Abstract

The objective of this work is to review literature, worldwide, in which the Rapid Entire Body Assessment (REBA) ergonomic assessment method was applied and count the number of times that REBA was applied together with other methods and subsequent incidence. The database used was the “Web of Science—Core Collection”. Only scientific articles and bibliographic reviews were included, analysing a total of 314 documents and selecting only 91. The use of the REBA method is indicated in terms of knowledge, country, year and journal sectors. It was most used in the knowledge areas of “Manufacturing” (24.18%), “Agriculture, forestry and fishing” (21.98%) and in “Other activities” (19.78%). One of the benefits of REBA is that it evaluates different body parts: upper limbs (arm, forearm and wrist), lower extremities, trunk and neck. It is a useful method to identify the forced postures adopted by workers to thus develop improvement measures if necessary. It is concluded that REBA method use has increased over the last decade, probably due to the digitization of knowledge. It is almost always applied in combination with other methods, and its use can be a positive indicator of company sustainability.

Keywords: musculoskeletal disorders, safety and health, biomechanics, physical load

1. Introduction

1.1. Musculoskeletal Disorders

According to the International Ergonomics Association [1], “ergonomics (or human factors) is the scientific discipline concerned with the understanding of interactions among humans and other elements of a system, and the profession that applies theory, principles, data, and methods to design in order to optimize human well-being and overall system performance”.

The World Health Organization (WHO) states that Musculoskeletal Disorders (MSD) “range from those that arise suddenly and are short-lived, such as fractures, sprains and strains, to lifelong conditions associated with ongoing pain and disability”. These disorders occur in people of any age and in all parts of the world. This disease has important economic consequences and implies a decrease in job performance, in addition to affecting the health of people who suffer from them [2].

The National Institute for Occupational Safety and Health (NIOSH) [3] defines musculoskeletal disorders as “a set of injuries and symptoms affecting the osteomuscular system and associated structures, such as bones, muscles, joints, tendons, ligaments, nerves and the circulatory system”.

To combat MSDs, ergonomic assessment methods are used to identify and assess the risk factors present in the workplace, and then, based on the results obtained, to propose redesign options that reduce the risk to acceptable exposure levels for the worker [4].

Currently, given that applying ergonomic methods is sometimes tedious because of the number of aspects to consider, software exists that makes it much easier, in terms of time and efficiency, to obtain the final results [5].

1.2. Assessment Methods

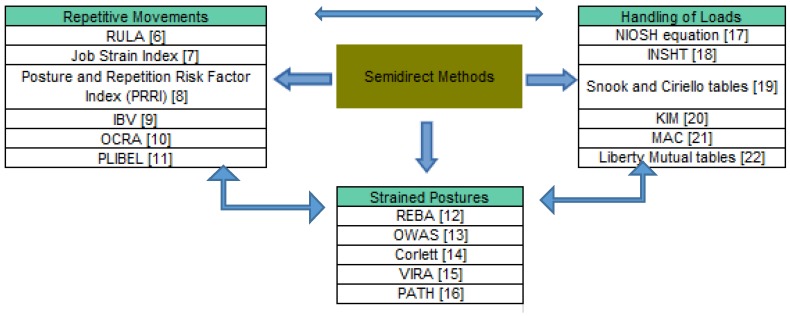

The methods used for evaluating musculoskeletal disorders vary depending on the country, the companies carrying them out and the working environment, etc. For this reason, it is possible to classify them as direct, semi-direct or indirect methods [5]. Direct methods require electronic devices to be placed on the individual’s body, evaluating the worker in real time. Semi-direct methods (Figure 1) are based on images that are subsequently evaluated while indirect methods use questionnaires.

Figure 1.

Semi-direct methods according to the cause of the musculoskeletal disorders and their combined use (adapted from Reference [5]). Rapid Upper Limb Assessment (RULA) [6]; Job Strain Index (JSI) [7]; Posture and Repetition Risk Factor Index (PRRI) [8]; Instituto de Biomecánica de Valencia (In Spanish; IBV) [9]; Occupational Repetitive Action (OCRA) [10]; Method for the identification of musculoskeletal stress factors which may have injurious effects (PLIBEL) [11]; Rapid Entire Body Assessment (REBA) [12]; Ovako Working Analysis System (OWAS) [13]; Corlett [14]; Video film technique for Registration and Analysis of working postures and movements (VIRA) [15]; Posture, Activity, Tools and Handling (PATH) [16]; National Institute of Occupational Safety and Health (NIOSH) [17]; Instituto Nacional de Seguridad e Higiene en el Trabajo (In Spanish; INSHT) [18]; Snook and Ciriello tables [19]; Key Indicator Method (KIM) [20]; Manual Handling Assessment Charts (MAC) [21]; Liberty Mutual tables [22].

Semi-direct methods can be classified according to the cause of the MSD. In this study, the Rapid Entire Body Assessment (REBA) method is one of the methods used for assessing forced postures (Figure 1).

The application of methods such as REBA has evolved over time. It started with photographs, paper and pen. Over time, progress was made using video recordings and employing analysis of this through software. Currently, some equipment is used to measure angles and evaluate in real time [23,24].

1.3. The Rapid Entire Body Assessment Method (REBA), Justification and Objective

This method was developed by Sue Hignett and Lynn McAtamney at Nottingham Hospital (The United Kingdom) and published in 2000 [12]. It is the result of cooperative work carried out by teams of ergonomists, physiotherapists and nurses after identifying/analysing around 600 working postures. REBA allows one to jointly analyse the postures of the upper limbs (arm, forearm, wrist), trunk, neck and lower extremities. In addition, it discriminates the type of grip and muscle activity performed. It identifies five levels of risk, from negligible to very high [12].

The main advantages of the REBA method are [25]:

The cost-effectiveness ratio is good.

It is easy to apply. Pen and paper are enough for data collection; however, there are computer applications that speed up/facilitate its use.

The most conflictive ergonomic aspects are identified from the individual score obtained after assessing each part of the body.

The main limitations are [25]:

It only allows the analysis of individual postures. It is not possible to analyse a set or sequence of postures.

Task evaluations will depend on the evaluator. Some of the positions adopted may or may not be examined.

It only measures the effort intensity. The duration of exposure and the frequency of postures throughout the working day are not considered.

One of the requirements of the method is to have the consent of the worker to obtain the necessary information. The evaluators observe all the tasks to be analysed. Observation can be completed in three ways: direct observation, video recording or taking photographs. The aim is to collect data that allows the method to be used to obtain results.

On the other hand, the method presents some differences with respect to others. One of the main differences is that it considers the lower extremities of the worker [12]. These are not considered by other evaluation methods such as RULA [6]. There are no better or worse methods, but they are applied depending on the evaluators’ situations and resources [26].

It should be noted that once the method has been published, over the years, it is very important to know its worldwide application.

Examining the use of the REBA method, since its inception, would justify the impact of this method on society.

The main objective of this work is to carry out a bibliographic review of the REBA method [12] application in the fields of knowledge, countries, years and journals from the period May 2002 to July 2019. In addition, this study aims to count the number of times that REBA has been applied together with other methods and subsequent incidence. Finally, an objective is to demonstrate whether it has been applied in the health field and what happens with respect to the rest of the knowledge categories.

2. Materials and Methods

2.1. Searching for Information

In order to search for the information, electronic access to the library of the University of Almeria was used. Then the “Web of Science—Core Collection (WOS)” database was accessed. Its license is granted by Spanish Foundation for Science and Technology (FECYT).

It was assumed that all the researchers who applied REBA in any field of knowledge would have cited the article where this method was published. Therefore, the search process was performed to access all the studies that cited it. “Advanced Search” was used in WOS with the terms “so=applied ergonomics and ti=Rapid entire body assessment (REBA)”. In this way, a single result was obtained, which was the original article of REBA [12]. Accessing this result, the “Times Cited” section was consulted, which showed all the studies that had cited the REBA article [12]. There was a total of 442, in the period from 2002 to 10/07/2019.

Of the 442 citations, books, book chapters or other formats were discarded, finally obtaining 314 citations for articles and reviews. It is worth reiterating that only the WOS database was used.

Of these 314 results, the number of studies finally selected for this document was 91. These do not include the original article of the method. Some studies were discarded because they were repeated articles, sometimes as reprints or as conferences that were subsequently published in journals, so only the original article was considered. Others were discarded because, although they cited the paper on the REBA method, they did not apply it in the research. Only articles using REBA method were considered, individually or in combination with other methods.

2.2. Data Analysis

Variables, categories and their abbreviations are shown below (Table 1). In addition, all journals were considered.

Table 1.

Variables, categories, and abbreviation.

| Variable | Categories | Abbreviation |

|---|---|---|

| Sector | Agriculture, forestry and fishing | A |

| Manufacturing | C | |

| Transportation and storage | H | |

| Water supply; sewerage, waste management and remediation activities | E | |

| Professional, scientific and technical activities | M | |

| Activities of households as employers; undifferentiated goods—and services—producing activities of households for own use | T | |

| Construction | F | |

| Education | P | |

| Human health and social work activities | Q | |

| Other activities | OTH | |

| Year | Items between 2006 or before | Y1 |

| Items between 2007 and 2010 | Y2 | |

| Items between 2011 and 2013 | Y3 | |

| Items between 2014 and 2016 | Y4 | |

| Items between 2017 and 2019 | Y5 | |

| Country | Europe: United Kingdom, Sweden, Poland, Croatia, Italy, Germany, Portugal and Spain | C1 |

| Asia: Israel, Iran, India, South Korea, China, Singapore, Malaysia and Turkey | C2 | |

| America: USA, Mexico, Brazil, Canada, Venezuela and Cuba | C3 | |

| Africa: Tunisia and Nigeria | C4 | |

| Journal | - | - |

The knowledge categories, countries and years were grouped to facilitate data management. Countries were grouped into continents. Not all countries on a continent are shown, only those where the REBA method was applied.

On the other hand, the 91 final studies were grouped according to field, year, country and journal. For the general grouping by sectors, an adapted classification was used [27]. Another classification was made within each sector, but in this case it was from the information obtained from studies analysed, for greater clarity and organization of this information.

