Abstract

We considered the magnetized micro polar fluid with hybrid nanomaterial flow over a curved stretching surface. We discussed the effects of single wall carbon nanotube and multiwall carbon nanotube with base fluids (water and propylene glycol). Under the flow assumptions, we developed the mathematical model and applied the boundary layer approximations to reduce the system of partial differential equations. Further, the suitable similarity transformations are applied on the partial differential equations to make dimensionless system. The dimensionless system solved by means of numerical scheme via bvp4c shooting methods. Involving the dimensionless physical parameters effects are highlighted in the form of graphs and tables. Additionally, significant physical quantities i.e. Nusselt number, Couple stress coefficient and Skin friction coefficient are also presented and evaluated numerically. These results are more important which may use in the field of engineering and industrial.

Subject terms: Mathematics and computing, Nanoscience and technology

Introduction

Heat transfer is an essential process of industrial sectors to establish transit of energy in the system. Huge demand of energy in the world has made the process of heat transfer a core task. In recent years a great attention has been gained by nanofluids because of their extensive usage in industrial technologies like paper, medical industry, pharmaceutical industry etc. Nanofluids are composed of nanoparticles (metals, oxides, carbides etc.) with a typical size of less than 100 nm which are dispersed into base fluids (oils, lubricants, ethylene glycol, polymeric solutions, biological fluids etc.). These are the dilute liquid suspensions of nanoparticles which are used to to improve the thermos-physical properties of base liquids and to improve their heat transfer characteristics because the solid particles have a larger thermal conductivity than liquids. The term nanofluids was first coined by Choi1 in 1995.Choi was of opinion that the nanofluids have much better thermal conductivity than base fluids. Nanofluids with carbon nanotubes dispersed in synthetic oil were developed at the forefront by Choi, Eastman2 in 2001.They found that copper and CNT results in elevated thermal conductivity as compared to those of their base fluid without dispersed CNTs. Some efforts in this direction are cited in3–10.

The gratifying results of nanofluids elicited researchers to think about the suspension of different combinations of nanoparticles in the base fluid. This extension of nanofluids gave rise to a remarkable class of fluids called ‘hybrid nanofluids’. When two or more nanoparticles are dispersed in base fluid than a hybrid nanofluid is evolved having intensified thermal conductivity than nanofluids containing a single type of nanoparticle. Many experimental studies have been conducted on this concept. Sadaf and Nadeem11 investigated that hybrid nanofluid Ag-/water provided vibrant improve in heat transfer rate as compared to nanofluid. Li and Xuan12 studied the convective heat transfer and flow characteristics in a tube with constant heat flux at the wall experimentally. Some well written articles are cited in Refs. 13–20.

In accordance with the law of viscosity, fluids are characterized as Newtonian and Non Newtonian fluids. Non Newtonian fluids are those in which shears stress is the function of viscosity that is why these fluids are deprived of regular viscosity. The dairy products such as cheese and butter and biological fluids like blood, etc. with respect to the specific characteristics non Newtonian fluids have a variety of names. Some of them are Casson, micropolar, Jafferly, Oldroyd and Walter’s-B. In this article Non Newtonian micropolar fluid is considered. Micropolar fluids are the fluids with microstructures consisting of rigid particles dealing with micro rotation and dispersed in a viscous medium provided the particle deformation is pushed aside. These fluids have nonsymmetrical stress tensor along with polar fluid’s characteristics. The term micropolar was raised by Eringen et al.21,22. In his theory, he revealed that micropolar fluids are composed of dilute suspensions of rigid micro molecules having individual motion that assist the stress and body movements. Some eminent writings on this concept are highlighted as23,24. Ghadikolaei25 investigated MHD boundary layer analysis for micropolar dusty fluid containing Hybrid nanoparticles (Cu-Al2O3) over a porous medium. Micropolar fluid is interpreted through a porous medium by Cao et al.13. A recently papers have been done by researchers with different aspects of the micropolar fluids see Refs. 8,26–30.

It is an established fact that magnetic field plays a vital role in engineering processes, medical field (MRI, cancer diagnosis, etc.). The effect of induced magnetic field has broad range of applications nowadays. The study of magneto-hydrodynamic fluid has always been an area of keen interest for researchers. Such studies are apposite to magneto-aerodynamics, MHD boundary layer control technologies and nuclear by Koshiba et al.31. Kumari et al.32 investigated the boundary layer flow and heat transfer characteristics on stretching surface with induced magnetic field. The idea of nanoparticles with induced magnetic field for drug delivery is also well focused by many researchers33–41.

Motivated by the aforementioned works, the present study is conducted to examine the impact of the induced magnetic field on heat transfer of steady micropolar hybrid nanofluid flow course towards a curved stretched sheet. Up till now, no attempt has been made for this kind of flow as per the best of researcher’s knowledge. For an ample analysis, common fluid such as water and propylene glycol are taken as base fluids and single and Multiwall carbon nanotubes are considered as nano particles. The system of governing equations is formulated in curvilinear coordinates which is further simplified through similarity analysis. The whole computation is done using bvp4c method in computational software MATLAB.

