Abstract

A study was conducted to examine the potential of diesel emissions control strategies based on retrofitting existing power packages with exhaust aftertreatment devices and repowering with advanced power packages. The retrofit systems, a diesel oxidation catalyst (DOC) and diesel particulate filter (DPF), were evaluated individually using a US EPA tier 2 (ter 2) engine operated under four steady-state conditions and one transient cycle. The DOC effectively curtailed emissions of CO, and to some extent organic carbon (OC), elemental carbon (EC), and aerosol number concentration. The DPF system offered substantially higher reductions in OC and EC mass and aerosol number concentrations. Both, the DOC and DPF achieved reductions in the aforementioned emissions without adversely affecting emissions of NO2 and nano-sized aerosols. The strategy of repowering with an advanced system was examined using a US EPA tier 4 final (tier 4f) engine equipped with a cooled exhaust gas recirculation system and diesel exhaust fluid-based selective catalytic reduction system, but not with a DPF system. The tier 4f engine contributed substantially less than the tier 2 engine to the EC and OC mass, aerosol number, and CO, NO, and NO2 concentrations. The tier 4f engine was very effective in reducing aerosol mass, NO, and NO2 concentrations, but it was not equally effective in reducing aerosol number concentrations. The implementation of viable exhaust after treatment systems and advanced diesel power packages could be instrumental to the underground mining industry to secure a clean, economical, and dependable source of power for mobile equipment.

Keywords: Diesel, Exhaust after treatment, Advanced engines, Underground mining

1. Introduction

Diesel-powered equipment is extensively used in the underground mining industry [1, 2]. As a result, some underground miners that work in the areas with limited quantities of ventilation air are exposed to diesel aerosols and gases [3–7]. Exposures to diesel exhaust have been linked to various adverse health outcomes including those on the pulmonary system [6, 8–10], bladder [8], cardiovascular system [11, 12], and brain [13]. Nitrogen oxides (especially NO2), various forms of organic compounds, and nanometer and ultrafine particulates are considered biologically active components of diesel exhaust emitted by traditional and contemporary engines [14–17]. The International Agency on Research on Cancer (IARC) categorized diesel engine exhaust as a carcinogen to humans (group 1) [18, 19].

Occupational exposure to diesel aerosols is limited directly or indirectly in several jurisdictions including the USA [20, 21], European Union [22], and Australia [23]. Exposures of underground miners to particulate matter and gases emitted by diesel engines can be controlled through the implementation of a variety of integrated, multifaceted control strategies—elimination, substitution, engineering controls, administrative controls, and the use of personal protective equipment [24]. In recent years, the substitution of diesel power with electric equipment has been discussed [25]. It appears that in spite of concerted efforts to substitute some heavy- and light-duty diesel-powered vehicles with electric (in particular lithium ion battery)-powered vehicles [25, 26], important limitations remain in electric equipment flexibility, quality of the build, durability, maintenance programs, and other engineering and economic factors. These limitations indicate that diesel equipment will continue to power an important part of underground mining process for some time. Therefore, engineering control strategies that allow the industry to curtail diesel pollutants at their source, prior to their release into the underground environment, should remain central to efforts to reduce exposures. Potential strategies for exposure reduction include (1) re-powering existing and powering new vehicles with advanced engine technologies, (2) retrofitting existing vehicles with exhaust aftertreatment technologies and crankcase emission controls, and (3) using alternative fuels such as fatty acid methyl ester biodiesel and hydrotreated vegetable oil renewable diesel.

Regulatory frameworks pertinent to the use of diesel engines [27, 28] resulted in the rapid development of engine, aftertreatment, and fuel technologies. Improvements in engine combustion technologies [29–31], exhaust aftertreatment technologies [32–35], and alternative fuels [36–38] have had profound effects on the levels of diesel emissions and the physical and chemical properties of aerosols emitted by diesel engines [32, 39–42]. Those advancements could be instrumental to the underground mining industry’s efforts to comply with currently enforced or recommended personal exposure limits for diesel particulate matter (DPM) and diesel exhaust [20–23].

Exhaust aftertreatment devices such as diesel oxidation catalyst (DOC), selective catalyst reduction (SCR) systems, and diesel particulate filter (DPF) systems are instrumental to efforts to substantially reduce diesel gaseous and particulate emissions. The DOCs are extensively used to control emissions of carbon monoxide (CO) and gas phase hydrocarbons (HC) [43, 44]. DOCs are also integrated into advanced DOC/DPF systems to promote generation of NO2 to assist passive regeneration of DPF substrates [44–46] and support active regeneration of DPF substrates via catalytic combustion [44], and into DOC/SCR systems to maintain an NO2/NO ratio needed to optimize performance of SCR systems [47, 48]. Full-flow DPF systems are a widely recognized technology for the reduction of solid diesel particulate mass (PM) and particulate number (PN) to levels required by current regulations [31, 49, 50]. The use of DPFs and filtration systems with disposable filter elements (DFEs) are critical in efforts to curtail DPM emissions from underground coal mining equipment in the USA [1]. For nitrogen oxide reduction, diesel exhaust fluid (DEF)-based SCR systems emerged as a most effective technology [35, 50, 51].

The use of exhaust aftertreatment devices was associated with the generation of secondary emissions in some cases [52, 53]. Increases in secondary emissions of highly toxic NO2 [54] are of particular concern to the underground mining industry and have been observed for DOCs and DPFs coated with platinum group metals [55–57]. Due to the potential for secondary emissions, the US Mine Safety and Health Administration included additional requirements for using existing DPF systems and banned the acquisition of new retrofit type DPF systems that increase NO2 concentrations beyond raw exhaust levels [58]. A potential solution to the problem is the use of alternative base metal-palladium (Pd) coatings. Those types of coatings were found to be effective in oxidizing CO and HC at exhaust temperatures above 190 °C and were also effective in removing NO2 at temperatures between 170 and 330 °C but promoted the limited formation of NO2 at temperatures above 330 °C [59, 60]. Emissions of potentially high concentrations of nucleation mode aerosols for certain DPF-equipped engines [32, 39, 40] and DPF/SCR-equipped engines [32, 42, 51, 61] are of additional concern.

The objective of this study was to examine the potential of selected engineering controls based on retrofitting existing power packages with DOCs and DPF systems or repowering equipment with advanced power packages to reduce contribution of diesel emissions to the concentrations of aerosols in underground mines. A comparison of emissions was made for the retrofitted and repowered systems to assess the potential benefits of each control strategy on the reduction of miners’ exposures.

