Abstract

The purpose of this research was to establish the nature and extent of the influence of microwaves and extrusion on the content of anti-nutritional substances of winter rye grain. There was performed two-factor laboratory experiment with the treatment of winter rye grain by electromagnetic waves of super-high frequency (microwave) on a LG MS-2042G installation and one-factor laboratory experiment with grain treatment using a MKP-30-500 extruder. Depending on the power and duration of the microwave treatment, the content of water-soluble pentosans decreased by 0.04–0.44% and the kinematic viscosity of the aqueous extract—by 2.4 times. As a result of extrusion processing, the content of water-soluble pentosans in the winter rye grain decreased by 1.34 times, the kinematic viscosity of the aqueous extract—by 2.42 times. For all the years of the research, extrusion has led to a certain decrease in starch in winter rye grain. During a 3-year period the original grain of winter rye contained on average 59.9% of starch. After extrusion, the value of this indicator decreased by 2.0% amounting to 57.9%. During the extrusion process, starch is partially hydrolyzed to form intermediate carbohydrates-dextrins and then glucose. Our research has shown an increase in the content of soluble carbohydrates in extruded rye grain. During a 3-year period, the content of soluble carbohydrates in grain increased on average from 31.45 to 51.36%, i.e. by 19.91%. Treatment by microwaves and extrusion are effective ways to reduce the anti-nutritional substances of winter rye grain and significantly increase the proportion of rye grain in the diet of farm animals.

Keywords: Rye, Grain, Anti-nutritional substances, Pentosans, Kinematic viscosity of the aqueous extract

Introduction

Cultivation of winter rye in the forest-steppe zone of the Russian Federation is expedient for a number of reasons. Compared to other grain crops, it is not a heavy feeder; it forms a higher and more stable yield. In recent years, there has been a reduction in acreage and, accordingly, in the total make of production of winter rye grain in the country which is caused by a decrease in demand for grain of this crop. One of the main reserves for driving up the demand for rye grain is to increase its share in the diet of farm animals. According to zootechnical standards, feeding diet for ruminants, pigs and poultry should include no more than 20–30%, 20% and 5–7% of rye grain given that the daily feeding rate makes up 1.5, 0.6 and 0.005–0.007 kg, respectively. In practice, the use of rye grain for the production of concentrated feed is even smaller and is equal to 3–5% (Ismagilov and Akhiyarova 2012).

In terms of nutrient content and energy intensity, rye grain is almost the same as the grain of other cereals. The energetic feed unit of winter rye grain is 1.13–1.16, the content of protein in the grain is 8.8–16.0%, of starch - 52–60%, crude fiber - 2.0–2.2%, fat - 2. At the same time, rye grain is characterized by a high content of the essential amino acid lysine, and exceeds the grain of oats and barley in energy intensity. The nutritional value of rye grain proteins is 83%, and wheat - 41% of the nutritional value of cow’s milk (Ismagilov and Akhiyarova 2012; Goncharenko 2014; Kucerova 2015).

The main reason for the limited use of rye grain for feeding farm animals is the high content of anti-nutritional substances, in particular, of water-soluble pentosans. Rye grain contains significantly more water-soluble pentosans (1.5–3.1%) than any other cereal (Ismagilov 2010, 2012; Karlsson 1988; Weipert 1983).

The viscosity of the aqueous extract reliably reflects the amount of water-soluble pentosans in grain and it is an anti-nutritional factor for rye grain (Goncharenko et al. 2005a, b; Ismagilov et al. 2018). With the exclusion of the influence of weather conditions, the correlation coefficient between the viscosity of the aqueous extract and the amount of water-soluble pentosans in the grain is 0.718 (Ismagilov et al. 2018).

