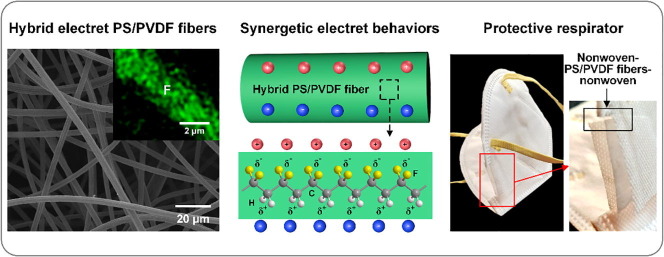

Graphical abstract

Keywords: Electrospinning, Dielectric property, Electret mechanism, Air filtration

Highlights

-

•

A new method to enhance electret property without using nanoparticles is reported.

-

•

All-polymer electret PS/PVDF fibers without nanotoxicity are prepared.

-

•

Novel theory describing the electret mechanisms of electrospinning is proposed.

-

•

The resultant electret fibers show competitive air filtration performance.

Abstract

A one-step and controllable strategy to prepare all-polymer hybrid electret fibers is reported based on the coupling of polystyrene and polyvinylidene fluoride in electric response. The complementary dielectric properties between PS and PVDF generate dual-system electret charges within PS/PVDF fibers, thereby improving the electret effect. The bi-component all-polymer electret fibers show enhanced electret property and structural continuity, contributing to a N95 protective respirator with high filtration efficiency (99.752%), low air resistance (72 Pa) and long service life. The fabrication of all-polymer electret fibers solves the challenge of nanoparticle toxicity for existing polymer/nanoparticle electret fibers.

1. Introduction

The outbreaks of emerging infectious diseases (EIDs), such as the ongoing Coronavirus Disease 2019 (COVID-19), always take a significant human toll and affect social stability [1], [2]. To protect the public from being infected via droplets and aerosols [3], protective respirators are highly demanded. Currently, respirators are mostly composed of micro-sized melt-blown fibers with large pore size (10–20 μm), rendering a low pressure drop thereby satisfying breathing comfort [4]. However, determined by the single filtration mechanism of size sieving, melt-blown filters suffer from low filtration efficiency towards aerosols with small particle size, which is especially poisonous [5]. Currently, increasing the fiber consumption has become a usual strategy to improve the protective ability. However, this strategy causes the sharp increase of pressure drop simultaneously [6].

Electret technology is effective in alleviating the conflict between filtration efficiency and pressure drop by endowing fibers with electrostatic effect, which contributes to particle adsorption while generating negligible impact on airflow [7], [8]. Compared to the current electret technologies [9], [10], electrospinning can achieve the in-situ charging along with the formation of fibers, achieving the one-step production of electret fibers [11], [12]. To enhance the electret effect of electrospun fibers, introducing nanoparticles is a state-of-art and common strategy [13], [14], [15], [16]. However, this strategy has two drawbacks: the intrinsic nano-agglomeration behavior makes nanoparticles hard to evenly distribute within fibers [11], [13]; particles, especially the accumulated ones, can easily detach from fibers and be inhaled, yielding additional threaten to human health [17]. The remaining challenge is to develop electrospun fibers with strong electret effect independent of particle charge enhancers.

Herein, we prepare all-polymer hybrid electret fibers by studying the complementarity of electric responses between electrospun polymers. The coupling of electric polarization behaviors of polystyrene (PS) and polyvinylidene fluoride (PVDF) enables the hybrid PS/PVDF fibers to show enhanced electret effect and high porosity. The protective respirator using PS/PVDF fibers as core layer exhibits high filtration efficiency, low air resistance, and long service life.

