Abstract

Fermentation by microorganisms is a key step in the production of traditional food products such as bread, cheese, beer and wine. In these fermentative ecosystems, microorganisms interact in various ways, namely competition, predation, commensalism and mutualism. Traditional wine fermentation is a complex microbial process performed by Saccharomyces and non-Saccharomyces (NS) yeast species. To better understand the different interactions occurring within wine fermentation, isolated yeast cultures were compared with mixed co-cultures of one reference strain of S. cerevisiae with one strain of four NS yeast species (Metschnikowia pulcherrima, M. fructicola, Hanseniaspora opuntiae and H. uvarum). In each case, we studied population dynamics, resource consumed and metabolites produced from central carbon metabolism. This phenotyping of competition kinetics allowed us to confirm the main mechanisms of interaction between strains of four NS species. S. cerevisiae competed with H. uvarum and H. opuntiae for resources although both Hanseniaspora species were characterized by a strong mortality either in mono or mixed fermentations. M. pulcherrima and M. fructicola displayed a negative interaction with the S. cerevisiae strain tested, with a decrease in viability in co-culture. Overall, this work highlights the importance of measuring specific cell populations in mixed cultures and their metabolite kinetics to understand yeast-yeast interactions. These results are a first step towards ecological engineering and the rational design of optimal multi-species starter consortia using modeling tools. In particular the originality of this paper is for the first times to highlight the joint-effect of different species population dynamics on glycerol production and also to discuss on the putative role of lipid uptake on the limitation of some non-conventional species growth although interaction processes.

1. Introduction

In natural or anthropized environments, microbial species are part of an ecosystem and interact positively or negatively, forming a complex network. Until recently, process optimization in agriculture or food processing was mostly based on the selection of single strains. However, this paradigm is now being challenged and the scientific community is increasingly seeking to exploit and optimize consortia of several strains and/or species. Indeed, many studies have shown that more diverse anthropized environments have many advantages in terms of resilience, disease resistance or yield. Efforts are now being made to design optimal consortia of various species and strains whose interactions will be exploited to maximize given criteria such as fermentation quality, aromatic complexity or other organoleptic characteristics.

Wine fermentation is both an economically and societally important food ecosystem, where the addition of fermentation ‘starters’ composed of selected yeasts at the beginning of the fermentation process is common. In fact, around 80% of oenological fermentations worldwide are conducted with starters [1,2]. Most often, these “starters” are only composed of a single Saccharomyces cerevisiae (S. c.) strain selected for its ability to complete fermentation. Indeed, numerous experiments have shown that S. cerevisiae, with an initially low population, most often becomes the predominant species at the end of the fermentation, demonstrating its superior fermentative abilities [3–6]. However, in recent years, multi-species starters have emerged, aimed at increasing the aromatic complexity of wines. They most often combine one strain of S. cerevisiae allowing to complete fermentation and another species, often from a different genus, contributing to a greater variety of flavors [3,4,6,7].

Indeed, there are numerous experiments and even industrial products making use of such mixed starters to improve wine’s organoleptic qualities [4,8,9]. The non-Saccharomyces (NS) strains used in these experiments are very diverse, with more than 23 different species including Torulaspora delbrueckii, Metschnikowia pulcherrima, Metschnikowia fructicola, Hanseniaspora opuntiae and Hanseniaspora uvarum. Species in the Metschnikowia genus ferment poorly in oenological conditions but can have interesting attributes: in conjunction with S. cerevisiae, a strain of M. pulcherrima could reduce ethanol concentrations [6,10], increase ‘citrus/grape fruit’ and ‘pear’ attributes [11], as well as allow the persistence of ‘smoky’ and ‘flowery’ characteristics [12]. M. pulcherrima also has an amensalism effect on S. cerevisiae through iron depletion via the production of pulcherriminic acid [13]. M. fructicola has been less studied and never in conjunction with S. cerevisiae although it presents the interesting ability to inhibit Botrytis growth [14]. Last, the Hanseniaspora genus, studied in sequential or simultaneous fermentation with S. cerevisiae, has been shown to increase volatile compound production during winemaking [6]. It notably increased the ‘tropical fruit’, ‘berry’, ‘floral’ and ‘nut aroma’ characters [15], that were linked to higher concentrations of acetate esters, esters of MCFAs, isoamyl alcohol, 2-phenylethanol and α-terpineol [16].

Despite these various studies, the composition and protocol of inoculation of these multi-strains starters are still very empirical and only based on the input/output balance, without considering the dynamics of the microbial populations or their interactions. This lack of knowledge about yeast-yeast interactions prevents implementing a rational design of multi-strain starters [17]. To address this problem, we decided to focus our study on population dynamics and metabolites produced during oenological fermentations performed in isolated or mixed yeast cultures. Since our goal was not to obtain optimal mixes but to understand the mechanism of microbial interaction, we chose to compare the population dynamics and yields between monocultures of strains from five species (one S. cerevisiae and four NS) and four corresponding mixed cultures always including the S. cerevisiae strain as reference. We were thus able to identify key microbial interaction mechanisms that are further discussed.

2. Results

In this work, we compared in winemaking conditions, the performance of single cell cultures of five different strains from five yeast species (Saccharomyces cerevisiae, Metschnikowia pulcherrima, Metschnikowia fructicola, Hanseniaspora opuntiae and Hanseniaspora uvarum) and mixed co-cultures combining each of the four NS species with one GFP-labelled S. cerevisiae strain representing 10% of the initial inoculate. We chose to stop the monitoring of fermentation at a given time, even if the sugar supply was not completely exhausted. Thus, for all fermentation with the S. cerevisiae reference strain, sugars were exhausted after around 200–220 h while in fermentations with single NS strains, the sugar supply was still not exhausted after 400h. Here, we focused on the first 300 hours of fermentation.

By comparing the output of single strain and mixed strain cultures, we evaluated the intensity of yeast-yeast interactions and/or their consequences on ecosystem service production.

