Abstract

Over the past few years, nanocellulose (NC), cellulose in the form of nanostructures, has been proved to be one of the most prominent green materials of modern times. NC materials have gained growing interests owing to their attractive and excellent characteristics such as abundance, high aspect ratio, better mechanical properties, renewability, and biocompatibility. The abundant hydroxyl functional groups allow a wide range of functionalizations via chemical reactions, leading to developing various materials with tunable features. In this review, recent advances in the preparation, modification, and emerging application of nanocellulose, especially cellulose nanocrystals (CNCs), are described and discussed based on the analysis of the latest investigations (particularly for the reports of the past 3 years). We start with a concise background of cellulose, its structural organization as well as the nomenclature of cellulose nanomaterials for beginners in this field. Then, different experimental procedures for the production of nanocelluloses, their properties, and functionalization approaches were elaborated. Furthermore, a number of recent and emerging uses of nanocellulose in nanocomposites, Pickering emulsifiers, wood adhesives, wastewater treatment, as well as in new evolving biomedical applications are presented. Finally, the challenges and opportunities of NC-based emerging materials are discussed.

Keywords: nanocellulose, cellulose nanocrystals, production, functionalization, application

Introduction

Nowadays, the application of green, renewable and sustainable materials has become increasingly important for producing various high-value products with low environmental impact (Oksman and Bismarck, 2014; Pandey et al., 2015; Thakur, 2015a,b; Kargarzadeh et al., 2018a,b). This area of research has attracted the interest of a great number of academicians and industrials as such materials turn out to be an alternative solution to the ever-depleting non-renewable sources, environmental pollution, global warming, and energy crisis. In this context, cellulose, starch, alginate, chitin, chitosan, and gelatin have been revealed to be promising candidates with regards to their abundant availability from various resources (Trache, 2018). Among them, cellulose is by far the most abundant renewable compound obtained from the biosphere and it can be found in plants, algae, tunicates, and some bacteria (Vazquez et al., 2015; Trache et al., 2016a,b). This fascinating polymer, seen as an inexhaustive source of raw materials, has potential to be modified and functionalized with several available industrial uses and there is still plenty to discover and celebrate in cellulose (Mokhena and John, 2020; Moohan et al., 2020; Trache et al., 2020). The benefit of cellulose can be further extended when cellulose chains are bundled together, generating highly ordered regions that can be subsequently isolated as nano-particles, known as cellulose nanomaterials or nanocelluloses, considered as useful class of futuristic materials (Foster et al., 2018) owing to their physicochemical features. In addition to be renewable and abundant, they combine chemical inertness, excellent stiffness, high strength, low coefficient of thermal expansion, low density, dimensional stability, and ability to modify its surface chemistry (Phanthong et al., 2018; Rajinipriya et al., 2018; Naz et al., 2019; Vineeth et al., 2019; Köse et al., 2020).

Typically, nanocellulose can be categorized into two major classes, (1) nanostructured materials (cellulose microcrystals and cellulose microfibrils) and (2) nanofibers (cellulose nanfibrils, cellulose nanocrystals, and bacterial cellulose) (Trache et al., 2017; Hussin et al., 2019; Pennells et al., 2020). A number of nanocellulose forms can be produced using different methods and from various cellulosic sources (Phanthong et al., 2018; Pires et al., 2019; Salimi et al., 2019). The morphology, size, and other characteristics of each nanocellulose class depend on the cellulose origin, the isolation and processing conditions as well as the possible pre- or post-treatments. The opportunity of producing nanocellulose with various features is considered fairly an exciting topic, which can promote the exploration of unexplored biomass. The benefits of the 3-D hierarchical nanostructure of nanocellulose and its physicochemical characteristics at nano scale open new prospects in several applications (Li et al., 2018; Vilarinho et al., 2018; Pires et al., 2019; Köse et al., 2020). According to Markets and Markets, the nanocellulose market is forecasted to achieve USD 783 Million by 2025. The rising demand and the employment of new applications have driven the researchers and the industry to exploit even more the employment of nanocellulose (Coelho et al., 2018). In addition, the number of papers is increasing year after year, reflecting the high concern in this type of nanomaterial. This attention expresses itself by the new International Organization for Standardization (ISO), Technical Association of the Pulp and Paper Industry (TAPPI), and Canadian Standards Association (CSA) Standards on CNCSs that are being developed and published, highlighting the market interest (Klemm et al., 2018). Nanocellulose, which can currently be produced in industrial scale at the tons per day, can be employed in several fields in our life, such as nanocomposite materials, biomedical products, wood adhesives, supercapacitors, template for electronic components, batteries, catalytic supports, electroactive polymers, continuous fibers and textiles, food coatings, barrier/separation membranes, antimicrobial films, paper products, cosmetic, cements, and many more emerging uses (Moon et al., 2016; Thomas et al., 2018).

The search of novel applications and improving the properties of the current nanocellulose-based materials are crucial driving forces for research and development (R&D) in various research groups and increasingly in companies. It can be seen that several literature review articles have been published during the last few years and most of them focused on the production of nanocelluloses, their modification and applications (Dufresne, 2019; He et al., 2019; Karimian et al., 2019; Kim J. H. et al., 2019; Luo et al., 2019; Miao and Hamad, 2019; Naz et al., 2019; Park et al., 2019; Salimi et al., 2019; Sharma et al., 2019; Shojaeiarani et al., 2019; Tan et al., 2019; Younas et al., 2019; Köse et al., 2020; Mokhena and John, 2020; Moohan et al., 2020; Tong et al., 2020). Certain recent findings and advances have not been enough addressed in previous publications, while here, we concisely provide some of the most recent applications of nanocellulose (NC), especially cellulose nanocrystals (CNC). The aims of this review is to make a brief summary on the study of nanocelluloses, with a special focus on CNCs, as well as their recent applications. At first, a brief introduction on cellulose, nanocellulose nomenclature, its isolation from several feedstocks, properties and functionalization are presented. Important challenges related to their production and new directions are addressed. In the subsequent sections, we shed light on current trends and recent research on the use of nanocellulose with special emphasis on nanocomposites, medical, Pickering emulsifiers, wood adhesives, adsorption, separation, decontamination, and filtration applications, to provide readers with a comprehensive overview of the advanced science and engineering of nanocellulose-based emerging materials and uses. Other emerging applications of nanocellulose such as papermaking, oil and gas drilling and cementing, energy storage systems, sensors and biosensors, which have been extensively reviewed in recent years (Du X. et al., 2017; Chen et al., 2018; Kim J. H. et al., 2019; Tayeb and Tayeb, 2019; Balea et al., 2020; Dai et al., 2020; Lasrado et al., 2020; Ramasamy and Amanullah, 2020; Zhang et al., 2020), are excluded and they are beyond the scope of the present review. It is expected that this review will forge new directions for the preparation of NC as well as the design and production of new NC-based materials for widespread advanced applications.

