Abstract

The data in this article present the effective parameters of experimental ultrasonication process on the dispersion stability of graphene nanoplatelets (GNPs) grafted with a natural polymer of Gum Arabic (GA). These datasets are supporting the article “Natural Polymer Non-Covalently Grafted Graphene Nanoplatelets for Improved Oil Recovery Process: A Micromodel Evaluation” [1]. The datasets were gained during experiments conducted at various dwell time (30, 60, 90 and 120 min) at constant power amplitude (60%) of sonication for preparing the stable GA-GNP/brine solutions aiming cost-effective and green agent solution for chemical enhanced oil recovery (C-EOR). The GA-GNPs dispersion data was verified using particle size analyser and UV–Vis measurements. The optimized time and power amplitude parameters of the sonication process were utilized for preparing stabilized samples of GA grafted GNPs in regarding to research work on Natural Polymer Non-Covalently Grafted Graphene Nanoplatelets for EOR. The dispersion stability of GA-GNPs nanofluids at reservoir conditions of high salinity and high temperatures (HSHT) was further demonstrated in the measured data through the sedimentation of nanoparticles.

Keywords: Dispersion stability, Functionalized graphene nanoplatelet, Grafted graphene nanoplatelets, Gum Arabic, High salinity high temperature, Ultrasonication process

Specifications table

| Subject | Materials Engineering/ Nanotechnology. |

| Specific subject area | Enhanced Oil Recovery/Dispersion stability. |

| Type of data | Tables Graphs |

| How data were acquired | Experimental dataset have been acquired using:

|

| Data format | Raw |

| Parameters for data collection |

|

| Description of data collection |

|

| Data source location | Advanced Fluid Dynamic Research Lab, Mechanical Engineering Department, Universiti Teknologi PETRONAS, 32,610 Bandar Seri Iskandar, Perak, Malaysia. |

| Data accessibility | Data is with this article. |

| Related research article | Sinan S. Hamdi, Hussain H. Al-Kayiem and Ali S. Muhsan, Natural Polymer Non-Covalently Grafted Graphene Nanoplatelets for Improved Oil Recovery Process: A Micromodel Evaluation. Journal of Moleculer Liquids. 2020. https://doi.org/10.1016/j.molliq.2020.113076 |

Value of the data

-

•

The data involved the effective parameters of an ultrasonication processto achieve successful dispersion stability of the functionalized graphene nanosheets at oil reservoir conditions of HSHT.

-

•

The introduced data shows theexceptional dispersion stability for a long period of time through cost-effective and green technique-based GNPs grafted with a natural polymer of Gum Arabic.

-

•

The data could be utilized as a reference to investigate the colloidal stability of different nanocarbon based fluids for a long period of time at harsh conditions for thermofluidic applications.

1. Data description

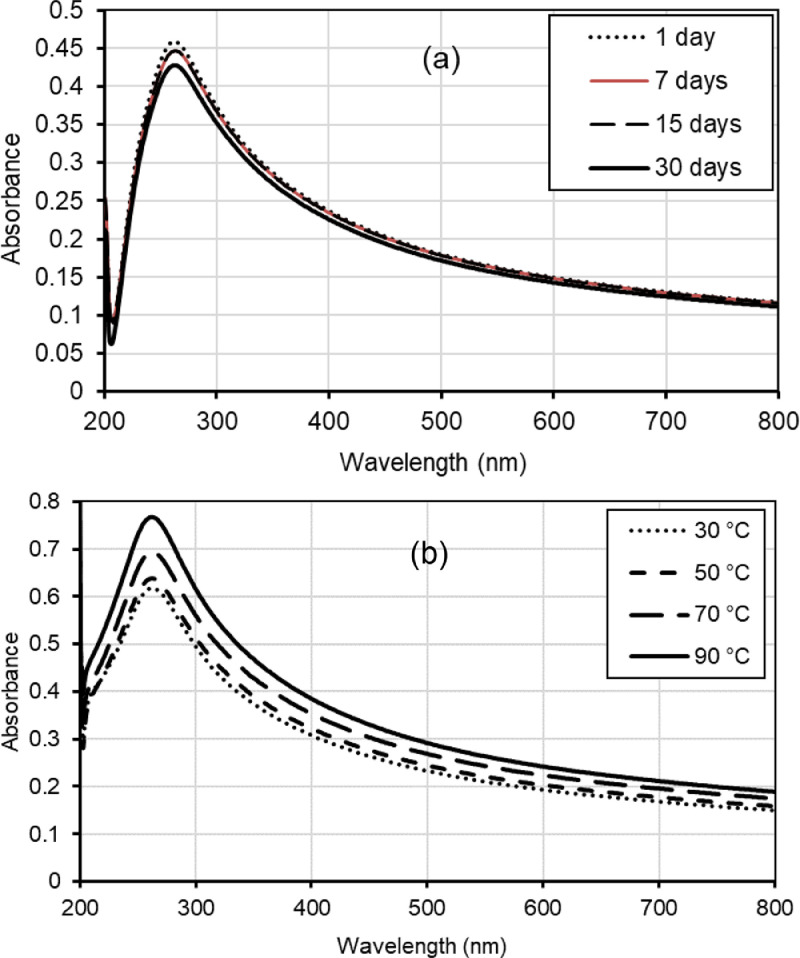

Various methods have been established to disperse GNPs in water-based solutions such as surfactant-based dispersion, physical and chemical functionalization and sonication to overcome this limitation [2], [3], [4]. Despite their success in low salinity mediums at room temperature, short term stability followed by re-agglomeration and precipitation of GNPs were commonly observed at high salinity solutions and high temperature conditions (HSHT) [5]. The data presented in this paper the dispersibility of the prepared GA-GNPs at optimized parameters for long period of time in high salinity brine (30 g/L) under various temperatures (30–90 °C) in Fig. 1. Furthermore, the impact of sonication parameters (time and amplitude) on the dispersion stability of GNPs grafted with GA were evaluated as a function of effective particle size and high dispersibility, Fig. 2.

