Abstract

One of the global challenges of our economy is to meet the demand of a growing population while reducing resource consumption and waste production. This means moving from a linear to a more circular economy model, in which the design of more durable products plays a key role. From a technical perspective, product design needs to be supported by sound testing methods. However, repeatable and reproducible methods for testing product durability under real-life stress conditions are often not available, as in the case of washing machines. The overall objective of this study is to make further progress in the know-how relating to the durability testing of washing machines. A procedure is developed which: 1) consists of washing and spinning cycles, thus imposing thermal and mechanical stresses typically occurring in household washing machines; 2) can be used to monitor the performance of the appliances over time with limited testing burdens. The procedure was applied in a trial with two washing machines for a simulated usage period of two years. Results imply that the procedure can be suitable for evaluating the occurrence of early failures in laboratory testing. The study also provides indications for the further analysis of the repeatability and reproducibility of the test procedure, as well as investigating the consequences associated with longer testing periods. However, a comprehensive assessment of these aspects was not possible in this study. All in all, this guidance could be used by manufacturers and consumer-focussed testing organisations for the assessment and verification of the durability of washing machines, as well as being used to develop standard testing methods for the potential implementation of ecodesign/labelling measures for washing machines.

Keywords: Circular economy, Durability, Eco-design, Testing, Washing machines

Highlights

-

•

Testing methods are needed to support the design of more durable products

-

•

A durability testing procedure for washing machines is developed and applied

-

•

The procedure simulates real life stress conditions over time

-

•

The procedure allow monitoring performance parameters

-

•

The procedure can be used as basis for the development of standard methods

1. Introduction

The Communications from the Commission about the Circular Economy Action Plan (European Commission, 2015a) and the Ecodesign Working Plan 2016–2019 (European Commission, 2016) point out the increased importance of improving the resource efficiency of products for promoting a transition towards a more circular economy in the EU. At the macro-level, resource consumption and waste production tend to decrease when product lifetimes increase. Designing more durable products can thus be a key strategy to save materials and to reduce the amount of waste to handle (Alfieri et al., 2018a; Iraldo et al., 2017; Tecchio et al., 2016).

Durability can be defined as the ability to function as required over time under defined conditions of use, maintenance and repair until a limiting state is reached (Alfieri et al., 2018b). The lifetime of a product is a parameter, typically expressed as number of years (or using different units of measure as the number of cycles or the hours of operation), which can serve to orient designers, researchers, policy makers and consumers in their decisions. The lifetime of a product can be influenced by many factors, such as stress, maintenance, technological change, fashion, shift in values and other external environmental influences (Prakash et al., 2020). Depending on the factors considered, a differentiation can be made between technical and functional lifetimes. While the technical lifetime is inherently related to the reliability and resistance of a product until a failure occurs, the functional lifetime is determined by conditions that are created around it (European Environment Agency, 2017). In the following the term durability is used with reference to the technical lifetime. External socio-economic factors that could influence the functional lifetime are not considered (e.g. availability of spare parts and willingness-to-repair a product in cases of failure).

The design of more durable products needs to be supported by sound assessment and verification methods (Dalhammar, 2016; Tecchio et al., 2017a). Internal testing protocols are typically implemented by manufacturers to assess the durability of products and obtain a proxy measure of their technical lifetime. However, there is in general a lack of standardised methods enabling the comparison of different product models on the market. With the implementing decision M/543 (European Commission, 2015b), CEN/CENELEC JTC10 was created at European level to develop horizontal and generic standards on material efficiency aspects for Energy-related Products, including the standard EN 45552:2020 “General method for the assessment of the durability of energy-related products”.

Among energy-related products, household appliances are relatively complex products for which relevant effects on resource consumption and generation of electrical and electronic waste could be minimised through design strategies oriented to ensure the durability of the product (Tecchio et al., 2016, Tecchio et al., 2017b). The importance of durability aspects for washing machines is supported by behavioural research investigating the reasons behind the replacement of different appliances by consumers (Hennies and Stamminger, 2016). It was found that 69% of the interviewed consumers discarded a washing machine because of a defect, thus emphasising the importance of focusing on the technical lifetime of the product. The age of discarded washing-machines varied between 1 and 40 years, with an average of 12 years. However, 50% of discarded washing machines were less than 10 years old, whereas 20% did not reach a lifetime of 5 years. Prakash et al. (2020) carried out an analysis on the disposal of washing machines in Germany. It was found out that about 50% of users had never had their washing machines repaired. Among those who had their washing machines repaired, 13% did it within the warranty period (normally 2 years). Based on such figures it can be roughly estimated that about 6–7% of washing machines may fail during the first 2 years of operation. Lifetime expectations and actual lifetimes were observed to increase with the product purchase price. Consumers seemed in general satisfied with the lifetime of their washing machines when this was longer than 11 years. Such findings are confirmed to a large extent by Seyffert et al. (2018).

The actual lifetime of washing machines has also a clear correlation with the frequency of use (Hennies and Stamminger, 2016), implying that the actual operation of the appliance is the major factor limiting its lifetime.

As summarised by Tecchio et al. (2017b), the most recurring failures of washing machines are related to electronics (e.g. control electronics, control panels, program selectors, relays), shock absorbers, bearings, doors (including seals, handles, hinges and locks) and motors (carbon brushes). An analysis of the failures observed in durability tests conducted on washing machines from 2000 to 2014 in Germany showed that practically all of the main washing machine parts can lead to failure (Prakash et al., 2020).

From an engineering point of view, washing machines are subject to mechanical, thermal and chemical stresses during use. Mechanical and thermal stresses are the main causes of damage (Prakash et al., 2020; Stamminger et al., 2018). Vibrations and other mechanical stresses can impact the whole washing machine (Boyraz and Gunduz, 2013; Tecchio et al., 2017b). Parts that are most exposed to vibrations (tub/drum system, including parts connected to the suds container as motor, transmission belt, springs and shock absorbers) were observed to fail more often than other parts (Prakash et al., 2020). This type of stress occurs on those parts during the washing operation, especially during the spinning phase, due to drum imbalance (Stamminger et al., 2018).

Ways to measure, reduce and control drum imbalance are indispensable for horizontal axis washing machines. Stresses due to the imbalance may be reduced either by decreasing the spinning speed or the duration of spinning at higher speed. However, this could result in an unsatisfactory decrease of the moisture content of the load, which is a key performance element for washing machines (Stamminger et al., 2018). The trade-off between spinning intensity and load moisture content highlights the importance of linking product durability with the fulfilment of performance requirements under real use conditions.

No internationally used standard method is currently available for the assessment of the durability of washing machines (Tecchio et al., 2017b). Consumer testing organisations typically focus on the measurement of washing performance parameters (such as dirt removal, spinning performance, rinse performance, water consumption, energy consumption, ease of use and noise) although they also perform durability tests for washing machines. However, their focus to date has been on component wear-out or failure without considering if the washing performance is negatively affected (Stiftung Warentest, 2013).