XLSTAT2019 (Addinsoft, Paris, France) [28] software was used for the results analysis.

3. Results and Discussion

The frequencies of each variable category are shown in Table 2.

Table 2.

Category frequencies.

| Variable | Category | Frequency | % |

|---|---|---|---|

| Sector | A | 20 | 21.98 |

| C | 22 * | 24.18 | |

| E | 2 | 2.20 | |

| F | 4 | 4.40 | |

| H | 4 | 4.40 | |

| M | 2 | 2.20 | |

| OTH | 18 | 19.78 | |

| P | 1 | 1.10 | |

| Q | 15 | 16.48 | |

| T | 3 | 3.30 | |

| Year | Y1 | 1 | 1.10 |

| Y2 | 8 | 8.79 | |

| Y3 | 18 | 19.78 | |

| Y4 | 30 | 32.97 | |

| Y5 | 34 * | 37.36 | |

| Country | C1 | 17 | 18.68 |

| C2 | 46 * | 50.55 | |

| C3 | 26 | 28.57 | |

| C4 | 2 | 2.20 | |

| Journal | - | 91 | 100 |

* Mode.

The area in which the method was applied most is the “Manufacturing (C)” followed by “Agriculture, forestry and fishing (A)” and “Other activities (OTH)”. Between the period 2014 and 2019 (Y5 and Y4), more than 70% of the REBA applications were published. Half of the studies with REBA were published in Asia (C2). The total number of journals is 91. The most striking observation is that, although the method was initially published in 2000, its application was not significant until about 15 years later, possibly because of the digitization of academic/scientific content and the massive user access via the internet [29]. This coincides with other applications concerning ergonomic assessment methods, namely the case of OWAS [5].

Risk assessment is mandatory in all companies. Each one chooses the evaluation method. REBA [12] allows for the identification of the musculoskeletal disorders suffered by workers in different fields, mainly forced postures.

3.1. Analysis by Field and Knowledge Categories

3.1.1. Human Health and Social Work Activities

Table 3 shows studies related to human health and social work activities.

Table 3.

Human health and social work activities.

| Reference | Country | Year | Objective |

|---|---|---|---|

| [30] | Iran | 2016 | REBA with SPSS in the ergonomic assessment of operating room nurses. |

| [31] | Poland | 2015 | Combination of ergonomic assessment methods on nursing and surgery personnel. |

| [32] | Portugal | 2015 | REBA on home-care nurses. |

| [33] | Germany | 2015 | REBA in comparing GlideScope and Macintosh in the tracheal intubation process. |

| [34] | United Kingdom | 2017 | REBA in the gynaecological field. |

| [35] | USA | 2006 | REBA for creating a hospital task scoring algorithm |

| [36] | South Korea | 2019 | REBA on dental hygienists. |

| [37] | South Korea | 2014 | REBA on radiologists. |

| [38] | South Korea | 2013 | REBA on dental hygienists. |

| [39] | Canada | 2008 | Readapting plans to help overcome bad practice in work activities. |

| [40] | Iran | 2013 | REBA and NMQ (Standardised Nordic questionnaires for the analysis of musculoskeletal symptoms) on the ergonomic assessment of dentists. |

| [41] | Israel | 2016 | REBA, NMQ and Karasek on the ergonomic assessment of nurses in hospitals. |

| [42] | Portugal | 2017 | REBA on nurses. |

| [43] | Cuba | 2012 | REBA and NIOSH for the refitting of a vaccine production centre. |

| [44] | USA | 2019 | REBA on otolaryngology surgeons. |

Hospitals

The REBA assessment method is sometimes combined with results support software, as was the case with Abdollahzade et al. [30] using SPSS in the study of 147 high-risk nurses in Tabriz, Iran. It is also common to create computer applications based on the REBA method. Janowitz et al. [35] created a hospital task-scoring algorithm while several authors [31] established a computer system based on information and communication technologies to support hospital processes.

In 2014, Kim and Roh [37] conducted a REBA method-based study on radiologists with more than five years of experience, demonstrating that MSDs occur mainly in the shoulder and lumbar regions, the same symptoms suffered by surgical nurses in a Portuguese hospital [42].

The combination of ergonomic methods developed by Ratzon et al. [41] in the study of 31 nurses, was not enough to determine the effect of poor postural habits on the job. Therefore, they recommend a longer period of study to see if the intervention might reduce MSDs.

Dentistry

Applying REBA to dental hygienists is a common practice in the study of plantar pressure [36] and in the taking of oral X-ray images [38]. On other occasions, it is combined with other methods, as was the case with Rafeemanesh et al. [40] in order to demonstrate that the neck area is the most vulnerable part for these professionals and to raise awareness of the importance of workplace design and rest periods during the activity as a basic prevention principle.

Gynaecology

Several authors [34] observed the need for engineering solutions that allow surgeons flexibility during their interaction with patients.

Otorhinolaryngology (ENT)

A study was carried out to evaluate the musculoskeletal disorders of ENT specialists in the surgical context. Their training and the ergonomic tools used were also analysed. The results show that only 24% of the workers were trained in ergonomics. It was also concluded that the workers adopted forced postures [44].

Others

According to Carneiro et al. [32], home-care nurses generally have a moderate postural assessment in their work activities.

When comparing different forms of tracheal intubation, several authors [33] used the REBA method to determine which technique, GlideScope or Macintosh, was less likely to cause musculoskeletal injuries during use, the former scoring the highest and therefore being the one chosen.

In the refitting of a vaccine production centre, Torres and Vina [43], in a study using REBA and NIOSH, established shelf redesigns and working method modifications as a measure to reduce the MSD risk level. On the other hand, Pascal and Naqvi [39] in a Canadian study outlined the need for retraining plans to help raise awareness of the risks posed by bad work activity practices.

3.1.2. Agriculture, Forestry and Fishing

Table 4 shows the studies related to agriculture, forestry and fishing.

Table 4.

Agriculture, forestry and fishing.

| Reference | Country | Year | Objective |

|---|---|---|---|

| [45] | Brazil | 2015 | REBA in the collection of ornamental plants. |

| [46] | Italy | 2019 | RULA and REBA on wood chippers in the forestry sector. |

| [47] | India | 2015 | REBA on potato growers. |

| [48] | India | 2012 | NMQ and REBA on seed collectors. |

| [49] | India | 2013 | NMQ, REBA and OWAS in the ergonomic assessment of child potato growers. |

| [50] | Brazil | 2018 | REBA in livestock activities. |

| [51] | Malaysia | 2016 | NMQ and REBA in oil palm plantations. |

| [52] | Turkey | 2019 | OWAS and REBA in wood harvesting in the forestry sector. |

| [53] | Iran | 2018 | NMQ and REBA in apple harvesting. |

| [54] | Canada | 2007 | Five ergonomic assessment methods in sawmill installations in the forestry sector. |

| [55] | Canada | 2008 | Five ergonomic assessment methods in sawmill installations in the forestry sector. |

| [56] | USA | 2010 | Five ergonomic assessment methods in sawmill installations in the forestry sector. |

| [57] | Croatia | 2019 | ErgoFellow, REBA and OWAS in the ergonomic assessment of forestry machinery use. |

| [58] | India | 2018 | Four ergonomic assessment methods in rice cultivation by women. |

| [59] | Israel | 2016 | REBA on special greenhouse crops. |

| [60] | Brazil | 2017 | REBA in the ergonomic assessment of forestry machinery. |

| [61] | USA | 2014 | REBA on tomato cultivation. |

| [62] | Iran | 2017 | REBA on dairy production. |

| [63] | Turkey | 2017 | Various ergonomic methods on forest nursery workers. |

| [64] | Italy | 2013 | Four ergonomic methods in the ergonomic study of forestry machinery use. |

Forestry

In this sector, REBA began to develop in Canada and the US with the combination of five ergonomic assessment methods in sawmill facilities [54,55,56]. In addition, ErgoFellow software combined REBA and OWAS methods in the ergonomic assessment of forestry machinery use [57], concluding that chainsaw operator work is more demanding and riskier than that of wood collector operators over the course of the activity [52]. The same conclusions were drawn in the study on chainsaw use employing the OCRA, OWAS, RNLE equation and REBA methods [64]. In 2019, REBA and RULA were compared in wood chipping activity concluding that the latter offered greater risk prevention when applying the method [46]. Likewise, in 2017, several authors [60] used REBA to assess management worker tasks.

In forest nurseries, Unver-Okan et al. [63] combined several ergonomic methods to study working postures, such as seed sifting or machine sowing. They finally chose the RULA method for assessment because of its increased sensitivity in the final result.

Livestock

In the livestock field, Taghavi and Mokarami [62] used the REBA method to assess the postural burden related to feeding, milking and dung removal during milk production. In Brazil, numerous authors [50] did the same with regard to milking and livestock management activities, demonstrating a high level of risk over the course of the activity.

Agriculture

Das and Gangopadhyay [47] applied REBA in potato growers in order to assess musculoskeletal disorders. They showed that one of the most affected body areas was the lumbar region. The same was stated by Das et al. [49] who applied it in the same crop type, but in this case studying children. The method has also been used in the study of crops such as tomato [59,61], pepper [59], rice [58], oil palm [51] and apples [53], as well as in the collection of ornamental plants [45] and seeds [48].

3.1.3. Manufacturing

Table 5 lists studies that used the REBA method in different areas of manufacturing.

Table 5.

