Abstract

Thyme oil in water nanomulsion was prepared under subcritical water conditions using water and saponin, as solvent and emulsifier, respectively. Gas chromatography revealed that there were 44 bioactive components in the extracted thyme essential oil which, thymol and carvacrol were two mains of them. Experiments were designed based on central composite design and effects of amounts of saponin and thyme essential oil were evaluated on particle size, polydispersity index (PDI) and zeta potential of the prepared nanoemulsions using response surface methodology. Obtained results revealed that more desirable thyme oil nanoemulsions with minimum particle size (184.51 nm) and PDI (0.514), and maximum zeta potential (− 22.51 mV) were prepared using 0.94 g of saponin and 0.28 mL of thyme essential oil. Furthermore, results indicated that prepared nanoemulsion using obtained optimum production conditions had relatively high antioxidant activity (24%) and high antibacterial and antifungal activities against Staphylococcus aureus and Penicillium digitatum.

Keywords: Nanoemulsion, Optimization, Saponin, Subcritical water, Thyme essential oil

Introduction

Plant essential oils are more interested and useable for application in numerous foods, pharmaceutical and supplement formulations and products (Chang et al., 2012; Ryu et al., 2018a; 2018b; Tan et al., 2017). Furthermore, it can be related to the growing consumer demand for natural bioactive compounds as compared to the synthetic ones (Chang et al., 2015). Nevertheless, due to non-polar nature of the essential oils, their solubility are low in water which that limits their applications in the watery based formulations (Chang et al., 2012). Thyme (Thymus vulgaris L.) is of the Lamiaceae family, with the Western Mediterranean origin. However, this aromatic plant is cultured in Southern and Central Europe, Southeast Asia, North America and Africa. Thyme and its derivatives such as leaves, root, essential oil and aqueous extract have been widely used in food, medical and cosmetics areas due to its pleasant odor and taste, and its highest antimicrobial activities against numerous microorganisms including bacteria and fungi strains. These unique attributes can be related to the presence of thymol and its isomer (carvacrol), β-caryophyllens, γ-terpinene, and p-cymene in the thyme essential oil (Pavela et al., 2018; Ryu et al., 2018a; 2018b).

Nanotechnology consists of the processes which those have ability to reduce particle size of non-polar bioactive compounds and increase their surface area to volume ratio to the submicron range (less than 1000 nm), which that improves their solubility in aqueous media and raises their saturation solubility (Anarjan et al., 2017; Anarjan et al., 2014a). Nanoemulsion consists of three main components namely; organic phase including oily compounds and non-polar solvents, aqueous phase based on water and emulsifiers (Anarjan et al., 2015). Type and concentration of emulsifiers have key role in the formation of small sized droplets of bioactive compounds, as those decrease interfacial tension and surface energy per unit area, between the oil and water phases (Gupta et al., 2016). Furthermore, presence of emulsifiers, protect main valuable and sensitive bioactive compounds from strict environment circumstances including, temperature, pH, light and oxidation (Sayyar and Jafarizadeh-Malmiri, 2019a). The most common emulsifiers used in the food emulsion formulations are amphiphilic natural materials such as proteins, polysaccharides, and small-molecule components (e.g. Tween 20, 40 and 80), which those can be utilized individually or in their combination (Anarjan et al., 2014b; Krstonošić et al., 2015). Saponin, as a natural surfactant, has gained more attentions and subjected in considerable researches because of its unique and excellent properties related to the foaming, emulsifying and stabilizing, these years. Furthermore, saponin has also some health benefits and pharmaceutical effects including antimicrobial and antiviral activities (Chung et al., 2017c). Several studies have been completed on preparation of corn oil, orange oil and vitamin E, fish oil, medium chain triglyceride oil, astaxanthin, lemon oil and orange oil nanoemulsions using saponin (Bai et al., 2016; Chen et al., 2018; Kaur et al., 2016; Ozturk et al., 2014; Shu et al., 2018; Taarji et al., 2018; Uluata et al., 2015; Yang et al., 2013; Zhang et al., 2015a; 2015b). Furthermore, an oil in water nanoemulsion using quillaja saponin has also been prepared which, that indicated high stability in the pH ranging 3 to 7 (Chung et al., 2017a; 2017b). Nanoemulsions can be fabricated using both low-energy and high-energy approaches (Ryu et al. ,2018a; 2018b; Taarji et al., 2018). However, most of the utilizing techniques, in the preparation of oil in water (O/W) nanoemulsions, are based on consuming large amounts of emulsifiers and organic solvents which those are not cost-effective and eco-friendly (McClements, 2011; McClements and Rao, 2011; Sayyar and Jafarizadeh-Malmiri, 2019b). Using subcritical water, as natural solvent, it is possible to prepare O/W nanoemulsions with minimum amounts of emulsifier (Sayyar and Jafarizadeh-Malmiri, 2019b). Subcritical water is defined as under pressurized water at high temperature (more than 100 °C) and pressure (more than 1 bar), that water preserves its liquid state but, its polarity decreases and it tends to the polarity of methanol, ethanol and acetone (Sayyar and Jafarizadeh-Malmiri, 2019b). In addition to, due to using water, as a safe and non-toxic solvent, no need to more additional processes such as solvent removal, at the end of nanoemulsion preparation (Sayyar and Jafarizadeh-Malmiri, 2019a). The main objectives of present work were to (1) prepare thyme oil nanoemulsions using subcritical water, as solvent, and saponin, as emulsifier, (2) optimize thyme oil nanoemulsion production parameter namely; amounts of saponin and thyme oil and (3) study of the physical, chemical, antimicrobial and antioxidant activities of the resulted nanoemulsions.

