Abstract

The envelope of gram-positive bacteria encompasses the cell wall, a rigid exoskeleton comprised of peptidoglycan that provides protection against lysis and governs bacterial cell shapes. Peptidoglycan also serves as the site of attachment for proteins and nonproteinaceous polymers that interact with the bacterial environment. Nonproteinaceous molecules include teichoic acids, capsular polysaccharides, and secondary cell wall polysaccharides (SCWP). Treatment of gram-positive bacterial cells with proteases, nucleases, and detergents results in the isolation of “murein sacculi” (i.e., peptidoglycan with bound carbohydrate polymers). Incubation of sacculi with acid or base releases carbohydrate polymers that can be purified for further biochemical characterization. This protocol describes the hydrofluoric acid extraction and purification of the secondary cell wall polymer of Bacillus anthracis that is also found in the envelope of the other members of the Bacillus cereus sensu lato group of bacteria.

Keywords: Secondary cell wall polysaccharide, Bacillus cereus, Murein sacculus, Peptidoglycan, Hydrofluoric acid, Phosphodiester bond

1. Introduction

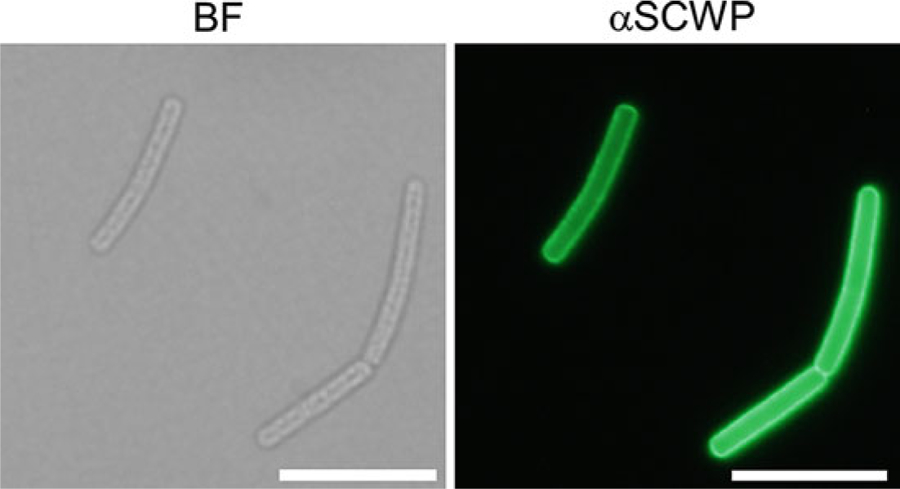

In gram-positive bacteria, which lack an outer membrane, the peptidoglycan cell wall represents the microbe’s most outer layer and surface organelle. Peptidoglycan consists of glycan strands comprising 5–30 repeating disaccharide units, N-acetylmuramic acid-(β1–4)-N-acetylglucosamine (MurNAc-GlcNAc). MurNAc residues are amide-linked to short wall peptides that incorporate both l- and d-forms of amino acids that make the cell wall impervious to proteolytic activity. Peptides of neighboring glycan strands are cross-linked via the crossbridge, that is, the amino group derived from position three of the wall peptide (l-lysine, mesodiaminopimelic acid, or peptide extensions appended to either one of these amino acids), generating a three-dimensional molecular network that surrounds the cell akin to an exoskeleton (reviewed by [1]). Peptidoglycan also functions as a scaffold for the immobilization of proteins [2], capsular polysaccharides [3, 4], wall teichoic acids (WTAs) [5], and secondary cell wall polysaccharides (SCWP) [6]. Cell wall-anchored proteins are covalently bound by the enzyme sortase to the peptide moiety of peptidoglycan (reviewed by [7]) while most other polymers are transferred onto the glycan strands of peptidoglycan by the LytR-CpsA-Psr (LCP) family of enzymes [4, 8–11]. Precursor polymers bound to the lipid carrier undecaprenol-(PO4)2 serve as substrates of LCPs, which attach the polymers to the C-6 hydroxyl of MurNAc via phosphodiester linkage and release undecaprenol-(PO4) [8]. Phosphodiester bonds are sensitive to acid and base treatments [5]. Thus, peptidoglycan purified at neutral pH is decorated with covalently linked polymers that can be released by altering the pH of suspended peptidoglycan [12, 13]. Members of the Bacillus cereus sensu lato group, which includes B. anthracis, synthesize a SCWP with the trisaccharide repeat structure [→4)-β-ManNAc-(1→4)-β-GlcNAc (O3-α-Gal)-(1→6)-α-GlcNAc(O3-α-Gal, O4-β-Gal)-(1→]6–12 [14]. The reducing end of the terminal repeat unit of SCWP is uniquely modified with ketal-pyruvyl to serve as a ligand for the S-layer homology (SLH) domains that are found in a subset of secreted proteins [15]. These include S-layer proteins, which assemble into a paracrystalline S-layer, as well as S-layer-associated proteins (BSLs) that fulfill unique functions such as host cell adhesion, nutrient transport, cell separation and chain length determination (reviewed by [16]). Unlike other gram-positive bacteria, B. anthracis lacks WTA and only the SCWP is released upon acid treatment of peptidoglycan preparations [17]. Figure 1 shows fluorescent micrographs of B. anthracis cells, revealing the surface display of SCWP.