2.1. CO2 kinetics

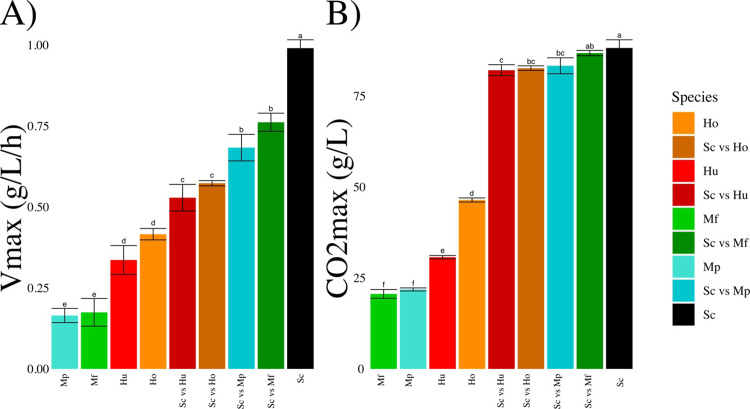

We first investigated the influence of species and co-culture on the dynamics of CO2 production (proportional to sugar consumption), which is a good indicator of the fermentation progress. Indeed, CO2 production is easy to monitor (based on weight measurement) and is directly proportional to ethanol synthesis and sugar consumption. The values of the maximum rate of CO2 production (Vmax, Fig 1A) and of the maximum CO2 produced were estimated (CO2max, Fig 1B). Vmax was highly dependent on the species (p.value < 0.001): S. cerevisiae cultures (Sc) displayed the highest value (VmaxSc = 0.99 ± 0.02 g.L-1.h-1), followed by both Hanseniaspora species (VmaxHu = 0.33 ± 0.04 g.L-1.h-1, and VmaxHo = 0.42 ± 0.02 g.L-1.h-1) and finally both Metschnikowia species (VmaxMp = 0.165 ± 0.02 g.L-1.h-1and VmaxMf = 0.17 ± 0.04 g.L-1.h-1). The four mixed cultures had intermediate Vmax values between those of Sc and the highest Vmax of all NS cultures (Fig 1A). Mixed cultures containing Metschnikowia species had significantly higher Vmax values than those containing Hanseniaspora species (Fig 1A). Although we did not monitor all cultures until the exhaustion of glucose and fructose, it was however possible to estimate the capacity of a given species to complete fermentation by estimating the amount of CO2 produced during the first 300 hours. Sc fermentations finished after around 220 hours with a CO2maxSc = 88.2 ± 2.2 g.L-1, all other fermentations did not complete it within 300 h. After 300 h, all mixed cultures are producing CO2 and produced more than 80g CO2.L-1 (90% of Sc maximum) while both Hanseniaspora (CO2maxHu = 30 ± 0.4 g.L-1, and CO2maxHo = 46 ± 0.6 g.L-1) and Metschnikowia (CO2maxMp = 22 ± 0.4 g.L-1 and CO2maxMf = 20 ± 1 g.L-1) monocultures stop producing CO2 at 300 h and will never finish the fermentation.

Fig 1.

Maximum rate of CO2 production, Vmax (A) and total CO2 produced (B) in function of the single or mixed species driving each fermentation. Values correspond to average ± standard deviation. The small letters indicate the statistical groups from a Tukey analysis.