Overview of Nanocellulose

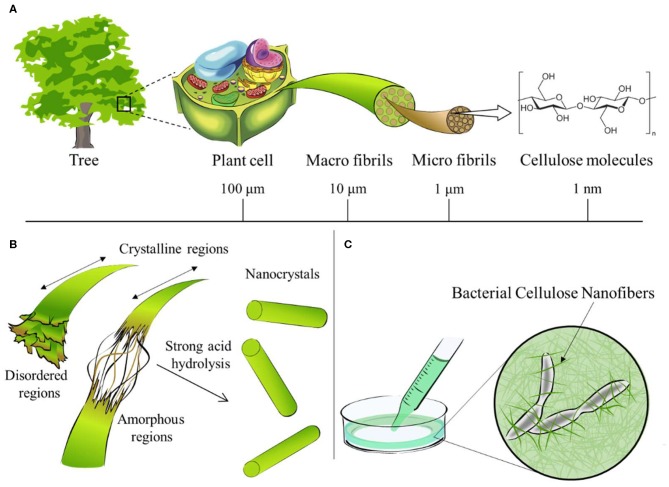

Structure and Source of Cellulose

Cellulose, a fascinating and sustainable feedstock, is the most abundant polymeric raw material on earth. Its annual production is estimated to be between 1010 and 1011 t, but only a small portion of 6 × 109 t is exploited by a number of industrial fields such as papers, textile, chemical, and material industries (Trache et al., 2020). Anselme Payen extracted this white biomacromolecule for the first time in 1838 and Herman Staudinger established its chemical structure few years later (Trache et al., 2016a). Cellulose is basically constituted by repeating β (1,4)-bound D-glucopyranosyl units (anhydroglucose unit, AGU) in the 4C1-chain configuration, in which every monomer unit is corkscrewed at 180° compared to its neighbors (Gopi et al., 2019). The generated cellobiose units are linked together to produce a crystalline structure of cellulose known as elementary fibrils. These latter are bundled together to produce micro-fibrils, which in turn formed macro-fibrils or cellulosic fibers. The intra- and intermolecular chemical groups impart cellulose its specific properties such as hydrophilicity, chirality, ease of chemical functionalization, insolubility in most aqueous solvents, and infusibility (Habibi et al., 2010). Obviously, cellulosic chains have a degree of polymerization of ~10 000 AGUs and 15 000 units, in wood- and cotton-derived cellulose, respectively. Cellulose characteristics are closely dependent on the degree of polymerization as well as the polymeric chain length. Native cellulose is composed of both ordered (crystalline) and disordered (amorphous) domains. Its crystallinity can vary from 40 to 70% depending on the natural source as well as the extraction procedure. The amorphous regions have low density compared to the crystalline ones and are prone to react with other molecular groups (Wertz et al., 2010; Dufresne and Belgacem, 2013; Kargarzadeh et al., 2017; Tarchoun et al., 2019a,b,c). Broadly, crystalline domains are more resistant to chemical, mechanical, and enzymatic treatments compared to the amorphous ones. Based on the molecular orientations, van der Waals, intra- and intermolecular interactions, isolation and treatment method, cellulose can be found as different polymorphs, i.e., cellulose I, II, IIII, IIIII, IVI, and IVII, which can be transformed from one to another by using thermal or chemical treatments (Thakur, 2015a,b). Various sources (Table 1) such as wood, herbaceous plants, grass, agricultural crops and their by-products, animal, algae and bacterial sources, waste paper, among others, can be used as raw material to produce cellulose (Trache, 2017; Trache et al., 2017; Nandi and Guha, 2018; Kumar V. et al., 2020). A graphical presentation of cellulose from its natural raw material to the fundamental molecule is displayed in Figure 1. Cellulose with different features can be obtained depending on the natural source, its origin and maturity, pretreatment, and processing methodologies and reaction parameters (Dufresne, 2013; Zhao and Li, 2014; Ummartyotin and Manuspiya, 2015; Campano et al., 2016; Trache et al., 2017). Broadly, lignocellulosic sources require the elimination of non-cellulosic components through the removal of extractive components (fat, tannins, rein, rosin, free sugars, flavonoids, terpenoids, terpene, fatty acid, and waxes), the delignification and bleaching processes (Pires et al., 2019; Fodil Cherif et al., 2020). Such pre-treatments can be carried out using various chemical, physical, biological, and combined methods (Agbor et al., 2011; Karimi and Taherzadeh, 2016; Rabemanolontsoa and Saka, 2016; Hassan et al., 2018). They allow disrupting the compact structure of the lignocellulosic and overcoming its recalcitrance. Pretreatments present more than 40% of the total processing cost (Bhutto et al., 2017). The most important procedures can be found in several recent review papers (Behera et al., 2014; Karimi and Taherzadeh, 2016; Rabemanolontsoa and Saka, 2016; Bhutto et al., 2017; Hassan et al., 2018). These pretreatments allow the separation of pure and crystalline cellulose, ensure the break of the linkages existing between cellulose and non-cellulosic compounds (lignin and hemicellulose), decrease the degree of polymerization, promote the accessibility toward cellulose-rich fraction and increase the porosity, the inner surface and reactivity (Kargarzadeh et al., 2017). However, a number of pretreatments may negatively affect the process through the generation of toxic and hazardous wastes, imperfect separation, degradation, and loss of cellulose as well as of the high overall process expenses. For these reasons, several studied are still in progress over the world to well-understand the phenomena that can occur during the pretreatments, optimize the efficiency and the easiness of the processes, and reduce their costs and environmental impact (Phanthong et al., 2018). In the case of animal cellulose, some pretreatments are usually required to produce pure cellulose as reported by Trache et al. (2017). On the other hand, bacterial cellulose does not contain extractives, hemicellulose, and lignin with respect to vegetable cellulose, and thus does not necessitate specific pretreatments. Nevertheless, its production in industrial scale remains relatively expensive (Oun et al., 2020).

Table 1.

Various sources for the production of cellulose fibers.

| Source group | Sources |

|---|---|

| Hardwood | Eucalyptus, Aspen, Balsa, Oak, Elm, Maple, Birch |

| Softwood | Pine, Juniper, Spruce, Hemlock, Yew, Larch, Cedar |

| Annual plants/Agricultural residues | Oil palm, Hemp, Jute, Agave, Sisal, triticale straw, soybean straw, Alfa, Kenaf, Coconut husk, Begasse, Corn leaf, Sunflower, Bamboo Canola, Wheat, Rice, pineapple leaf and coir, Peanut shells, Potato peel, Tomato peel, Garlic straw residues, Mulberry fiber, Mengkuang leaves |

| Animal | Tunicates, Chordata, Styela clava, Halocynthia roretzi Drasche |

| Bacteria | Gluconacetobacter„ Salmonella, Acetobacter, Azotobacter, Agrobacterium, Rhizobium, Alkaligenes, Aerobacter, Sarcina, Pseudomonas, Rhodobacter |

| Algae | Cladophora, Cystoseria myrica, Posidonia oceanica |

Figure 1.

Cellulose contained in plants or trees has a hierarchical structure from the meter to the nanometer scale, as shown in (A). A schematic diagram of the reaction between cellulose and strong acid to obtain Nanocellulose is shown in (B). Bionanocellulose cultured from cellulose-synthesizing bacteria is shown in (C). Reprinted with permission from Miyashiro et al. (2020) as distributed by creative common license CC BY license, MDPI publisher.

Nomenclature and Types of Nanocellulose

Nanotechnology has become one of the driving forces behind a new industrial revolution in several fields, ranging from bionanocomposites, passing through medical, or even sensing and biosensing applications (Arof et al., 2019). Nanoscale materials have a size of about 100 nm in at least one dimension with specific physicochemical, optical, magnetic, and biological features compared to the bulk materials (He et al., 2019). Despite cellulose is widely studied for several decades, nanocellulose has emerged as a prominent and outstanding material in the last two decades, as indicated by three widely employed databases, namely Web of Science, PubMed, and ProQuest (Bacakova et al., 2019). This nanomaterial endows useful features such as high surface area-to-volume ratio, high Young's modulus and high tensile strength, low coefficient of thermal expansion, hydrogen-bonding capacity, biocompatibility, eco-friendliness, renewability, and lack of toxicity character (Salimi et al., 2019). The open literature has revealed that several terminologies have been and are currently used to define nanocellulose or cellulose nanomaterials, which unfortunately lead to misunderstanding and ambiguities (Trache et al., 2017; Hussin et al., 2019). Since anomalies still exist for nanocellulose nomenclature, it is important to introduce a standard nomenclature for the family of nanocelluloses, and efforts have to be devoted to rationalize the employment of the various terms based on their morphology, size, and synthetic procedures. Few years ago, the Technical Association of the Pulp and Paper Industry (TAPPI) has established a Nanotechnology Division dedicated to standardize the nomenclature of cellulose nanomaterials. A draft version standard, TAPPI WI 3021: Standard Terms and Their Definition for cellulose Nanomaterials, has been established (Dufresne, 2017; Kargarzadeh et al., 2018b). Broadly, nanocellulose can be categorized into nanostructured materials and nanofibers. The first category includes microcrystalline cellulose and cellulose microfibrils, whereas the second one comprises cellulose nanocrystals, cellulose nanofibrils, and bacterial cellulose. Cellulose nanocrystals (CNCs), usually produced by acid hydrolysis, consist of cylindrical, elongated, less flexible, and rod like nanoparticles with 4–70 nm in width, 100–6,000 nm in length, and 54–88% crystallinity index (Naz et al., 2019). It received a number of names throughout the two last decades encompassing nanocrystalline cellulose, rodlike cellulose crystals, nanowires, nanorods, nanoballs, cellulose crystallites, cellulose nanowhiskers, and cellulose whiskers (Brinchi et al., 2013; Charreau et al., 2013; Mariano et al., 2014; Vazquez et al., 2015; Trache et al., 2017). However, in the last few years the nomenclature has progressively converged to cellulose whiskers, cellulose nanowhiskers, and, more recently, to cellulose nanocrystals and nanocrystalline cellulose (Charreau et al., 2020). Nanofibrillated cellulose (CNF), commonly obtained by mechanical treatment, presents an entangled network structure with flexible, longer and wide nanofibers (20–100 nm in width and >10,000 nm in length), and lower crystallinity with respect to CNCs. Various names have been used for CNF such as cellulose nanofbril, nanofibrillar cellulose, and nanofibrous cellulose. The production of CNF from lignocellulosic biomass has most commonly performed through a range of chemical, mechanical, and enzymatic treatments, or a combination thereof, as recently described in detail elsewhere (Nechyporchuk et al., 2016; Osong et al., 2016). The common sources of CNF as well as its top research fields have been recently reviewed by Pennells et al. (2020). On the other hand, bacterial nanocellulose, also known as microbial nanocellulose, is considered as a promising and cost-effective natural nanomaterial for biomedical uses (Carvalho et al., 2019; Sharma and Bhardwaj, 2019). It consists of ultrafine, pure and ribbon-shaped nanofibers with 20–100 nm in diameter and micrometers lengths, which entangled to produce three-dimensional network as a hallmark. Such kind of nanocellulose is typically produced from bacteria, but its synthesis is seen extremely expensive because of the high costs of synthetic media (Trache, 2018). The amorphous nanocellulose (ANC) is another class of nanocellulose of spherical to elliptical shape with a diameter ranging from 80 to 120 nm. It can be prepared using acid hydrolysis with subsequent ultrasound disintegration from a regenerated cellulose, which can be obtained directly from cellulose solution via a physical dissolution, shaping, and regeneration process (Wang et al., 2016). ANC with enhanced properties such as high accessibility, improved sorption, and higher functional group amount can be primarily used as thickening agent in aqueous systems and carriers for bioactive substances (Kargarzadeh et al., 2017; Ram and Chauhan, 2018). Cellulose nanoyarn (CNY), one of the less investigated nanocellulose with diameters of 100–1,000 nm, is often obtained by electrospining of solutions containing cellulose or its derivatives. CNY finds application as wound dressings (Grumezescu, 2016). More recently, cellulose nanoplatelets (CNP), which are formed by entangled cellulose nanofibrils of 3 nm in diameter, have been prepared through oxidation under mild conditions. The thickness of such CNP is around 80 nm (Chávez-Guerrero et al., 2018).