2. Methodology

The results of laboratory evaluations of aerosol and gaseous emissions for two electronically controlled turbocharged diesel engines with similar power ratings but from different generations were used to support the evaluation. The first evaluated engine, Engine 1, is a 2004 4.3-liter Mercedes-Benz Model OM 904 LA (family 4MB XL4.25RJA) rated at 130 kW (174 bhp) @ 2200 rpm and 675 Nm (498 lb-ft) @ 1400 rpm and is typical of those currently used in underground mining in the USA [1]. That engine complied with the US Environmental Protection Agency (US EPA) tier 2 emission standards [27], and it was approved by the US Mine Safety and Health Administration (MSHA) for use in underground mines in the USA (Approval number: 7E-B098). Engine 1 was tested in three different configurations: (1) without exhaust aftertreatment (Engine 1), (2) retrofitted with a DOC Model MinNoDOC from AirFlow Catalyst Systems, Rochester, NY (Engine 1 DOC), and (3) retrofitted with full-flow DPF system Model Green Trap 1100 from NETT Technologies, Mississauga, ON (Engine 1 DPF). The results were used to examine the potential of retrofit-type exhaust after treatment devices as a control strategy, to curtail emissions of aerosol and selected gaseous emissions from the previous generations of engines. It is important to note that the washcoat on the metal substrate of MinNoDOC was impregnated with a catalyst formulation intended to allow for the effective control of CO and HC emissions while also controlling NO2 emissions [56]. The DPF substrate was also impregnated with a catalyst formulation that was designed to suppress generation of secondary NO2 emissions. The DOC cylindrical canister was 622 mm (24.5″) long and 305 mm (12″) in diameter. The DPF cylindrical canister was 787 mm (31″) long and 305 mm (12″) in diameter.

The second engine, Engine 2, was 5.1-liter 2014 Mercedes Benz Model OM 934 LA (family EMBXL07.7RJA) rated at 129 kW (173 bhp) @ 2200 rpm and 750 Nm (535 lb-ft) @ 1400 rpm. That engine complied with US EPA tier 4 final emission standards [27] but did not have MSHA approval. Engine 2 is representative of the group of US EPA tier 4 final compliant advanced non-road engines that meet emissions standards through (1) implementation of combustion improvements, (2) use of cooled exhaust gas recirculation (EGR), and (3) use of an exhaust aftertreatment system that consisted of the DOC, DEF-based SCR, and ammonia slip catalyst (ASC) [31, 34, 35, 62].

The engines were coupled to a 400-kW water-cooled eddy-current dynamometer (SAJ, AE400) and evaluated at four steady-state (SS) operating conditions and one transient (TR) cycle. The SS modes, (1) rated speed 100 percent load (R100), (2) rated speed 50 percent load (R50), (3) intermediate speed 100 percent load (I100), and (4) intermediate speed 50 percent load (I50), were the subset of the International Organization for Standardization (ISO) 8-mode test cycle [63]. The selected engine operating parameters for the SS modes are shown for both engines in Table 1.

Table 1.

Engine operating conditions for Engine 1 and Engine 2

| Engine operating conditions | Engine 1 | Engine 2 | ||||

|---|---|---|---|---|---|---|

| Engine Speed rpm | Torque Nm (lb-ft) | Power kW (hp) | Engine Speed rpm | Torque Nm (lb-ft) | Power kW (hp) | |

| R100 | 2200 | 515 (380) | 119 (159) | 2200 | 542 (400) | 125 (168) |

| R50 | 2200 | 258 (190) | 59 (80) | 2200 | 271 (200) | 63 (84) |

| I100 | 1400 | 637 (470) | 93 (125) | 1400 | 719 (530) | 105 (141) |

| I50 | 1400 | 319 (235) | 47 (63) | 1400 | 359 (265) | 53 (71) |

Back-to-back repetitions of a 900-s duration TR cycle (Fig. 1), custom-designed to recreate the duty cycle of an engine in underground mining load-haul-dump vehicles, were used for the evaluation of both engines over TR conditions. It is important to note that Engine 2 produced higher torque and power outputs at all test conditions than Engine 1 [Table 1].

Fig. 1.

TR mining cycles for a Engine 1 and b Engine 2

Test duration was determined based on requirements for the collection of adequate quantities of diesel aerosols on filters used for carbon analysis. The SS tests conducted to evaluate Engine 1, when tested without after treatment and retrofitted with a DOC, were 3600 s long. The tests conducted to evaluate Engine 1 when retrofitted with DPF and Engine 2 were 21,300 s and 14,400 s long, respectively. The TR cycle was repeated the necessary number of times to ensure that total duration of the TR tests was similar to the duration of the corresponding SS tests.

