Abstract

A study was conducted in an underground mine with the objective to assess relative contributions of different types and categories of diesel-powered vehicles to submicron aerosol concentrations and to assess the effectiveness of selected diesel particulate matter control strategies and technologies. The net contributions of each of six heavy-duty (HD) vehicles, five light-duty (LD) vehicles, and the effects of disposable filter elements (DFEs), a sintered metal filter (SMF) system, and repowering were assessed using isolated zone methodology. On average, the HD vehicles powered by engines that were not retrofitted with filtration systems contributed approximately three times more to the number of aerosols and six times more to elemental carbon (EC) mass concentrations than LD vehicles powered by engines that were not retrofitted with filtration systems. Replacing an Environmental Protection Agency (EPA) pre-Tier engine in the non-permissible HD vehicle with an EPA Tier 3 engine resulted in 63% lower EC concentrations and 41% lower aerosol number concentrations. The evaluated filtration system with DFEs reduced the contribution of diesel-powered vehicles to number concentrations of aerosols by 77 to 92% and the average EC concentrations by 95%. The SMF reduced the contribution of diesel-powered vehicles to number concentrations of aerosols and EC concentrations by 93 and 95%, respectively. When compared with older units, one of the newer model personnel carriers contributed noticeably less to EC mass concentrations but almost equally to the number concentrations of diesel aerosols in the mine air. The second newer type of alternative personnel carrier vehicle contributed more to number and EC mass concentrations than the old-style personnel carrier. The LD vehicle powered by an EPA Tier 4f engine equipped with a DPF system contributed least of all tested vehicles to aerosol number and EC mass concentrations. This information is critical to the efforts of the underground mining industry to reduce exposures of workers to diesel aerosols.

Keywords: Control technologies and strategies, diesel aerosols, underground mining

Introduction

Diesel-powered mobile equipment is essential to the underground mining industry. A large number of diesel engines that meet a variety of superseded and current emissions standards (30 CFR Part 7; 40 CFR Parts 9, 69, et al.; EU 2004; EU 2016) are currently used in underground mines around the world (MSHA 2020; The Raw Materials Group and Parker Bay Company 2012). However, diesel emissions contribute to concentrations of submicron aerosols, oxides of nitrogen, carbon monoxide, and hydrocarbons in underground mines (Bugarski et al. 2009; 2010; 2012; Saarikoski et al. 2018). Since long-term exposure to diesel exhaust has been linked to various adverse pulmonary, cardiovascular, and other health outcomes (Attfield et al. 2012; Peters et al. 2017; Power et al. 2011: Mills et al. 2011; Silverman et al. 2012), occupational exposure to submicron aerosols emitted by diesel-powered equipment is a health concern for underground miners, operators, and regulators (30 CFR Part 57.5060). In 2012, the International Agency for Research on Cancer classified diesel exhaust as a Group 1 carcinogen (IARC 2012).

Technology-forcing emissions regulations promulgated over the past few decades (40 CFR Parts 9, 69, et al.; EU 2004; EU 2016), stimulated dramatic advancements in both diesel engine and exhaust after-treatment technologies. Since the first introduction of the emissions standards for nonroad diesel engines used in the U.S. in 1998, the U.S. Environmental Protection Agency (EPA) gradually tightened the exhaust emissions standards through tiered progression (EPA 2016). For the engines with power outputs typically used in medium-and heavy-duty applications in underground mines (56 and 560 kW), the current nitrogen oxides (NOx) and particulate mass (PM) emissions standards (US EPA Tier 4f) are approximately 90% lower than those for the previous generation of engines (US EPA Tier 3). The European standards promulgated in 2016, introduced particulate number (PN) standards. Those regulations require that the Euro Stage V engines with power outputs between 56 and 560 kW emit less than 1×1012 particles/kWh (EU, 2016) and promote the use of integrated exhaust aftertreatment systems with diesel oxidation catalytic catalyst (DOC)/selective catalyst reduction (SCR)/ammonia slip catalyst (ASC) and wall flow diesel particulate filter (DPF) systems. The technological advancements resulted in reductions in emission levels and changes in the properties of aerosols emitted by modern diesel engines (Khalek et al. 2011; 2015; Ruehl et al. 2015). However, due to good durability, relatively low maintenance costs, availability of rebuild programs, and some regulatory and economic factors, older-technology engines will remain for some time a source of power for mobile underground mining equipment (Bugarski and Barone 2016). The retrofit-type exhaust after-treatment might be used to address emissions from the existing diesel fleets.

Emissions from HD diesel engines in mobile equipment and the effects of exhaust aftertreatment systems on those engines have been extensively evaluated in laboratories and in the field (Cao et al. 2016; Grigoratos et al. 2019; Herner et al. 2011; Lucachick et al. 2014; Thiruvengadam et al. 2012). However, limited information is available in the literature on contributions of in-use vehicles (Bugarski et al. 2012) and systems (Bugarski et al. 2009; 2011), and different categories of vehicles (Rubeli et al. 2004) to concentrations of MSHA-criteria gases and aerosols in underground mines.

This study was conducted to identify, quantify, and characterize the relative contribution of various types and categories of vehicles currently used in underground mining operations to submicron aerosols in workplaces. Additionally, the results were used to examine the effectiveness of some of the already implemented control technologies and strategies. This information is critical to advancing implementation of integrated and multifaceted programs targeting the reduction in exposures of underground miners to diesel aerosols and gases.

Methods

The isolated zone methodology, similar to one utilized in previous studies (Bugarski et al. 2006a; 2006b; 2012; 2014), was used to assess the contribution of various individual vehicles and examine the effectiveness of control technologies. From an experimental point of view, the isolated zone testing was designed to achieve repeatability and accuracy while preserving the genuineness of testing under the actual ambient conditions in the underground mine where the testing took place, and over duty cycles that closely mimic those characteristics for the same vehicles when operated in a production environment. These tests were not compromised by artifacts usually generated or found under laboratory conditions while attempting to simulate real-life conditions and processes. Conversely, laboratory accuracy and repeatability cannot be matched in isolated zone testing, primarily because engines are loaded by vehicles and controlled by humans rather than by a tightly controlled engine dynamometer.

Vehicles and control technologies

Eleven diesel-powered vehicles used by the mine during longwall move operations were tested during this study (Table 1). The vehicles were selected to represent a cross section of the vehicles and power packages used by the study mine and the mining industry. Three of those were permissible HD (30 CFR Part 75.1907) vehicles (P1-P3), three were non-permissible HD (30 CFR Part 75.1908) vehicles (NP1-NP3), and five were LD non-permissible (30 CFR Part 75.1908) vehicles (LD1-LD5).

Table 1.

The vehicles used during the isolated zone study.

| # | Equip-ment Manuf. | Equipment Model | Equipment Type | Equipment Category | Engine Manuf. and Model | Output, kW (hp) @ rpm | MSHA Approval Number | EPA | MSHA VR, m3/s / cfm | MSHA PI, m3/s / cfm | Exhaust System Type |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | Wagner | 14X | LHD | HD permissible | Caterpillar 3306 PCNA | 112 (150) @ 2200 | 7E-B003 | Pre-Tier | 3.54 / 7,500 | 10.85 / 23,000 | Water scrubber |

| P2 | Eimco | EJC130 | LHD | HD permissible | Caterpillar 3306 PCNA | 112 (150) @ 2200 | 7E-B003 | Pre-Tier | 3.54 / 7,500 | 10.85 / 23,000 | Water scrubber |

| P3 | Sandvik | LS175 | LHD | HD permissible | Caterpillar 3126B HEUI | 168 (225) @ 2500 | 07-EPA060001 | Tier 2 | 7.32 / 15,500 | 4.25 / 9,000 | Dry heat exchanger and DFE |

| NP1 | Eimco | 913 | LHD | HD non-permissible | Cummins QSB4.5 | 127 (170) @ 2500 | 07-ENA070006 | Tier 3 | 3.07 / 6,500 | 4.01 / 8,500 | DOC/m uffler |

| NP2 | Eimco | 915 | LHD | HD non-permissible | Cummins QSB6.7 | 144 (193) @ 2500 | 07-ENA060010 | Tier 3 | 4.01 / 8,500 | 4.48 / 9,500 | Sintered Metal Filter (SMF) |

| NP3 | Eimco | 915 | LHD | HD non-permissible | Caterpillar 3306 ATAAC | 224 (300) @ 2200 | 7E-B017 | Pre-Tier | 5.43 / 11,500 | 5.66 /12,000 | DOC |

| LD1 | Duce | III | Personnel carrier | LD non-permissible | Cummins 4B3.3 | 48 (65) @ 2000 | 7E-B093 | Pre-Tier | 1.65 / 3,500 | 3.78 / 8,000 | DOC |

| LD2 | Tomcar | TM4 | Supervisor carrier | LD non-permissible | Daihatsu DM950DTH | 25 (33) @ 3500 | N/A | Tier 2 | N/A | N/A | muffler |

| LD3 | Jeep | J8 | Supervisor carrier | LD non-permissible | VM North America RA428JE8.05A | 118 (158) @ 3600 | 07-ENA110012 | none | 4.72 / 10,000 | 3.30 / 7,000 | DOC |

| LD4 | Gehl | RS5–19 | Telescopic handler | LD non-permissible | Yanmar 4TNV98C-NYEM | 52 (69) @ 2500 | N/A | Tier 4f | N/A | N/A | DPF |

| LD5 | Eimco | 975 | Water truck | LD non-permissible | Deutz F6L912W | 69 (93) @ 2500 | 7E-B028 | Pre-Tier | 2.12/5,000 | 2.36 / 5,000 | DOC |

As required by U.S. Mine Safety and Health Administration (MSHA) regulations limiting exposures of underground metal and nonmetal miners to diesel particulate matter (30 CFR Part 57.5060), the engines used in the mine and in this study were approved by MSHA (30 CFR Part 7) and/or the U.S. Environmental Protection Agency (EPA) (40 CFR Parts 9, 69, et al.). Tested vehicles were powered by a wide variety of power packages (Table 1): (1) permissible and non-permissible power packages that have been used to power underground mining equipment over the past few decades (P1 approved in 1997, P2 approved in 1997, and NP3 approved in 1998); (2) a power package that was introduced with the vehicle acquired during the last decade (P3 approved in 2006); and (3) engines that were used to repower existing vehicles with EPA Tier 3 engines (NP1 approved in 2007 and NP2 approved in 2006). The LD vehicles were powered by: (1) engines that have been used to power personnel carriers and support equipment over the past few decades (LD1 approved in 2002 and LD5 approved in 1998); (2) engines that were introduced over the past decade (LD2 and LD3 approved in 2014); and (3) a recently introduced engine with advanced combustion and exhaust after-treatment that meets EPA Tier 4 final emission standards (LD4). For the engines certified by MSHA, the MSHA ventilation rates (VRs) and particulate indices (PIs) (30 CFR Part 7) are included in Table 1.

