Abstract

This study investigated the effects of microbial transglutaminase (TG) and sodium alginate (AL) on the water-binding, textural and oil absorption properties of soy patties as a representative meat analog. The addition of TG increased all textural parameters and decreased the expressible moisture of the product. Alternately, AL showed the high water-binding properties of soy patties but caused a decrease in the textural parameters of the product. Both TG and AL were effective in reducing oil absorption during the frying of the product, particularly TG, which was more effective than AL. Therefore, the results indicated that TG and AL were involved in the quality modification of soy-based meat analogs, and palatable eating quality was obtained by combining optimal levels of the two binding agents.

Keywords: Soy patties, Meat analog, Transglutaminase, Alginate, Eating quality

Introduction

Due to concerns about the carcinogenicity of red meat and meat product consumption, there has been growing interest in meat analog products manufactured by nonmeat ingredients (Asgar et al., 2010). Because plant resources, such as soy, wheat and mushroom, are the representative ingredients applied for meat analog products, these products are also called plant meat for convenience. Although plant-based meat analog products are commercially manufactured as forms of hamburger patties, sausage or dumplings, these products still do not organoleptically satisfy the preferences of the consumers.

Soy is a protein investigated intensively due to its availability in various food processing. Soybeans contain more than 40% protein and globulin accounts for 90% of the soy protein (Belitz et al., 2009). Globulin forms a fibrous structure upon extrusion, and the structure of the extruded protein matrix is highly similar to that of muscle (Asgar et al., 2010). For that reason, soy protein has been estimated as an economic and feasible source for meat analogs. Nevertheless, regulating the flavor, texture, and juiciness of soy-based meat analogs has been challenging for successful commercialization (Egbert and Borders, 2006).

Soy patties are the representative commercially available meat analog products. Texturized soy protein (TSP) is the main ingredient to produce soy patties. The TSP produced by extrusion processing was denatured by heating and shearing, which allowed the interaction of new chemical bonds and the creation of a structure with exposed inner amino acids (Cheftel et al., 1992). The textural limitations, such as less chewiness, cohesiveness, and juiciness, of patties using TSP were based on poor protein and water-binding capacity due to denatured proteins. The high denaturation temperature of isolated soy protein (ISP) is also a factor influencing the textural limitations of soy-based patties (Kitabatake et al., 1989).

Frying as the final step for consumption is a general cooking method influenced by consumer preference (Gisslen, 1999). The oil uptake of food products during frying is dependent on cooking conditions (temperature, duration, oil quality, and prefrying treatment) and product conditions (moisture content, porosity, shape, coating, and strength) (Moreira et al., 1997; Pinthus and Saguy, 1994). In panfrying soy patties, sufficient oil on the pan is generally required to cook while avoiding burning at high temperature. Soy patties have the possibility to induce an unintentional excessive oil uptake during panfrying of the products.

Microbial transglutaminase (TG) and sodium alginate (AL) are widely used binding agents in food processing without inductions of changes in the appearance or flavor of the products (Atilgan and Kilic, 2017; Park et al., 2017; Suklim et al., 2004; Temiz and Dağyıldız, 2017). Each of these binding agents acts in different ways for protein binding or gelling systems. TG has been used as a cold-set binder because it forms protein polymers by catalyzing covalent bonds between the ε-amino group of peptide-bound lysine and the γ-carboxamide group of peptide-bound glutamine (Belitz et al., 2009). The AL, which is an anionic hydrocolloid extracted from brown seaweed, can form a thermostable and irreversible gel in the presence of Ca2+ (Huang and Clarke, 2017). AL has an advantage in the preparation of restructured foods, and representatively, the structuring and water-binding properties of AL improve the eating qualities of protein-based foods. Additionally, AL can reduce the oil uptake of foods (Mousa, 2016; Pinthus et al., 1993).

Numerous information regarding the effect of TG and AL on the physicochemical properties of meat or fish products is available, but there is little information regarding the effect of these binders on soy-based meat analog products. One could expect that the impact of binding agents on the denatured proteins (TSP) was different from one with native proteins. In this study, therefore, the effects of TG and AL on the quality characteristics of soy patties were investigated.