2.2. Population kinetics

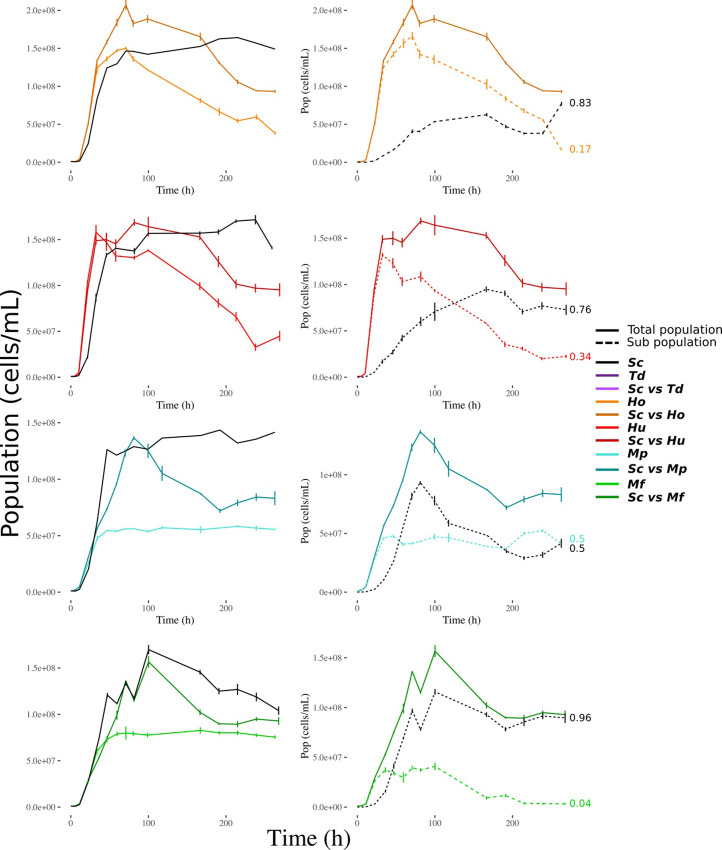

We also looked at population dynamics in each culture (Fig 2) and determined the maximum growth rate of the population (μ), the maximum population size, also termed carrying capacity (K) and the relative abundance (by cytometry) of each species after 300 hours of mixed culture, corresponding in our case to the end of the monitoring period (S1 Table). Fermentations with S. cerevisiae alone went through an exponential growth rate (μSc = 0.15 ± 0.02 h-1) and reached a maximum population of around 1.5*108cells.mL-1 (KSc = 1.55 ± 0.15 108cells.mL-1) that remained constant until the end of the fermentation. Fermentations with either Hanseniaspora species alone had a growth dynamic like Sc at the beginning of the fermentation but a higher growth rate (μHo = 0.19 ± 0.03 h-1, μHu = 0.62 ± 0.18 h-1). In contrast, their stationary phase was quite different from that of Sc and characterized by a higher cell mortality with a population drop of about 70% by the end of the process. Fermentations performed by Metschnikowia species in monocultures had growth dynamics mostly similar to Sc fermentations: a similar growth rate (μMp = 0.18 ± 0.03 h-1, μMf = 0.17 ± 0.2 h-1), no mortality during the stationary phase but a much reduced maximum population (KMp = 0.57 ± 0.01 106cells.mL-1, KMf = 0.8 ± 0.05 106cells.mL-1). In most cases, mixed cultures displayed an intermediate pattern between the two corresponding monocultures (Fig 2). However, mixed or monocultures with Metschnikowia displayed different cell mortality rates during the stationary phase: in the case of ScvsMp fermentations, only the S. cerevisiae population decreased significantly during the stationary phase, while in ScvsMf fermentations, both subpopulations significantly decreased. As a measure of fitness, we also followed the variations of S. cerevisiae frequency along the fermentation. In all mixed cultures, S. cerevisiae was found dominant (frequency > 50%) in the end, increasing significantly during fermentation from 10% initially to frequencies varying between 50% (ScvsMp) and 96% (ScvsMf) (Fig 2).

Fig 2. Global monitoring of the kinetics of the total living population (left), and sub-population in the mixed cultures (right) across fermentation.

Each population was detected by flow cytometry as indicated in the Material and Methods section. Each point represents a sample (average ± standard error). Full lines are for total population and dashed lines for the two sub populations in mixed cultures. At the end of dashed lines, the final proportion of both sub-populations in mixed cultures is indicated. The light colors represent monocultures of ‘non-Saccharomyces’ species and dark ones to the corresponding culture in competition with S. cerevisiae. The single strand cultures of S. cerevisiae are represented in black.

2.3. Sugar and nitrogen assimilable source consumption

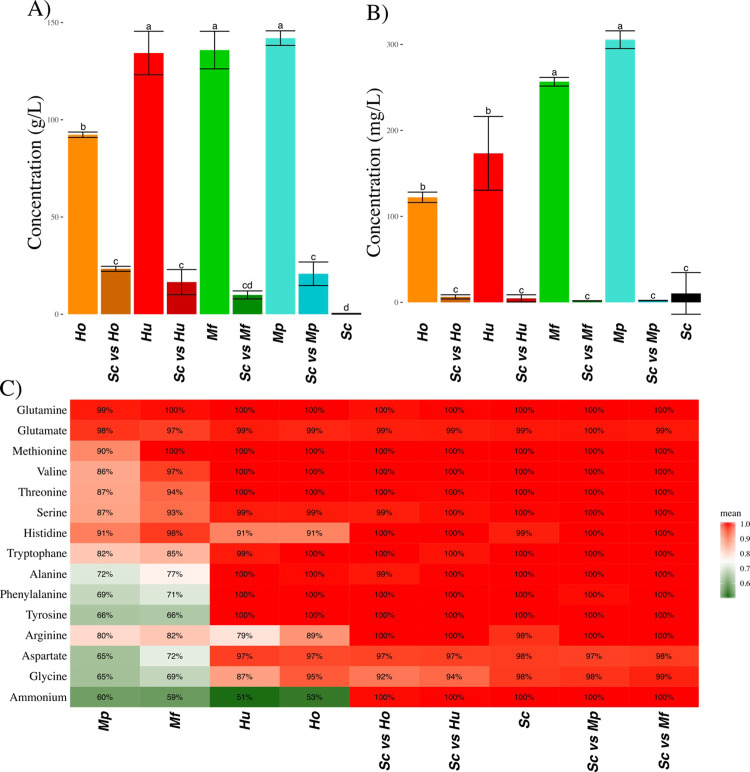

We then looked at the final concentration of resources: sugars (fructose and glucose) and nitrogen assimilable source (NAS) i.e. ammonium and amino-acids (Fig 3). In Sc fermentations, less than 0.1% of the initial concentration of both sugars remained (Fig 3A). As seen in the paragraph concerning CO2 production, NS species in monocultures did not complete fermentation in the 300 h period and left respectively 45% of sugars for Ho, 67% for Hu, 68% for Mf and 71% for Mp. Furthermore, all species except H. opuntiae preferentially consumed glucose (S1 Fig). Sugar consumption was higher in mixed cultures than in single NS species cultures (Fig 3A). However, it was still lower than in Sc species cultures, also with a preference for glucose. This indicates the major impact of S. cerevisiae on sugar consumption (consistent with the CO2 production observed), compared to the other NS species studied.

Fig 3. Consumption of sugars and nitrogen assimilable sources (NAS) for each type of fermentation.

A) Final concentration of sugar (average ± standard deviation). B) Final concentration of NAS (average ± standard deviation). C) Percentage of consumption of each NAS in each type of fermentation represented as a color gradient from green (<75%) to red (> 75%).

The consumption of NAS displayed the same pattern (Fig 3b). NAS were almost entirely consumed both in Sc monocultures and in all co-cultures. In NS monocultures the consumption of NAS varied between 84% and 94%. However, the preference for different nitrogen sources varied with each NS species (Fig 3c). Both Hanseniaspora species had similar behaviors, consuming only half of the available ammonium, 90% of histidine and 89% or 79% of arginine (Fig 3C). Metschnikowia species presented a similar pattern. It was possible to classify these NS species preferences for the various NAS. The resulting ranking by order of preference was glutamine, methionine, glutamate, valine, threonine, serine, tryptophan, alanine, histidine, arginine, aspartate, glycine and, surprisingly last, ammonium.