The outstanding properties of cellulose nanofibers such as the nanometric scale, non-toxicity, high specific surface area, easy processing, high aspect ratio and stiffness, interesting mechanical characteristics, and good thermal stability have built up new opportunities for developing of novel kind of nanocellulose-based systems (Almeida et al., 2018; Dufresne, 2019; Liu et al., 2019b). Furthermore, many structures of nanocellulose, which can be prepared from various cellulosic sources based on several manufacturing methodologies, have permitted the development of different types of applications.

The emphasis of the following sections of this paper will be placed on one type of nanocellulose, i.e., cellulose nanocrystals, where the preparation methods, properties, surface modification as well as the recent applications of these nanomaterials will be treated. A special interest will be given to the studies carried out during the last 3 years and the term “nanocellulose” will be mainly reserved to describe CNCs, whereas only few details on CNFs are provided.

Isolation Methods of Cellulose Nanocrystals

Despite being the most available biomacromolecule on the earth, only on the recent years that cellulose has received more attention as an outstanding nanomaterial for many applications and new added-values products. Owing to its nanoscale, nanocellulose exhibits various advantageous features than the bulk material, encompassing nanoscale effect, biocompatibility, biodegradability, high specific surface area, high crystallinity, purity, amphiphilic nature, surface chemical reactivity, barrier properties, high mechanical strength, green and non-toxic (Chen et al., 2018; Klemm et al., 2018; Nascimento et al., 2018). However, depending on the natural source, isolation procedure, conditions, and pre-post-treatments, the characteristics of nanocellulose such as crystallinity, yield, dimensions and morphology, surface chemistry, physicochemical, and thermal properties can be tailored for a specific use, opening an extensive range of possibilities to develop new materials and devices (Wang Z. et al., 2017; Phanthong et al., 2018; Thomas et al., 2018; Wohlhauser et al., 2018). They can be employed in energy storage, substrate for printing electronics, aerogels, emulsion stabilizers, support for catalysts and immobilization of enzymes, low-calorie food additives, templates, reinforcing polymer composite, liquid crystals, pharmaceutical binder, biomimetic materials, biosensors and bio-imaging, etc. (Serpa et al., 2016; Agate et al., 2018; Seabra et al., 2018; Dufresne, 2019; Kim J. H. et al., 2019).

The preparation of nanocellulose from cellulose requires typically two main stages (Trache et al., 2017; Nandi and Guha, 2018; Xie et al., 2018). The first, as summarized in Table 2 (See also the above section: Structure and source of cellulose), focuses on the pretreatments of feedstocks to obtain pure cellulose, whereas the second stage is dedicated to the transformation of cellulose to nanocellulose. During the first stage, extractives (monomers, dimers and polymers of fat, free sugar, tannins, resin, rosin, flavonoids, terpenoids, terpene, waxes, fatty acids, etc.), hemicelluloses and lignin have to be partially or totally eliminated from the feedstocks based on specific pre-treatment methods (Kargarzadeh et al., 2017; Chen et al., 2018). The second stage, however, is usually dedicated to the production of cellulose nanocrystals. This latter ensures the elimination of amorphous domains form pristine cellulose, giving rise to the production of CNCs (Dufresne, 2013, 2017; Jonoobi et al., 2015). The disordered regions distributed as chain dislocations on segments along the elementary fibril are prone to hydrolytic action because of the reduced steric hindrance and kinetic factors, whereas the ordered domains, which present a higher resistance to the hydrolysis process, remain intact. Subsequently, the cellulose fibrils are transversely cleaved, generating the short CNCs with relatively high crystallinity. Nevertheless, after this second stage, further post-treatments such as solvent elimination, neutralization, washing, purification, filtration, centrifugation, sonication, dialysis, fractionation, surface modification, stabilization, and drying (freeze-drying, spray-drying) need to be undertaken after the hydrolysis process to recuperate CNC product.

Table 2.

The most employed and/or recently explored pre-treatment processes of lignocellulosic biomass, their advantages and shortcomings.

| Category | Pre-treatment process | Advantages | Shortcomings | References |

|---|---|---|---|---|

| Chemical | Diluted acid | - Low acid consumption. - Extensive hemicellulose degradation. |

- Corrosion of the equipment but low temperature is necessitated. - Degradation of cellulose. - Inhibitor formation increases with increase in temperature. |

Agbor et al., 2011; Rabemanolontsoa and Saka, 2016; Bhutto et al., 2017; Chen et al., 2017; Hassan et al., 2018; Satlewal et al., 2018 |

| Concentrated acid | - Extensive hemicellulose degradation. | - Corrosion of the equipment, toxicity of the environment, requires high amount of acid, and energy consumption for acid recovery. - Degradation of cellulose. - Inhibitor formation increases with increase in concentration. |

||

| Organic acids | - Avoid equipment corrosion, low energy consumption for acid recovery. | - Less efficient for biomass with higher hemicellulose content. | ||

| Alkaline | - Disrupts the lignin structure. - Removes acetyl groups from hemicellulose. - Mild reaction conditions. |

- Long residence time. - Neutralization issues. |

||

| Ionic liquids (ILs) | - Efficient lignin elimination. - Mild reaction conditions. - Some of them are reusable. - Better thermal stability. |

- Commercial application requires more implementation to overcome the scaling challenges. - The challenge of polysaccharides recovery. - High price of chemical products. - Cellulose degradation. |

||

| Deep eutectic solvents (DES) | - Easy to prepare, stable, cost-effective, and most of them are environmental-friendly. - Mild reaction conditions. - Efficient dissolution of lignin. Disrupts lignin-carbohydrate complexes. |

- Its efficiency depends on the nature of biomass. - Present high viscosity. - DES need to be manufactured at an industrial scale for availability as low-cost green solvents. |

||

| Oxidation | - Elimination of hemicellulose and lignin. | |||

| Organosolv | - Selective pretreatment methodology generating three separate fractions: dry lignin, relatively pure cellulose fraction, and an aqueous hemicellulose stream. - Low boiling point organic solvents are always easy to recover by distillation. - Efficient biomass delignification. - Increase the surface area. - Lack of toxicity, low price, and ease of recovery. |

- Formation of inhibitor during lignin dissolution. - Required high pressure during pretreatment. |

||

| Physical | Mechanical splintered | - Increase the specific surface area and decrease the particle size, which improve the hydrolysis yield. | - Requires more energy for hardwood than agricultural residues. - Less efficient process. |

Singh R. et al., 2014; Bhutto et al., 2017; Rodriguez et al., 2017; Hassan et al., 2018; Liu et al., 2019a; Rezania et al., 2020 |

| High-intensity ultrasonication | - Lignocellulosic biomass is commonly treated by ultrasound acoustic wave with the frequency range from 10 kHz to 20 MHz. - The generated cavitations, which depend on the frequency, will collapse and release huge amount of energy that create a localized hot spots at temperature of 2,000–5,000°C and pressure of 500–1,800 bars with a life time of a few microseconds. - No toxic with reduced reaction time. - Degrades preferentially the lignin. - Decreases hemicellulose content. |

- Depends closely on the nature of biomass and experimental conditions. - The efficiency and reliability of the operation depend on the ultrasonic mode (continuous or pulse), frequency, power, processing temperature, solvent, aeration, and the design of reactors with proper geometric construction. |

||

| Microwave radiation | - The process can be carried out at temperature of 50 to 210°C for 5–25 min. - A non-ionizing microwave radiation with a wavelengths ranging from 1 mm to 1m has frequency of 300 to 300,000 Mhz. |

|||

| - Higher microwave power with short pretreatment time and the low microwave power with long pretreatment time had almost same effect. - The process insures fast heat transfer, short duration time, selectivity and uniform volumetric heating performance, easy operating and energy efficient. - Green technology. - Fast fractionation and lignin disruption. - Degrade hemicellulose. |

- Increase the degradation of cellulose. | |||

| Gamma radiation | - Gamma radiation, obtained fromradioisotopes (Cobalt-60 or Cesium-137) can easily penetrate the lignocellulosic structure. - The most effective irradiation doses (891–1,200 kGy) possesses the most efficiency as ILs pretreatment. - Improves the post-treatments efficiency. |

- May cause the cellulose degradation. | ||

| Physicochemical | Wet oxidation | –The process requires treatment with water and air or oxygen at temperatures above 120°C under pressure up to 20 MPa for a period time 5–120 min. - Economic and available. - Assists to hemicellulose hydrolysis. |

- Costs may be high. | Singh R. et al., 2014; Karimi and Taherzadeh, 2016; Bhutto et al., 2017; Chen et al., 2017; Hassan et al., 2018; Rezania et al., 2020; Zhao et al., 2020 |

| Hydrothermolysis | - The process can be carried out at temperature of 140 to 220°C for 4–180 min. - Environmentally friendly. - No corrosion problems. - Effectively removes hemicellulose. - Reduces the need for post-treatments. |

- More energy demanding. | ||

| Steam explosion | - Biomass is treated with hot steam at 180–240°C under pressure (1–3.5 MPa) to improve the hemicellulose hydrolysis and the depolymerization of lignin, which are than enhanced with the second stage of depressurization. - Cost-effective process and low energy consuming. - Disruption of lignin and hemicellulose. - Can be used at commercial scale. - Less energy consumption and cost effective. |

- Incomplete disruption of lignin-carbohydrate matrix. - Generation of inhibitors that can affect the post-processing. - Requires high pressure. - Excessive cellulose degradation. |

||

| Supercritical fluid | - Moderate critical temperature of 31.1°C and pressure of 7.4 MPa, and high solid capacity. - CO2 is inert in nature, inexpensive, non-toxic, non-inflammable, and available from the by-products of several industrial processes. - No generation of toxins. - Green technology and readily available. |