Materials and methods

Materials

TSP (Supromax® 5050, DuPont Nutrition & Health, New Century, KS, USA) and ISP (Shandong Yuxin Biotech Co. Ltd., Shangdong, China) were obtained from a local supplier. NaCl, CaCl2, AL and soybean oil were purchased from a local food market. A TG preparation (ACTIVA Supercurd, Ajinomoto Co., Tokyo, Japan), comprising 0.2% enzyme and 99.8% maltodextrin, was kindly donated by Ajinomoto Korea Inc. (Seoul, Korea). All ingredients used for the soy patties were food grade.

Preparation of soy patties

TSP was soaked in 10 volumes of water at ambient temperature for 3 h, and excessive exudates were removed by gently centrifugation until the moisture content of TSP reached 70.9 ± 0.19%. The hydrated TSP was ground through a 3 mm plate, and soy patties were formulated as shown in Table 1. All ingredients were mixed using a food processor (KMX 51, Kenwood Co. Ltd., Havant, UK) for 5 min. Aliquots of the 30 g mixture were formed in a cylinder using a plastic mold (60 mm in diameter and 15 mm in height), vacuum packaged without removing the mold using poly nylon pouches and placed in a refrigerator (4 °C) for 24 h to allow TG activation. The vacuum-packaged samples were cooked in a water bath at 95 °C for 15 min and cooled at room temperature. The samples were stored in a refrigerator (4 °C) prior to analysis.

Table 1.

Formulation (%) of soy patties and experimental design

| Ingredients | Treatment | |||

|---|---|---|---|---|

| Control | TG | AL | TG + AL | |

| Hydrated-TSP | 65.0 | 65.0 | 65.0 | 65.0 |

| ISP | 6.0 | 6.0 | 6.0 | 6.0 |

| NaCl | 1.1 | 1.1 | 1.1 | 1.1 |

| CaCl2 | 0.4 | 0.4 | 0.4 | 0.4 |

| TG | – | 0.5 | – | 0.5 |

| AL | – | – | 0.5 | 0.5 |

| Water | 27.5 | 27.0 | 27.0 | 26.5 |

TSP texturized soy protein, ISP isolated soy protein, TG microbial transglutaminase, AL alginate

Cooking loss

After depackaging, the soy patties which cooked at 95 °C for 15 min as described above were carefully removed from the mold, and surface exudate was gently removed. The soy patties were weighed, and cooking loss was expressed as percent weight loss before and after cooking.

Expressible moisture

An approximately 2 g (MS) sample was taken from each soy patty and placed in a centrifuge tube in which gauze, as a water absorber, was present. The tubes were centrifuged at 1500 × g for 5 min under refrigeration temperature, and the pellet was carefully removed. The tube with gauze was weighed before (M1) and after drying at 105 °C for 24 h (M2). Expressible moisture was expressed as percent moisture loss over sample weight as follows

Texture profile analysis (TPA)

The TPA profiles of soy patties were estimated using a texture analyzer (CT3, Brookfield Engineering Laboratories, Inc., Middleboro, MA, USA) equipped with a 38.1 mm probe (TA4/1000, Brookfield Engineering Laboratories, Inc.). A cylinder was taken from the center of each patties using a cork borer (20 mm diameter), and the cylinder was compressed twice to 50% of its height twice under the condition of 0.1 g trigger load and 2.0 mm/s head speed.

Scanning electron microscopy (SEM)

The microstructures of the samples were observed with a tabletop scanning electron microscope (TM400plus-MA, Hitachi Science System Ltd., Hitachinaka, Japan) at an intensity of 15 kV.

