Abstract

The effects of feed moisture content (14, 17 and 20% db), die temperature (120, 145 and 170 °C) and carrot pomace content (10, 17.5 and 25%) on the sectional expansion index, hardness, porosity, micro and macro structure and sensory properties of high fiber expanded barley–carrot pomace snack were investigated using a central composite design. Results showed that with increasing the moisture content the hardness of the extruded snacks increased while their expansion ratio decreased. The hardness decreased with increasing the die temperature, but the expansion ratio increased with increasing the die temperatures to up to 145 °C and decreased afterwards. An increase in carrot pomace content decreased the expansion ratio and cell average size while the hardness and cell wall thickness increased. The optimum condition for production of expanded barley–carrot pomace snack was 10% carrot pomace content, 142.7 °C die temperature and 14.02% moisture content. During extrusion cooking, the soluble dietary fiber of barley–carrot pomace snack increased, but no change on the total dietary fiber content was observed. Therefore, the extruded snacks prepared from barley flour and carrot pomace had high nutritional value.

Keywords: Expanded snack, Extrusion cooking, Barley, Carrot pomace, Dietary fiber

Introduction

Ready-to-eat expanded snacks are part of the human diet especially children (Özer et al. 2004). Maize is a major raw material for production of extruded snack, has high starch content, which gives good expansion characteristic to the ready-to-eat product (O’Shea et al. 2013). The only disadvantage of maize is its low dietary fiber and minerals (O’Shea et al. 2013). Dietary fibers which exist in soluble and insoluble forms might retard the uptake of glucose, blood cholesterol, risk of coronary heart disease, colon cancer and obesity (Chau et al. 2004). Many efforts have been made to improve the nutritional value of extruded snacks. For this purpose, ingredients that have high dietary fiber such as fruits and vegetables can be used for production of high fiber expanded snacks. (Potter et al. 2013).

Food scientists are trying to find new sources to produce high fiber ready-to-eat expanded snacks (Chau et al. 2004). Vegetable wastes produced by juice production industry has high fiber content (Stojceska et al. 2008). Carrot (Daucus carota L.) is an important root vegetable which is commonly used for carrot juice production. Carrot pomace is rich in vitamins, minerals and dietary fibers (Alam and Kumar 2014). Due to the high fiber content of carrots, it can be used to develop high fiber products (Alam and Kumar 2014).

Using other cereals flours is another way for production of extruded snacks with suitable nutritional value. Among cereals barley (Hordeum vulgare L.) is important from a nutritional and functional point of view due to its high dietary fiber content, particularly soluble fiber such as β-glucan and phenolic compounds (Alu’datt et al. 2012). Several studies have focused on the production of extruded snacks from barley flours such as barley-tomato pomace blends (Altan et al. 2008a) and barley–grape pomace blends (Altan et al. 2008c).

One of the application of extrusion technology is to produce dietary snacks from other sources of cereals (Potter et al. 2013). According to Stojceska et al. (2010) the extrusion cooking technology can be used for production of high level dietary fiber expanded snacks from cereal and vegetable co-products. Some studies have shown that the extrusion changes the ratio of soluble and insoluble dietary fiber due to the transglycoside reaction, but does not reduce the total dietary fiber content (Chang et al. 2015). The quality of the high fiber extruded product depends on the extrusion die temperature, feed moisture, screw speed, feed rate, extruder type and chemical composition of raw materials (Rodríguez-Miranda et al. 2011).

Presence of fiber restricts the starch gelatinisation required for expansion of expanded snacks (Altan et al. 2008a). Therefore, high fiber snacks will have less expanded structure and harder texture (Alam et al. 2016). As a results, it is important to optimize the extrusion process in order to obtain the highest quality for production of high fiber ready-to-eat extruded snacks. Therefore, in this study the effects of feed moisture content, die temperature and carrot pomace content on the physical properties, morphology, cell structure and dietary fiber (TDF, SDF and IDF) of the extruded snack made from barley flour and carrot pomace has been investigated.

Materials and methods

Materials

Barley flour with 7 ± 0.14% moisture (db), 9.35 ± 0.19% protein (db), 2.31 ± 0.18% fat (db), 1.79 ± 0.36% ash (db) and 2.96 ± 0.70% crude fiber (db) (AOAC 2000) was purchased from Chooraktoos factory (Mashhad, Iran). Carrot pomace were collected from juice vendors in the Mashhad. The carrot pomace had 81.3 g/100 g moisture content (db). Therefore, the pomace was dried in an air-oven at 40 °C for 24 h to obtain a moisture content of 7 ± 0.44 g/100 g (db). The dried carrot pomace with 5.57 ± 0.50% protein (db), 1.23 ± 0.25% fat (db), 5.63 ± 0.51% ash (db) and 7.04 ± 0.42% crude fiber (db) (AOAC 2000) was coarsely ground, milled and passed through a sieve with 40 mesh (425 micron). The resulting carrot pomace powder was packaged in a polyethylene bag at 25 °C (room temperature) for further usage.