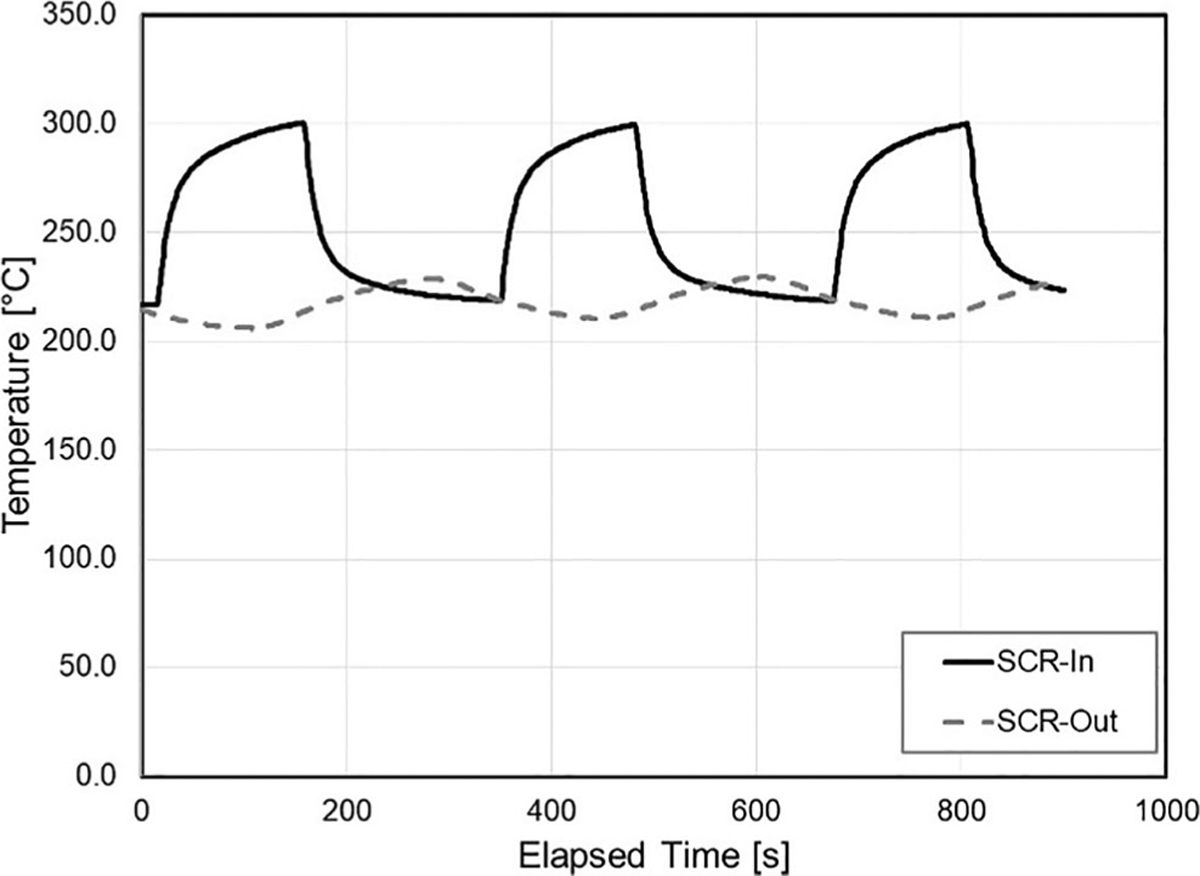

Additional testing was done on Engine 2 in order to assess (1) the volatility of SCR-Out aerosols and (2) the effects of exhaust temperature on CO, NO, and NO2 emissions before (SCR-In) and after (SCR-Out) DOC/SCR/ASC system. The volatility tests were performed for Engine 2 operated at four SS engine operating conditions shown in Table 1 and three additional low engine speed and load operating conditions: LI (700 rpm and 0 Nm [0 lb-ft]), R12 (2200 rpm and 68 Nm [50 lb-ft]), and I9 (1400 rpm and 68 Nm [50 lb-ft]). In order to characterize CO, NO, and NO2 emissions over the majority of its operating temperature range, Engine 2 was operated at several SS conditions at the rated and intermediate engine speeds (Fig. 2). For each of the engine speeds, the across spectrum exhaust temperatures were achieved by keeping engine speed constant while gradually intensifying engine load. The increased variabilities in SCR-In and SCR-Out temperatures for the cases when Engine 2 was operated at rated speed and torque outputs of 115 Nm (85 lb-ft), 136 Nm (100 lb-ft), and 163 Nm (120 lb-ft) (Fig. 2) were result of the attempts of the engine/exhaust aftertreatment management systems to keep SCR-Out exhaust temperatures above approximately 200 °C (392 °F) by managing additional fuel injections and EGR rate (Fig. 3).

Fig. 2.

Exhaust temperatures as a function of generated torque for Engine 2 operated at rated and intermediate engine speeds

Fig. 3.

SCR-In and SCR-Out exhaust temperatures for Engine 2 operated at rated engine speed and 136 Nm (100 lb-ft) of load

Throughout the study, both engines were fueled with ultra-low sulfur diesel (ULSD) obtained from a single batch. The results of the analyses performed on that fuel are shown in Table 2. Engine 2 was supplied with DEF that meets ISO standard (32.5 percent urea) [64].

Table 2.

Properties of the ULSD fuel used for this study

| Property | Test method | Unit | Value |

|---|---|---|---|

| Specific gravity | ASTM D1298 | - | 0.830 |

| Aromatics content | ASTM D1319 | % volume | 21.7 |

| Olefins content | ASTM D1319 | % volume | 3.1 |

| Parafins content | ASTM D1319 | % volume | 75.2 |

| Cetane number | ASTM D613 | - | 47.3 |

| Flash point | ASTM D93 | K | 340 |

| Heat of combustion | ASTM D240 | MJ/kg | 45.9 |

| Sulfur content | ASTM D5453 | ppm | 5.6 |

Measurements with direct reading instruments and filter samplings for aerosol characterizations were executed in exhaust diluted approximately 30 times using a two-stage partial dilution system (Dekati, Tampere, Finland, Model FPS4000). In order to account for test-to-test variations in dilution rates, the results were normalized to a nominal dilution ratio of 30. Triplicate filter samples for carbon analysis were collected from the dilution system on tandem 37-mm quartz fiber filters (QFFs, Pall Corporation, Ann Arbor, MI, 2500QAT-UP) enclosed in five-piece cassettes (SKC, Eighty Four, PA, 225–3050LF and 225–304). In order to minimize OC contamination of the media, the QFFs were pre-baked in a muffle furnace at 800 °C for 4 h. A nominal sampling flow rate of 1.7 lpm was maintained by subsonic critical orifices, installed in the manifolds coupled to a single vacuum pump (Oerlikon Leybold Vacuum GmbH, Cologne, Germany, Sogevac SV25B). The actual sampling flow rates were determined using results of flow verifications with a primary flow calibrator (Mesa Laboratories, Lakewood, CO, Bios Defender 530). The carbon analysis was performed at NIOSH PMRD using the thermal optical transmittance-evolve gas analysis (TOT EGA) method NIOSH Method 5040 [65]. The analysis was performed using an OC/EC Aerosol Analyzer from Sunset Laboratory Inc. (Portland, OR). The results of the analysis performed on the secondary QFFs were used as a dynamic blank correction for the primary QFFs [65].

The fast mobility particle sizer spectrometer (FMPS, TSI, Minneapolis, MN, Model 3091) was used to measure, at 1 Hz frequency, the number concentrations and size distributions of non-volatile and volatile aerosols in diluted exhaust with an electrical mobility diameter between 5.6 and 560 nm. In order to enhance the clarity of the figures, the aerosol size distributions were fitted with log-normal curves using DistFit software from Chimera Technologies (Forest Lake, MN). The volatility of diesel aerosols in the diluted exhaust of Engine 2, operated at the selected SS engine operating conditions, was assessed. The assessment was made using a scanning mobility particle sizer spectrometer (SMPS, TSI, Model 3936), which measures the number concentrations and size distributions of aerosols with electrical mobility diameters between 10 and 400 nm. The SMPS measurements were performed on (1) exhaust diluted in partial dilution tunnel and (2) exhaust diluted in partial dilution tunnel and subsequently treated in the low-flow thermodenuder (TD, TSI, Model 3065). In the first section of the TD, the diluted exhaust was preheated to 400 °C (752 °F) and subsequently, in the second section of the TD, the semi-volatile compounds were denuded via diffusion toward activated charcoal adsorbent. The concentrations of CO, NO, and NO2 in undiluted exhaust were measured in 20-s intervals using a Fourier transform infrared (FTIR) spectrometer (Gasmet Technologies Oy, Vantaa, Finland, DX-4000).

It is important to note that Engine 2 was equipped with closed crankcase breather while Engine 1 was equipped with an open filtered crankcase breather. As a result, the crankcase emissions were included in the assessed emissions for Engine 2, but not for Engine 1.

3. Results

The results of carbon analysis performed on the QFF samples collected from the 30:1 diluted exhaust are summarized in Fig. 4. The dilution factor was selected because it is representative of conditions in underground mines. The results showed that, depending on the SS operating mode, the evaluated DOC reduced, on average, 20 to 83% of OC and 24 to 49% of EC mass concentrations in exhaust emitted by Engine 1. At TR conditions, the use of the same DOC resulted in slight increase, within measurement error range, in average OC and EC mass concentrations.

Fig. 4.

Effects of the evaluated engine/exhaust aftertreatment technologies on concentrations of (a) OC and (b) EC in diluted exhaust (30 times)

The evaluated DPF removed on average over 92% of OC and 98% of EC emitted by Engine 1. Engine 2 emitted between 23 and 93% less OC and between 43 and 88% less EC than Engine 1 without aftertreatment. The OC and EC emissions for Engine 2 were particularly lower than the corresponding emissions for Engine 1 for high load conditions. However, it is important to note that Engine 2 emitted much more OC and EC than Engine 1 retrofitted with a DPF. For the selected test conditions, EC comprised between 66 and 92% of total carbon (TC) emitted by Engine 1, 77 to 91% of TC emitted by Engine 1 retrofitted with a DOC, and 76 to 85% of TC emitted by Engine 2. The uncertainty of measurements of relatively low OC and EC concentrations in the diluted exhaust of Engine 1 retrofitted with DPF was too high to assess the carbon makeup of those aerosols.