- Less treatment efficiency. - High costs. |

||

| Ammonia fiber explosion (AFEX) | - AFEX is a dry-to-dry process. No wash stream in the process, and no toxic chemicals are produced for downstream processes. - Requires moderate temperature (<100°C), pH (<12), and short time duration. - Ammonia is the common chemical. - Insure the cleavage of lignin-carbohydrate complex linkages as well as the C-O-C bonds in lignin. |

- Less effective for biomass containing high lignin content. - Requires high energy input for recycling and recovery. |

||

| Ammonia recycle percolation (APR) | - In APR process, the aqueous ammonia (10–15 wt%) pass through biomass at elevated temperature (150–170°C). Lower temperature (80–150°C) was also reported. The residence time varies between 5 and 30 min. - Efficient treatment for hardwood and herbaceous plants. |

|||

| - Recyclable. - Causes the depolymerization of lignin and cleavage of lignin-carbohydrates linkages. - Relatively low cost process. |

- Less effective for softwoods. | |||

| Biological | Microbial | - Elimination of lignin and hemicellulose. - Low energy consumption. - Mild reaction conditions - No release of hazardous and harmful compounds. |

- Relatively time consuming processes. - Some additional pre-treatments may increase costs. - Require large space and specific growth conditions. - Require further research activities to understand some important parameters such as kinetics. |

Behera et al., 2014; Singh R. et al., 2014; Chen et al., 2017 |

| Fungal species | ||||

| Enzymatic | ||||

| Consolidated bioprocessing | ||||

| Combined | At least two of the above-mentioned pre-treatment processes | - Increase the efficiency of the elimination of lignin and hemicellulose at reasonable time. | - May enhance the operating cost. - Require further research work to optimize the processes. - Balance needs to be struck between efficiency improvement and cost. |

Chen et al., 2017; Liu et al., 2019a |

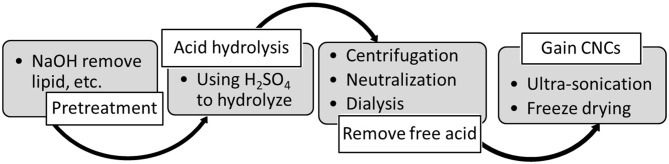

Despite acid hydrolysis using sulfuric acid is the oldest process, it remains the most common preparation method of CNCs. A typical approach starts with alkali and bleaching pretreatments followed by acid hydrolysis. It was reported that Calvert was the first author who performed the hydrolysis of cellulose in 1855 (Mao et al., 2017). Few decades later, in 1951, Rånby has successfully prepared stable colloidal suspensions of cellulose using H2SO4 (Nascimento et al., 2018). Nonetheless, the presence of sulfate esters at the cellulose surface decreases its thermal stability, but permits a well-dispersion of individual CNC bundles in aqueous media. An example of the procedure used to prepare CNCs form hardwood is depicted in Figure 2.

Figure 2.

An example of the procedure used to prepare CNC form hardwood. Reprinted with permission from Lin K. H. et al. (2019) as distributed by creative common license CC BY license, MDPI publisher.

In recent years, hydrochloric, phosphoric, and hydrobromic either liquid, solid or gaseous acids, organic acids, or mixtures of inorganic and organic acids have been used to produce CNC (Trache et al., 2017). For instance, the use of hydrochloric acid instead of sulfuric acid for cellulose hydrolysis will generate CNCs with better thermal stability, but the lack of electrostatic repulsion force between crystals causes them agglomeration and less stable aqueous solution can be obtained (Gopi et al., 2019). Thus, both of reaction conditions and cellulose origin affect the properties of the obtained CNCs such as the morphology, aspect ratio, density, mechanical features, thermal stability, dimensional dispersity, and crystallinity.

In the pursuit of lowering production costs, improving the characteristics of nanocellulose, several preparation methods of CNCs have been published and others continue to be developed worldwide, seeking an economic/sustainable approach to produce CNCs with preferred features. A number of processes have been reported to obtain CNCs, namely, improved chemical acid hydrolysis (Thakur, 2015b; Du et al., 2016; Kontturi et al., 2016), mechanical treatment (Pandey et al., 2015), oxidation methods (Sun et al., 2015; Vazquez et al., 2015), enzymatic hydrolysis (Anderson et al., 2014; Tong et al., 2020), ionic liquid treatments (Lazko et al., 2016), deep eutectic solvents (Sirviö et al., 2016), subcritical water hydrolysis (Novo et al., 2015, 2016), and combined processes (Trache et al., 2017, 2020; Xie et al., 2018). This latter class seems to be an interesting path since these methods combine two or many processes, which can overcome the shortcomings of the single approaches by improving the CNC properties, increasing the yield and reducing the cost. Some recent approaches to produce CNCs are displayed in Table 3. Trache et al. have recently reported the advantages and shortcomings of some important hydrolysis processes (Trache et al., 2017, 2020). Despite the aforesaid reports, there are some potential concerns associated with CNCs preparations. Broadly, their isolation is time consuming, high energy-demanding and requires more attention to avoid the use of toxic chemicals, which are detrimental to human and the environment.

Table 3.

A selection of recent CNC production methods from the corresponding natural source.

| Natural source | Methodology | References |

|---|---|---|

| Filter paper and microcrystalline cellulose | Solution plasma-chemical processing as an oxidation–hydrolysis strategy | Surov et al., 2018 |

| Cotton linters | Single step ammonium persulfate-assisted swelling, followed by oxidation | Wang et al., 2019 |

| Cellulose fibers | Ball mill assisted fully recyclable solid acid hydrolysis | Song et al., 2018 |

| Broomcorn Stalks | Acid hydrolysis followed by sonication | Langari et al., 2019 |

| Eucalyptus hardwood | Irradiation oxidation and organosolv solubilization | Zhang and Liu, 2018 |

| Microcrystalline cellulose | Ultrasonic pretreatment in ionic liquid followed by acid hydrolysis | Pang et al., 2018 |

| Nata de coco | Ultrasonic irradiation coupled with microwave treatment | Wardhono et al., 2018 |

| Oil palm | Sono-assisted TEMPO oxidation | Rohaizu and Wanrosli, 2017 |

| Wood sawdust | Sono-chemical synthesis using acid hydrolysis | Shaheen and Emam, 2018 |

| Microcrystalline cellulose | Recyclable citric/hydrochloric acids | Yu et al., 2019 |

| Commercial microcrystalline cellulose | Facile and rapid one-step hydrolysis by H2SO4/HNO3 mixed acid | Cheng et al., 2020 |

| Blue agave leaves and bagasse fibers | Sonochemical acid hydrolysis enhanced with sonication | Robles et al., 2018 |

| Eucalyptus pulp | Periodate oxidation route followed by reductive treatment with NaBH4 | Errokh et al., 2018 |

| Cotton cellulose powder | High-pressure homogenization controlling a process temperature | Park et al., 2019 |

| Commercial microcrystalline cellulose | A two-step collaborative process combining solvothermal pretreatment and mechanical exfoliation | Gao et al., 2019 |

| Commercial microcrystalline cellulose | Ball milling with water followed by centrifugation | Kang et al., 2018 |

| Lignocellulosic biomass | Hydrolysis by Ni(II)-transition metal salt followed by washing with distilled water, centrifugation, sonication and dialysis | Yahya et al., 2018 |

More recently, Charreau et al. have emphasized the increasing industrial interest on the field of cellulosic nanomaterials, which is evidenced by the astonishing increase in nanocellulose patents since 2010, and especially within the last 5 years, suggesting that the increasing trend would not stop in the following years (Charreau et al., 2020). For instance, more than 950 documents refereeing to CNCs have been published from 2010 and 2017. Most of them refer to the isolation methods, derivatization techniques as well as to different products containing these particles. However, it is worthy to note that the technology transfer, i.e., scaling-up form laboratory to bulk-scale is one of the major problem (Mishra et al., 2019). Overall, some methods are shorter and others are longer, some are environmentally benign whereas others are not, some are economic and less effective while others are efficient but expensive. Therefore, the journey so far not been so worthwhile. Nonetheless, more efforts are being devoted on the path to surmount all present-day obstacles. Besides that, some commercial producers currently prepare CNCs at capacities beyond pilot plant scale such as CelluForce (Canada, 1,000 kg/day), American Process Inc. (USA, 500 kg/day), Melodea/Holmen (Sweden, 100 kg/day), Blue Goose Biorefineries (Canada, 10 kg/day), Alberta Innovates (Canada, 100 kg/week), US forest products lab (USA, 10 kg/day), India Council for Agricultural Research (India, 10 kg/day), FPInnovation (Canada, 3 kg/day) (Xie et al., 2018; Trache et al., 2020). Nonetheless, the utilization of alternative cellulose sources to produce large-scale of CNCs remains timid. In this sense, the price of these nanomaterials is expected to decrease with the employment of cheaper sources of pulps and the optimization of extraction process. Moreover, The increase of the production rate worldwide, in the years to come as forecasted could bring down the cost significantly as well.