Two of the permissible vehicles (P1 and P2) were powered by the same kind of the non-permissible, mechanically controlled, naturally aspirated engine (Caterpillar, Peoria, IL, 3306 PCNA). In order to make those power packages permissible, both of those engines were retrofitted with water-jacketed exhaust headers and water scrubbers. However, neither of those two engines were fitted with a filtration system with disposable filter elements (DFEs). The third permissible vehicle (P3) was powered by a permissible power package based on an electronically controlled turbocharged engine (Caterpillar 3126B HEUI, EPA Tier 2) equipped with a dry heat exchanger and filtration system with two DFEs. Two of the non-permissible vehicles (NP1 and NP2) were powered by an electronically controlled turbocharged Cummins (Columbus, IN) QSB engines. The engine in NP1 was retrofitted with a diesel oxidation catalyst (DOC)/muffler (DCL, Model Mine-X). The engine in NP2 was retrofitted with the sintered metal filter (SMF) system (T.F. Hudgins Inc., Stratus SMF-AR). The third non-permissible vehicle (NP3) was powered by a mechanically controlled and turbocharged engine (Caterpillar 3306 ATAAC) retrofitted with a DOC (Catalytic Exhaust Products, Model 10SXC). The LD1 was powered by a Cummins 4B3.3 engine that was retrofitted with DOC (Catalytic Exhaust Products, Model 6SXC). The LD2 was powered by a turbocharged Daihatsu DM950DTH engine equipped with muffler. The LD3 was powered by an electronically controlled engine from VM North America (RA428JE8.05A) equipped with DOC. The LD4 was powered by a naturally aspirated engine equipped with diesel particulate filter (DPF). The engine in the LD5 was retrofitted with DOC (Catalytic Exhaust Products, Model 6SXC).

In order to evaluate the effectiveness of diesel emissions control technologies, two of the vehicles, P3 and NP2, were tested twice. The results of the tests performed on P3 for two configurations of the filtration system used on that vehicle were used to evaluate the effectiveness of the Donaldson P604516 DFEs: (1) the DFEs removed from the canister, P3 and (2) DFEs installed in the canister, P3 (DFEs). The second test was done with a “fresh” DFEs. The results of the tests performed on P2 for two configurations were used to evaluate the effectiveness of the SMF-AR system: (1) the SMF system was bypassed and fuel dosing disabled, NP2, and (2) a fully functional SMF system, NP2 (SMF).

All tested vehicles were fueled from a single batch of ultralow sulfur diesel (ULSD) fuel. The fuel tanker was parked close to the test site, but in a different air split. The results of the analyses performed on the fuel sample collected from the tanker are shown in Table 2.

Table 2.

Properties of the diesel fuel used for this study.

| Fuel Property | Test Method | ULSD |

|---|---|---|

| Heat of Combustion [MJ/kg] | ASTM D240 | 45.7 |

| API Gravity @ 15.6 °C [°API] | ASTM D1298 | 36.3 |

| Cetane Number | ASTM D613 | 46.2 |

| Sulfur by Ultraviolet [ppm] | ASTM D5453 | 11.0 |

| Flash Point, Closed Cup [°C] | ASTM D93 | 59.0 |

Test site

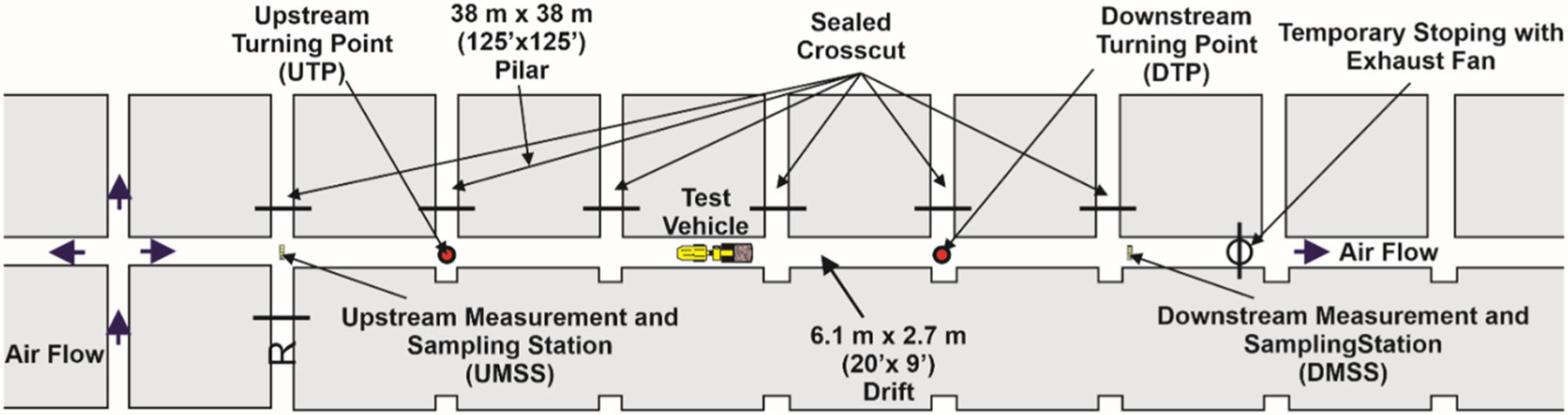

The layout of the isolated zone test site used in this study is shown in Figure 1. All drifts within the test site were 6.1-m (20-ft) wide and 2.7-m (9-ft) high. Temporary stoppings were used to isolate the zone from the adjacent areas of the mine. A temporary stopping at the downstream end of the zone (Figure 1) housed a 610-mm-diameter (24-in.-diameter) exhaust duct.

Figure 1.

The layout of the isolated zone test site.

The zone was ventilated with air supplied from the main ventilation shaft. A stable flow rate through the zone was maintained with a two-stage fan (Spendrup Fan Co., Grand Junction, CO, Model 60×2–30-3600 CR FP). The fan was installed in the exhaust duct upstream of the permanent stopping. A stainless steel pitot airflow traverse probe (Air Monitor Corporation, Santa Rosa, CA, VOLU-probe/SS) was inserted upstream of the fan and was used to continuously measure airflow through the duct. The Digiquartz Portable Standard Model 765 (Paroscientific Inc., Redmond, WA) pressure transducer was used to measure differential pressure across the pitot probe. The fan was set to achieve a nominal flow rate of 5.43 m3/s (11,500 cfm). The selected nominal flow rate fell in the middle of the range of MSHA ventilation rates (VRs) and particulate indexes (PIs) for the tested engines (Table 1). The average actual airflow rates for all tests are summarized in Table 3. The intra- and inter-test variabilities in the flow rates were found to be relatively minor (Table 3). All reported concentrations are those at the actual ventilation rates.

Table 3.

Mean ± standard deviation ventilation airflow rates for all tests.

| Test # | Q, m3/s | Q, cfm |

|---|---|---|

| P1 | 5.25 ± 0.08 | 11,164 ± 173 |

| P2 | 5.47 ± 0.08 | 11,645 ± 176 |

| P3 | 5.39 ± 0.05 | 11,469 ± 113 |

| P3 (DFEs) | 5.52 ± 0.09 | 11,754 ± 185 |

| NP1 | 5.39 ± 0.04 | 11,462 ± 75.0 |

| NP2 | 5.46 ± 0.06 | 11,625 ± 123 |

| NP2 (SMF) | 5.35 ± 0.06 | 11,375 ± 133 |

| NP3 | 5.35 ± 0.13 | 11,389 ± 285 |

| LD1 | 5.42 ± 0.07 | 11,526 ± 146 |

| LD2 | 5.37 ± 0.05 | 11,415 ± 105 |

| LD3 | 5.59 ± 0.13 | 11,892 ± 268 |

| LD4 | 5.30 ± 0.04 | 11,268 ± 84.0 |

| LD5 | 5.28 ± 0.06 | 11,240 ± 119 |

In order to assure the lowest possible levels of background particulate concentrations, the experimental work was scheduled during the night hours when the diesel-powered traffic in the drifts leading from the main ventilation shaft to the zone was rather low. In order to suppress dust entrainment, the roadways leading to the zone and in the zone were treated with water/oil dust-suppressing emulsion. The ventilation layout described above secured a steady-state flow of fresh air through the zone. This concept also minimized the effects of the presence and movement of vehicles in the zone on the ventilation airflow.

Each of the tested vehicles was introduced in the isolated zone through the upstream measurement and sampling station (UMSS) and was operated by a single operator in the 150-m (500-ft) section of the main drift, between the upstream turning point (UTP) and downstream turning point (DTP) (Figure 1). The vehicles were operated over custom-designed cycles simulating representative cycles for the specific vehicles. The load-haul dump (LHD) vehicles (P1–P3 and NP1–NP3) and telescopic handler (LD4) were transporting various types of loads between the UTP and DTP. The water truck (LD5) was tested with the tank full of water/oil dust-suppressing emulsion. The cycle for the LHD vehicles and telescopic handler included simulation of loading and unloading using three-point turns at UTP and DTP. The other four LD vehicles (LD1-LD3 and LD5) were driven back and forth between UTP and DTP at approximately 15 mph, the speed limit enforced at the mine. Those vehicles made simple three-point turns at UTP and DTP.