Manufacturing.

| Reference | Country | Year | Objective |

|---|---|---|---|

| [65] | Nigeria | 2016 | REBA and NMQ on beverage bottlers. |

| [66] | Tunisia | 2018 | REBA and RULA in milling, turning and drilling operations. |

| [67] | Turkey | 2015 | REBA and BREBA in the metallurgical sector. |

| [68] | Iran | 2016 | REBA in mineral packers. |

| [69] | Venezuela | 2012 | REBA and OCRA in electric motor assembly. |

| [70] | Turkey | 2017 | Ergonomic comparison between the Kinect sensor and electrogoniometer to assess posture. |

| [71] | Spain | 2013 | REBA and RULA in the metallurgical sector |

| [72] | Turkey | 2018 | Creation of an ergonomic assessment questionnaire at Cornell University for the manufacture of harnesses. |

| [73] | Sweden | 2018 | REBA in manual collection operations. |

| [74] | United Kingdom | 2016 | Research on work practices. |

| [75] | Turkey | 2018 | Ergonomic methods in the textile industry. |

| [76] | South Korea | 2007 | OWAS, RULA and REBA in the metallurgical sector. |

| [77] | Mexico | 2015 | REBA in computer repair. |

| [78] | India | 2017 | REBA in sand dredging in Karnataka. |

| [79] | India | 2019 | Ergonomic methods in the Sri Lankan textile industry. |

| [80] | India | 2013 | RULA and REBA in operations carried out by potters and sculptors. |

| [81] | India | 2018 | REBA in brick kiln workers in Rajasthan. |

| [82] | Iran | 2017 | REBA and NMQ in the rubber industry. |

| [83] | India | 2015 | Ergonomic methods in the plastic furniture manufacturing industry. |

| [84] | South Korea | 2016 | REBA on automotive assembly lines. |

| [85] | Poland | 2014 | REBA in the packaging industry. |

| [86] | Iran | 2012 | REBA in an electrical products factory. |

Metallurgical Sector

The first analyses appeared in 2013 in Spain with REBA combined with RULA [71], and with BREBA [67] in 2015 in Turkey, the common goal being to eliminate economic risks and improve the production systems in factories. In the first case, this was achieved by means of simulations and, in the second, by means of photographs. Subsequently, several authors again combined methods (OWAS, RULA and REBA) [66,76] in iron and steel operations that involved milling, turning and drilling.

Textiles

Isler et al. [75] studied 65 operators from different departments (cutting, sewing, ironing, quality control, etc.) in eight companies using video cameras, resulting in a REBA score of more than 11 points; thus, they recommended immediate intervention. In Sri Lanka, 552 female foot-sewing-machine operators were tested, with the medium-high REBA intervention warning regarding problems in the knees, feet and thighs [79].

Technology

The application of REBA in manufacturing technology is defined by activities such as computer repair [77] or the manufacturing of electrical products [86]. In addition, it was combined with other methods such as OCRA to study the ergonomic assessment of electric motor assembly line operators [69]. Felekoglu and Tasan [70] have replaced traditional REBA assessment with Kinect sensors and electrogoniometers.

Production Lines

Many authors analysed production lines for automotive elements [84], plastics [83] or brick furnaces [81] using the REBA method. Conversely, Cornell University [72] developed a REBA-inspired musculoskeletal discomfort questionnaire, the AnyBody Modeling System (AMS) and electromyography measurements that identified the musculoskeletal disorders of employees on a harness assembly line.

At other times, the method was applied individually or in conjunction with other methods in packing factories dealing with varied orders [85], beverages [65] and even minerals [68], or in operations carried out by potters and sculptors [80] who suffer curvature in various parts of the body derived from forced postures.

In rubber production in Iran, Samanei et al. [82] combined the REBA and NMQ methods with a subsequent results analysis using SPSS software, concluding by identifying the need for immediate intervention in the lumbar region.

In sand-dredging operations in Udupi (India) [78], the REBA method, with a 12-point assessment, advised immediate intervention to reduce injuries, specifically in the lower back, as did the assessment by Hanson et al. [73] in manual collection operations. Furthermore, recent studies in the United Kingdom [74] gathered information on the effects of individual skills on job performance and safety in the workplace as well as human well-being, to design more inclusive work practices.

3.1.4. Transportation and Storage

Table 6 shows the four publications that have applied REBA individually or collectively in the study of forced postures related to transportation and storage.

Table 6.

Transportation and storage.

There were two publications combining RULA and REBA. In the first, Balaji and Alphin [88] took photographs of operators who handled industrial excavators, observing that 46% of workers were exposed to high levels of danger; this resulted in the tasks being optimized and redesigned. In the second, Bora et al. [89] evaluated posture parameters in industrial vehicles using CATIA software.

Ahmed et al. [87], using a combination of ergonomic methods, assessed bus drivers who transported people with reduced mobility, looking at three different wheeled mobility devices: manual, scooter and electric. The results determined a high level of risk during the WTORS (Wheelchair Clamping and Occupant Restriction System) procedure. In the railway sector, several authors [90] combined REBA and NMQ in the ergonomic study of 51 railway workers, determining that the shoulder was the most affected body area followed by the neck.

3.1.5. Water Supply; Sewerage, Waste Management and Remediation Activities

Table 7 shows two studies related to waste management.

Table 7.

Water supply; sewerage, waste management and remediation activities.

Cakit [91] combined the REBA and RULA methods in the study of waste collection movements, mainly in lifting and unloading tasks, considering it essential that these tasks be changed as soon as possible. Jozwiak et al. [92], used REBA, FirstBeat and stadiometry in the ergonomic study of urban solid waste collectors.

3.1.6. Professional, Scientific and Technical Activities

Table 8 shows publications that focus on different professional, scientific and technical activities.

Table 8.

Professional, scientific and technical activities.

In professionals working with laboratory sample preparation [94], the REBA method assessed six subtasks for each of the six tasks analysed, concluding there was a medium-high risk level in at least one subtask for each task.

This method was also used, in combination with others, in sales assistants in Italy [93].

3.1.7. Activities of Households as Employers; Undifferentiated Goods—and Services—Producing Activities of Households for Own Use

There are three publications related to activities of households in which the REBA method has been applied: Lim et al. [95], Lofqvist et al. [96] and Rui et al. [97], corresponding to vacuum cleaning work, basic household chores and tasks associated with drying clothes, respectively (Table 9).

Table 9.

Activities of households as employers; undifferentiated goods—and services—producing activities of households for own use.

3.1.8. Education

In the field of education, only Hashim et al. [98] combined REBA and RULA to assess the different positions students take while they do their schoolwork, demonstrating that the majority need immediate intervention to prevent greater prejudicial effects (Table 10).

Table 10.

Education.

| Reference | Country | Year | Objective |

|---|---|---|---|

| [98] | Malaysia | 2012 | RULA and REBA on students while performing their schoolwork. |

3.1.9. Construction

Table 11 shows studies related to construction.

Table 11.

Construction.

| Reference | Country | Year | Objective |

|---|---|---|---|

| [99] | India | 2018 | Ergonomic methods in the construction sector. |

| [100] | USA | 2011 | Ergonomic methods on prefabricated-panel construction workers. |

| [101] | Canada | 2018 | 3D body modelling to reduce musculoskeletal disorders in construction. |

| [102] | China | 2019 | Creation of an ergonomic assessment tool to apply the REBA method in construction. |

Several authors [102] created an ergonomic assessment tool using videos that allowed for postures to be assessed while working. Kim et al. [100], for their part, demonstrated how the manufacture of goods from prefabricated panels negatively influenced the spinal column of the workers.

In addition, other authors [101] made use of new 3D technologies to screen workers in different workplaces thus reducing the costs derived from MSDs and correcting bad habits. Conversely, in Western Bengal (India), Chatterjee and Sahu [99] combined different ergonomic assessment methods to demonstrate that a more conciliatory schedule and rest times, accompanied by technical modifications in the workplace and the use of redesigned equipment, reduced the risk of MSD.

3.1.10. Other Activities

Table 12 includes studies that could not be classified in any of the above areas.

Table 12.

Other activities.

| Reference | Country | Year | Objective |

|---|---|---|---|

| [103] | USA | 2019 | NMQ and REBA in aircraft maintenance. |

| [104] | Turkey | 2017 | OWAS and REBA in an electrical equipment factory |

| [105] | Canada | 2012 | Eight ergonomic assessment methods in various industrial sectors. |

| [106] | India | 2015 | REBA applied to women who carry a load of bricks around their necks. |

| [107] | Spain | 2017 | Error detection in the real-life practice of ergonomic assessment methods. |

| [108] | Canada | 2014 | REBA in African women who endure head loads during pregnancy. |

| [109] | Brazil | 2016 | REBA in the collection of molluscs. |

| [110] | Brazil | 2014 | Translation of the REBA method into Portuguese. |

| [111] | India | 2015 | REBA in bike repair. |

| [112] | India | 2010 | Ergonomic assessment methods in three key Jaipur business sectors. |

| [113] | India | 2010 | REBA in Jaipur stone carving. |

| [114] | South Korea | 2017 | OWAS, RULA and REBA in the ergonomic assessment of armament cleaning. |

| [115] | Poland | 2014 | Comparative analysis of musculoskeletal load assessment methods |

| [116] | USA | 2019 | Reliability assessment of the REBA method. |

| [117] | Canada | 2013 | RULA and REBA in the ergonomic assessment of casual work. |

| [118] | Iran | 2011 | REBA in an engine oil company. |

| [119] | USA | 2010 | REBA, RULA and NIOSH used on firefighters and medical emergency technicians. |

| [120] | USA | 2015 | REBA and RULA used on librarians. |

The REBA method has been translated into other languages such as Portuguese [110]. Its reliability was also evaluated in 2019 by Schwartz et al. [116]. Moreover, it has been compared to other methods [115], raising the possibility of creating a comprehensive method for all work tasks and all body parts. Diego-Mas et al. [107] produced a study that detected the anomalies of different ergonomic assessment methods.

In Jaipur, India, two studies by Mukhopadhyay analysed the ergonomic assessment of operators in three artisanal sectors [112] as well as in stone carving [113]. Other authors assessed African women as they carried out two tasks related to loading bricks on their heads [106] and the load variance during pregnancy [108]. Bicycle repair [111] and marine mollusc collection [109] were also assessed using the REBA method.

Furthermore, the use of ergonomic assessment methods is common in areas such as aircraft maintenance [103], electrical equipment manufacture [104], armament cleaning tasks [114], engine oil companies [118], various industrial sectors [105] and even in multitasking jobs [117].

Yuan [120] assessed 39 employees from nine different library divisions on two occasions by combining the REBA and RULA methods. The workers’ bad habits were improved once action guidelines were established.

Finally, REBA was also combined with other evaluation methods in the case of firefighters and medical emergency technicians [119].