Properties and Surface Modification of Nanocellulose

Characterization and Properties of Nanocellulose

Depending on the source or origin (mainly from higher plants, algae, and bacteria), cellulose consists of varying portions of mostly crystalline (highly ordered) regions accompanied by some amorphous (disordered) fractions (George and Sabapathi, 2015). Upon isolating the crystalline regions from the biomass, it results in attaining polysaccharide nanocrystals, most commonly in the form of rod-shaped cellulose nanocrystals (Lin et al., 2012). Cellulose, the most ubiquitous biopolymer, in the form of nanocellulose (NC) has gained growing interest among researchers corroborating to its mechanical, physicochemical, and biological properties in consort with being eco-friendly (Saba et al., 2017). Nanocellulose (NC) can be obtained from natural cellulose, with few to tens of nanometers size range at least in one dimension. Xu et al. systematically discussed on nanocrystalline cellulose suspensions in the perspective of rheology, liquid crystal ordering, and colloidal phase behavior (Xu Y. et al., 2019). It was pointed out that geometrical dimensions and the morphology of cellulose nanocrystals vary based on their origin, extraction methods, and manufacturing conditions, which causes inconsistencies in suspension rheology and colloidal behaviors. The authors concluded that the rheology and colloidal behavior of aqueous nanocrystalline cellulose suspensions are comprehensively explained by colloidal volume fraction, the dimension of nanocrystalline cellulose rods and interparticle forces. Moreover, nanocrystalline cellulose suspensions form an ordered liquid crystal state when its concentration reaches a critical value. Abitbol et al. deduced that the stability of cellulose nanocrystal suspensions in water could be amended by regulating the surface charge, i.e., the degree of substitution of sulfate groups on their surface (Abitbol et al., 2018). The study presented that the viscosity of nanocellulose suspensions was inclined by surface charge, where CNCs with lower surface charge forms more viscous suspensions, consequently undergo gelation at lower concentrations. Researchers concluded that the effective volume of suspensions plays a major role throughout the concentration range relevant to liquid crystalline phase formation once the surface charge density of CNCs reaches a threshold value.

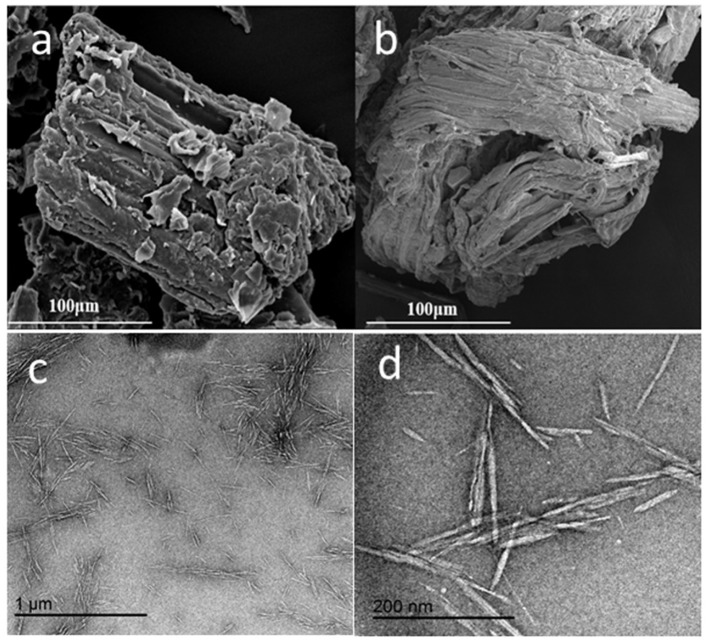

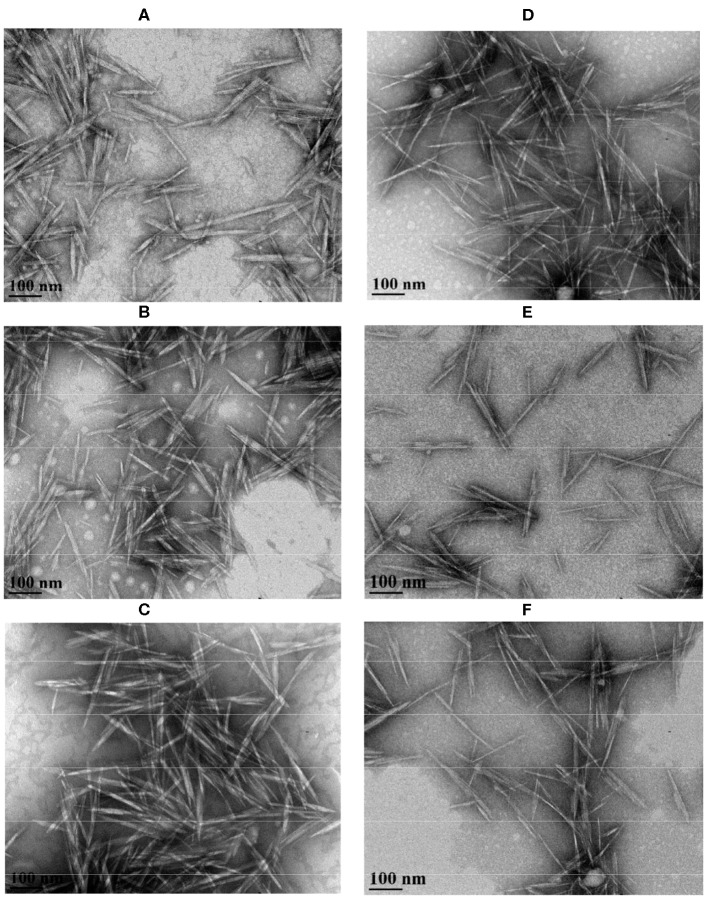

Nanocellulosic materials can be characterized by employing various techniques for instance; nitrogen gas and water adsorption isotherms, X-ray diffraction (XRD), helium pycnometry, dielectric spectroscopy, and mechanical testing to infer their properties (Le Bras et al., 2015). The crystallinity index (crystallinity percentage), which governs the mechanical and physical properties of nanocellulose is calculated employing an X-ray diffractometer, based on the maximum intensity of diffraction of the (002) lattice peak representing crytsalline region (I002) and the intensity of diffraction between (002) and (101) lattice peaks representing amorphous region (Iam). Thus, XRD peak position (2θ) and their intensities are referred in order to determine crystallinity. Morphological and dimensional evaluation of nanocellulose can be carried out using transmission electron microscopy (TEM), field emission scanning electron microscopy (FESEM), and atomic force microscopy (AFM) (Mohaiyiddin et al., 2016; Foster et al., 2018). Some TEM micrographs of CNCs prepared from different sources are displayed in Figures 3, 4, showing that their particle size ranges from 70 to 300 nm in length and 4 to 20 nm in width.

Figure 3.

SEM micrographs of (a) the raw material (corn stalk) and (b) the extracted cellulose; (c,d) transmission electron microscopy (TEM) micrographs of the cellulose nanocrystals (CNCs). Reprinted from Huang et al. (2017) as distributed by creative common license CC BY license, MDPI publisher.

Figure 4.

Transmission electron microscopy (TEM) micrographs of CNC isolated from: filter paper enzyme-treated for (A) 0 h, (B) 2 h, and (C) 10 h and wood pulp enzyme-treated for (D) 0 h, (E) 2 h, and (F) 10 h. Reprinted from Beyene et al. (2018) as distributed by creative common license CC BY license, MDPI publisher.

Density and the porosity of nanocellulose are measured using a helium pycnometer. Specific surface area and total pore volume can be obtained through the characterization involving N2 sorption analysis (Le Bras et al., 2015). Yang et al. (2017) reported that the zeta potential value, which examines the surface charge, reflects the dispersion stability of nanocellulose. Elemental composition on the surface of nanocellulose samples can be analyzed via X-ray photoelectron spectroscopy (XPS), while thermal stability, which signifies the thermal decomposition and impurities of nanocellulose, can be investigated through differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and differential thermogravimetry (DTG) (Jordan et al., 2019).

Utilization of dynamic nuclear polarization (DNP)-enhanced NMR spectroscopy has been an emerging tool to comprehend the surface chemistry of cellulose as it enhances conventional NMR sensitivity by several orders of magnitude (Smith et al., 2019). In a most recent study (Kumar A. et al., 2020), high-field dynamic nuclear polarization enhanced solid-state NMR technique has been employed to characterize surface species of metronidazole drug-functionalized TEMPO-oxidized cellulose nanofibrils, where comprehensive structural and chemical characterization of nanocellulose surface chemistry is still limited, especially for a very low level of functionalization (<1 wt.%). The researchers grafted the metronidazole drug onto CNF through a Diels-Alder reaction under heterogeneous aqueous conditions. Dynamic nuclear polarization enhanced-NMR data explicitly accounted the presence of trace amounts of TEMPO components and depolymerized cellulosic units in CNF, as well as coupling agents (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide and N-hydroxysuccinimide) on its surface. Moreover, their study showed that DNP-enhanced NMR spectroscopy is the only technique that can differentiate between surface adsorption and grafting.

With regards to cellulose's natural nano-structure, various methods can be employed to discover the characteristics of its structure through obtaining three different forms of nanocellulose such as cellulose nanocrystals (CNC), otherwise known as whiskers or microcrystallites, micro-fibrillated cellulose (MFC), also denoted as cellulose nanofiber (CNF), or nano-fibrillated cellulose (NFC) (Kaboorani and Riedl, 2015), and bacterial nanocellulose (BNC) (Gao et al., 2020). These three different forms of nanocellulose vary in their morphology (Liu et al., 2016). The isolation method governs the morphology and properties of nanocellulose (Yang et al., 2017). Nanocellulose exhibits some exclusive features such as exceptional mechanical properties (i.e., low density, high flexibility, and strength while being chemically inert) (Lavoine and Bergström, 2017) and thermal properties (Gan et al., 2020). Over the past few decades, many research studies have been conducted on the reinforcement of polymer matrix nanocomposites, for instance, natural rubber nanocomposites (Neto et al., 2016; Cao et al., 2018; Dominic et al., 2020), polylactic acid nanocomposites (Gitari et al., 2019; Rigotti et al., 2019), epoxy nanocomposites (Ayrilmis et al., 2019; Yan et al., 2019; Yue et al., 2019), and polystyrene nanocomposites (Clarke et al., 2019; Neves et al., 2019), where nanocellulose has been introduced as a reinforcing agent.