2.4. Metabolite production

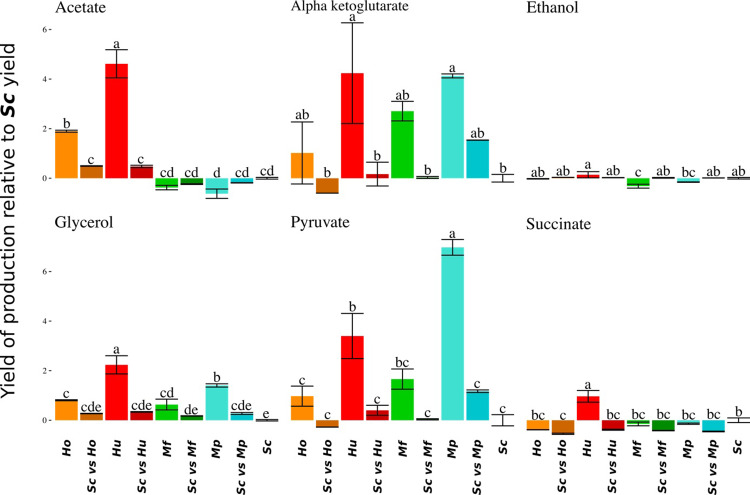

In parallel with must resources consumption monitoring, we also investigated the production of metabolites from Central Carbon Metabolism (CCM): ethanol, glycerol, succinate, pyruvate, acetate and alpha-ketoglutarate (Fig 4). These measurements of metabolite production were taken after 300 hours when sugars consumptions were quite different from one culture to another depending on their dynamics. To allow figures comparison, we computed the production yield (total production / sugar consumption) for each culture and, from these data, we then estimated this yield relatively to that of Sc in single strain culture (Fig 4).

Fig 4. Yield of carbon metabolite production relative to the yield of production of single S. cerevisiae.

Average Yield are given with standard deviations for acetate, alpha-ketoglutarate, ethanol, glycerol, pyruvate and succinate and each type of fermentation.

In the case of ethanol, only Mf fermentations had a relative yield significantly inferior (-32%) to 0 (0 being Sc yield). For glycerol, all NS monocultures had a greater yield than Sc and mixed fermentations were intermediate between (but not significantly different from) the corresponding monocultures. For acetate, only Hanseniaspora species displayed a higher yield (Fig 4).

Finally, all mixed cultures seemed to have a lower succinate yield than both corresponding monocultures (but not significantly after correction for multiple tests).

For each fermentation, the total production of metabolites resulted from the combination of species yields, total sugar consumption and respective population dynamics during fermentation. Therefore, differences observed in the total productions of mixed cultures were the consequences of additive or subtractive effects observed for these 3 components. Considering ethanol, its total production was directly linked to the consumption of resources and all mixed cultures were equivalent to Sc fermentations (S2 Fig). The case of glycerol was more interesting. Indeed, even if the average sugar consumption was lower in ScvsHu and ScvsMp mixed cultures than in single strain Sc culture, the total production of glycerol was significantly higher than that of the corresponding monocultures (GlycerolSCvsMp = 6.1±0.1 g.L-1, GlycerolSc = 5.3±0.4 g.L-1, GlycerolMp = 3.7±0.2 g.L-1). This resulted from the positive combination of the greater glycerol yield by Hanseniaspora and Metschnikowia and their population dynamics. For acetate, Hanseniaspora species have a higher production in monoculture compared to S. cerevisiae and mixed cultures, whereas it was the converse for Metschnikowia species. For all other metabolites, the total production of mixed cultures was not significantly different from the corresponding monocultures (S1 Table).

3. Discussion

This study presents one of the first works focusing on the population dynamics and kinetics of yeast-yeast interactions between two species (S.C. and NS) during the alcoholic fermentative process [18]. The counterpart of this deep phenotyping is two limitations: the monitoring time and the number of strains by species. Due to experiment constraints, we followed the fermentations during 300 hours and until sugar exhaustion. Sc fermentations consume all sugars and therefore finish the fermentation in around 200h, while Metschnikowia and Hanseniaspora monocultures are enabled to finish it (consuming around a quarter of available sugars). However, it is not clear if the mixed cultures are able to finish it. At the end of our experiment all mixed cultures were still producing CO2 and produced more than 80g CO2.L-1 (90% of Sc maximum) and still have a high viable population. Although without kinetic tracking, these mixed cultures have already been tested under similar conditions [16,19]. In most of the cases they were able to finish the fermentation. Therefore, it is reasonable to make the hypothesis that all our mixed cultures will finish the fermentation in more than 300 hours. Another limitation is that we only used one strain by species. Indeed, here we studied a limited sample of species and strains that raises the question of the genericity of interactions. This question can be found in other similar papers and is difficult to address as increasing the number of species or strains increase exponentially the number of mixed cultures to be tested. In our cases we have tested 5 mixed cultures in triplicate. To test all possible mixed cultures (including NS-NS mixed) represent 25 fermentations. With for example 3 strains for each species tested in this study, it would represents 15 strains and 225 mixed fermentations. It is very difficult if not impossible to follow experimentally the kinetics of so much fermentation.

Despite the small number of species and strains, it is important to note that a deep phenotyping was performed in the current work, making it possible a better understanding of the interactions between two yeast strains. Indeed, the following parameters were measured for every experiment: fermentation kinetics, cell growth, cell viability, percentage of non-saccharomyces yeast, concentration of metabolites of central carbon metabolism, nitrogen compounds.

A notable observation is that monocultures studied here can be grouped by genus as respectively Metschnikowia and Hanseniaspora are more similar between them than across them (S3 Fig). Of course, this observation has to be confirmed with further investigations.

Even though Metschnikowia maintains a high viability throughout fermentation, the medium resources (sugars and nitrogen) were not entirely consumed. The reason why the cells stopped growing despite the availability of these resources remains unclear. A possible explanation could be linked to oxygen availability. Our hypothesis is that Metschnikowia is not able to import lipid from the extracellular medium and that this species stops growing when oxygen content in the must is equal to zero. For all yeast, lipid synthesis requires oxygen and is therefore impossible in anaerobic conditions [20]. With the progress of fermentation, ensuing oxygen limitation and ethanol accumulation yeast should import lipids to survive [21]. If not, it stops to multiply [22,23]. Metschnikowia species growth (studied in this work) depends thus on their initial (internal) lipid content and lipid synthesis from initial concentration of oxygen (see S1 Fig).