Extrusion cooking process

The blends of barley flour and carrot pomace were prepared at the ratios of 90:10, 82.5:17.5 and 75:25 on a dry-to-dry weight basis. The samples were prepared by spraying a calculated amount of water to obtain the desired moisture levels (14, 17 and 20%), sealed in polyethylene bags and stored at 4 °C overnight. The moisture content of the barley flour and carrot pomace were measured using the oven method (AOAC 2000). Extrusion cooking was performed in a co-rotating twin screw extruder (DS56, Jinan Saxin, China) with L/D ratio of 10:1 and die diameter of 4 mm. The feed rate and the screw speed were set at 40 kg/h and 160 rpm, respectively. The barrel temperatures at the transition section were at 120 °C, 145 °C and 170 °C.

Sectional expansion index, hardness and porosity

Expansion of snacks were evaluated based on the method given by Alam and Kumar (2014). The diameter of extrudates were determined as the mean of 10 random measurements made with a digital caliper. The expansion ratio was calculated using Eq. (1).

| 1 |

The hardness of the extruded snacks were measured using Texture Analyzer (TAXT plus, England). The cylinder steel probe (2 mm diemeter) was set to move at a speed of 1 mm/s. The samples were punctured by the probe to a distance of 8 mm. Maximum force needed to break the samples was recorded and analysed by Texture Exponent software associated with the texture analyser. Measurements were reported as an average of five replicates (Hashemi et al. 2017).

Porosity was calculated using the following equation (Eq. 2):

| 2 |

where bulk volume and apparent volume were calculated using Eqs. (3) and (4), respectively.

| 3 |

where m is the mass (g); l is the length (cm) and d is diameter (cm) of extrudates

| 4 |

Apparent density was calculated from the volume of ground extrudates using a graduated cylinder (O’Shea et al. 2013).

Cell structure analysis

Cylindrical shape extrudates were cut using a blade to obtain a product with 10 mm length. Three loaves of each type of snack were placed on the flat bed under five fluorescent lights in a wooden box. The camera were placed in 20 cm above the sample. Images of cross sections of expanded snacks were captured with a digital camera (Canon EOS 1000D, Taiwan) and saved as a JPG file. Digital images of snack were acquired with the lens aperture of 5.6, ISO100 and shutter speed of 1.80 s to achieve high uniformity. The image analysis was managed using Adobe Photoshop (version 12.0). The center images of the snack pieces were taken at a size of 39.336 × 35.112 mm and converted to grey-level image (8 bits). After adjusting threshold, cell total area, average size cell, porosity and wall thickness were investigated using ImageJ software (National Institutes of Health, USA version 1.46 r) (Naji-Tabasi and Mohebbi 2014).

Microstructure

The microstructure of expanded snacks were studied using a scanning electron microscope (VP 1450, LEO Company, Germany). Snacks were mounted on an aluminum stub and coated with a thin film of gold. The pictures were then taken at voltage of 20 kv (Yanniotis et al. 2007).

Sensory analysis

Ten panelists from the department of food science master students were asked to score each attribute (from 1 dislike extremely to 5 like extremely). Sensory characteristics were divided into four main categories: appearance, texture and overall acceptability (Lazou et al. 2010).

Nutritional properties

The unextruded raw materials and the expanded snack extruded at optimum extrusion conditions were analysed for protein, fat, ash and dietary fiber (TDF, SDF and IDF). Samples were ground with a laboratory grinder and passed through a 40 mesh sieve prior to analysis. All analyses were performed in two replicates. Protein, fat and ash were determined by standard methods (AOAC 2000). The contents of TDF, SDF and IDF were measured using the Megazyme total dietary fiber analysis kit (Megazyme International Ireland Ltd, Wicklow, Ireland). In brief, one gram of samples were treated with phosphate buffer and then digested in water bath by thermo-stable α-amylase at 100 °C for 15 min and protease and amyloglucosidase at 60 °C for 30 min. After filtration, residue on the filter was dried at 105 °C and then weighed as IDF. Ethanol was added to precipitate the SDF. The residue was filtered and washed with ethanol and acetone. The precipitate, referred to as SDF, was dried at 105 °C and weighed. The TDF content was calculated as the sum of IDF and SDF (Huang and Ma 2016).

Experimental design and statistical analysis

Response surface methodology (RSM) was used to estimate the effect of independent variables (carrot pomace content, A; die temperature, B; moisture content, C) on the sectional expansion index (%), hardness (N), porosity, cell structure and sensory properties of barley–carrot pomace snack. Central composite rotatable design was used to for designing the experimental data. The RSM was applied to the experimental data using a commercial statistical package, Design-Expert version 7.0.0 (Statease Inc., Minneapolis, USA). The response functions (Y) were the experimental response and A, B and C were the independent variables calculated by a second order polynomial equation (Eq. 5):

| 5 |

The coefficients of the polynomial model were represent by b0 (constant); b1, b2 and b3 (linear effects); b11, b22 and b33 (quadratic effects); b12, b13 and b23 (interaction effects). Data were modeled by multiple regression analysis adopting backward stepwise analysis. The variables significant at p < 0.01 and p < 0.05 levels were only selected for the model construction. The fitted polynomial equations were expressed as surface plots in order to visualize the relationship between the response and experimental levels of each factor and to interpret the optimum conditions. Numerical technique of the Design- Expert software was used for optimization of the extrusion process (Koocheki et al. 2009).