Materials and methods

Materials

Thyme plant was provided from a local market in Tabriz, East Azerbaijan province of Iran. Saponin was purchased from Merck Company (Darmstadt, Germany). 2, 2-diphenyl-2-picrylhydrazyl (DPPH) was purchased from Sigma Company (St. Louis, MO, USA). Bacteria strain of Staphylococcus aureus (PTCC 1112) and Penicillium digitatum (PTCC 5251) were provided from microbial Persian Type Culture Collection (PTTC, Tehran, Iran). Plate count agar (PCA) and potato dextrose agar (PDA) and were obtained from Oxoid (Oxoid Ltd., Hampshire, England). Distilled water was used through of experiments including extraction and nanoemulsion preparation.

Thyme essential oil extraction

In order to prepare thyme essential oil extract, 100 g of dried thyme powder was added into 700 mL of distilled water and placed into a laboratory hydro distillation glass-clevenger apparatus for 2 h. 2.5 mL of light yellow colored oil with a pleasant odor was separated from the extract and stored in a tightly sealed dark glass bottle at 4 °C, for the further processes and analyses.

Thyme O/W nanoemulsions preparation

According to the experimental design (Table 1), different amounts of saponin ranging 0.5 to 2 g were added into 45 mL distilled water and the solutions were mixed using heater and stirrer, adjusted at 70 °C and 30 rpm, for 10 min. After that, defined amount of thyme essential oil ranging 0.2 to 0.8 mL (Table 1) was added into the prepared solutions and the solutions were stirred at same conditions for 5 min. Finally, the mixture solutions were placed in a completely sealed Teflon hydrothermal autoclave, with capacity of 100 mL, and heated in oven (Behdad Medical Production Co., SP88, Tehran, Iran) at 120 °C and pressure of 1.5 atm, for 2 h.

Table 1.

CCD and values of response variables (predicted and experimental) for preparation of thyme O/W nanoemulsions

| Runs | Amount of saponin (g) | Amount of thyme oil (mL) | Particle size (nm) | PDI | Zeta potential (mV) | |||

|---|---|---|---|---|---|---|---|---|

| Expa | Preb | Expa | Preb | Expa | Preb | |||

| 1 | 0.719 | 0.287 | 283.6 | 259.6 | 0.601 | 0.598 | − 24.9 | − 25.5 |

| 2 | 1.250 | 0.500 | 121.5 | 127.4 | 0.575 | 0.596 | − 20.6 | − 19.8 |

| 3 | 1.780 | 0.287 | 356.2 | 352.5 | 0.583 | 0.559 | − 10.1 | − 9.5 |

| 4 | 1.250 | 0.500 | 112.2 | 127.4 | 0.601 | 0.596 | − 19.8 | − 19.8 |

| 5 | 1.250 | 0.500 | 148.7 | 127.4 | 0.612 | 0.596 | − 19 | − 19.8 |

| 6 | 1.250 | 0.800 | 492.8 | 587.8 | 0.721 | 0.765 | − 21.4 | − 20.7 |

| 7 | 2.000 | 0.500 | 479.5 | 512.6 | 0.683 | 0.723 | − 13.6 | − 14.1 |

| 8 | 1.250 | 0.200 | 245.3 | 245.1 | 0.414 | 0.421 | − 16.9 | − 16.9 |

| 9 | 1.780 | 0.712 | 678.6 | 607.5 | 0.771 | 0.721 | − 17.1 | − 16.4 |

| 10 | 1.250 | 0.500 | 127.5 | 127.4 | 0.596 | 0.596 | − 19.8 | − 19.8 |

| 11 | 1.250 | 0.500 | 127.4 | 127.4 | 0.596 | 0.596 | − 19.8 | − 19.8 |

| 12 | 0.719 | 0.712 | 580.5 | 489.2 | 0.952 | 0.923 | − 17.9 | − 19.0 |

| 13 | 0.500 | 0.500 | 301.6 | 363.3 | 0.881 | 0.892 | − 24.8 | − 23.7 |

aExperimental values of studied responses

bPredicted values of studied responses

Analysis

Thyme essential oil

Gas chromatography (GC–MS Agilent 6890, Santa Clara, CA, USA) coupled with a 30 m × 0.25 mm HP-5 capillary column and a HP 5989A mass spectrometer, which was operated in electron ionization mode at 70 eV, was used to determine the main existed bioactive compounds in the extracted thyme essential oil. Nitrogen was used as carrier gas.

Thyme oil nanoemulsions

Dynamic light scattering (DLS) particle size analyzer (Malvern instruments, Zetasizer Nano ZS, Worcestershire, UK) was utilized to measure particle size, polydispersity index (PDI) and zeta potential values of the resulted thyme O/W nanoemulsions. Furthermore, transmission electron microscopy (TEM, CM120, Philips Co., Amsterdam, Netherlands) with an acceleration voltage of 120 kV, was employed to assess morphological attributes of the prepared nanoemulsions such as shape and size.

Antioxidant activity

Antioxidant activity of prepared thyme O/W nanoemulsions, based on the free radical-scavenging activity, was measured using described technique by Sayyar and Jafarizadeh-Malmiri (2019a). In this method, a UV–Visible spectrophotometer (250–800 nm, Perkn Elmer’s Co., Rodgau, Germany), adjusted at wavelength of 517 nm, was used to measure absorbance of the control (Acontrol) and sample (Asample). In fact the samples were provided by addition of 100 µL of the prepared nanoemulsions into 5 mL of methanol (50% v/v), which that was contained 1 mM DPPH radicals. While, control sample was prepared by mixing of pure DPPH and methanol. Antioxidant activity of the samples, as inhibition percentage (I%), was calculated using Eq. (1):

| 1 |

Antimicrobial activity

Antibacterial activity of the extracted thyme essential oil, saponin and prepared thyme O/W nanoemulsions was evaluated using agar diffusion method (Ahmadi et al., 2018; Sayyar and Jafarizadeh-Malmiri, 2019c). In this method, suspension of gram positive bacteria, Staphylococcus aureus (S. aureus), including cfu (colony forming unit) was prepared based on 0.5 McFarland standard. After that 0.1 mL of the suspension was inoculated on the surface of the set PCA and spread. Afterward, three holes (5 mm in diameter) were created in each plate and 10 µL of the extracted thyme essential oil, saponin and prepared nanoemulsion was decanted in the holes. Prepared plates were then placed in incubator, adjusted at 37 °C for 24 h. Bactericidal effect of the samples was presented as diameter of formed clear zone nearby the holes.