3.2. Analysis by Country

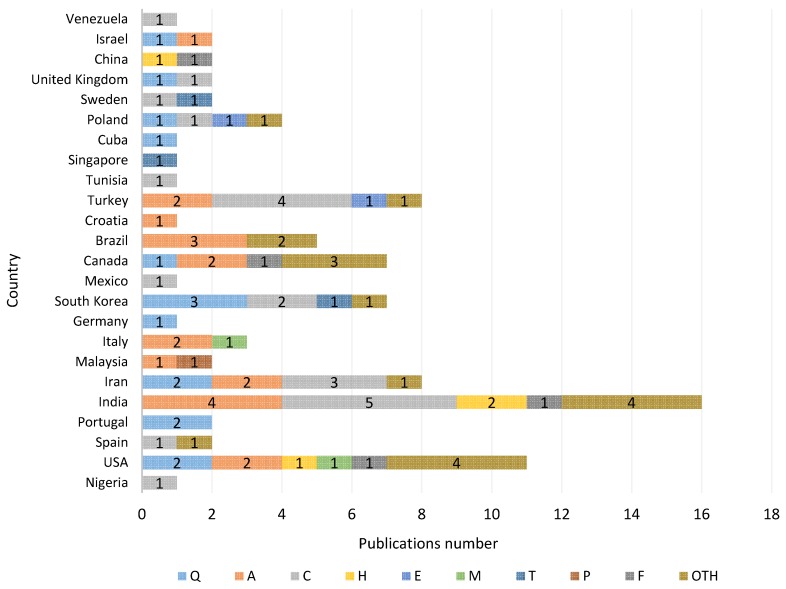

The REBA method has been applied in 91 cases and in 24 different countries. The country where the highest number of studies has been carried out is India, with a total of 16; followed by the USA with 11; Iran and Turkey with eight; Canada and South Korea with seven; Brazil with five; Poland with four; Italy with three; Spain, Portugal, Malaysia, The United Kingdom, China, Sweden, and Israel with two, and Nigeria, Germany, Mexico, Croatia, Tunisia, Singapore, Cuba, and Venezuela with one publication each (Figure 2). One can observe that approximately 50% of the countries where REBA was used are in the process of developing.

Figure 2.

Publications by field and by country (see abbreviations Table 2).

In “manufacturing”, five REBA applications in India and four in Turkey stand out. In turn, in “agriculture, forestry and fishing”, four research studies in India and three in Brazil are highlighted. In “other activities”, four studies in the USA and India and three in Canada stand out.

The USA is one of the countries with the highest number of contributions over diverse fields: human health and social work activities (2), agriculture, forestry and fishing (2), transportation and storage (1), professional, scientific and technical activities (1), construction (1) and others activities (4).

If you look at the United Kingdom, the country where the REBA method arose, there were only two studies in which the method was applied. This fact is countered by the much higher use of other methods, such as OWAS [13], in its country of origin [5]. Perhaps this is because the REBA method is more recent (the year 2000) than OWAS (1977).

3.3. Analysis by Year

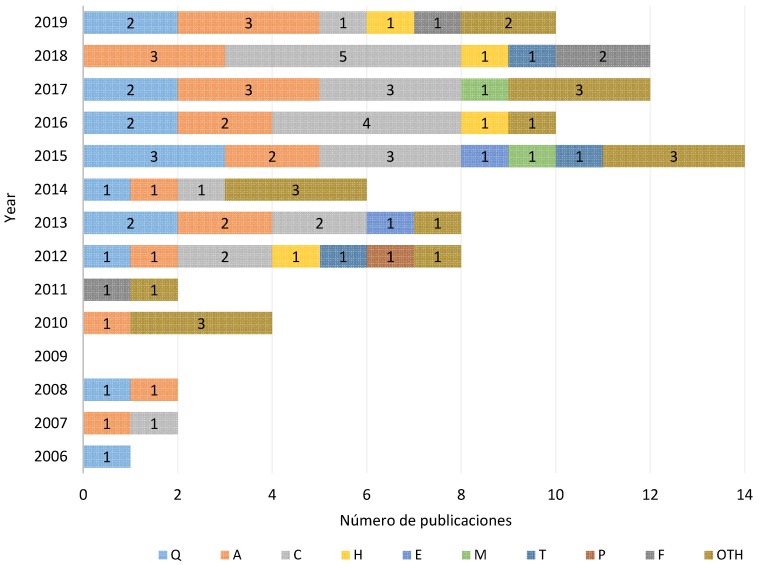

The year with the highest number of publications was 2015, when there were fourteen in seven different areas, followed by 2017 and 2018 with twelve publications and 2016 and 2019 with ten (Figure 3). The years when there were the lowest number of research studies were 2007, 2008 and 2011 with two publications and 2006 with only one. On the other hand, over the years spanning the bibliographic review, there is no indication of any REBA method being applied in 2009 (Figure 3).

Figure 3.

Publications by field and by year.

Thanks to society’s awareness of the risks of MSD in the workplace, the publication of studies is growing exponentially over recent years, no doubt because of the developments in information and communication technologies, as mentioned before.

3.4. Analysis by Journal

The journals that most stand out are: “Work-A Journal of Prevention Assessment and Rehabilitation” with 18.68% of the publications and the “International Journal of Industrial Ergonomics” with 15.38% (Table 13). “Applied Ergonomics”, “Human Factors and Ergonomics in Manufacturing and Service Industries”, “Journal of the Faculty of Engineering and Architecture of Gazi University” and the “International Journal of Occupational Safety and Ergonomics” are next with 3.30% each (Table 13).

Table 13.

Number of publications per scientific journal, knowledge categories (Web of Science), impact factor, rank and quartile (2018).

| Journal | P * | Impact Factor | Categories | Rank | Quartile |

|---|---|---|---|---|---|

| Work-A Journal of Prevention Assessment and Rehabilitation | 17 | 1.009 | Public, environmental and occupational health—SSCI | 138/164 | Q4 |

| Health Promotion Perspectives | 1 | No impact factor. | |||

| International Journal of Industrial Ergonomics | 14 | 1.571 | Ergonomics—SSCI | 7/16 | Q2 |

| Engineering, industrial—SCIE | 28/46 | Q3 | |||

| International Journal of Injury Control and Safety Promotion | 1 | 0.87 | Public, environmental and occupational health—SSCI | 146/164 | Q4 |

| Safety Science | 1 | 3.619 | Engineering, industrial—SCIE | 10/46 | Q1 |

| Operations research and management science—SCIE | 16/84 | Q1 | |||

| Journal of Clinical and Analytical Medicine | 1 | No impact factor. | |||

| Human Factors and Ergonomics in Manufacturing and Service Industries | 3 | 1.000 | Ergonomics—SSCI | 13/16 | Q4 |

| Engineering, manufacturing—SCIE | 45/49 | Q4 | |||

| Global Nest Journal | 1 | 0.869 | Environmental sciences—SCIE | 232/251 | Q4 |

| International Journal on Working Conditions | 2 | No impact factor. | |||

| Journal of the Faculty of Engineering and Architecture of Gazi University | 3 | 0.652 | Engineering, multidisciplinary—SCIE | 76/88 | Q4 |

| Journal of Back and Musculoskeletal Rehabilitation | 1 | 0.814 | Orthopedics—SCIE | 65/76 | Q4 |

| Rehabilitation—SCIE | 60/65 | Q4 | |||

| International Journal of Environmental Research and Public Health | 1 | 2.468 | Environmental Sciences—SCIE | 112/251 | Q2 |

| Public, environmental and occupational health—SSCI | 38/164 | Q1 | |||

| Public, environmental and occupational health—SCIE | 67/186 | Q2 | |||

| Environmental Health and Preventive Medicine | 1 | 1.568 | Public, environmental and occupational health—SSCI | 88/164 | Q3 |

| Public, environmental and occupational health—SCIE | 120/186 | Q3 | |||

| Asia-Pacific Journal of Public Health | 1 | 1.743 | Public, environmental and occupational health—SSCI | 73/164 | Q2 |

| Public, environmental and occupational health—SCIE | 108/186 | Q3 | |||

| International Journal of Occupational Safety and Ergonomics | 3 | 1.377 | Ergonomics—SSCI | 9/16 | Q3 |

| Public, environmental and occupational health—SSCI | 110/164 | Q3 | |||

| Journal of Occupational Health | 1 | 1.8 | Public, environmental and occupational health—SCIE | 105/186 | Q3 |

| Cahiers Agricultures | 1 | 0.78 | Agriculture, multidisciplinary—SCIE | 38/57 | Q3 |

| Agronomy—SCIE | 63/89 | Q3 | |||

| Iranian Journal of Public Health | 1 | 1.225 | Public, environmental and occupational health—SSCI | 122/164 | Q3 |

| Public, environmental and occupational health—SCIE | 149/186 | Q4 | |||

| Journal of Health and Safety at Work | 1 | No impact factor. | |||

| Human Factors | 1 | 2.649 | Behavioral sciences—SCIE | 20/53 | Q2 |

| Engineering, industrial—SCIE | 18/46 | Q2 | |||

| Ergonomics—SSCI | 2/16 | Q1 | |||

| Psychology—SCIE | 25/77 | Q2 | |||

| Psychology, applied—SSCI | 24/82 | Q2 | |||

| Dyna Colombia | 1 | No impact factor. | |||

| Anaesthesia | 1 | 5.879 | Anesthesiology—SCIE | 4/31 | Q1 |

| Aquacultural Engineering | 1 | 2.143 | Agricultural, engineering—SCIE | 5/13 | Q2 |

| Fisheries—SCIE | 17/52 | Q2 | |||

| Journal of Minimally Invasive Gynecology | 1 | 2.547 | Obstetrics and Gynecology- SCIE | 25/83 | Q2 |

| International Journal of Clothing Science and Technology | 1 | 0.752 | Materials science, textiles—SCIE | 12/24 | Q2 |

| Applied Ergonomics | 3 | 2.610 | Ergonomics—SSCI | 3/16 | |

| Psychology, applied—SSCI | 25/82 | ||||

| Engineering, industrial—SCIE | 20/46 | ||||

| Medycyna Pracy | 1 | 0.778 | Public, environmental and occupational health—SCIE | 171/186 | Q4 |