Since the objective of the study was to assess the effects of the vehicles in-use, modifications on the vehicles were limited to those needed to generate the test cases. It is important to note that the contributions of the whole vehicles rather than the engines alone were assessed in this study. Therefore, aerosols at the downstream measurement and sampling station (DMSS) included not only those emitted via tailpipe but also those sourced to potential leaks in the exhaust systems and/or crankcase breathers.

It is also important to note that the study was conducted at approximately 1,500 m (4,921 ft) above sea level, and the reduced availability of O2 might affect the emissions results, particularly those from naturally aspirated engines. All engines used in this study were de-rated for the altitude. With the exception of LD4, the engines in LD vehicles were operated under less load than those in HD vehicles.

Sampling and measurement methods

During the study, the net effects of each tested vehicles/technologies were assessed using the results of sampling and measurements performed at the UMSS and DMSS. The UMSS was located at the upstream end of the isolated zone (Figure 1), 50 m (164 ft) upwind of the UTP, and the DMSS was located between 230 and 250 m (755 ft and 820 ft) downwind of the DTP (Figure 1).

The Fast Mobility Particle Sizer, FMPS, (TSI, Shoreview, MN, Model 3091) spectrometer (Johnson et al. 2004) was used at the UMSS and DMSS to measure the number concentrations (#/cm3) and size distributions of aerosols with an electrical mobility diameter from 5.6 nm to 560 nm. The samples for the FMPS were drawn from the vicinity of the inlets for the carbon samplers. The data were collected at 1 Hz. The FMPS column was cleaned prior to each of the tests to avoid fouling of the column. The size distributions were fitted with log-normal curves using DistFit 2009 (Chimera Technologies, Inc., Forest Lake, MN). The results of the FMPS measurements at DMSS and UMSS were used to assess the effects of HD and LD vehicles and exhaust aftertreatment systems on size distribution of aerosols with an electrical mobility diameter from 5.6 nm to 560 nm and net contribution of tested vehicles to total number concentrations of aerosols. The average concentrations for the specific tests were calculated using the results of measurements performed between the end of equilibration and the end of the measurement periods. The net contributions to the total number concentrations of aerosols were calculated by correcting the results of the measurements at DMSS with the background concentrations assessed from the measurements at UMSS. For comparison purposes, the total number concentrations were normalized with respect to the maximum average number concentration observed for any of the tested vehicles.

The aerosol samples for carbon analysis were collected at the UMSS and DMSS using the custom-designed systems. The samples were collected on tandem 37-mm quartz fiber filters (QFFs) enclosed in diesel particulate matter cassettes (SKC, Eighty Four, PA, Model 225–317), used for compliance sampling in underground mines in the U.S. (Noll et al. 2004). Dorr-Oliver 10-mm cyclones (Zefon, Ocala, FL, Model 456243) were used to remove coarse aerosols from the submicron and respirable samples. In the case of the UMSS system, a fixture with inlets was mounted on a stationary tripod. For the DMSS sampling system, the fixture with inlets was mounted on the rotating head that allowed for the collection of integrated aerosol samples along the perimeter of the circle defined by the center of rotation approximately 1.82 m (6.0 ft) from the ground with a 0.91-m (3.0-ft) radius. The sampling head rotated at approximately 1 rpm, which translated into a sampling head angular speed of approximately 100 mm/s. The nominal sampling flow rates of 1.7 Lpm were maintained for all samples by subsonic critical orifices, installed in manifolds coupled to a single vacuum pump (Oerlikon Leybold Vacuum GmbH, Cologne, Germany, Segovac SV25B). The actual sampling flow rates were determined using results of flow verifications with a primary flow calibrator (Mesa Laboratories, Lakewood, CO, Bios Defender 530). The carbon analysis was performed at NIOSH PMRD using the NIOSH Method 5040 (NIOSH 2016), which is a thermo-optical transmittance (TOT) method. The analysis was performed using an OC/EC Aerosol Analyzer from Sunset Laboratory Inc. (Portland, Oregon). The results of the analysis performed on the secondary filters were used as a dynamic blank correction for the primary filters. Due to the uncertainty associated with high OC contamination of the QFF media in DPM cassettes, along with short sampling times, only the EC concentration (μg/m3) data were used for the analysis. The results of the EC analysis performed on the samples collected at DMSS and UMSS for the duration of the filter sampling sessions were used to assess the background-corrected average net contributions of HD and LD vehicles to the mass concentrations of EC. For comparison purposes, the results were normalized with respect to the maximum EC concentration observed for any of the tested vehicles.

The efficiencies of the evaluated filtration systems were expressed as a percentage of change in the total number and EC concentrations between the cases when the selected vehicles were operated with and without the systems.

Results and discussion

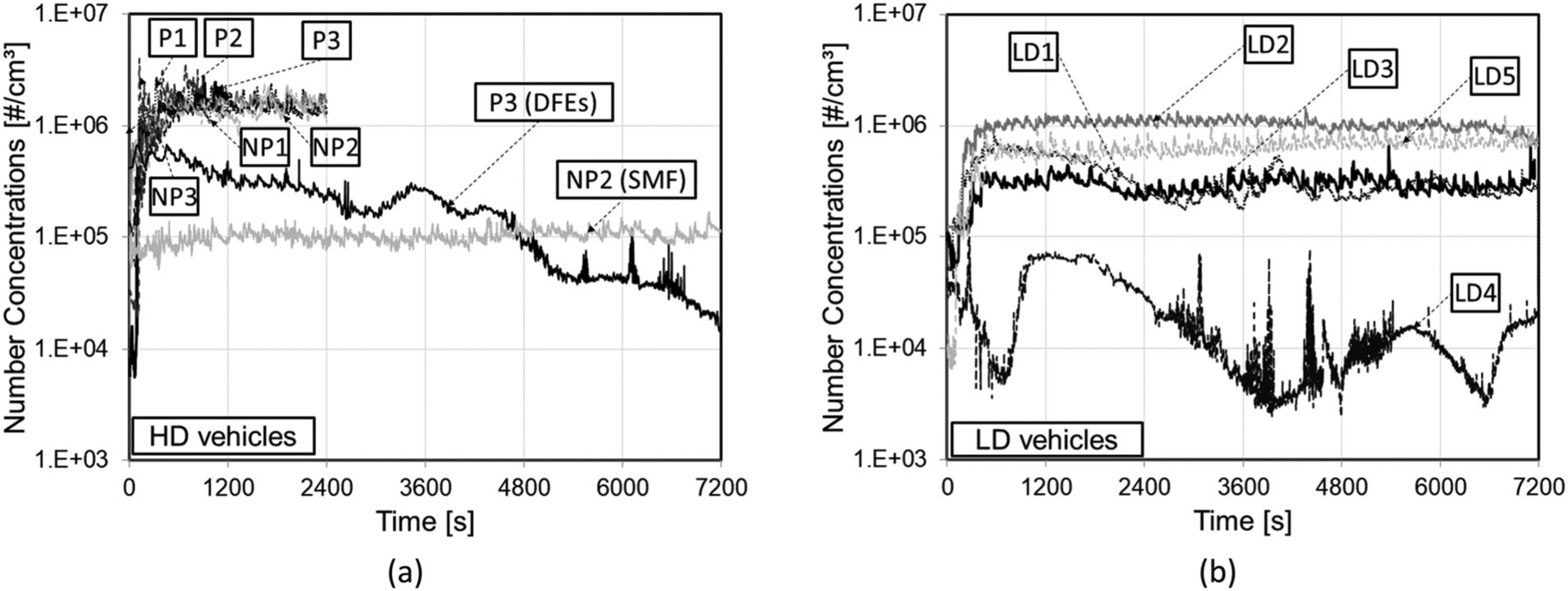

The traces of number concentrations of aerosols measured with FMPS at the DMSS for tests involving HD and LD vehicles are shown in Figure 2. The length of the FMPS scans and duration of filter sampling at the DMSS were customized for the individual tests to accommodate for a wide spectrum of aerosol concentrations at the DMSS among the tests. The FMPS scans and filter sampling at the UMSS were synchronized in time with those performed at the DMSS. For the majority of the HD tests, the size distributions and concentrations were scanned with FMPS for at least 2,400 sec (Figure 2a). In the case of the P3 and NP3 tests, the scans were only 1,750 and 900 sec long, respectively. The durations of those scans were shorter due to fouling of the FMPS column and saturation of the electrometers by high concentrations of diesel aerosols at the DMSS during those tests. The P3 DFEs and NP2 SMF tests were at least 7,200-sec long (Figure 2a). All tests involving LD vehicles were at least 7,200-sec long (Figure 2b). For all tests, the initial 600 sec was considered an equilibration period, and concentrations recorded during that period were not considered in number concentration calculations. The filter sampling times were between 1,680 and 7,500 sec. These included times needed for the concentrations to reach quasi-steady-state levels.

Figure 2.

Number concentrations of aerosols at the downstream measurement and sampling station (DMSS).