Fig. 1.

Micrographs of B. anthracis strain Sterne cells revealing the surface display of SCWP. Cells were fixed in formalin, stained with anti-SCWP antibodies (αSCSWP) and observed by bright-field microscopy (BF, left panel) or fluorescence microscopy (right panel). Scale bar, 10 μm

Here we describe a simple method for the extraction and purification of SCWP that can be adapted to other peptidoglycan-bound polymers. Such preparations can be used for the determination of structure and composition using size exclusion chromatography, MALDI-TOF mass spectrometry, and NMR. The protocol may be useful to compare the composition of SCWP from different bacterial strains [14, 18–20] to study the enzymes that are implicated in SCWP synthesis [21], and to characterize ligands of the SCWP such phage endolysin [22] as well as SLH domain-containing proteins [15].

2. Materials

All solutions and buffers should be prepared with deionized water and analytical grade reagents. Unless indicated, reagents, solutions, and buffers are stored at room temperature.

2.1. Purification of Murein Sacculi (See Note 1)

Brain–heart infusion (BHI) broth: Dissolve 37 g of BHI in 1 L of water. Autoclave at 121 °C for 15 min.

BHI agar plates: add 15 g of agar to 1 L of BHI. Autoclave at 121 °C for 15 min.

B. anthracis Sterne strain (or any B. cereus group bacteria).

250 mL conical flask.

Sodium dodecyl sulfate (SDS) 20%: dissolve 10 g of SDS in 500 mL of water using a water bath at 55 °C to help dissolution.

50-mL conical centrifuge tubes.

500-mL heat- and acid-resistant centrifuge bottles.

Boiling water bath.

15-mL conical centrifuge tubes.

0.1-mM glass beads.

Bead beater.

100 mM Tris–HCl pH 7.5: Dissolve 12.1 g of Tris in 900 mL of water. Adjust the pH with 1 M HCl and complete 1 L with water.

1 M MgSO4: Dissolve 6.02 g of MgSO4 in 50 mL of water.

RNase 10 mg/mL: Dissolve 10 mg of RNase in 1 mL of water.

Dnase 10 mg/mL: Dissolve 10 mg of DNase in 1 mL of water.

Trypsin 10 mg/mL: Dissolve 10 mg of trypsin in 1 mL of water.

1 M CaCl2: Dissolve 5.55 g of CaCl2 in 50 mL of water.

100 mM Tris–HCl, pH 8.0: Dissolve 12.1 g of Tris in 900 mL of water. Adjust the pH with 1 M HCl and complete 1 L with water.

100 mM ethylenediaminetetraacetic acid (EDTA), pH 8.0: Dissolve 37.2 g of disodium EDTA (Na2EDTA) in 800 mL of water and adjust the pH to 8 with NaOH (see Note 2). Bring volume to 1 L.

Acetone 100%.

2.2. Extraction of SCWP

Hydrofluoric acid (HF) 48%.

Ethanol 100% kept at −20 °C.

Centrifugal evaporator such as a Speed-Vac.

2.3. Reverse-Phase High-Performance Liquid Chromatography (rpHPLC)

One 4.6 × 250 mM Hypersil ODS C18 column (particle size 3 μm) and one 3-μm-particle-size guard column set between injector and C18 column.