Results and discussion

Model description

Regression analysis and ANOVA were used to select the appropriate model and investigate the statistical significance of the response variables. The model adequacy were checked using the coefficients of determination (R2) and coefficient of variation (CV). The lack of fit was not significant for all response variables (Table 1), indicating that these models were accurate for predicting the responses. The R2 is an indication of the suitability of empirical model to the actual data (Koocheki et al. 2009). The R2 for all variables were higher than 0.80, suggesting the high power of the model in fitting the data (Table 1). The coefficient of variations (CV), which describes the amount of data dispersion were less than 13% for all the responses variables (Table 1).

Table 1.

ANOVA for the response variables of extruded snack

| Expansion | Hardness | Porosity (Eq. 2) | Total area | Average size | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Source | Sum of squares | p Value | Sum of squares | p Value | Sum of squares | p Value | Sum of squares | p Value | Sum of squares | p Value |

| Model | 11747.74 | 0.0001** | 510.74 | 0.0001** | 337.16 | 0.0001** | 31298.646 | 0.0001** | 1744.8 | 0.0003* |

| Linear | ||||||||||

| A | 5929.71 | 0.0001** | 221.54 | 0.0001** | 33.42 | 0.0061* | 15933.5 | 0.0001** | 339.94 | 0.0049* |

| B | 131.84 | 0.0499* | 67.18 | 0.0003** | 14.02 | 0.0554 ns | 45.48 | 0.6061 ns | 9.77 | 0.5761 ns |

| C | 3397.02 | 0.0001** | 156.67 | 0.0001** | 169.91 | 0.0001** | 1869.21 | 0.0049* | 111.17 | 0.0751 ns |

| Interaction | ||||||||||

| AB | – | – | 20.44 | 0.0190* | – | – | – | – | – | – |

| AC | – | – | – | – | – | – | 1645.6 | 0.0073* | 244.39 | 0.0132* |

| BC | – | – | 44.90 | 0.0015* | 59.79 | 0.0007* | 4175.79 | 0.0002* | – | – |

| Quadratic | ||||||||||

| A2 | 1007.10 | 0.0001** | – | – | – | – | – | – | – | – |

| B2 | 1041.74 | 0.0001** | – | – | 60.03 | 0.0007* | 7628.96 | 0.0001** | 324.15 | 0.0057* |

| C2 | 453.16 | 0.0015* | – | – | – | – | – | – | 112.25 | 0.0738 ns |

| Residual | 366.75 | 40.69 | 44.97 | 2117.78 | 386.02 | |||||

| Lack of fit | 151.98 | 0.8540 ns | 32.61 | 0.1940 ns | 32.34 | 0.3647 ns | 1343.15 | 0.4871 ns | 22.83 | 0.9999 ns |

| Pure error | 214.77 | 8.09 | 12.63 | 774.63 | 363.18 | |||||

| Total | 12114.49 | 551.43 | 382.13 | 33416.4 | 2130.82 | |||||

| R2 | 0.9697 | 0.9262 | 0.8823 | 0.9366 | 0.8188 | |||||

| Adj-R2 | 0.9558 | 0.8998 | 0.8403 | 0.9074 | 0.7352 | |||||

| CV | 2.16 | 11.69 | 10.97 | 6.37 | 11.41 | |||||

| Porosity (image analysis) | Wall thickness | Color | Crunchiness | Overal acceptability | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Source | Sum of squares | p Value | Sum of squares | p Value | Sum of squares | p Value | Sum of squares | p Value | Sum of squares | p Value |

| Model | 371.15 | 0.0001** | 35.9 | 0.0001** | 15.66 | 0.0001** | 13.28 | 0.0001** | 7.70 | 0.0001** |

| Linear | ||||||||||

| A | 14.30 | 0.0123* | 17.61 | 0.0001** | 10.55 | 0.0001** | 0.15 | 0.2365 ns | 1.7 | 0.0016* |

| B | 35.23 | 0.0005* | 3.39 | 0.0002* | 0.27 | 0.1396 ns | 2.84 | 0.0002* | 0.16 | 0.2625 ns |

| C | 183.10 | 0.0001** | 4.4 | 0.0001** | 0.083 | 0.3956 ns | 3.35 | 0.0001** | 3.46 | 0.0001** |

| Interaction | ||||||||||

| AB | – | – | – | – | 0.60 | 0.0343* | – | – | – | – |

| AC | – | – | – | – | 0.81 | 0.0165* | 1.97 | 0.0009* | – | – |

| BC | 66.64 | 0.0001** | – | – | – | – | 0.51 | 0.043* | – | – |

| Quadratic | ||||||||||

| A2 | – | – | – | – | – | – | 3.51 | 0.0001** | – | – |

| B2 | 24.83 | 0.0021* | 10.51 | 0.0001** | 3.35 | 0.0001** | 1.89 | 0.001* | 2.39 | 0.0004* |

| C2 | 6.23 | 0.0772 ns | – | – | – | – | 0.61 | 0.0292* | – | – |

| Residual | 22.01 | 2.16 | 1.39 | 1.06 | 1.73 | |||||

| Lack of fit | 9.81 | 0.8152 ns | 0.31 | 0.9994 ns | 0.65 | 0.7909 ns | 0.79 | 0.1772 ns | 0.74 | 0.9139 ns |