Thermo-physical hybrid nanoparticles and base fluids

The thermos-physical characteristics of micropolar hybrid nanofluid i.e. viscosity, density, thermal conductivity and volumetric heat capacity are defined by empirical relations as follows:

The following are experimentally determined values of the thermophysical characteristics of base fluids i.e. water and propylene glycol and nanoparticles i.e. single and Multiwall CNTs (Hone42, Ruoff and Lorentz43).

Mathematical Formulation

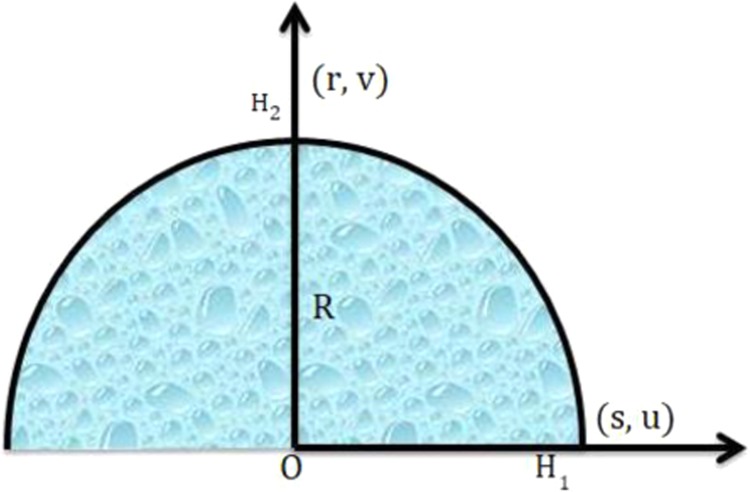

In this investigation a steady, two-dimensional micropolar hybrid nanofluid is considered. For the mathematical description of flow, system of curvilinear coordinates is chosen and sees Fig. 1 Single and Multiwall CNTs are dispersed in water and propylene glycol taken as base fluids over a stretched sheet curved over a ring of radius R. the surface is strained along s-coordinate by applying forces of equal magnitude in the opposite direction. Let be the velocity of stretched surface and r-direction is orthogonal to it. Furthermore, induced magnetic field H is also introduced to discover its effect on heat transfer of the flow. Parallel and normal components of induced magnetic are , while free stream value is taken as is the constant upstream magnetic field which equalizes vanishing at the surface. The surface temperature is considered to be constant throughout nanofluid where A is material constant and . After applying the boundary layer approximations, the continuity equation, the momentum equation, micropolar momentum equation and energy equation take the form (Refs. 44–46)

| 1 |

| 2 |

| 3 |

| 4 |

| 5 |

| 6 |

| 7 |

Figure 1.

Flow of hybrid nanoparticles with base fluids.

Subjected to the boundary conditions

| 8 |

Here are the longitudinal and transverse components of velocity and magnetic field taken in s and r-direction respectively. is spin gradient viscosity as is expressed as , where is micropolar parameter. Also is pressure, is temperature, is slip length, is volumetric heat rate depending upon temperature, is vortex viscosity and is radiative heat flux which can be expressed as

| a |

Here is Stefan-Boltzmann constant and K* is mean proportion constant. Expanding about and neglecting higher powers i.e,

| b |

By applying above mentioned approximations (a) and (b) Eq. (6) turned into

| 9 |

In which and are Prandtl number and Radiation parameter respectively. Following are the similarity transformation used in the analysis

| 10 |

Using above transformations, Eqs. (1) and (2) are identically satisfied and Eqs. (3–7), (9), (10) simplify to

| 11 |

| 12 |

| 13 |

| 14 |

| 15 |

Boundary conditions are transformed as

| 16 |

Here are the dimensionless magnetic parameter, Prandtl number, curvature parameter, heat generation parameter, reciprocal magnetic Prandtl number, slip parameter and dimensionless parameter respectively and are defined as

| 17 |

Differentiating Eq. (12) and using (11) to eliminate pressure, we get the following equation

| 18 |

The pressure profile can be computed from (12) as

| 19 |

Substantial measurable quantities Shear stress and heat flux rate are defined as

| 20 |

where the heat transfer and wall friction along direction is expressed as

| 21 |

The Skin friction coefficient and Nusselt number is evaluated as

| 22 |

| 23 |

where is local Reynold number.