HPLC with a photodiode array (PDA) detector.

HPLC grade water.

HPLC grade acetonitrile.

HPLC grade trifluoroacetic acid (TFA).

Buffer A: water–0.1% TFA. Add 1 mL of TFA in 1 L of water (HPLC grade).

Buffer B: acetonitrile–0.1% TFA. Add 1 mL of TFA in 1 L of acetonitrile (HPLC grade).

1.5-mL Eppendorf tubes for sample collection.

2.4. Size Exclusion Chromatography (SEC)

One 7.8 × 300 mM BioBasic SEC300 column.

HPLC with PDA detector.

50 mM sodium phosphate buffer pH 7.5. This buffer is prepared by mixing: 40 mL of 0.2 M NaH2PO4 H2O (weigh 27.6 g in 1 L water), 210 mL of 0.2 M Na2HPO4 7H2O (weigh 53.65 g in 1 L water) and 750 mL of water. Use HPLC grade water to prepare solutions and buffer.

1.5-mL Eppendorf tubes for sample collection.

3. Methods

When manipulating Risk Group 2 (RG2) live bacteria such as B. anthracis strain Sterne, use sterile conditions, work in a Biosafety cabinet and use proper protective equipment as stipulated by your Institutional Biosafety Committee. Discard all live and contaminated reagents and materials in a biosafety hazard container and insure that the materials are appropriately destroyed.

3.1. Purification of Murein Sacculi

Inoculate a single colony of B. anthracis into 20 mL of BHI in a 250-mL conical flask and incubate at 37 °C with aeration (220 revolution per min) until the culture reaches stationary growth or up to 12 h.

Transfer and spread culture aliquots of 300 μL onto 50 BHI plates. Incubate plates overnight at 37 °C or up to 16 h.

Scrape cells from plates and transfer to a 250-mL conical flask filled with 25 mL of water.

Transfer suspension to a 50-mL conical centrifuge tube and harvest cells by centrifugation at 6000 × g for 10 min at room temperature.

Discard supernatant and resuspend cells in 10 mL of water, transfer the suspension to a 500-mL centrifuge bottle. Add 270 mL water and 70 mL of 20% SDS to yield a final concentration of ~4% SDS.

Close bottle and securely place in a boiling water bath for 30 min.

Cool to room temperature, and harvest cells by centrifugation at 6000 × g for 10 min at room temperature. This treatment will effectively kill bacterial cells and samples may be considered safe at this point.

Wash materials in pellet at minimum five times with water to eliminate all traces of SDS (see Notes 3 and 4).

Suspend pellet in 40 mL of water, and distribute sample roughly into six 15-mL conical centrifuge tubes prefilled with roughly 3 mL of 0.1 mM glass beads (use tubes with graduation to facilitate this step).

Securely fasten tubes to the bead beater and subject cells to mechanical lysis by performing 10 pulses of 1 min. Transfer tubes on ice for 5 min between each pulse to avoid overheating of samples. If using the MP Biomedicals™ FastPrep −24™ Classic Instrument, set the instrument on TN 12 × 15, speed 6 m/s.

After the final pulse, allow beads to sediment by gravity and carefully pipette the lysates and transfer to a clean 50-mL conical centrifuge tube.

Refill once more the 15-mL conical centrifuge tube with water as in step 9, and pulse one more time as described in steps 10 and 11. Transfer all materials that do not sediment into the same 50-mL conical centrifuge tube.

Allow any leftover glass beads to sediment by gravity and carefully transfer lysate to a new 50-mL conical centrifuge tube.

Centrifuge tube at 6000 × g for 10 min at room temperature. Wash pellet once with water.

Repeat step 14, discard all fluids without perturbing pellet.

Suspend materials in pellet with 25 mL 100 mM Tris–HCl, pH 7.5. Add 25 μL of RNAse solution (10 mg/mL), 25 μL of DNAse solution (10 mg/mL), and 250 μL of 1 M MgSO4. Incubate tube for 4 h at 37 °C with gentle agitation if possible (use a tube rotator if available).

Add to the same tube, 25 μL of trypsin solution (10 mg/mL) and 250 μL of 1 M CaCl2. Place tube back at 37 °C for 16 h.