An endurance test consisting of 2600 h of continuous cycle operation at 1000 rpm (equivalent to 5200 washing cycles) was run by Ishiyama and Iga (2000), although the tests relevance for real-life operations can be challenged. Park et al. (2006) performed a step-stress test using high temperature and voltage as stress factors in order to verify the operating limit of the pump assembly of a washing machine in a more reasonable amount of time (250–500 h). In an effort to reduce the testing time, accelerated degradation tests (ADT) and accelerated life tests (ALT) were applied by De Carlo et al. (2013) and Tucci et al. (2014), respectively, to estimate the reliability of parts. However, such tests are not relevant for washing machines on the market since an external imbalance control was used. This confirms the difficulty of testing the long-term performance and investigating the failure-time distribution of parts of high-reliability products (Escobar and Meeker, 2007).

Stamminger et al. (2018) worked on a procedure for the accelerated testing of the endurance of washing machines. The procedure consisted of 500 spinning cycles where stresses were applied by a fixed imbalance mass with intermediate washing cycles. This work was important to understand the effects on durability and performance due to mechanical stresses occurring during unbalanced spinning cycles. However, a testing procedure based merely on spinning cycles would induce stresses that are unusual during the use of washing machines.

The aim of this paper is to further develop the know-how relating to the durability testing of washing machines. A procedure is defined to test the durability of washing machines under conditions as far as possible close to real life, as well as based on the monitoring of performance parameters. The procedure is applied to two models of washing machines. Results of the tests are critically discussed and used to draw conclusions and recommendations for possible future improvements and applications (e.g. for the design and assessment of the product or for standardisation and decision making purposes). Indications are also provided for the analysis of the repeatability and reproducibility of the testing procedure, although a comprehensive assessment of these aspects was not possible in this study.

2. Methods

Building on the work of Stamminger et al. (2018), an improved durability testing procedure for washing machines was defined and applied to two models on the market (Alfieri et al., 2018b).

Innovative elements were introduced in the development of this new testing procedure to test the entire product under real life conditions, as suggested by Stamminger et al. (2018):

-

•

Coverage of both mechanical and thermal stresses;

-

•

Combination of washing and spinning cycles;

-

•

Avoidance of a fixed imbalance in the spinning cycle.

Moreover, the testing procedure was developed considering the following aspects:

-

•

Monitoring of both failures and loss of performance, as these are possible limiting states due to mechanical and thermal stresses (Stamminger et al., 2018);

-

•

Application of ALT to limit testing costs and reducing the test duration, in order to make the procedure potentially suitable for laboratory testing and verification purposes (Alfieri et al., 2018b);

Additionally, the testing procedure has been kept adherent to the international standards IEC 60546 (IEC, 2010) and EN 60456 (CENELEC, 2016). These are well-established methods to allow repeatable and reproducible results. Adaptations of the requirements set in international standards were however applied (e.g. for the age of the textile load and the hardness of the water used) to allow a time and cost efficient execution of the tests. Such adaptations are unlikely to have a significant influence on the results.

2.1. Selection of washing machines

Two models of front loading washing machines were tested. The main characteristics of these washing machines are described in Table 1. Both machines are declared as A+++ energy class with maximum spin speed of 1400 rpm and class B spinning performance.

Table 1.

Characteristics of the selected washing machines.

| Parameter | Device WM-1 | Device WM-2 |

|---|---|---|

| Energy Efficiency class | A+++ | A+++ |

| Annual energy consumption | 166 kWh | 153 kWh |

| Annual water consumption | 9586 L | 10560 L |

| Rated capacity | 7 kg | 6 kg |

| Maximum spin speed | 1400 rpm | 1400 rpm |

| Spinning performance class | B | B |

| Price | 329 EUR | 379 EUR |

2.2. Durability testing procedure

The testing procedure is structured in the following phases (Alfieri et al., 2018b): (1) Pre-conditioning, set-up and preparation; (2) Initial examination; (3) Testing; (4) Final examination.

2.2.1. Pre-conditioning, set-up and preparation

The machines were equipped with drum speed and temperature measurement devices and installed according to the instructions provided by the manufacturer in the user manual.

The location of the machine was marked on the floor of the laboratory to give an indication of any movement of the machine during the tests.

The test load was conditioned according to EN 60456 (CENELEC, 2016) to have the equilibrium condition (to the defined laboratory climate) for the weight of the load.

2.2.2. Initial examination

An initial visual inspection was carried out in order to verify whether the machines were intact and undamaged, and fit for the testing.

The main washing programmes for cotton load (cotton wash from cold up to 60 °C, separate spinning, separate rinse and spin cycles) were executed with empty load following the instructions from manufacturers. The operation was repeated using any option allowing programme duration reduction. Data was recorded in both sequences.

2.2.3. Testing

The testing consisted in the repetition of two phases:

-

1.

Washing performance tests;

-

2.

Stress tests.

Washing performance tests were executed to check the capability of the washing machine to perform the washing functions before and after the stress induced tests and detect any possible functional losses.

A washing performance test consisted of 10 washing cycles, to be run following closely to the harmonised European measurement standard EN 60456 (CENELEC, 2016), which is suitable for verification purposes. More specifically, the test was composed of:

-

•

2 cycles at normal cotton 40 °C programme half load;

-

•

3 cycles at normal cotton 40 °C programme full load;

-

•

2 cycles at normal cotton 60 °C programme half load; and

-

•

3 cycles at normal cotton 60 °C programme full load.

Even though time reduction options were available for these programmes, they were not applied in the washing performance tests.

In all wash cycles, test loads and test strips of type 108 (IEC, 2010) from Swissatest Testmaterialien AG batch 120 were applied and evaluated after the test. The following performance parameters were measured for cycles in accordance with EN 60456:

-

•

Total energy consumption (in kWh);

-

•

Total water consumption (in L);

-

•

Cycle duration (in min);

-

•

Water extraction performance (in %);

-

•

Washing performance.

Moreover, other parameters were monitored:

-

•

Actual maximum spin speed (in rpm);

-

•

Duration of maximum spin speed (in s);

-

•

Inlet water temperature (in °C).

Operational data was recorded at 1 s intervals.

The test load was conditioned and normalised following IEC 60456 (IEC, 2010). IEC A∗ detergent was used and dosed according to EN 60456 (CENELEC, 2016). A visual inspection was carried out to detect any leakage.

Stress tests were executed to check the resistance of the machine to typical mechanical and thermal stress conditions occurring during its operation.

The stress tests were 4 blocks of 100 washing and spinning cycles. For each block of cycles, 70% of the cycles were rinse and spin cycles, and the other 30% were washing cycles. The 100 cycles were executed in arbitrary order to allow adaptation to local testing conditions, e.g. to adjust the workflow in an optimal way.

To be as close as possible to real life conditions, the fixed imbalance mass used by Tecchio et al., 2017b was replaced by a textile load to wash and spun at highest possible speed. As the formation of imbalance is known to be higher when the drum is partly filled, a textile mass of two thirds of the rated textile capacity was applied for the rinse and spin cycles.

Washing cycles were cotton programmes run with half load at different temperatures. Cotton programmes are the most used programmes by consumers (Alborzi et al., 2017). They were selected in a way that they were representative for the average washing temperature in Europe of about 40 °C (Alborzi et al., 2017) and close to the average load size of consumers (Kruschwitz et al., 2014).