2. Results and discussion

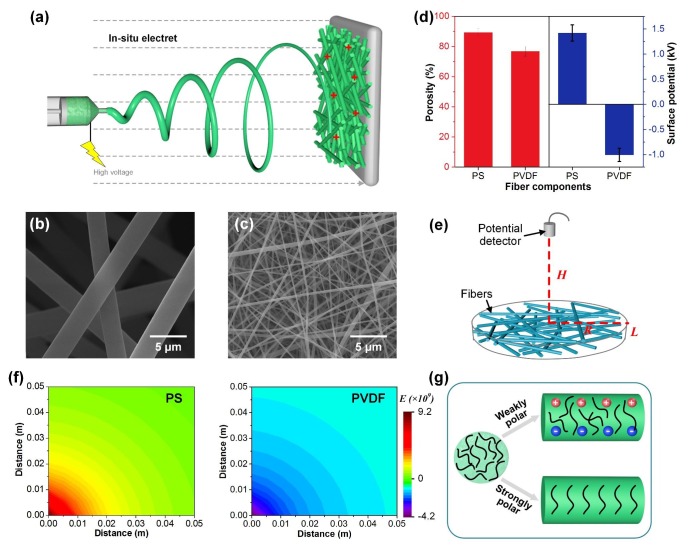

The premise to design all-polymer electret fibers is the reveal of electret mechanisms while electrospinning polymers with different dielectric properties. A general overview of electrospinning process in Fig. 1 a. Under the high voltage, solutions were ejected from a metal needle and evolved into electrified jets, which finally deposited on a collector as solid fibers after being continuously elongated and charged, as well as the simultaneous phase separation [18]. Obviously, electrospinning can in situ endow fibrous assemblies with electret effect during the evolution from solutions to solid fibers, implying that the electret property and structures could be simultaneously tailored by solution properties [19]. PS and PVDF were selected bacause they belong to the weakly and strongly polar polymers due to their ultralow and ultrahigh dielectric constants, respectively [20], [21]. Additiononally, they were widely studied electret matrials and were easily electrospun. The dielectret property of PS and PVDF was provided in Fig. S1, which also showed the relationship between dielectret property and polarity. The dielectric properties of other commonly used electrospun polymers were provided in Fig. S1 for comparison.

Fig. 1.

(a) A schematic overview of electrospinning. SEM images of (b) PS and (c) PVDF electrospun fibers. (d) Porosities and surface potentials. (e) Schematic illustrating the measure principle of surface potential. (f) Color maps showing the variation of . (g) Schematic describing the electret mechanism of polymers. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

The morphologies of PS and PVDF electrospun fibers (Fig. 1b and c) indicated that fibrous assemblies composed of PS possessed larger fiber diameter and higher porosity (89%) than PVDF (Fig. 1d). The effect of dielectric property on structures was discussed in Supplementary Discussion 1. The electret property of fibers was evaluated by the electric field intensity () of single fibers, which was deduced from the tested surface potential of fibrous assembilies () (Fig. 1d). Based on the non-contact measuring principle (Fig. 1e), the were calculated by:

| (1) |

where is the charge density of single fiber, is the dielectric constant, L is the distance, and refer to the thickness and porosity of fibrous membranes, R and H are the radius of testing samples and testing distance, respectively [22]. The detailed deducing process was provided in Supplementary Method 1. PVDF membranes exhibited negative surface potential, implying that dipole charges played a predominant role in PVDF fibers considering that was calculated by:

| (2) |

where and resultting from space and dipole charges, respectively [23]. The comparison of among different fibers was intuitively visualized by color maps (Fig. 1f). The largest red zones of PS fibers indicated the highest sensibility of electret effect on dielectric property. Namely, synthesizing polymers showing the similar dielectric property with PS could be an effective strategy to acquire electrospun electret fibers with high positive . The of PVDF fibers was negative due to the negative surface potential. The electret effect of fibers composed of weakly and strongly polar polymers (typical for PS and PVDF) resulted from the injection of charges into polymer traps and the dipoles orientation, respectively (Fig. 1g).