| Pure error | 12.20 | 1.86 | 0.75 | 0.27 | 0.99 | |||||

| Total | 393.17 | 38.06 | 17.06 | 14.34 | 9.43 | |||||

| R2 | 0.9440 | 0.9431 | 0.9182 | 0.9260 | 0.8167 | |||||

| Adj-R2 | 0.9182 | 0.9280 | 0.8805 | 0.8721 | 0.7678 | |||||

| CV | 8.58 | 10.31 | 8.22 | 9.2 | 8.41 | |||||

A: Carrot pomace, B: Temperature, C: Moisture

*p < 0.05, **p < 0.001, ns not significant

Sectional expansion index, hardness and porosity

Linear and quadratic terms for carrot pomace content and moisture had a significant effect on the expansion ratio (p < 0.0001) (Table 1). Only the quadratic term of temperature was statistically significant (p < 0.0001) (Table 1). The expansion ratio indicates the degree of extrudate puffing when the melt passes through the die of the extruder (O’Shea et al. 2013). The expansion ratio decreased when the content of carrot pomace in feed increased (Fig. 1). The degree of gelatinization is one of the most important factors affecting the expansion ratio (Yao et al. 2006). The fiber particles tend to rupture the cell walls before the air bubbles could expand and thus reduce the overall expansion ratio (Liu et al. 2000). Therefore, addition of carrot pomace reduces the expansion ratio of the final product.

Fig. 1.

Response surface for the effect of carrot pomace content, moisture and temperature on the a expansion ratio and b hardness of snack

The expansion ratio increased with increasing the die temperature from 120 to 145 °C (Fig. 1). An increase in barrel temperature will decrease the melt viscosity, which favors the bubble growth during extrusion (Ding et al. 2005). The expansion ratio decreased at temperatures higher than 145 °C due to the degradation of the starch structure (Mendonça et al. 2000).

Feed moisture is among the main factors affecting the expansion (Ding et al. 2005). Increasing the feed moisture decreased the expansion of the extrudate (Fig. 1). High moisture serves as a lubricant inside the extruder, reducing the effect of die temperature in the extruder, and in turn, results in a drop in the gelatinization and thus decreases the expansion of the extrudate (Ding et al. 2006). Therefore, in order to produce extruded snack from barley flour–carrot pomace blends with maximum expansion ratio, the extruder temperature and the initial moisture content should be set at 145 °C and 14%, respectively.

The linear term of carrot pomace content, temperature and moisture were highly significant for hardness (p < 0.0001) (Table 1). Moreover, among the interaction terms, the interactions between temperature and moisture and also the carrot pomace content and temperature were significant (p < 0.05) (Table 1). As shown in Fig. 1, hardness increased with increase in moisture content. Moisture restricts the bubble growth which result in denser structure and harder texture (Saeleaw et al. 2012).

The hardness decreased with increasing the die temperature (Fig. 1). This result is in line with the results of Altan et al. (2008b) for extruded barley flour. An increase in barrel temperature would decrease the melt viscosity, which favors the bubble growth, decreases the cell wall thickness during extrusion and decreases the hardness of snack (Altan et al. 2008b). Addition of carrot pomace increased the hardness of the final product. The fibers cause a premature rupture in the air bubbles as a result of its effect on cell thickness (Stojceska et al. 2008), leading to a higher hardness. Similar results have been reported by Mendonça et al. (2000), Yanniotis et al. (2007) for corn bran, pectin with wheat fibers, respectively. Therefore, in order to produce carrot pomace extruded snack with preferable texture the temperature and initial moisture content should be set at 170 °C and 14%, respectively.