Results and discussion

The magnetized micropolar base fluid with nanoparticles over a curved surface is considered. The system of differential equations is solved through numerical technique. In this segment of problem, the impact of different parameters is examined by means of graphs plotted for numerically calculated velocity, temperature and micro rotation for distinct values of curvature parameter , velocity slip parameter , magnetic parameter , reciprocal magnetic Prandtl number , CNTs volumetric fraction for hybrid fluid and dimensionless parameter . The range of the physical parameters are taken from the literature (see Refs. 44–46). Such numerical values are used in the experimental data. Our results are shown to be the most reliable and has good agreement with the decay literature as shown in Table 1.

Table 1.

Validity of our results with decay when the rest of the physical parameters are zero.

Numerical analysis

Table 2 delineates the strong concentration of Nusslet number and skin friction coefficients for the base fluids water and propylene glycol. The variation of physical parameters use in this study, i.e. and are shown below in Table 2. It is revealed that enhancing curvature parameter results which are declining for both water and propylene glycol. The magnitude of the skin fraction reduced for enhancing the values of curvature parameter . The impact of a reciprocal magnetic Prandtl number is worth noting, increase in leads to increase in for both base fluids and opposite behavior is seen for . The neutral behavior of skin friction coefficient is examined when is increased, i.e.t remained constant for both water and propylene glycol, but Nusselt number indicated a decreasing behavior for both base fluids. It is demonstrated that decreases for water and increases for propylene glycol as the value of upsurges where as Nusselt number increases for propylene glycol and declines for water when is enhanced. Table 2 disclosed that the escalated value of cause to elevate for both base fluids while presents no variation. The impact of enhancing is that skin friction coefficient larger for propylene glycol and also for water whereas. depicts an increase for water and a decrement for propylene glycol. The slip parameter has a vital impact on skin friction and Nusselt number. When is escalated then decreases for both base fluids and results in drastic increament. Increase in value of display a sharp reduction in for water and propylene glycol while upswings for both base fluids. Lastly, it is reported that skin friction coefficient upturns for water and propylene glycol as micropolar parameter increases. On the other side Nusselt number declines for water and grows for propylene glycol.

Table 2.

Numerical outcomes of and when .

| Water | Propylene glycol | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.4 | 0.5 | 0.5 | 0.4 | 0.5 | 0.5 | 0.4 | 0.05 | 0.8 | 3.2667 | −1.1789 | 3.2256 | −1.1879 |