Interestingly, even though S. cerevisiae, M. pulcherrima and M. fructicola mortality rates were low in monocultures, the corresponding mixed cultures (ScvsMp and ScvsMf) presented 30% mortality (after 200 hours of fermentation). Moreover, this mortality seemed to impact species differently. In the mixed ScvsMp culture, only S. cerevisiae cells eventually died, whereas in ScvsMf both species were negatively affected. The survival of M. pulcherrima cells compared to S. cerevisiae cells could be explained by the production of pulcherriminic acid by M. pulcherrima [24]. Indeed, pulcherriminic acid is known to deplete iron from the medium, which has a lethal effect on S. cerevisiae cells [13,25,26]. In ScvsMf cultures, the mortality observed in both species suggests a more complex mechanism of interaction (although it is not clear whether M. fructicola also produces pulcherriminic acid [14]. To explain these results, we could hypothesize the conjunction of two different mechanisms of interaction. It could be that M. fructicola synthesized a metabolite (pulcherriminic acid?) impacting the viability of S. cerevisiae cells (through iron depletion?), with M. fructicola cells dying thereafter for another reason such as sensitivity to ethanol. Indeed, the production of ethanol was almost four times higher in mixed cultures than in single strain Metschnikowia fermentations. Under such hypothesis, the reason why no loss of viability was observed for M. pulcherrima in mixed culture with S. cerevisiae could probably be related to a better tolerance of M. pulcherrima to ethanol stress compared to M. fructicola.

Mixed population dynamics were all characterized by similar growth rate (reaching a maximum population like S. cerevisiae single strain culture), followed by a long phase with decreasing viability (NS viability dropped to 30% in accordance with [16,27]). Moreover, their yield and total production of CCM metabolites were very similar. For almost all these characteristics, mixed cultures presented intermediate phenotypes compared to the corresponding monocultures. However, there is a remarkable exception considering the total production of glycerol that is superior in mixed cultures whereas their sugar consumption was inferior (Fig 4). This point is characteristic of a transgressive interaction (often referred to as over-yielding), i.e. a situation in which the ecosystem performance is higher than the best-yielding species performance in monoculture. This glycerol overproduction in mixed cultures has already been observed in previous works [16,28] but seems to depend on the species and experimental conditions [27]. In the present study, the glycerol and sugar consumption observed in mixed cultures can be explained without any change of individual behavior but by the synergic effects of population dynamics (S. cerevisiae slowly dominating the population), resource consumptions (the NS fermentation leaving ⅔ of sugars) and the glycerol yields of NS species that were two to three times higher that of S. cerevisiae. These overproductions of glycerol is clear example of how mixing species can produce a better result of any monoculture. Thus exploiting specific yield, population dynamics and inoculation protocol could lead to high-performance fermentations. As overproduction appears to be highly dependent of population dynamics it will be interesting to test different inoculation protocols. Decreasing the frequency of S. cerevisiae at t0 (0.01, 0.001, 0.0001) could increase the transgressive interaction and lead to higher glycerol and thus eventually lower ethanol.

So far we only discussed transgressive interactions when mixed cultures over-produced (or under-produced) a given metabolite. Indeed, it was very difficult to identify interactions when the productions of mixed fermentations were within the range of monocultures productions. As the relative frequency of both species in mixed cultures evolved during fermentation, it was difficult to link the final mix to the contributions of each species. It was even more difficult to assess whether these contributions combined additively or with interaction. New statistical developments or dual transcriptomics will be needed to answer this question [29–31].

To discuss more generally the mechanisms of interactions of Metschnikowia and Hanseniaspora cultures mixed with S. cerevisiae, we could not observe any major antagonistic phenomena. For almost all assays, mixed cultures performance stood always between that of the corresponding monocultures (Figs 1, 2 and 3), except for the total production of glycerol. Moreover, despite the differences in yield and interactions between species, the rapid dominance of S. cerevisiae (increasing from 10% to at least 50% during the fermentation) resulted in mixed cultures that were overall not different from S. cerevisiae monocultures. This result is in agreement with the good adaptation of S. cerevisiae to winemaking conditions [4–6,32] but could be different with a different set of species. This result is important in the context of ecological engineering. In fact, our results confirmed that S. cerevisiae has a much better fitness than the NS species studied in this paper. Therefore, if we want mixed culture behavior to deviate from that of S. cerevisiae single strain culture, it must be ensured that NS cells dominate the culture as soon as possible. To achieve this, two conceivable options are currently tested: either to reduce the proportion of S. cerevisiae at t0 or to perform a sequential inoculation [16]: first the NS species and then the S. cerevisiae strain in a second time. These two options could be equivalent depending on the type of interaction(s) that occurs. If strain behaviors in single strain or mixed cultures are identical, then all interactions are mediated by the medium through the competition for resources and the production of constitutive toxins such as ethanol (producing a toxin only in mixed fermentation would be a behavior change) and could be qualified as “indirect”.

In the case of indirect interaction, mathematical models could be designed from data on monocultures to predict the mixed cultures. This would allow simulating numerous mixes of species with various initial conditions and identify optimal strategies depending on one or several given criteria. Using these approaches could limit the number of necessary tests, potentially saving a lot of time and money and opening the way to a more methodical ecological engineering. The development of such mathematical models will only be possible thanks to a deep tracking of population dynamics to understand underlying mechanisms of growth and mortality. Obviously, it is also critical to validate this approach by i) first extending the number of species co-cultured with S. cerevisiae, ii) investigating intra-specific variability and strain-strain interactions between species, iii) investigating the impact of the environment of culture (temperature, grape variety, nutrient availability, etc.).