Antifungal activity of the samples against P. digitatum, was measured according to inhibition in mycelia growth radial of the selected fungus on the plates including PDA amended with 1 mL of each sample as described by Mohammadlou et al. (2017). In this method an agar disk of pure culture of the fungus, with diameter of 5 mm, was separated and placed in the middle of provided plates containing PDA, as control sample, and PDA amended with prepared nanoemulsion and extracted essential oil, and the plates were put in incubator, set at 26 °C for 10 days. Mycelia growth radial for the control and samples were measured daily and fungicidal effect of the samples was stated as fungal mycelia growth (mm).

Design of experiments and statistical analysis

Using central composite design (CCD), 13 randomized experiments were achieved and response surface methodology (RSM) was utilized to evaluate effectiveness of the selected independent factors, including amounts of saponin (X1, 0.5–2 g) and thyme essential oil (X2, 0.2–0.8 mL) on the response variables of the formed nanoemulsions namely; particle size (Y1, nm), PDI (Y2) and zeta potential (Y3, mV). To minimize of the pure error, center point (X1 = 1.25 g and X2 = 0.5) was repeated five times (Ahmadi et al., 2019). Response variables were correlated to the linear (Xi), quadratic (X2i) and interaction (Xi Xj) terms of independent factors based on a second-order polynomial model (Eq. 2).

| 2 |

This equation contains constant (β0) and coefficients of main (βi), quadratic (βii) and interaction (βij) terms of the studied independent factors. Suitability of the created models for the response variables was evaluated using obtained values for coefficient of determination (R2) and adjusted coefficient of determination (R2-adj). Importance of the terms of independent factors was assessed using analysis of variance (ANOVA) based on p value, where small p value (p < 0.05) was chosen as a significant effect.

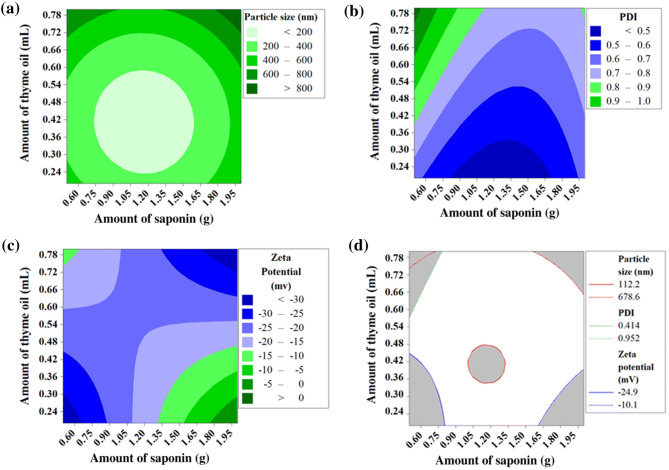

To well imagine interactive influences of the independent factors on the selected response factors, two dimensions contour plot and three dimensions surface plot were provided. Numerical optimization was used to achieve exact values for the amounts of saponin and thyme essential oil to prepare nanoemulsions with minimum particle size and PDI, and maximum zeta potential. Graphical optimization, according to overlade contour plot, was also plotted to better visualize the optimum area for amounts of the two main components for nanoemulsions preparation. CCD, RSM, ANOVA, model generation and optimization procedures were carried out using Minitab software (v.16 statistical package, Minitab Inc., Pennsylvania State, PA, USA).

Results and discussion

Model generation

Based on CCD, values for the response variables were achieved (Table 1) and were utilized to generate their second order polynomial models as function of saponin and thyme essential oil amounts. Coefficients of the generated models terms, R2 and R2-adj, show in Table 2. High values of R2 and R2-adj for particle size (> 88.9%), PDI (> 94.1%) and zeta potential (> 95.1%), with higher lack of fit (p > 0.05) for all three of them, verified desirable suitability of the fitted models to predict values of the particle size, PDI and zeta potential of the thyme O/W nanoemulsions as function of the amounts of emulsifier and essential oil. p values of linear, quadratic, and interactive terms of the obtained final models similarly show in Table 2. Commonly, more significance effect of each term is related to its lower p value. As evidently presented in Table 2, the interaction term of both independent factors, quadratic term of amount of thyme essential oil, and quadratic term of both saponin and essential oil amounts had insignificant (p > 0.05) effects on the particle size, PDI and zeta potential of the prepared thyme oil nanoemulsions under subcritical water conditions.

Table 2.

Regression coefficients R2, R2-adj and p values for the generated models

| Regression coefficient | Particle size (nm) | p value | PDI | p value | Zeta potential (mV) | p value |