| International Journal of Occupational and Environmental Health | 2 | 0.973 | Public, environmental and occupational health—SSCI | 141/164 | Q4 |

| Public, environmental and occupational health—SCIE | 165/186 | Q4 | |||

| International Journal of Dental Hygiene | 1 | 1.233 | Dentistry, oral surgery and medicine—SCIE | 68/91 | Q3 |

| Ergonomics | 1 | 2.181 | Engineering, industrial—SCIE | 21/46 | Q2 |

| Ergonomics—SSCI | 5/16 | Q2 | |||

| Psychology—SCIE | 38/77 | Q2 | |||

| Psychology, applied—SSCI | 35/82 | Q2 | |||

| Journal of Physical Therapy Science | 2 | 0.392 | Rehabilitation—SCIE | 61/64 | Q4 |

| Brazilian Journal of Physical Therapy | 1 | 1.879 | Orthopedics—SCIE | 38/76 | Q2 |

| Rehabilitation—SCIE | 27/65 | Q2 | |||

| Seefor-South-East European Forestry | 1 | No impact factor. | |||

| Journal of Construction Engineering and Management | 2 | 2.734 | Construction and Building Technology—SCIE | 15/63 | Q1 |

| Engineering, civil -SCIE | 32/132 | Q1 | |||

| Engineering, industrial -SCIE | 17/46 | Q2 | |||

| International Journal of Precision Engineering and Manufacturing | 1 | 1.779 | Engineering, manufacturing | 33/49 | Q3 |

| Engineering, mechanical—SCIE | 64/129 | Q2 | |||

| Journal of Clinical and Diagnostic Research | 1 | No impact factor. | |||

| Journal of Chemical Health and Safety | 1 | No impact factor. | |||

| Design Journal | 1 | No impact factor. | |||

| Indian Journal of Occupational and Environmental Medicine | 1 | No impact factor. | |||

| Biosystems Engineering | 1 | 2.983 | Agricultural engineering -SCIE | 4/13 | Q2 |

| Agriculture, multidisciplinary -SCIE | 7/57 | Q1 | |||

| International Journal of Workplace Health Management | 1 | No impact factor. | |||

| Revista Arvore | 1 | 0.367 | Forestry—SCIE | 64/67 | Q4 |

| Progress in Community Health Partnerships-Research Education and Action | 1 | 0.64 | Public, environmental and occupational health—SSCI | 153/164 | Q4 |

| International Journal of Occupational and Environmental Medicine | 1 | No impact factor. | |||

| Fresenius Environmental Bulletin | 1 | 0.691 | Environmental Sciences—SCIE | 240/251 | Q4 |

| Laryngoscope | 1 | 2.343 | Medicine, research and experimental- SCIE | 78/136 | Q3 |

| Otorhinolaryngology—SCIE | 12/42 | Q2 | |||

| Logforum | 1 | No impact factor. | |||

| Journal of Agricultural Engineering | 1 | No impact factor. | |||

| Health Scope | 1 | No impact factor. | |||

| Journal of Research in Health Sciences | 1 | No impact factor. | |||

* Mode; P = Publications number.

3.5. Combination with Other Methods

REBA is normally applied in conjunction with other assessment methods for musculoskeletal disorders. The REBA method [12] is mainly used to evaluate forced postures (Figure 1). However, it is sometimes combined with methods that study other risk factors. One of them, the RULA method, is also used to analyse repetitive movements (associated with REBA) [6]. Due to these considerations, some studies present a broader and more complete analysis [46,66].

In 47 of the studies reviewed, REBA is applied along with other methods [31,40,41,43,46,48,49,51,52,53,54,55,56,57,58,63,64,65,66,67,68,69,71,75,76,79,80,82,83,87,88,89,90,91,92,93,98,99,100,103,104,105,112,114,117,119,120]. These 47 results are included in the following categories: “human health and social work activities”, “agriculture, forestry and fishing”, “manufacturing”, “transportation and storage”, “water supply; sewerage, waste management and remediation activities”, “professional, scientific and technical activities”, “education”, “construction” and “other activities”. Of these, “agriculture, forestry and fishing” stands out with 13 studies, followed by “manufacturing” with 12. Thanks to the combined use of the methods, the upper limbs, trunk, neck and lower extremities can be evaluated with greater precision [12].

4. Conclusions

The REBA method is mainly used for the analysis of forced postures. It is not useful for the evaluation of repetitive movements.

Although this method was initially intended to be applied to the analysis of forced postures in personnel related to the human health and social work activities field, as well as various activities in the service sector, it can be applied to any sector or labour activity. In fact, it is observed that the application number is greater in other knowledge categories than in the original field.

In this literature review, the REBA method was mainly applied to three areas: “manufacturing”, “agriculture, forestry and fishing” and “other activities”.

It is often widely used in combination with other methods and has was greatly by the digitization of scientific content over the last decade.

In addition, unlike other methods which that are combined with REBA, this one focuses on the upper limbs (arm, forearm and wrist), lower extremities, trunk and neck.

In the Americas, its application is highly diversified over the different fields of knowledge. Conversely, in Asia, it is applied more specifically in two sectors: “manufacturing” and “agriculture, forestry and fishing”.

In countries immersed in the development process, it is not easily used since they do not have enough technology or information on the method. However, the fact that approximately 50% of the studies were carried out in developing countries may be an indicator of sustainable processes starting in companies there.

The journals that have published the most studies on applying the REBA method are “Work-A Journal of Prevention Assessment and Rehabilitation” and the “International Journal of Industrial Ergonomics”.

Acknowledgments

Laboratory-Observatory Andalusian Working Conditions in the Agricultural Sector (LASA; C.G. 401487) and the Research Own Plan of the University of Almería.

Author Contributions

Conceptualization, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; methodology, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; software, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; validation, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; formal analysis, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; research, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; resources, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; data curation, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; writing—original draft preparation, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; writing—review and editing, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; visualization, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F.; project administration, M.H.-G., M.G.-G., M.D.-P., and Á.-J.C.-F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- 1.International Ergonomics Association (IEA) What Is Ergonomics? [(accessed on 3 April 2020)]; Available online: https://iea.cc/what-is-ergonomics/

- 2.World Health Organization (WHO) Musculoskeletal Conditions. [(accessed on 3 April 2020)]; Available online: https://www.who.int/news-room/fact-sheets/detail/musculoskeletal-conditions.

- 3.NIOSH . Work Practices Guide for Manual Lifting. US Dept. of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, Division of Biomedical and Behavioral Science; Cincinnati, OH, USA: 1981. Technical Reports. Division of Biomedical, and Behavioral Science; pp. 1–198. [Google Scholar]

- 4.Asensio-Cuesta S., Bastante-Ceca M., Diego-Más J. Evaluación Ergonómica de Puestos de Trabajo. Paraninfo; Madrid, Spain: 2012. [Google Scholar]

- 5.Gómez-Galán M., Pérez-Alonso J., Callejon-Ferre A.J., López-Martínez J. Musculoskeletal disorders: OWAS review. Ind. Health. 2017;55 doi: 10.2486/indhealth.2016-0191. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.McAtamney L., Corlett E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993;24:91–99. doi: 10.1016/0003-6870(93)90080-S. [DOI] [PubMed] [Google Scholar]

- 7.Moore J.S., Garg A. The Strain Index: A proposed method to analyze jobs for risk of distal upper extremity disorders. Am. Ind. Hyg. Assoc. J. 1995;56:443–458. doi: 10.1080/15428119591016863. [DOI] [PubMed] [Google Scholar]

- 8.James C.P.A., Harburn K.L., Kramer J.F. Cumulative trauma disorders in the upper extremities: Reliability of the postural and repetitive risk-factors index. Arch. Phys. Med. Rehabil. 1997;78:860–866. doi: 10.1016/S0003-9993(97)90201-X. [DOI] [PubMed] [Google Scholar]

- 9.García C., Chirivela C., Page del Pozo A., Moraga R., Jorquera J. Método Ergo IBV. Evaluación de Riesgos Laborales Asociados a la Carga Física. Instituto de Biomecánica de Valencia (IBV); Valencia, Spain: 1997. [Google Scholar]

- 10.Colombini D. An observational method for classifying exposure to repetitive movements of the upper limbs. Ergonomics. 1998;41:1261–1289. doi: 10.1080/001401398186306. [DOI] [PubMed] [Google Scholar]

- 11.Kemmlert K. A method assigned for the identification of ergonomic hazards—PLIBEL. Appl. Ergon. 1995;26:199–211. doi: 10.1016/0003-6870(95)00022-5. [DOI] [PubMed] [Google Scholar]

- 12.Hignett S., Mcatamney L. Rapid entire body assessment (REBA) Appl. Ergon. 2000;31:201–205. doi: 10.1016/S0003-6870(99)00039-3. [DOI] [PubMed] [Google Scholar]

- 13.Karhu O., Kansi P., Kuorinka I. Correcting working postures in industry: A practical method for analysis. Appl. Ergon. 1977;8:199–201. doi: 10.1016/0003-6870(77)90164-8. [DOI] [PubMed] [Google Scholar]

- 14.Corlett E., Madeley S., Manenica I. Posture targetting: A technique for recording working postures. Ergonomics. 1979;22:357–366. doi: 10.1080/00140137908924619. [DOI] [Google Scholar]

- 15.Kilbom A., Persson J., Jonsson B. Risk factors for workrelated disorders of the neck and shoulder—With special emphasis on working postures and movements. In: Corlett E.N., Wilson J., Manenica I., editors. The Ergonomics of Working Postures. Taylor and Francis; London, UK: 1986. pp. 44–53. [Google Scholar]

- 16.Buchholz B., Paquet V., Punnett L., Lee D., Moir S. PATH: A work sampling-based approach to ergonomic job analysis for construction and other non-repetitive work. Appl. Ergon. 1996;27:177–187. doi: 10.1016/0003-6870(95)00078-X. [DOI] [PubMed] [Google Scholar]

- 17.NIOSH (National Institute for Occupational Safety and Health) Work Practices Guide for Manual Lifting. NIOSH; Cincinnaty, OH, USA: 1981. pp. 81–122. NIOSH Technical Report. [Google Scholar]