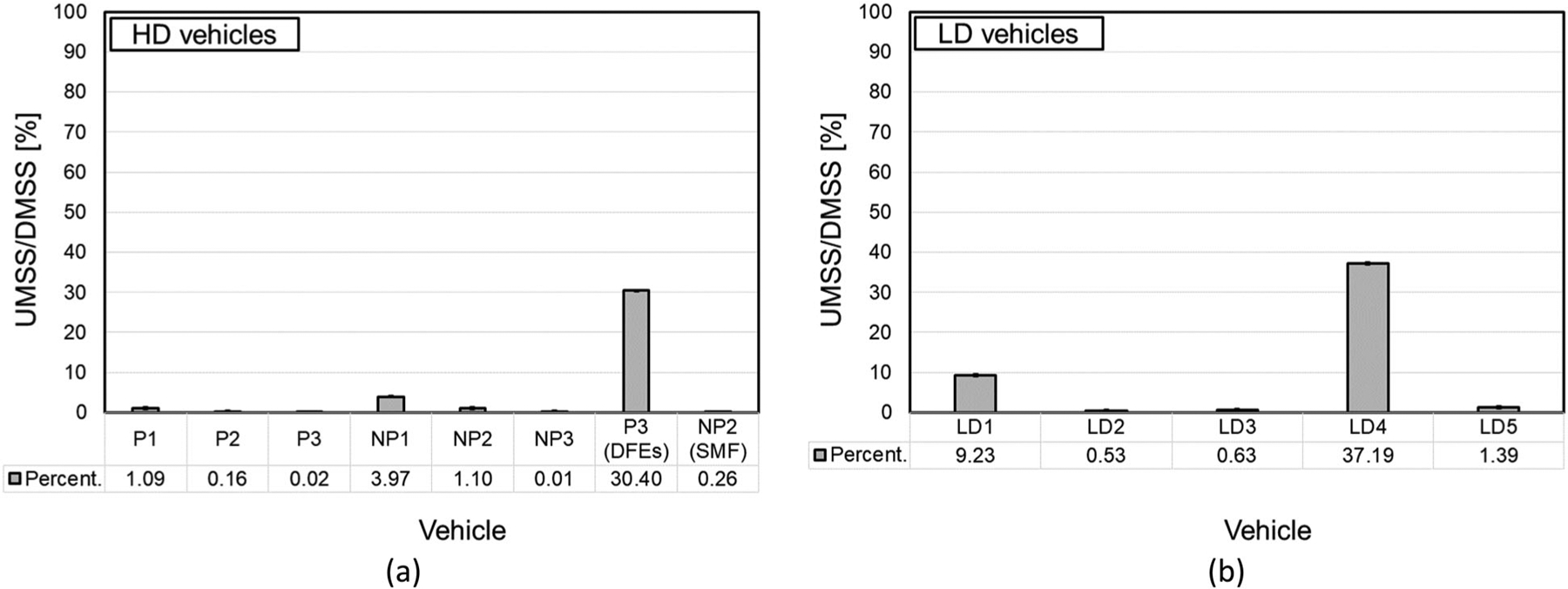

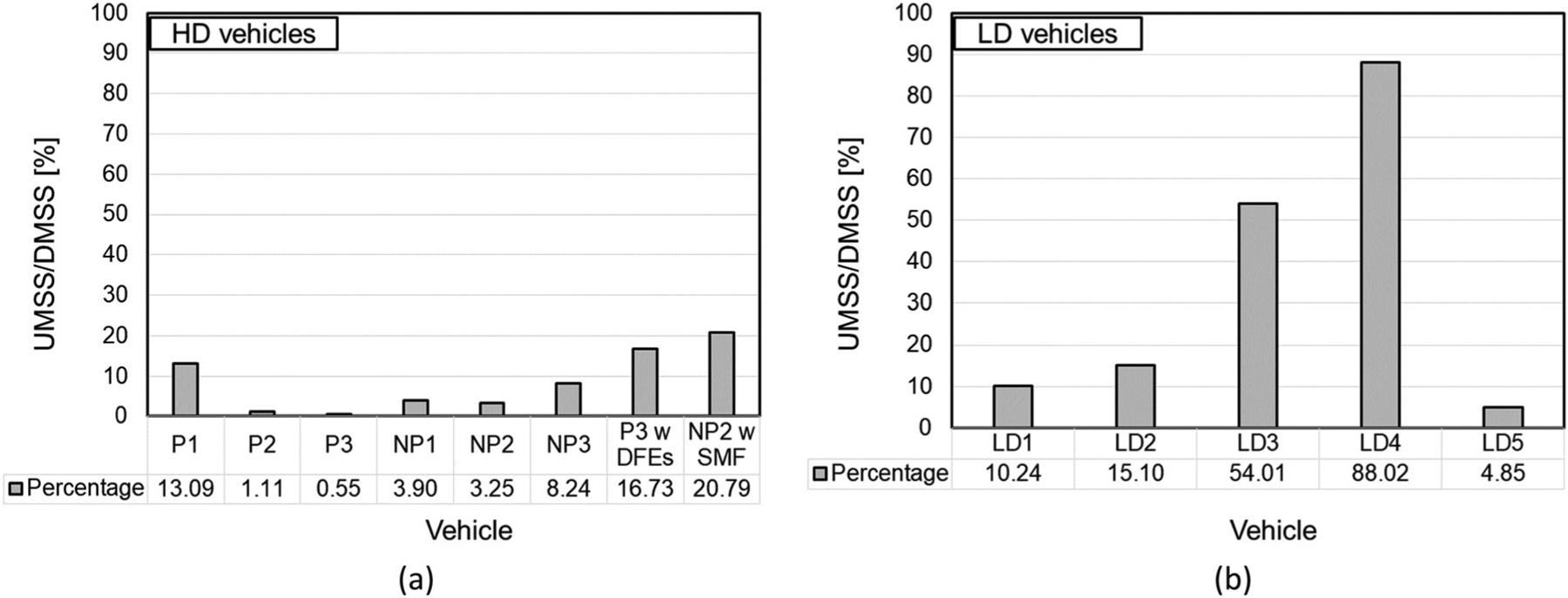

Effects of aerosols at UMSS and background correction

Emissions from a small number of diesel-powered vehicles intermittently operated between the ventilation shaft and isolated zone contributed to the number and EC concentrations in the zone. The measurements showed that contributions of background concentrations measured at UMSS to the concentrations measured at DMSS (UMSS/DMSS) were small, but measurable. With the exception of two tests, P3 (DFEs) and LD 4, the average total number concentrations of aerosols at UMSS were less than 10 percent of the corresponding number concentrations at DMSS (Figure 3). For the P3 (DFEs) and LD 4 tests, the background concentrations were 30 and 37%, respectively (Figure 3 and Figure 4). With the exception of the two tests performed with low-emitting LD vehicles (LD3 and LD4), the UMSS EC mass concentrations were less than 21% of the corresponding DMSS concentrations (Figure 4). The background corrections for total number and EC mass concentrations were obtained by subtracting UMSS concentrations from the corresponding DMSS concentrations. The delays associated with propagation of the vehicle plume with contaminants from the UMSS to the DMSS were not taken into consideration.

Figure 3.

Relationship between aerosol number concentrations at the upstream measurement and sampling station (UMSS) and the downstream measurement and sampling station (DMSS) for (a) HD vehicles (no filtration systems) and (b) LD vehicles (no filtration systems).

Figure 4.

Relationship between EC concentrations at the upstream measurement and sampling station (UMSS) and the downstream measurement and sampling station (DMSS) for (a) HD vehicles (no filtration systems) and (b) LD vehicles (no filtration systems).

Effects of tested vehicles on aerosols

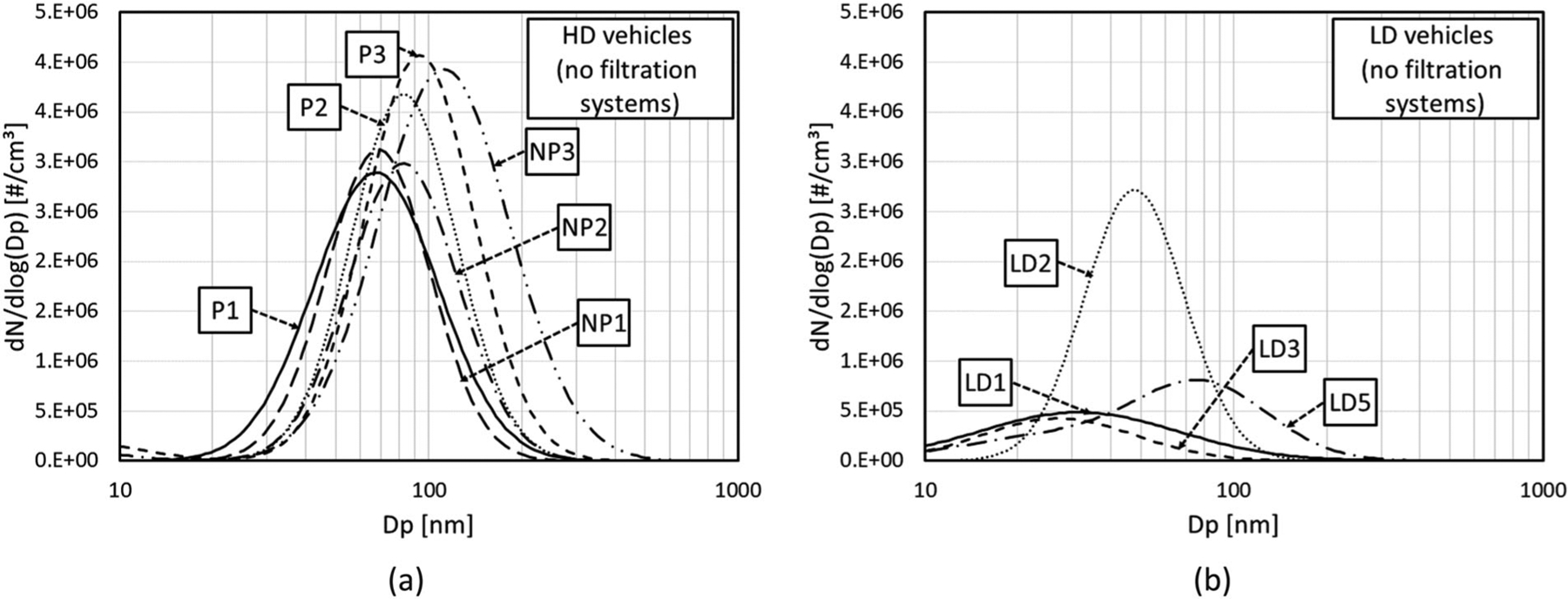

The size distributions of aerosols at the DMSS for selected time instances for HD and LD vehicles without filtration systems are shown in Figure 5. The statistical parameters of the distributions, including electrical mobility count median diameter (CMDs), geometric standard deviation (r), and total number concentrations, for HD and LD vehicles are reported in Table 4 and Table 5, respectively.

Figure 5.

Size distributions of aerosols measured with FMPS at the downstream measurement and sampling station (DMSS) at selected time instances at actual ventilation rates for (a) HD vehicles (no filtration systems) and (b) LD vehicles (no filtration systems).

Table 4.