Proximate compositions after frying

Prior to frying, 0.1% (w/w) Sudan red B dye was added to 60 °C commercial soybean oil to visualize oil absorption. The soy patties were prepared according to the suggested method for commercial soy patties products. Approximately 60 mL dyed oil per soy patties was poured into a pan and heated on a hot plate (MSH-20D, Daihan Scientific Co., Wonju, Korea). When the temperature of the pan reached 190 °C, the soy patties were fried for 2 min and then further fried for 2 min by turning upside down. The fried soy patties were cooled on a paper towel for 15 min and more 15 min after turning upside down with new towel. Thin slices were taken from the center area of fried soy patties, and dyed oil absorption was observed using a digital microscope (UM039 Mustcam 5 M, Mustech Electronics Co., Ltd., Shenzhen, China) at a magnification of × 83. The remaining portion of soy patties was used to determine proximate compositions. The moisture content of soy patties was determined by the 105 °C hot-air drying method (AOAC, 1990). Crude protein and crude lipid of soy patties were measured by Kjeldahl (%N × 6.25) and Soxhlet, respectively.

Statistical analysis

All data were statistically analyzed using the one-way analysis of variance (ANOVA) procedure of the SAS 9.2 system (SAS Institute Inc., Cary, NC, USA). Duncan’s multiple range tests were applied to separate means when the main effect was significant (p < 0.05).

Results and discussion

Water-binding properties

In this study, both TG and AL affected the water-binding properties of soy patties but in a different way (Table 2). The cooking loss of TG treatment was 7.73%, which was not different from 7.27% for the control, however, the addition of TG increased the moisture content up to 21.1% compared to 17.3% in the control (p < 0.05). As reported, TG enhanced protein–protein interactions, which manifested a decrease in protein-water interactions (Chin et al., 2009). Because the activity of TG depends on the concentration or solubility of the substrate (Gaspar and de Góes-Favoni, 2015), the impact of TG on denatured protein would be lower than one reacted with the native protein substrate (Seki et al., 1998). In the case of soy protein, however, Bin Md Yasir et al. (2007) postulated that the denatured state was a better substrate for TG. Therefore, the increased expressible moisture of the TG treatment was evidence of the crosslinking of TSP and ISP. In this study, the selected TG preparation contained only 0.2% enzyme, which was lower than the 1% enzyme used in previous studies (Atilgan and Kilic, 2017; Chin et al., 2009). Nonetheless, the addition of TG had a disadvantage in yielding soy patties, thereby requiring the addition of water-binding agents.

Table 2.

Effects of microbial transglutaminase (TG) and alginate (AL) on the cooking loss and expressible moisture (EM) of soy patties

| Parameters | Treatments | |||

|---|---|---|---|---|

| Control | TG | AL | TG + AL | |

| Cooking loss (%) | 7.27 ± 0.74a | 7.73 ± 0.54a | 2.72 ± 0.69b | 2.98 ± 0.63b |

| EM (%) | 17.3 ± 0.57b | 21.1 ± 2.67a | 14.3 ± 1.34c | 13.4 ± 0.45c |

Data are means ± standard deviations (n = 3 of each triplicate determinations)

Means with different superscripts within the same row are significantly different (p < 0.05)

AL showed the high water-binding properties of soy patties alone or in combination with TG. Although Ca-mediated AL gelation caused syneresis (Draget et al., 2001), the water-binding properties of soy patties were greatly improved by the addition of AL, as characterized by lower cooking loss (2.72–2.98%) and expressible moisture (13.38–14.31%) than those of the control (p < 0.05). The improvement of the water-binding properties of AL was also reported by research on meat and fish products (Atilgan and Kilic, 2017; Moreno et al., 2013). Additionally, TG did not affect the water-binding properties of soy patties when AL was simultaneously applied. Considering the poor water-binding properties of soy patties, AL would be an effective ingredient to improve the juiciness of these products.