Figure 5 shows the results of number concentration measurements of aerosols in 30:1 diluted exhaust. For the SS tests, the DOC reduced the average number concentrations of aerosols emitted by Engine 1 by 22 to 52%. In the case of TR tests, the DOC increased average number concentrations of aerosols emitted by Engine 1 by 62%. For all test conditions, the DPF captured over 99% of particles emitted by Engine 1. The average number concentrations of aerosols emitted by Engine 2 (with DOC/SCR/ASC system) at all test conditions, were between 78 and 95% lower than the corresponding number concentrations of aerosols emitted by Engine 1. However, the average number concentrations of aerosols emitted by Engine 2 were between 88 and 99% higher than the corresponding average concentrations in the exhaust of the DPF-filtered Engine 1.

Fig. 5.

Effects of the evaluated engine/exhaust aftertreatment technologies on average number concentrations of aerosols in diluted exhaust (30 times) for SS (R100, R50, I100, and I50) and TR operating conditions

The size distribution of aerosols in the diluted exhaust for SS and TR engine operating conditions are shown in Figs. 6 and 7, respectively. Engine 1, when operated without after treatment at the R100 and R50 conditions, produced aerosols distributed predominantly in the accumulation mode with count median diameters (CMDs) around 60 nm and 70 nm, respectively, with the remaining aerosols distributed in the weaker nucleation mode with count median diameters around 10 nm (Fig. 6; Table 3) When operated at the I100 and I50 conditions, the same engine emitted aerosols distributed in single accumulation mode. When retrofitted with the DOC and operated in all SS modes, Engine 1 emitted aerosols distributed in single accumulation mode (Fig. 6) with the count median diameters similar to those observed for the size distributions of aerosols emitted the same engine operated without aftertreatment (Table 3). The peak concentrations emitted by Engine 1 retrofitted with DOC were found to be somewhat lower than those of the agglomeration aerosols emitted by Engine 1 when operated without aftertreatment at SS modes (Table 3). The earlier mentioned increases in the average number concentrations observed after Engine 1 was retrofitted with DOC and operated over TR conditions can be primarily attributed to the increase in concentrations of nucleation mode aerosols (Fig. 7b).

Fig. 6.

Effects of the evaluated engines and exhaust aftertreatment technologies on size distribution of aerosols in diluted exhaust (30 times) for SS engine operating conditions. a R100. b R50. c I100. d I50

Fig. 7.

Effects of the evaluated engines and exhaust aftertreatment technologies on size distribution of aerosols in diluted exhaust (30 times) for TR engine operating conditions. a Selected instance of low number concentrations (TR low). b Selected instance of high number concentrations (TR high)

Table 3.

Statistical parameters for the size distributions of aerosols emitted by the engines operated at SS and TR conditions

| Mode | Exhaust Aftertreatment | Nucleation | Accumulation 1 | Accumulation 2 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CMD | σ | Total Conc. | CMD | σ | Total Conc. | CMD | σ | Total Conc. | ||

| nm | - | #/cm3 | nm | - | #/cm3 | nm | - | #/cm3 | ||

| R100 | Engine 1 Muffler | 10.1 | 1.340 | 8.94E+04 | 72.6 | 1.570 | 2.46E+06 | |||

| Engine 1 DOC | 71.5 | 1.570 | 1.36E+06 | |||||||

| Engine 1 DPF | 10.0 | 1.130 | 1.57E+03 | 29.7 | 1.560 | 3.87E+03 | ||||

| Engine 2 SCR | 12.4 | 1.310 | 1.94E+04 | 48.7 | 1.760 | 2.44E+05 | ||||

| R50 | Engine 1 Muffler | 12.1 | 1.400 | 3.50E+04 | 60.3 | 1.600 | 1.32E+06 | |||

| Engine 1 DOC | 58.6 | 1.620 | 1.27E+06 | |||||||

| Engine 1 DPF | 9.3 | 1.160 | 3.07E+02 | 31.3 | 1.190 | 9.47E+01 | 85.6 | 1.310 | 1.69E+02 | |

| Engine 2 SCR | 13.7 | 1.400 | 3.04E+04 | 47.6 | 1.650 | 2.83E+05 | ||||

| I100 | Engine 1 Muffler | 79.5 | 1.580 | 2.40E+06 | ||||||

| Engine 1 DOC | 82.2 | 1.540 | 1.25E+06 | |||||||

| Engine 1 DPF | 10.0 | 1.100 | 3.50E+03 | 31.4 | 1.350 | 2.57E+03 | 80.5 | 1.480 | 2.10E+04 | |

| Engine 2 SCR | 12.4 | 1.400 | 2.20E+04 | 51.5 | 1.910 | 8.70E+04 | ||||

| I50 | Engine 1 Muffler | 68.7 | 1.670 | 1.82E+06 | ||||||

| Engine 1 DOC | 64.5 | 1.660 | 7.49E+05 | |||||||

| Engine 1 DPF | 9.7 | 1.140 | 1.26E+03 | 26.8 | 1.380 | 1.09E+03 | 45.9 | 1.630 | 2.99E+03 | |

| Engine 2 SCR | 12.1 | 1.560 | 2.03E+04 | 56.5 | 1.740 | 1.32E+05 | ||||

| TR Low | Engine 1 Muffler | 83.9 | 2.050 | 1.12E+05 | ||||||

| Engine 1 DOC | 82.8 | 1.520 | 6.78E+04 | |||||||

| Engine 1 DPF | 9.6 | 1.100 | 5.00E+02 | 32.5 | 1.390 | 6.10E+02 | ||||

| Engine 2 SCR | 21.6 | 2.460 | 1.85E+04 | 87.8 | 1.580 | 3.44E+04 | ||||

| TR High | Engine 1 Muffler | 86.1 | 1.590 | 1.70E+06 | ||||||

| Engine 1 DOC | 88.1 | 1.490 | 2.41E+06 | |||||||

| Engine 1 DPF | 7.0 | 1.370 | 2.23E+03 | 64.3 | 1.460 | 8.27E+03 | ||||

| Engine 2 SCR | 15.4 | 2.229 | 4.54E+04 | 67.2 | 1.690 | 1.55E+05 | ||||

The relatively less abundant aerosols in the DPF-treated exhaust of Engine 1 were distributed between two or three modes (Figs. 6 and 7). Nucleation mode aerosols with count median diameters around 10 nm were found in filtered exhaust for all SS and TR operating conditions. The concentrations of nucleation mode aerosols were comparable or less than those of accumulation mode aerosols (Figs. 6 and 7). Slight increases in concentrations of aerosols in the sub-20 nm range over engine-out levels were only found for I100 and I50 conditions. For R50 and I100 conditions, one of the remaining modes appeared to be a carbon-based accumulation mode with count median diameter around 80 nm.

The distributions of aerosols emitted by Engine 2 were bimodal with the majority of aerosols in the accumulation mode with count median diameters around 49 nm and 57 nm and remaining aerosols distributed in less pronounced nucleation modes with count median diameters between 12 and 14 nm (Fig. 6). It is important to note that the count median diameters of the agglomeration aerosol emitted by Engine 2 were 10 to 25 nm smaller than those of the agglomeration aerosols emitted by Engine 1, when operated without after treatment and with DOC (Table 3).