Gan et al. reviewed plant-based nanocellulose composites and their properties, with a focus, especially on their thermal-related and dynamic mechanical characteristics (Gan et al., 2020). The authors pointed out that nanocellulose-reinforced composites possess outstanding properties due to the presence of nanosize filler, which makes them potential candidates to replace conventional synthetic polymer composites. It was noted that the exceptional reinforcing capability of nanocellulose is attributable to its light-weight, high stiffness, and superior mechanical strength. Nanocellulose has established to be a substantial reinforcement, even at low filler loading, where its modulus of elasticity could reach up to 150 GPa with a staggering aspect ratio up to 640, low thermal expansion coefficient (0.01 ppm·K−1), and high specific surface area (several 100 m2·g−1). Dominic et al. studied the effect of rice husk derived nanocellulose in replacing carbon black in natural rubber compounding (Dominic et al., 2020). The dynamic mechanical analysis demonstrated that the loss tangent (tan δ) at 60 °C is lower for the composite containing 5 wt.% of rice husk-nanocellulose and 25 wt.% carbon black compared to the composite containing 30 wt.% carbon black, implying that rice husk-nanocellulose contributes to low rolling resistance, which is a crucial parameter for green tire applications. Thus, the study has proven the potential replacement of carbon black with nanocellulose.

The maximum processing temperature of nanocellulose-based composites depends on its thermal characteristics. Nepomuceno et al. detailed that understanding the thermal behavior of nanocellulose is essential, particularly during the processing of nanocellulose and polymer composites (Nepomuceno et al., 2017). Since nanocellulose decompose at a temperature around 200–300°C, the processing temperature should be controlled at ~200°C to prevent the degradation of nanocellulose. The researchers found out that a longer duration of acid hydrolysis minimizes the thermal stability and subsequently, the degree of crystallinity of nanocellulose. Moreover, the thermal stability of nanocellulose is influenced by several factors, including the cellulose source, the processing methods used to isolate the nanocellulose and the sulfate content. Polymer matrices with the incorporation of cellulose nanocrystals usually have a low decomposition temperature in comparison to nanofibrillated cellulose owing to the existence of sulfate groups on the surface of cellulose nanocrystals because of the use of sulfuric acid during the preparation. However, the thermal stability can be enhanced by the desulfation of nanocellulose and other physical or chemical modifications (Gan et al., 2020).

Besides nanocellulose's nano-reinforcement function, it also possesses properties such as renewability, high specific surface area, biocompatibility (Zhang et al., 2017), biodegradability, optical transparency, and low thermal expansion. Nonetheless, vital properties explicitly crystallinity, surface morphology, surface chemistry, and the dimension of nanocellulose differ reliant on the source of raw material and its extraction process, which will ultimately determine their applicability (Liu et al., 2016). Yang et al. noted that nanocellulose with higher crystallinity usually possess improved mechanical and thermal properties (Yang et al., 2017). CNCs are highly crystalline stiff rod-like fragments of several hundred nanometers in length and a width or diameter around 5 to 70 nm (Liu et al., 2016; Lavoine and Bergström, 2017), typically prepared using strong acid (sulfuric acid or hydrochloric acid) hydrolysis of cellulosic fibers. Defibrillation involving acid hydrolysis dissolves the amorphous regions of cellulosic fibers, leaving tiny rod-shaped particles denoted as CNC with improved crystallinity (Moberg et al., 2017). CNCs typically possess a high specific surface area of around 150 m2·g−1 (Kaboorani and Riedl, 2015) and Young's modulus up to 170 GPa attributable to high crystallinity (typically around 50–90%) (Wei et al., 2017).

CNFs possess a width of 3–50 nm and a few micrometers of length, where the dimensions mainly depend on the conditions employed during its preparation and chemical modification (Lavoine and Bergström, 2017). CNFs possess an extended network of flexible fibers and interchangeable amorphous and crystalline regions in comparison to CNCs (Liu et al., 2016). Due to the presence of different colloidal forms, both types of nanocellulose have different physical characteristics even though they are chemically similar (Saba et al., 2017). Le Bras and co-workers characterized dielectric properties of nanocellulose from wood (cellulose nanofibrils) and algae (Cladophora cellulose) for electrical insulator applications (Le Bras et al., 2015). The study demonstrated a high crystallinity for Cladophora nanocellulose and a lower moisture adsorption capacity in comparison to CNF. Furthermore, algae nanocellulose sample was much more porous, resulting in higher dielectric loss and lower strength. It was concluded that solid-state properties of nanocelluloses might govern its dielectric properties with regards to electrical insulator applications. Table 4 depicts some of the properties and features of various forms of nanocelluloses based on the source of extraction and their preparation method.

Table 4.

Properties and characteristics of nanocellulose substrates reliant on the cellulosic source and defibrillation method.

| Cellulosic substrate | Nanocellulose | Preparation method | Diameter (nm) and structural morphology | Average Young's modulus (GPa) | Apparent crystallinity (%) | Maximum degradation temperature (°C) | Average tensile strength (MPa) | Zeta potential (mV) | References |

|---|---|---|---|---|---|---|---|---|---|

| Corncob residue | CNC | H2SO4 hydrolysis | 5.5 ± 1.9, short rod-shaped | – | 55.9 | 313 | – | −33.8 ± 1.7 | Liu et al., 2016 |

| CNC | Formic acid hydrolysis | 6.5 ± 2.0, long rod-shaped | – | 63.8 | 360 | – | −14.3 ± 0.4 | ||

| CNF | TEMPO-mediated oxidation | 2.1 ± 1.1, twisted structure | – | 49.9 | 305 | – | −23.1 ± 2.3 | ||

| CNF | PFI refining | 43.1 ± 25.3, twisted | – | 52.1 | 336 | – | −40.3 ± 1.5 | ||

| Stalks of wheat straw (Triticum paleas) | CNF | H2SO4 hydrolysis and ultrasound treatment | 10–40, a mesh-like multilayer structure | 11.45 | 72.5 | ca. 400 | 42.3 | – | Barbash et al., 2017 |

| Cornhusk | CNC | H2SO4 hydrolysis | 26.9 ± 3.35, short rod-shaped | – | 83.5 | 351 | – | −34.6 ± 2.3 | Yang et al., 2017 |

| CNF | TEMPO-mediated oxidation | 10.48 ± 1.83, slender interconnected webs | – | 72.3 | 279 | – | −69.4 ± 1.7 | ||

| CNF | High-intensity ultrasonication | 20.14 ± 4.32, slender interconnected webs | – | 53.4 | 348 | – | −24.3 ± 2.5 | ||

| Banana pseudostem | CNF | High-pressure homogenization | 30–50, entangled network of polydisperse bundles | – | 67.0 | 337 | – | – | Velásquez-Cock et al., 2016 |

| Cotton | CNC | H3PO4 hydrolysis | 31 ± 14, rod-like shape | – | 81.0 | 325 | – | – | Camarero Espinosa et al., 2013 |

| Ushar (Calotropis procera) seed fiber | CNC | H2SO4 hydrolysis | 14–24, needle shape | – | 70.0 | ca. 330 | – | – | Oun and Rhim, 2016 |

| CNF | TEMPO- oxidation | 10–20, web-like shape | – | 59.0 | 316 | – | – | ||

| Bacterial strain Komagataeibacter xylinus (BCC529) | BNC | Static culture for 96 h at 30 °C | 29.13 ± 6.53, denser network structure | 0.72 | 47.4 | 335 | 0.235 | −44.1 ± 0.9 | Gao et al., 2020 |

| BNC | Agitated culture: 300 rpm at 30 °C | 29.51 ± 8.03, loose and porous network | – | 22.1 | 310 | – | −46.5 ± 1.5 | ||

| Kenaf (Hibiscus cannabinus L.) fiber | CNC | H2SO4 hydrolysis and ultrasonic treatment | 10–28, morphology not defined | − | 80.0 | ca. 420 | 61.4 | − | Barbash and Yashchenko, 2020 |

TEMPO, 2,2,6,6-tetramethylpiperidine-1-oxyl.

Surface Modification of Nanocellullose

The study of functional nanoscale materials has emerged as an attractive field of research since they possess vastly improved properties and characteristics, enabling these high value-added substrates to be applied in the field of materials science. Cellulose is a natural polysaccharide, and an abundant biopolymer serves as building blocks in the structural hierarchy (Lin et al., 2012). Concerning the vastly hydrophilic nature of nanocellulose owing to the existence of OH groups on their surface, the surface chemistry can be tuned chemically, physical interactions (Huang et al., 2020), and biological approaches. Surface functionalization can be carried out during the preparation step or post-production of nanocellulose (Wei et al., 2017). These modifications lead to attaining desirable properties, which, in turn, enhance their effectiveness for a given application (Lin et al., 2012; Afrin and Karim, 2017; Liang et al., 2020; Tao et al., 2020). Through the incorporation of any chemical functionality, the surface of a nanocellulosic material can be modified the way it reacts with foreign substances (George and Sabapathi, 2015). Lin et al. remarked that polymeric matrices with improved reinforcement, i.e., enhanced thermal and mechanical performances, can be obtained through the surface modification of polysaccharide nanocrystals (Lin et al., 2012).