Programme time reduction options were used for the stress tests in order to reduce the length of the phases which impose less stress (e.g. the washing and rinsing phase), but the maximum spin speed was not reduced.

Table 2 gives an overview of the whole testing procedure. All in all, the testing procedure can be considered representative of approximately 2 years of use of a washing machine (e.g. EU ecodesign and energy labelling requirements for household washing machines assume 220 wash cycles per year (European Commission, 2010a, 2010b)). However, it should be observed that the lifetime target could be varied depending on the availability of resources and on the scope of the analysis (e.g. to verify the occurrence of early failures in worst-performing products on the market or to demonstrate a satisfactorily long lifetime of the product).

Table 2.

Overview of the durability testing procedure.

| Step | Test cycle # | Details of the step |

|---|---|---|

| 1. Pre-conditioning, set-up and preparation | – | Installation of measurement devices. Marking of the machine on the floor. Conditioning of the load. |

| 2. Initial inspection | – | To be done visually outside and inside the machine. Time-temperature-spin diagrams of all relevant programmes with empty load, with and without applying time reduction options. |

| 3. Testing | ||

| Performance tests (10 cycles) – series I | 1–10 | Normalisation of the load. Washing cycles:

|

| Stress tests (100 cycles) – series I | 11–110 | In arbitrary order: 70% rinse and spin cycles (two third load) and 30% washing cycles (half load). Washing cycles:

|

| Performance tests (10 cycles) – series II | 111–120 | As for test cycles #1–10. |

| Stress tests (100 cycles) – series II | 121–220 | As for test cycles #11–110. |

| Performance tests (10 cycles) – series III | 221–230 | As for test cycles #1–10. |

| Stress tests (100 cycles) – series III | 230–330 | As for test cycles #11–110. |

| Performance tests (10 cycles) – series IV | 331–340 | As for test cycles #1–10. |

| Stress tests (100 cycles) – series IV | 341–440 | As for test cycles #11–110. |

| Performance tests (10 cycles) – series V | 441–450 | As for test cycles #1–10. |

| 4. Final examination | – | To be done outside and inside of the machine. Parts may be extracted and taken apart. |

2.2.4. Final examination

At the end of the test, the following assessment was carried out:

-

•

Analysis of the spin speed profile for all washing and spinning cycles executed during the entire test;

-

•

Analysis of the performance parameters assessed in the five blocks of the washing performance test, each one consisting of 10 washing cycles;

-

•

Analysis of the movement of the machine during the entire set of 450 cycles;

-

•

Analysis of the level of abrasion or wear and tear for all parts which can be visually checked, in comparison with the results of the initial inspection;

-

•

Analysis of the durability of the machine with respect to reference failure and malfunctioning categories (see below).

Reference failures and malfunctioning categories were defined for this analysis based on their severity and ease of recognition:

-

•Cat. 1: damage to parts of the machine during the test

-

-Cat. 1a: damages which cannot be repaired at a reasonable cost (≥50% of the price of the machine);

-

-Cat. 1b: damages which can be repaired by a service technician with reasonable cost (<50% of the price of the machine).

-

-

-

•

Cat. 2: visible wear and tear of parts of the machine, which neither caused damages nor loss of function, but which may lead to failures at a later stage of use of the machine;

-

•

Cat. 3: misbehaviour of the machine during the tests, like non-conventional noise, vibrations or movements of the machine;

-

•

Cat. 4: loss of functional performance between the initial and the final washing runs. A loss in performance is considered to have occurred if the difference is found to be larger than twice the verification tolerance values as defined in Regulation 1061/2010.

3. Results and discussion

3.1. Initial examination

The two washing machines underwent an initial visual inspection. There was no visual damage on the packaging or on the machines itself.

All relevant cotton washing programmes were operated once to observe the main characteristics of these programmes. The analysis showed that both machines have different characteristics for how they run cotton programmes and for the sensor systems applied to detect load and, probably, also imbalance. Further details can be found in Alfieri et al. (2018b).

3.2. Performance tests

The results of the performance tests for device WM-1 and device WM-2 are shown in Fig. 1 and Fig. 2. Raw data and parameter variation is expressed as both standard deviation and relative standard deviation (RSD, standard deviation as a % of the average value) in Tables A1–A7 of the Appendix.

Fig. 1.

Average behaviour of device WM-1 during the washing performance test cycles in terms of water consumption (upper right), duration of washing cycle (upper left), average energy consumption (lower left) and water extraction (lower right) for the five washing performance test series.

Fig. 2.

Average behaviour of device WM-2 during the washing performance test cycles in terms of water consumption (upper right), duration of washing cycle (upper left), average energy consumption and (lower left) and water extraction (lower right) for the five washing performance test series.

Moderate variations in performance are observed in both device WM-1 and device WM-2 for all four parameters across the operated washing cycle series.

Looking at different programmes, the performance parameters generally appear more stable for full loads and with the higher temperature programme (i.e. 60 °C) than half loads with a lower temperature (i.e. 40 °C) for both WM-1 and WM-2. For example, energy consumption RSD was 3% vs. 26% for WM-1 and 4% vs. 10% for WM-2 when comparing the 60 °C full load and 40 °C half load results). Similar trends can be observed for water consumption (RSD = 1% vs. 6% for WM-1 and 4% vs. 11% WM-2) and programme duration (RSD = 2% vs. 16% for WM-1 and 1% vs. 16% WM-2). The higher stability of performance in the case of full loads can be partly attributed to a higher proportion of full-to-half load cycles in the testing (3:2).

In general, WM-1 uses more water and energy than WM-2 for performing a washing cycle. The Sinner’s circle (Sinner, 1960), describing the principles of the washing process, would suggest that reduced uses of water and energy should be compensated by longer cycle times to achieve a given performance. However, this general rule does not apply to WM-1 and WM-2, although the price and characteristics of the two devices can be considered similar (see Table 1).

In terms of water extraction performance, both WM-1 and WM-2 seem to fluctuate moderately over cycles (RSD = 8–12% for WM-1 and 1–5% for WM-2) and to improve progressively (on average) before converging towards a residual moisture content slightly higher than 50%.

The performance parameters described above do not seem affected by the mechanical and thermal stresses applied to WM-1 and WM-2, since no clear performance degradation trends appear from Series I (test cycles 1–10) to Series V (test cycles 441–450).

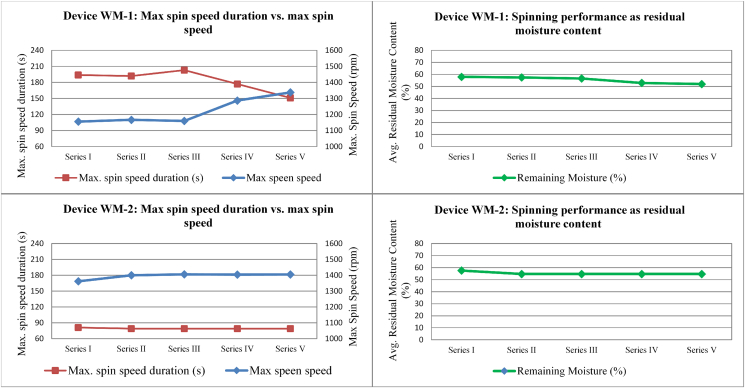

Results for maximum spin speed and its duration are shown in Fig. 3, and compared with the residual moisture content in order to better understand the behaviour of WM-1 and WM-2.