|---|---|---|---|---|---|---|

| β0 (constant) | 5.362 | 5.650 | − 10.131 | |||

| β1 (main) | − 5.003 | 0.002 | − 6.195 | 0.000 | 5.220 | 0.002 |

| β2 (main) | − 4.145 | 0.004 | 2.988 | 0.020 | 3.120 | 0.021 |

| β11 (quadratic) | 6.405 | 0.000 | 8.107 | 0.000 | 1.246 | 0.259 |

| β22 (quadratic) | 5.961 | 0.001 | − 0.096 | 0.927 | 1.315 | 0.236 |

| β12 (interaction) | 0.199 | 0.848 | 2.363 | 0.049 | − 7.671 | 0.000 |

| R2 | 93.50% | 96.50% | 97.30% | |||

| R2-adj | 88.90% | 94.10% | 95.10% |

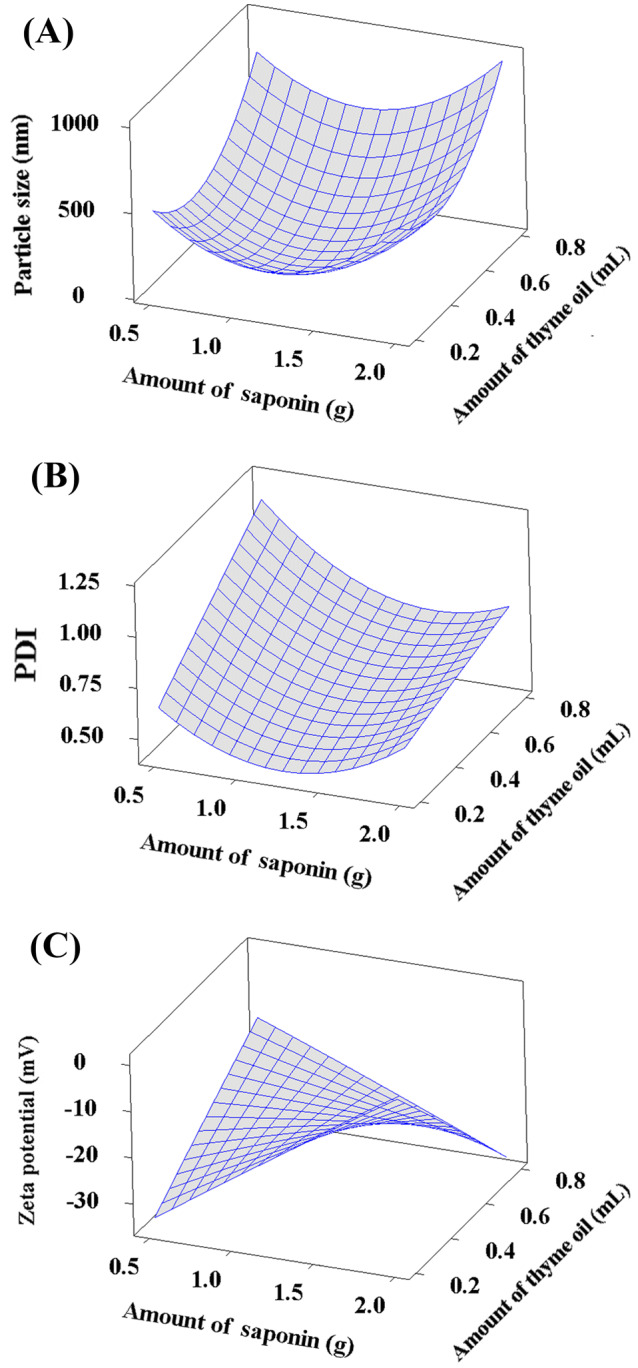

Particle size of the prepared nanoemulsions

Mean particle size of the resulted thyme O/W nanoemulsions under subcritical water conditions, varied from 121 to 678 nm for different 13 experimental runs (Table 1). Effects of the amounts of saponin and thyme essential oil on the particle size of the formed nanoemulsions show in Fig. 1(A). As evidently presented in this figure, at constant amount of emulsifier, by increasing in the amount of thyme essential oil particle size of the prepared nanoemulsions increased. Attained result demonstrated that lower amounts of emulsifier could not surround the dispersed thyme oil nanodroplets in aqueous media which in turn, nanodroplets move to each other due to their hydrophobicity. Absence of curvature in the Fig. 1(A) indicated that interaction of both selected and studied independent factors had insignificant effect on particle size of the prepared nanoemulsions. This result can be reconfirmed by the high p value (p > 0.05) of interactive term, as mentioned in Table 2. As evidently presented in Fig. 2(A), maximum particle size values for the prepared nanoemulsions were obtained using highest amount of thyme essential oil and lowest and highest amounts of emulsifier. Attained results were in line with finding of Taarji et al. (2018) and Ryu et al. (2018a; 2018b). They studied the formation and stability of thyme O/W nanoemulsions using saponin as emulsifier, and found that using high amounts of saponin and thyme essential oil, the particle size of the prepared nanoemulsions increased.

Fig. 1.

Surface plots for particle size (A), PDI (B) and zeta potential (C) of the prepared thyme O/W naoemulsions, as function of amounts of saponin (g) and thyme oil (mL)

Fig. 2.

Contour plots for particle size (A), PDI (B), zeta potential (C), and overlaid contour plot (D) of the prepared thyme O/W naoemulsions, as function of amounts of saponin (g) and thyme oil (mL)

PDI of the prepared nanoemulsions

PDI values of the prepared thyme oil in water nanoemulsions, according to CCD, changed from 0.414 to 0.952 (Table 1). Effects of the amounts of saponin and thyme essential oil on the PDI of the resulted nanoemulsions appear in Fig. 1(B). As can be seen in this figure, at the low amounts of saponin, by rising amount of thyme essential oil, the PDI of the resulted nanoemulsions increased, sharply. While, at high amount of emulsifier, by increasing the amount of thyme essential oil, the PDI of the formed nanoemulsions increased, slowly. This demonstrated that the interactive term of both studied factors had significant effect on PDI of the prepared nanoemulsions, as that was reconfirmed by its low p value which that was indicated at Table 2. Figure 2(B) indicates that the maximum value of PDI was related to the prepared nanoemulsions using lowest and highest amounts of saponin and thyme essential oil, respectively. PDI is a dimensionless factor that displays homogeneity of the formed nanoemulsions. This parameter has key effect on stability of the resulted nanoemulsions. One of the unfavorable phenomena in nanoemulsion preparation, is Ostwald ripping and coalescence which, those occur in nanoemulsions with high PDI values (Sayyar and Jafarizadeh-Malmiri, 2019b). Obtained result reconfirmed the maximum particle size of the prepared thyme essential O/W nanoemulsions using lowest and highest amounts of saponin and thyme essential oil, respectively, as can be observed in Fig. 2(B).