Textural properties

As depicted in Table 3, the addition of TG increased the textural properties of soy patties. All TPA parameters of the TG treatment were significantly greater than those of the control (p < 0.05). Although the addition of the actual enzyme was 0.001% in the total formulation, long chilled standing (24 h) prior to cooking enabled the crosslinking between soy proteins. Tang et al. (2007) reported that the heating (95 °C for 5 min) of soymilk manifested a partial exposure of soy protein by which TG promoted the crosslinking of soy proteins. Bin Md Yasir et al. (2007) indicated that the TG-mediated crosslinking of soy protein was favorable for a denatured state compared to a native state. Although TG was incubated at a chilled temperature prior to the cooking of soy patties in this study, the applied soy proteins (TSP and ISP) were hydrated from a denatured state, which may be attributed to textural modification and the improvement of soy patties.

Table 3.

Effects of microbial transglutaminase (TG) and alginate (AL) on the textural properties of soy patties

| Parameters | Treatments | |||

|---|---|---|---|---|

| Control | TG | AL | TG + AL | |

| Hardness (N) | 36.1 ± 0.29b | 51.9 ± 1.02a | 26.3 ± 0.79c | 34.1 ± 3.88bc |

| Cohesiveness | 0.51 ± 0.07b | 0.62 ± 0.04a | 0.30 ± 0.01d | 0.40 ± 0.01c |

| Springiness | 0.81 ± 0.01b | 0.91 ± 0.01a | 0.67 ± 0.04c | 0.79 ± 0.02b |

| Chewiness (N) | 15.0 ± 0.51b | 29.2 ± 1.09a | 5.20 ± 0.53d | 10.8 ± 1.02c |

| Gumminess (N) | 18.3 ± 0.60b | 32.1 ± 0.71a | 7.90 ± 0.59d | 13.7 ± 1.21c |

Data are means ± standard deviations (n = 3 of each repeated 10 times)

Means with different superscripts within the same row are significantly different (p < 0.05)

In contrast, AL decreased all TPA parameters of soy patties compared to the control (p < 0.05). AL forms a network structure when Ca2+ ions were present, which improved the textural properties of protein-based foods (Atilgan and Kilic, 2017). However, the Ca2+ ion-induced gelling ability of AL was diminished by the presence of high amounts of monovalent ions, such as Na+, due to the competitive action of both ions (Draget et al., 1991). In addition, soy protein cannot produce a self-network under boiling conditions (< 100 °C), and CaCl2 is the representative coagulant of soy protein in the tofu-making process. The addition of AL would hinder the reaction between Ca2+ ions and soy protein, whereas binding large amounts of moisture (Montero et al., 2000). Eventually, the AL resulted in weak TPA parameters of soy patties. The attribution of AL was also similar when formulated together with TG (TG + AL treatment). The hardness and springiness of the TG + AL treatment did not differ from that of the control, however, the gumminess, chewiness and cohesiveness of the treatment were lower than those of the control (p < 0.05), which probably resulted from the AL-mediated water-binding properties.

Microstructure

The microstructure of soy patties processed with TG or AL alone or in combination are given in Fig. 1. For control, ISP formed a thick filamentous structure that connected hydrated TSP particles. In addition, a large amount of void space filled with moisture was also observed in the control. Additionally, TG treatment showed fine ISP network formation, which filled the void space and attached to the TSP particles. This effect is attributed to the water retention and textural properties of soy patties. Similarly, AL also filled the void space, while the structuring of ISP was not as intense as that of the control or TG treatment. In addition, partially formed AL gel was placed along with the ISP network. In the case of TG + AL treatment, a crosslinked network structure was rarely found, but the structure was completely similar to that of the AL treatment. The results indicated that the water retention and textural properties of soy patties were closely related to the type and nature of the applied binder. Even if AL acted as a filler or an extender of soy patties, this binding agent was not related to the strengthening of the texture of soy patties. Therefore, the overall eating qualities of soy patties could be regulated by selection or mixing one or more binding agents appropriately.

Fig. 1.