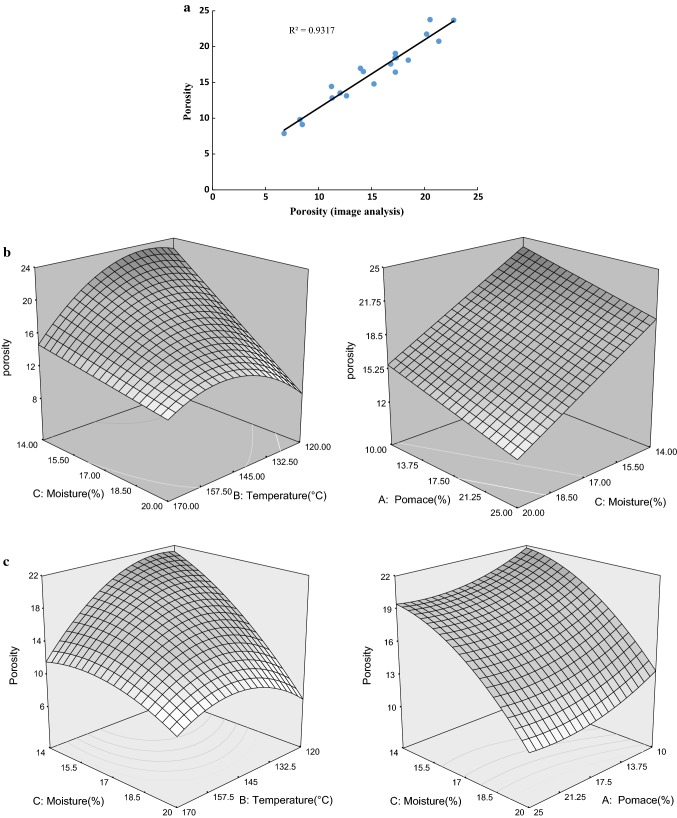

The linear terms of carrot pomace and moisture content and the interaction of temperature and moisture content had significant effect on the porosity measured by Eq. 2 (p < 0.05). The quadratic term of temperature was also significant for the measured porosity (p < 0.0001) (Table 1). For the porosity measured by image analysis similar terms were significant. However, the quadratic term of moisture content had also significant effect on this porosity. Porosity given by the image analysis was highly correlated (R2 = 0.93) with the porosity measured using Eq. 2 (Fig. 2). Due to the high fiber content in carrot pomace, an increase in its content decreased the porosity (Fig. 2). The pomace fiber ruptures the premature gas cells before they could expand (Altan et al. 2008b; Liu et al. 2000; Yanniotis et al. 2007). The porosity increased with increase in the extrusion temperature to up to 145 °C (maximum peak) and decreased afterwards (Fig. 2). Increasing the die temperature increases the degree of superheating of water in the extruder and decreases the melt viscosity (Ding et al. 2006). Therefore, increasing the die temperature leads to higher porosity in the extrudate. At temperatures above 145 °C, the porosity decreased due to the degradation in the structure of melted starch (Moraru and Kokini 2003). The equations of the fitted models after neglecting the effect of non-significant factors for the uncoded form of the process variables were as follows:

Fig. 2.

a Correlation between porosity measured by Eq. 2 and porosity calculated by image analysis of the extruded snacks. Response surface for the effect of carrot pomace content, moisture and temperature on the b Porosity measured using Eq. 2 and c porosity from image analysis

Cell structure analysis

The results tabulated in Table 1, showed that the linear terms of carrot pomace and moisture (p < 0.0001, p < 0.05) and the interaction terms of temperature-moisture and also the carrot pomace content-moisture (p < 0.05) were significant for total area. The quadratic term of temperature was also significant for total area (p < 0.05) (Table 1). For average size the linear term of carrot pomace (p < 0.05), the interaction terms of carrot pomace and moisture (p < 0.05) and the quadratic term of temperature were significant (p < 0.05) (Table 1). The results for cell wall thickness indicated that all linear terms (p < 0.0001) and the quadratic term of temperature (p < 0.0001) were highly significant (Table 1).

Cell total area and cell average size in extruded snack decreased with increasing the moisture content (Fig. 3). However, with increasing the moisture content, cell wall thickness increased. The increased moisture content limits the bubble growth and results in dense structures which reducs the expansion of the extrudate (Saeleaw et al. 2012).

Fig. 3.

Response surface for the effect of carrot pomace content, moisture and temperature on the cell a average size, b total area, c wall thickness of snack

Cell total area and cell average size of extruded snack increased with increasing the die temperatures from 120 to 145 °C and decreased afterwards. Whilst, cell wall thickness had opposite trend and decreased with increasing the die temperatures from 120 to 145 °C and increased afterwards (Fig. 3). The expansion structure of extruded snacks depends on the equilibrium of the vapor pressure inside the bubble, the resistance of the bubble wall to collapse and the rapid release of vapor from the structure (Moraru and Kokini 2003). Moraru and Kokini (2003) stated that the expansion of starch in a critical temperature reaches to its maximum. At temperatures above the critical temperature, the expansion ratio decreases due to the degradation of the melted starch structure (Moraru and Kokini 2003). Thus, the starch cannot retain its structure at high vapor pressure inside the cell and therefore collapses.

Increasing the carrot pomace content decreased the cell total area and cell average size of the extrudate (Fig. 3). On the other hand, the wall thickness increased with the addition of carrot pomace (Fig. 3). Fibers cause discontinuity in the starch matrix, resulting in an increase in the non-expanded cell number and thus decreases the expansion (Ganjyal et al. 2004). Similar result was obtained by Yanniotis et al. (2007), according to whom wheat fiber reduced the cell size in extruded products. Followings are the predicted models for total area, average size and wall thickness:

Microstructure

The effects of carrot pomace content, die temperature and moisture content on the microstructure of extrudates were investigated using Scanning Electron Microscopy (SEM) (Fig. 4). The microstructure of extrudates could be related to their expansion. When the content of carrot pomace in feed increased, the cell size decreased, whilst the wall thickness increased (Fig. 4). When cells are expanded, larger cells with extended thinner walls would be achieved, resulting in an increase in the expansion (Stojceska et al. 2008). The increase in extrusion temperature increased the formation of air cells and thinner cell walls (Fig. 4). The higher temperatures lead to the collapse of the cell due to the weakening effect of die temperatures on starch structure. Therefore, cell size were decreased and wall thickness were increased. On the other hand, a high moisture serves as a lubricant inside the extruder and reduces the effect of die temperature in the extruder (Ding et al. 2006). Therefore, starch gelatinization and expansion of the extrudate is reduced (Ding et al. 2006), resulting in a decrease in the cell size and increase in the cell wall thickness.

Fig. 4.