On the contrary, cellulose nanocrystals not only consist of primary reactive sites (i.e., hydroxyl groups), they possess high surface area to volume ratio, making CNC highly reactive and easy to be functionalized. Cellulose nanocrystals are chemically modified in order to impart stable positive or negative electrostatic charges on the surface for a better distribution of particles and to enhance their compatibility (Kaboorani and Riedl, 2015). In 2019, Lu and co-workers studied the interfacial compatibility of hydroxyapatite modified nanocellulose with polylactic acid (PLA) matrix to overcome PLA's inherent hydrophobicity (Lu et al., 2019). Morphological study via transmission electron microscopy, Fourier transform infrared spectroscopy, and X-ray diffraction analysis corroborated successful structural modification of nanocellulose obtained from cotton pulp. The study revealed that hydroxyapatite modified nanocellulose enhanced the mechanical properties of PLA based nanocomposite films pertaining to the occurrence of strong hydrogen bonding interaction at the interface, which resulted in a good dispersion in the PLA composite. Moreover, the surface modification significantly improved the tensile strength, tensile modulus, and thermal stability of the nanocomposite, signifying that hydroxyapatite modified nanocellulose is a good reinforcing material for PLA.

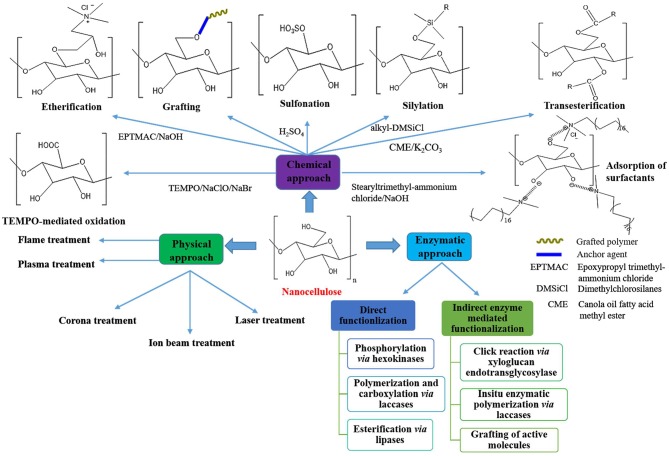

According to previous literature (George and Sabapathi, 2015; Afrin and Karim, 2017; Daud and Lee, 2017; Huang et al., 2020), the surface of cellulose nanocrystals can be chemically modified using numerous methods, mainly covalent surface modification including sulfonation, polymer grafting, oxidation, esterification, nucleophilic substitution, etherification, silylation, and carbamation. In a recent study, polyacrylamide has been grafted onto cellulose nanocrystals (CNC) to integrate into poly(vinyl alcohol) (PVA) employing a solution casting method to reinforce nanocomposite films. Infrared spectroscopy affirmed the occurrence of strong hydrogen bonding on the surface of CNC, i.e., between hydroxyl groups of PVA matrix and polyacrylamide chains, which improved the interfacial compatibility. The study revealed that prepared nanocomposite films at 0 and 50% relative humidity achieved an increase in elastic modulus. The thermogravimetric analysis demonstrated the enhanced thermal stability of reinforced PVA-nanocomposites, corroborating the significance of surface modification of CNC through grafting in view of enhancing its thermal and tensile properties (Li B. et al., 2020). In a study carried out by Tang et al. discovered that hydrophobically modified cellulose nanofibrils through the grafting of cinnamoyl chloride and butyryl chloride displayed favorable surface properties, capable of stabilizing oil-water emulsions (Tang C. et al., 2019). They noted that nanocelluloses possessing high surface charge density do not effectively stabilize Pickering emulsions, which limit their application as interfacial stabilizers. Thus, surface modification via grafting hydrophobic polymers onto nanocelluloses improve their wettability by the oil phase, resulting in reduced interfacial tension.

Moreover, the use of adsorbing surfactants (Kaboorani and Riedl, 2015) and polymer coatings (Islam et al., 2013) have also been employed.

Bertsch and Fischer discussed on the adsorption and interfacial structure of nanocelluloses (NC) at the fluid interface, where nanocelluloses with their native hydrophilic and hydrophobized surfaces impart essentially different interfacial structure and adsorption characteristics (Bertsch and Fischer, 2019). It was noted that nanocelluloses are green alternative for the stabilization of fluid interfaces. The adsorption of NCs at oil-water interfaces facilitates the formation of stable and biocompatible Pickering emulsions. Furthermore, the review study elaborated that unmodified NCs cannot stabilize foams. In contrast, NCs with covalent surface modifications or through the adsorption of surfactants could hydrophobize its surface (contact angle, θ > 90°), consequently stabilize foams or inverse and multiple emulsions. Many pioneering applications already employ nanocellulose-stabilized colloids, for instance, preparation of 3D-printing inks (Huan et al., 2018, 2019), novel bio-nanocomposites (Reid et al., 2019; Bielejewska and Hertmanowski, 2020), and in gastric stable delivery systems (Bai et al., 2019; Liu and Kong, 2019), pertaining to NCs' outstanding stability and biocompatible nature. Xiang et al. discovered that cellulose nanofibrils form more stable foams compared to cellulose nanocrystals, attributed to cellulose nanofibrils ability to spread into the bulk, ensuing enhanced interfacial and bulk elasticity (Xiang et al., 2019). Bai et al. investigated the stabilization of concentrated edible oil-in-water Pickering emulsions by modifying the surface of naturally derived cellulose nanocrystals with a food-grade cationic surfactant (ethyl lauroyl arginate) (Bai et al., 2018). The researchers revealed that as surfactant-covered NCs are more hydrophobic, their surfaces impart lower surface tension and higher surface coverage, contributing to enhanced electrostatic stabilization and emulsifying ability.

Some of the physical surface functionalization techniques may include electric discharge (plasma treatment), ultrasonic treatment, irradiation, and surface fibrillation (Islam et al., 2013). Enzymes can also be used to modify the surface of nanocellulose, for instance, Afrin and Karim (2017) employed two approaches in their study; (a) direct modification, where the enzyme directly gets in contact with nanocellulose, and (b) indirect enzyme-mediated modification. They concluded that the enzymatic approach to produce nanocellulose and to further functionalize them is a viable greener modification method compared to chemical modification route. Islam et al. (2013) pointed out that the main obstacle in modifying cellulose nanofibrils (CNF) is that the approach needs to alter only the surface without disrupting the morphology to preserve the crystal structure. According to Robles et al. (2015), surface modification of CNC and CNF with silanes generates hydrophobic surfaces, which increase their stability.

Hydrolases and oxidoreductases are two of the most commonly used classes of enzymes. Glycosidases, proteases, and lipases are the frequently used hydrolase enzymes, while in the case of oxidoreductases, laccase, tyrosinase, and peroxidase are the majorly employed enzymes. Concerning biomedical applications, nanocellulosic materials functionalized via enzymatic approach possess a significant advantage over the chemical route, which avoids the toxicity of the modified product (Karim et al., 2017). Besides, based on the presence of a high density of hydroxyl groups, BNCs can also be modified (Wang et al., 2020). Kalhori and Bagherpour (2017) pointed out that the utilization of bacterial cellulose for engineering applications is a growing topic of interest among materials scientists and engineers. For instance, Akhlaghi et al. (2020) investigated the susceptibility of bacterial nanocellulose fibers as reinforcement in cement composites, in which they observed that BNCs improved the mechanical properties of cement mortars. Consequently, the development of modified nanocellulose substrates with intact surface properties through “sustainability” is still an uphill task in nanocellulose research. Figure 5 depicts a schematic diagram representing the most commonly used surface modification routes of nanocellulose, while Table 5 portrays some previous studies on surface modification of nanocellulose substrates along with their salient features and applications.

Figure 5.

Schematic representation of the most commonly used surface modification routes of nanocellulose.

Table 5.

Previous studies on surface modification of nanocellulose substrates along with their salient features and applications.

| Cellulosic source | Nanocellulose | Preparation method | Surface modification strategy | Salient features | Application | References |

|---|---|---|---|---|---|---|

| Eucalyptus dry lap wood pulp | CNC | H2SO4 hydrolysis | Transesterification with canola oil fatty acid methyl ester | Higher hydrophobicity and thermal stability | Hydrophobic coatings and reinforcing agents to hydrophobic polymer for nanocomposites | Wei et al., 2017 |

| Blue agave (A. tequilana) bagasse | CNF | High-pressure homogenization | Silanization with 3-aminopropyl triethoxysilane | Enhanced mechanical properties and hydrophobicity | Additive in poly(lactic acid) to form strengthened composites | Robles et al., 2015 |

| CNC | H2SO4 hydrolysis | Esterification with dodecanoyl chloride | ||||

| Softwood pulp | CNF | TEMPO-mediated oxidation | Grafting of cetyltrimethylammonium bromide surfactant | Increased hydrophobicity and thermal stability | Improve the redispersibility of TEMPO-oxidized CNFs in N, N-dimethylformamide | Qu et al., 2019 |

| Softwood sulphite fibers | CNF | Successive grinding | Sonication in the presence of lactic acid | Rapid water draining and enhanced mechanical properties | Performance-enhancement additive in traditional papermaking | Sethi et al., 2018 |

| Sugarcane bagasse | CNC | H2SO4 hydrolysis | Functionalization using adipic acid | Improved dispersion and thermodynamic wetting | Reinforcements for hydrophobic polymer matrices | Ferreira et al., 2018 |

| Bacterial strain Gluconobacter xylinus (53582) | BNC | Static culture at 26°C for 168 h | Incorporation of polyvinyl alcohol and Ag nanoparticles | Outstanding antimicrobial and mechanical properties | Packaging films for the food industry | Wang et al., 2020 |

| Sea pineapple (Halocynthia roretzi) | CNF | TEMPO-mediated oxidation | Grafting of polyethylenimine | Well-developed pore structure with excellent adsorption ability | To develop circular routes in recovering metals and reuse them directly | Hong et al., 2020 |

| Aspen kraft pulp | CNC | H2SO4 hydrolysis | Oxidizing CNC by sodium periodate followed by covalent immobilization of black wattle tannin | Better regeneration and reusability with high metal adsorption capacity | Novel nanocomposite to eliminate contaminants from industrial effluents | Xu et al., 2017 |