The high content of water-soluble pentosans and, accordingly, the high viscosity of the aqueous extract of rye grain for bread making are favoured (Goncharenko et al. 2005a, b, 2017; Ismagilov et al. 2018; Wang et al. 2016). By contrast, for feeding purposes, these indicators of rye grain quality are undesirable (Ismagilov and Akhiyarova 2012; van Krimpen et al. 2017). The negative feeding properties of water-soluble pentosans are caused by their ability to absorb large amounts of water and form a highly viscous solution. In the digestive tract of animals, a highly viscous solution of pentosans impedes the absorption of nutrients of the food eaten. Consumption of rye grain in a high volume slows down the passage of forage in the gastrointestinal tract, leads to indigestion and finally weakens and decreases the productivity of farm animals. In poultry, stomach and esophagus may get clogged (Rusakov and Kosolapov 2012). Adding rye to the broiler diet will affect the immunity of birds (van Krimpen et al. 2017).

Therefore, to reduce the anti-nutritional properties of rye grain, it is necessary to develop ways of reducing the content of water-soluble pentosans in it.

There are various ways to prepare rye grain for feeding animals. Currently, to neutralize the anti-nutritional properties and increase the digestibility of nutrients of winter rye grain, they are treated with enzymatic preparations. Research show that it is possible to significantly reduce the viscosity of the aqueous grain extract of winter rye by treating it with enzyme preparations (Arczewska-Wlosek et al. 2019; Choct 2006; Norgaard et al. 2016, 2018).

Exogenous enzymes are activated by a humid and acidic environment, the temperature of the digestive tract, purposefully acting primarily on the substrate of the feed which contains soluble polysaccharides (pentosans, pectins) with high anti-nutritional properties. Endogenous enzymes secreted by the digestive system of monogastric animals can break only α-bonds and cannot break the β-bonds of polysaccharides. Hydrolysis of non-starch polysaccharides (including pentosans) results in the destruction of the glucid link, which gives endogenous enzymes access to the trapped nutrients of the diet. The introduction of xylanase enzyme from rye grain into the feed has a beneficial effect on weight gain and feed conversion rate in young chickens (1–21 days) (Arczewska-Wlosek et al. 2019). Adding xylanase to pig feed can hydrolyze arabinoxylan to lower molecular weight compounds and thereby reduce viscosity and improve nutrients’ utilization (Norgaard et al. 2016).

At the same time, the biotechnological method of preparing rye grain for feeding farm animals and poultry is not technologically simple enough and requires large lump-sum costs to get the necessary equipment.

It is possible to reduce the water soluble pentosans in winter rye grain to some extent by selection, sorting and long-term storage of grain (Goncharenko 2014; Goncharenko et al. 2017; Kobylyansky and Solodukhina 2013). Thus, according to the research results, a relatively low content of water-soluble pentosans is observed in the grain of the varieties, Saratovskaya 7 (2.13%), Antares (2.16%), Snezhana (2.29%) and Parom (2.26%) (Ismagilov and Akhiyarova 2012).

Large grains contain less pentosans, while increasing the thickness of the rye grain by 1 mm, the content of water-soluble pentosans decreases by 0.24% (Ismagilov et al. 2018). This dependence of the content of pentosans on the grain size allows, by sorting, to isolate the grain mass with a higher feed quality.

An effective way to reduce the anti-nutritional properties of grain is to store it for at least 4 months after harvesting. During this period of storage, the viscosity of the aqueous extract of Chulpan 7 variety of grain decreased by 2.33 times 3 years average; for example, in 2005–from 48.57 to 20.42 cCt (Ismagilov and Akhiyarova 2012).

Extrusion makes it possible to introduce more rye grain into the diet of feeding animals (Andersson et al. 2017; Jasinska-Kuligowska et al. 2013; Sitnikov and Morozkov 2016). During the extrusion process, the grain is affected by pressure and temperature. As a result of the influence of these factors, a decrease in the activity of inhibitors of digestion as well as sterilization, hydrolysis of starch and partially fiber to glucose occurs. Due to the extrusion, the digestibility of the nutrients of the grain increases.