Zeta potential of the prepared nanoemulsions

Zeta potential is a measure of electrostatic stability with positive or negative values. Each one has a greater amount; surface charge of the material is greater and nanoeulsion is more stable. In the case of low surface loads, the particles tend to gravitate toward each other, and thus the particle size increases and the nanoemulsion stability decreases (Chung et al., 2017b). As evidently presents in Table 1, zeta potential values of the resulted thyme O/W nanoemulsions, varied from − 10.1 to − 24.9 mV. Influences of the amounts of both saponin and thyme essential oil on the zeta potential of the resulted nanoemulsions, show in Fig. 1(C). As can be seen clearly in this figure, at lower and constant amounts of emulsifier, by reduction in amount of thyme essential oil, zeta potential increased sharply, and at higher and constant amounts of saponin, by decreasing amount of oil, zeta potential decreased. Presence of curvature in the Fig. 1(C), demonstrated that interaction of the selected independent factors, had significant (p < 0.05) effect on zeta potential of the formed nanoemulsions. This result was in line with achieved result presented in Table 2. Figure 2(C) indicated that the highest stability and high Zeta potential of the resulted nanoemulsions was obtained using low amounts of saponin and thyme essential oil. However, lowest zeta potential was related to the prepared nanoemulsions using high amounts of emulsifier and low amounts of thyme essential oil. It seems that in the formed nanoemulsions using high amounts of emulsifier and low amounts of essential oil, by adding extra amount of saponin, resulted micelles, which those can interfere with the stability of the nanoemulsion, reduce overall charge of the nanoemulsions. Obtained results were in line with finding of Zhang et al. (2015b). They prepared orange O/W nanoemulsions using saponin, with high electrostatic stability (zeta potential value).

Optimization of the process

Graphical optimization, according to the generated models which those correlate response variables into the independent parameters shows in Fig. 2(D). White colored area in Fig. 2(D) indicated the desired amounts of saponin and thyme essential oil. Numerical multiple optimization also demonstrated that preparation of thyme O/W nanoemulsions under subcritical water conditions, and using 0.28 mL thyme essential oil and 0.94 g saponin could result nanoemulsions with minimum particle size (184.51 nm) and PDI (0.514), and maximum zeta potential (− 22.51 mV). In order to verify the accuracy and adequacy of the generated models and predicted optimum amounts of saponin and thyme essential oil, three thyme oil nanoemulsions were provided using the predicted optimum amounts of the saponin and thyme oil. Results revealed that experimental values for particle size, PDI and zeta potential of the prepared thyme O/W nanoemulsions using optimum amounts of two main components, were 184 ± 3 nm, 0.5 ± 0.1 and − 22 ± 1 mV, respectively and statistical analysis indicated that there were insignificant differences between the predicted and experimental values for the response variables.

Main bioactive compounds of thyme essential oil

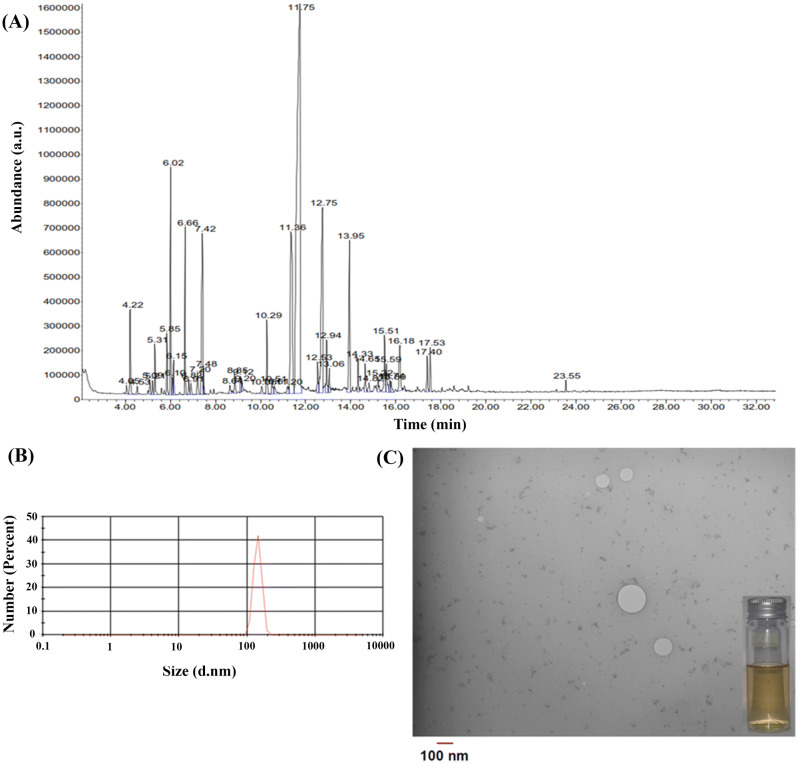

GC–MS chromatogram of the thyme essential oil shows in Fig. 3(A). As shown in this chromatogram, approximately 44 detected components were indicated in the extracted essential oil, within 32 min of retention time. As can be seen in this figure, thymol and carvacrol were two main known bioactive compounds of the thyme essential oil, which those had maximum peak height at retention times of 11.36 and 11.75 min, respectively. However, cymene and caryophyllene, with retention times of 6.02 and 12.75 min, were other two important bioactive compounds existed in thyme essential oil.

Fig. 3.

GC-MS chromatogram of the extracted thyme essential oil (A), particle size distribution (B) and TEM image of the prepared thyme O/W nanoemulsion using obtained optimum production conditions

Physico-chemical attributes of the prepared thyme oil nanoemulsion using obtained optimum conditions

Particle size distribution of the prepared nanoemulsion using attained optimum amounts of saponin and thyme essential oil indicates in Fig. 3(B). Sharp and narrow observed peak demonstrated that PDI value of the prepared nanoemulsion was low and the resulted nanodroplets in the nanoemulsion were monodispersed. As can be seen in Fig. 3(B), particle size of the resulted thyme oil nanodroplets changed between 83 and 191 nm, with an average size of 184 nm. A typical TEM image of the prepared thyme O/W nanoemulsion, using obtained optimum amounts of saponin and thyme essential oil, shows in Fig. 3(C). As evidently presented in this figure, formed thyme oil nanodroplets in the emulsion were well dispersed with spherical structures and particle size ranging 20 to 100 nm. Spherical shape of the nanodroplets demonstrated that the prepared nanoemulsions had minimum surface energy and high thermodynamic stability, and verified high zeta potential value of the resulted nanoemulsions. Figure 3(C) shows also the appearance of the prepared thyme essential O/W nanoemulsion using achieved optimum amounts of the emulsifier and oil. Transparency of the prepared nanoemulsion revealed that the formed thyme oil nanodroplets in the emulsion, had lower particle size which that was in line with obtained results by DLS and TEM.