Scanning electron micrographs of extruded snack at 110 × (1) and 2000 × (2) magnification. a: 145 °C—10% carrot pomace—17% moisture; b: 145 °C—17.5% carrot pomace—17% moisture; c: 145 °C—25% carrot pomace—17% moisture; d: 120 °C—17.5% carrot pomace—17% moisture; e: 170 °C—17.5% carrot pomace—17% moisture; f: 145 °C—17.5% carrot pomace—14% moisture; g: 145 °C—17.5% carrot pomace—20% moisture

Sensory analysis

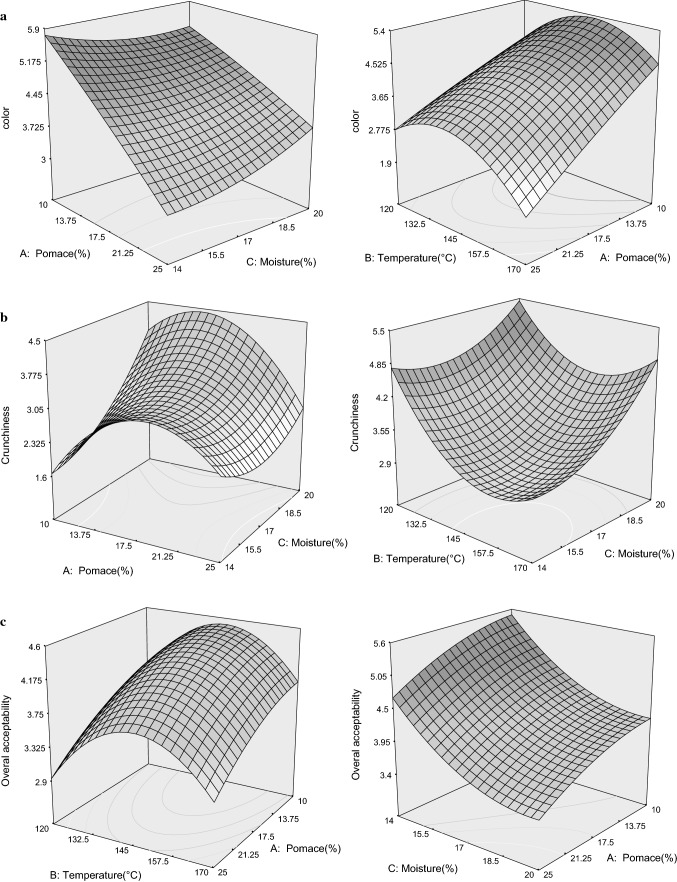

The linear term of carrot pomace content were highly significant for color (p < 0.0001). Moreover, the interactions between carrot pomace content and temperature and also the carrot pomace content and moisture were significant (p < 0.05). For color only the quadratic term of temperature was highly significant (p < 0.0001) (Table 1). The linear terms for temperature and moisture had a significant effect on crunchiness (p < 0.0001 and p < 0.05). The interaction terms of carrot pomace and moisture and also temperature and moisture had significant effect on the crunchiness (p < 0.05). The results indicated that all quadratic terms were significant for snack crunchiness (p < 0.005) (Table 1). For overall acceptability the linear term of carrot pomace and moisture (p < 0.05) and the quadratic term of temperature were significant (Table 1).

The sensory score for color decreased with increase in carrot pomace content and die temperature, but it increased with increasing the moisture content (Fig. 5). The texture of extrudates was evaluated in terms of crunchiness. The extrudate crunchiness increased with increasing the carrot pomace from 10 to 17.5% and decreased afterwards (Fig. 5). Moreover, with increasing the temperature, the crunchiness decreased, while it increased when moisture content increased (Fig. 5). The extrudate crunchiness can be attributed to the cell wall thickness and expansion of snack. Therefore, reduction in cell wall thickness at high temperature, low carrot pomace content and low moisture content, lead to a reduction in snack crunchiness. In general, the addition of carrot pomace for the production of snack decreased the overall acceptability of the extrudates (Fig. 5). The most acceptable snacks were produced at low feed moisture contents (Fig. 5). These results might be due to the denser structures of the extrudate at high moisture and carrot pomace contents. Increasing the die temperature from 120 to 145 °C increased the overall acceptability of the extrudates (Fig. 5). This could be related to the maximum expansion ratio of the extruded snack at 145 °C die temperature. Model for sensory analysis were developed as follows:

Fig. 5.

Response surface for the effect of carrot pomace content, moisture and temperature on the sensory properties snack (a: color, b: crunchiness, c: overall acceptability)

Optimum extrusion condition

The optimum condition for production of barley flour–carrot pomace snack were determined for the maximum expansion ratio, porosity and overall acceptability with minimum hardness. The optimum conditions for production of snacks were 10% carrot pomace content, 142.70 °C die temperature and 14.02% moisture. The optimum condition provides the highest value of expansion ratio of 315.3 (%), porosity of 22.1 and overall acceptability of 4.5 with lowest hardness of 3.937 (N). The experimental value for production of snacks were expansion ratio of 310.5 (%), porosity of 20.1, hardness of 4.694 (N) and overall acceptability of 4.5. For snacks produced under this optimal extrusion condition, there was no difference between the optimal value and the experimental value.