Nanocellulose Based Nanocomposites

The unique and attractive characteristics of cellulose nanocrystals are already well-documented, which pushed the scientific community to focus on the development of practical applications for this nanoscale material (Kiziltas et al., 2013; Pandey et al., 2015; Thakur, 2015b; Abitbol et al., 2016; Jawaid et al., 2017; Wang X. et al., 2017; Nascimento et al., 2018; Salimi et al., 2019; Younas et al., 2019). The employment of CNCs as reinforcing agent of polymers is one of the most studied area in composites field. A nanocomposite is considered as a heterogeneous mixture, which contains two or more different components with substantially various physicochemical features. By definition, such mixture consists of a homogeneous matrix (polymer or biopolymer) constituent that is reinforced by a stiffer, stronger component with a small amount of nanosized of organic or mineral fillers of specific shape, size, and surface chemistry (Abdul Khalil et al., 2019). CNCs have been revealed to be an interesting nanofiller owing to their chemical structure (abundance of -OH groups), reactivity, high specific surface area, mechanical, thermal and optical properties, even when incorporated at low concentrations (Chen et al., 2019). Broadly, it is pointed out that the incorporation of CNCs into a polymeric matrix enhances the tensile strength and decreases the elasticity. Such behavior can be assigned to the strong intermolecular linkages such as covalent bonds, van der Waals forces, mechanical interlocking and molecular entanglement between CNCs and the polymeric matrix (Pires et al., 2019). Besides that, compared to the conventional nanofillers such as carbon black, mica, silica, nanoclay, and non-aluminum oxide, CNCs present lower health and environmental negative impacts (Ng et al., 2017). Various processing methods have been developed to produce CNC-based nanocomposites. The most important ones are the solution casting, melt extrusion, ball milling, injection molding, compression molding, precipitation routes, 3D printing, layer-by-layer assembly, wet- and elector-spinning, and micropattering techniques (Oksman et al., 2016; Dufresne, 2018; Nascimento et al., 2018; Thomas et al., 2018; Sharma et al., 2019). This kind of nanocomposites can be used in several scientific area and industries such as packaging, automotive, aerospace, paints and coatings, adhesives, hydrogels, nanobarriers, inks and printing, fire retardants, cementitious materials, and defense, to name a few. CNC-based composites presenting wide range of applications have been comprehensively reviewed in recent years (Malucelli et al., 2017; Ilyas et al., 2018; Klemm et al., 2018; Thomas et al., 2018; Dufresne, 2019; Fiss et al., 2019; Naz et al., 2019; Sharma et al., 2019; Montes et al., 2020).

Nonetheless, most synthetic polymers are hydrophobic materials, giving rise to week adhesion, reduced dispersion, and poor wettability of CNCs with the polymer matrix. Furthermore, the use of non-polar media causes a poor dispersion of CNCs due to their ability to generate aggregates owing to the presence of polar chemical groups and the high surface energy of these nanoparticles (Dufresne, 2019; Younas et al., 2019). Hence, surface modifications via covalent binding, surfactants, ionic interactions, reductive amination, physical adsorption, and molecule/polymer grafting have been demonstrated as efficient approaches for enhancing the compatibility between nanocomposite components, thereby improving the dispersion and interaction between them (Thakur et al., 2013; Abitbol et al., 2016; Younas et al., 2019; Nigmatullin et al., 2020). Moreover, the processing temperature of CNCs and some engineering plastics such as polyethylene and polypropylene is another shortcoming, which requires the development of high-performance natural fiber-reinforced composites (Gopi et al., 2019).

CNCs have been employed to reinforce a wide range of polymer matrixes. Both thermoplastic polymers and thermosets have been reinforced with CNCs to produce high-quality and cost-effective materials (Lu et al., 2014). Many in-depth research papers and reviews dealing with CNC-based thermoplastics have been published over the past 20 years, covering the preparation methods, potential applications, shortcomings and advantages. Various polymers such as polymethyl methacrylate, polybutyl methacrylate, polyvinyl chloride, poly exo-ethylene, ethylene oxide-epichlorohydrin co-polymers, polyurethane, polycarbonate, poly lactic acid, poly vinyl acetate, and polyvinyl alcohol (Abitbol et al., 2016; Nandi and Guha, 2018). The mechanical features of this kind of nanocomposites are deeply affected by the interfacial adhesion between CNCs and the polymer matrix, which can enhanced by caring out specific modifications on these components (Gopi et al., 2019). On the other hand, the combination of CNCs and thermosets (unsaturated polyesters, some polyurethanes, epoxy and phenolic resins) in nanocomposites aims to couple attractive features from each compound in a synergetic manner (Peng et al., 2017; Yue et al., 2018). CNCs provide better strength and stiffness along with resistance to corrosion. These nanfillers could be beneficial in reducing the internal stresses introduced during curing process and can increase the cross-linking density and impart nanocomposites with significantly improved toughness (Miao and Hamad, 2019). Recently, Yue et al. have pointed out that the use of modified CNCs enables physical interlocking points in the cured epoxy matrix restricting chain mobility, and the homogeneity of the dispersion is a key factor, which enhances the filler-matrix dispersion contributing to the significant improvement in storage modulus and glass transition (Yue et al., 2018). Furthermore, the formation of CNC-polymer matrix network depends on the percolation threshold that relies on the aspect ratio of the nanofillers and strength of the filler/filler interactions. Nevertheless, despite such nanocomposites present interesting characteristics compared to thermoplastics (Gopi et al., 2019), they show some drawbacks such as the high curing temperature and time as well as some recycling issues (Liu et al., 2012). Notwithstanding, with constancy proposing environmental and sustainable concerns in the last decades, the employment of natural fillers and polymer matrixes from natural and renewable resources in nanocomposites have drawn more and more attention. Various bionanocomposites have been produced using CNCs as nanofillers and natural polymer matrixes such as chitosan, gelatin, proteins, cyclodextrin, starch, gluten, alginate, natural rubber, xanthine, and cellulose derivatives (carboxymethyl cellulose, hydroxypropylcellulose, regenerated cellulose and cellulose diacetate) (Younas et al., 2019). This latter class may find potential real applications in the near future. Recently, despite much progress has been made, more effective and efficient methodologies and strategies require to be developed to obtain nanocomposites with optimal features, encompassing the scale up to industrial level at economic way (Vilarinho et al., 2018). To resolve this, efforts are being made to seek for new approaches capable of improving the existing processes or promoting large scale synthesis.

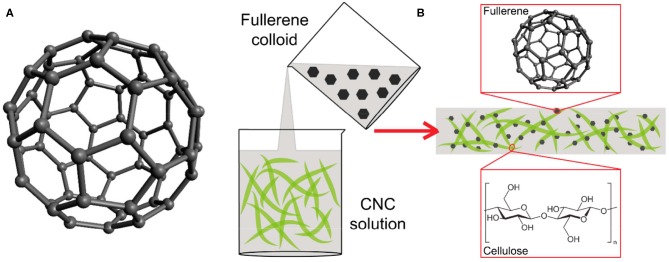

On the other hand, owing to the surface characteristics of CNCs, they can be modified by oxidation of hydroxyl groups using the TEMPO-oxidation or ammonium persulfate method to produce multifunctional hybrid nanomaterials coupled with metal or metal oxide nanoparticles such as Ag, ZnO, CuO, and Fe2O3, as recently described by Oun et al. (2020). These composites have a high potential to be employed in different fields encompassing food packaging and other biotechnological applications. Nanocomposites, containing nanocellulose and nanocarbons such as graphene, graphene oxide, carbon nanotube, nanodiamond, and graphene, are considered as newly emerging smart hybrid materials, where nanocellulose component acts as a dispersing agent (Bacakova et al., 2020; Miyashiro et al., 2020). For instance, CNCs were considered ideal for immobilization of fullerene nanoparticles. A scheme of preparation of CNC/fullerene composite is depicted in Figure 6. Such composite showed a higher radical scavenging capacity in vitro than fullerenes alone, and therefore are promising for biomedical application in antioxidant therapies, e.g., as components of skin care product (Awan et al., 2016). Nanocellulose/nanocarbon composites present outstanding properties such as stretchability, flexibility, high mechanical strength, tunable optical transparency, tunable electrical and thermal conductivity, photothermal and photodynamic activity, nanoporous character, and high adsorption capacity. Consequently, they are prominent for a wide range applications such as food packaging, water purification, energy harvesting, storage and conversion, shape memory devices, construction of fire retardants, and biomedical uses (Bacakova et al., 2020). Other CNC hybrids based on metals, oxides, mineral salts, and non-metallic elements have been also investigated. These nanocomposites exhibited numereous innovative features due to synergetic effects, which are unachievable by nano-structured materials alone (Zhang et al., 2020). For instance, CNC-loaded with noble metal nanoparticles found applications in the field of antibacterial, biomedical, protein/enzyme immobilization, catalysis, photoelectric materials, and sensing. However, some challenges in controlling size, shape, distribution uniformity, and density of nanoparticles on CNCs need to be overcome. Moreover, the interactions and the complex mechanisms between these nanomaterials from a fundamental point of view have to be illucidated. Besides, more environmentally friendly and green synthetic approaches should also be considered to meet the sustainable development and the strong demands. Nonetheless, the fabrication and exploring CNC loaded with nano objects and their extended uses will remain as one of the key focuses of future research activities.

Figure 6.

Scheme of fullerene C60 (A) and of the preparation and structure of nanocellulose/fullerene composites (B). Reprinted from Bacakova et al. (2020) as distributed by creative common license CC BY license, MDPI publisher.

Nanocellulose for Biomedical Applications