Volatility tests performed on aerosols emitted by Engine 2 showed that the TD heated to 400 C (752 °F) removed 45 to 85% of aerosols emitted at selected steady state conditions (Fig. 8). In the case of LI conditions, the majority of the removed aerosols were sub-40 nm nucleation mode aerosols. In other cases, the TD removed aerosols in whole spectrum of sizes.

Fig. 8.

Average fractions of non-volatile aerosols in the exhaust of Engine 2 (TD temperature 400 °C [752 °F])

The 3600-s averages of CO, NO, and NO2 concentrations in the raw exhaust of Engine 1 and Engine 2 operated over four steady-state and TR conditions are shown in Fig. 9. When retrofitted with the DOC, Engine 1 emitted less CO (33 to 86%), more NO (3 to 31%), and less NO2 (52 to 89%) than without the retrofit. When operated with the DPF, Engine 1 emitted less CO (32 to 87&), more NO (3 to 31%), and less NO2 (52 to 89%) than without the retrofit. At the corresponding engine operating conditions, Engine 2 with DOC/SCR/ASC after treatment emitted on average between 59 and 99% less CO, 70 and 93% less NO, and 30 to 97% less NO2 than Engine 1 operated without aftertreatment.

Fig. 9.

Effects of the evaluated engines and exhaust aftertreatment technologies on a CO, b NO, and c NO2 emissions

The results of the additional 900-s tests conducted at rated and intermediated speeds (Fig. 2) were used to examine the effects of exhaust temperature on SCR-Out CO, NO, and NO2 emissions from Engine 2 (Fig. 10). Due to low catalytic activity and the absence of urea injections, the CO and NO emissions were highest for the engine operating conditions that generated exhaust temperatures below 200 °C (392 °F) (Fig. 10). At temperatures above 200 °C (392 °F), the system was found to effectively convert CO and NO. Evidence of limited NO2 formation was found for an engine operating condition that generated temperatures above 300 °C (572 °F) (I100).

Fig. 10.

Effects of exhaust temperatures of CO, NO, and NO2 SCR-Out emissions

4. Discussion and Conclusion

The results indicated that the evaluated DOC effectively curtailed US EPATier 2 engine emissions of CO, and to some extent OC, EC, and aerosol number concentrations. The reductions were achieved while avoiding secondary emissions of acutely toxic NO2, which suggests that the DOC is a viable option for reducing exposures in underground mines. Nevertheless, substantially higher reductions of OC and EC mass concentrations and total number concentrations of aerosols were achieved by retrofitting the Tier2 engine with a DPF system. EC concentrations were about 100 times lower for the DPF-treated exhaust. The results showed that both evaluated systems, the DOC and DPF, achieved reductions in aforementioned emissions without adversely affecting emissions of NO2 and nucleation mode aerosols, and therefore, those two devices could be suitable for addressing selected emissions from diesel-powered vehicles from existing fleets. The suitability of the DPF systems for the specific applications would depend on a number of engineering parameters and primarily on the viability of the applied DPF regeneration strategy. Establishing a relationship between exhaust temperature profiles for the specific vehicle duty cycles and balance point temperatures for the passive DPF regeneration is critical to the success of those applications. In terms of developing adequate DPF regeneration strategies and optimizing the performance of other exhaust aftertreatment devices, retrofit solutions have disadvantages over OEM solutions that allow for the integration of engine and exhaust aftertreatment systems. One example was the manipulation of fuel injection and EGR rates to achieve desired SCR-Out exhaust temperatures.

The evaluations showed that, for all test conditions, the EPA Tier 4f engine contributed substantially less than the US EPATier 2, when operated without exhaust aftertreatment, to the mass concentrations of EC and OC, number concentrations of aerosols, and concentrations of CO, NO, and NO2. It is important to note that the relatively low DPM mass emissions were achieved without the use of a DPF system and that reductions in NO and NO2 emissions were achieved in part using cooled EGR and SCR systems. The results of size distribution measurements indicated that the reductions in mass concentrations of aerosols may have been partially achieved through better in-cylinder fuel and air mixing and hence reductions in the size of emitted aerosols. Therefore, repowering existing vehicles currently powered by US EPA Tier 2 (and US EPA Tier 3) with US EPA Tier 4 final engines fitted with DEF-based SCR systems, similar to the one tested in this study, could substantially reduce the contribution of existing and newly introduced diesel-powered underground mining vehicles to mass concentrations of submicron aerosols and criteria gases in underground mines. Tier 4f engines may prove to be a viable technology for helping the underground mining industry to comply with current mass-based regulations limiting the exposure of underground metal/nonmetal miners to DPM [21].

In addition, the results demonstrated that tested US EPA Tier 4 engine was effective in reducing particulate mass and cumulative emissions of nitrogen oxides, but not equally effective in reducing particulate number emissions. The results confirmed findings of Lucachick et al. [31] and Fiebig et al. [66] that the use of DPFs in advanced exhaust aftertreatment systems would be critical to efforts to reduce contributions of such engines to aerosol number concentrations. Exhaust aftertreatment systems with DOC, DPF, and SCR systems are expected to be an integral part of European Stage V non-road power packages with power outputs between 56 and 560 kW (75 and 750 hp) [67, 68]. The results demonstrate that the effects of control technologies and strategies on physical and chemical properties of emitted aerosols should not be neglected during the selection process.

A number of economic and technical aspects need to be taken into consideration prior to the industrywide implementation of advance exhaust aftertreatment systems and engine systems in underground mining. Some of the parameters affecting implementation of these technologies in underground mining operations are of additional technical complexity, space requirements, higher capital and operational costs, and fluid requirements. Implementation of technologies needed to meet stringent standards are associated with an increase in technical complexity and capital cost [67]. The higher costs are associated with improvements in a number of engine systems including fuel injection, turbocharging, EGR, and engine and exhaust aftertreatment control. Dallmann et al. [68] suggested that the increase in incremental cost is primarily driven by the adoption of DPF and SCR systems. The space requirements for the installation of the DPF system, similar to the one retrofitted to the Tier 2 engine, and the SCR system and associated hardware, similar to the one on the Tier 4f, could be considerable. The installation of those in the engine bays of existing and new underground mining equipment might prove to be difficult and only possible with extensive redesign and optimization of the equipment and systems.

Increased maintenance costs are associated with increased complexity of engine and exhaust aftertreatment systems. The operation of advanced engines depends strongly on the use of pressure, temperature, and gas sensors, and special precautions should be taken to avoid potential problems associated with the overexposure of underground miners to NO and NO2 due to the failure of the SCR systems to inject DEF [69]. Implementation of engines fitted with DEF-based SCR systems would require establishing procedures for managing the supply of DEF. The availability of high-quality fuels with low sulfur content (< 15 ppm) and lubricants with low ash content (API CJ-4 and CK-4) are critical to the operation of catalyzed DPF systems [46]. The cleanliness of the fuel is critical to protecting the fuel system components of modern engines equipped with high-pressure common rail systems [70].

Implementation of viable exhaust aftertreatment systems and advanced diesel power packages would be instrumental to the underground mining industry worldwide to secure an economical and dependable source of power for mobile equipment that does not generate emissions that adversely affect miner’s health.