Microstructure of soy patties manufactured with microbial transglutaminase (TG) and alginate (AL). Scale bar indicates 500 μm

Oil absorption properties

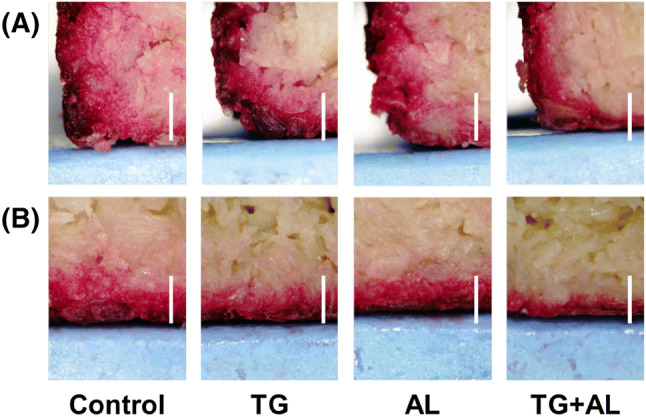

In fried soy patties, absorbed oil was placed on the surface area and formed a thin and uniform layer (Fig. 2). The control showed an ~ 2 mm depth of the absorbed oil layer, while the depth was decreased to ~ 1.5 mm when TG or AL was individually applied. Moreover, the combination of TG and AL exhibited a great impact on minimizing the oil absorption during frying, as shown in the less than 1 mm depth of the oil layer. In the formulation, it was expected that the amount of oil uptake would decrease the moisture content of the fried product. Initially, the soy patties were formulated to moisture (73–74%), protein (25.5%) and salts (1.5%). Although the TG treatment had a lower moisture content than the other treatments, the overall moisture contents of all treatments ranged from 71.3 to 73.2% (data not shown). After frying, the protein content was rarely affected and ranged from 23.2 to 24.1% (Table 4). In addition, the moisture and lipid contents in fried soy patties were 61.9–65.5% and 5.99–8.02%, respectively. It is worth mentioning that the oil content was based on the total weight, but the oil only accumulated on a narrow surface area. Both ISP and TSP have high fat adsorption ability, and this nature provided advantages in the physicochemical and organoleptic properties of protein-based foods (Singh et al., 2008). In meat analogs, however, a large amount of oil absorption can affect the perception of the consumer since the oil absorption properties of soy protein are completely different from those of meat protein. Consequently, it is necessary to consider additives that prevent or reduce excessive oil accumulation in soy patties. It was expected that the high water-binding properties and the hydrophilic nature of AL were effective in reducing oil uptake during frying. However, it was unclear why TG showed a better impact on reducing oil uptake compared to AL, thus, the TG-mediated crosslinking improved the emulsification ability of food proteins (Ali et al., 2010; Hu et al., 2011). Therefore, the lower oil uptake of TG treatment result from maltodextrin, which is an excipient of TG preparation.

Fig. 2.

Oil absorption in (A) the edge and (B) the bottom parts of fried soy patties manufactured with microbial transglutaminase (TG) and alginate (AL). Scale bar indicates 2 mm

Table 4.

Effects of microbial transglutaminase (TG) and alginate (AL) on the proximate compositions of fried soy patties

| Parameters | Treatments | |||

|---|---|---|---|---|

| Control | TG | AL | TG + AL | |

| Protein (%) | 24.1 ± 0.69 | 23.7 ± 0.51 | 23.2 ± 0.48 | 23.3 ± 1.02 |

| Moisture (%) | 63.3 ± 1.58a | 61.9 ± 1.10b | 64.6 ± 0.41a | 63.5 ± 0.62a |

| Lipid (%) | 8.02 ± 0.20a | 6.48 ± 0.38c | 7.36 ± 0.39b | 5.99 ± 0.16c |

Data are means ± standard deviations (n = 3 of each triplicate determinations)

Means with different superscripts within the same row are significantly different (p < 0.05)

Implications

In protein-based foods or protein gelling systems, TG has been combined with AL to modify textural properties without changing deteriorative physicochemical properties, such as water-binding properties (Atilgan and Kilic, 2017; Moreno et al., 2013). AL showed potential application when Ca2+ was available. However, meat products contain more than 1.5% NaCl in formulation, hence, the usage of NaCl in manufacturing meat analogs, such as soy patties, is inevitable. In this condition, AL did not form a Ca–AL gel network, therefore, AL acted as a water-binding ingredient of soy patties. In contrast, TG-mediated crosslinking was more useful in the preparation of soy products, since these products were manufactured by thermally denatured proteins, such as TSP or ISP. Crosslinking enabled a reduction in the amount of TG in the formulation of soy patties. However, the action of TG was involved in moisture loss, which could be attributed to the reduced juicy mouthfeel of soy products, hence, the combination of TG and AL could provide a complementary effect on the eating quality of soy patties. To optimize the formulation, it was still necessary to evaluate the organoleptic properties of the soy patties, which warrants further exploration.