Nutritional analyses of extrudates

The approximate composition of the extruded snack were 9.31 ± 0.04% protein (db), 1.88 ± 0.36% fat (db), 2.1 ± 0.29% ash (db), 12.98 ± 0.47% TDF (db), 9.27 ± 0.06% SDF (db) and 3.71 ± 0.44% IDF (db) and the unextruded raw materials were 9.18 ± 0.03% protein (db), 2.98 ± 0.42% fat (db), 2 ± 0.11% ash (db), 12.87 ± 0.28% TDF (db), 7.63 ± 0.46% SDF (db) and 5.24 ± 0.12% IDF (db). Extrusion cooking did not affect protein and ash contents but it decreased the fat content of snack. Probably, at high extrusion temperature complexes between lipids or lipids with protein are formed (Li et al. 2012).

During extrusion cooking, the SDF increased from 7.63 to 9.27% while the IDF decreased from 5.24 to 3.71%. An explanation for this result is the accelerated depolymerization of polysaccharides due to the increased temperature, which improves the solubility of the dietary fiber (Li et al. 2012). The results showed that extrusion cooking did not affect the TDF content in barley flour–carrot pomace snack. These results are consistent with those reported by Yao et al. (2006) for oat. The results obtained in this study indicated that blends of barley flour and carrot pomace can be used for production of high fiber ready-to-eat expanded snacks.

Conclusion

Expansion ratio which is one of the most important parameters in quality property for snacks was at its highest when 10% carrot pomace content, 145 °C die temperature and 14% moisture content was used. Images taken from the cross section showed that extruded snack prepared at these condition had larger bubble size. Reduction of bubble growth increased the cell wall thickness and the hardness of extruded snack. Snacks produced at 145 °C die temperature with low moisture and carrot pomace content had the highest overall acceptance. The optimum conditions for production of barley–carrot pomace snack were 10% carrot pomace content, 142.70 °C die temperature and 14.02% (db) moisture content. The results obtained from nutritional analyses indicated that extrusion cooking caused an increase in the SDF content, but did not affect the TDF content of barley–carrot pomace snack. Therefore, blends of barley flour and carrot pomace can be extruded to produce high fiber ready-to-eat expanded snacks.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Alam S, Kumar S. Optimization of extrusion process parameters for red lentil-carrot pomace incorporated ready-to-eat expanded product using response surface. Food Sci Technol. 2014;2(7):106–119. doi: 10.13189/fst.2014.020703. [DOI] [Google Scholar]

- Alam MS, Pathania S, Sharma A. Optimization of the extrusion process for development of high fibre soybean-rice ready-to-eat snacks using carrot pomace and cauliflower trimmings. LWT Food Sci Technol. 2016;74:135–144. doi: 10.1016/j.lwt.2016.07.031. [DOI] [Google Scholar]

- Altan A, Mccarthy KL, Maskan M. Evaluation of snack foods from barley–tomato pomace blends by extrusion processing. J Food Eng. 2008;84:231–242. doi: 10.1016/j.jfoodeng.2007.05.014. [DOI] [Google Scholar]

- Altan A, Mccarthy KL, Maskan M. Extrusion cooking of barley flour and process parameter optimization by using response surface methodology. J Sci Food Agric. 2008 doi: 10.1002/jsfa. [DOI] [Google Scholar]

- Altan A, Mccarthy KL, Maskan M. Twin-screw extrusion of barley–grape pomace blends: extrudate characteristics and determination of optimum processing conditions. J Food Eng. 2008;89:24–32. doi: 10.1016/j.jfoodeng.2008.03.025. [DOI] [Google Scholar]

- Alu’datt MH, Rababah T, Ereifej K, Alli I, Alrababah MA, Almajwal A, Alhamad MN. Effects of barley flour and barley protein isolate on chemical, functional, nutritional and biological properties of Pita bread. Food Hydrocoll. 2012;26(1):135–143. doi: 10.1016/j.foodhyd.2011.04.018. [DOI] [Google Scholar]

- AOAC . Official methods of analysis of AOAC international. Arlington: AOAC; 2000. [Google Scholar]

- Chang C, Yang C, Samanros A, Lin J. Collet and cooking extrusion change the soluble and insoluble β-glucan contents of barley. J Cereal Sci. 2015;66:18–23. doi: 10.1016/j.jcs.2015.09.005. [DOI] [Google Scholar]

- Chau C, Chen C, Lee M. Comparison of the characteristics, functional properties, and in vitro hypoglycemic effects of various carrot insoluble fiber-rich fractions. Lebensm-Wiss U-Technol. 2004;37:155–160. doi: 10.1016/j.lwt.2003.08.001. [DOI] [Google Scholar]

- Ding Q, Ainsworth P, Tucker G, Marson H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. J Food Eng. 2005;66:283–289. doi: 10.1016/j.jfoodeng.2004.03.019. [DOI] [Google Scholar]

- Ding Q, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;73:142–148. doi: 10.1016/j.jfoodeng.2005.01.013. [DOI] [Google Scholar]

- Ganjyal GM, Reddy N, Yang YQ, Hanna MA. Biodegradable packaging foams of starch acetate blended with corn stalk fibers. J Appl Polym Sci. 2004;93:2627–2633. doi: 10.1002/app.20843. [DOI] [Google Scholar]