Fig. 3.

Average “Maximum Spin Speed” versus “Maximum Spin Speed Duration” and resulting average spinning performance of WM-1 and WM-2 for the five washing performance test series.

In the case of WM-1 the claimed spin speed of 1400 rpm was only reached (i.e. with average data exceeding 1300 rpm) in the final series (Series V) of washing performance tests (it was reached in less than 50% of individual cycles in Series I). This is remarkable, as it means that the device WM-1 did not always deliver the claimed spin speed at the beginning of the test. However, the residual moisture content measured did not seem to be as adversely affected by the lower maximum spin speed as might be expected (residual moisture improved from 58% to 52% as average maximum spin speed improved from 1150 to 1350 rpm). This may be explained by the corrective action of the machine itself. Namely, that whenever the maximum spin speed was not reached, the machine automatically prolonged the spinning process and was thus still able to perform a relatively consistent moisture removal. It would be necessary to monitor WM-1 for a longer period to confirm the stability of this behaviour.

On the other hand, device WM-2 always performed in line with claimed performance (in terms of spin speed duration and maximum spin speed) and showed a much more consistant behaviour for these parameters compared to WM-1.

The results show the relevance of the imbalance control procedure for the stress induced to the washing machines. This control procedure influences the distribution of the textile load during the start of the spinning action. When an equal distribution is achieved, the imbalance is low and a high spinning speed may be achieved (allowed). If the load cannot be equally distributed, this imbalance control procedure limits the mechanical stress by modifying the spinning profile, especially by reducing the maximum spin speed. This control procedure allows mechanical stresses to be limited the likelihood of failures reduced (Tecchio et al., 2017b). However, the consumer could experience the problem of not reaching the maximum spin speed if higher moisture contents remain in the load after spinning. Interestingly, one of the devices tested (WM-1) counterbalanced this effect by prolonging the spinning duration when the maximum spin speed could not be reached. On the one hand, this strategy can both guarantee the lifetime of those parts affected by mechanical stress and allow achieving an acceptable spinning performance. On the other hand, the consumer may have to wait longer for the execution of washing programmes.

Coupled with the learning from Stamminger et al. (2018), it has been possible to identify different manufacturer strategies for coping with the effects of imbalance on induced stress and water extraction performance:

-

•

The imbalance does not affect the execution of spinning cycles: declared spinning speeds and water extraction performances are achieved (e.g. WM-2);

-

•

The imbalance affects the execution of the spinning cycles and the machine counter-reacts by reducing the spin speed and prolonging the spinning duration to achieve the desired water extraction performance: although the declared spinning speed is not reached, the declared water extraction performance is achieved (e.g. WM-1).

3.3. Stress tests

The maximum spin speeds and spinning duration measured during the tests (Alfieri et al., 2018b) reconfirmed the results achieved in the performance tests: WM-1 did not reach the claimed spinning speed in most of the cycles (probably due to imbalance problems) but tried to compensate the effect of not reaching the maximum speed by prolonging the spinning process at lower spin speed. Device WM-2 reached the maximum spin speed of 1400 rpm in most cycles but stayed at this maximum speed for different times, depending on the programme temperature.

3.4. Final examination

For device WM-1, a yellowish colour was observed in the door gasket after the third test run of the initial check of programmes, conducted without load and without detergent. In some tests (nos. 17, 18, 287, 392) the machine moved a few centimetres during the spinning. This was probably due to imbalance conditions which were not detected by the control system of the device. A movement of 10 cm was observed in test no. 186. Interestingly, after test no. 360 (spin cycle) the display did not work properly and the machine did not provide any sound to indicate the end of the cycle. Nevertheless, everything returned to normal conditions after turning the knob.

For device WM-2, abrasions was noted on the door gasket after test no. 3. Further abrasions were visible on the door gasket after test no. 118. This was due to one cloth that was stuck in the door gasket. However, the device was still able to function properly. After test no. 387, white smoke came out of the drum when opening the door. The device was checked by a technician who could not find any defect. No additional malfunctioning was detected in the remaining tests.

Both devices were taken apart for inspection of individual parts. Photographs were taken to compare their state between the initial and the final inspections. A detailed track of visual observations is reported in Alfieri et al. (2018b).

Abrasion was visible in folds of the door gasket of WM-1. Closer inspection revealed that there was a hole in the gasket which could cause a water leakage during washing operation when the water level is sufficiently high (e.g. in synthetic programmes).

Abrasion was visible also in folds of the door gasket of device WM-2. This was likely to be due to clothes stuck in between the gasket and the drum. To try to identify the origin of the smoke observed in test no. 387, the tub of WM-2 was dismounted and opened. No indication of any failure mechanism could be found. However, at the outer side of the front drum ring, a thin grey layer was observed and wiped away.

Some additional abrasion was observed on the heating elements of both WM-1 and WM-2 but they were not considered to affect the technical lifetime of the machines.

To sum up, the following failures/malfunctioning categories were detected in the two devices:

-

•

WM-1 had a category 2 failure (a hole in the door gasket which could lead to a water leakage during the lifetime of the appliance) and a category 3 event (occasional movement during the operation).

-

•

WM-2 had two category 1b failures (a cloth stuck in the door gasket that was worn out and soiled by rubber abrasion; a smell that appeared after opening the door).

No loss of function was observed for either WM-1 or WM-2 at the end of the tests (category 4 failure) and no significant failure of electronic parts was observed, at least for the representative time of this experiment (∼2 years).

3.5. Repeatability and reproducibility of the testing procedure

The testing procedure was designed to stress washing machines in conditions that are very close to real life use, and to allow the measurement of their performance. This was based on the IEC 60456 and EN 60456 standards, which describe how to test washing machines and deliver results that are repeatable (i.e. almost the same results are obtained when the test is repeated later in time in the same laboratory) and reproducible (i.e. almost the same results are obtained when the test is repeated in another laboratory) (IEC, 2015). Modifications were introduced for speeding up the testing procedure (i.e. use of normal programmes in stress tests) and reducing the testing costs (i.e. use of normal textiles for stress test). Although testing two single devices cannot demonstrate the repeatability and reproducibility of results (which is out of the scope of this work), it can be at least considered that a testing procedure built-up on standards used internationally is expected to lead to repeatable and reproducible results.

4. Conclusions

The purpose of this work was to develop further knowledge about how to assess and verify the durability of washing machines, expressed in terms of technical lifetime.

A new testing procedure was developed and applied to two washing machines. The experience gained allows highlighting the importance of linking durability tests to real life conditions and performance of the product. The main strengths of the procedure developed in this work are that:

-

•

It is potentially suitable for laboratory testing since it applies accelerated life testing for reducing test duration and costs as far as reasonable;

-

•

It simulates thermal and mechanical stresses occurring in household washing machines in real life conditions,

-

•

It includes the monitoring of washing performance over time.

Such aspects are important since they allow taking into consideration how the imbalance control systems are able to handle the stress induced during the operation of washing machines and how the performance is affected.