Acronyms

- ACGIH

American Conference of Governmental Industrial Hygienists

- AIOH

Australian Institute of Occupational Hygienist

- ASC

Ammonia slip catalyst

- ASTM

ASTM International, an international standards organization that develops and publishes voluntary consensus technical standards

- CMD

Count median diameter

- CO

Carbon monoxide

- CO2

Carbon dioxide

- DOC

Diesel oxidation catalytic converter

- Dem

Electrical mobility diameter

- DEF

Diesel exhaust fluid

- DPF

Diesel particulate filter

- DPM

Diesel particulate matter

- EC

Elemental carbon

- EGR

Exhaust gas recirculation

- FMPS

Fast Mobility Particle Sizer

- HC

Hydrocarbons

- I50

Intermediate speed 50 percent load (ISO M8)

- I100

Intermediate speed 100 percent load (ISO M6)

- IARC

International Agency on Research on Cancer

- MSHA

Mine Safety and Health Administration

- N

Number

- NIOSH

National Institute for Occupational Safety and Health

- NO

Nitric oxide

- NO2

Nitrogen dioxides

- NOX

Nitric oxides (NOx = NO + NO2)

- OC

Organic carbon

- OEM

Original equipment manufacturer

- ON

Ontario

- Pd

Palladium

- PM

Particulate mass

- PN

Particulate number

- QFF

Quartz fiber filters

- R50

Rated speed 50% load (ISO M3)

- R100

Rated speed 100% load (ISO M1)

- SAE

Society of Automotive Engineers

- SCR

Selective catalyst reduction

- SCR-In

Before DOC/SCR/ASC system

- SCR-Out

After DOC/SCR/ASC system

- SS

Steady-state

- TC

Total carbon

- TD

Thermodenuder

- TLV

Threshold limit values (ACGIH)

- TOT-EGA

Thermal optical transmittance-evolve gas analysis

- TR

Transient

- ULSD

Ultralow sulfur diesel

- US EPA

US Environmental Protection Agency

- σ

Log-normal distribution spread

Footnotes

Conflict of Interest The authors declare that they have no conflict of interest.

Publisher's Disclaimer: Disclaimer The findings and conclusions in this paper are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. Mention of company names or products does not constitute endorsement by NIOSH.

Publisher’s Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.MSHA (2018) The DPM personal sampling compliance data. https://arlweb.msha.gov/OpenGovernmentData/OGIMSHA.asp. Accessed 29 March 2019

- 2.The Parker Bay Company and Raw Materials Group (2012) Market analysis: underground mining mobile equipment. September 2012 [Google Scholar]

- 3.Pronk A, Coble J, Stewart PA (2009) Occupational exposure to diesel engine exhaust: a literature review. J Exp Sci Environ Epi 19:443–457 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Coble JB, Stewart PA, Vermeulen R, Yereb D, Stanevich R, Blair A, Silverman DT, Attfield M (2010) The Diesel Exhaust in Miners Study: II. Exposure monitoring surveys and development of exposure groups. Ann Occup Hyg 54(7):747–761 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.CAREX (2015) Mining sector Occupational Exposure Summary Package. CAREX; Canada: https://www.carexcanada.ca/CAREX_Mining_Package_July-16-2015.pdf. Accessed 29 March 2019 [Google Scholar]

- 6.Peters S, de Klerk N, Reid A, Fritischi L, Musk AW, Vermulen R (2016) Quantitative levels of diesel exhaust exposure and the health impact in the contemporary Australian mining industry. Occup. Environ. Med 4:282–289 [DOI] [PubMed] [Google Scholar]

- 7.MSHA (2018) National coal diesel inventory. Mine Safety and Health Administration. https://lakmshaegov01.msha.gov/DieselInventory/ViewDieselInventoryExternal.aspx. Accessed 29 March 2019 [Google Scholar]

- 8.Attfield MD, Schleiff PL, Lubin JH, Blair A, Stewart PA, Vermeulen R, Coble JB, Silverman DT (2012) The Diesel Exhaust in Miners Study: a cohort mortality study with emphasis on lung cancer. J Natl Cancer Inst 104:869–883 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Silverman DT, Samanic CM, Lubin JH, Blair A, Stewart PA, Vermeulen R, Coble JB, Rothman N, Schleiff PL, Travis WD, Ziegler RG, Wacholder S, Attfield MD (2012) The Diesel Exhaust in Miners Study: a nested case-control study of lung cancer and diesel exhaust. J Natl Cancer Inst 104:855–868 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Vermeulen R, Silverman DT, Garshick E, Vlaanderen J, Portengen L, Steenland K (2014) Exposure-response estimates for diesel engine exhaust and lung cancer mortality based on data from three occupational cohorts. Environ Health Pers. 122:172–177 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Brook RD, Rajagopalan S, Pope CA III, Brook JR, Bhatnagar A, Diez-Roux AV, Holguin F, Hong Y, Luepker RV, Mittleman MA, Peters A, Siscovick D, Smith SC, Whitsel L, Kaufman JD (2010) Particulate matter air pollution and cardiovascular disease: an update to the scientific statement from the American Heart Association. Circulation 121:2331–2378 [DOI] [PubMed] [Google Scholar]

- 12.Mills NL, Miller MR, Lucking AJ, Beveridge J, Flint L, Boere AJ, Fokkens PH, Boon NA, Sandstrom T, Blomberg A, Duffin R, Donaldson K, Hadoke PW, Cassee FR, Newby DE (2011) Combustion-derived nanoparticulate induces the adverse vascular effects of diesel exhaust inhalation. Eur Heart J 32(21):2660–2671 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Power MC, Weiskopf MG, Alexeeff SE, Coull BA, Spiro A III, Schwartz J (2011) Traffic-related air pollution and cognitive functions in a cohort of older men. Environ Health Perspec 119:682–687 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Donaldson K, Tran L, Jimenez LA, Duffin R, Newby DE, Mils N, MacNee W, Stone V (2005) Combustion-derived nanoparticles: a review of their toxicology following inhalation exposure. Part Fiber Toxic 2:10–24 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.McDonald JD, Doyle-Eisele M, Gigliotti A, Miller RA., Seilkop S, Mauderly JL, Seagrave J, Chow J, Zielinska B (2012) Part 1. Biologic responses in rats and mice to subchronic inhalation of diesel exhaust from U.S. 2007- compliant engines: report on 1-, 3-, and 12-month exposures in the ACES bioassay In: Advanced Collaborative Emissions Study (ACES). 2012. Advanced Collaborative Emissions Study (ACES). Subchronic exposure results: biologic responses in rats and mice and assessment of genotoxicity. Research Report 166. Health Effects Institute, Boston: [PubMed] [Google Scholar]

- 16.Karthikeyan S, Thomson EM, Kumarathasan P, Guénette J, Rosenblatt D, Chan T, Rideout G, Vincent R (2013) Nitrogen dioxide and ultrafine particles dominate the biological effects of inhaled diesel exhaust treated by a catalyzed diesel particle filter. Toxic Sci 135(2):437–450 [DOI] [PubMed] [Google Scholar]

- 17.Taxel P, Santonen T (2017) Diesel engine exhaust: Basis for occupational exposure limit value. Toxic Sci 158(2):243–251 [DOI] [PubMed] [Google Scholar]