Antioxidant activity of the prepared thyme oil nanoemulsion

Obtained results demonstrated that the prepared thyme O/W nanoemulsion using obtained optimum conditions, saponin and thyme essential oil had antioxidant activity of 24, 10.5 and 95.1%, respectively. Obtained results revealed that thyme essential oil and saponin had maximum and minimum antioxidant activities, respectively. Lower antioxidant activity of the prepared thyme essential O/W nanoemulsion, as compared to the pure (100%) thyme essential oil could be related to the lower amount of thyme essential oil (0.279 mL) in the 45 mL of the prepared nanoemulsion. In fact, due to mixing of low amount of thyme oil with saponin and water, its concentration was approximately 0.006 times lower than that of the pure thyme oil.

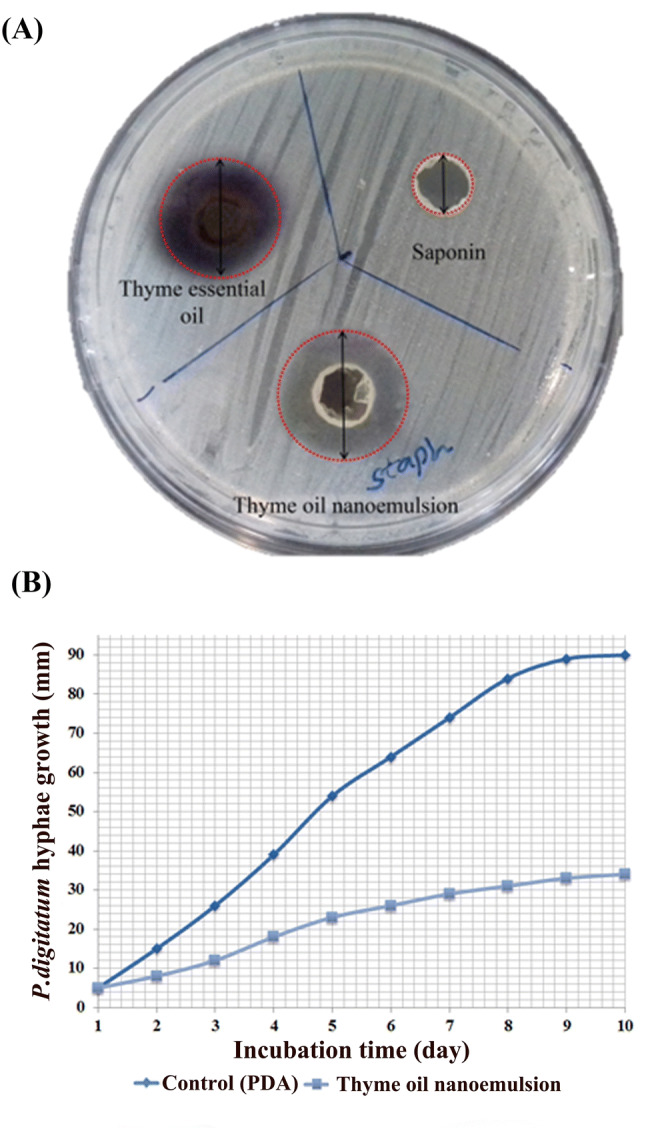

Antimicrobial activity of the resulted thyme O/W nanoemulsion

Antibacterial activity of the prepared thyme O/W nanoemulsion, thyme essential oil and saponin against S. aureus shows in Fig. 4(A). As evidently observed in this figure, diameter of created clear zones around the holes containing extracted thyme oil, thyme O/W nanoemulsion and saponin were 24 ± 1, 28 ± 1 and 5 nm, respectively. Statistical analysis indicated that there was significant difference between bactericidal effect of the extracted thyme essential oil and that of the prepared O/W nanoemulsion. Higher bactericidal activity of the prepared nanoemulsions could be related to their small particle size, which that increased the surface to volume ration of the nanodroplets and increased their attachment into the membrane cell or penetration among that (Ryu et al., 2018a; 2018b). Antifungal activity of the resulted thyme O/W nanoemulsion using obtained optimum conditions on inhibition of the hyphae growth of P. digitatum during 10 days of incubation at 25 ± 2 °C shows in Fig. 4(B). As evidently observed in this figure, the growth of P. digitatum mycelia was significantly (p < 0.05) inhibited by the thyme oil nanoemulsions as compared to the control plate.

Fig. 4.

Created zones of inhibition for the prepared thyme O/W nanoemulsion using obtained optimum production conditions, extracted thyme essential oil and saponin on the inoculated plates with S. aureus incubated at 37 °C for 24 h (A), and antifungal activity of the prepared thyme O/W nanoemulsion using obtained optimum conditions against P. digitatum. (B)

As conclusion, a bottom-up green approach based on using subcritical water, as a safe and non-toxic solvent, and saponin, as a natural emulsifier, was used to prepare thyme essential O/W nanoemulsions. As compared to the conventional nanoemulsion preparation techniques, in the one-step preparation of O/W nanoemulsions under subcritical water conditions, due to changes in the polarity of water and turns that into the polarity of methanol, minimum amount of emulsifier was used without need to organic solvents and their removal at the end of process. These mentioned benefits, make subcritical water nanoemulsion preparation method as a rapid, clean and cost-effective technique in the preparation of O/W nanoemulsion. Furthermore, results indicated that RSM could successfully optimize thyme O/W nanoemulsion preparation process conditions to form more stable nanoemulsion with minimum nanodrplet size, which that caused high surface to volume ratio of the formed thyme oil nanodroplets in the emulsions, which in turn, increased antioxidant and antimicrobial activities of the prepared nanoemulsions using predicted optimum preparation conditions. The developed technique in the present study can be successfully used for preparation of O/W nanoemulsions of other valuable oil based components for more applications in food and pharmaceutical formulations.