| 0.6 | — | — | — | — | — | — | — | — | 2.8465 | −1.1579 | 2.8014 | −1.1769 |

| 0.8 | — | — | — | — | — | — | — | — | 2.1095 | −1.1479 | 2.0809 | −1.1579 |

| 0.8 | 0.1 | — | — | — | — | — | — | — | 1.2082 | −0.6538 | 0.9514 | −0.5714 |

| — | 0.3 | — | — | — | — | — | — | — | 1.3324 | −0.7640 | 1.3144 | −0.7640 |

| — | 0.5 | — | — | — | — | — | — | — | 2.1095 | −1.1486 | 2.0809 | −1.1486 |

| — | 0.5 | 0.2 | — | — | — | — | — | — | 2.1095 | −0.8484 | 2.0809 | −0.8484 |

| — | — | 0.3 | — | — | — | — | — | — | 2.1095 | −0.9484 | 2.0809 | −0.9485 |

| — | — | 0.4 | — | — | — | — | — | — | 2.1095 | −1.0485 | 2.0809 | −1.0485 |

| — | — | 0.5 | — | — | — | — | — | — | 2.1095 | −1.1486 | 2.0809 | −1.1486 |

| — | — | 0.5 | 0.1 | — | — | — | — | — | 2.2223 | −1.1479 | 2.0867 | −1.1486 |

| — | — | — | 0.2 | — | — | — | — | — | 2.1190 | −1.1479 | 2.0906 | −1.1479 |

| — | — | — | 0.3 | — | — | — | — | — | 2.1099 | −1.1479 | 2.0938 | −1.1479 |

| — | — | — | 0.4 | 0.1 | — | — | — | — | 2.0325 | −1.1486 | 2.0039 | −1.1486 |

| — | — | — | — | 0.3 | — | — | — | — | 2.0793 | −1.1486 | 2.0514 | −1.1486 |

| — | — | — | — | 0.5 | — | — | — | — | 2.1095 | −1.1486 | 2.0809 | −1.1486 |

| — | — | — | — | 0.5 | 0.1 | — | — | — | 2.1095 | −1.1486 | 1.8078 | −0.9596 |

| — | — | — | — | — | 0.2 | — | — | — | 2.1095 | −1.1486 | 2.0809 | −1.1486 |

| — | — | — | — | — | 0.3 | — | — | — | 2.0782 | −1.1489 | 2.0809 | −1.1486 |

| — | — | — | — | — | 0.4 | — | — | — | 2.0681 | −1.1479 | 2.0809 | −1.1486 |

| — | — | — | — | — | 0.5 | 0.1 | — | — | 2.2828 | −1.1489 | 2.5369 | −1.1489 |

| — | — | — | — | — | — | 0.3 | — | — | 2.2459 | −1.1485 | 2.3203 | −1.1483 |

| — | — | — | — | — | — | 0.5 | — | — | 2.0470 | −1.1486 | 2.0194 | −1.1482 |

| — | — | — | — | — | — | 0.4 | 0.01 | 2.1933 | −1.2288 | 2.1682 | −1.2288 | |

| — | — | — | — | — | — | — | 0.03 | 2.1498 | −1.1872 | 2.1229 | −1.1872 | |

| — | — | — | — | — | — | — | 0.05 | 2.1095 | −1.1486 | 2.0809 | −1.1486 | |

| — | — | — | — | — | — | — | 0.05 | 0.4 | 1.6976 | −1.1483 | 1.4668 | −1.1489 |

| — | — | — | — | — | — | — | — | 0.6 | 1.9218 | −1.1485 | 2.0157 | −1.1483 |

| — | — | — | — | — | — | — | — | 0.8 | 2.1095 | −1.1486 | 2.0809 | −1.1481 |

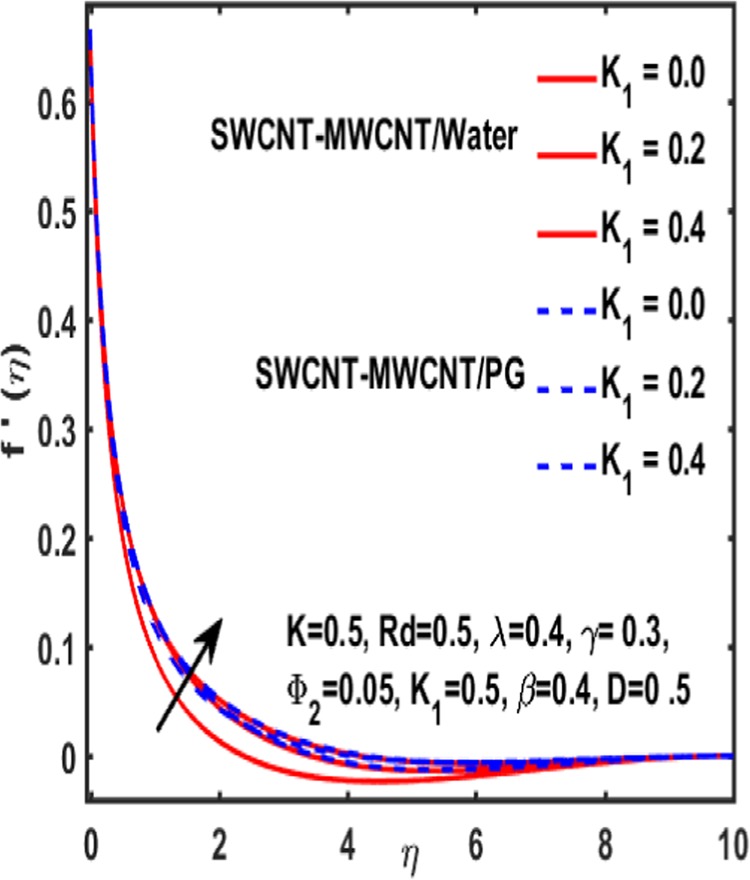

Velocity distribution

The effect of curvature parameter , velocity slip parameter , magnetic parameter , reciprocal magnetic Prandtl number , solid nanoparticle , dimensionless parameter and material parameter are studied through graphs drawn in Figs. 2–6. Figure 2 reveals the consequence of increasing on velocity profile. It is observed that an increment in magnetic parameter declines the velocity function for both types of base fluids i.e. water and Propylene glycol. The effect of dimensionless parameter on fluid flow is examined through Fig. 3. From this figure it is noted that there is a decrement in velocity profile whenever is increased. Figure 4 is drawn to depict the behavior of velocity when an uplift is done in curvature parameter . This graph indicates that velocity profile accelerates with an increase in curvature parameter. Figure 5 is plotted to explain the impact of material parameter on velocity profile of the hybrid nano fluid flow. A downfall in velocity function is observed when material parameter is increased. It is witnessed that presence of induced magnetic field plays a vital role in accelerating fluid flow. Figure 6 is plotted to demonstrate the effect of nanoparticle volume fraction on velocity.

Figure 2.

Variation of on velocity.

Figure 6.

Impact of on velocity.

Figure 3.

Variation of on velocity.

Figure 4.

Variation of k on velocity.

Figure 5.

Variation of on velocity.