Fig. 1.

UV–Vis profile of grafted GA-GNPs nanofluid in high salinity solution (30 g/L) as function of (a) different period of time (b) various temperature (30, 50, 70 and 90 °C) for 1 day.

Fig. 2.

Effect of sonication parameter on functionalized graphene nanoplatelets size and dispersibility with GA (a, b) Sonication time at 60% power amplitude, (c, d) Sonication power at maximum time 120 min.

2. Experimental design, materials, and methods

The GNPs powder has been used in this study as a raw material with particle size of less than 2 µm and thickness of few nanometers, average specific surface area of 750 m2/g, and purity of 99.5%. The GNPs powder was purchased form Sigma Aldrich. The fine powder of natural polymer, GA, was procured from the local markets in Malaysia and utilized as an exfoliation solvent. The nanofluid samples used for optimizing the effective sonication parameters have been prepared by dispersing 1 g of GNPs and 0.5 g of GA dissolved in 100 mL of deionized water for different sonication time (30, 60, 90 and 120 min) at specific power amplitude of 60%. After that, 5 mL of each solution was diluted by 10 times to be detectable and measurable sample with the principle of operation for particle size analyser and UV–Vis spectrophotometry. The colloidal stability of the prepared nanofluids was evaluated via UV–Vis spectrometer analysis based on an optical absorbance of GNPs suspended in GA solution at the operating range of wavelength (200–800 nm) was used. Meanwhile, the UV–Vis technique was performed for further confirmation of GA-GNPs dispersion stability in high salinity under elevated temperatures. The hydrodynamic particle size of diluted nanofluids was measured by utilizing the dynamic light scattering (DLS) principle. The GA-GNPs powder and nanofluids have prepared based on the optimized parameters of ultrasonication process are characterized and discussed in the related research work.

Declaration of Competing Interest

The authors declare that:

-

1.

All funding sources to acquire the dataset are acknowledged.

-

2.

No financial relationship with any entity.

-

3.

No sources of revenue have been made.

-

4.

The financial support provided by the abovementioned institutes have been used to conduct further joint researches and joint publications not related to the current data.

-

5.

Authors are planning to apply for Intellectual property patent (IP) to Intellectual Property Corporation of Malaysia (MyIPO) to protect the right of the produced Natural Polymer Non-Covalently Functionalized Graphene Nanoplatelets.

-

6.

The authors declare that they have no known competing financial interests or personal relationships which have, or could be perceived to have, influenced the work reported in this article.

Acknowledgments

Authors are expressing their thankful remarks to Universiti Teknologi PETRONAS (UTP) - Malaysia and Ural Federal University (UrFU) – Russia for supporting the research under International matching research grant, UTP; CS: 015ME0-064 and Act 211 Government of the Russian Federation; contract № 02.A03.21.0006. The first author, in particular, is grateful to UTP for supporting his PhD study under Graduate Assistance (GA) scheme.

Footnotes

Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.dib.2020.105702.

Appendix. Supplementary materials

References

- 1.Hamdi Sinan S., Al-Kayiem Hussain H., Muhsan Ali S. Natural polymer non-covalently grafted graphene nanoplatelets for improved oil recovery process: a micromodel evaluation. J. Mol. Liq. 2020;310 doi: 10.1016/j.molliq.2020.113076. [DOI] [Google Scholar]

- 2.Lee H., Song Y., Ko J., Ryu J., Kim M., Sohn D. Preparation and Characterization of Surfactant-Exfoliated Graphene. Bull. Korean Chem. Soc. 2014;35:2009–2012. doi: 10.5012/bkcs.2014.35.7.2009. [DOI] [Google Scholar]

- 3.Shazali S.S., Amiri A., Zubir M.N.M., Rozali S., Zabri M.Z., Sabri M.F.M., Soleymaniha M. Investigation of the thermophysical properties and stability performance of non-covalently functionalized graphene nanoplatelets with Pluronic P-123 in different solvents. Mater Chem. Phys. 2018;206:94–102. doi: 10.1016/j.matchemphys.2017.12.008. [DOI] [Google Scholar]

- 4.Sadri R., Hosseini M., Kazi S., Bagheri S., Ahmed S., Ahmadi G., Zubir N., Sayuti M., Dahari M. Study of environmentally friendly and facile functionalization of graphene nanoplatelet and its application in convective heat transfer. Energy Conver. Manag. 2017;150:26–36. doi: 10.1016/j.enconman.2017.07.036. [DOI] [Google Scholar]

- 5.Luo D., Wang F., Alam M.K., Yu F., Mishra I.K., Bao J., Willson R.C., Ren Z. Secondary oil recovery using graphene-based amphiphilic Janus nanosheet fluid at an ultralow concentration. Ind .Eng. Chem. Res. 2017;29:11125–11132. doi: 10.1021/acs.iecr.7b02384. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.