Statistical parameters including CMD, σ, and total concentrations for size distributions of aerosols measured with FMPS at the downstream measurement and sampling station (DMSS) for HD vehicles (actual ventilation rates).

| Nucleation Mode | Agglomeration Mode | ||||||

|---|---|---|---|---|---|---|---|

| Vehicle (Exhaust Configuration) | Time Instance s |

CMD, nm |

σ – |

Total Conc., #/cm3 |

CMD, nm |

σ – |

Total Conc., #/cm3 |

| P1 | 2,000 | 67.5 | 1.590 | 1.46E + 06 | |||

| P2 | 2,000 | 83.0 | 1.480 | 1.57E + 06 | |||

| P3 | 1,200 | 8.2 | 1.520 | 7.31E + 04 | 93.1 | 1.500 | 1.80E + 06 |

| P3 (DFE) | 3,000 | 78.2 | 1.510 | 1.63E + 05 | |||

| NP1 | 2,000 | 68.6 | 1.470 | 1.31E + 06 | |||

| NP2 | 2,000 | 2.8 | 1.880 | 3.22E + 05 | 82.6 | 1.500 | 1.32E + 06 |

| NP2 (SMF) | 3,000 | 4.9 | 1.850 | 2.23E + 04 | 63.5 | 1.500 | 7.68E + 04 |

| NP3 | 900 | 111.8 | 1.630 | 2.09E + 06 | |||

Table 5.

Statistical parameters including CMD, σ, and total concentrations for size distributions of aerosols measured with FMPS at the downstream measurement and sampling station (DMSS) for LD vehicles (actual ventilation rates).

| Nucleation Mode | Agglomeration Mode | ||||||

|---|---|---|---|---|---|---|---|

| Vehicle (Exhaust Configuration) | Time Instance, s |

CMD, nm |

σ – |

Total Conc., #/cm3 |

CMD, nm |

σ – |

Total Conc., #/cm3 |

| LD1 (muffler) | 2,000 | 31.4 | 2.100 | 3.92E + 05 | |||

| LD2 (muffler) | 2,000 | 47.7 | 1.450 | 1.10E + 06 | |||

| LD3 (muffler) | 2,000 | 27.0 | 1.770 | 2.64E + 05 | |||

| LD4 (DOC/DPF) | 6,600 | 11.2 | 1.130 | 6.33E + 02 | 39.8 | 1.790 | 3.79E + 03 |

| LD5 (DOC) | 2,000 | 26.6 | 2.000 | 1.92E + 05 | 79.7 | 1.630 | 3.90E + 05 |

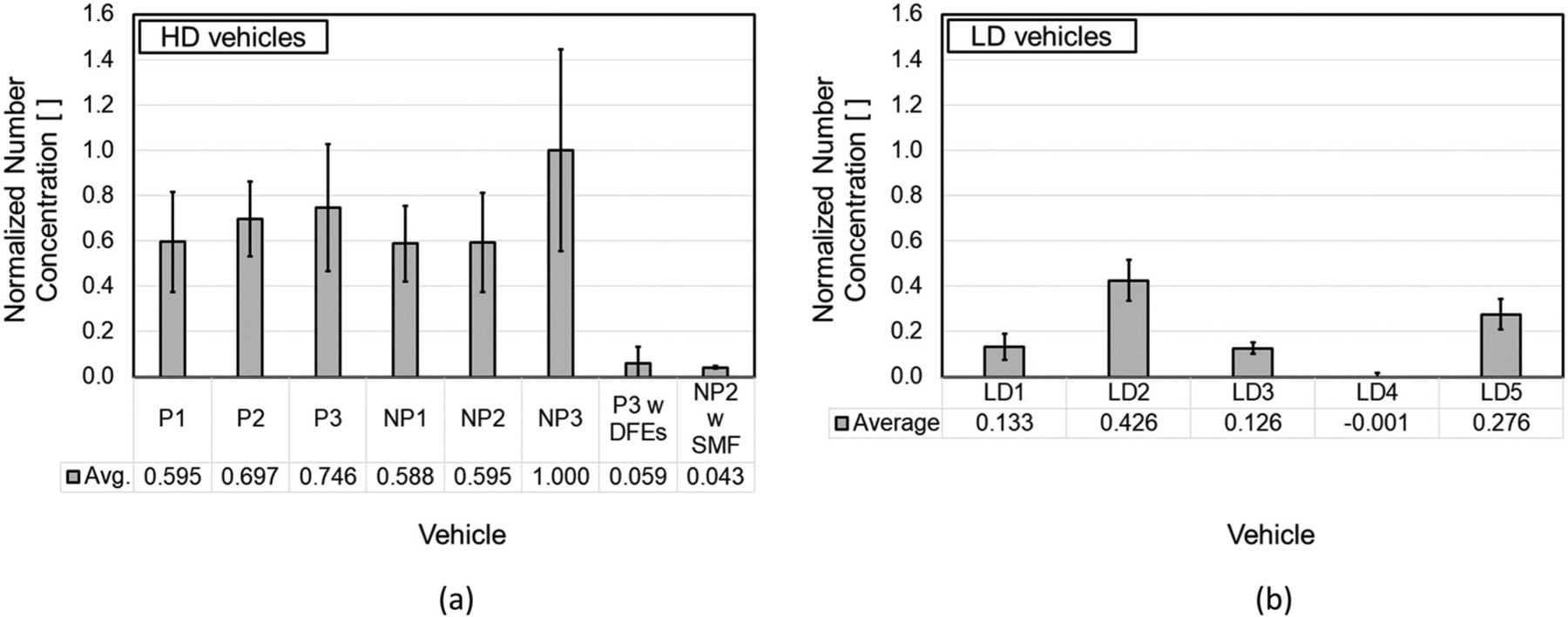

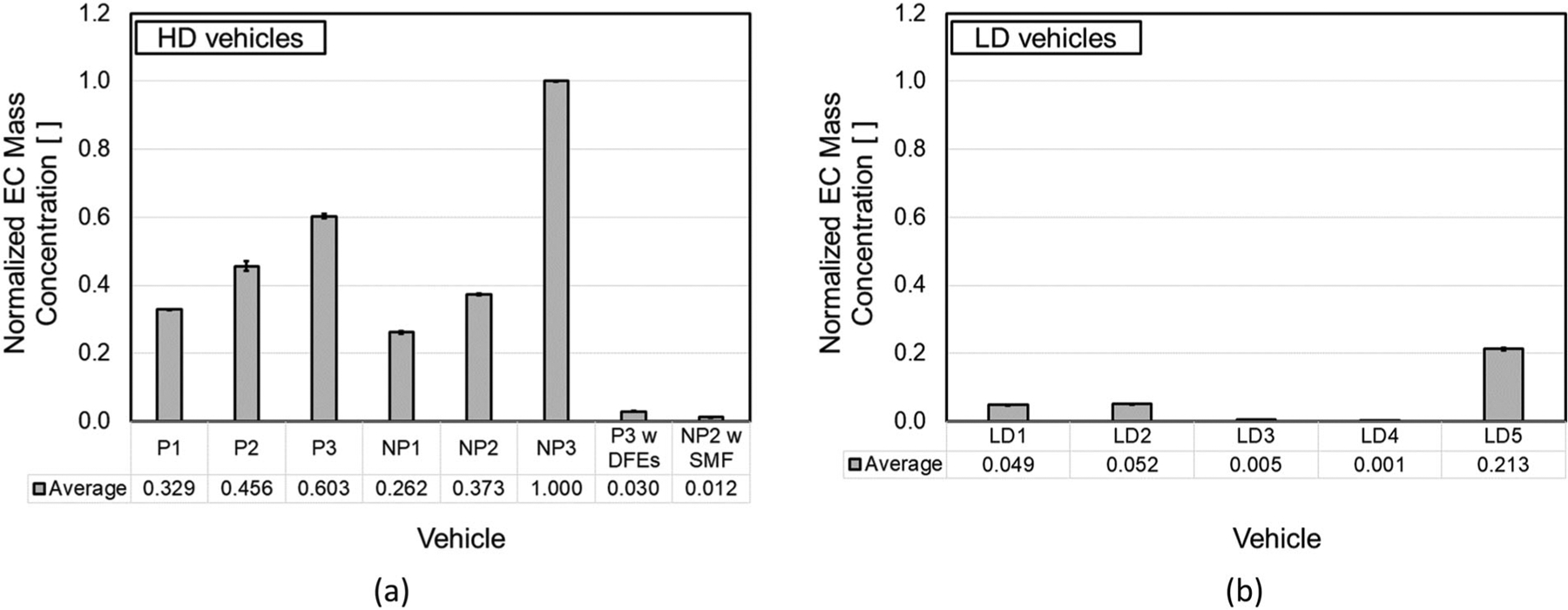

The aerosols contributed by all six HD vehicles (engines without filtration systems) were predominantly distributed in a single agglomeration mode (Figure 5a and Table 4) with CMDs between 67 and 112 nm. The differences were relatively minor among average CMDs for agglomeration mode aerosols contributed by vehicles powered with the EPA pre-Tier engines in permissible vehicles (P1 and P2) and the vehicles powered with the EPA Tier 3 engines in non-permissible vehicles (NP1 and NP2). The contributions of the vehicles in those two groups to the number and EC concentrations were relatively similar (Figures 6 and 7).

Figure 6.

Normalized average net contribution of tested vehicles to number concentrations for (a) HD vehicles (no filtration systems) and (b) LD vehicles (no filtration systems).

Figure 7.

Normalized average net contribution of tested vehicles to EC concentrations.

The observed distributions are similar to those reported in the literature for “traditional” diesel aerosols (Khalek et al. 2011; 2015; Ruehl et al. 2015). At actual test conditions, a small fraction of the aerosols emitted by P3 (w/o DFEs) and NP2 (w/o SMF) engines were distributed in nucleation modes with sub-10 nm CMDs (Table 4).

The aerosols contributed by LD vehicles (without filtration systems) were characterized by single (LD1, LD2, and LD3) or bimodal (LD5) distributions (Figure 5b and Table 5). For all five vehicles, the majority of aerosols were distributed in agglomeration mode. With the exception of those emitted by EPA pre-Tier LD5, the CMDs of agglomeration mode aerosols emitted by LD vehicles (27–80 nm) (Table 5) were lower than CMDs of agglomeration mode aerosols emitted by HD vehicles (Table 4). The average CMDs for agglomeration modes for LD5 were similar to those for aerosols contributed by other tested pre-Tier and Tier 3 engines in HD vehicles.