There are results of the use of microwaves for drying and disinfecting seed, grain and manure (Krausp and Vasiliev 2014; Soboleva et al. 2017). The use of electromagnetic waves in the microwave range and high frequencies for seed treatment is characterized by a very high intensity of heating from within, alternatively to infrared radiation which heats the object from the outside (Krausp and Vasiliev 2014).

At the same time, there are no results of the study of the influence of ultrahigh frequency electromagnetic waves on the content of pentosans in grain. There is also not sufficient scientific information on the effect of winter rye grain extrusion as a way to reduce soluble pentosans which are the main anti-nutrient substances. The use of ultra-high frequency electromagnetic waves and extrusion to reduce the content of water-soluble pentosans will allow introducing rye grains into the diet of farm animals in greater quantities and reduce the cost of feed.

In this regard, the purpose of our research was to establish the nature and extent of the influence of microwaves and extrusion on the content of anti-nutritional substances of winter rye grain. As a result of our research, we have established for the first time the possibility of reducing the amount of anti-nutritional substances in winter rye grain by extruding it and processing with an ultra-high frequency electromagnetic field. It was found that the content of water-soluble pentosans in grain as well as water extract kinematic viscosity significantly decrease when microwave radiation power and exposure time increase. As a result of extrusion, a significant decrease in the content of water-soluble pentosans and kinematic viscosity of the water extract of grain was found. Extrusion leads to an increase in the content of soluble carbohydrates in rye grain.

Materials and methods

To achieve the purpose of the study, two-factor laboratory experiment was performed with the treatment of winter rye grain by electromagnetic waves of super-high frequency (microwave) on a LG MS-2042G installation and one-factor laboratory experiment with grain treatment using a MKP-30-500 extruder. A LG MS-2042G microwave is powered by an electrical network with a voltage of 220 V and a frequency of 50 Hz. The power range can be changed from 250 to 750 W. The heating duration is set by a timer. A MKP-30-500 extruder is designed for processing feed grain. It operates from an electrical network with a voltage of 380 V and a frequency of 50 Hz, its power is 31.65 kW. The capacity of the extruder is 450 kg/h.

Winter rye grain of Chulpan 7 variety grown in the southern forest-steppe of the Republic of Bashkortostan in 2016–2018 served as the material for the study.

The scheme of the experiment was as follows. Factor A—microwave power. Options: (1) No treatment (check); (2) 280 watts; (3) 420; (4) 560; (5) 700 watts. Factor B—duration of grain exposure to microwave. Options: (1) No treatment (check); (2) 60; (3) 90; (4) 120; (5) 150; (6) 180 s.

The repetition of options is threefold. In each option of the experiment, the same rye grain weight equal to 160 grams was treated. A sample of grain was placed in a layer of 1 cm in a glass container. The grain was ground in a laboratory mill LMC-1, sampling and determining of sample weight of grain was carried out according to GOST (All-Union State Standard) 13586.3-83.

The laboratory experiment with extrusion included 2 options: (1) No extrusion (check); (2) Extruded winter rye grain. The grain was extruded under a pressure of 40–60 atmospheres and at a temperature of 140–150 °C.

The grain was analyzed at the Laboratory of Biochemical Analysis and Biotechnology of Bashkir State Agrarian University. Grinding of grain was carried out by the laboratory mill LMT-2. The moisture content of the grain was determined in a fivefold repetition with a Wile-65 moisture meter, and the grain temperature was determined using an AKIP-9309 pyrometer. The content of pentosans in the grain was determined by an orcinol-chloride method modified by Hashimoto et al. (1987). The kinematic viscosity of the aqueous extract of the grain was determined on a capillary viscometer VSH-1 according to the specified method (Goncharenko et al. 2005a, b). The starch content was determined according to GOST 10845-98. Soluble carbohydrates in the grain and extrudate were determined according to Bertrand GOST 261776-91. A graphic presentation of the dependence of water extract viscosity of grain on power and exposure time was carried out by regression analysis of experimental data. Experimental data collection was 60. Regression analysis of the experimental data was carried out using the “Statistics” computer program.