- 18.Instituto Nacional de Seguridad e Higiene en el Trabajo (INSHT) Guía Técnica para la Evaluación y Prevención de los Riesgos Relativos a la Manipulación Manual de Cargas. INSHT; Madrid, Spain: 1998. [(accessed on 1 November 2019)]. Guías Técnicas; Available online: https://www.insst.es/documents/94886/509319/GuiatecnicaMMC.pdf/27a8b126-a827-4edd-aa4c-7c0ca0a86cda. [Google Scholar]

- 19.Snook S.H., Ciriello V.M. The design of manual handling tasks: Revised tables of maximum acceptable weights and forces. Ergonomics. 1991;34:1197–1213. doi: 10.1080/00140139108964855. [DOI] [PubMed] [Google Scholar]

- 20.Jürgens W.W., Mohr D., Pangert R., Pernack E., Schultz K., Steinberg U. Handlungsanleitung zur Beurteilung der Arbeitsbedingungen beim Heben und Tragen von Lasten. LASI Veröffentlichung; Saarbrücken, Germany: 2001. pp. 1–37. [Google Scholar]

- 21.Monnington S., Quarrie C., Pinder A., Morris L. Contemporary Ergonomics. CRC Press; London, UK: 2003. Development of manual handling assessment charts (MAC) for health and safety inspectors; pp. 3–8. [Google Scholar]

- 22.Liberty-Mutual Manual Materials Handling Tables. [(accessed on 2 November 2019)];2011 Available online: http://libertymmhtables.libertymutual.com/CM_LMTablesWeb/pdf/LibertyMutualTables.pdf.

- 23.von Macard T., Rosenhahn B., Black M.J., Pons-Moll G. Spare inertial poser: Automatic 3D human pose estimation from sparse IMUs. Comput. Graph. Forum. 2017;36:349–360. doi: 10.1111/cgf.13131. [DOI] [Google Scholar]

- 24.ViveLab Ergo Ergonomic Verification in 3D Virtual Space. [(accessed on 3 April 2020)]; Available online: https://www.vivelab.cloud/

- 25.INSST . NTP 601: Evaluación de las Condiciones de Trabajo: Carga Postural. Método REBA. Instituto de Seguridad e Higiene del Trabajo; Madrid, Spain: 2001. [Google Scholar]

- 26.Takala E.P., Pehkonen I., Forsman M., Hansson G.A., Mthiassen S.E., Neumann W.P., Sjogaard G., Veiersted K.B., Westgaard R.H., Winkel J. Systematic evaluation of observational methods assessing biomechanical exposures at work. Scand. J. Work Environ. Health. 2010;36:3–24. doi: 10.5271/sjweh.2876. [DOI] [PubMed] [Google Scholar]

- 27.Eurostat NACE Rev. 2. Structure and Explanatory Notes. [(accessed on 18 March 2020)]; Available online: https://ec.europa.eu/eurostat/documents/1965800/1978839/NACE_rev2_explanatory_notes_EN.pdf/b09f2cb4-5dac-4118-9164-bcc39b791ef5.

- 28.Addinsoft . XLSTAT2019, Analyse de Données et Statistique Avec MS Excel. Addinsoft; Paris, France: 2019. [(accessed on 24 November 2019)]. Available online: https://www.xlstat.com/es/empresa. [Google Scholar]

- 29.Aguillo I. Tecnologías, investigación y futuro de la profesión. Prof. Inf. 2012;21:5–8. doi: 10.3145/epi.2012.ene.01. [DOI] [Google Scholar]

- 30.Abdollahzade F., Mohammadi F., Dianat I., Asghari E., Asghari-Jafarabadi M., Sokhanvar Z. Working posture and its predictors in hospital operating room nurses. Health Promot. Perspect. 2016;6:17–22. doi: 10.15171/hpp.2016.03. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Bartnicka J. Knowledge-based ergonomic assessment of working conditions in surgical ward—A case study. Saf. Sci. 2015;71:178–188. doi: 10.1016/j.ssci.2014.08.010. [DOI] [Google Scholar]

- 32.Carneiro P., Martins J., Torres M. Musculoskeletal disorder risk assessment in home care nurses. Work J. Prev. Assess. Rehabil. 2015;51:657–665. doi: 10.3233/WOR-152024. [DOI] [PubMed] [Google Scholar]

- 33.Grundgeiger T., Roewer N., Grundgeiger J., Hurtienne J., Happel O. Body posture during simulated tracheal intubation: GlideScope (R) videolaryngoscopy vs. Macintosh direct laryngoscopy for novices and experts. Anaesthesia. 2015;70:1375–1381. doi: 10.1111/anae.13190. [DOI] [PubMed] [Google Scholar]

- 34.Hignett S., Gyi D., Calkins L., Jones L., Moss E. Human Factors Evaluation of Surgeons’ Working Positions for Gynecologic Minimal Access Surgery. J. Minim. Invasive Gynecol. 2017;24:1178–1184. doi: 10.1016/j.jmig.2017.07.011. [DOI] [PubMed] [Google Scholar]

- 35.Janowitz I.L., Gillen M., Ryan G., Rempel D., Trupin L., Swig L., Mullen K., Rugulies R., Blanc P.D. Measuring the physical demands of work in hospital settings: Design and implementation of an ergonomics assessment. Appl. Ergon. 2006;37:641–658. doi: 10.1016/j.apergo.2005.08.004. [DOI] [PubMed] [Google Scholar]

- 36.Kim J., Park B.Y., Mun S.J., Shim J., Choi E.S., Noh H. Differences in plantar pressure by REBA scores in dental hygienists. Int. J. Dent. Hyg. 2019;17:177–182. doi: 10.1111/idh.12375. [DOI] [PubMed] [Google Scholar]

- 37.Kim T., Roh H. Analysis of risk factors for work-related musculoskeletal disorders in radiological technologists. J. Phys. Ther. Sci. 2014;26:1423–1428. doi: 10.1589/jpts.26.1423. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Noh H., Roh H. Approach of industrial physical therapy to assessment of the musculoskeletal system and ergonomic risk factors of the dental hygienist. J. Phys. Ther. Sci. 2013;25:821–826. doi: 10.1589/jpts.25.821. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Pascual S.A., Naqvi S. An investigation of ergonomics analysis tools used in industry in the identification of work-related musculoskeletal disorders. Int. J. Occup. Saf. Ergon. 2008;14:237–245. doi: 10.1080/10803548.2008.11076755. [DOI] [PubMed] [Google Scholar]

- 40.Rafeemanesh E., Jafari Z., Kashani F.O., Rahimpour F. A study on job postures and musculoskeletal illnesses in dentists. Int. J. Occup. Med. Environ. Health. 2013;26:615–620. doi: 10.2478/s13382-013-0133-z. [DOI] [PubMed] [Google Scholar]

- 41.Ratzon N.Z., Bar-Niv N.A., Froom P. The effect of a structured personalized ergonomic intervention program for hospital nurses with reported musculoskeletal pain: An assigned randomized control trial. Work J. Prev. Assess. Rehabil. 2016;54:367–377. doi: 10.3233/WOR-162340. [DOI] [PubMed] [Google Scholar]

- 42.Torres M., Carneiro P., Arezes P. WMSDs in nurses that provide care in surgical internment context. Int. J. Work. Cond. 2017;14:33–49. [Google Scholar]

- 43.Torres Y., Vina S. Evaluation and redesign of manual material handling in a vaccine production centre’s warehouse. Work J. Prev. Assess. Rehabil. 2012;41:2487–2491. doi: 10.3233/WOR-2012-0486-2487. [DOI] [PubMed] [Google Scholar]

- 44.Vaisbuch Y., Aaron K.A., Moore J.M., Vaughan J., Ma Y.F., Gupta R., Jackler R.K. Ergonomic hazards in otolaryngology. Laryngoscope. 2019;129:370–376. doi: 10.1002/lary.27496. [DOI] [PubMed] [Google Scholar]

- 45.Camargo V.M., Hembecker P.K., Lima I.A.X., Moro A.R.P., Gontijo L.A. Ergonomic assessment in a producer of ornamental plants in Brazil. Int. J. Work. Cond. 2015;10:138–151. [Google Scholar]

- 46.Cremasco M.M., Giustetto A., Caffaro F., Colantoni A., Cavallo E., Grigolato S. Risk assessment for musculoskeletal disorders in forestry: A comparison between RULA and REBA in the manual feeding of a wood-chipper. Int. J. Environ. Res. Public Health. 2019;16:793. doi: 10.3390/ijerph16050793. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Das B., Gangopadhyay S. Prevalence of musculoskeletal disorders and physiological stress among adult, male potato cultivators of West Bengal, India. Asia-Pac. J. Public Health. 2015;27:1669–1682. doi: 10.1177/1010539511421808. [DOI] [PubMed] [Google Scholar]

- 48.Das B., Ghosh T., Gangopadhyay S. Assessment of ergonomic and occupational health-related problems among female prawn seed collectors of Sunderbans, West Bengal, India. Int. J. Occup. Saf. Ergon. 2012;18:531–540. doi: 10.1080/10803548.2012.11076949. [DOI] [PubMed] [Google Scholar]

- 49.Das B., Ghosh T., Gangopadhyay S. Child work in agriculture in West Bengal, India: Assessment of musculoskeletal disorders and occupational health problems. J. Occup. Health. 2013;55:244–258. doi: 10.1539/joh.12-0185-OA. [DOI] [PubMed] [Google Scholar]

- 50.De Oliveira C.C., Xavier A.A.D., Ulbricht L., Moro A.R.P., Belinelli M.M. Health in the rural environment: A postural evaluation of milking workers in Brazil. Cah. Agric. 2018;27 doi: 10.1051/cagri/2018021. [DOI] [Google Scholar]

- 51.Deros B.M., Ali M.H., Mohamad D., Daruis D.D.I. Ergonomic risk assessment on oil palm industry workers. Iran. J. Public Health. 2016;45:44–51. [Google Scholar]