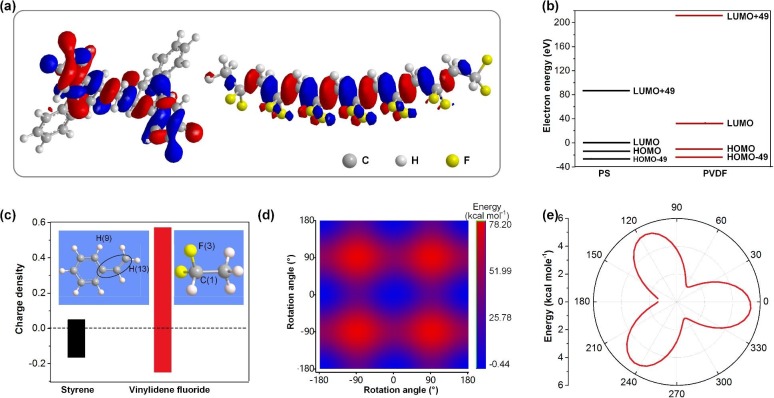

To proof the proposed electret mechanisms, stoichiometric calculations associated with polymer traps and group motion were performed. The detailed calculation process of Fig. 2 was provided in Supplementary Method 2. Charge-trapping sites, generally contributed by chemical and physical defects in a pure polymer insulator, are necessary for the injection of space charges [24]. To compare the chemical defects between PS and PVDF under the same weight, their oligomers with the minimum polymerization degrees of 4 and 7 respectively were constructed, donated as PS(4) and PVDF(7). Fig. 2a revealed the overlapping molecular orbitals in PS(4), which could serve as charge trapping sites. PS(4) and PVDF(7) exhibited higher energy of the Highest Occupied Molecular Orbital (HOMO) levels and the Lowest Unoccupied Molecular Orbital (LUMO) levels (Fig. 2b), suggesting holes and electrons tended to be injected into PS and PVDF, respectively [25], [26]. The comparison of energy band density between PS and PVDF also indicated that charges were more likely to be trapped within PS (Fig. S2 and Supplementary Discussion 2). Additionally, more charge traps resulting from physical defects were expected in PS since PS was amorphous with low crystalline (usually <30%), whereas PVDF was semicrystalline [27], [28].

Fig. 2.

(a) Molecular orbitals and (b) typical energy bands of PS(4) and PVDF (7). (c) Charge densities of styrene and VDF. Energies for the internal rotation of (d) styrene and (e) VDF.

The dipole orientation was reflected by the intramolecular rotation of PS and PVDF monomers. The charge density was calculated first to reveal the most easily rotating groups. According to Tab. S1 and S2, the highest and lowest charge densities were achieved by atoms H(9) (0.05) and H(13) (−0.165) in styrene, as well as atoms C(1) (0.573) and F(3) (−0.249) in VDF (Fig. 2c). The energy needed for dipole orientation, including H(9)-H(13) and C(1)-F(3), could be reflected by the internal rotation barriers of molecular main chain (Fig. 2d and e, Fig. S3). The internal rotation barrier of VDF was an order of magnitude lower than that of styrene, implying that dipole charges were predominant in electrospun PVDF fibers. Detailed discussions could also be found in Supplementary Discussion 3.