Nomanclature

| Curvature parameter | Thermal conductivity of fluid | ||

| Velocity slip | Thermal conductivity of nanofluid | ||

| Micropolar parameter | Thermal conductivity of hybrid nanofluid | ||

| Radiation parameter | Viscosity of hybrid nanofluid | ||

| Dimensionless parameter | Viscosity of nanofluid | ||

| Solid nanoparticle | Heat capacity of nanofluid | ||

| Reciprocal Magnetic Prandtl number | thermal diffusivity of hybrid nanofluid | ||

| Magnetic parameter | thermal diffusivity of nanofluid | ||

| Heat source parameter | Hybrid nanofluid kinematic Viscosity | ||

| Microgyration parameter | Heat capacity of hybrid nanofluid |

Temperature distribution

Figures 7–12 are drawn for the ample interpretation of fluid flow temperature when CNTs are dispersed in micropolar hybrid nanofluid. In these figures blue lines depict the results for water and red lines represents propylene glycol respectively. The effect of heat generation parameter D on the temperature function which is displayed in Fig. 7. It is witnessed that decelerating behavior is shown by fluid temperature as the heat generation parameter up surges. Figure 8 is plotted to represent the impact of dimensionless parameter on temperature gradient of fluid flow. It is observed that temperature profile is decreasing function of . Figure 9 demonstrates the effect of curvature parameter on temperature. It is revealed that temperature is enhanced with an increasing value of curvature parameter. The role of slip parameter is studied through Fig. 10 which demonstrates that enhancing the slip parameter results in drastic increase in temperature profile in case of propylene glycol and a decrease is reported in temperature when water is considered as base fluid. Figure 11 reveals the influence of on the temperature gradient. It is seen that temperature function declines due to higher values of solind particles because the thermal boundary layer thikness redued. The impacts of on the temperature gradienct which see in Fig. 12. The temperature gradient declines due to higher values of .

Figure 7.

Variation of D on temperature.

Figure 12.

Influence of on .

Figure 8.

Influence of on temperature.

Figure 9.

Variation of k on temperature.

Figure 10.

Impact of K on temperature.

Figure 11.

Impact of on .

Micropolar rotation distribution

The influence of significant parameters on micropolar rotation is analyzed through Fig. 13–18. Figure 13 is plotted to represent the influence of magnetic parameter on and reveals that micropolar rotation is a declining function of magnetic parameter. The effect of material parameter is studied through Fig. 14. It shows that micropolar rotation decreases for an increasing value of . Figure 15 illustrates the influence of reciprocal magnetic Prandtl number on . It is witnessed that for water the micropolar rotation is enhanced as material parameter increases while a decrement is observed in case of propylene glycol as the value of up surges. The impact of curvature parameter on is examined through Fig. 16. It explains that curvature parameter enhances the curviness of micropolar rotation . Figure 17 is plotted to show the effect of volumetric fraction of nanoparticle on . It is observed that micropolar rotation increases as volumetric fraction enhances. Finally, the impact of on micropolar rotation is demonstrated in Fig. 18. It is reported that enhancing the value of reciprocal magnetic Prandtl number results in shrinkage of curviness of .

Figure 13.

Variation of β on .

Figure 18.

Influence of on .

Figure 14.

Impact of on .

Figure 15.

Influence of on .

Figure 16.

Impact of k on .

Figure 17.

Variation of on .

Effect on induced magnetic field

Here the implications of various parameters like curvature parameter , magnetic parameter , reciprocal magnetic Prandtl number , CNTs volumetric fraction for hybrid fluid , dimensionless parameter and material parameter on induced magnetic field are examined and reported through Figs. 19–23. Consequence of increasing dimensionless parameter is depicted in Fig. 19. It is revealed that induced magnetic field increases as value of upsurges. Figure 20 is plotted to demonstrate the impact of material parameter on magnetic field which shows that a induced magnetic field is escalated with the increasing value of . in order to determine the influence of volumetric fraction on Fig. 21 is drawn. This figure illustrates that enhancing the value of lead to a declining behavoiur of induced magnetic field i.e. curviness decreases. Fig. 22 depicts the variation of on induced magnetic field. It is reported that induced magnetic field curve mounts drastically as value of grows. Finally, the influence of curvature parameter on is shown in Fig. 23. It describes that a sharp uplift is sight in curviness of induced magnetic field as the value of is mounted.

Figure 19.

Influence of on .

Figure 23.

Impact of k on .

Figure 20.

Influence of on .

Figure 21.

Influence of on .

Figure 22.

Influence of on .

Conclusions

The present study was conducted to analyze the role of induced magnetic field on microolar hybrid nanofluid flowing towards a stretching curved surface. Single and multiwall CNTs are considered as nanoparticles whereas water and propylene glycol are taken as base fluids. Bvp4c method is selected for mathematical computation of equation obtained from similarity transform. The most convinent and impartant resulst are gained which presented below

The micropolar rotation increases as volumetric fraction enhances.

The enhancing the value of lead to a declining behavoiur of induced magnetic field.

The micropolar rotation increases as volumetric fraction enhances.