As defined, the procedure covers the first 2 years of use of a washing machine (the average lifetime of the product is about 12 years) and could be useful for evaluating the occurrence of early failures in a relatively limited amount of time. Based on the evidence available, the authors consider that statistics about early failures may differ significantly, depending on the quality of devices. However, manufacturers keep this information confidential for sensitivity reasons.

This study as such did not assess if results are repeatable and reproducible, and do not analyse the behaviour of the tested devices for longer periods of use. However, the testing procedure built-up on standards used internationally to produce repeatable and reproducible results for the performance of washing machines. A broader analysis would be needed for concluding about the repeatability and reproducibility of the testing procedure. At least three samples of the same washing machine model should be tested in parallel, and in different laboratories.

The procedure could potentially cover more extended periods of use (e.g. to verify a satisfactorily-long technical lifetime of the product). It is worth noting that the testing procedure described in this work has already required a considerable amount of time (in total 697 h for one person running two devices in parallel). This serves to highlight the importance of human resource availability and the need for cooperation and knowledge sharing in the development of widely agreed methods (e.g. with manufacturers and testing organisations).

Considering that testing the durability of washing machines is a lengthy process, options to reduce the testing time could include:

-

•

Leave out or reduce the number/frequency of performance tests in between stress tests;

-

•

Use shorter programme options for the performance tests;

-

•

Leave out the intermediate (spin) drying of the load between different stress test cycles.

If points 1 and 3 are implemented, robots could be potentially used for restarting programmes during the stress tests (rinse and spin cycles, and washing cycles), with possible saving of costs and time since only the execution of the washing performance tests at the start and at the end of the stress tests would necessarily need an operator. It is estimated that the overall duration of the test could potentially decrease by one third.

Future research efforts should be oriented towards the analysis of the repeatability and reproducibility of the testing procedure, and its application to a larger sample of devices over longer periods of time. The analysis of the functional performance of washing machines after the first 2 years of use, as well as the potential occurrence of major failures, can allow understanding which parameters to monitor, and for how long, in the procedure.

Finally, it is recommended to align the performance testing methods with those used for regulatory purposes in a certain market (e.g. those resulting from the final revision of the EU ecodesign and energy labelling requirements for household washing machines).

All in all, this work can act as a guide to manufacturers and consumer-focussed testing organisations for the assessment of the durability of washing machines. Moreover, if integrated in a standardised method, these could support the potential implementation of regulatory measures contributing to the prevention of premature obsolescence of washing machines. This can be of particular importance for a product group such as washing machines, in which obsolescence is mainly associated to technical aspects, while a less relevant role is played by other factors (e.g. technological change, fashion).

CRediT authorship contribution statement

Rainer Stamminger: Methodology, Resources, Validation, Writing - original draft. Alexander Bues: Investigation, Data curation. Felice Alfieri: Conceptualization, Supervision, Formal analysis, Writing - original draft. Mauro Cordella: Conceptualization, Supervision, Project administration, Writing - original draft.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The opinions expressed in this paper are purely those of the authors and may not in any circumstances be regarded as stating an official position of the European Commission.

The authors are grateful to the European Commission for financing this work through the Administrative Agreement N. 070201/2015/SI2.719458/ENV.A.1 signed by DG ENV and DG JRC.

The authors would like also to thank the experts who participated in two workshops organised on 15 March and 22 March 2018 to discuss the testing procedure referred to in this work (see: http://publications.jrc.ec.europa.eu/repository/handle/JRC114329) as well as Mr. Shane Donatello for the proofreading of the paper.

Handling editor: M.T. Moreira

Contributor Information

Rainer Stamminger, Email: stamminger@uni-bonn.de.

Alexander Bues, Email: s7mrbues@uni-bonn.de.

Felice Alfieri, Email: Felice.ALFIERI@ec.europa.eu.

Mauro Cordella, Email: Mauro.CORDELLA@ec.europa.eu.

Appendix. Results of the performance tests for WM-1 AND WM-2

Table A.1.

Energy consumption values measured for each washing cycle for the washing performance test - WM-1 and WM-2

| Energy (Wh) | 40 °C ½ load | 40 °C ½ load | 40 °C 1 load | 40 °C 1 load | 40 °C 1 load | 60 °C ½ load | 60 °C ½ load | 60 °C 1 load | 60 °C 1 load | 60 °C 1 load | Avg. of 10 runs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Device WM-1 | |||||||||||

| 1–10 | 647 | 631 | 1083 | 1202 | 1206 | 1643 | 1047 | 1683 | 1814 | 1844 | 1280 |

| 111–120 | 599 | 608 | 1084 | 1035 | 1107 | 1079 | 1130 | 1813 | 1804 | 1825 | 1208 |

| 221–230 | 605 | 627 | 1119 | 1110 | 1062 | 1112 | 1059 | 1773 | 1729 | 1719 | 1191 |

| 331–340 | 602 | 582 | 1091 | 1017 | 1064 | 1137 | 1099 | 1787 | 1712 | 1689 | 1178 |

| 441–450 | 1148 | 581 | 1090 | 1119 | 1165 | 1155 | 1112 | 1793 | 1797 | 1799 | 1276 |

| Avg. | 663 | 1103 | 1157 | 1772 | |||||||

| Std. | 172 | 54 | 174 | 52 | |||||||

| Std./Avg. (%) | 26% | 5% | 15% | 3% | |||||||

| Device WM-2 | |||||||||||

| 1–10 | 536 | 600 | 845 | 852 | 832 | 946 | 962 | 1200 | 1239 | 1275 | 929 |

| 111–120 | 652 | 614 | 625 | 757 | 747 | 915 | 890 | 1134 | 1212 | 1290 | 883 |

| 221–230 | 470 | 604 | 679 | 741 | 737 | 894 | 927 | 1246 | 1156 | 1160 | 861 |

| 331–340 | 568 | 482 | 767 | 684 | 692 | 927 | 867 | 1192 | 1229 | 1227 | 863 |

| 441–450 | 588 | 584 | 748 | 795 | 802 | 938 | 900 | 1258 | 1268 | 1295 | 918 |

| Avg. | 570 | 754 | 917 | 1225 | |||||||

| Std. | 58 | 65 | 29 | 50 | |||||||

| Std./Avg. (%) | 10% | 9% | 3% | 4% | |||||||

Table A.2.