- 52.Enez K., Nalbantoglu S.S. Comparison of ergonomic risk assessment outputs from OWAS and REBA in forestry timber harvesting. Int. J. Ind. Ergon. 2019;70:51–57. doi: 10.1016/j.ergon.2019.01.009. [DOI] [Google Scholar]

- 53.Houshyar E., Kim I.J. Understanding musculoskeletal disorders among Iranian apple harvesting laborers: Ergonomic and stop watch time studies. Int. J. Ind. Ergon. 2018;67:32–40. doi: 10.1016/j.ergon.2018.04.007. [DOI] [Google Scholar]

- 54.Jones T., Kumar S. Comparison of ergonomic risk assessments in a repetitive high-risk sawmill occupation: Saw-filer. Int. J. Ind. Ergon. 2007;37:744–753. doi: 10.1016/j.ergon.2007.05.005. [DOI] [Google Scholar]

- 55.Jones T., Kumar S. Comparison of ergonomic risk assessment output in a repetitive sawmill occupation: Trim-saw operator. Work J. Prev. Assess. Rehabil. 2008;31:367–376. [PubMed] [Google Scholar]

- 56.Jones T., Kumar S. Comparison of ergonomic risk assessment output in four sawmill jobs. Int. J. Occup. Saf. Ergon. 2010;16:105–111. doi: 10.1080/10803548.2010.11076834. [DOI] [PubMed] [Google Scholar]

- 57.Landekic M., Katusa S., Mijoc D., Sporcic M. Assessment and comparison of machine operators’ working posture in forest thinning. Seefor-South-East Eur. For. 2019;10:29–37. doi: 10.15177/seefor.19-02. [DOI] [Google Scholar]

- 58.Pal A., Dhara P.C. Work related musculoskeletal disorders and postural stress of the women cultivators engaged in uprooting job of rice cultivation. Indian J. Occup. Environ. Med. 2018;22:163–169. doi: 10.4103/ijoem.IJOEM_104_18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 59.Riemer R., Bechar A. Investigation of productivity enhancement and biomechanical risks in greenhouse crops. Biosyst. Eng. 2016;147:39–50. doi: 10.1016/j.biosystemseng.2016.03.009. [DOI] [Google Scholar]

- 60.Schettino S., Campos J.C.C., Minette L.J., de Souza A.P. Work precariousness: Ergonomic risks to operators of machines adapted for forest harvesting. Revista Arvore. 2017;41 doi: 10.1590/1806-90882017000100009. [DOI] [Google Scholar]

- 61.Silver K., Hoffman K., Loury S., Fethke N.B., Liebman A., Manz N., Manock S., Andino A., Bradfield M., Morrissette D., et al. Campus-community partnership for farmworkers’ health: Interventions for tomato workers in Tennessee. Prog. Community Health Partnersh. Res. Educ. Act. 2014;8:501–510. doi: 10.1353/cpr.2014.0056. [DOI] [PubMed] [Google Scholar]

- 62.Taghavi S.M., Mokarami H., Ahmadi O., Stallones L., Abbaspour A., Marioryad H. Risk factors for developing work-related musculoskeletal disorders during dairy farming. Int. J. Occup. Environ. Med. 2017;8:39–45. doi: 10.15171/ijoem.2017.861. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 63.Unver-Okan S., Acar H.H., Kaya A. Determination of work postures with different ergonomic risk assessment methods in forest nurseries. Fresenius Environ. Bull. 2017;26:7362–7371. [Google Scholar]

- 64.Gallo R., Mazzetto F. Ergonomic analysis for the assessment of the risk of work-related musculoskeletal disorder in forestry operations. J. Agric. Eng. 2013;44 doi: 10.4081/jae.2013.389. [DOI] [Google Scholar]

- 65.Abaraogu U.O., Odebiyi D.O., Olawale O.A. Association between postures and work-related musculoskeletal discomforts (WRMD) among beverage bottling workers. Work J. Prev. Assess. Rehabil. 2016;54:113–119. doi: 10.3233/WOR-162262. [DOI] [PubMed] [Google Scholar]

- 66.Boulila A., Ayadi M., Mrabet K. Ergonomics study and analysis of workstations in Tunisian mechanical manufacturing. Hum. Factors Ergon. Manuf. Serv. Ind. 2018;28:166–185. doi: 10.1002/hfm.20732. [DOI] [Google Scholar]

- 67.Can G.F., Atalay K.D., Eraslan E. Working posture analysis in fuzzy environment and ergonomic work station design recommendations. J. Fac. Eng. Gazi Univ. 2015;30:451–460. [Google Scholar]

- 68.Dehghani F., Zakerian S.A., Zare A., Omidi F., Moradpour Z., Eynipour A., Kakavandi M.G. Ergonomic interventions for improving working postures associated with manual materials handling (case study: A mineral processing plant) J. Health Saf. Work. 2016;6:85–94. [Google Scholar]

- 69.Escalona L.Y., Venot R.S., Escalona E., Yanes L. The reality of the women who make our lives easier: Experience in a company that assemblies electric motors in Venezuela. Work J. Prev. Assess. Rehabil. 2012;41:1775–1777. doi: 10.3233/WOR-2012-0384-1775. [DOI] [PubMed] [Google Scholar]

- 70.Felekoglu B., Tasan S.O. Ergonomic risk assessment for work-related musculoskeletal disorders: A systematic reactive/proactive integrated approach. J. Fac. Eng. Archit. Gazi Univ. 2017;32:777–793. doi: 10.17341/gazimmfd.337625. [DOI] [Google Scholar]

- 71.Garcia-Garcia M., Sanchez-Lite A., Camacho A.M., Domingo R. Analysis of postural assessment methods and virtual simulation tools into manufacturing engineering. Dyna-Colombia. 2013;80:5–15. [Google Scholar]

- 72.Gonen D., Karaoglan A.D., Ocaktan M.A.B., Oral A., Aticti H., Kaya B. A new risk assessment approach for the analysis of musculoskeletal disorders. J. Fac. Eng. Archit. Gazi Univ. 2018;33:423–438. doi: 10.17341/gazimmfd.416351. [DOI] [Google Scholar]

- 73.Hanson R., Medbo L., Berlin C., Hansson J. Manual picking from flat and tilted pallet containers. Int. J. Ind. Ergon. 2018;64:199–212. doi: 10.1016/j.ergon.2017.07.001. [DOI] [Google Scholar]

- 74.Hussain A., Case K., Marshall R., Summerskill S. Using Ergonomic Risk Assessment Methods for Designing Inclusive Work Practices: A Case Study. Hum. Factors Ergon. Manuf. Serv. Ind. 2016;26:337–355. doi: 10.1002/hfm.20650. [DOI] [Google Scholar]

- 75.Isler M., Kucuk M., Guner M. Ergonomic assessment of working postures in clothing sector with scientific observation methods. Int. J. Cloth. Sci. Technol. 2018;30:757–771. doi: 10.1108/IJCST-06-2017-0084. [DOI] [Google Scholar]

- 76.Kee D., Karwowski W. A comparison of three observational techniques for assessing postural loads in industry. Int. J. Occup. Saf. Ergon. 2007;13:3–14. doi: 10.1080/10803548.2007.11076704. [DOI] [PubMed] [Google Scholar]

- 77.Maldonado-Macias A., Realyvasquez A., Hernandez J.L., Garcia-Alcaraz J. Ergonomic assessment for the task of repairing computers in a manufacturing company: A case study. Work J. Prev. Assess. Rehabil. 2015;52:393–405. doi: 10.3233/WOR-152118. [DOI] [PubMed] [Google Scholar]

- 78.Mohapatra S., Shaikh A., Nayak P., Navada R. Hazards and health risks encountered by manual sand dredgers from Udupi, India: A cross-sectional study. J. Clin. Diagn. Res. 2017;11:11–17. doi: 10.7860/JCDR/2017/28960.10280. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 79.Nagaraj T.S., Jeyapaul R., Mathiyazhagan K. Evaluation of ergonomic working conditions among standing sewing machine operators in Sri Lanka. Int. J. Ind. Ergon. 2019;70:70–83. doi: 10.1016/j.ergon.2019.01.006. [DOI] [Google Scholar]

- 80.Sahu S., Moitra S., Maity S., Pandit A.K., Roy B. A comparative ergonomics postural assessment of potters and sculptors in the unorganized sector in West Bengal, India. Int. J. Occup. Saf. Ergon. 2013;19:455–462. doi: 10.1080/10803548.2013.11077001. [DOI] [PubMed] [Google Scholar]

- 81.Sain M.K., Meena M.L. Exploring the musculoskeletal problems and associated risk-factors among brick kiln workers. Int. J. Workplace Health Manag. 2018;11:395–410. doi: 10.1108/IJWHM-05-2018-0061. [DOI] [Google Scholar]

- 82.Samaei S.E., Tirgar A., Khanjani N., Mostafaee M., Hosseinabadi M.B. Effect of personal risk factors on the prevalence rate of musculoskeletal disorders among workers of an Iranian rubber factory. Work J. Prev. Assess. Rehabil. 2017;57:547–553. doi: 10.3233/WOR-172586. [DOI] [PubMed] [Google Scholar]

- 83.Sanjog J., Patel T., Chowdhury A., Karmakar S. Musculoskeletal ailments in Indian injection-molded plastic furniture manufacturing shop-floor: Mediating role of work shift duration. Int. J. Ind. Ergon. 2015;48:89–98. doi: 10.1016/j.ergon.2015.04.004. [DOI] [Google Scholar]

- 84.Yoon S.Y., Ko J., Jung M.C. A model for developing job rotation schedules that eliminate sequential high workloads and minimize between-worker variability in cumulative daily workloads: Application to automotive assembly lines. Appl. Ergon. 2016;55:8–15. doi: 10.1016/j.apergo.2016.01.011. [DOI] [PubMed] [Google Scholar]

- 85.Lasota A.M. A REBA-based analysis of packers workload: A case study. LogForum. 2014;10:87–95. [Google Scholar]

- 86.Moussavi-Najarkola S., Mirzaei R. Assessment of musculoskeletal loads of electric factory workers by rapid entire body assessment. Health Scope. 2012;1:71–79. doi: 10.5812/jhs.6654. [DOI] [Google Scholar]