Increase in value of display a sharp reduction in for water and propylene glycol while enhancing for both base fluids

Author contributions

Nadeem Abbas developed the mathematical model. Farrah Sajid help in the manuscript to write and find the numerical results. Prof. Dr. Sohail Nadeem has introduced the concept and guide fomulation while Dr. A.M. Al-Hanaya helped in the revised manuscript and shared funding with us.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Choi, S. U. & Eastman, J. A. Enhancing thermal conductivity of fluids with nanoparticles (No. ANL/MSD/CP-84938; CONF-951135-29). Argonne National Lab., IL (United States) (1995).

- 2.Eastman JA, Choi SUS, Li S, Yu W, Thompson LJ. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Applied physics letters. 2001;78(6):718–720. doi: 10.1063/1.1341218. [DOI] [Google Scholar]

- 3.Hosseinzadeh K, Amiri AJ, Ardahaie SS, Ganji DD. Effect of variable lorentz forces on nanofluid flow in movable parallel plates utilizing analytical method. Case studies in thermal engineering. 2017;10:595–610. doi: 10.1016/j.csite.2017.11.001. [DOI] [Google Scholar]

- 4.Derakhshan R, Shojaei A, Hosseinzadeh K, Nimafar M, Ganji DD. Hydrothermal analysis of magneto hydrodynamic nanofluid flow between two parallel by AGM. Case Studies in Thermal Engineering. 2019;14:100439. doi: 10.1016/j.csite.2019.100439. [DOI] [Google Scholar]

- 5.Zangooee MR, Hosseinzadeh K, Ganji DD. Hydrothermal analysis of MHD nanofluid (TiO2-GO) flow between two radiative stretchable rotating disks using AGM. Case Studies in Thermal Engineering. 2019;14:100460. doi: 10.1016/j.csite.2019.100460. [DOI] [Google Scholar]

- 6.Hosseinzadeh K, et al. Entropy generation analysis of (CH2OH) 2 containing CNTs nanofluid flow under effect of MHD and thermal radiation. Case Studies in Thermal Engineering. 2019;14:100482. doi: 10.1016/j.csite.2019.100482. [DOI] [Google Scholar]

- 7.Ghadikolaei, S. S., Hosseinzadeh, K. & Ganji, D. D. Investigation on Magneto Eyring-Powell nanofluid flow over inclined stretching cylinder with nolinear thermal radiation and Joule heating effect. World Journal of Engineering (2019).

- 8.Sheikholeslami M, Shah Z, Shafee A, Khan I, Tlili I. Uniform magnetic force impact on water based nanofluid thermal behavior in a porous enclosure with ellipse shaped obstacle. Scientific reports. 2019;9(1):1196. doi: 10.1038/s41598-018-37964-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Safaei MR, et al. Evaluating the effect of temperature and concentration on the thermal conductivity of ZnO-TiO2/EG hybrid nanofluid using artificial neural network and curve fitting on experimental data. Physica A: Statistical Mechanics and its Applications. 2019;519:209–216. doi: 10.1016/j.physa.2018.12.010. [DOI] [Google Scholar]

- 10.Nadeem, S., Abbas, N., Elmasry, Y. & Malik, M. Y. Numerical analysis of water based CNTs flow of micropolar fluid through rotating frame. Computer Methods and Programs in Biomedicine, 105194 (2019). [DOI] [PubMed]

- 11.Sadaf H, Nadeem S. Influences of slip and Cu-blood nanofluid in a physiological study of cilia. Computer methods and programs in biomedicine. 2016;131:169–180. doi: 10.1016/j.cmpb.2016.04.008. [DOI] [PubMed] [Google Scholar]

- 12.Li, Q., & Xuan, Y. Convective heat transfer performances of fluids with nano-particles. In International Heat Transfer Conference Digital Library. Begel House Inc (2002).

- 13.Ghadikolaei SS, Yassari M, Sadeghi H, Hosseinzadeh K, Ganji DD. Investigation on thermophysical properties of Tio2–Cu/H2O hybrid nanofluid transport dependent on shape factor in MHD stagnation point flow. Powder technology. 2017;322:428–438. doi: 10.1016/j.powtec.2017.09.006. [DOI] [Google Scholar]

- 14.Ghadikolaei SS, Hosseinzadeh K, Ganji DD. Investigation on ethylene glycol-water mixture fluid suspend by hybrid nanoparticles (TiO2-CuO) over rotating cone with considering nanoparticles shape factor. Journal of Molecular Liquids. 2018;272:226–236. doi: 10.1016/j.molliq.2018.09.084. [DOI] [Google Scholar]

- 15.Ghadikolaei SS, Hosseinzadeh K, Hatami M, Ganji DD, Armin M. Investigation for squeezing flow of ethylene glycol (C2H6O2) carbon nanotubes (CNTs) in rotating stretching channel with nonlinear thermal radiation. Journal of Molecular Liquids. 2018;263:10–21. doi: 10.1016/j.molliq.2018.04.141. [DOI] [Google Scholar]