4. Mat & met

4.1. Strains

In this work, we used one strain of 5 different species (one strain per species): Saccharomyces cerevisiae (Sc), Metschnikowia pulcherrima (Mp), M. fructicola (Mf), Hanseniaspora uvarum (Hu) and H. opuntiae (Ho). The S. cerevisiae strain is a haploid strain from EC1118 labelled with GFP (59A-GFP, [1]). The Hanseniaspora uvarum (CLIB 3221) H. opuntiae (CLIB 3093) and Metschnikowia pulcherrima (CLIB 3235) species originated from the yeast CIRM (https://www6.inrae.fr/cirm_eng/Yeasts/Strain-catalogue) and were isolated from grape musts. The Metschnikowia fructicola strain was from the Lallemand collection.

For each strain, 3 replicates of monocultures were performed (except for S. cerevisiae that had a total of 8 replicates in different blocks). In addition, for each NS strain, 3 replicates of a mixed culture with the Sc strain were performed. In all mixed fermentations, the starting proportion of S. cerevisiae cells was set at 10%. In this text, fermentations were referred to by the species that performed them, i.e. monocultures were referred to as: Sc, Mp, Mf, Hu and Ho and mixed strain cultures as ScvsMp, ScvsMf, ScvsHu and ScvsHo.

4.2. Medium

Initial cultures (12 h, in 50 ml YPD medium, 28°C) were used to inoculate fermentation media at a total density of 106 cells/mL; therefore, for mixed culture the S. cerevisiae cells density was 0.1x106 /mL and the NS cells density was 0.9x106 /mL. Fermentations were carried out in a synthetic medium (SM) mimicking standard grape juice [33]. The SM used in this study contained 200 g/L of sugar (100 g glucose and 100 g fructose per liter) and 200 mg/L of assimilable nitrogen (as a mix of ammonium chloride and amino acids). The concentrations of weak acids, salts and vitamins were identical to those described by [34]. The pH of the medium was adjusted to 3.3 with 10M NaOH. The SM medium was first saturated with bubbling air for 40 minutes, then it was supplemented with 5 mg/L phytosterols (85451, Sigma Aldrich) solubilized in Tween 80 to fulfill the lipid requirements (sterols and fatty acids) of yeast cells during anaerobic growth.

4.3. Measurements

Fermentation took place in 1.1-liter fermentors equipped with fermentation locks to maintain anaerobiosis, at 20°C, with continuous magnetic stirring (500 rpm) during approximately 300h. CO2 release was followed by automatic measurements of fermentor weight loss every 20 min. The amount of CO2 released allowed us to monitor the progress of the fermentation and evaluate the maximum of released CO2 (CO2max) as well as the maximum rate of CO2 released (Vmax). Samples were harvested after 6h, 12h and 24h, then every 12h during the first week and every 24h during the second week of fermentation. For each sample, the population density cells were determined using a BD Accuri™ C6 Plus flow cytometer as described in [35]. Viability was determined using propidium iodide staining and BD Accuri™ C6 Plus flow cytometer adapted from [36]. Proportions of S. cerevisiae in mixed-culture was established thanks to the green fluorescence produced by the S. cerevisiae 59A-GFP, the forward and side scatters from the BD Accuri™ C6 Plus flow cytometer and machine learning using the caret package in R [37]. From these population densities (without taking into account viability), we fitted a growth population model (with the growthcurver package in R, [38], and determined the carrying capacity (K) and maximum growth rate (mu) for each fermentation.

The final concentrations of carbon metabolites in the medium (acetate, succinate, glycerol, alpha-ketoglutarate, pyruvate, ethanol, glucose and fructose) were determined with high-pressure liquid chromatography [39]. From these metabolite concentrations, we first calculated the consumed sugar concentration as the difference between the final and the initial concentration of either glucose or fructose. Then we calculated the yield of metabolite production by dividing the final concentration by the corresponding consumed sugar concentration. Finally, we compared these yields to the yield of S. cerevisiae monocultures considered as reference.

Finally, the ammonium concentration after 100h of fermentation was determined enzymatically with R-Biopharm (Darmstadt, Germany) and the free amino acid content of the must was estimated through cation exchange chromatography with post-column ninhydrin derivatization [40].

4.4. Statistical analysis

The experimental work was performed in 5 different blocks. Each block was composed of three replicates of NS fermentations (for example Hu), three replicates of the corresponding mixed fermentations with S. cerevisiae (for example ScvsHu) and one or two fermentations of single strain S. cerevisiae cells (Sc). The block effect was evaluated on the parameters of the Sc fermentation. For most studied parameters, the block effect was not significant. For those parameters where a block effect was observed (mu and K), a statistical correction for block effect did not modify our results. Therefore, for simplification purposes, we compared all fermentations without any correction for the block effect parameter. For each measured parameter, an ANOVA was performed to evaluate the type of fermentation (Sc, Mp, Mf, Hu, Ho, ScvsTd, ScvsMp, ScvsMf, ScvsHu and ScvsHo) effect and then a Tukey t-test was performed to determine statistical groups and two-by-two statistical differences. All statistical analyses were performed using R [41] and Rstudio [42]. All data, analysis and figures scripts can be found in this github address: https://github.com/tnidelet/Git-Harle-et-al-2019.

Supporting information

Each point represents a sample (average ± standard deviation).

(TIF)

Average production are given with standard deviations for acetate, alpha-ketoglutarate, ethanol, glycerol, pyruvate and succinate.

(TIF)

The mixed cultures are a second time projected on the plan determiner by only monocultures. In the top right is represented the circle of variables.

(TIF)

Serial tenfold dilutions of two Metschnikovia pulcherrima strains (A and B) spotted onto various synthetic standard agar media (SM425, 425 mg/l assimilable nitrogen) with Tween 80, (Tw, 0.06%), supplemented or not with phytosterol (Phyto, 20 mg/L), in the presence or not of fluconazole (FLC, 256 μg/mL). Plates were incubated at 28°C for five days in air or in anaerobiosis

(TIF)

(DOCX)

Acknowledgments

We thank the CIRM, the Lallemand company, Jean-Luc Legras, Virginie Galeote and Jean-Nicolas Jasmin for providing the species used in this study. We thank also Christian Picou, Marc Perez, Faiza Macna for technical assistance and Delphine Sicard for advices.