Water consumption values measured for each washing cycle for the washing performance test - WM-1 and WM-2

| Water (L) | 40 °C ½ load | 40 °C ½ load | 40 °C 1 load | 40 °C 1 load | 40 °C 1 load | 60 °C ½ load | 60 °C ½ load | 60 °C 1 load | 60 °C 1 load | 60 °C 1 load | Avg. of 10 runs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Device WM-1 | |||||||||||

| 1–10 | 45.7 | 45.5 | 52.6 | 53.1 | 54.5 | 53.0 | 44.5 | 55.7 | 54.5 | 53.7 | 51.3 |

| 111–120 | 46.4 | 49.6 | 54.7 | 49.7 | 54.6 | 45.5 | 45.2 | 54.2 | 53.3 | 55.7 | 50.9 |

| 221–230 | 45.3 | 46.4 | 53.2 | 53.9 | 54.1 | 46.0 | 44.7 | 53.5 | 54.4 | 53.4 | 50.5 |

| 331–340 | 44.8 | 46.1 | 54.4 | 54.6 | 54.7 | 45.3 | 44.5 | 53.7 | 53.7 | 54.6 | 50.6 |

| 441–450 | 54.3 | 45.4 | 54.6 | 53.8 | 53.9 | 45.3 | 45.5 | 53.3 | 53.7 | 55.2 | 51.5 |

| Avg. | 47.0 | 53.8 | 46.0 | 54.2 | |||||||

| Std. | 2.9 | 1.3 | 2.5 | 0.8 | |||||||

| Std./Avg. (%) | 6% | 2% | 5% | 1% | |||||||

| Device WM-2 | |||||||||||

| 1–10 | 37.6 | 38.1 | 43.5 | 44.1 | 43.0 | 35.7 | 36.3 | 41.2 | 43.2 | 43.4 | 40.6 |

| 111–120 | 36.0 | 36.3 | 39.5 | 40.3 | 41.1 | 34.6 | 35.2 | 40.3 | 39.8 | 40.7 | 38.4 |

| 221–230 | 24.9 | 36.0 | 39.3 | 39.6 | 39.7 | 34.4 | 35.1 | 41.0 | 39.4 | 39.8 | 36.9 |

| 331–340 | 33.9 | 32.6 | 39.1 | 38.7 | 37.6 | 33.1 | 33.2 | 38.5 | 38.6 | 38.6 | 36.4 |

| 441–450 | 33.0 | 33.2 | 36.4 | 38.5 | 38.8 | 33.2 | 33.2 | 38.4 | 38.3 | 38.6 | 36.2 |

| Avg. | 34.2 | 40.0 | 34.4 | 40.0 | |||||||

| Std. | 3.8 | 2.2 | 1.2 | 1.7 | |||||||

| Std./Avg. (%) | 11% | 5% | 3% | 4% | |||||||

Table A.3.

Duration of each washing cycle for the washing performance test - WM-1 and WM-2

| Duration (min) | 40 °C ½ load | 40 °C ½ load | 40 °C 1 load | 40 °C 1 load | 40 °C 1 load | 60 °C ½ load | 60 °C ½ load | 60 °C 1 load | 60 °C 1 load | 60 °C 1 load | Avg. of 10 runs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Device WM-1 | |||||||||||

| 1–10 | 130 | 125 | 128 | 199 | 200 | 166 | 146 | 168 | 178 | 179 | 162 |

| 111–120 | 126 | 125 | 191 | 199 | 199 | 146 | 151 | 178 | 180 | 177 | 167 |

| 221–230 | 120 | 125 | 202 | 203 | 191 | 148 | 145 | 173 | 174 | 172 | 165 |

| 331–340 | 123 | 125 | 198 | 197 | 200 | 148 | 150 | 174 | 172 | 171 | 166 |

| 441–450 | 192 | 121 | 194 | 196 | 196 | 154 | 149 | 173 | 175 | 174 | 172 |

| Avg. | 131 | 193 | 150 | 175 | |||||||

| Std. | 22 | 18 | 6 | 3 | |||||||

| Std./Avg. (%) | 16% | 9% | 4% | 2% | |||||||

| Device WM-2 | |||||||||||

| 1–10 | 130 | 133 | 131 | 130 | 133 | 127 | 129 | 128 | 129 | 128 | 130 |

| 111–120 | 131 | 133 | 130 | 132 | 137 | 128 | 128 | 127 | 129 | 127 | 130 |

| 221–230 | 132 | 132 | 131 | 131 | 130 | 128 | 128 | 129 | 128 | 128 | 130 |

| 331–340 | 130 | 129 | 129 | 131 | 131 | 126 | 128 | 129 | 127 | 128 | 129 |

| 441–450 | 130 | 130 | 129 | 131 | 130 | 128 | 129 | 128 | 126 | 127 | 129 |

| Avg. | 131 | 131 | 128 | 128 | |||||||

| Std. | 1 | 2 | 1 | 1 | |||||||

| Std./Avg. (%) | 1% | 2% | 1% | 1% | |||||||

Table A.4.

Maximum spin speed measured in each washing cycle for the washing performance test - WM-1 and WM-2

| Max. spin speed (rpm) | 40 °C ½ load | 40 °C ½ load | 40 °C 1 load | 40 °C 1 load | 40 °C 1 load | 60 °C ½ load | 60 °C ½ load | 60 °C 1 load | 60 °C 1 load | 60 °C 1 load | Avg. of 10 runs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Device WM-1 | |||||||||||

| 1–10 | 1382 | 1030 | 1032 | 1334 | 1372 | 1020 | 1020 | 1020 | 969 | 1381 | 1156 |

| 111–120 | 870 | 962 | 1247 | 1371 | 1322 | 1385 | 994 | 1295 | 914 | 1310 | 1167 |

| 221–230 | 920 | 960 | 1010 | 992 | 1386 | 995 | 1389 | 1386 | 1243 | 1315 | 1160 |

| 331–340 | 1385 | 1384 | 984 | 1010 | 1388 | 1198 | 1388 | 1362 | 1386 | 1381 | 1287 |

| 441–450 | 1393 | 1388 | 1392 | 1386 | 1355 | 1346 | 1390 | 1353 | 1344 | 1028 | 1338 |

| Avg. | 1167 | 1239 | 1213 | 1246 | |||||||

| Std. | 234 | 175 | 186 | 170 | |||||||

| Std./Avg. (%) | 20% | 14% | 15% | 14% | |||||||

| Device WM-2 | |||||||||||

| 1–10 | 1401 | 1400 | 1401 | 1400 | 1403 | 995 | 1405 | 1404 | 1404 | 1403 | 1362 |

| 111–120 | 1405 | 1401 | 1406 | 1407 | 1404 | 1403 | 1405 | 1364 | 1403 | 1402 | 1400 |

| 221–230 | 1407 | 1405 | 1409 | 1405 | 1409 | 1408 | 1403 | 1406 | 1405 | 1407 | 1406 |

| 331–340 | 1405 | 1406 | 1407 | 1406 | 1404 | 1402 | 1404 | 1404 | 1403 | 1403 | 1404 |

| 441–450 | 1408 | 1409 | 1406 | 1409 | 1409 | 1407 | 1404 | 1375 | 1408 | 1411 | 1405 |

| Avg. | 1405 | 1406 | 1364 | 1400 | |||||||

| Std. | 3 | 3 | 130 | 13 | |||||||

| Std./Avg. (%) | 0% | 0% | 9% | 1% | |||||||

Table A.5.