- 16.Ghadikolaei SS, Hosseinzadeh K, Ganji DD. Investigation on three dimensional squeezing flow of mixture base fluid (ethylene glycol-water) suspended by hybrid nanoparticle (Fe3O4-Ag) dependent on shape factor. Journal of Molecular Liquids. 2018;262:376–388. doi: 10.1016/j.molliq.2018.04.094. [DOI] [Google Scholar]

- 17.Ghadikolaei SS, Hosseinzadeh K, Ganji DD, Hatami M. Fe3O4–(CH2OH) 2 nanofluid analysis in a porous medium under MHD radiative boundary layer and dusty fluid. Journal of Molecular Liquids. 2018;258:172–185. doi: 10.1016/j.molliq.2018.02.106. [DOI] [Google Scholar]

- 18.Amini F, Miry SZ, Karimi A, Ashjaee M. Experimental Investigation of Thermal Conductivity and Viscosity of SiO2/Multiwalled Carbon Nanotube Hybrid Nanofluids. Journal of nanoscience and nanotechnology. 2019;19(6):3398–3407. doi: 10.1166/jnn.2019.16127. [DOI] [PubMed] [Google Scholar]

- 19.Provensi, A., & Barbosa, J. R. Jr. Analysis and optimization of air coolers using multiple-stage thermoelectric modules arranged in counter-current flow. International Journal of Refrigeration (2019).

- 20.Dinarvand S, Rostami MN, Pop I. A novel hybridity model for TiO2-CuO/water hybrid nanofluid flow over a static/moving wedge or corner. Scientific reports. 2019;9(1):1–11. doi: 10.1038/s41598-019-52720-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Eringen AC. Simple microfluids. International Journal of Engineering Science. 1964;2(2):205–217. doi: 10.1016/0020-7225(64)90005-9. [DOI] [Google Scholar]

- 22.Eringen, A. C. Theory of micropolar fluids. Journal of Mathematics and Mechanics, 1–18 (1966).

- 23.Lukaszewicz, G. Micropolar fluids: theory and applications. Springer Science & Business Media (1999).

- 24.Srinivasacharya D, RamReddy C. Heat and mass transfer by natural convection in a doubly stratified non-Darcy micropolar fluid. International Communications in Heat and Mass Transfer. 2010;37(7):873–880. doi: 10.1016/j.icheatmasstransfer.2010.05.001. [DOI] [Google Scholar]

- 25.Nazar RM, Amin N, Groşan T, Pop I. Free convection boundary layer on a sphere with constant surface heat flux in a micropolar fluid. International communications in heat and mass Transfer. 2002;29(8):1129–1138. doi: 10.1016/S0735-1933(02)00441-4. [DOI] [Google Scholar]

- 26.Ghadikolaei SS, Hosseinzadeh K, Yassari M, Sadeghi H, Ganji DD. Boundary layer analysis of micropolar dusty fluid with TiO2 nanoparticles in a porous medium under the effect of magnetic field and thermal radiation over a stretching sheet. Journal of Molecular Liquids. 2017;244:374–389. doi: 10.1016/j.molliq.2017.08.111. [DOI] [Google Scholar]

- 27.Ghadikolaei SS, Hosseinzadeh K, Ganji DD. Numerical study on magnetohydrodynic CNTs-water nanofluids as a micropolar dusty fluid influenced by non-linear thermal radiation and joule heating effect. Powder Technology. 2018;340:389–399. doi: 10.1016/j.powtec.2018.09.023. [DOI] [Google Scholar]

- 28.Ghadikolaei SS, Hosseinzadeh K, Hatami M, Ganji DD. MHD boundary layer analysis for micropolar dusty fluid containing Hybrid nanoparticles (Cu-Al2O3) over a porous medium. Journal of Molecular Liquids. 2018;268:813–823. doi: 10.1016/j.molliq.2018.07.105. [DOI] [Google Scholar]

- 29.Ghadikolaei SS, Hosseinzadeh K, Ganji DD. MHD raviative boundary layer analysis of micropolar dusty fluid with graphene oxide (Go)-engine oil nanoparticles in a porous medium over a stretching sheet with joule heating effect. Powder Technology. 2018;338:425–437. doi: 10.1016/j.powtec.2018.07.045. [DOI] [Google Scholar]

- 30.Braga, V. M., Barbosa, J. R. Jr. & Deschamps, C. J. Numerical investigation of refrigerant outgassing in the screw pump of a hermetic reciprocating compressor oil supply system. In IOP Conference Series: Materials Science and Engineering (Vol. 604, No. 1, p. 011009). IOP Publishing (2019, August).

- 31.Koshiba, Y., Matsushita, T. & Ishikawa, M. Influence of induced magnetic field on large-scale pulsed MHD generator. In 33rd Plasmadynamics and Lasers Conference (p. 2145) (2002).