Results

Microwave treatment was accompanied by an increase in the temperature of the grain. As the power increased to 700 W and the treatment time to 180 s, the grain temperature increased from 20.0 to 159.3 °C (Table 1). With a further increase in the power of the microwave electromagnetic field, the grain got charred.

Table 1.

Change in grain temperature after treatment by microwave (average for 2016–2018)

| Power (W) | Temperature (°C) | ||||

|---|---|---|---|---|---|

| 60 s | 90 s | 120 s | 150 s | 180 s | |

| 280 | 40.0 | 47.5 | 60.7 | 65.2 | 78.5 |

| 420 | 53.3 | 59.8 | 79.0 | 90.2 | 120.0 |

| 560 | 70.9 | 81.5 | 99.8 | 138.8 | 145.9 |

| 700 | 88.3 | 110.1 | 122.8 | 140.9 | 159.3 |

With an increase in the power and duration of the treatment by microwave, the moisture content of winter rye grain decreased. The greatest decrease in grain moisture (by 4.1%) occurred at the power of 700 W and treatment time of 180 s (Table 2).

Table 2.

Moisture of winter rye grain after treatment by microwave (average for 2016–2018)

| Power (W) | Moisture (%) | ||||

|---|---|---|---|---|---|

| 60 s | 90 s | 120 s | 150 s | 180 s | |

| 280 | 12.0 | 11.7 | 11.4 | 10.9 | 10.4 |

| 420 | 12.0 | 11.3 | 11.1 | 10.1 | 9.4 |

| 560 | 11.9 | 10.9 | 10.6 | 9.4 | 9.0 |

| 700 | 11.7 | 9.8 | 9.3 | 9.2 | 8.9 |

The content of water-soluble pentosans in the winter rye grain in the check option of 2018 yield was 3.81%. With the increase in the power and duration of exposure to microwave, the content of water-soluble pentosans sank by 0.04–0.44%. The maximum decrease in water-soluble pentosans (by 0.44%) was observed during the treatment by microwave at power of 700 W and an exposure of 180 s (Table 3). In the remaining years of the study, the maximum decrease in the water-soluble content was 0.32–0.39%.

Table 3.

Content of water-soluble pentosans in winter rye grain after treatment by microwave (2018)

| Power (W) | Water-soluble pentosans (%) | ||||

|---|---|---|---|---|---|

| 60 s | 90 s | 120 s | 150 s | 180 s | |

| 280 | 3.77 | 3.76 | 3.62 | 3.57 | 3.51 |

| 420 | 3.63 | 3.53 | 3.48 | 3.26 | 3.07 |

| 560 | 2.98 | 2.87 | 2.81 | 2.78 | 2.59 |

| 700 | 2.53 | 2.48 | 2.44 | 2.39 | 2.37 |

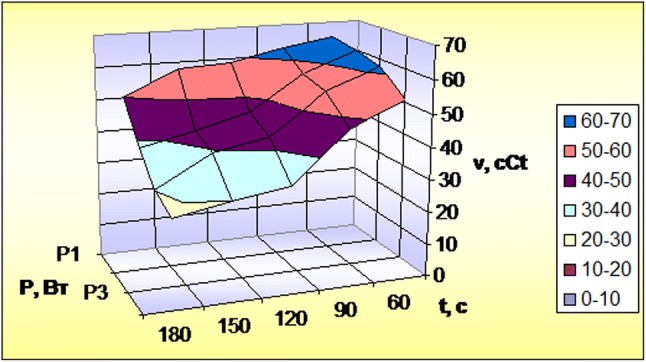

Treatment of grain by microwave has led to a decrease in the kinematic viscosity of the aqueous extract of rye grain throughout the years of the study. Moreover, the higher the power and duration of treatment, the greater the decrease in the kinematic viscosity of the aqueous grain extract. The maximum decrease in the kinematic viscosity of the aqueous extract of grain occurred in the treatment by microwave option at power of 700 W and the exposure of 180 s. For example, in 2018, the value of this indicator decreased from 64.31 to 26.92 cCt or by 2.4 times (Table 4).