Duration of max. spin speed in each washing cycle for the washing performance test - WM-1 and WM-2

| Duration of max. spin speed (s) | 40 °C ½ load | 40 °C ½ load | 40 °C 1 load | 40 °C 1 load | 40 °C 1 load | 60 °C ½ load | 60 °C ½ load | 60 °C 1 load | 60 °C 1 load | 60 °C 1 load | Avg. of 10 runs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Device WM-1 | |||||||||||

| 1–10 | 142 | 273 | 172 | 142 | 135 | 272 | 264 | 134 | 267 | 136 | 194 |

| 111–120 | 287 | 168 | 242 | 131 | 140 | 138 | 273 | 146 | 258 | 139 | 192 |

| 221–230 | 146 | 278 | 269 | 253 | 139 | 270 | 141 | 139 | 256 | 143 | 203 |

| 331–340 | 141 | 139 | 267 | 268 | 139 | 265 | 141 | 134 | 138 | 139 | 177 |

| 441–450 | 142 | 143 | 136 | 136 | 134 | 145 | 142 | 131 | 138 | 258 | 151 |

| Avg. | 186 | 180 | 205 | 170 | |||||||

| Std. | 65 | 59 | 67 | 56 | |||||||

| Std./Avg (%) | 35% | 33% | 33% | 33% | |||||||

| Device WM-2 | |||||||||||

| 1–10 | 93 | 92 | 92 | 92 | 93 | 74 | 66 | 67 | 68 | 68 | 81 |

| 111–120 | 91 | 92 | 91 | 91 | 92 | 66 | 66 | 70 | 66 | 68 | 79 |

| 221–230 | 91 | 92 | 93 | 91 | 93 | 66 | 66 | 66 | 69 | 66 | 79 |

| 331–340 | 92 | 92 | 92 | 91 | 92 | 67 | 67 | 68 | 65 | 66 | 79 |

| 441–450 | 93 | 92 | 92 | 91 | 91 | 67 | 66 | 67 | 66 | 67 | 79 |

| Avg. | 92 | 92 | 67 | 67 | |||||||

| Std. | 1 | 1 | 2 | 1 | |||||||

| Std./Avg (%) | 1% | 1% | 4% | 2% | |||||||

Table A.6.

Water extraction performance at the end of each washing cycle for the washing performance test – WM-1 and WM-2

| Water extraction performance (%) | 40 °C ½ load | 40 °C ½ load | 40 °C 1 load | 40 °C 1 load | 40 °C 1 load | 60 °C ½ load | 60 °C ½ load | 60 °C 1 load | 60 °C 1 load | 60 °C 1 load | Avg. of 10 runs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Device WM-1 | |||||||||||

| 1–10 | 53.9 | 58.5 | 59.9 | 53.0 | 53.6 | 65.3 | 60.8 | 62.2 | 60.4 | 52.6 | 58.0 |

| 111–120 | 70.5 | 61.8 | 53.8 | 50.1 | 54.0 | 55.4 | 60.5 | 53.1 | 63.0 | 52.8 | 57.5 |

| 221–230 | 65.7 | 58.6 | 59.1 | 60.0 | 51.3 | 52.3 | 61.8 | 50.0 | 52.9 | 54.6 | 56.6 |

| 331–340 | 51.7 | 50.3 | 58.7 | 58.2 | 50.4 | 56.9 | 50.7 | 51.2 | 50.3 | 50.7 | 52.9 |

| 441–450 | 52.6 | 49.0 | 50.0 | 50.5 | 51.7 | 55.1 | 50.6 | 51.5 | 51.7 | 57.0 | 52.0 |

| Avg. | 57.3 | 54.3 | 56.9 | 54.3 | |||||||

| Std. | 7.1 | 3.8 | 5.0 | 4.3 | |||||||

| Std./Avg (%) | 12% | 7% | 9% | 8% | |||||||

| Device WM-2 | |||||||||||

| 1–10 | 54.2 | 57.5 | 66.8 | 53.9 | 53.7 | 67.3 | 60.8 | 53.2 | 54.4 | 54.0 | 57.6 |

| 111–120 | 53.5 | 59.1 | 52.9 | 52.1 | 53.1 | 54.4 | 61.2 | 54.3 | 53.1 | 53.3 | 54.7 |

| 221–230 | 57.1 | 56.2 | 51.4 | 52.2 | 52.3 | 59.7 | 54.1 | 52.3 | 52.3 | 53.3 | 54.1 |

| 331–340 | 56.5 | 50.6 | 51.5 | 51.8 | 52.1 | 59.0 | 53.7 | 52.2 | 52.6 | 52.9 | 53.3 |

| 441–450 | 56.9 | 51.8 | 50.9 | 52.1 | 52.7 | 59.9 | 53.3 | 53.1 | 52.5 | 52.7 | 53.6 |

| Avg. | 55.3 | 53.3 | 58.3 | 53.1 | |||||||

| Std. | 2.7 | 3.8 | 4.5 | 0.7 | |||||||

| Std./Avg (%) | 5% | 7% | 8% | 1% | |||||||

Table A.7.

Washing performance in each washing cycle for the washing performance test – WM-1 and WM-2

| Washing performance | 40 °C ½ load | 40 °C ½ load | 40 °C 1 load | 40 °C 1 load | 40 °C 1 load | 60 °C ½ load | 60 °C ½ load | 60 °C 1 load | 60 °C 1 load | 60 °C 1 load | Avg. of 10 runs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Device WM-1 | |||||||||||

| 1–10 | 0.98 | 0.99 | 1.01 | 1.02 | 1.03 | 1.10 | 1.07 | 1.05 | 1.06 | 1.06 | 1.04 |

| 111–120 | 1.03 | 1.03 | 1.03 | 1.03 | 1.04 | 1.14 | 1.12 | 1.07 | 1.07 | 1.07 | 1.06 |

| 221–230 | 0.97 | 0.99 | 1.02 | 1.02 | 1.03 | 1.13 | 1.09 | 1.05 | 1.07 | 1.07 | 1.04 |

| 331–340 | 1.00 | 1.01 | 1.01 | 1.01 | 1.02 | 1.11 | 1.12 | 1.05 | 1.06 | 1.07 | 1.05 |

| 441–450 | 1.08 | 1.00 | 1.01 | 1.02 | 1.02 | 1.12 | 1.13 | 1.05 | 1.06 | 1.06 | 1.06 |

| Avg. | 1.01 | 1.02 | 1.11 | 1.06 | |||||||

| Std. | 0.03 | 0.01 | 0.02 | 0.01 | |||||||

| Std./Avg (%) | 3% | 1% | 2% | 1% | |||||||

| Device WM-2 | |||||||||||

| 1–10 | 1.02 | 1.02 | 0.98 | 0.98 | 0.99 | 1.08 | 1.08 | 1.00 | 1.03 | 1.02 | 1.02 |

| 111–120 | 1.01 | 1.03 | 0.97 | 0.96 | 0.97 | 1.08 | 1.10 | 1.01 | 1.02 | 1.05 | 1.02 |

| 221–230 | 1.02 | 1.03 | 0.96 | 0.98 | 0.99 | 1.08 | 1.12 | 1.02 | 1.03 | 1.04 | 1.03 |

| 331–340 | 1.00 | 1.01 | 0.97 | 0.97 | 0.97 | 1.11 | 1.09 | 0.99 | 1.01 | 1.04 | 1.01 |

| 441–450 | 1.01 | 1.01 | 0.96 | 0.99 | 0.99 | 1.10 | 1.09 | 1.03 | 1.04 | 1.04 | 1.03 |

| Avg. | 1.02 | 0.97 | 1.09 | 1.02 | |||||||

| Std. | 0.01 | 0.01 | 0.01 | 0.02 | |||||||

| Std./Avg (%) | 1% | 1% | 1% | 2% | |||||||

References

- Alborzi F., Schmitz A., Stamminger R. Effects of socio demographic factors on laundry behaviours in Europe and their implications on sustainability. Int. J. Consum. Stud. 2017;41:671–684. doi: 10.1111/ijcs.12380. [DOI] [Google Scholar]