Acknowledgements

The authors would like to acknowledge the Sahand University of Technology for funding the development of an innovative methodology for safety assessment of industrial nanomaterials (Grant No. 30.5592).

Compliance with ethical standards

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Omid Ahmadi, Email: o_ahmadi@sut.ac.ir.

Hoda Jafarizadeh-Malmiri, Email: h_jafarizadeh@sut.ac.ir, Email: h_jafarizadeh@yahoo.com.

References

- Ahmadi O, Jafarizadeh-Malmiri H, Jodeiri N. Eco-friendly microwave-enhanced green synthesis of silver nanoparticles using Aloe vera leaf extract and their physico-chemical and antibacterial studies. Green Process. Synth. 2018;7:231–240. doi: 10.1515/gps-2017-0039. [DOI] [Google Scholar]

- Ahmadi O, Jafarizadeh-Malmiri H, Jodeiri N. Optimization of processing parameters for hydrothermal silver nanoparticles synthesis using Aloe vera leaf extract and estimation of their physico-chemical and antifungal properties. Z. Phys. Chem. 2019;233:651–667. doi: 10.1515/zpch-2017-1089. [DOI] [Google Scholar]

- Anarjan N, Fahimdanesh M, Jafarizadeh-Malmiri H. β-Carotene nanodispersions synthesis by three-component stabilizer system using mixture design. J. Food Sci. Technol. 2017;54:3731–3736. doi: 10.1007/s13197-017-2764-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Anarjan N, Jaberi N, Yeganeh-Zare S, Banafshehchin E, Rahimirad A, Jafarizadeh-Malmiri H. Optimization of mixing parameters for α-tocopherol nanodispersions prepared using solvent displacement method. J. Am. Oil Chem’. Soc. 2014;91:1397–1405. doi: 10.1007/s11746-014-2482-6. [DOI] [Google Scholar]

- Anarjan N, Jafarizadeh-Malmiri H, Ling TC, Tan CP. Effects of pH, ions, and thermal treatments on physical stability of astaxanthin nanodispersions. Int. J. Food Prop. 2014;17:937–947. doi: 10.1080/10942912.2012.685680. [DOI] [Google Scholar]

- Anarjan N, Jafarizadeh-Malmiri H, Nehdi IA, Sbihi HM, Al-Resayes SI, Tan CP. Effects of homogenization process parameters on physicochemical properties of astaxanthin nanodispersions prepared using a solvent-diffusion technique. Int. J. Nanomedicine. 2015;10:1109–1118. doi: 10.2147/IJN.S72835. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bai L, Huan S, Gu J, McClements DJ. Fabrication of oil-in-water nanoemulsions by dual-channel microfluidization using natural emulsifiers: Saponins, phospholipids, proteins, and polysaccharides. Food Hydrocoll. 2016;61:703–711. doi: 10.1016/j.foodhyd.2016.06.035. [DOI] [Google Scholar]

- Chang Y, McLandsborough L, McClements DJ. Physical properties and antimicrobial efficacy of thyme oil nanoemulsions: Influence of ripening inhibitors. J. Agric. Food Chem. 2012;60:12056–12063. doi: 10.1021/jf304045a. [DOI] [PubMed] [Google Scholar]

- Chang Y, McLandsborough L, McClements DJ. Fabrication, stability and efficacy of dual-component antimicrobial nanoemulsions: essential oil (thyme oil) and cationic surfactant (lauric arginate) Food Chem. 2015;172:298–304. doi: 10.1016/j.foodchem.2014.09.081. [DOI] [PubMed] [Google Scholar]

- Chen Z, Shu G, Taarji N, Barrow CJ, Nakajima M, Khalid N, Neves MA. Gypenosides as natural emulsifiers for oil-in-water nanoemulsions loaded with astaxanthin: Insights of formulation, stability and release properties. Food Chem. 2018;261:322–328. doi: 10.1016/j.foodchem.2018.04.054. [DOI] [PubMed] [Google Scholar]

- Chung C, Sher A, Rousset P, Decker EA, McClements DJ. Formulation of food emulsions using natural emulsifiers: Utilization of quillaja saponin and soy lecithin to fabricate liquid coffee whiteners. J. Food Eng. 2017;209:1–11. doi: 10.1016/j.jfoodeng.2017.04.011. [DOI] [Google Scholar]

- Chung C, Sher A, Rousset P, McClements DJ. Influence of homogenization on physical properties of model coffee creamers stabilized by quillaja saponin. Food Res. Int. 2017;99:770–777. doi: 10.1016/j.foodres.2017.06.060. [DOI] [PubMed] [Google Scholar]

- Chung C, Sher A, Rousset P, McClements DJ. Use of natural emulsifiers in model coffee creamers: Physical properties of quillaja saponin-stabilized emulsions. Food Hydrocoll. 2017;67:111–119. doi: 10.1016/j.foodhyd.2017.01.008. [DOI] [PubMed] [Google Scholar]

- Gupta A, Eral HB, Hatton TA, Doyle PS. Nanoemulsions: formation, properties and applications. Soft Matter. 2016;12:2826–2841. doi: 10.1039/C5SM02958A. [DOI] [PubMed] [Google Scholar]

- Kaur K, Kumar R, Mehta SK. Formulation of saponin stabilized nanoemulsion by ultrasonic method and its role to protect the degradation of quercitin from UV light. Ultrason. Sonochem. 2016;31:29–38. doi: 10.1016/j.ultsonch.2015.11.017. [DOI] [PubMed] [Google Scholar]