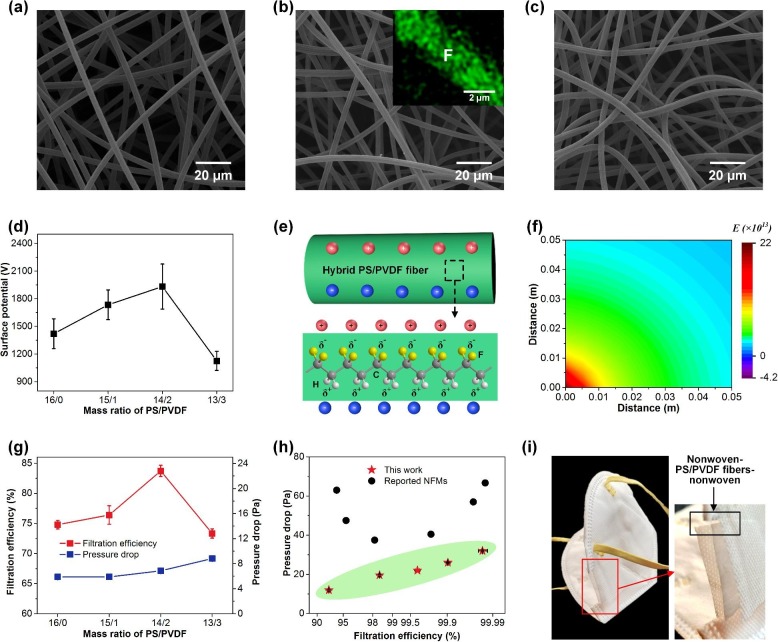

The reveal of electret mechanisms linked to the dielectric properties provides a new insight to improve electret property, that is, taking advantages of the synergistic effect of weakly and strongly polarized polymers. Hybrid PS/PVDF fibers with the mass ratios of 16/0 (PS/PVDF-0), 15/1 (PS/PVDF-1), 14/2 (PS/PVDF-2), 13/3 (PS/PVDF-3) were fabricated. Their morphologies displayed negligibly changed fiber diameter (Fig. 3 a–c, Fig. S4). However, the surface roughness appeared with the introduction of PVDF (Fig. S5 and Supplementary Discussion 4). The SEM-energy dispersive spectrometer image suggested the charge enhancer of PVDF evenly distributed in fibers (inset of Fig. 3b). The surface potential achieved improved by 36% by introducing 2/16 content of PVDF (Fig. 3d). The contribution of PVDF on electret property was illustrated by Fig. 3e. Charges injected into the matrix PS fibers generated local electric fields exhibiting the same direction with the external electrostatic field; however, the dipoles orientation of PVDF generated local electric fields showing the opposite direction with the external one. Different electronic transport capabilities between PVDF and PS rendered the charge accumulation at the interfacial zones instead of being transferred from one to another [29]. Thus, induced charges within PS were generated, which interestingly showed the same direction with the injected charges. As a result, the electret effect of whole fibers was enhanced. PS/PVDF-3 membranes exhibited declined surface potential due to decreased interfacial zones. The highest porosity was achieved by PS/PVDF-2 fibers (94.4%) and porosity exhibited the same variation trend as surface potential. The electric field intensity () around single PS/PVDF-2 fiber was calcultaed by eliminating the effects of porosity and thickness (Fig. S6). Compared to pure PS, a wider range of scale bar (from −4.2 × 109 to 22 × 109) implied a higher (Fig. 3f). Notably, the electret property was enhanced without relying on toxic nanoparticle as charge enhancers, which has never been reported in the previously developed electrospun electret fibers and melt-blown electret fibers. The comparison of surface potentials among PS/PVDF fibers and recently reported electret fibers were provided in Tab. S3 and Supplementary Discussion 5.

Fig. 3.

SEM images of electret (a) PS/PVDF-1, (b) PS/PVDF-2, and (c) PS/PVDF-3 fibers. Inset of (b) is the distribution of atom F. (d) Surface potentials of PS/PVDF electret fibers. (e) Schematic illustrating the contribution of PVDF on electret effect. (f) A color map showing the electric field around single PS/PVDF-2 fiber. (g) Filtration performance of various electret PS/PVDF materials. (h) Comparison of filtration performances [17], [20], [32]. (i) A N95 respirator using PS/PVDF-2 fibers as the core material. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

PS/PVDF-2 membranes exhibited the highest filtration efficiency of 83.726%, improved by 12% than PS/PVDF-0 membranes (Fig. 3g). The pressure drops of various PS/PVDF membranes were extremely low (<10 Pa), <0.01% of atmosphere pressure. The filtration efficiency was further increased to meet different protective requirements (Fig. S7). The excellent filtration performance of PS/PVDF fibers was highlighted by comparing with previously reported air filtration materials (Fig. 3h) [13], [16], [30], [31], [32]. Furthermore, a wearable respirator was fabricated by using PS/PVDF membranes as the core functional layer (Fig. 3i). The filtration performance of this respirator was evaluated according to the method proposed by the National Institute for Occupational Safety and Health (NIOSH). Its filtration efficiency (99.752%) met the requirements of N95 respirators for protective function (>95%). More importantly, its air resistance (72 Pa) was only one fifth of the maximum limit (~320 Pa) in NIOSH standard, ensuring the breath comfort. It also exhibited a long service life (Fig. S8), the detailed information were provided in Supplementary Discussion 6.

3. Conclusions

All-polymer hybrid electret fibers relying on the coupling behaviors of PS and PVDF in electric polarization were fabricated. First, the electret mechanism of electrospinning technology was revealed by focusing on the dielectret property of polymers. The electret effect of electrospun fibers, composed of polymers with ultralow and ultrahigh dielectret constants, came from the injection of charges into polymer traps and the dipoles orientation, respectively. Moreover, hybrid PS/PVDF fibers with structural continuity and enhanced electret effect were obtained, exhibiting high filtration efficiency (99.752%), low air resistance (72 Pa) and long service life. They were promising candidate as the core materials of low-resistance N95 protective masks.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work is supported by National Natural Science Foundation of China (No. 51973028, 51925302), Fundamental Research Funds for the Central Universities (No. 223201900081, CUSF-DH-D-2017019), State Key Laboratory for Modification of Chemical Fibers and Polymer Materials (ZR1902).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.cej.2020.125626.