18. Harvest insoluble material by centrifugation at 6000 × g for 10 min at room temperature, wash once with water.

Repeat steps 5 through 8 (see Note 5).

Perform one wash with 25 mL of 100 mM Tris–HCl, pH 8.0. Centrifuge tube at 6000 × g for 10 min at room temperature, discard supernatant.

Repeat step 20 with water.

Repeat step 20 with 25 mL of 100 mM EDTA, pH 8.0.

Repeat step 20 with water.

Repeat step 20 with 25 mL acetone but centrifuge tube at 3000 × g (see Note 6).

Repeat step 20 twice with water (see Note 7).

The pellet containing cell wall fragments (murein sacculi) can be stored at −20 °C until further use.

3.2. Extraction of SCWP

Resuspend pellet containing cell wall fragments (as prepared above) in 5 mL of water in a 50-mL conical tube and add 25 mL of 48% HF (see Note 8).

Incubate for 18 h shaking gently at 4 °C.

Centrifuge tube at 8000 × g for 15 min at 4 °C.

Transfer the supernatant to a 500-mL centrifuge bottle and discard the HF-laden pellet in a dedicated chemical waste container.

Add 5 volumes of cold ethanol (−20 °C) to the bottle, close and keep overnight at −20 °C.

Centrifuge bottle at 10,000 × g for 15 min at 4 °C to harvest precipitated SCWP. Discard the HF-laden supernatant in a dedicated chemical waste container.

Wash pellet five times with ethanol, gently resuspending between each wash and centrifuging bottle at 10,000 × g for 15 min at 4 °C.

After the last wash, gently suspend pellet with ethanol and transfer suspension to an empty Eppendorf tube previously weighed empty.

Transfer tube containing sample to a Speed-Vac, and dry to completion before weighing tube once more to evaluate the yield of purified SCWP (see Note 9).

Store tube with dried SCWP at −20 °C.

This material can be used for rpHPLC and SEC purification and further analyzed by MALDI-TOF mass spectrometry or NMR.

3.3. rpHPLC Purification

Resuspend dried SCWP obtained in Subheading 3.2 in water to a final concentration of 100 mg/mL.

Using HPLC, load 100 μL of SCWP over the Hypersil ODS C18 column using the guard column set between injector and C18 column.

- Load and elute sample with a flow rate of 0.5 mL/min and use the following separation gradient of Buffers A and B:

- 10 min: 0% Buffer B (100% Buffer A).

- 5 min: 0–10% linear gradient of Buffer B.

- 20 min: 10–20% linear gradient of Buffer B.

- 65 min: 20–100% linear gradient of Buffer B.

- 10 min: 100% Buffer B.