- 32.Kumari M, Takhar HS, Nath G. MHD flow and heat transfer over a stretching surface with prescribed wall temperature or heat flux. Wärme-und Stoffübertragung. 1990;25(6):331–336. doi: 10.1007/BF01811556. [DOI] [Google Scholar]

- 33.Hatami M, Hosseinzadeh K, Domairry G, Behnamfar MT. Numerical study of MHD two-phase Couette flow analysis for fluid-particle suspension between moving parallel plates. Journal of the Taiwan Institute of Chemical Engineers. 2014;45(5):2238–2245. doi: 10.1016/j.jtice.2014.05.018. [DOI] [Google Scholar]

- 34.Hayat T, Imtiaz M, Alsaedi A. Impact of magnetohydrodynamics in bidirectional flow of nanofluid subject to second order slip velocity and homogeneous–heterogeneous reactions. Journal of magnetism and magnetic materials. 2015;395:294–302. doi: 10.1016/j.jmmm.2015.07.092. [DOI] [Google Scholar]

- 35.Ghadikolaei SS, Hosseinzadeh K, Ganji DD. Analysis of unsteady MHD Eyring-Powell squeezing flow in stretching channel with considering thermal radiation and Joule heating effect using AGM. Case studies in thermal engineering. 2017;10:579–594. doi: 10.1016/j.csite.2017.11.004. [DOI] [Google Scholar]

- 36.Panchal, H., Patel, J., Parmar, K., & Patel, M. Different applications of Scheffler reflector for renewable energy: a comprehensive review. International Journal of Ambient Energy, 1–13 (2018).

- 37.Gholinia M, Gholinia S, Hosseinzadeh K, Ganji DD. Investigation on ethylene glycol nano fluid flow over a vertical permeable circular cylinder under effect of magnetic field. Results in Physics. 2018;9:1525–1533. doi: 10.1016/j.rinp.2018.04.070. [DOI] [Google Scholar]

- 38.Shojaei A, Amiri AJ, Ardahaie SS, Hosseinzadeh K, Ganji DD. Hydrothermal analysis of Non-Newtonian second grade fluid flow on radiative stretching cylinder with Soret and Dufour effects. Case Studies in Thermal Engineering. 2019;13:100384. doi: 10.1016/j.csite.2018.100384. [DOI] [Google Scholar]

- 39.Hosseinzadeh K, et al. Nonlinear thermal radiation and chemical reaction effects on Maxwell fluid flow with convectively heated plate in a porous medium. Heat Transfer—Asian Research. 2019;48(2):744–759. doi: 10.1002/htj.21404. [DOI] [Google Scholar]

- 40.Gholinia M, Hosseinzadeh K, Mehrzadi H, Ganji DD, Ranjbar AA. Investigation of MHD Eyring–Powell fluid flow over a rotating disk under effect of homogeneous–heterogeneous reactions. Case Studies in Thermal Engineering. 2019;13:100356. doi: 10.1016/j.csite.2018.11.007. [DOI] [Google Scholar]

- 41.Abbas, N., Malik, M. Y., & Nadeem, S. Transportation of Magnetized Micropolar Hybrid Nanomaterial Fluid Flow over a Riga Curface Surface. Computer methods and programs in biomedicine, 105136 (2019). [DOI] [PubMed]

- 42.Ruoff RS, Lorents DC. Mechanical and thermal properties of carbon nanotubes. carbon. 1995;33(7):925–930. doi: 10.1016/0008-6223(95)00021-5. [DOI] [Google Scholar]

- 43.Hakeem AA, Sathiyanathan K. An analytic solution of an oscillatory flow through a porous medium with radiation effect. Nonlinear Analysis: Hybrid Systems. 2009;3(3):288–295. [Google Scholar]

- 44.Saleh, S. H. M., Arifin, N. M., Nazar, R. & Pop, I. Unsteady micropolar fluid over a permeable curved stretching shrinking surface. Mathematical Problems in Engineering, 2017 (2017).

- 45.Shaiq S, Maraj EN. Role of the Induced Magnetic Field on Dispersed CNTs in Propylene Glycol Transportation Toward a Curved Surface. Arabian Journal for Science and Engineering. 2019;44(9):7515–7528. doi: 10.1007/s13369-019-03828-4. [DOI] [Google Scholar]

- 46.Nadeem, S., Abbas, N. & Malik, M. Y. Inspection of hybrid based nanofluid flow over a curved surface. Computer Methods and Programs in Biomedicine, 105193 (2020). [DOI] [PubMed]

- 47.Wang CY. Stagnation flow towards a shrinking sheet. International Journal of Non-Linear Mechanics. 2008;43(5):377–382. doi: 10.1016/j.ijnonlinmec.2007.12.021. [DOI] [Google Scholar]