- 18.IARC (2012) IARC Press Release No. 213, June 12. Diesel engine exhaust carcinogenic. International Agency for Research on Cancer, World Health Organization [Google Scholar]

- 19.IARC (2014) Diesel and gasoline engine exhausts and some nitroarenes Volume 105 International Agency for Research on Cancer (IARC) IARC Monographs on the evaluation of carcinogenic risks to humans. Lyon: [PMC free article] [PubMed] [Google Scholar]

- 20.66 FR 5704 (2001) 30 CFR 72 Subpart D - Diesel Particulate Matter - underground areas of underground coal mines Code of Federal Regulations. Washington: U.S. Government Printing Office, Office of the Federal Register [Google Scholar]

- 21.70 FR 32996 (2005) 30 CFR 57.5060. Limit on Exposure to Diesel Particulate Matter. Safety and Health Standards—underground metal and nonmetal mines. Mine Safety and Health Administration Code of Federal Regulations. Washington, DC: U.S. Government Printing Office, Office of the Federal Register [Google Scholar]

- 22.P8_TA-PROV(2018)0488 (2018) Protection of workers from the risks related to exposure to carcinogens or mutagens at work. European Parliament. [Google Scholar]

- 23.AIOH (2013) Diesel particulate matter & occupational health issues. Position Paper. Australian Institute of Occupational Hygienists (AIOH). AIOH Exposure Standards Committee. July [Google Scholar]

- 24.Bugarski AD, Janisko S, Cauda EG, Noll JD, Mischler SE (2012) Controlling exposure - diesel emissions in underground mines. Society for Mining, Metallurgy, and Exploration. pp. 58–61 [Google Scholar]

- 25.GMG (2018) GMG Recommended Practices for Battery Electric Vehicles in Underground Mining – 2nd Edition. The Underground Mining Working Group. Global Mining Guidelines Group (GMG). 20180621_UG_Mining_BEV-GMG-WG-v02-r01 [Google Scholar]

- 26.Mullally J (2018) Borden gold: mine of the future: update 24th Annual Mining Diesel Emissions Council (MDEC) Conference. Toronto, Canada, October 2–4 [Google Scholar]

- 27.US EPA (2016) Nonroad compression-ignition engines: exhaust emission standards. United States Environmental Protection Agency. Office of Transportation and Air Quality. EPA-420-B-16–02240 [Google Scholar]

- 28.EU (2016) Regulation (EU) 2016/1628 of the European Parliament and of the Council. Official Journal of the European Union, L252/3, September 16 [Google Scholar]

- 29.Lähde T, Rönkkö T, Happonen M, Söderström C, Virtanen A, Solla A, Kytö M, Rothe D, Keskinen J (2011) Effect of fuel injection pressure on a heavy-duty diesel engine nonvolatile particle emission. Environ. Sci. Technol 45:2504–2509 [DOI] [PubMed] [Google Scholar]

- 30.Nousiainen P, Niemi S, Rönkkö T, Karjalainen P, Keskinen J, Kuuluvainen H, Pirjola L, Saveljeff H (2013) Effect of injection parameters on exhaust gaseous and nucleation mode particle emissions of a Tier 4i nonroad diesel engine. SAE Technical Paper 2013-01-2575 [Google Scholar]

- 31.Lucachick G, Avenido A, Watts W, Kittelson D, Nortrop W (2014) Efficacy of in-cylinder control of particulate emissions to meet current and future regulatory standards. SAE Technical Paper 2014-01-1597 [Google Scholar]

- 32.Herner JD, Hu S, Robertson WH, Huai T, Chang M-CO, Rieger P, Ayala A (2011) Effect of advanced aftertreatment for PM and NOx reduction on heavy-duty diesel engine ultrafine particle emissions. Environ Sci Technol 45:2413–2419 [DOI] [PubMed] [Google Scholar]

- 33.Karjalainen P, Ronkko T, Lahde T, Rostedt A, Keskinen J, Saarikoski S, Aurela M, Hillamo R, Malinen A, Pirjola L, Amberla A (2013) Reduction of heavy-duty diesel exhaust particulate number and mass at low exhaust temperature driving by the DOC and the SCR. SAE Int J Fuels Lubr 5(3):1114–1122 [Google Scholar]

- 34.Yoo D, Kim D, Jung W, Kim N, Lee D (2013) Optimization of diesel combustion system for reducing PM to meet Tier 4-final emission regulation without diesel particulate filter. SAE Technical Paper 2013-01-2538 [Google Scholar]

- 35.Jeon J, Lee JT, Park S (2016) Nitrogen compounds (NO, NO2, N2O, and NH3) in NOX emissions from commercial EURO VI type heavy-duty diesel engines with a urea-selective catalytic reduction system. Energy & Fuels 30:6828–6834 [Google Scholar]

- 36.Smagala TG, Christensen E, Christison KM, Mohler RE, Gjersing E, McCormick RL (2013) Hydrocarbon renewable and synthetic diesel fuel blendstocks: composition and properties. Energy & Fuels 27:237–246 [Google Scholar]

- 37.Bugarski AD, Hummer JA, Vanderslice S (2016) Effects of hydrotreated vegetable oil on emissions of aerosols and gases from light-duty and medium-duty older technology engines. J Occup Environ Hyg 13(4):297–306 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Bugarski AD, Hummer JA, Vanderslice SE (2017) Effects of FAME biodiesel and HVORD on emissions from an older technology diesel engine. Min Eng 69(12):43–49 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Biswas S, Hu S, Verma V, Herner JD, Robertson WH, Ayala A, Sioutas C (2008) Physical properties of particulate matter (PM) from late model heavy-duty diesel vehicle operating with advanced PM and NOx emissions control technologies. Atmos Environ 42: 5622–5634 [Google Scholar]

- 40.Khalek IA, Bougher TL, Merritt PM, Zielinska B (2011) Regulated and unregulated emissions from highway heavy-duty diesel engines complying with U.S. Environmental Protection Agency 2007 emissions standards. J Air Waste Manage Assoc 61:427–442 [DOI] [PubMed] [Google Scholar]

- 41.Khalek IA, Blanks MG, Merritt PM, Zielinska B (2015) Regulated and unregulated emissions from modern 2010 emissions-compliant heavy-duty on highway diesel engines. J Air Waste Manage Assoc 65(8):987–1001 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Ruehl C, Herner JD, Yoon S, Collins JF, Misra C, Na K, Robertson WH, Biswas S, Chang M-CO, Ayala A (2015) Similarities and differences between “traditional” and “clean” diesel PM. Emiss Control Sci Technol 1:17–23 [Google Scholar]

- 43.Khair M, McKinnon DL [1999) Performance evaluation of advanced emissions control technologies for diesel heavy-duty engines. SAE Technical Paper 1999-01-3564 [Google Scholar]

- 44.Dou D (2012) Application of diesel oxidation catalyst and diesel particulate filter for diesel engine powered non-road machines. Platinum Metals Rev. 56(3):144–154 [Google Scholar]

- 45.Allansson R, Blakeman PG, Cooper BJ, Hess H, Silcock PJ, Walker AP (2002) Optimizing the low temperature performance and regeneration efficiency of the continuously regenerating diesel particulate filter (Cr-Dpf) system. SAE Technical Paper 2002-01-0428 [Google Scholar]