Acknowledgements

This work was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry (iPET) through High Value-added Food Technology Development Program, funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA), Korea (317040-05).

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Eun-Jung Lee, Email: lejung0393@naver.com.

Geun-Pyo Hong, Email: gphong@sejong.ac.kr.

References

- Ali NA, Ahmed SH, Mohamed EA, Mohamed Ahmed IA, Babiker EE. Effect of transglutaminase cross linking on the functional properties as a function of NaCl concentration of legumes protein isolate. Int. J. Nutr. Food Eng. 2010;4:27–32. [Google Scholar]

- Asgar MA, Fazilah A, Huda N, Bhat R, Karim AA. Nonmeat protein alternatives as meat extenders and meat analogs. Compr. Rev. Food Sci. Safety. 2010;9:513–529. doi: 10.1111/j.1541-4337.2010.00124.x. [DOI] [PubMed] [Google Scholar]

- Atilgan E, Kilic B. Effects of microbial transglutaminase, fibrimex and alginate on physicochemical properties of cooked ground meat with reduced salt level. J. Food Sci. Technol. 2017;54:303–312. doi: 10.1007/s13197-016-2463-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Belitz HD, Grosch W, Schieberle P. Food chemistry. Springer, Berlin, Germany. pp. 93-157, 746-769 (2009)

- Bin Md Yasir S, Sutton KH, Newberry MP, Andrews NR, Gerrard JA. The impact of transglutaminase on soy proteins and tofu texture. Food Chem. 104: 1491-1501 (2007)

- Chin KB, Go MY, Xiong YL. Konjac flour improved textural and water retention properties of transglutaminase induced porcine myofibrillar protein gel: Effect of salt level and transglutaminase incubation. Meat. Sci. 2009;81:565–572. doi: 10.1016/j.meatsci.2008.10.012. [DOI] [PubMed] [Google Scholar]

- Cheftel J, Kitagawa M, Queguiner C. New protein texturization processes by extrusion cooking at high moisture levels. Food Rev. Int. 1992;8:235–275. doi: 10.1080/87559129209540940. [DOI] [Google Scholar]

- Draget KI, Gaserød O, Aune I, Andersen PO, Storbakken B, Stokke BT, Smidsrød O. Effects of molecular weight and elastic segment flexibility on syneresis in Ca-alginate gels. Food Hydrocolloid. 2001;15:485–490. doi: 10.1016/S0268-005X(01)00046-7. [DOI] [Google Scholar]

- Draget KI, Østgaard K, Smidsrød O. Homogenous alginate gels: A technical approach. Carbohydr. Polym. 1991;14:159–178. doi: 10.1016/0144-8617(90)90028-Q. [DOI] [Google Scholar]

- Egbert R, Borders C. Achieving success with meat analogs. Food Technol. Chicago. 2006;60:28–34. [Google Scholar]

- Gaspar ALC, de Góes-Favoni SP. Action of microbial transglutaminase (MTGase) in the modification of food proteins: A review. Food Chem. 2015;171:315–322. doi: 10.1016/j.foodchem.2014.09.019. [DOI] [PubMed] [Google Scholar]

- Gisslen W. Professional cooking. Publisher Inc, New York, NY: John Wiley & Sons; 1999. pp. 46–61. [Google Scholar]