- Hashemi N, Mortazavi SA, Milani E, Tabatabai Yazdi F. Microstructural and textural properties of puffed snack prepared from partially deffated almond powder and corn flour. J Food Process Preserv. 2017 doi: 10.1111/jfpp.13210. [DOI] [Google Scholar]

- Huang YL, Ma YS. The effect of extrusion processing on the physiochemical properties of extruded orange pomace. Food Chem. 2016;192:363–369. doi: 10.1016/j.foodchem.2015.07.039. [DOI] [PubMed] [Google Scholar]

- Koocheki A, Taherian AR, Razavi SMA, Bostan A. Response surface methodology for optimization of extraction yield, viscosity, hue and emulsion stability of mucilage extracted from Lepidium perfoliatum seeds. Food Hydrocoll. 2009;23(8):2369–2379. doi: 10.1016/j.foodhyd.2009.06.014. [DOI] [Google Scholar]

- Lazou A, Krokida M, Tzia C. Sensory properties and acceptability of corn and lentil extruded puffs. J Sens Stud. 2010;25(6):838–860. doi: 10.1111/j.1745-459X.2010.00308.x. [DOI] [Google Scholar]

- Li H, Long D, Peng J, Ming J, Zhao G. A novel in situ enhanced blasting extrusion technique- Extrudate analysis and optimization of processing conditions with okara. Innov Food Sci Emerg Technol. 2012;16:80–88. doi: 10.1016/j.ifset.2012.04.009. [DOI] [Google Scholar]

- Liu Y, Hsieh F, Heymann H, Huuff HE. Effect of process conditions on the physical and sensory properties of extruded oat–corn puff. J Food Sci. 2000;65:7. doi: 10.1111/j.1750-3841.2000.tb00613.x. [DOI] [Google Scholar]

- Mendonça S, Grossmann MVE, Verhe R. Corn bran as a fibre source in expanded snacks. Lebensm-Wiss U-Technol. 2000;33:2–8. doi: 10.1006/fstl.1999.0601. [DOI] [Google Scholar]

- Moraru CI, Kokini JL. Nucleation and expansion during extrusion and microwave heating of cereal foods. Compr Rev Food Sci Food Saf. 2003;2(4):147–165. doi: 10.1111/j.1541-4337.2003.tb00020.x. [DOI] [PubMed] [Google Scholar]

- Naji-Tabasi S, Mohebbi M. Evaluation of cress seed gum and xanthan gum effect on macrostructure properties of gluten-free bread by image processing. J Food Meas Charact. 2014;9(1):110–119. doi: 10.1007/s11694-014-9216-1. [DOI] [Google Scholar]

- O’Shea N, Arendt E, Gallagher E. Enhancing an extruded puffed snack by optimising die head temperature, screw speed and apple pomace inclusion. Food Bioprocess Technol. 2013 doi: 10.1007/s11947-013-1181-x. [DOI] [Google Scholar]

- Özer EA, Ibanoğlu Ş, Ainsworth P, Yağmur C. Expansion characteristics of a nutritious extruded snack food using response surface methodology. Eur Food Res Technol. 2004;218:474–479. doi: 10.1007/s00217-004-0884-7. [DOI] [Google Scholar]

- Potter R, Stojceska V, Plunkett A. The use of fruit powders in extruded snacks suitable for Children’s diets. LWT-FoodSci Technol. 2013;51(2):537–544. doi: 10.1016/j.lwt.2012.11.015. [DOI] [Google Scholar]

- Rodríguez-Miranda J, Ruiz-López II, Herman-Lara E, Martínez-Sánchez CE, Delgado-Licon E, Vivar-Vera MA. Development of extruded snacks using taro (Colocasia esculenta) and nixtamalized maize (Zea mays) flour blends. LWT Food Sci Technol. 2011;44(3):673–680. doi: 10.1016/j.lwt.2010.06.036. [DOI] [Google Scholar]

- Saeleaw M, Dürrschmid K, Schleining G. The effect of extrusion conditions on mechanical-sound and sensory evaluation of rye expanded snack. J Food Eng. 2012;110(4):532–540. doi: 10.1016/j.jfoodeng.2012.01.002. [DOI] [Google Scholar]

- Stojceska V, Ainsworth P, Plunkett A, Ibanog E. Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready-to-eat expanded snacks. J Food Eng. 2008;87:554–563. doi: 10.1016/j.jfoodeng.2008.01.009. [DOI] [Google Scholar]

- Stojceska V, Ainsworth P, Plunkett A, Ibanoğlu Ş. The advantage of using extrusion processing for increasing dietary fibre level in gluten-free products. Food Chem. 2010;121:156–164. doi: 10.1016/j.foodchem.2009.12.024. [DOI] [Google Scholar]

- Yanniotis S, Petraki A, Soumpasi E. Effect of pectin and wheat fibers on quality attributes of extruded cornstarch. J Food Eng. 2007;80:594–599. doi: 10.1016/j.jfoodeng.2006.06.018. [DOI] [Google Scholar]

- Yao N, Jannink JL, Alavi S, White PJ. Physical and sensory characteristics of extruded products made from two oat lines with different β-glucan concentrations. Cereal Chem. 2006;83(6):692–699. doi: 10.1094/CC-83-0692. [DOI] [Google Scholar]