Table 4.

Kinematic viscosity of winter rye grain after treatment by microwave (2018)

| Power (W) | Viscosity (cCt) | ||||

|---|---|---|---|---|---|

| 1 min | 1 min 30 s | 2 min | 2 min 30 s | 3 min | |

| 280 | 65.33 | 62.40 | 58.86 | 57.77 | 49.94 |

| 420 | 63.56 | 57.42 | 46.55 | 42.03 | 38.30 |

| 560 | 61.51 | 55.02 | 42.84 | 39.54 | 30.35 |

| 700 | 55.08 | 47.81 | 32.60 | 30.07 | 26.92 |

The regression analysis showed a close dependence of the viscosity of the aqueous grain extract on the duration and power of electromagnetic microwave treatment. A graphic presentation of this dependency is shown in Fig. 1.

Fig. 1.

Change in the kinematic viscosity of the grain depending on the duration and power of electromagnetic microwave processing (2018). 1. With the increase in the power and time of the microwave treatment, grain moisture decreases. 2. The content of water-soluble pentosans in the grain decreased from 0.04 to 0.44%. 3. Treatment by microwaves is effective to reduce the anti-nutritional substances of winter rye grain

The content of water-soluble pentosans after extrusion in all the years of the study was lower than the initial value of that indicator (Table 5). In 2016, the content of water-soluble pentosans in the grain of the check option was 3.69%; in extruded grain, that indicator decreased by 1.18% and equaled 2.51%. In 2017, the content of water-soluble pentosans of the check option was 3.40%, after extrusion it sank by 0.73% and equaled 2.67%. In 2018, the content of water-soluble pentosans after extrusion decreased by 0.86% and came to 2.67%. The content of water-soluble pentosans in winter rye grain as a result of extrusion decreased by 1.34 times, 3-year average.

Table 5.

Indicators of the quality of extruded winter rye grain

| Sample | Content of water-soluble pentosans (%) | Kinematic viscosity of the aqueous extract (cCt) | Starch content (%) | Content of soluble carbohydrates (%) |

|---|---|---|---|---|

| 2016 | ||||

| Untreated grain (check) | 3.69 | 50.72 | 55.6 | 32.21 |

| Extruded grain | 2.51 | 20.10 | 53.2 | 50.37 |

| 2017 | ||||

| Untreated grain (check) | 3.40 | 48.70 | 62.2 | 31.63 |

| Extruded grain | 2.67 | 21.15 | 60.1 | 51,91 |

| 2018 | ||||

| Untreated grain (check) | 3.53 | 58.70 | 61.8 | 30.52 |

| Extruded grain | 2.76 | 24.19 | 60.4 | 51.79 |

| 3-year average | ||||

| Untreated grain (check) | 3.54 | 52.71 | 59.9 | 31.45 |

| Extruded grain | 2.64 | 21.81 | 57.9 | 51.36 |

The kinematic viscosity of the aqueous extract of winter rye grain also decreased after extrusion. In 2016, the viscosity reduction occurred from 50.72 to 20.10 cCt, i.e. by 2.77 times (Table 5). In 2017, the kinematic viscosity of the aqueous extract of the check option was 48.70 cCt, after the winter rye grain was extruded it sank by 2.30 times and came to 21.15 cCt. In 2018, the kinematic viscosity before extrusion was 58.70 cCt, after extrusion, the value of that indicator decreased by 2.32 times and made 23.15 cCt. 3-year average, the kinematic viscosity of the aqueous extract of winter rye grain after extrusion processing decreased by 2.42 times.