Appendix A. Supplementary data

The following are the Supplementary data to this article:

References

- 1.Bermejo M., Rodriguez-Teijeiro J.D., Illera G., Barroso A., Vila C., Walsh P.D. Ebola outbreak killed 5000 gorillas. Science. 2006;314 doi: 10.1126/science.1133105. 1564–1564. [DOI] [PubMed] [Google Scholar]

- 2.Heitman J., Morens D.M., Fauci A.S. Emerging infectious diseases: threats to human health and global stability. PLoS Pathog. 2013;9 doi: 10.1371/journal.ppat.1003467. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Tellier R. Review of aerosol transmission of influenza a virus. Emerg. Infect. Dis. 2006;12:1657–1662. doi: 10.3201/eid1211.060426. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Penconek A., Jackiewicz A., Moskal A. Penetration of diesel exhaust particles (DEPs) through fibrous filters produced using melt-blown technology. KONA Powder Part. J. 2015:2015008. [Google Scholar]

- 5.Zhu M., Han J., Wang F., Shao W., Xiong R., Zhang Q., Pan H., Yang Y., Samal S.K., Zhang F., Huang C. Electrospun nanofibers membranes for effective air filtration. Macromol. Mater. Eng. 2017;302(1) [Google Scholar]

- 6.Zhang Q., Welch J., Park H., Wu C.Y., Sigmund W., Marijnissen J.C.M. Improvement in nanofiber filtration by multiple thin layers of nanofiber mats. J. Aerosol Sci. 2010;41:230–236. [Google Scholar]

- 7.Thakur R., Das D., Das A. Electret air filters. Sep. Purif. Rev. 2013;42:87–129. [Google Scholar]

- 8.Oh Y.-W., Jeon K.-J., Jung A.-I., Jung Y.-W. A simulation study on the collection of submicron particles in a unipolar charged fiber. Aerosol Sci. Technol. 2002;36:573–582. [Google Scholar]

- 9.Cheng Y.L., Wang C.Y., Zhong J.W., Lin S.Z., Xiao Y.J., Zhong Q.Z., Jiang H.L., Wu N., Li W.B., Chen S.W., Wang B., Zhang Y.Y., Zhou J. Electrospun polyetherimide electret nonwoven for bi-functional smart face mask. Nano Energy. 2017;34:562–569. [Google Scholar]

- 10.Gu G.Q., Han C.B., Lu C.X., He C., Jiang T., Gao Z.L., Li C.J., Wang Z.L. Triboelectric nanogenerator enhanced nanofiber air filters for efficient particulate matter removal. ACS Nano. 2017;11:6211–6217. doi: 10.1021/acsnano.7b02321. [DOI] [PubMed] [Google Scholar]

- 11.Ding X., Li Y., Si Y., Yin X., Yu J., Ding B. Electrospun polyvinylidene fluoride/SiO2 nanofibrous membranes with enhanced electret property for efficient air filtration. Compos. Commun. 2019;13:57–62. [Google Scholar]

- 12.Huang Z., Liu X., Zhang X., Wong S., Chase G., Qu J., Baji A. Electrospun polyvinylidene fluoride containing nanoscale graphite platelets as electret membrane and its application in air filtration under extreme environment. Polymer. 2017;131:143–150. [Google Scholar]

- 13.Wang S., Zhao X.L., Yin X., Yu J.Y., Ding B. Electret polyvinylidene fluoride nanofibers hybridized by polytetrafluoroethylene nanoparticles for high-efficiency air filtration. ACS Appl. Mater. Interfaces. 2016;8:23985–23994. doi: 10.1021/acsami.6b08262. [DOI] [PubMed] [Google Scholar]

- 14.Li X.Q., Wang N., Fan G., Yu J.Y., Gao J., Sun G., Ding B. Electreted polyetherimide–silica fibrous membranes for enhanced filtration of fine particles. J. Colloid Interf. Sci. 2015;439:12–20. doi: 10.1016/j.jcis.2014.10.014. [DOI] [PubMed] [Google Scholar]