- 46.Kittelson DB, Watts WF, Johnson JP, Thorne C, Higham C, Payne M, Goodier S, Warrens C, Preston H, Zink U, Pickles D, Goersmann C, Twigg MV, Walker AP, Boddy R (2008) Effect of fuel and lube oil sulfur on the performance of a diesel exhaust gas continuously regenerating trap. Environ Sci Technol 42(24):9276–9282 [DOI] [PubMed] [Google Scholar]

- 47.Sluder CS, Storey JME, Lewis SA, Lewis LA (2005) Low temperature urea decomposition and SCR performance. SAE Technical Paper 2005-01-1858 [Google Scholar]

- 48.Goo JH, Irfan MF, Kim SD, Hong SC (2007) Effects of NO2 and SO2 on selective catalytic reduction of nitrogen oxides by ammonia. Chemosphere 67:718–723 [DOI] [PubMed] [Google Scholar]

- 49.Mayer A, Kasper M, Mosimann Th, Legerer F, Czerwinski J, Emmenegger L, Ulrich A, Mohr J, Kirchen P (2007) Nanoparticle-emission of EURO 4 and EURO 5 HDV compared to EURO 3 with and without DPF. SAE Technical Paper 2007-01-1112 [Google Scholar]

- 50.Johnson TV (2009) Diesel emission control in review. SAE Int. J. Fuels Lubr 2(1):1–12 [Google Scholar]

- 51.Robinson M, Backhaus J, Foley R, Liu Z (2016) The effect of diesel exhaust fluid dosing on tailpipe particle number emissions. SAE Technical Paper 2016-01-0995 [Google Scholar]

- 52.Heeb NV, Schmid P, Kohler M, Gujer E, Zennegg M, Wenger D, Wichser A, Ulrich A, Gfeller U, Honegger P, Zeyer K, Emmenegger L, Petermann J-L, Czerwinski J, Mosimann T, Kasper M, Mayer A (2008) Secondary effects of catalytic diesel particulate filters. Environ Sci Technol 42(10):3773–3779 [DOI] [PubMed] [Google Scholar]

- 53.Mayer A, Czerwinski J, Kasper M, Leutert G, Heeb N, Ulrich A, Jaussi F (2010) VERT particle filter test procedure and quality standard for new and in-use diesel engines. J KONES Powertrain Transp 17(4) [Google Scholar]

- 54.ACGIH (2018) 2018 TLVs® and BEIs®. ACGIH, Cincinnati [Google Scholar]

- 55.Stachulak J, Gangal M, Allen C (2014) The effects of diesel oxidation catalyst on NO2 emissions from mining vehicles In: von Glenn F, Biffi M (eds) Proceedings of the 10th International Mine Ventilation Congress. The Mine Ventilation Society of South Africa, Sun City, pp 293–297 [Google Scholar]

- 56.Bugarski AD, Hummer JA, Robb GM (2015) Diesel oxidation catalytic converters for underground mining applications In: Jong E, Sarver E, Schafrik S, Luxbacher K (eds) Proceeding of 15th North American Mine Ventilation Symposium, vol 19–23, Blacksburg, pp 289–296 [Google Scholar]

- 57.Czerwinski J, Péterman J, Comte P, Lemaire J, Mayer A (2007) Diesel NO/NO2/NOX emissions - new experiences and challenges. SAE Technical Paper 2007-01-0321 [Google Scholar]

- 58.MSHA (2011) Reissue of P02–07 - Compliance with diesel particulate matter standard in underground coal mines. U.S. Department of Labor, Mine Safety and Health Administration, Program Information Bulletin No. P11–26. [https://arlweb.msha.gov/regs/complian/PIB/2011/pib11-26.asp) [Google Scholar]

- 59.Johansen K, Dahl S, Mogense G, Pehrson S, Schramm J, Ivarsson A (2007) Novel base metal-palladium catalytic diesel filter coating with NO2 reducing properties. SAE Technical Paper 2007-01-1921 [Google Scholar]

- 60.Khair M, Merritt P, Lu Q, Lemaire J, Morin J-P, Johansen K (2009) Catalytic formulation for NO2 suppression and control. SAE Int. J. Fuels Lubr 1(1):803–812 [Google Scholar]

- 61.Thiruvengadam A, Besch MC, Carder DK, Oshinuga A, Gautam M (2011) Influence of real-world engine load conditions on nanoparticle emissions from a DPF and SCR equipped heavy-duty diesel engine. Environ Sci Technol 46:1907–1913 [DOI] [PubMed] [Google Scholar]

- 62.Girard J, Cavataio G, Lambert C (2007) The influence of ammonia slip catalysts on ammonia, N2O and NOX emissions for diesel engines. SAE Technical Paper 2007-01-1572 [Google Scholar]

- 63.ISO 8178 [1996) ISO 8178–1:1996: reciprocating internal combustion engines. Exhaust emission measurement, part 1: test-bed measurement of gaseous and particulate exhaust emissions International Organization for Standardization. Geneva [Google Scholar]

- 64.ISO 22241–4 (2009) ISO 22241–4:2009: Diesel engines – NOx reduction agent AUS 32 – part 1: quality requirements International Organization for Standardization. Geneva, Switzerland [Google Scholar]

- 65.NIOSH (2016) Monitoring diesel exhaust in the workplace In: NIOSH Manual of Analytical Methods (NMAM), 5th Edition, Chapter DL, Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health DHHS (NIOSH) Publication No. 2014–151 [Google Scholar]

- 66.Fiebig M, Wiartalla A, Holdenbaum B, Kiesow S (2014) Particulate emissions from diesel engines: correlation between engine technology and emissions. J Occup Medic Toxic 9(1):6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Dallmann T, Menon A (2016) Technology pathways for diesel engines used in non-road vehicles and equipment. White Paper. The International Council on Clean Transportation (icct). September Retrieved from https://www.theicct.org/sites/default/files/publications/Non-Road-Tech-Pathways_white-%20paper_vF_ICCT_20160915.pdf. Accessed 29 March 2019 [Google Scholar]

- 68.Dallmann T, Posada F, Bandivadekar A (2018) Cost of emissions reductions technologies for diesel engines used in non-road vehicles and equipment. Working Paper 2018–10. The International Council on Clean Transportation (icct). July 11 https://www.theicct.org/publications/emission_reduction_tech_cost_non_road_diesel. Accessed 29 March 2019 [Google Scholar]

- 69.Bugarski AD, Cauda EG, Janisko SJ, Patts LD, Hummer JA, Terrillion T, Keifer J (2012) Isolated zone evaluation of the Tier 4i engine equipped with SCR system In: Calizaya F, Nelson MG (eds) Proceeding of 14th United States/North American Mine Ventilation Symposium, vol 17–20, Salt Lake City, pp 205–212 [Google Scholar]

- 70.Donaldson (2015) The effect of hard particle wear on diesel injectors. Donaldson Company, Inc., Minneapolis, MN: Brochure No. F111422 ENG (2/15). https://www.donaldson.com/content/dam/donaldson/engine-hydraulics-bulk/literature/north-america/bulk-fluids/F111422-ENG/Diesel-Injector-Wear-White-Paper.pdf. Accessed 29 March 2019 [Google Scholar]