In rye grain, starch is an important nutrient. During all the years of the research, extrusion led to some reduction of starch in winter rye grain. 3-year average, starch made up 59.9% in the initial grain of winter rye; after extrusion, the value of that indicator came to 57.9%, that is, there was a decrease by 2.0%. In the extrusion process, the starch is partially hydrolyzed to form intermediate carbohydrates—dextrins and then glucose. Our studies have shown an increase in the soluble carbohydrate content in the extruded rye grain. On average, over 3 years, the content of soluble carbohydrates in the grain increased from 31.45 to 51.36%, that is, by 19.91%.

Discussion

From the results of the experimental studies, it follows that the treatment by microwave led to a significant change in the physical and biochemical parameters of rye grain. That treatment was accompanied by a rise in the temperature of the grain as the power increased to 700 W and the treatment time to 3 min. With a further increase in the power of the microwave electromagnetic field, the grain became charred. An increase in temperature when exposed to microwave is due to the fact that organic matter consists of water, fats, and other substances that contain dipole molecules (Kozyrsky et al. 2012). Dipole molecules interact with the electric component of the electromagnetic field only. In the usual state, organic substances are electrically neutral and their dipoles are spaced chaotically; when placed in the constant electric field, the dipoles are strictly aligned along their lines of force. In the alternating electromagnetic field, the dipoles rotate continuously and, with flips, rub against each other, generating heat. It is the friction of the dipoles that causes the heating of food placed into the microwave. Microwaves penetrate the product to the depth of 1–3 cm; further heating of the product inward occurs due to its thermal conductivity. The use of electromagnetic waves in the microwave range and at high frequencies for seed treatment is characterized by a very high intensity of heating from the inside, unlike infrared radiation which heats the object from the outside (Krausp and Vasiliev 2014). With the increase in the power and duration of treatment by microwave, the moisture content of winter rye grain decreased. Treatment by microwave significantly reduced the content of water-soluble pentosans in the grain of winter rye, regardless of the initial value of that indicator (by 0.04–0.44%).

The viscosity of the aqueous extract is a fairly reliable indicator of the amount of water-soluble pentosans in the grain and it is an anti-nutritional factor for rye grain (Goncharenko et al. 2005a, b; Ismagilov et al. 2018). With the exclusion of the influence of weather conditions, the correlation coefficient between the viscosity of the aqueous extract and the amount of water-soluble pentosans in the grain is 0.718 (Ismagilov et al. 2018). Treatment of grain by microwave led to a significant decrease in the kinematic viscosity of the aqueous extract of rye grain (up to 2.4 times) in all the years of the study. Apart from that, the higher the power and duration of treatment, the greater the decrease in the kinematic viscosity of the aqueous grain extract.

Studies have shown that extrusion significantly reduces the content of the main anti-nutrient of rye grain–water-soluble pentosans. The content of water-soluble pentosans after extrusion in all the years of the study was lower than the initial value of that indicator. 3-year average, the content of water-soluble pentosans in winter rye grain as a result of extrusion sank by 1.34 times. Extrusion also significantly reduced the kinematic viscosity of the aqueous extract of winter rye grain (by 2.42 times). When extruded, the grain is affected by pressure, shift deformation, temperature and humidity. As a result of the influence of these factors, the structure of grain constituents changes, the activity of digestive inhibitors decreases, harmful substances are reduced, sterilization, hydrolysis of starch and partly cellulose to glucose takes place. A positive result is the improvement of the taste of the grain as a result of the formation of aromatic substances. As a result of extrusion, the digestibility of the nutrients of the grain increases dramatically due to the swelling and rupture of the membranes of plant cells and the denaturation of proteins. With the introduction of extruded grain into the diet of store pigs, the digestibility of dry matter, crude protein and crude fat increases (Andersson et al. 2017; Jasinska-Kuligowska et al. 2013; Sitnikov and Morozkov 2016). In all the years of the research, extrusion led to some reduction of starch in winter rye grain. In the extrusion process, the starch is partially hydrolyzed to form intermediate carbohydrates–dextrins and then glucose. Our research has shown that extrusion increases the soluble carbohydrate content in rye grain. Studies by Jasinska-Kuligowska (2013) also showed that the extrusion process using an extruder leads to an increase in fructan content.

