Abstract

Leasing instead of purchasing scientific instruments is an economic option for academic core facilities to stay technologically ahead and competitive with predictable, consistent costs.

Subject Categories: S&S: Economics & Business, Methods & Resources

The ever‐increasing speed of technological development has made leasing, in its various forms, an attractive strategy for procuring a wide range of products. Renewal programs are built into mobile phone contracts, employers lease computer hardware and software for their employees, and the number of drivers who lease their car continues to increase. In contrast, most research institutions still purchase high‐tech scientific equipment. Here, we examine the advantages of leasing scientific research instruments and provide an example of a successful implementation of a lease‐based procurement strategy.

Similar to mobile phones, computers and cars, scientific equipment has a finite lifespan and quickly ends in obsolescence.

Leasing scientific infrastructure

Multi‐user core facilities are an integral resource at many research institutions. These facilities provide access to expensive technologies along with staff and expertise that are beyond the resources of individual research groups 1. Many core facilities are initially funded through government or philanthropic grants to provide for space and purchase a suite of instruments; however, the long‐term viability of the facility is often not guaranteed. Similar to mobile phones, computers, and cars, scientific equipment has a finite lifespan and quickly ends in obsolescence. Here, we discuss whether the most common equipment acquisition model—outright purchase of instruments—is appropriate for renewing instruments and maintaining the long‐term viability of a core facility.

In 1976, Nobel laureate (Economics) Merton Miller and Charles Upton published “Leasing, Buying, and the Cost of Capital Services”, a paper that would become the basis for modern corporations’ decisions on how to procure capital equipment 2. Miller and Upton reasoned that market forces will prevent a clear financial cost advantage for either leasing or buying to emerge over time. Therefore, the decision of whether to lease or buy capital equipment must be based on factors other than financial cost, such as tax code implications (for both buyer and seller), productivity incentives (technological advances that increase output), out‐of‐pocket contracting costs (maintenance contracts and disposal costs), and other factors. Because many research institutions operate as tax‐free entities, we will not address tax considerations but rather the other factors raised by Miller and Upton.

Advantages of leasing

Lease agreements can take many forms. For the purpose of this article, we define a lease as a financial agreement between two parties where the lessor provides equipment to a lessee in exchange for monetary payments over a defined term. The ownership of the equipment remains with the lessor, and, at the end of the term, the lessee can choose to buy the equipment outright or refresh the instrument with a newly leased model. Based on the study by Miller and Upton, and more recent work by Smith and Wakeman 3, we believe the following five factors indicate that capital equipment leasing is more favorable over outright purchase when establishing new, or refreshing old, scientific instruments.

Rate of technological improvement

The speed of technological development is the most common rationale provided in support of leasing. Although it is human nature to always want the latest and best gadget, is this emotional response based in fact? Let's compare two scientists: Scientist A has access to a brand‐new scientific device that can process 10 samples per day. Scientist B has a 5‐year‐old version that can analyze only one sample per day. If scientists A and B are in competition, scientist A is at an advantage. In the context of scientific output, maintaining an instrument replacement rate equivalent to the rate of technological improvement therefore provides an advantage over other researchers who refresh their equipment at a slower pace. In this regard, the more rapid the rate of technological improvement is, the more advantageous a lease becomes.

… the more rapid the rate of technological improvement is, the more advantageous a lease becomes.

The risk of competition should also be considered. Although the functional lifespan of an instrument may be 10 years or more, it is unlikely to be in high demand over that entire time. Smith and Wakeman refer to this as the “Expected Period of Asset Use 3”. As components age, they become less sensitive and are prone to malfunction. Meanwhile, new models are released with new functionalities causing reducing demand for the older system. If usership is lost to a neighboring facility with newer equipment, the core facility may be faced with unexpected financial pressure.

… when equipment ownership is retained by a lessor, there is added pressure for the lessor to maintain the equipment in optimal condition.

Maintenance expenditures

Ownership of scientific equipment requires choices regarding preventative maintenance and repairs. In core facilities, these items are triaged based on the available maintenance budget. Miller and Upton point out that when equipment ownership is retained by a lessor, there is added pressure for the lessor to maintain the equipment in optimal condition. First, at the conclusion of the lease, the lessor will attempt to resell the item as a used piece of equipment. If the instrument is well maintained, it can be resold for a higher price. Potentially, the lease charges, in combination with the resale price, can provide a greater profit to the lessor than selling a similar piece of equipment in a single transaction. Second, if the equipment is not fully functional for a certain length of time, the lessee may have the right to suspend or reduce their lease payments. Therefore, it is in the lessor's best interest to ensure that equipment downtime is minimal.