Data Availability

All data files for: Kinetic analysis of yeast-yeast interactions in oenological conditions files are available from the Mendeley database (https://data.mendeley.com/datasets/wmhcznvgf4/draft?a=c8b0813a-d27a-45c3-88e0-3f6fe5110130, doi: 10.17632/wmhcznvgf4.1).

Funding Statement

The authors received no specific funding for this work.

References

- 1.Marsit S, Dequin S. Diversity and adaptive evolution of Saccharomyces wine yeast: a review. FEMS Yeast Research. 2015;15: fov067. 10.1093/femsyr/fov067 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Sablayrolles J. Fermented beverages: the example of winemaking. Advances in Fermentation Technology New Delhi: Asiatech Publishers. 2008; 322–47.

- 3.García-Ríos E, Gutiérrez A, Salvadó Z, Arroyo-López FN, Guillamon JM. The Fitness Advantage of Commercial Wine Yeasts in Relation to the Nitrogen Concentration, Temperature, and Ethanol Content under Microvinification Conditions. Appl Environ Microbiol. 2014;80: 704–713. 10.1128/AEM.03405-13 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Jolly NP, Varela C, Pretorius IS. Not your ordinary yeast: non‐Saccharomyces yeasts in wine production uncovered. Fems Yeast Res. 2014;14: 215–237. 10.1111/1567-1364.12111 [DOI] [PubMed] [Google Scholar]

- 5.Pinto C, Pinho D, Cardoso R, Custódio V, Fernandes J, Sousa S, et al. Wine fermentation microbiome: a landscape from different Portuguese wine appellations. 2015;6: 905. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Varela C. The impact of non-Saccharomyces yeasts in the production of alcoholic beverages. Appl Microbiol Biot. 2016;100: 9861–9874. 10.1007/s00253-016-7941-6 [DOI] [PubMed] [Google Scholar]

- 7.Ivey M, Massel M, Phister TG. Microbial Interactions in Food Fermentations. Annual Review of Food Science and Technology. 2013;4: 141–162. 10.1146/annurev-food-022811-101219 [DOI] [PubMed] [Google Scholar]

- 8.Sadineni V, Kondapalli N, Obulam V. Effect of co-fermentation with Saccharomyces cerevisiae and Torulaspora delbrueckii or Metschnikowia pulcherrima on the aroma and sensory properties of mango wine. Ann Microbiol. 2012;62: 1353–1360. 10.1007/s13213-011-0383-6 [DOI] [Google Scholar]

- 9.P H-O, Cersosimo M, Loscos N, Cacho J, E G-M, Ferreira V. The development of varietal aroma from non-floral grapes by yeasts of different genera. Food Chem. 2008;107: 1064–1077. 10.1016/j.foodchem.2007.09.032 [DOI] [Google Scholar]

- 10.Contreras A, Hidalgo C, Henschke PA, Chambers PJ, Curtin C, Varela C. Evaluation of Non-Saccharomyces Yeasts for the Reduction of Alcohol Content in Wine. Appl Environ Microbiol. 2014;80: 1670–1678. 10.1128/AEM.03780-13 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Belda I, Navascués E, Marquina D, Santos A, Calderon F, Benito S. Dynamic analysis of physiological properties of Torulaspora delbrueckii in wine fermentations and its incidence on wine quality. Appl Microbiol Biot. 2015;99: 1911–1922. 10.1007/s00253-014-6197-2 [DOI] [PubMed] [Google Scholar]

- 12.Elena G-R, Pascual O, Kontoudakis N, Esteruelas M, Braulio E-Z, Mas A, et al. Oenological consequences of sequential inoculation with non-Saccharomyces yeasts (Torulaspora delbrueckii or Metschnikowia pulcherrima) and Saccharomyces cerevisiae in base wine for sparkling wine production. Eur Food Res Technol. 2015;240: 999–1012. 10.1007/s00217-014-2404-8 [DOI] [Google Scholar]

- 13.Oro L, Ciani M, Comitini F. Antimicrobial activity of Metschnikowia pulcherrima on wine yeasts. J Appl Microbiol. 2014;116: 1209–1217. 10.1111/jam.12446 [DOI] [PubMed] [Google Scholar]

- 14.Kurtzman CP, Droby S. Metschnikowia fructicola, a New Ascosporic Yeast with Potential for Biocontrol of Postharvest Fruit Rots. Systematic and Applied Microbiology. 2001;24: 395–399. 10.1078/0723-2020-00045 [DOI] [PubMed] [Google Scholar]

- 15.Hu K, Qin Y, Tao Y-S, Zhu X-L, Peng C-T, Ullah N. Potential of Glycosidase from Non-Saccharomyces Isolates for Enhancement of Wine Aroma. Journal of Food Science. 81: M935–M943. 10.1111/1750-3841.13253 [DOI] [PubMed] [Google Scholar]

- 16.Tristezza M, Tufariello M, Capozzi V, Spano G, Mita G, Grieco F. The Oenological Potential of Hanseniaspora uvarum in Simultaneous and Sequential Co-fermentation with Saccharomyces cerevisiae for Industrial Wine Production. Front Microbiol. 2016;7 10.3389/fmicb.2016.00007 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Song H-S, Cannon WR, Beliaev AS, Konopka A. Mathematical Modeling of Microbial Community Dynamics: A Methodological Review. Processes. 2014;2: 711–752. 10.3390/pr2040711 [DOI] [Google Scholar]

- 18.Wang C, Mas A, Esteve-Zarzoso B. The Interaction between Saccharomyces cerevisiae and Non-Saccharomyces Yeast during Alcoholic Fermentation Is Species and Strain Specific. Front Microbiol. 2016;7 10.3389/fmicb.2016.00007 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Zhang B-Q, Shen J-Y, Duan C-Q, Yan G-L. Use of Indigenous Hanseniaspora vineae and Metschnikowia pulcherrima Co-fermentation With Saccharomyces cerevisiae to Improve the Aroma Diversity of Vidal Blanc Icewine. Front Microbiol. 2018;9 10.3389/fmicb.2018.00009 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Valero E, Millán C, Ortega José M. Influence of oxygen addition during growth phase on the biosynthesis of lipids in Saccharomyces cerevisiae (M330-9) in enological fermentations. Journal of Bioscience and Bioengineering. 2001;92: 33–38. 10.1263/jbb.92.33 [DOI] [PubMed] [Google Scholar]