Conclusions

Treatment by microwave raises the temperature of the grain. The maximum temperature of winter rye grain was recorded at the power of 700 W and the exposure of 3 min. With the increase in the power and time of the microwave treatment, grain moisture naturally decreases. The amount of anti-nutritional substances and the kinematic viscosity of the aqueous extract of winter rye grain decreased with the increasing power and exposure to microwave. The content of water-soluble pentosans in the grain decreased from 0.04 to 0.44%. A significant decrease in the kinematic viscosity of the aqueous extract of rye grain occurred with the increase in the temperature of the grain above 80 °C. The kinematic viscosity of the aqueous extract fell from 64.31 to 26.92 cCt.

The content of water-soluble pentosans and the kinematic viscosity of the aqueous extract of rye grain as a result of extrusion drop dramatically. 3-year average, the content of water-soluble pentosans in the grain decreased from 3.54 to 2.64%, the kinematic viscosity of the aqueous extract of the grain—from 52.71 to 21.81 cCt. A relatively small decrease occurred in the starch content in the grain (by 2.0%); a significant increase in soluble carbohydrates (by 19.91%) was observed. Thus, treatment by microwaves and extrusion are effective ways to reduce the anti-nutritional substances of winter rye grain.

Compliance with ethical standards

Conflict of interest

No potential conflict of interest was reported by the authors.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Andersson AAM, Andersson R, Jonsall A, Andersson J, Fredriksson H. Effect of different extrusion parameters on dietary fiber in wheat bran and rye bran. J Food Sci. 2017;82(6):1344–1350. doi: 10.1111/1750-3841.13741. [DOI] [PubMed] [Google Scholar]

- Arczewska-Wlosek A, Swiatkiewicz S, Bederska-Lojewska D. The efficiency of xylanase in broiler chickens fed with increasing dietary levels of rye. Animals. 2019;9(2):46. doi: 10.3390/ani9020046. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Choct M. Enzymes for the feed industry: past, present and future. Worlds Poult Sci J. 2006;62(1):5–15. doi: 10.1079/WPS200480. [DOI] [Google Scholar]

- Goncharenko AA. Current issues of winter rye breeding. Moscow: Agrorus; 2014. [Google Scholar]

- Goncharenko AA, Ismagilov RR, Berkutova NS, Vanyushina TN. Evaluation of the baking qualities of winter rye grain by the viscosity of the aqueous extract. Rep RAAS. 2005;1:6–9. [Google Scholar]

- Goncharenko AA, Ismagilov RR, Berkutova NS, Vanyushina TN, Ayupov DS (2005b) Evaluation of the bread-making quality of rye grain by viscosity of water extract. Doklady Rossiyskoy Akademii Selskokhozyaystvennykh Nauk = Proceedings of the Russian Academy of Agricultural Sciences 1, 6–9

- Goncharenko AA, Osipova AV, Ermakov SA, Makarov AV, Semenova TV, Tochilin VN, Davidova EI, Yashina NA, Kondrateva OP, Shcherbakova ZN, Krahmaleva OA. Dynamics of technological and baking qualities of winter rye grain depending on flour yield and water extract viscosity. Rus Agric Sci. 2017;43(5):360–362. [Google Scholar]

- Hashimoto S, Shogren MD, Pomeranz Y. Cereal pentosans: their estimation and significance. I. Pentosans in wheat and milled wheat products. Cereal Chem. 1987;64(1):30–34. [Google Scholar]

- Ismagilov RR (2010) Intervarietal variations in the content of water-soluble pentosans in winter rye grains. In: International symposium on rye breeding & genetics. Zhodino, Minsk, 29 June–02 July 2010, 93–94

- Ismagilov RR. The variability of the content of water-soluble pentosans in the grain of winter rye. Achiev Sci Technol Agro Ind Complex. 2012;6:35–36. [Google Scholar]