The average background-corrected contributions of HD and LD vehicles to the total number concentrations of aerosols, normalized with the maximum average concentration observed for any of the tested vehicles, are summarized in Figure 6. The averages were calculated for the concentrations recorded at the actual ventilation rates (Table 3) between the end of equilibration and the end of the measurement period. The average net contributions of HD and LD vehicles to the mass concentrations of EC, normalized with the maximum EC concentration observed for any of the tested vehicles, are summarized in Figure 7. Those averages were calculated at the actual ventilation rates (Table 3) for the duration of the filter sampling sessions.

Out of two permissible HD vehicles (P1 and P2) powered by similar rebuilt Caterpillar 3306 PCNA engines and fitted with OEM-supplied water scrubber exhaust conditioning systems, P2 emitted aerosols with larger CMD (Table 4) and had a measurably larger net contribution to the total number (Figure 6) and EC mass (Figure 7) concentrations. Out of all permissible engines, the one in P3 (Caterpillar 3126B HEUI with the dry exhaust conditioning system, but without DFEs in the canister) produced aerosols with the largest CMD (Table 4) and had the largest net contribution to the total number (Figure 6) and EC mass (Figure 7) concentrations. Out of the two non-permissible HD vehicles powered by the EPA Tier 3 engines, including NP1 (Cummins QSB4.5, 4.5 liter, 127 kW) and NP2 (Cummins QSB6.7, 6.7 liter, 144 kW), NP2 emitted aerosols with larger CMDs (Table 4) and had a larger net contribution to the total number (Figure 6) and EC mass (Figure 7) concentrations.

The NP3 vehicle powered with a Caterpillar 3306 ATAAC (EPA pre-Tier) contributed more than other tested engines to the number (Figure 6) and EC concentrations (Figure 7). The aerosols emitted by that engine were characterized by the largest electrical mobility CMDs (Table 4). The NP1 powered by EPA Tier 3 Cummins QSB4.5 (equipped only with DOC) and NP2 vehicle powered by EPA Tier 3 Cummins QSB6.7 (when tested without the SMF system) contributed less to EC concentrations than NP3 (Figure 7). The Caterpillar 3306 ATAAC engine has a larger displacement, and consequently a higher exhaust flow rate and power output than each of Cummins engines in NP1 and NP2 (Table 1).

The results of two tests conducted on the Eimco 915 LHD vehicles (NP2 and NP3) were used to access the benefits of repowering non-permissible HD vehicles with smaller displacement and less emitting engines. The contributions from the NP3, powered by an EPA pre-Tier Caterpillar 3306 ATAAC engine (10.5 liter, 224 kW, 1322 Nm), were compared with those of the NP2, powered by an EPA Tier 3 Cummins QSB6.7 engine (6.7 liter, 144 kW, 930 Nm). The EPA Tier 3 engines were found to emit aerosols with smaller CMDs (Table 4) and had lower net contributions to the total number (41%, Figure 6) and EC mass (63%, Figure 7) concentrations than the EPA pre-Tier engine.

The contributions of tested LD vehicles to total number and EC mass concentrations were lower than those of tested HD vehicles (Figures 6 and 7). Generally smaller engines in LD vehicles were operated at lighter loads and had lower exhaust flow rates. However, due to their substantial presence in underground operations (Rubeli et al. 2004), LD vehicles could still contribute to the exposure of underground miners to diesel aerosols.

The effects of replacing older personnel carrier (jeep style) vehicles—powered with “traditional” EPA pre-Tier engines—with a similar style of vehicle powered by contemporary engines certified by MSHA in 2014 on aerosols in mine air were examined using results of LD1 (Cummins 4B3.3) and LD3 (VM North America RA428JE8.05A) tests. The MSHA PI for the significantly more powerful 117 kW engine in LD3 (3.30 m3/sec) is somewhat lower than for the 48-kW engine in the LD1 (3.78 m3/sec). The LD3 was found to contribute almost 90% less to EC mass concentrations than LD1 (Figure 7), but only slightly less to the total number concentrations (Figure 6). The aerosols emitted by LD3 had somewhat smaller CMDs than aerosols emitted by LD1.

We also examined the effects of replacing an older personnel carrier (jeep style) powered with a “traditional” EPA pre-Tier engine with an all-terrain- vehicle powered by a smaller displacement Tier 2 engine. The effects of an LD1 powered by a 48-kW Cummins 4B3.3 engine were compared with those of an LD2 powered by a 25-kW Daihatsu DM950DTH engine. The LD2 was found to contribute more to the EC mass (Figure 7) and total number concentrations (Figure 6) than LD1. The size distributions of aerosols emitted by the LD2 were characterized with larger CMDs and narrower geometric standard deviation (r) than those of aerosols emitted by LD1 (Table 5).

Effects of exhaust filtration systems

Filtration system with DFEs

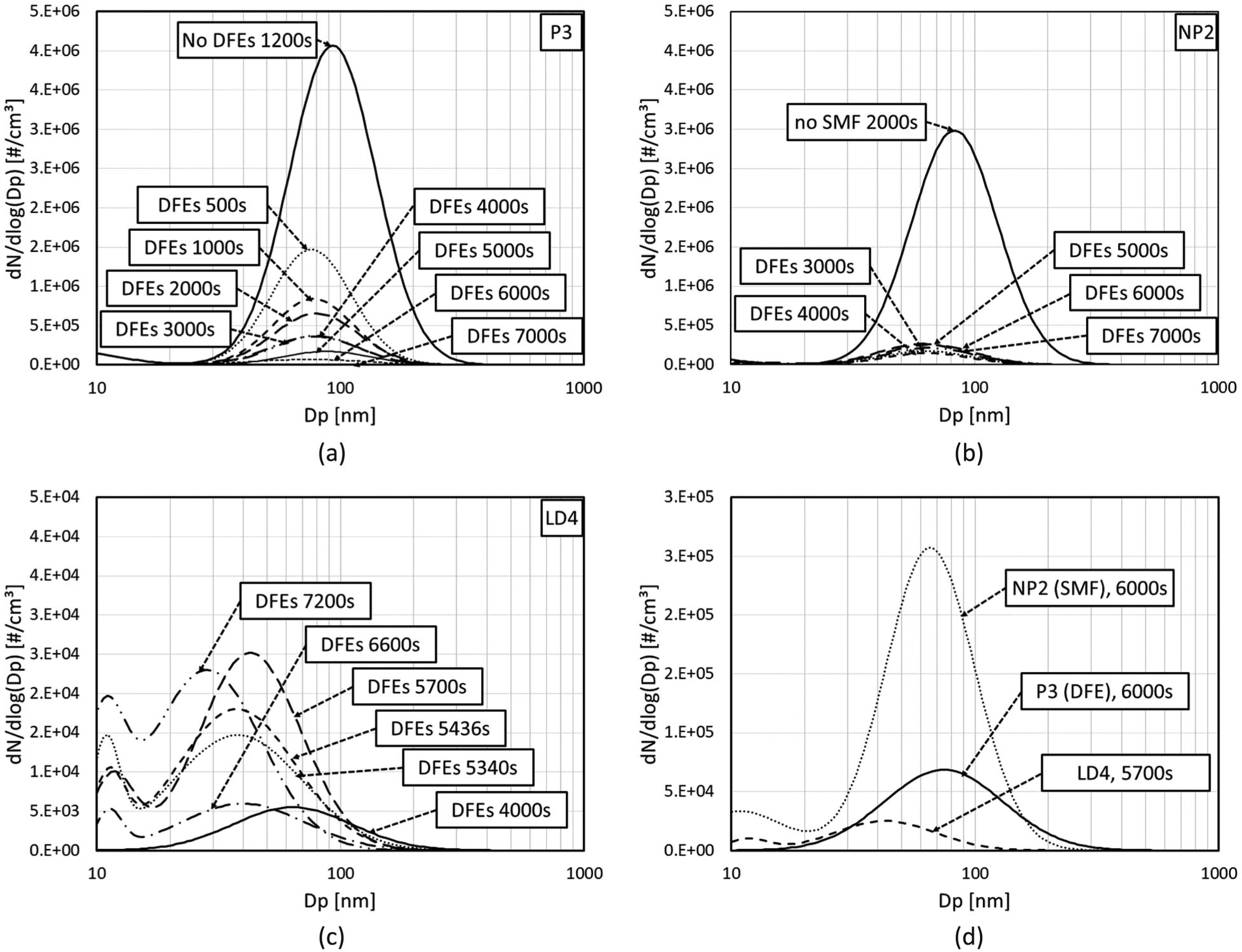

The results of the tests performed with P3 in two configurations, P3 and P3 (DFEs), were used to evaluate the effects of the Donaldson P604516 DFEs on aerosols at the DMSS.

The net contribution of P3 (without DFEs) to aerosol number concentrations was averaged over the 1,150-sec period, between 600 and 1,750 sec of the test. Since the number concentrations of aerosols at the DMSS gradually decreased during the P3 (DFEs) test (Figure 2), the net average contributions of P3 (DFEs) to aerosol number concentrations were calculated for the six different 600-sec intervals between 600 and 3,600 sec of the test. Due to a power failure that inhibited collection of the FMPS data at the UMSS for the period between 3,600 sec and 7,200 sec of the P3(DFEs) test, the 600-sec averages were not calculated for the second half of the test.

The aerosols contributed by P3 (DFEs) were mostly distributed in the agglomeration modes (Figure 8a). Few of those aerosols were found in nucleation modes. The CMDs for agglomeration modes contributed by the engine in P3 were somewhat smaller when that vehicle was tested with the DFEs than when that same vehicle was tested without those in the filtration systems (Figure 8 and Table 6).

Figure 8.

Size distributions of aerosols measured with FMPS at the downstream measurement and sampling station (DMSS) at selected time instances at actual ventilation rates for: (a) P3 and P3 (DFEs) tests, (b) of NP2 and NP2 (SMF) tests, (c) LD4, and (d) P3 (DFEs), NP2 (SMF), and LD4.