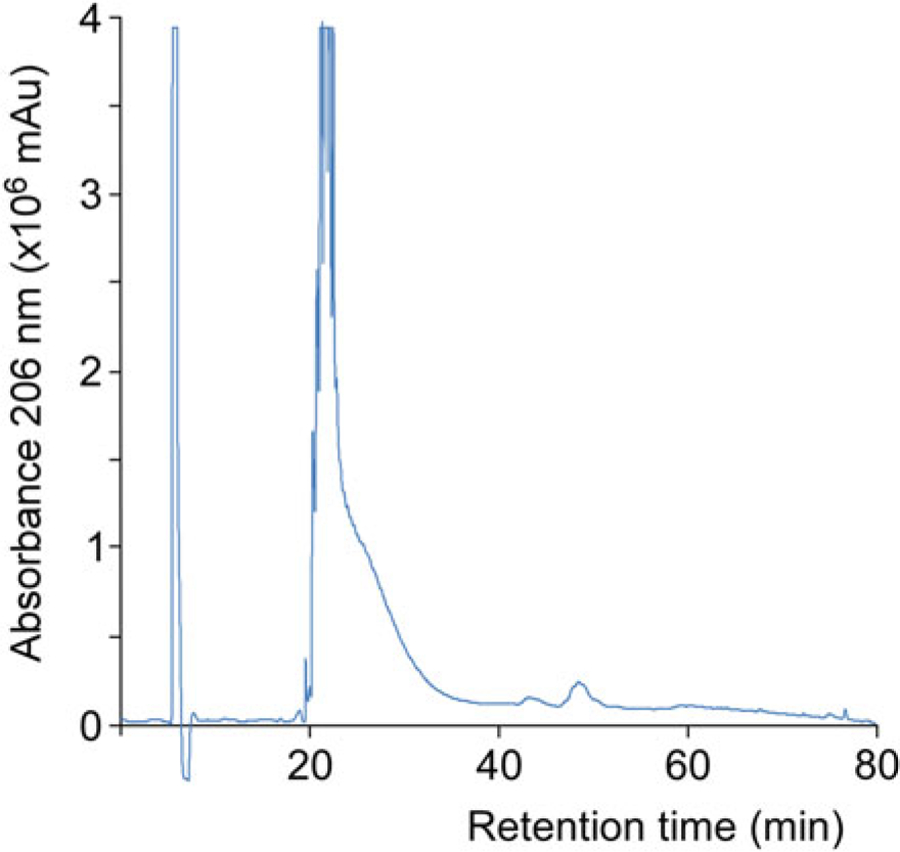

Collect 0.5-mL fractions and record chromatographic UV absorption profile with PDA by monitoring absorbance at 206 nm (A206). A typical elution profile for HF purified SCWP is shown in Fig. 2. The majority of the material elutes at ~25 min with 15% acetonitrile.

Fractions containing SCWP can be collected and stored at −20 °C for structural characterization and biochemical assays.

Fig. 2.

rpHPLC chromatograph of HF purified SCWP from B. anthracis Sterne strain. Milli-Absorbance units (mAu) were recorded at 206 nm

3.4. SEC

Resuspend dried SCWP obtained in Subheading 3.2 in 50 mM sodium phosphate pH 7.5 to a final concentration of 100 mg/mL.

Using HPLC, load 100 μL of SCWP over the BioBasic SEC300 column equilibrated with 50 mM sodium phosphate buffer pH 7.5.

Load and elute sample with a flow rate of 1 mL/min in 50 mM sodium phosphate buffer pH 7.5.

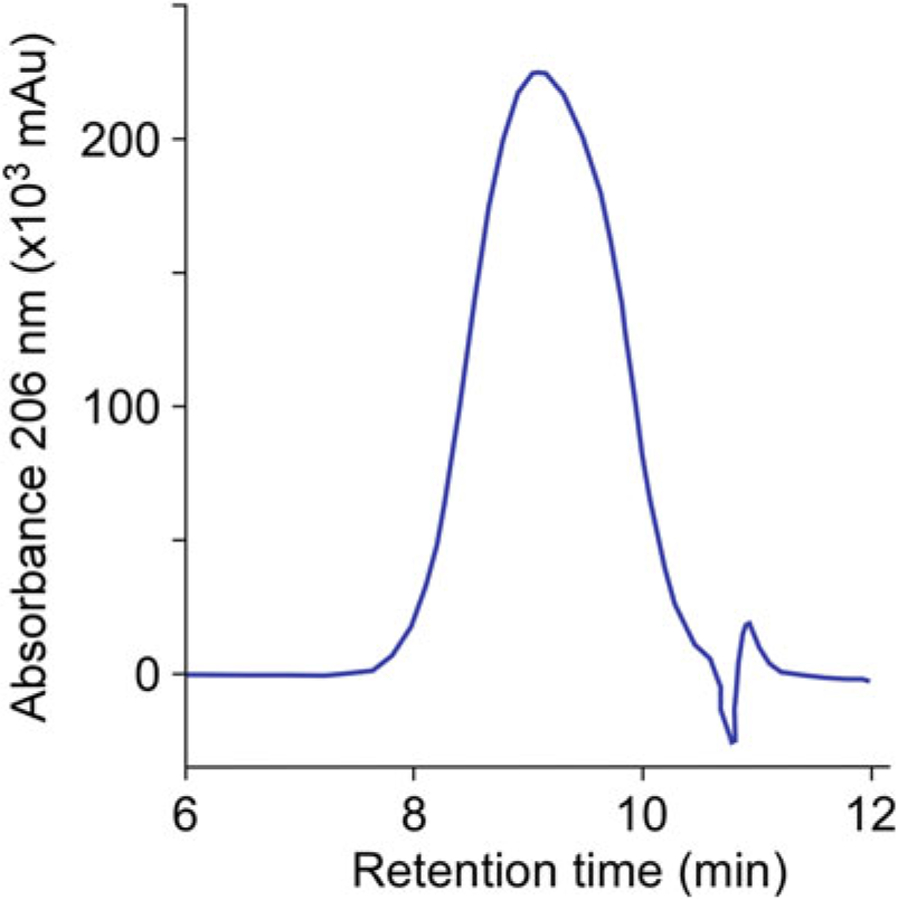

Collect 0.5-mL fractions and record chromatographic UV absorption profile with PDA by monitoring absorbance at 206 nm (A206). The typical retention time for HF purified SCWP (~ 12 kDa) is shown in Fig. 3. The column can be calibrated using the same settings and buffer with known molecular weight markers.