- 21.Pina C, Santos C, Couto JA, Hogg T. Ethanol tolerance of five non-Saccharomyces wine yeasts in comparison with a strain of Saccharomyces cerevisiae—influence of different culture conditions. Food Microbiology. 2004;21: 439–447. 10.1016/j.fm.2003.10.009 [DOI] [Google Scholar]

- 22.Morales P, Rojas V, Quirós M, Gonzalez R. The impact of oxygen on the final alcohol content of wine fermented by a mixed starter culture. Appl Microbiol Biotechnol. 2015;99: 3993–4003. 10.1007/s00253-014-6321-3 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Shekhawat K, Bauer FF, Setati ME. Impact of oxygenation on the performance of three non-Saccharomyces yeasts in co-fermentation with Saccharomyces cerevisiae. Appl Microbiol Biotechnol. 2017;101: 2479–2491. 10.1007/s00253-016-8001-y [DOI] [PubMed] [Google Scholar]

- 24.MacDonald. Biosynthesis of pulcherriminic acid. Biochem J. 1965;96: 533–8. 10.1042/bj0960533 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Sipiczki M. Metschnikowia Strains Isolated from Botrytized Grapes Antagonize Fungal and Bacterial Growth by Iron Depletion. Appl Environ Microb. 2006;72: 6716–6724. 10.1128/aem.01275-06 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Türkel S, C E-B. Isolation and characterization of new Metschnikowia pulcherrima strains as producers of the antimicrobial pigment pulcherrimin. Zeitschrift für Naturforschung C. 2009. [DOI] [PubMed] [Google Scholar]

- 27.Moreira N, Mendes F, de Pinho P, journal of … H-T. Heavy sulphur compounds, higher alcohols and esters production profile of Hanseniaspora uvarum and Hanseniaspora guilliermondii grown as pure and …. International journal of …. 2008. [DOI] [PubMed]

- 28.Ciani M, Ferraro L. Enhanced Glycerol Content in Wines Made with Immobilized Candida stellata Cells. Appl Environ Microbiol. 1996;62: 128–132. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Barot S, Allard V, Cantarel A, Enjalbert J, Gauffreteau A, Goldringer I, et al. Designing mixtures of varieties for multifunctional agriculture with the help of ecology. A review. Agron Sustain Dev. 2017;37: 13 10.1007/s13593-017-0418-x [DOI] [Google Scholar]

- 30.Finckh MR (International RRI, Mundt CC. Stripe rust, yield, and plant competition in wheat cultivar mixtures. Phytopathology (USA). 1992. [cited 17 Jan 2019]. Available: http://agris.fao.org/agris-search/search.do?recordID=US9307396 [Google Scholar]

- 31.Wolf T, Kämmer P, Brunke S, Linde J. Two’s company: studying interspecies relationships with dual RNA-seq. Current Opinion in Microbiology. 2018;42: 7–12. 10.1016/j.mib.2017.09.001 [DOI] [PubMed] [Google Scholar]

- 32.García M, Braulio E-Z, Arroyo T. Non-Saccharomyces Yeasts: Biotechnological Role for Wine Production. 2016. 10.5772/64957 [DOI] [Google Scholar]

- 33.Bely M, Sablayrolles JM, Barre P. Description of Alcoholic Fermentation Kinetics: Its Variability and Significance. Am J Enol Vitic. 1990;41: 319–324. [Google Scholar]

- 34.Seguinot P, SANCHEZ I, Bloem A, Ortiz-Julien A, Camarasa C. Impact of nitrogen sources on the fermentative kinetic of non—Saccharomyces yeasts. 2017. Available: https://hal.archives-ouvertes.fr/hal-01604146

- 35.Delobel P, Pradal M, Blondin B, Tesniere C. A ‘fragile cell’ sub-population revealed during cytometric assessment of Saccharomyces cerevisiae viability in lipid-limited alcoholic fermentation. Letters in Applied Microbiology. 55: 338–344. 10.1111/j.1472-765X.2012.03301.x [DOI] [PubMed] [Google Scholar]

- 36.Riccardi C, Nicoletti I. Analysis of apoptosis by propidium iodide staining and flow cytometry. Nat Protoc. 2006;1: 1458–1461. 10.1038/nprot.2006.238 [DOI] [PubMed] [Google Scholar]

- 37.Kuhn M. Building Predictive Models in R Using the caret Package. Journal of Statistical Software. 2008;28: 1–26. 10.18637/jss.v028.i07 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Sprouffske K, Wagner A. Growthcurver: an R package for obtaining interpretable metrics from microbial growth curves. BMC Bioinformatics. 2016;17: 172 10.1186/s12859-016-1016-7 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Camarasa C, Sanchez I, Brial P, Bigey F, Dequin S. Phenotypic landscape of Saccharomyces cerevisiae during wine fermentation: evidence for origin-dependent metabolic traits. PLoS ONE. 2011;6: e25147 10.1371/journal.pone.0025147 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Crépin L, Nidelet T, Sanchez I, Dequin S, Camarasa C. Sequential Use of Nitrogen Compounds by Saccharomyces cerevisiae during Wine Fermentation: a Model Based on Kinetic and Regulation Characteristics of Nitrogen Permeases. 2012;78: 8102–8111. 10.1128/AEM.02294-12 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.R Core Team (2016). R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria: URL https://www.R-project.org/. [Google Scholar]

- 42.RStudio (2012). RStudio: Integrated development environment for R (Version 0.96.122) [Computer software]. Boston, MA. Retrieved May 20, 2012. Available from http://www.rstudio.org/.