End‐of‐life disposal

When a piece of scientific equipment reaches its end of life, it is either broken or has become irrelevant. Disposal of electronic waste with potential biohazard or chemical contamination can be costly for a research institution. If the instrument is still functional, identifying another institute that could benefit from the item is difficult and requires time and effort. Further, disassembling the instrument, packaging for delivery, arranging for delivery, and reassembly at the new site often require assistance from the manufacturer at a cost. A leasing scheme that constantly refreshes instruments eliminates all disposal costs for the lessee. In a situation where a buyer cannot be found for a used system, the lessor can scavenge parts for the repair of similar systems in the field.

Risk

Points 1–3 above outline four significant risks to manufactures and end users of scientific instruments: technological obsolescence, competition risk, cost of maintenance and repair, and end‐of‐life disposal costs. Miller and Upton show that the proportion of this risk born by the end user increases, the longer the instrument is in their possession. Therefore, a lease‐based acquisition scheme with a high frequency refresh rate reduces these and other risk dramatically for the leasing institution.

Adaptability

The discussion to this point has focused on a single piece of equipment. Realistically, core facilities have many pieces of equipment with different uses. The relative demand for each of these instruments can vary over time. Therefore, it is advantageous to be able to adapt the mix of technologies to match demand. If demand exceeds capacity on an individual piece of equipment, a second unit can be acquired via lease at a significantly lower initial cost. Assuming the core charge fees for the use of the equipment, and demand is high enough, this acquisition could be revenue neutral. Conversely, if an instrument is underutilized, the lessee can discuss whether it should be exchanged for a different technology or simply not refreshed at the conclusion of its lease.

In our opinion, the factors outlined above provide strong support for leasing scientific equipment. In the field of light microscopy, it has been our experience that several manufacturers are open to leasing arrangements. In addition, third‐party financial institutions will purchase equipment from manufacturers and lease it to a research institute. Therefore, we believe there is sufficient competition in the market to prevent unreasonably high leasing costs.

Budgeting for scientific equipment acquisition

The literature surrounding leasing versus buying decisions primarily focuses on commercial businesses and therefore assumes that the entity procuring the equipment maintains a consistent annual capital equipment budget. Unfortunately, this is not the case for many core facilities. Research institutions generally have limited equipment budgets that are thinly spread across many cores. This can result in lengthy equipment refresh rates owing to competition between cores for internal funds. Other facilities rely solely on governmental or philanthropic grants to fund equipment purchases, and these funds are sought out only when the need arises. Relying on grant funding can stretch the procurement of a novel technology or replacement of an instrument to many months or years if grant submissions (and resubmissions) are required.

Interestingly, lease‐based procurement can provide what conservative budgets most desire: predictable, consistent costs year after year.

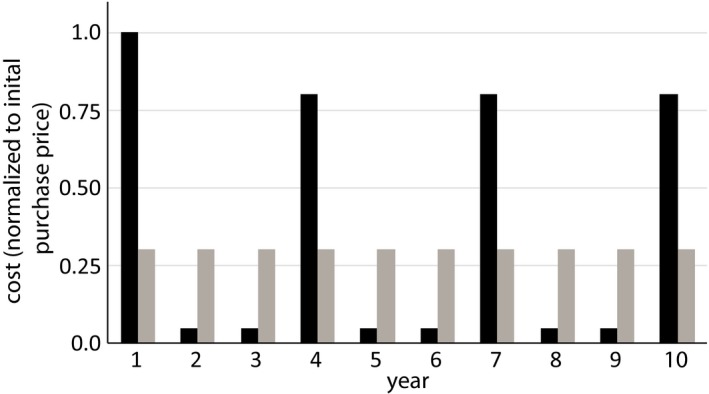

Most core facility funding models are not designed to support a lease‐based procurement strategy. Therefore, convincing administrators to consider a new model that requires substantial budgetary adjustments can be a major barrier to leasing. Interestingly, lease‐based procurement can provide what conservative budgets most desire: predictable, consistent costs year after year. Leasing spreads the upfront cost over time, provides a lower initial financial barrier, and prevents the need to hastily redistribute budgeted funds if a piece of equipment unexpectedly reaches its end of life (Fig 1). In addition, there are many leasing models—such as operating or capital leases—and there are many terms to be negotiated within a lease agreement including the leasing term, monthly payment, purchase options, renewal and refresh options, and others. Negotiating a lease can be daunting at first, but since every core facility is unique, careful attention to these details will ensure the most suitable financing option.

Figure 1. Ten‐year cost comparison of purchase versus lease procurement.