Fractions containing SCWP can be collected and stored at −20 °C for structural characterization and biochemical assays (see Note 10).

Fig. 3.

Size exclusion chromatography of SCWP from B. anthracis Sterne strain. Absorbance was measured in milli-Absorbance units (mAu) at 206 nm

Acknowledgments

We thank current and past members of the laboratory who helped develop and refine this protocol. Research in our laboratory is supported by grant number AI069227 from the National Institute of Allergy and Infectious Diseases, Infectious Diseases Branch.

4 Notes

We use the term murein sacculi to refer to peptidoglycan with bound polymers and use a bead beater during the extraction procedure to mechanically break the exoskeletal network of peptidoglycan. This procedure results largely in murein fragments with bound polymers rather than intact sacculi.

The disodium salt of EDTA will not dissolve until the pH of the solution is adjusted to 8.0 with NaOH.

Eliminating SDS: to wash sample and eliminate all SDS, add 10–12 mL of water to the decanted cells in the 500-mL centrifuge bottle. Carefully resuspend cells before adding another 350 mL of water. Make sure to completely resuspend the cells. Repeat as needed. SDS is a detergent that is responsible for the formation of bubbles. The absence of bubbles indicates that all SDS has been washed away. Incomplete removal of SDS will interfere with the bead beating process.

Following removal of SDS, pellets can be stored at −20 °C before tackling the next steps. Make sure to remove all the SDS otherwise it will precipitate at the lower temperatures.

Second SDS boiling: this is done to heat-inactivate the enzymes added as a result of the procedure.

Sample solubility is decreased following acetone wash; thus, a smaller centrifugal (g) force is applied to the samples to facilitate resuspension of pellets.

Following acetone and first water washes, pellets will appear more compact. Pellets will recover a more normal and fluffy appearance with subsequent water washes.

HF is extremely toxic and should be used with extreme caution! A 25-square inch burn with HF can be lethal. HF should always be handled inside a chemical fume hood. HF and HF-waste products should be placed in clearly marked vials and containers. Other laboratory members should be made aware of the presence and use of HF. Use chemical gloves that cover the hands, wrists, and forearms when using HF. Call appropriate Environmental Health & Safety personnel for the immediate removal of waste material and unused HF.

The typical yield for SCWP purification is between 10 to 40 mg. Purity of the preparation can be rapidly validated by performing a UV–visible scan using a spectrophotometer. SCWP absorbs light with a maximum absorption at 206 nm.

Most purification procedures use rpHPLC and the use of SEC is offered as an alternative. One advantage of SEC is the ability to compare sizes of polysaccharides between related species or between isogenic mutants that might be impaired in the synthesis of SCWP.

References

- 1.Navarre WW, Schneewind O (1999) Surface proteins of gram-positive bacteria and the mechanisms of their targeting to the cell wall envelope. Microbiol Mol Biol Rev 63:174–229 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Schneewind O, Fowler A, Faull KF (1995) Structure of the cell wall anchor of surface proteins in Staphylococcus aureus. Science 268:103–106 [DOI] [PubMed] [Google Scholar]

- 3.Munoz E, Ghuysen J-M, Heymann H (1967) Cell walls of Streptococcus pyogenes type 14. C polysaccharide-peptidoglycan and G polysaccharide-peptidoglycan complexes. Biochemistry 6:3659–3670 [DOI] [PubMed] [Google Scholar]

- 4.Chan YG, Kim HK, Schneewind O et al. (2014) The capsular polysaccharide of Staphylococcus aureus is attached to peptidoglycan by the LytR-CpsA-Psr (LCP) family of enzymes. J Biol Chem 289:15680–15690 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Coley J, Archibald AR, Baddiley J (1976) A linkage unit joining peptidoglycan to teichoic acid in Staphylococcus aureus H. FEBS Lett 61:240–242 [DOI] [PubMed] [Google Scholar]