- Alfieri F., Cordella M., Sanfelix J., Dodd N. An approach to the assessment of durability of Energy-related Products. Proc. CIRP. 2018;69:878–881. doi: 10.1016/j.procir.2017.11.082. [DOI] [Google Scholar]

- Alfieri F., Cordella M., Stamminger R., Bues A. Publications Office of the European Union; Luxembourg: 2018. Durability Assessment of Products: Analysis and Testing of Washing Machines. EUR 29487 EN. 2018. [DOI] [Google Scholar]

- Boyraz P., Gunduz M. Dynamic modeling of a horizontal washing machine and optimization of vibration characteristics using Genetic Algorithms. Mechatronics. 2013;23:581–593. doi: 10.1016/j.mechatronics.2013.05.006. [DOI] [Google Scholar]

- CEN/CENELEC JTC10. Energy-related products – Material Efficiency Aspects for Eco-design. https://standards.cen.eu/dyn/www/f?p=204:7:0::::FSP_ORG_ID:2240017&cs=146F3F0C3434E2342477B7A2945D5E308, 25 March 2020.

- CENELEC . 2016. EN 60456:2016, Clothes Washing Machines for Household Use - Methods for Measuring the Performance (IEC 60456:2016, Modified) [Google Scholar]

- Dalhammar C. Industry attitudes towards ecodesign standards for improved resource efficiency. J. Clean. Prod. 2016;123:155–166. doi: 10.1016/j.jclepro.2015.12.035. [DOI] [Google Scholar]

- De Carlo F., Borgia O., Tucci M. Accelerated degradation tests for reliability estimation of a new product: a case study for washing machines. Proc. Inst. Mech. Eng. O J. Risk Reliab. 2013;228:127–138. doi: 10.1177/1748006X13500650. [DOI] [Google Scholar]

- Escobar L.A., Meeker W.Q. A review of accelerated test models. Stat. Sci. 2007;21:552–577. doi: 10.1214/088342306000000321. [DOI] [Google Scholar]

- European Commission . 2010. Commission Delegated Regulation (EU) No 1061/2010 of 28 September 2010 Supplementing Directive 2010/30/EU of the European Parliament and of the Council with Regard to Energy Labelling of Household Washing Machines. [Google Scholar]

- European Commission . 2010. Commission Regulation (EU) No 1015/2010 of 10 November 2010 Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Household Washing Machines. [Google Scholar]

- European Commission . 2015. COM/2015/614, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Closing the Loop - an EU Action Plan for the Circular Economy. [Google Scholar]

- European Commission . EC of the European Parliament and of the Council; 2015. M/543, Commission Implementing Decision C(2015) 9096 of 17.12.2015 on a Standardisation Request to the European Standardisation Organisations as Regards Ecodesign Requirements on Material Efficiency Aspects for Energy-Related Products in Support of the Implementation of Directive 2009/125. [Google Scholar]

- European Commission . 2016. COM/2016/773, Communication from the Commission, Ecodesign Working Plan 2016-2019. [Google Scholar]

- European Environment Agency . Publications Office of the European Union; Luxembourg: 2017. Circular by Design, Products in the Circular Economy. 2017, 1977–8449. [DOI] [Google Scholar]

- Hennies L., Stamminger R. An empirical survey on the obsolescence of appliances in German households. Resour. Conserv. Recycl. 2016;112:73–82. doi: 10.1016/j.resconrec.2016.04.013. [DOI] [Google Scholar]

- IEC . 2010. IEC 60456:2010, Clothes Washing Machines for Household Use - Methods for Measuring the Performance. [Google Scholar]

- IEC . 2015. IEC TR 62617:2015, Home Laundry Appliances - Uncertainty Reporting of Measurements. [Google Scholar]

- Iraldo F., Facheris C., Nucci B. Is product durability better for environment and for economic efficiency? A comparative assessment applying LCA and LCC to two energy-intensive products. J. Clean. Prod. 2017;140:1353–1364. doi: 10.1016/j.jclepro.2016.10.017. [DOI] [Google Scholar]

- Ishiyama T., Iga K. Development of one-way clutch with built-in ball bearing. Koyo Eng. J. English Ed. 2000;157:17–20. [Google Scholar]

- Kruschwitz A., Karle A., Schmitz A., Stamminger R. Consumer laundry practices in Germany. Int. J. Consum. Stud. 2014;38:265–277. doi: 10.1111/ijcs.12091. [DOI] [Google Scholar]

- Park S.J., Park S.D., Kim K.S., Cho J.H. Reliability evaluation for the pump assembly using an accelerated test. Int. J. Pres. Ves. Pip. 2006;83:283–286. doi: 10.1016/j.ijpvp.2006.02.014. [DOI] [Google Scholar]

- Prakash S., Dehoust G., Gsell M., Schleicher T., Stamminger R. 2020. Influence of the service life of products in terms of their environmental impact: Establishing an information base and developing strategies against "obsolescence".https://www.umweltbundesamt.de/publikationen/influence-of-the-service-life-of-products-in-terms 24 March 2020. [Google Scholar]

- Seyffert F., Belke L., Stamminger R. Obsolescence of large household appliances in Germany. Tenside Surfactants Deterg. 2018;55:424–431. doi: 10.3139/113.110586. [DOI] [Google Scholar]

- Sinner H. 1960. Über das Waschen mit Haushaltwaschmachinen: in welchem Umfang erleichtern Haushaltwaschmaschinen und -geräte das Wäschehaben im Haushalt? Haus & Heim Verlag, (8) [Google Scholar]

- Stamminger R., Tecchio P., Ardente F., Mathieux F., Niestrath P. Towards a durability test for washing-machines. Resour. Conserv. Recycl. 2018;131:206–215. doi: 10.1016/j.resconrec.2017.11.014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stiftung Warentest . Stiftung Warentest (Hrsg.); 2013. “Schon Kaputt?”. test 9/2013. [Google Scholar]

- Tecchio P., Ardente F., Mathieux F. Publications Office of the European Union, EUR 28042 EN; 2016. Analysis of Durability, Reusability and Reparability - Application to Washing Machines and Dishwashers. [Google Scholar]

- Tecchio P., McAlister C., Mathieux F., Ardente F. In search of standards to support circularity in product policies: a systematic approach. J. Clean. Prod. 2017;168:1533–1546. doi: 10.1016/j.jclepro.2017.05.198. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tecchio P., Stamminger R., Ardente F., Niestrath P., Mathieux F. EUR 28759 EN, Publications Office of the European Union; Luxembourg: 2017. Study for the Development of an Endurance Testing Method for Washing Machines. [DOI] [Google Scholar]

- Tucci M., De Carlo F., Borgia O., Fanciullacci N. Accelerated life tests as an integrated methodology for product design, qualification and production control: a case study in household appliances. Prod. Manuf. Res. 2014;2:112–127. doi: 10.1080/21693277.2014.893415. [DOI] [Google Scholar]