Ten‐year annual costs of a theoretical scientific instrument acquired by purchase (black bars) or lease (gray bars) with a 3‐year refresh rate. Lease costs are consistent year to year (30% of initial purchase price). Purchase costs include an outright instrument purchase (every 3 years), service/maintenance contracts (5% of initial purchase price) in non‐purchase years, and a 20% trade‐in discount on purchases after year 1. Costs are normalized to the initial purchase price of the instrument.

In May 2020, we will reach the 10‐year mark of our experiment with a lease‐based equipment procurement model at the Harvard Center for Biological Imaging (HCBI). In May 2010, the HCBI was launched with three leased microscopes and several other systems previously purchased by Harvard University. We have rapidly increased our use of the leasing model and expect that by June 2020 12 of 15 microscopes and 5 of 7 image analysis workstations will be under lease (Fig 2). All instruments under lease are replaced no sooner than 2 years, and no later than 3 years, after installation. Nearly 30 leased microscopes have passed through the HCBI since 2010, and our user base has expanded from less than 200 to over 700 individual users per year. The longevity of this experiment, and the continued growth of users and instruments, suggests both university administrators and scientific users have high levels of satisfaction with our program.

Figure 2. Annual growth in leased instruments at the HCBI.

Growth of leased instruments at the Harvard Center for Biological imaging over time.

Costs

As discussed above, the open market dictates that there should not be a financial cost advantage of leasing versus purchasing. However, the refresh rate of the equipment can impact this to some degree. Here, we have performed a rough calculation to compare the financial costs of leasing or buying over a 10‐year time frame. We have set the annual cost of a leased instrument to 30% of its initial purchase price. This includes the instrument as well as service/maintenance. We further assume the total cost of a purchased system is the sum of its initial purchase price and the cost of a service/maintenance contract in all subsequent years. Additionally, a “trade‐in” discount on owned instruments can be negotiated; therefore, we also include a 20% discount on all subsequent purchases beyond the first year. We only include service contract costs (at 5% of the initial purchase price per year) after the first year as scientific instruments are provided with a 1‐year warranty.

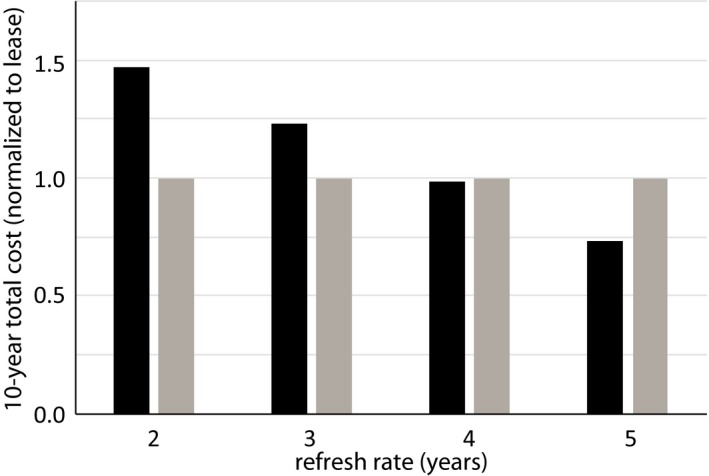

Figure 1 displays how the annual equipment costs fluctuate for a purchase‐based model using a refresh rate of once every 3 years relative to the consistent costs of a lease‐based model. Figure 3 shows that for the lease rate chosen here there is a potential cost savings if the refresh rate is more frequent than once every 4 years. However, we should assume that increasing or decreasing the refresh rate should also result in an increased or reduced annual lease payment. Unfortunately, the usage fees charged by most biomedical core facilities are unable to completely offset their costs. At the HCBI, the annual net cost of our leasing program—that is, the cost of lease fees, salaries, and consumables beyond what is recouped in usage fees—is roughly equivalent to buying one microscope system per year.

Figure 3. Effect of refresh rate on the 10‐year cost of purchase versus lease procurement.

Comparison of 10‐year total cost for a theoretical scientific instrument acquired by purchase (black bars) or lease (gray bars) with various refresh rates. Costs assume a lease rate of 30%. For purchased instrumentation, a service contract (5% of initial purchase) is included in non‐purchase years and a trade‐in discount (20%) is applied to purchases after year 1. All costs are normalized to the annual lease payment.

Determining the optimal refresh rate

This question is difficult to answer and will depend on the type of scientific equipment. For light microscopy, we found that refreshing microscopes once every 2–3 years is optimal. The major light microscopy manufacturers now release new features/products on an annual basis. However, many of these updates are minor and major product updates, such as new model series, happen every 3–5 years. Of the nearly 30 systems we have acquired in the past decade, only one was identical to its predecessor. Conversely, only one system had to be replaced early (after approximately 12 months) due to the release of a significant upgrade.