- 6.Ries W, Hotzy C, Schocher I et al. (1997) Evidence that the N-terminal part of the S-layer protein from Bacillus stearothermophilus PV72/p2 recognizes a secondary cell wall polymer. J Bacteriol 179:3892–3898 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Schneewind O, Missiakas D (2014) Sec-secretion and sortase-mediated anchoring of proteins in gram-positive bacteria. Biochim Biophys Acta 1843:1687–1697 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Kawai Y, Marles-Wright J, Cleverley RM et al. (2011) A widespread family of bacterial cell wall assembly proteins. EMBO J 30:4931–4941 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Eberhardt A, Hoyland CN, Vollmer D et al. (2012) Attachment of capsular polysaccharide to the cell wall in Streptococcus pneumoniae. Microb Drug Resist 18:240–255 [DOI] [PubMed] [Google Scholar]

- 10.Chan YGY, Frankel MB, Dengler V et al. (2013) Staphylococcus aureus mutants lacking the LytR-CpsA-Psr (LCP) family of enzymes release wall teichoic acids into the extracellular medium. J Bacteriol 195:4650–4659 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Liszewski Zilla M, Chan YG, Lunderberg JM et al. (2015) LytR-CpsA-Psr enzymes as determinants of Bacillus anthracis secondary cell wall polysaccharide assembly. J Bacteriol 197:343–353 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Kojima N, Arakai Y, Ito E (1985) Structure of the linkage units between ribitol teichoic acids and peptidoglycan. J Bacteriol 161:299–306 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.de Jonge BL, Chang YS, Gage D et al. (1992) Peptidoglycan composition of a highly methicillin-resistant Staphylococcus aureus strain. The role of penicillin binding protein 2A. J Biol Chem 267(16):11248–11254 [PubMed] [Google Scholar]

- 14.Choudhury B, Leoff C, Saile E et al. (2006) The structure of the major cell wall polysaccharide of Bacillus anthracis is species specific. J Biol Chem 281:27932–27941 [DOI] [PubMed] [Google Scholar]

- 15.Mesnage S, Fontaine T, Mignot T et al. (2000) Bacterial SLH domain proteins are non-covalently anchored to the cell surface via a conserved mechanism involving wall polysaccharide pyruvylation. EMBO J 19:4473–4484 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Missiakas D, Schneewind O (2017) Assembly and function of the Bacillus anthracis S-layer. Annu Rev Microbiol 71:79–98 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Molnár J, Prágai B (1971) Attempts to detect the presence of teichoic acid in Bacillus anthracis. Acta Microbiol Acad Sci Hung 18:105–108 [PubMed] [Google Scholar]

- 18.Leoff C, Saile E, Sue D et al. (2008) Cell wall carbohydrate compositions of strains from Bacillus cereus group of species correlate with phylogenetic relatedness. J Bacteriol 190:112–121 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Forsberg LS, Choudhury B, Leoff C et al. (2011) Secondary cell wall polysaccharides from Bacillus cereus strains G9241, 03BB87 and 03BB102 causing fatal pneumonia share similar glycosyl structures with the polysaccharides from Bacillus anthracis. Glycobiology 21:934–948 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Forsberg LS, Abshire TG, Friedlander A et al. (2012) Localization and structural analysis of a conserved pyruvylated epitope in Bacillus anthracis secondary cell wall polysaccharides and characterization of the galactose deficient wall polysaccharide from avirulent B. anthracis CDC 684. Glycobiology 22:1103–1117 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Chateau A, Lunderberg JM, Oh SY et al. (2018) Galactosylation of the secondary cell wall polysaccharide of Bacillus anthracis and its contribution to anthrax pathogenesis. J Bacteriol 200 (5). 10.1128/JB.00562-17 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Mo KF, Li X, Li H et al. (2012) Endolysins of Bacillus anthracis bacteriophages recognize unique carbohydrate epitopes of vegetative cell wall polysaccharides with high affinity and selectivity. J Am Chem Soc 134:15556–15562 [DOI] [PMC free article] [PubMed] [Google Scholar]