- Hu X, Ren J, Zhao M, Cui C, He P. Emulsifying properties of the transglutaminase-treated crosslinked product between peanut protein and fish (Decaperus maruadsi) protein hydrolysates. J. Sci. Food Agr. 2011;91:578–585. doi: 10.1002/jsfa.4229. [DOI] [PubMed] [Google Scholar]

- Huang H, Clarke AD. Performances of cold-set binders, food hydrocolloids, and commercial meat binder on the physical and chemical characteristics of tilapia fish balls. Int. J. Anim. Sci. 2017;1:1005. doi: 10.36876/ijas.1005. [DOI] [Google Scholar]

- Kitabatake N, Tahara M, Doi E. Denaturation temperature of soy protein under low moisture conditions. Agric. Biol. Chem. 53: 1201-1202 (1989)

- Montero P, Hurtado JL, Pérez-Mateos M. Microstructural behavior and gelling characteristics of myosystem protein gels interacting with hydrocolloids. Food Hydrocolloid. 2000;14:455–461. doi: 10.1016/S0268-005X(00)00025-4. [DOI] [Google Scholar]

- Moreira RG, Sun X, Chen Y. Factors affecting oil uptake in tortillas chips in deep-fat feying. J. Food Eng. 1997;31:485–498. doi: 10.1016/S0260-8774(96)00088-X. [DOI] [Google Scholar]

- Moreno H, Carballo J, Borderías J. Raw-appearing restructured fish models made with sodium alginate or microbial transglutaminase and effect of chilled storage. Food Sci. Technol. Campinas. 2013;33:137–145. doi: 10.1590/S0101-20612013005000004. [DOI] [Google Scholar]

- Mousa RMA. Hydrocolloids of date pits used as edible coating to reduce oil uptake in potato strip during deep-fat frying. Alex. J. Fd. Sci. Technol. 2016;13:39–50. [Google Scholar]

- Park YS, Choi YS, Hwang KE, Kim TK, Lee CW, Shin DM, Han SG. Physicochemical properties of meat batter added with edible silkworm pupae (Bombyx mori) and transglutaminase. Korean J. Food Sci. An. 2017;37:351–359. doi: 10.5851/kosfa.2017.37.3.351. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pinthus EJ, Weinberg P, Saguy IS. Criterion for oil uptake using deep fat frying. J. Food Sci. 1993;58:204–205. doi: 10.1111/j.1365-2621.1993.tb03245.x. [DOI] [Google Scholar]

- Pinthus EJ, Saguy IS. Initial interfacial tension and oil uptake by deep-fat fried foods. J. Food Sci. 1994;59:804–807. doi: 10.1111/j.1365-2621.1994.tb08132.x. [DOI] [Google Scholar]

- Seki N, Nozawa H, Shaowei N. Effect of transglutaminase on the gelation of heat-denatured surimi. Fish Sci. 1998;64:959–963. doi: 10.2331/fishsci.64.959. [DOI] [Google Scholar]

- Singh P, Kumar R, Sabapathy SN, Bawa AS. Functional and edible uses of soy protein products. Compr. Rev. Food Sci. Safety. 2008;7:14–28. doi: 10.1111/j.1541-4337.2007.00025.x. [DOI] [Google Scholar]

- Suklim K, Flick GJ, Marcy JE, Eigel WN, Haugh CG, Granata LA. Effect of cold-set binders: alginates and microbial transglutaminase on the physical properties of restructured scallops. J. Textural stud. 2004;35:634–642. doi: 10.1111/j.1745-4603.2004.35514.x. [DOI] [Google Scholar]

- Tang CH, Li L, Wang JL, Yang XQ. Formation and rheological properties of ‘cold-set’ tofu induced by microbial transglutaminase. LWT Food Sci. Technol. 2007;40:579–586. doi: 10.1016/j.lwt.2006.03.001. [DOI] [Google Scholar]

- Temiz H, Dağyıldız K. Effects of microbial transglutaminase on physicochemical. Microbial and sensorial properties of Kefir produced by using mixture cow’s and soymilk. Korean J. Food Sci. An. 37: 606-616 (2017) [DOI] [PMC free article] [PubMed]