- 15.Zhang Q., Liu F., Yang T., Si X., Hu G., Chang C. Deciphering effects of surface charge on particle removal by TiO2 polyacrylonitrile nanofibers. Aerosol Air Qual. Res. 2017;17:1909–1916. [Google Scholar]

- 16.Yeol Y., Eunkyoung S., Pourdeyhimi B. Boehmite nanoparticles incorporated electrospun nylon-6 nanofiber web for new electret filter media. Macromol. Res. 2010;18:884–890. [Google Scholar]

- 17.Mossman B., Borm P., Castranova V., Costa D., Donaldson K., Kleeberger S. Mechanisms of action of inhaled fibers, particles and nanoparticles in lung and cardiovascular diseases. Part. Fibre Toxicol. 2007;4:1–10. doi: 10.1186/1743-8977-4-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Wang X., Ding B., Sun G., Wang M., Yu J. Electro-spinning/netting: a strategy for the fabrication of three-dimensional polymer nano-fiber/nets. Prog. Mater. Sci. 2013;58:1173–1243. doi: 10.1016/j.pmatsci.2013.05.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Li Y., Yin X., Yu J., Ding B. Electrospun nanofibers for high-performance air filtration. Compos. Commun. 2019;15:6–19. [Google Scholar]

- 20.Ahmad Z. IntechOpen; US: 2012. Dielectric Material, Polymer Dielectric Materials. [Google Scholar]

- 21.Mark J. Oxford University Press; UK: 2009. Polymer Data Handbook. [Google Scholar]

- 22.Nanis L., Kesselman W. Engineering applications of current and potential distributions in disk electrode systems. J. Electrochem. Soc. 1971;118:454–461. [Google Scholar]

- 23.Takada T., Hayase Y., Tanaka Y., Okamoto T. Space charge trapping in electrical potential well caused by permanent and induced dipoles for LDPE/MgO nanocomposite. IEEE Trans. Dielectr. Electr. Insulation. 2008;15:152–160. [Google Scholar]

- 24.Huzayyin A., Boggs S., Ramprasad R. Quantum mechanical studies of carbonyl impurities in dielectric polyethylene. IEEE Trans. Dielectr. Electr. Insulation. 2010;17:920–925. [Google Scholar]

- 25.Meunier M., Quirke N., Aslanides A. Molecular modeling of electron traps in polymer insulators: Chemical defects and impurities. J. Chem. Phys. 2001;115:2876–2881. [Google Scholar]

- 26.Takada T., Kikuchi H., Miyake H., Tanaka Y., Yoshida M., Hayase Y. Determination of charge-trapping sites in saturated and aromatic polymers by quantum chemical calculation. IEEE Trans. Dielectr. Electr. Insulation. 2015;22:1240–1249. [Google Scholar]

- 27.Xin Y., Zhu J., Sun H., Xu Y., Liu T., Qian C. A brief review on piezoelectric PVDF nanofibers prepared by electrospinning. Ferroelectrics. 2018;526:140–151. [Google Scholar]

- 28.Zheng J., He A., Li J., Xu J., Han C.C. Studies on the controlled morphology and wettability of polystyrene surfaces by electrospinning or electrospraying. Polymer. 2006;47:7095–7102. [Google Scholar]

- 29.Kravtsov A., Brünig H. Phase separation events induce the coexistence of distinct nanofeatures in electrospun fibres of poly(ethyl cyanoacrylate) and polycaprolactone. Fibre Chem. 2000;32:180–186. [Google Scholar]

- 30.Zhao X., Li Y., Hua T., Jiang P., Yin X., Yu J., Ding B. Low-resistance dual-purpose air filter releasing negative ions and effectively capturing PM2.5. ACS Appl. Mater. Interfaces. 2017;9:12054–12063. doi: 10.1021/acsami.7b00351. [DOI] [PubMed] [Google Scholar]

- 31.Han K., Lee S., Kim M., Park P., Lee M., Nah J. Functional nanofibers for environmental applications. Adv. Funct. Mater. 2019:1903633. [Google Scholar]

- 32.Li X., Wang C., Huang X., Zhang T., Wang X., Min M., Wang L., Huang H., Hsiao B. Filters based on carbon nanotubes. ACS Appl. Mater. Interfaces. 2018;10:42891–42904. doi: 10.1021/acsami.8b16564. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.