- Ismagilov RR, Akhiyarova LM. Feed quality of winter rye grain. Ufa: Gilem; 2012. [Google Scholar]

- Ismagilov RR, Gaysina LF, Akhiyarova LM, Ayupov DS, Nurlygayanov RB, Akhiyarov BG, Abdulvaleev RR, Malyutina KV, Ismagilov KR, Abdulloev VK. Crop yields and baking qualities of f1 winter rye hybrids grain in the forest-steppe of the Republic of Bashkortostan. J Eng Appl Sci. 2018;13(58):6487–6493. [Google Scholar]

- Jasinska-Kuligowska I, Kuligowski M, Kolodziejczyk P, Michniewicz J. Effect of fermentationextrusion and baking processes on content of fructans in rye products. Zywnosc-nauka technologia jakosc. 2013;20(5):129–141. [Google Scholar]

- Karlsson R. Pentosans in rye. Sveriges Utsadesforenings Tidskrift. 1988;98:213–225. [Google Scholar]

- Kobylyansky VD, Solodukhina OV. Theoretical bases of breeding grain rye with a low content of water-soluble pentosans. Agric Biol. 2013;2:31–39. [Google Scholar]

- Kozyrsky VV, Savchenko VV, Sinyavsky AYu. The influence of the magnetic field on the diffusion of molecules through the cell membrane of seeds of agricultural crops. Vestnik VISKh. 2012;2:16–20. [Google Scholar]

- Krausp VR, Vasiliev AA (2014) Microwave processing of grain—from electrical technology to nanotechnology. In: Proceedings of the international scientific and technical conference on energy supply and energy saving in agriculture. All-Russian Scientific Research Institute of Electrification of Agriculture, Moscow, 178–181

- Kucerova J. Technology of cereals. Brno: Vida Science Center; 2015. [Google Scholar]

- Norgaard JV, Pedersen TF, Blaabjerg K, Knudsen KEB, Laerke HN. Xylanase supplementation to rye diets for growing pigs. J Anim Sci. 2016;94:91–94. doi: 10.2527/jas.2015-9775. [DOI] [Google Scholar]

- Norgaard JV, Malla N, Dionisio G, Madsen CK, Pettersson D, Laerke HN, Hjortshoj RL, Brinch-Pedersen H. Exogenous xylanase or protease for pigs fed barley cultivars with high or low enzyme inhibitors. Anim Feed Sci Technol. 2018;248:59–66. doi: 10.1016/j.anifeedsci.2018.12.005. [DOI] [Google Scholar]

- Rusakov RV, Kosolapov VM. The effectiveness of different ways of preparing winter rye grains in feeding highly productive cows. Achiev Sci Technol Agro Ind Complex. 2012;6:61–65. [Google Scholar]

- Sitnikov VA, Morozkov NA. The use of winter rye grain extrusion processing in feeding cows: a monograph. Perm: Prokrost CPI; 2016. [Google Scholar]

- Soboleva OM, Kolosova MM, Filipovich LA, Aksenov VA. Electromagnetic processing as a way of increasing microbiological safety of animal waste. All Rus Res Pract Conf Ecol Saf Technosphere. 2017;66(1):012025. [Google Scholar]

- van Krimpen MM, Torki M, Schokker D. Effects of rye inclusion in grower diets on immune competence-related parameters and performance in broilers. Poult Sci. 2017;96(9):3324–3337. doi: 10.3382/ps/pex152. [DOI] [PubMed] [Google Scholar]

- Wang P, Tao H, Jin ZY, Xu XM. Impact of water extractable arabinoxylan from rye bran on the frozen steamed bread dough quality. Food Chem. 2016;200:117–124. doi: 10.1016/j.foodchem.2016.01.027. [DOI] [PubMed] [Google Scholar]

- Weipert D. The pentosan-starch ratio in milled rye products. In: Inglett G, editor. Cereals for food and beverages. New York: Academic Press; 1983. pp. 459–512. [Google Scholar]