070. [Google Scholar]

- Singh RP, Murthy KNC, Jayaprakasha GK. Studies on the antioxidant activity of pomegranate (Punica granatum) peel and seed extracts using in vitro models. J. Agric. Food Chem. 2002;50:81–86. doi: 10.1021/jf010865b. [DOI] [PubMed] [Google Scholar]

- Yangilar F. Mineral contents and physical, chemical, sensory properties of ice cream enriched with date fiber. Ital. J. Food Sci. 2015;27:397–406. [Google Scholar]