Table 6.

Statistical parameters including CMD, σ, and total concentrations for size distributions of aerosols measured with FMPS at the downstream measurement and sampling station (DMSS) at selected instances at actual ventilation rates for distributions shown in Figure 8.

| Nucleation Mode | Accumulation Mode | ||||||

|---|---|---|---|---|---|---|---|

| Vehicle (Exhaust Configuration) | Time Instance, s |

CMD, nm |

σ – |

Total Conc., #/cm3 |

CMD, nm |

σ – |

Total Conc., #/cm3 |

| P3 | 1,200 | 8.2 | 1.520 | 7.31E + 04 | 93.1 | 1.500 | 1.80E + 06 |

| P3 (DFEs) | 500 | 76.1 | 1.460 | 6.06E + 05 | |||

| 1,000 | 77.6 | 1.460 | 3.47E + 05 | ||||

| 2,000 | 79.7 | 1.490 | 2.84E + 05 | ||||

| 3,000 | 78.2 | 1.510 | 1.63E + 05 | ||||

| 4,000 | 79.5 | 1.490 | 1.60E + 05 | ||||

| 5,000 | 88.1 | 1.510 | 7.67E + 04 | ||||

| 6,000 | 74.3 | 1.750 | 4.18E + 04 | ||||

| 7,000 | 1.1 | 2.390 | 1.86E + 04 | 104.1 | 1.500 | 3.30E + 03 | |

| NP2 | 2,000 | 2.8 | 1.880 | 3.22E + 05 | 82.6 | 1.500 | 1.32E + 06 |

| NP2 (SMF) | 3,000 | 4.9 | 1.850 | 2.23E + 04 | 63.5 | 1.500 | 7.68E + 04 |

| 4,000 | 4.9 | 1.890 | 2.17E + 04 | 64.0 | 1.500 | 6.52E + 04 | |

| 5,000 | 60.7 | 1.500 | 1.17E + 05 | ||||

| 6,000 | 10.7 | 1.540 | 1.58E + 04 | 65.5 | 1.520 | 1.17E + 05 | |

| 7,000 | 11.7 | 1.270 | 3.41E + 03 | 65.6 | 1.520 | 9.76E + 04 | |

| LD4 | 4,000 | 63.5 | 1.750 | 3.36E + 03 | |||

| 5,340 | 10.9 | 1.140 | 1.85E + 03 | 37.9 | 1.840 | 9.75E + 03 | |

| 5,436 | 11.2 | 1.160 | 1.44E + 03 | 37.6 | 1.740 | 1.09E + 04 | |

| 5,700 | 11.7 | 1.220 | 2.05E + 03 | 42.7 | 1.610 | 1.30E + 04 | |

| 6,600 | 11.2 | 1.130 | 6.33E + 02 | 39.8 | 1.790 | 3.79E + 03 | |

| 7,200 | 10.7 | 1.210 | 3.21E + 03 | 28.3 | 1.680 | 1.30E + 04 | |

The efficiency of the evaluated DFEs in curtailing aerosols by number was found to be between 76.5% (600–1,200 sec) and 92.0% (3,000–3,600 sec). Apparently, the efficiency of the tested DFEs improved with the accumulation of operating time and the buildup of diesel particulate matter in the filtration media. Taking into consideration that concentrations of aerosols at the DMSS further decreased after 3,600 sec in the test (Figure 2), one could hypothesize that the efficiency of the elements increased further during the second part of the P3 (DFEs) test. The overall reduction in the net EC concentrations by DFEs, averaged over a 14,940-sec sampling time, was approximately 95%. These results are in agreement with previous findings (Bugarski et al. 2009; 2011) that showed that after a “de-greening” period, the same type of DFEs are effective in removing aerosols by number and by mass.

It is important to note that P3 (DFEs), the vehicle equipped with filtration systems with dry heat exchanger and DFEs, contributed on average 10.1 and 11.9 times less to number concentrations of aerosols at the DMSS than P1 and P2, the vehicles equipped with water scrubbers but not with DFEs, respectively. Similarly, P3 (DFEs) contributed on average 11.1 and 15.4 times less to the EC mass concentrations than P1 and P2, respectively.

Sintered metal filter (SMF) system

The results of the tests performed with NP2 in two configurations, NP2 (muffler) and NP2 (SMF), were used to assess the effects of the SMF system. For the baseline test, the SMF system on NP2 was replaced with a muffler, and the additive dosing system was disabled. For the main test, the SMF system was fully functional. The net contributions of NP2 (muffler) and NP2 (SMF) to aerosol number concentrations were averaged over the periods between 600 and 2,400 sec and 600 and 3,600 sec of the corresponding tests.

For both configurations, the majority of aerosols were distributed in the agglomeration modes (Figure 8b and Table 6). The log-normal curves fitted to the data for both configurations indicate that smaller fractions of aerosols were in nucleation modes with CMDs smaller than 12 nm (Table 6). The CMDs for the agglomeration modes contributed by the engine in NP2 were somewhat smaller when that vehicle was tested with the SMF than when that same vehicle was tested with the muffler (Figure 8 and Table 6).

When retrofitted with the SMF system, the NP2 contributed 96 and 93 percent less to the EC concentrations and aerosol number concentrations, respectively. The number concentrations of aerosols during the NP2 (SMF) test were steady throughout duration of the test (Figure 2), indicating that the removal efficiency of the system did not change with accumulation of DPM in the filter element. Those results corroborate findings from the evaluation of the similar SMF system in the laboratory (Bugarski et al. 2016).

DOC/DPF-equipped EPA tier 4 final power package

The results of the tests performed with LD4 were used to assess the effects of contemporary DOC/DPF-equipped engines that meet EPA Tier 4 standards (40 CFR Parts 9, 69, et al.). Bimodal distributions, with the majority of aerosols in agglomeration mode, characterized aerosols measured during the LD4 test (Figure 8c and Table 6). The CMDs of the agglomeration mode aerosols were smaller than those observed for the other filtered vehicles (Figure 8d). The CMDs for the nucleation mode aerosols were around 11 nm. The LD4 contributed less to EC mass concentrations and number concentrations of aerosols than any other tested LD or HD vehicles (Figures 6 and 7).

Conclusion

The concentrations and size distributions of aerosols contributed by tested vehicles were found to depend on the engine design and operating conditions. The aerosols contributed by the engines in tested HD and LD vehicles were predominantly distributed in agglomeration modes. The presence of nucleation mode aerosols was evident for the vehicles operated with DPFs and DFEs. The permissible and non-permissible HD vehicles powered by engines that were not retrofitted with filtration systems (P1, P2, NP1, and NP3) were found to be, by a large margin, the highest contributors to EC mass and aerosol number concentrations. The moderate differences in contributions of the vehicles powered by EPA pre-Tier (P1 and P2) and EPA Tier 3 engines (NP1 and NP2) to the number and EC concentrations indicate that repowering vehicles with EPA Tier 3 would not result in sizable reductions in DPM concentrations in mine air. The reductions would be expected if various filtration technologies were to be more widely implemented. The filtration system with DFEs was found to be effective in curtailing the contribution of P3. However, data indicated that there is potential for improvement in efficiency of DFEs. The contribution of permissible vehicles equipped with water scrubbers to EC mass and aerosol number concentrations can be reduced if those vehicles are retrofitted with filtration systems that use tested or similar DFEs. A number of similar systems have been fitted to permissible HD underground coal mining vehicles that used to be equipped only with the water scrubbers (MSHA 2020). The evaluated SMF system was found to be an effective technology in reducing the contribution of the HD non-permissible diesel-powered vehicle NP2. Following the study, similar systems were retrofitted to NP1 and NP3 to reduce the contribution to EC mass and aerosol number concentrations.

The contributions of tested LD vehicles to total number and EC mass concentrations were found to be lower than those of tested HD vehicles. However, due to their substantial presence in operations (Rubeli et al. 2004), LD vehicles could potentially contribute to concentrations of diesel aerosols in underground mines. The alternative vehicles (LD3) to the old-style LD personnel carrier (LD1) contributed less to EC mass concentrations, but almost equally to the number concentrations of diesel aerosols in the mine air. The other alternative vehicle to LD1 (LD2) contributed more to the EC mass and total number concentrations. Only the LD vehicle powered by a DPF-equipped EPA Tier 4f engine (LD4) did not contribute measurably to EC mass and aerosol number concentrations in the mine air.

The limited set of data collected in this study indicates that the physical properties of diesel aerosols contributed by modern technology engines are different than those of diesel aerosols contributed by older technology diesel engines. More testing is needed to capture the effects of different emissions solutions on properties of aerosols contributed by modern technology engines.

Footnotes

This work was authored as part of the Contributor’s official duties as an Employee of the United States Government and is therefore a work of the United States Government. In accordance with 17 U.S.C. 105, no copyright protection is available for such works under U.S. Law.

Publisher's Disclaimer: Disclaimer

Publisher's Disclaimer: The findings and conclusions in this paper are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. Mention of company names or products does not constitute endorsement by NIOSH.