- Krstonošić V, Dokić L, Nikolić I, Milanović M. Influence of xanthan gum on oil-in-water emulsion characteristics stabilized by OSA starch. Food Hydrocoll. 2015;45:9–17. doi: 10.1016/j.foodhyd.2014.10.024. [DOI] [Google Scholar]

- McClements DJ. Edible nanoemulsions: fabrication, properties, and functional performance. Soft Matter. 2011;7:2297–2316. doi: 10.1039/C0SM00549E. [DOI] [Google Scholar]

- McClements DJ, Rao J. Food-grade nanoemulsions: formulation, fabrication, properties, performance, biological fate, and potential toxicity. Crit. Rev. Food Sci. 2011;51:285–330. doi: 10.1080/10408398.2011.559558. [DOI] [PubMed] [Google Scholar]

- Mohammadlou M, Jafarizadeh-Malmiri H, Maghsoudi H. Hydrothermal green synthesis of silver nanoparticles using Pelargonium/Geranium leaf extract and evaluation of their antifungal activity. Green Process. Synth. 2017;6:31–42. [Google Scholar]

- Ozturk B, Argin S, Ozilgen M, McClements DJ. Formation and stabilization of nanoemulsion-based vitamin E delivery systems using natural surfactants: Quillaja saponin and lecithin. J. Food Eng. 2014;142:57–63. doi: 10.1016/j.jfoodeng.2014.06.015. [DOI] [Google Scholar]

- Pavela R, Žabka M, Vrchotová N, Tříska J. Effect of foliar nutrition on the essential oil yield of Thyme (Thymus vulgaris L) Ind. Crop. Prod. 2018;112:762–765. doi: 10.1016/j.indcrop.2018.01.012. [DOI] [Google Scholar]

- Ryu V, McClements DJ, Corradini MG, McLandsborough L. Effect of ripening inhibitor type on formation, stability, and antimicrobial activity of thyme oil nanoemulsion. Food Chem. 2018;245:104–111. doi: 10.1016/j.foodchem.2017.10.084. [DOI] [PubMed] [Google Scholar]

- Ryu V, McClements DJ, Corradini MG, Yang JS, McLandsborough L. Natural antimicrobial delivery systems: Formulation, antimicrobial activity, and mechanism of action of quillaja saponin-stabilized carvacrol nanoemulsions. Food Hydrocoll. 2018;82:442–450. doi: 10.1016/j.foodhyd.2018.04.017. [DOI] [Google Scholar]

- Sayyar Z, Jafarizadeh-Malmiri H. Temperature effects on thermodynamic parameters and solubility of curcumin O/W nanodispersions using different thermodynamic models. Int. J. Food Eng. 2019;15:1–14. doi: 10.1515/ijfe-2018-0311. [DOI] [Google Scholar]

- Sayyar Z, Jafarizadeh-Malmiri H. Preparation, Characterization and evaluation of curcumin nanodispersions using three different methods - Novel subcritical water conditions, spontaneous emulsification and solvent displacement. Z. Phys. Chem. 2019;233:1485–1502. doi: 10.1515/zpch-2018-1152. [DOI] [Google Scholar]

- Sayyar Z, Jafarizadeh-Malmiri H. Photocatalytic and antibacterial activities study of prepared self-cleaning nanostructure surfaces using synthesized and coated ZnO nanoparticles with Curcumin nanodispersion. Z. Kristallogr. Cryst. Mater. 2019;234:307–328. doi: 10.1515/zkri-2018-2096. [DOI] [Google Scholar]

- Shu G, Khalid N, Chen Z, Neves MA, Barrow CJ, Nakajima M. Formulation and characterization of astaxanthin-enriched nanoemulsions stabilized using ginseng saponins as natural emulsifiers. Food Chem. 2018;255:67–74. doi: 10.1016/j.foodchem.2018.02.062. [DOI] [PubMed] [Google Scholar]

- Taarji N, Rabelo CA, Khalid N, Gadhi C, Hafidi A, Kobayashi I, Neves MA, Isoda H, Nakajima M. Formulation and stabilization of oil-in-water nanoemulsions using a saponins-rich extract from argan oil press-cake. Food Chem. 2018;246:457–463. doi: 10.1016/j.foodchem.2017.12.008. [DOI] [PubMed] [Google Scholar]

- Tan Y, Deng X, Liu T, Yang B, Zhao M, Zhao Q. Influence of NaCl on the oil/water interfacial and emulsifying properties of walnut protein-xanthan gum. Food Hydrocoll. 2017;72:73–80. doi: 10.1016/j.foodhyd.2017.05.031. [DOI] [Google Scholar]

- Uluata S, McClements DJ, Decker EA. Physical stability, autoxidation, and photosensitized oxidation of ω-3 oils in nanoemulsions prepared with natural and synthetic surfactants. J. Agric. Food Chem. 2015;63:9333–9340. doi: 10.1021/acs.jafc.5b03572. [DOI] [PubMed] [Google Scholar]

- Yang Y, Leser ME, Sher AA, McClements DJ. Formation and stability of emulsions using a natural small molecule surfactant: Quillaja saponin (Q-Naturale®) Food Hydrocoll. 2013;30:589–596. doi: 10.1016/j.foodhyd.2012.08.008. [DOI] [Google Scholar]

- Zhang J, Bing L, Reineccius GA. Comparison of modified starch and Quillaja saponins in the formation and stabilization of flavor nanoemulsions. Food Chem. 2015;192:53–59. doi: 10.1016/j.foodchem.2015.06.078. [DOI] [PubMed] [Google Scholar]

- Zhang J, Bing L, Reineccius GA. Formation, optical property and stability of orange oil nanoemulsions stabilized by Quallija saponins. LWT-Food Sci. Technol. 2015;64:1063–1070. doi: 10.1016/j.lwt.2015.07.034. [DOI] [Google Scholar]