- 87.Ahmed M., Campbell-Kyureghyan N., Frost K., Bertocci G. Ergonomic evaluation of a wheelchair transportation securement system. Work J. Prev. Assess. Rehabil. 2012;41:4924–4930. doi: 10.3233/WOR-2012-0787-4924. [DOI] [PubMed] [Google Scholar]

- 88.Balaji K.K., Alphin M.S. Computer-aided human factors analysis of the industrial vehicle driver cabin to improve occupational health. Int. J. Inj. Control Saf. Promot. 2016;23:240–248. doi: 10.1080/17457300.2014.992351. [DOI] [PubMed] [Google Scholar]

- 89.Bora S., Bhalerao Y., Goyal A., Chakrabarti D., Chen D.Z., Bao N.S., Niu X., Garg A. Computation of safety design indexes of industry vehicle operators based on the reach angle, the distance from elbow to ground and the popliteal height. Int. J. Ind. Ergon. 2019;71:155–164. doi: 10.1016/j.ergon.2019.03.005. [DOI] [Google Scholar]

- 90.Khan M.R., Singh N.K. Prevalence of musculoskeletal disorders among Indian railway sahayaks. Int. J. Occup. Environ. Health. 2018;24:27–37. doi: 10.1080/10773525.2018.1507187. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 91.Cakit E. Assessment of the physical demands of waste collection tasks. Glob. Nest J. 2015;17:426–438. [Google Scholar]

- 92.Jozwiak Z.W., Bortkiewicz A., Makowiec-Dabrowska T., Kapitaniak B. Assessment of musculoskeletal load in refuse collectors. Med. Pracy. 2013;64:507–519. doi: 10.13075/mp.5893.2013.0042. [DOI] [PubMed] [Google Scholar]

- 93.Capodaglio E.M. Occupational risk and prolonged standing work in apparel sales assistants. Int. J. Ind. Ergon. 2017;60:53–59. doi: 10.1016/j.ergon.2016.11.010. [DOI] [Google Scholar]

- 94.Mork M.A., Choi S.D. An ergonomic assessment of sample preparation job tasks in a chemical laboratory. J. Chem. Health Saf. 2015;22:23–32. doi: 10.1016/j.jchas.2014.11.003. [DOI] [Google Scholar]

- 95.Lim D., Cho Y.K., Choi H.H., Hwang S.J., Han P., Woo D.G., Hwang G., Kim Y.H., Chu J., Shin J., et al. Evaluation of loads imposed on muscles and joints by repeated vacuum cleaning works for estimation of a potentiality of musculo-skeletal disorder occurrence. Int. J. Precis. Eng. Manuf. 2012;13:429–438. doi: 10.1007/s12541-012-0055-x. [DOI] [Google Scholar]

- 96.Lofqvist L., Osvalder A.L., Bligard L.O., Pinzke S. An analytical ergonomic risk evaluation of body postures during daily cleaning tasks in horse stables. Work J. Prev. Assess. Rehabil. 2015;51:667–682. doi: 10.3233/WOR-152022. [DOI] [PubMed] [Google Scholar]

- 97.Rui L.H., Cheung T.W.C., Yang Z.X., Pratt A.L. A pilot study: Exploring the musculoskeletal risk exposure associated with drying laundry using the public housing pipe-socket system amongst women in Singapore. Work J. Prev. Assess. Rehabil. 2018;61:449–461. doi: 10.3233/WOR-182809. [DOI] [PubMed] [Google Scholar]

- 98.Hashim A.M., Dawal S.Z.M., Yusoff N. Ergonomic evaluation of postural stress in school workshop. Work J. Prev. Assess. Rehabil. 2012;41:827–831. doi: 10.3233/WOR-2012-0249-827. [DOI] [PubMed] [Google Scholar]

- 99.Chatterjee A., Sahu S. A physiological exploration on operational stance and occupational musculoskeletal problem manifestations amongst construction labourers of West Bengal, India. J. Back Musculoskelet. Rehabil. 2018;31:775–783. doi: 10.3233/BMR-170935. [DOI] [PubMed] [Google Scholar]

- 100.Kim S., Nussbaum M.A., Jia B.C. Low back injury risks during construction with prefabricated (panelised) walls: Effects of task and design factors. Ergonomics. 2011;54:60–71. doi: 10.1080/00140139.2010.535024. [DOI] [PubMed] [Google Scholar]

- 101.Li X.M., Han S., Gul M., Al-Hussein M., El-Rich M. 3D visualization-based ergonomic risk assessment and work modification framework and its validation for a lifting task. J. Constr. Eng. Manag. 2018;144 doi: 10.1061/(ASCE)CO.1943-7862.0001412. [DOI] [Google Scholar]

- 102.Yu Y.T., Yang X.C., Li H., Luo X.C., Guo H.L., Fang Q. Joint-level vision-based ergonomic assessment tool for construction workers. J. Constr. Eng. Manag. 2019;145 doi: 10.1061/(ASCE)CO.1943-7862.0001647. [DOI] [Google Scholar]

- 103.Asadi H., Yu D., Mott J.H. Risk factors for musculoskeletal injuries in airline maintenance, repair and overhaul. Int. J. Ind. Ergon. 2019;70:107–115. doi: 10.1016/j.ergon.2019.01.008. [DOI] [Google Scholar]

- 104.Beyan A.C., Alici N.S., Cimrin A. A perspective on occupational musculoskeletal diseases in turkey; case cluster study. J. Clin. Anal. Med. 2017;8:117–120. doi: 10.4328/jcam.4924. [DOI] [Google Scholar]

- 105.Chiasson M.E., Imbeau D., Aubry K., Delisle A. Comparing the results of eight methods used to evaluate risk factors associated with musculoskeletal disorders. Int. J. Ind. Ergon. 2012;42:478–488. doi: 10.1016/j.ergon.2012.07.003. [DOI] [Google Scholar]

- 106.Das B. An evaluation of low back pain among female brick field workers of West Bengal, India. Environ. Health Prev. Med. 2015;20:360–368. doi: 10.1007/s12199-015-0476-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 107.Diego-Mas J.A., Alcaide-Marzal J., Poveda-Bautista R. Errors using observational methods for ergonomics assessment in real practice. Hum. Factors. 2017;59:1173–1187. doi: 10.1177/0018720817723496. [DOI] [PubMed] [Google Scholar]

- 108.Dumas G.A., Preston D., Beaucage-Gauvreau E., Lawani M. Posture analysis of lifting a load for head carriage and comparison between pregnant and non-pregnant women. Work J. Prev. Assess. Rehabil. 2014;47:63–72. doi: 10.3233/WOR-131686. [DOI] [PubMed] [Google Scholar]

- 109.Guertler C., Speck G.M., Mannrich G., Merino G., Merino E.A.D., Seiffert W.Q. Occupational health and safety management in Oyster culture. Aquac. Eng. 2016;70:63–72. doi: 10.1016/j.aquaeng.2015.11.002. [DOI] [Google Scholar]

- 110.Lamarao A.M., Costa L.C.M., Comper M.L.C., Padula R.S. Translation, cross-cultural adaptation to Brazilian-Portuguese and reliability analysis of the instrument Rapid Entire Body Assessment-REBA. Braz. J. Phys. Ther. 2014;18:211–217. doi: 10.1590/bjpt-rbf.2014.0035. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 111.Mukhopadhyay P., Jhodkar D., Kumar P. Ergonomic risk factors in bicycle repairing units at Jabalpur. Work J. Prev. Assess. Rehabil. 2015;51:245–254. doi: 10.3233/WOR-141852. [DOI] [PubMed] [Google Scholar]

- 112.Mukhopadhyay P., Srivastava S. Ergonomic design issues in some craft sectors of jaipur. Des. J. 2010;13:99–124. doi: 10.2752/146069210X12580336766446. [DOI] [Google Scholar]

- 113.Mukhopadhyay P., Srivastava S. Evaluating ergonomic risk factors in non-regulated stone carving units of Jaipur. Work J. Prev. Assess. Rehabil. 2010;35:87–99. doi: 10.3233/WOR-2010-0960. [DOI] [PubMed] [Google Scholar]

- 114.Nam K.H., Lee S., Kyung G., An J., An S. Development of ergonomic gun barrel cleaning method: Automation and its advantages. Hum. Factors Ergon. Manuf. Serv. Ind. 2017;27:243–248. doi: 10.1002/hfm.20706. [DOI] [Google Scholar]

- 115.Roman-Liu D. Comparison of concepts in easy-to-use methods for MSD risk assessment. Appl. Ergon. 2014;45:420–427. doi: 10.1016/j.apergo.2013.05.010. [DOI] [PubMed] [Google Scholar]

- 116.Schwartz A.H., Albin T.J., Gerberich S.G. Intra-rater and inter-rater reliability of the rapid entire body assessment (REBA) tool. Int. J. Ind. Ergon. 2019;71:111–116. doi: 10.1016/j.ergon.2019.02.010. [DOI] [Google Scholar]

- 117.Shanahan C.J., Vi P., Salas E.A., Reider V.L., Hochman L.M.L., Moore A.E. A comparison of RULA, REBA and Strain Index to four psychophysical scales in the assessment of non-fixed work. Work J. Prev. Assess. Rehabil. 2013;45:367–378. doi: 10.3233/WOR-121540. [DOI] [PubMed] [Google Scholar]

- 118.Motamedzade M., Ashuri M., Golmohammadi R., Mahjub H. Comparison of ergonomic risk assessment outputs from rapid entire body assessment and quick exposure check in an engine oil company. J. Res. Health Sci. 2011;11:26–32. [PubMed] [Google Scholar]

- 119.Gentzler M., Stader S. Posture stress on firefighters and emergency medical technicians (EMTs) associated with repetitive reaching, bending, lifting, and pulling tasks. Work J. Prev. Assess. Rehabil. 2010;37:227–239. doi: 10.3233/WOR-2010-1075. [DOI] [PubMed] [Google Scholar]

- 120.Yuan L. Reducing ergonomic injuries for librarians using a participatory approach. Int. J. Ind. Ergon. 2015;47:93–103. doi: 10.1016/j.ergon.2015.03.004. [DOI] [Google Scholar]