Based on our experience, we think that our refresh rate of 2–3 years is an ideal match to the current rate of technological improvements in light microscopy. Further, our leasing program has allowed us to expand our capacity on popular techniques while replacing seldomly used systems with technologies more appropriate for our broad user base. For example, the HCBI originally hosted an upright wide‐field fluorescence microscope that was underutilized as many researchers had similar systems in their own labs. This microscope was exchanged for a dedicated whole‐slide scanner at the end of its lease, which quickly became one of the facilities most‐used microscopes. In fact, we had to add a second slide scanner to satisfy demand. Addition of this instrument was revenue neutral as our user fees cover the cost of our monthly lease payments. The flexibility offered by leasing has been instrumental in preventing wasted investment in underused equipment and ensures that the HCBI can constantly adapt to the changing needs of our researchers.

Establishing a global used‐equipment marketplace

Scientists clearly prefer new equipment, but funding constraints or the specific nature of a research project can sometimes be better addressed by obtaining a used piece of equipment. An expanded marketplace for lightly used scientific instruments could promote inter‐ and intra‐institute reallocation of scientific equipment and enhance overall efficiency in the scientific instrument market. However, such a market for second‐hand equipment is disincentivized when the expenses—the financial and time costs to locate a buyer and retain a party who can pack, remove, ship, and install the equipment—are high or if supply is low. Since most research institutes do not have dedicated staff to buy, sell, and ship instrumentation, they hold on to most instruments until they no longer function. By not allowing these instruments back into the marketplace, the global volume of used scientific instruments remains small. Currently, it comprises a few demonstration units from manufacturers and repossessed items from biomedical liquidators.

… as more institutions and manufacturers turn to the lease‐based model, competition within the leasing market will increase and reduce this risk.

However, an active leasing market would offer a new source of used equipment with the lessor or manufacturer serving as an intermediary; the lessor's experience in refurbishing and reselling instruments would greatly increase efficiency. A similar expansion of used‐equipment markets has already been observed for other durable goods. In the aircraft market, for example, the number of transactions for narrow‐body aircraft on the secondary market is about four times the number of newly acquired aircraft. At the same time, a substantial share of new aircraft acquisitions is leases. In fact, owing to the longevity of aircraft, procurement in the secondary market is also often lease‐based 4. Therefore, the emergence of a lightly used scientific equipment market where systems could be purchased or leased at 20–30% discounts relative to new products could benefit institutions with lower budgets or individual labs that customize their instrumentation.

Benefits to large and small institutions

Considering the factors discussed above, small institutions stand to benefit as much from leasing as large organizations. First, small institutions are likely subject to higher volatility in equipment demand. With fewer overall researchers, the demand for niche technologies will be highly sporadic. Here, leasing allows such institutions to adapt to uncertainties by adjusting their equipment portfolios more frequently. However, small institutions are more likely to suffer funding gaps that would prevent them from being able to cover the monthly lease payments. In a lease‐based model, consistent payments are required and delaying the purchase of a new instrument until internal funding stabilizes is not an option.

An additional concern for smaller facilities is that they may be at a disadvantage when negotiating lease terms. For example, a smaller institution may not have the administrative staff to negotiate a lease‐based model and may not have the credit rating required for reasonable rates or the institution may not be able to acquire a large enough portfolio of equipment to meet the lessor's minimum requirements. This could result in unfairly high lease rates. However, as more institutions and manufacturers turn to the lease‐based model, competition within the leasing market will increase and reduce this risk. Additionally, as discussed above, smaller institutions who do not lease may still benefit from an expanded used‐equipment market of off‐lease instruments that are sold at discounted prices.

We believe a lease‐based model could become the new standard for acquiring scientific equipment. We also understand that not all organizations have the internal funding to support such an endeavor. Therefore, we strongly encourage funding agencies to consider offering financial support for leasing agreements in core facility operating grants.

EMBO Reports (2020) 21: e49971

References

- 1. Meder D, Morales M, Pepperkok R, Schlapbach R, Tiran A, Van Minnebruggen G (2016) Institutional core facilities: prerequisite for breakthroughs in the life sciences: core facilities play an increasingly important role in biomedical research by providing scientists access to sophisticated technology and expertise. EMBO Rep 17: 1088–1093 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2. Miller MH, Upton CW (1976) Leasing, buying, and the cost of capital services. J Finan 31: 761–786 [Google Scholar]

- 3. Smith CW, Wakeman LM (1985) Determinants of corporate leasing policy. J Finan 40: 895–908 [Google Scholar]

- 4. Gavazza A (2011) Leasing and secondary markets: theory and evidence from commercial aircraft. J Polit Econ 199: 325–377 [Google Scholar]