References

- Attfield MD, Schleiff PL, Lubin JH, Blair A, Stewart PA, Vermeulen R, Coble JB, Silverman DT. 2012. The Diesel Exhaust in Miners Study: a cohort mortality study with emphasis on lung cancer. J. Natl. Cancer Inst 104(11): 869–883. doi: 10.1093/jnci/djs035 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bugarski A, Barone T. 2016. Controlling Exposure of Underground Coal Miners to Diesel Aerosols. Paper presented at: 22nd Annual MDEC Conference; Toronto, Ontario, Canada, October 4–6. [Google Scholar]

- Bugarski AD, Cauda E, Janisko SJ, Hummer JA, Patts LD. 2010. Aerosols emitted in underground mine air by diesel engine fueled with biodiesel. J. Air Waste Manag. Assoc 60(2):237–244. doi: 10.3155/1047-3289.60.2.237 [DOI] [PubMed] [Google Scholar]

- Bugarski AD, Cauda EG, Janisko SJ, Patts LD, Hummer JA, Terrillion T, Keifer J. 2012. Isolated zone evaluation of the Tier 4i engine equipped with SCR system. In the Proceeding of 14th United States/North American Mine Ventilation Symposium, Calizaya F and Nelson MG (eds.). Salt Lake City, UT, June 17–20, pp. 205–212. [Google Scholar]

- Bugarski AD, Hummer JA, Miller A, Patts LD, Cauda EG, Stachulak JS. 2016. Emissions from a diesel engine using Fe-based fuel additives and sintered metal filtration system. ANNHYG. 60(2):252–262. doi: 10.1093/annhyg/mev071 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bugarski AD, Janisko SJ, Cauda EG, Patts LD, Hummer JA, Westover C, Terrillion T. 2014. Aerosols and criteria gases in an underground mine that uses FAME biodiesel blends. Ann Occup Hyg 58(8):971–982. doi: 10.1093/annhyg/meu049 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bugarski AD, Schnakenberg GH Jr, Hummer JA, Cauda E, Janisko SJ, Patts LD. 2009. Effects of diesel exhaust after-treatment devices on concentrations and size distribution of aerosols in underground mine air. Environ Sci Technol 43(17):6737–6743. doi: 10.1021/es9006355 [DOI] [PubMed] [Google Scholar]

- Bugarski AD, Schnakenberg GH Jr, Hummer JA, Cauda E, Janisko SJ, Patts LD. 2011. Evaluation of high-temperature disposable filter elements in an experimental underground mine. Soc. Mining Met. Explor. Trans 330: 373–382. [Google Scholar]

- Bugarski AD, Schnakenberg GH Jr, Mischler SE, Noll JD, Patts LD, Hummer JA. 2006b. Effectiveness of selected diesel particulate matter control technologies for underground mining applications: isolated zone study, 2004. (DHHS (NIOSH) Publication No. 2006–138, RI9668). Pittsburgh, PA: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. [Google Scholar]

- Bugarski AD, Schnakenberg GH Jr, Noll JD, Mischler SE, Patts LD, Hummer JA, Vanderslice SE. 2006a. Effectiveness of selected diesel particulate matter control technologies for underground mining applications: isolated zone study, 2003. (DHHS (NIOSH) Publication No. 2006–126, RI9667). Pittsburgh, PA: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. [Google Scholar]

- Cao T, Durbin TD, Russell RL, Cocker D II, Scora G, Maldonado H, Johnson KC. 2016. Evaluations of in-use emission factors from off-road construction equipment. Atmos. Environ 147:234–245. doi: 10.1016/j.atmosenv.2016.09.042 [DOI] [Google Scholar]

- 30 CFR Part 57.5060. 2018. Limit on concentration of diesel particulate matter. 30 CFR, Part 57.5060: p. 372–373. [Google Scholar]

- 30 CFR Part 7. 2020. Diesel engines intended for use in underground coal mines 30 C.F.R., Part 7 Subpart E: p. 28–46. [Google Scholar]

- 30 CFR Part 75. 1907. Diesel-powered equipment intended for use in underground coal mines. 30 C.F.R., Part 75; 1907: p. 671 2018). [Google Scholar]

- 30 CFR Part 75. 1908. Nonpermissible diesel-powered equipment; categories. 30 C.F.R., Part 75; 1908: p. 671–672. 2018). [Google Scholar]

- 40 CFR Parts 9, 69, et al. 2004. Control of emissions of air pollution from nonroad diesel engines and fuel; final rule. 40 C.F.R., Parts 9, 69, 80, 86, 89, 94, 1039, 1048, 1051, 1065, and 1068: p. 38957–39273. [Google Scholar]

- EPA. 2016. Nonroad compression-ignition engines: exhaust emissions standards. United States Environmental Protection Agency. Office of transportation and Air Quality. EPA-420-B-16–022. March. [Google Scholar]

- EU. 2004. Measures against the emission of gaseous and particulate pollutants from internal combustion engines to be installed in non-road mobile machinery. Directive 2004/26/EC of the European Parliament and of the Council. Official Journal of the European Union. OJ L. 146 :1–107. [Google Scholar]

- EU. 2016. Requirements relating to gaseous and particulate pollutant emission limits and type-approval for internal combustion engines for non-road mobile machinery, amending Regulations (EU) No 1024/2012 and (EU) No 167/2013, and amending and repealing Directive 97/68/EC Regulation (EU) 2016/1628 of the European Parliament and of the Council. Official Journal of the European Union. OJ L. 252:53–117. [Google Scholar]

- Grigoratos T, Fontaras G, Giechaskiel B, Zacharof N. 2019. Real world emissions and performance of heavy-duty Euro VI diesel vehicles. Atmos. Environ 201:348–359. doi: 10.1016/j.atmosenv.2018.12.042 [DOI] [Google Scholar]

- Herner JD, Hu S, Robertson WH, Huai T, Chang MCO, Rieger P, Ayala A. 2011. Effect of advanced aftertreatment for PM and NOx reduction on heavy-duty diesel engine ultrafine particle emissions. Environ Sci Technol 45(6):2413–2419. doi: 10.1021/es102792y [DOI] [PubMed] [Google Scholar]

- IARC. 2012. Diesel engine exhaust carcinogenic International Agency for Research on Cancer; IARC Press Release No. 213, June 12, World Health Organization, 2012. [Google Scholar]

- Johnson T, Caldow R, Pöcher A, Mirme A, Kittelson D. 2004. A new electrical mobility particle sizer spectrometer for engine exhaust particle measurements. SAE Technical Paper 2004–01-1341.

- Khalek IA, Blanks MG, Merritt PM, Zielinska B. 2015. Regulated and unregulated emissions from modern 2010 emissions-compliant heavy-duty on highway diesel engines. J. Air Waste Manage. Assoc 65(8):987–1001. doi: 10.1080/10962247.2015.1051606 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Khalek IA, Bougher TL, Merritt PM, Zielinska B. 2011. Regulated and unregulated emissions from highway heavy-duty diesel engines complying with U.S. Environmental Protection Agency 2007 emissions standards. J. Air Waste Manage. Assoc 61(4):427–442. doi: 10.3155/1047-3289.61.4.427 [DOI] [PubMed] [Google Scholar]

- Lucachick G, Avenido A, Watts W, Kittelson D, Northrop W. 2014. Efficacy of in-cylinder control of particulate emissions to meet current and future regulatory standards SAE Technical Paper 2014–01-1597. doi: 10.4271/2014-01-1597 [DOI]

- Mills NL, Miller MR, Lucking AJ, Beveridge J, Flint L, Boere AJF, Fokkens PH, Boon NA, Sandstrom T, Blomberg A, et al. 2011. Combustion-derived nanoparticulate induces the adverse vascular effects of diesel exhaust inhalation. Eur. Heart J 32(21):2660–2671. doi: 10.1093/eurheartj/ehr195 [DOI] [PMC free article] [PubMed] [Google Scholar]

- MSHA. 2020. National diesel inventory lookup. Mine Safety and Health Administration (MSHA) [accessed 2020 Jan 8]. https://www.msha.gov/support-resources/forms-online-filing/2018/05/23/manageupdate-diesel-inventory. [Google Scholar]

- NIOSH 2016. Monitoring diesel exhaust in the workplace In NIOSH Manual of Analytical Methods (NMAM), 5thEdition, Chapter DL, Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. [Google Scholar]

- Noll JD, Timko RJ, McWilliams LJ, Hall P, Haney R. 2005. Sampling results of the improved SKC® diesel particulate matter cassette. J. Occup. Environ. Hyg 2(1):29–37. doi: 10.1080/15459620590900320 [DOI] [PubMed] [Google Scholar]

- Peters S, de Klerk N, Reid A, Fritschi L, Musk A(B), Vermeulen R. 2017. Quantitative levels of diesel exhaust exposure and the health impact in the contemporary Australian mining industry. Occup Environ Med 74(4): 282–289. doi: 10.1136/oemed-2016-103808 [DOI] [PubMed] [Google Scholar]

- Power MC, Weisskopf MG, Alexeeff SE, Coull BA, Spiro A, Schwartz J. 2011. Traffic-related air pollution and cognitive functions in a cohort of older. Men. Environ. Health. Perspec 119(5):682–687. doi: 10.1289/ehp.1002767 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rubeli B, Gangal M, Butler K, Alder W. 2004. Evaluation of the concentration of light-duty vehicle to the underground atmosphere diesel emissions burden In: Ganguli R, Bandopadhyay S, editors. Proceedings of the 10th U.S./ North American Mine Ventilation Symposium. Leiden, Netherlands: Balkema; p. 99–108. [Google Scholar]

- Ruehl C, Herner JD, Yoon S, Collins JF, Misra C, Na K, Robertson WH, Biswas S, Chang CO, Ayala A. 2015. Similarities and differences between “traditional” and “clean” diesel PM. Emiss Control Sci. Technol 1(1): 17–23. doi: 10.1007/s40825-014-0002-7 [DOI] [Google Scholar]

- Saarikoski S, Teinilä K, Timonen H, Aurela M, Laaksovirta T, Reyes F, V asques Y, Oyola P, Artaxo P, Pennanen AS, et al. 2018. Particulate matter characteristics, dynamics and sources in an underground mine. Aerosol. Sci. Technol 52(1):114–122. doi: 10.1080/02786826.2017.1384788 [DOI] [Google Scholar]

- Silverman DT, Samanic CM, Lubin JH, Blair AE, Stewart PA, Vermeulen R, Coble JB, Rothman N, Schleiff PL, Travis WD, et al. 2012. The Diesel Exhaust in Miners Study: A nested case-control study of lung cancer and diesel exhaust. J. Natl. Cancer Inst 104(11):855–868. doi: 10.1093/jnci/djs034 [DOI] [PMC free article] [PubMed] [Google Scholar]

- The Raw Materials Group and Parker Bay Company. 2012. Market analysis: Underground mining mobile equipment.: September.

- Thiruvengadam A, Besch MC, Carder DK, Oshinuga A, Gautam M. 2012. Influence of real-world engine load conditions on nanoparticle emissions from a DPF and SCR equipped heavy-duty diesel engine. Environ Sci Technol 46(3):1907–1913. doi: 10.1021/es203079n [DOI] [PubMed] [Google Scholar]